Sandblasting or spraying method for slit workpiece

A workpiece, sandblasting technology, applied in the direction of the spraying device, etc., can solve the problems of difficult removal of the iron sheet, hidden quality problems, etc., and achieve the effects of good quality, high efficiency, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

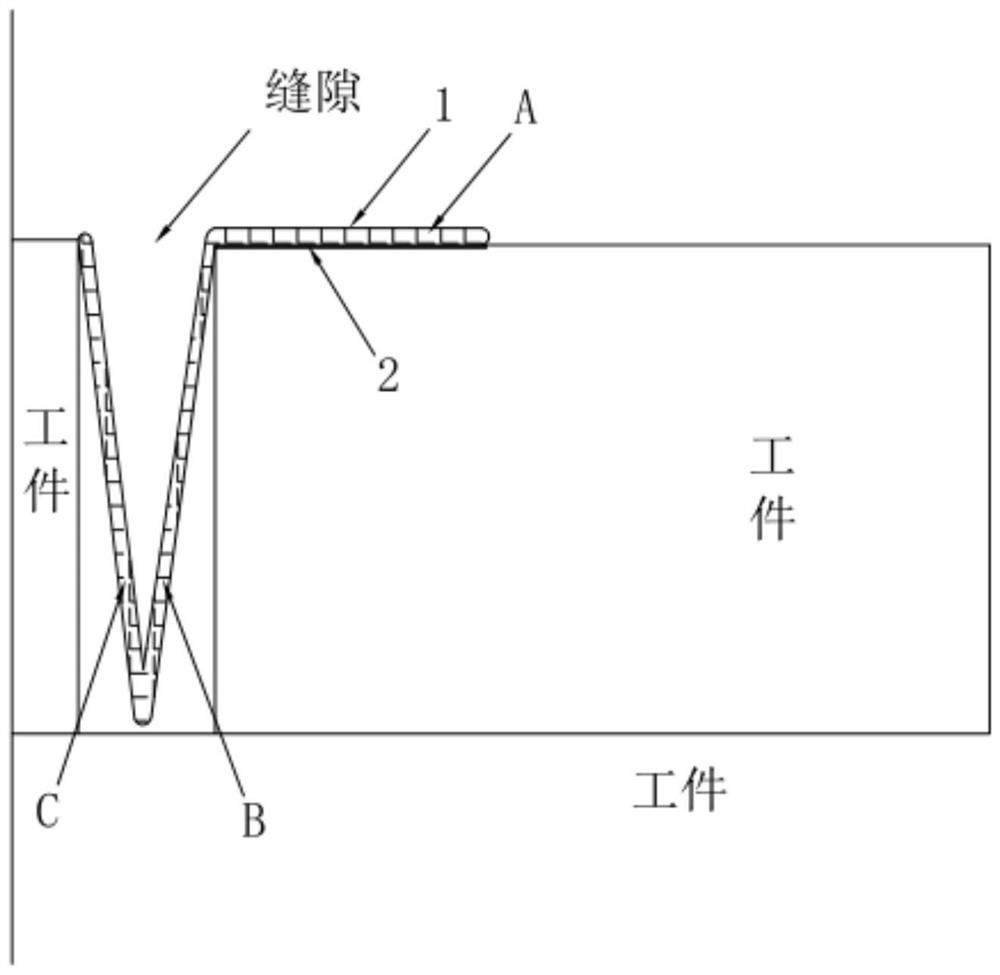

[0046] A sandblasting or spraying method for slit workpieces, combined with figure 1 and figure 2 shown, including the following steps:

[0047] Step S1, first measure the width of the gap with a caliper, the measurement result shows that the width of the gap at this position is 4 mm, select a shielding material, and the shielding material is a plastically deformable metal material, such as an iron sheet for the shielding material or an alloy sheet for the shielding material, and the shielding material is selected. The thickness of 0.4mm thickness iron sheet.

