Patents

Literature

34results about How to "Optimize the spraying process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

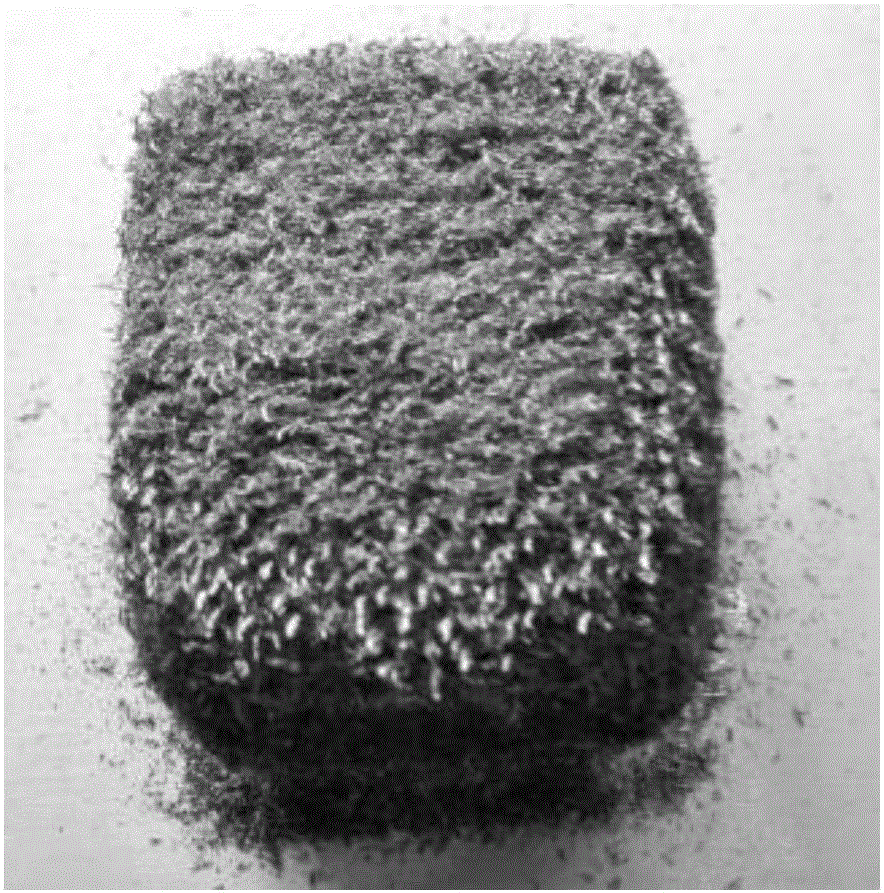

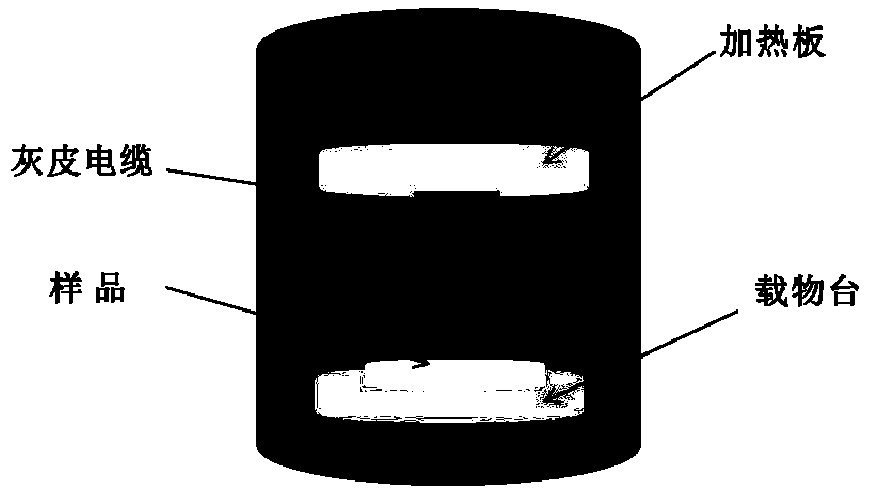

