Sandblasting equipment for sandblasting and derusting pipe surface

A technology of surface sandblasting and sandblasting equipment, which is applied in the direction of metal processing equipment, cleaning methods using tools, and used abrasive treatment devices, etc., can solve problems such as low work efficiency and poor rust removal quality, and achieve steel pipe removal Rust is convenient, rust removal quality is good, rust removal effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

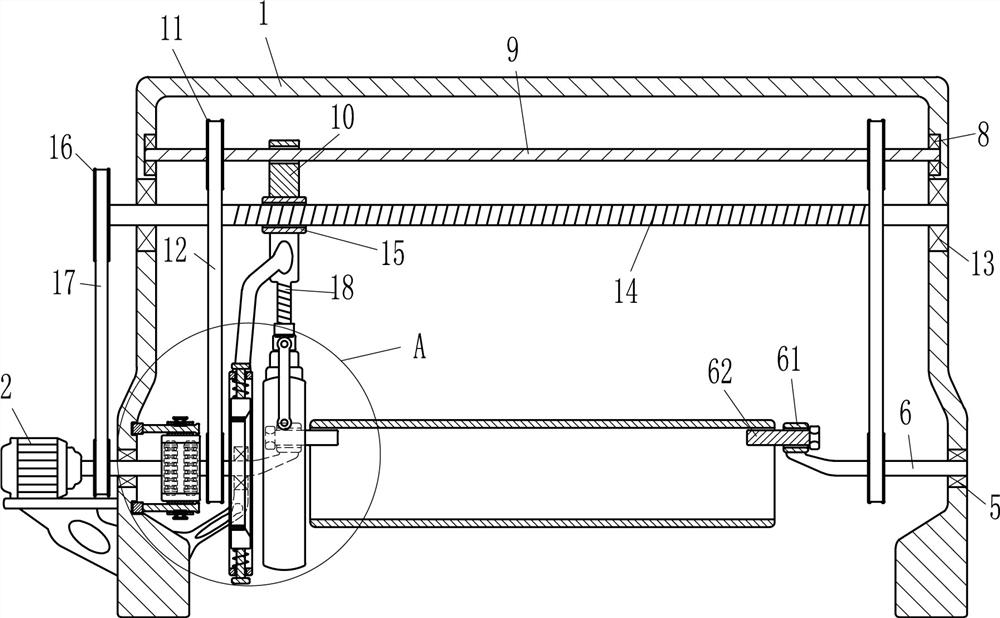

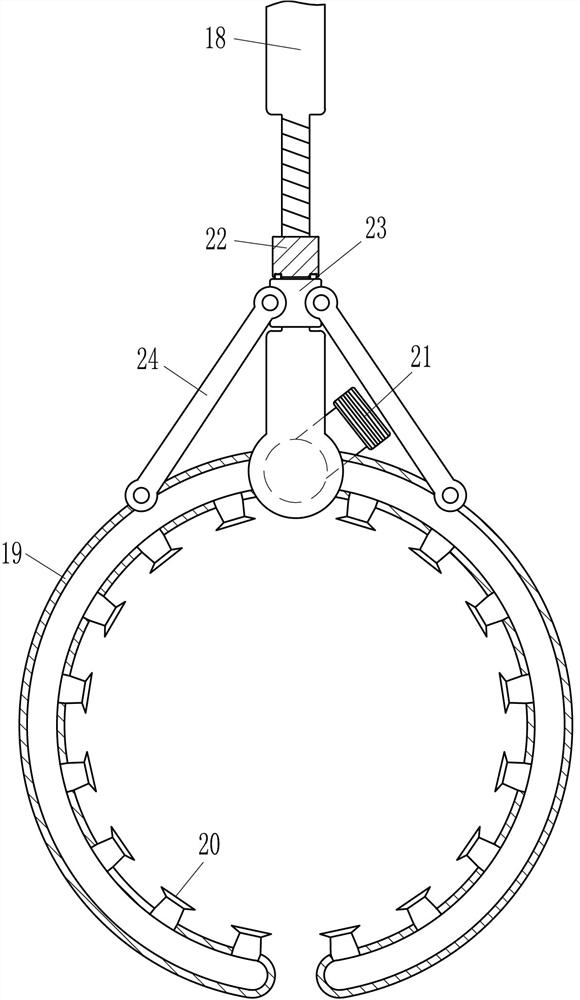

[0021] Such as Figure 1-3 As shown, a sandblasting equipment used for sandblasting and rust removal on the surface of pipelines includes a mounting frame 1, a power assembly, a lifting assembly, a rotating assembly, a transmission assembly and a sandblasting assembly. The power assembly that provides power by means of the installation frame 1. The lower left and right sides of the installation frame 1 are equipped with lifting components that can be lifted and lowered by rotation. The lower left side of the installation frame 1 is installed with a rotating assembly that rotates by rotation. There is a transmission assembly for transmission by rotation, and a sandblasting assembly for sandblasting by sliding is installed in the installation frame 1 . Specifically, when using this equipment to sandblast and derust steel pipes, first put a steel pipe under the equipment, then the staff adjusts the rotating assembly, then starts the power assembly to drive the lifting assembly to...