[0048] Step S2, forming the shielding material into a V-shape, one side of the shielding material is provided with part A of the cantilever 1, and the size of the opening of the V-shaped shielding material is equal to the width of the workpiece gap minus twice the thickness of the shielding material; It is required to be folded into a V-shape. The width of the V-shape opening is the slit width of 4mm minus twice the ...

Embodiment 2

[0055] The difference between this embodiment and the shielding method of Embodiment 1 is that the support structure is configured as a trapezoidal block. The material of the trapezoidal block can be metal, cork, rubber, plastic, etc. The trapezoidal block makes the iron sheet of the C part close to the surface of the workpiece.

Embodiment 3

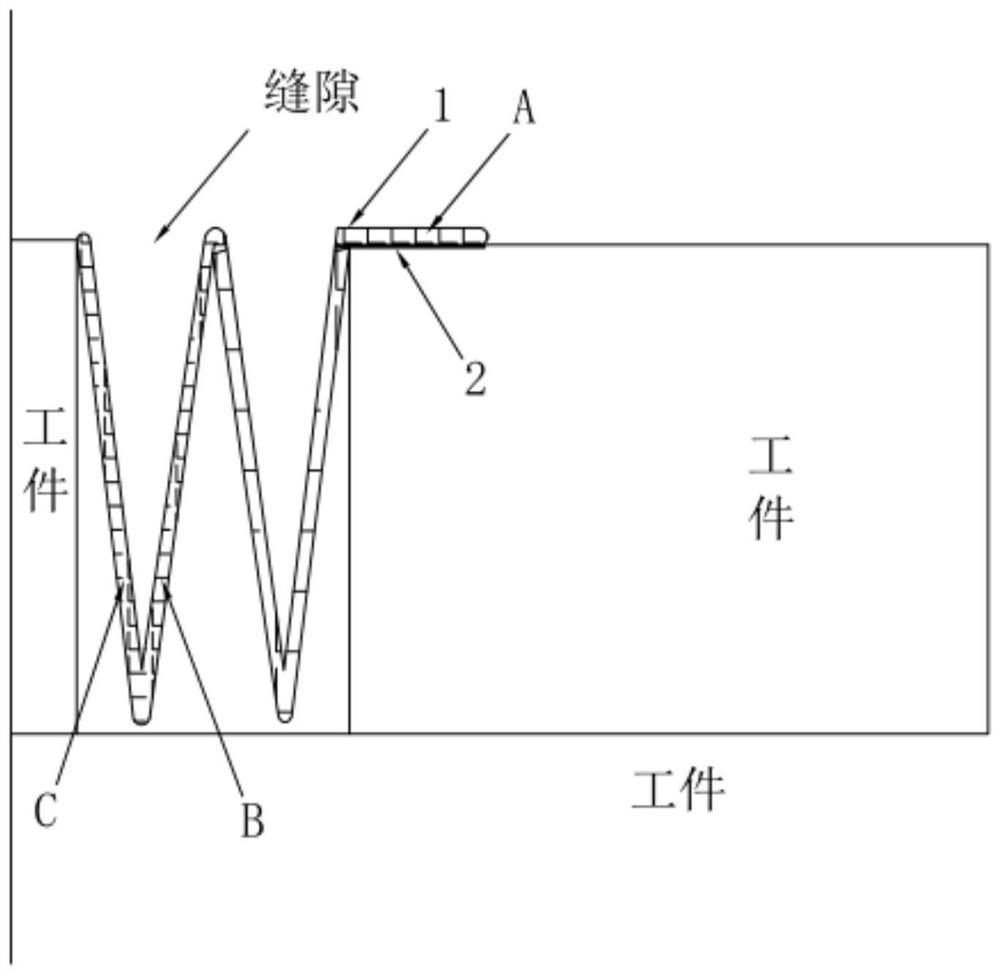

[0057] The difference between this embodiment and the shielding method of Embodiment 1 is that refer to image 3 , Design the masking material into a W shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com