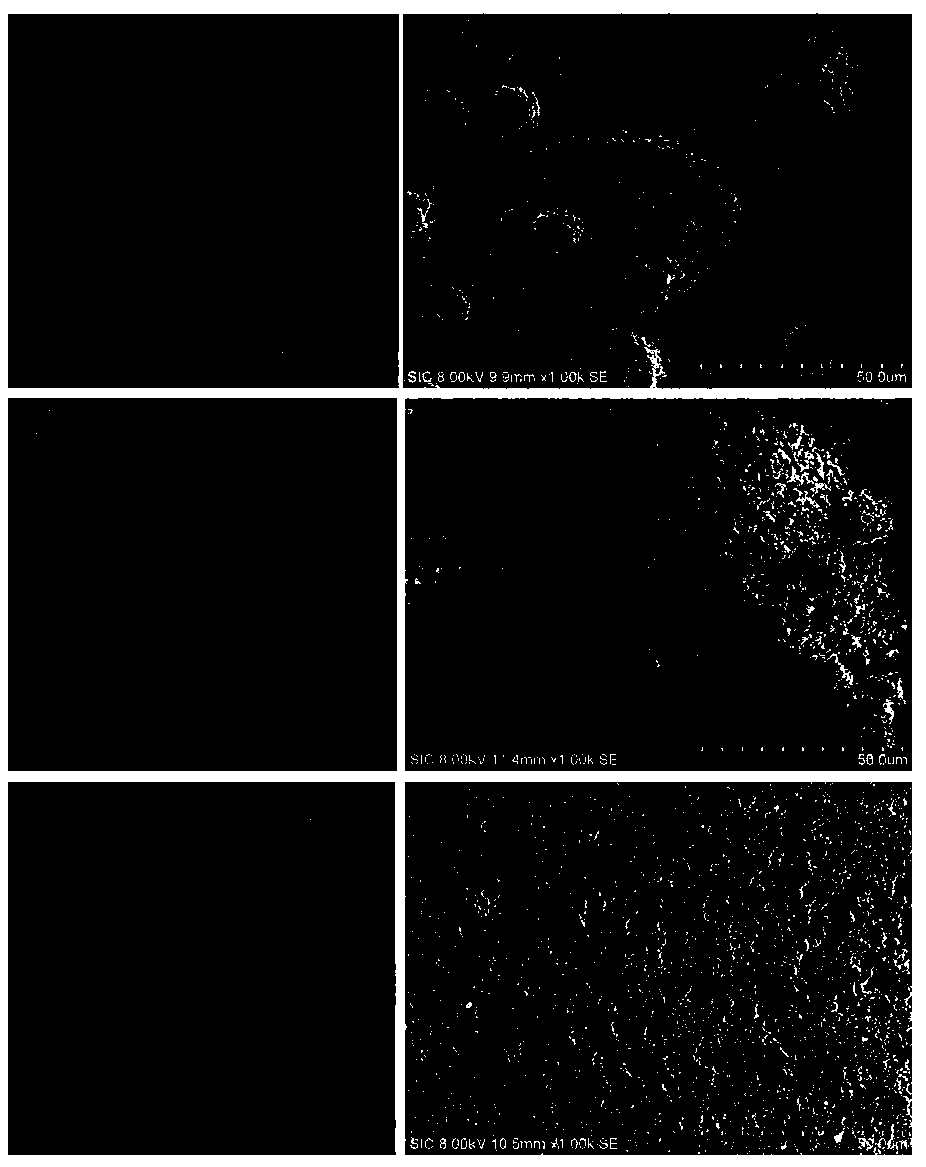

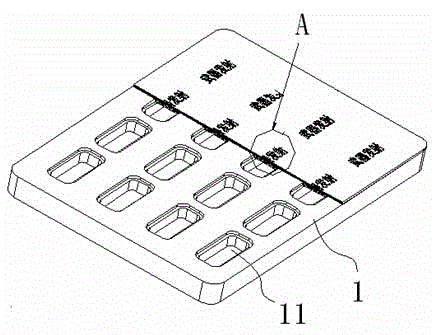

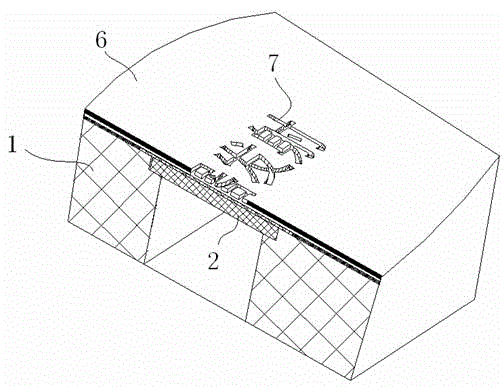

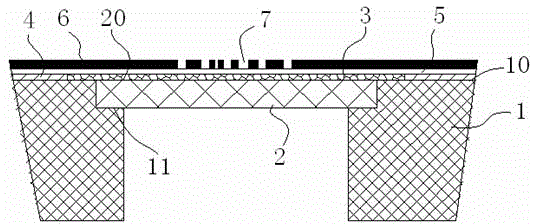

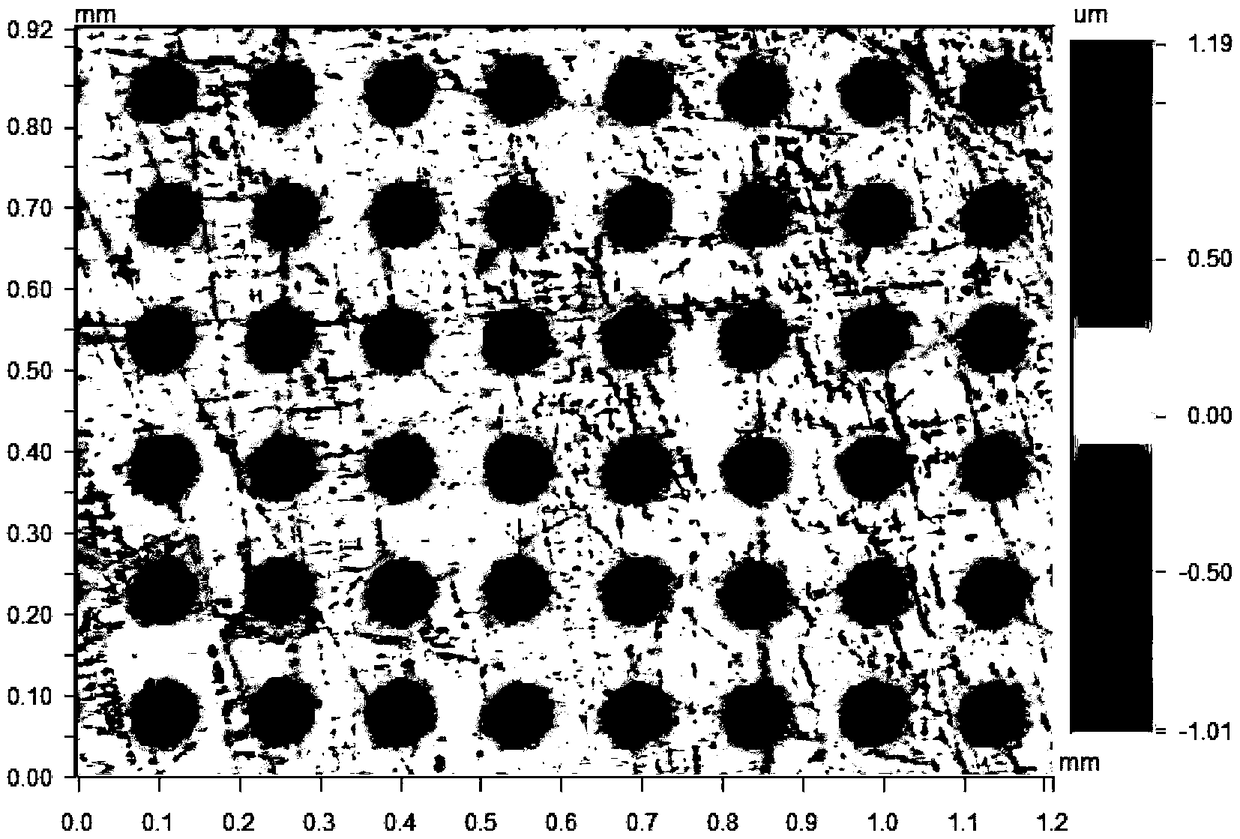

Solid lubrication treatment method for friction pair laser micro-texture surface

InactiveCN105782243AImprove carrying capacityOptimize the spraying processShaftsBearing componentsPre treatmentHigh pressure