Embodiment 2

[0024] Such as figure 1 with image 3 As shown, the lifting assembly includes a second bearing seat 5, an L-shaped rotating rod 6, a first sliding sleeve 61, an insertion rod 62 and a second gear 63, and the second bearing seat 5 is installed on the left and right sides of the mounting frame 1, L-shaped rotating rods 6 are installed in the second bearing housing 5, and the inner sides of the L-shaped rotating rods 6 are all fixedly connected with first sliding sleeves 61 by screws. The first sliding sleeves 61 are all slidably provided with inserting rods 62, and the left side The outer end of the L-shaped rotating rod 6 is equipped with a second gear 63 . Specifically, the staff pushes the insertion rod 62 to move inwardly into the steel pipe in the first sliding sleeve 61, and then starts the reduction motor 2 to drive the second gear 63 to rotate through the rotating assembly, thereby driving the L-shaped rotating rod 6 to rotate on the second bearing seat 5 Rotate inside...

Embodiment 3

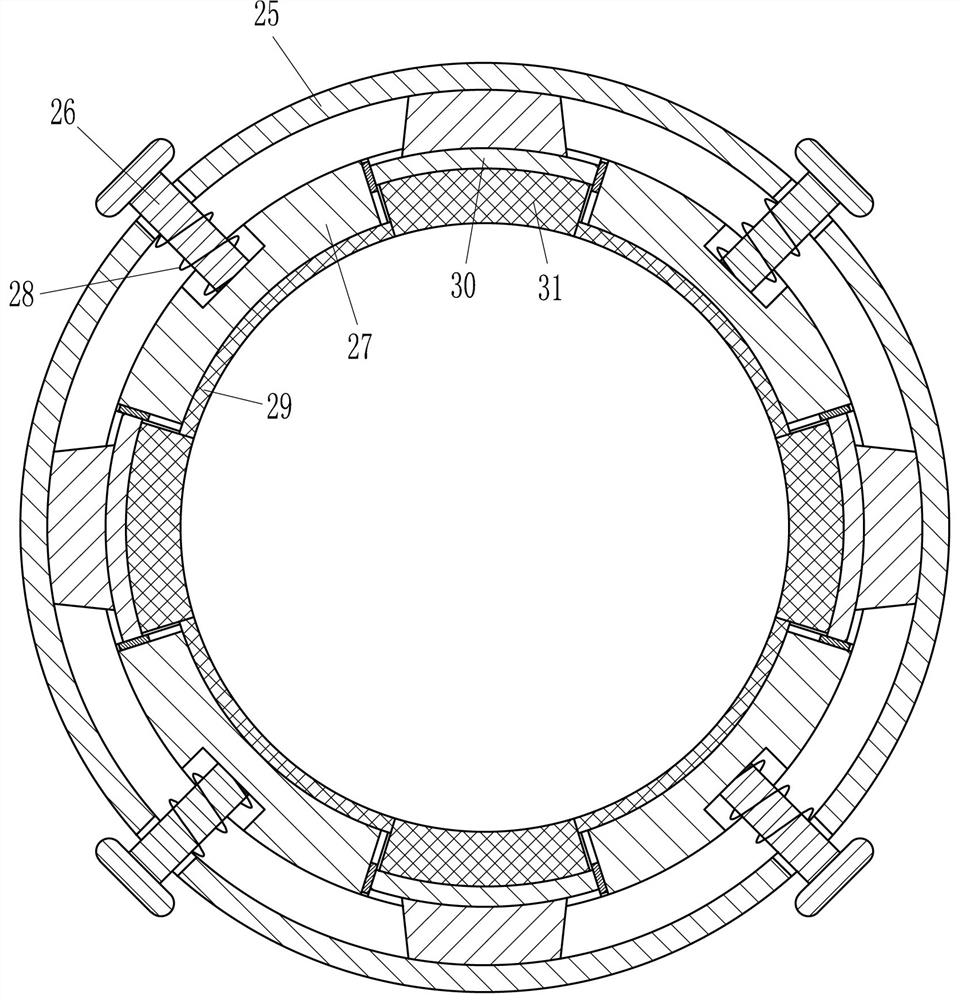

[0027] Such as figure 1 As shown, the transmission assembly includes a third bearing seat 8, a second rotating shaft 9, a third sliding sleeve 10, a first pulley 11, a first flat belt 12, a fourth bearing seat 13, a threaded rod 14, a first nut 15, The second belt pulley 16 and the second flat belt 17, the third bearing seat 8 is installed symmetrically on the left and right sides of the upper part of the mounting frame 1, and the second rotating shaft 9 is installed between the third bearing seat 8 on the left and right sides, on the second rotating shaft 9 The sliding type is provided with a third sliding sleeve 10, the left and right sides of the second rotating shaft 9 and the L-shaped rotating rods 6 on the left and right sides are all equipped with first pulleys 11, and the first pulleys 11 on both sides are connected with the first flat belt. Belt 12, the fourth bearing seat 13 is installed symmetrically on the left and right sides of the upper part of the mounting fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com