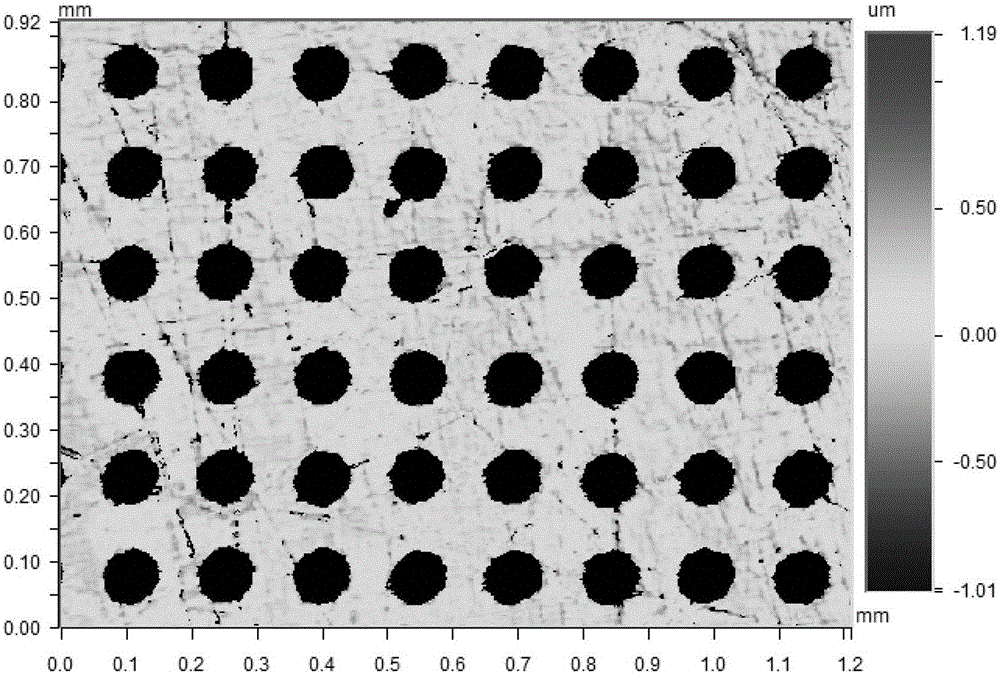

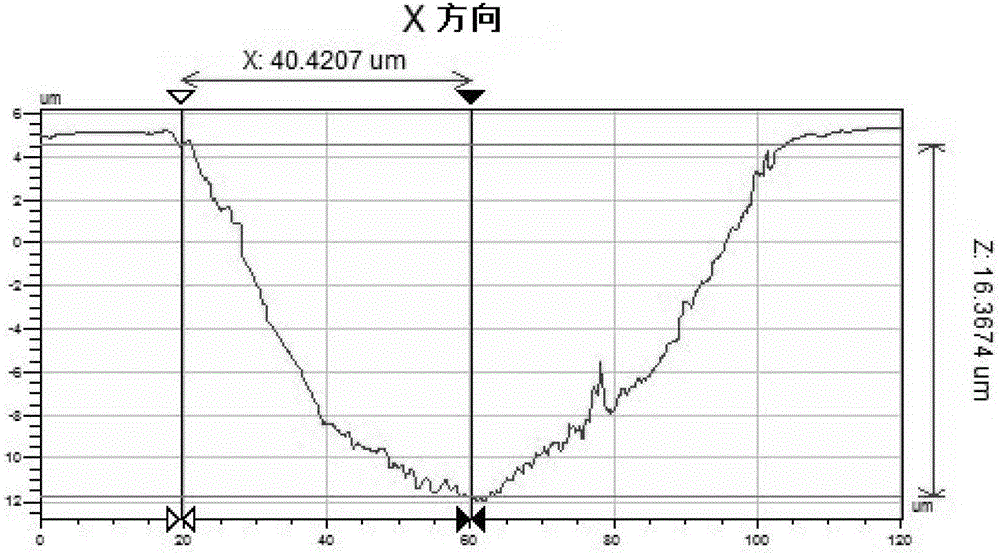

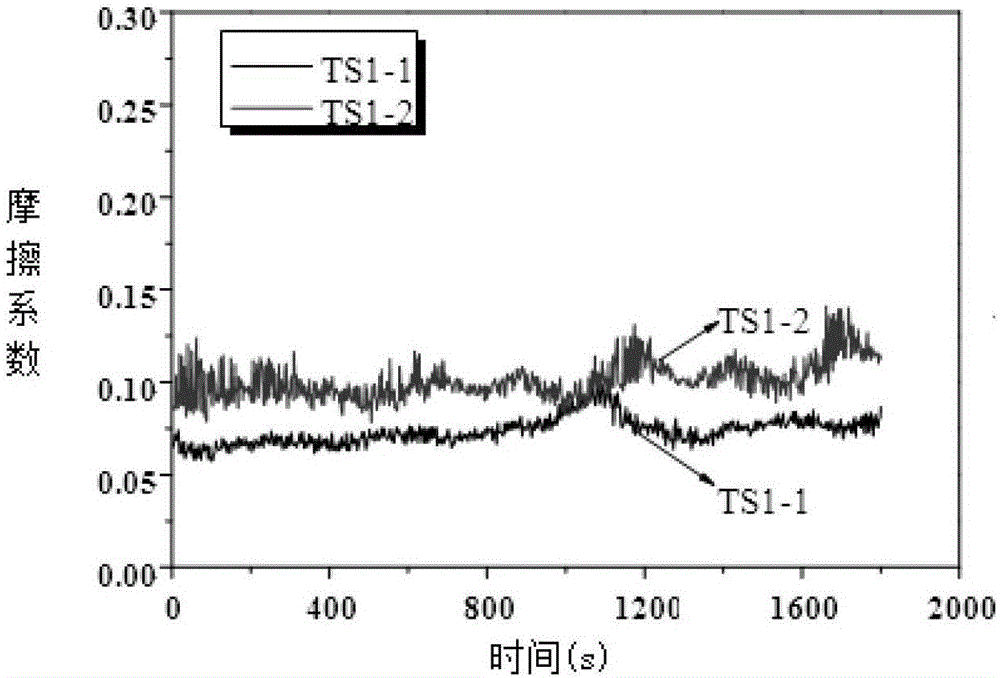

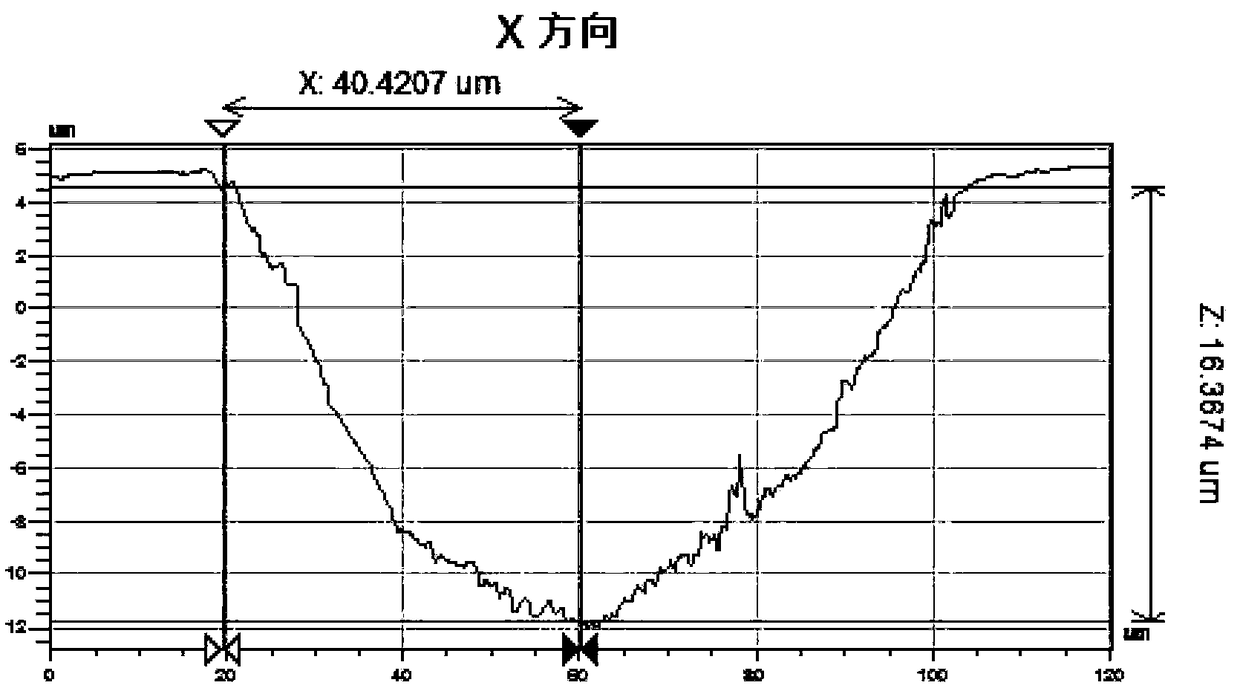

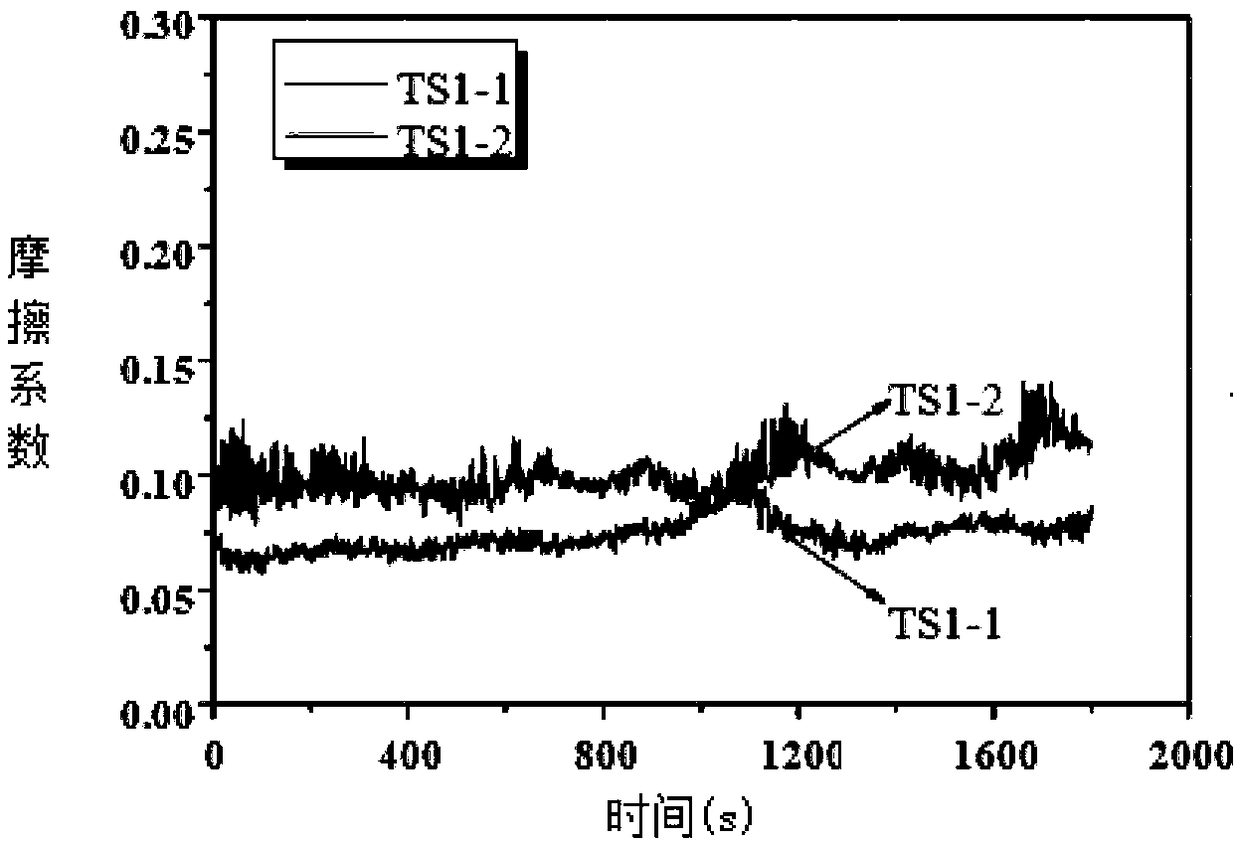

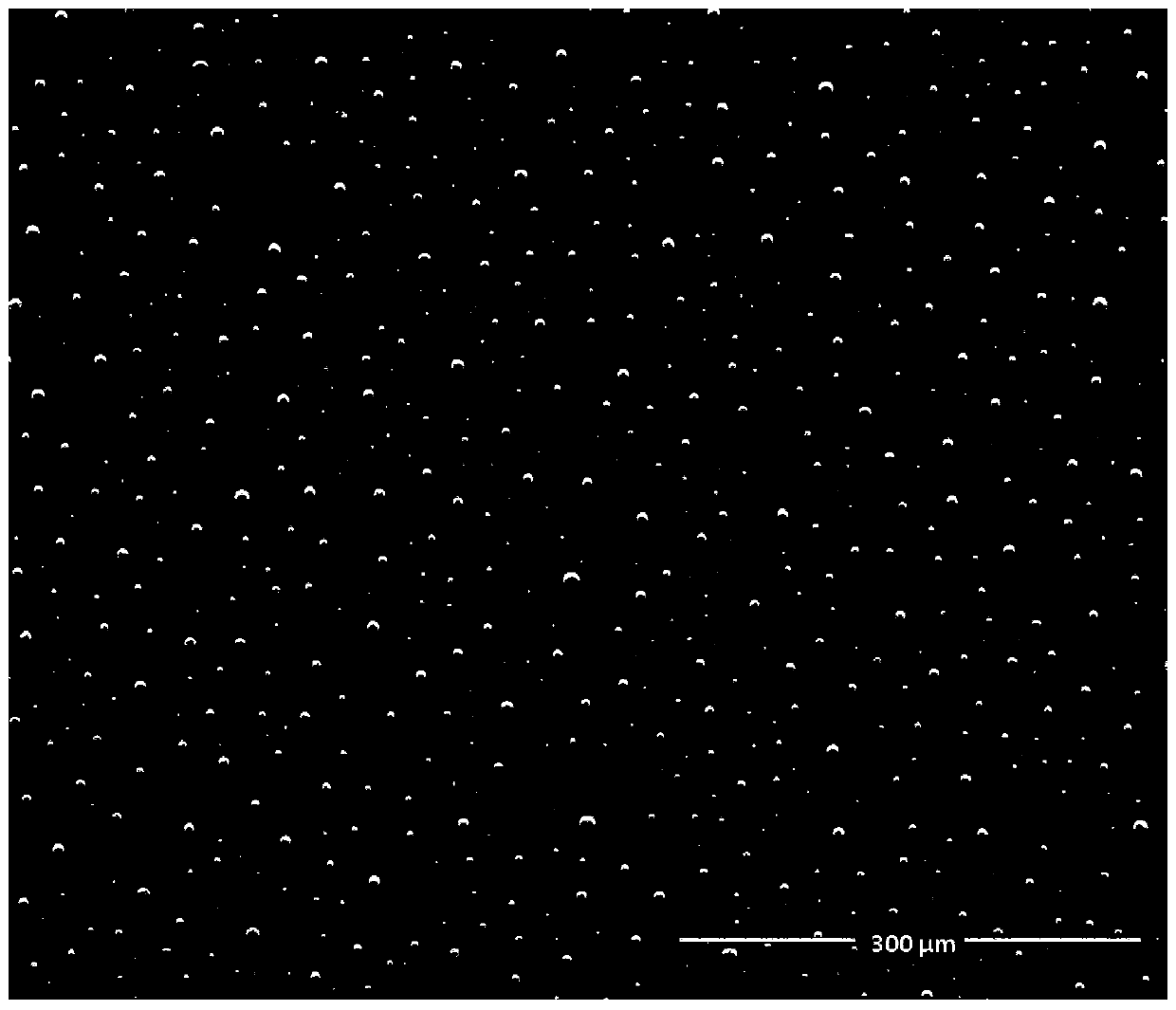

The invention provides a solid lubrication treatment method for a friction pair laser micro-texture surface. The method comprises the steps that a micro-pit shape is machined on the surface of a friction pair through the laser surface texturing technology; all components in a self-lubrication composite are evenly mixed and dried to be used later; the surface micro-pit in a pre-treated die is filled with the self-lubrication composite through a die hot-press curing filling method; pressure maintaining hot-press curing filling is conducted through a hot press; then, the filled friction pair is heated for 20 min at the temperature of 250 DEG C and then protected by 99.9% of N2 to be heated for 30 min at the temperature ranging from 370 DEG C to 385 DEG C, insulating sintering is conducted for 0.5 h-1.0 h, and sintering forming is conducted after cooling; and solid lubrication can be finished after surface posttreatment. According to the method, the high-temperature sliding friction performance of the self-lubrication surface of a micro-texture can be improved, a good lubricating effect can be achieved under the conditions such as the high temperature and the high pressure, the bearing capability of a nanometer composite solid lubricating agent is effectively improved, and the nanometer composite solid lubricating agent can be applied under some complex and strict work conditions.

Owner:JIANGSU UNIV

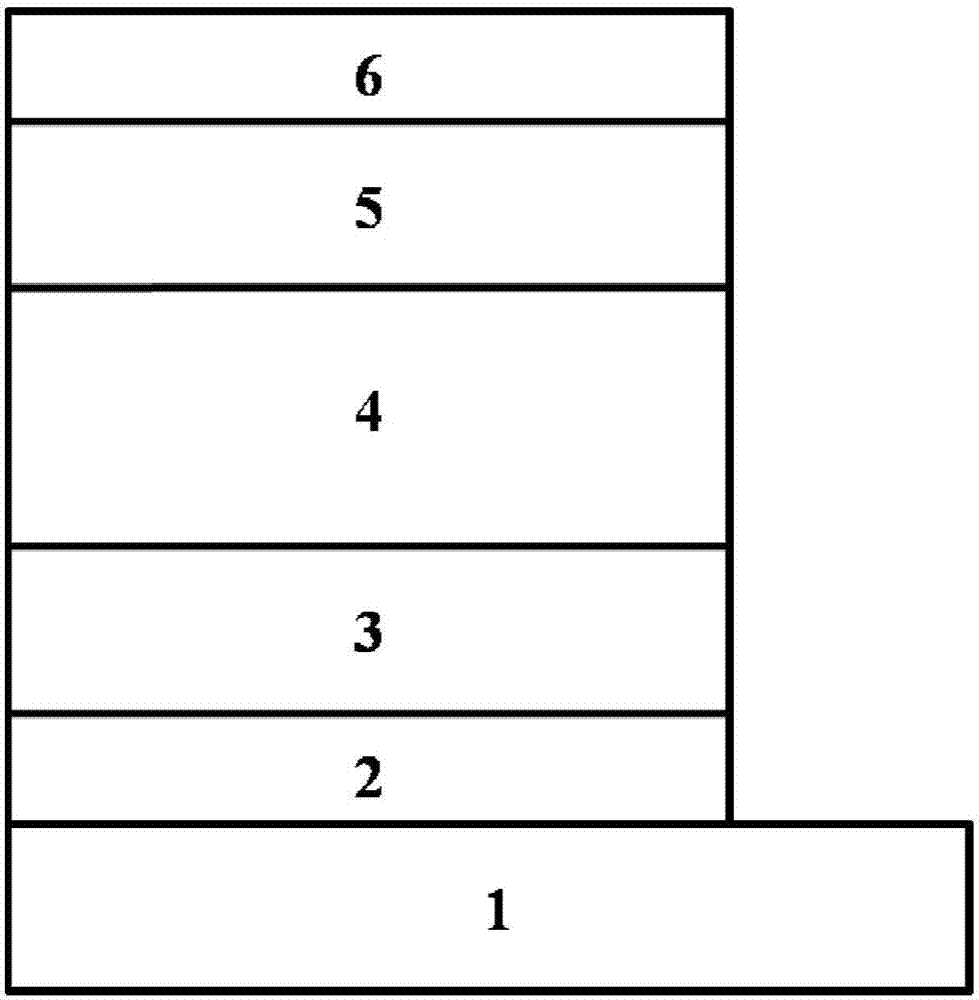

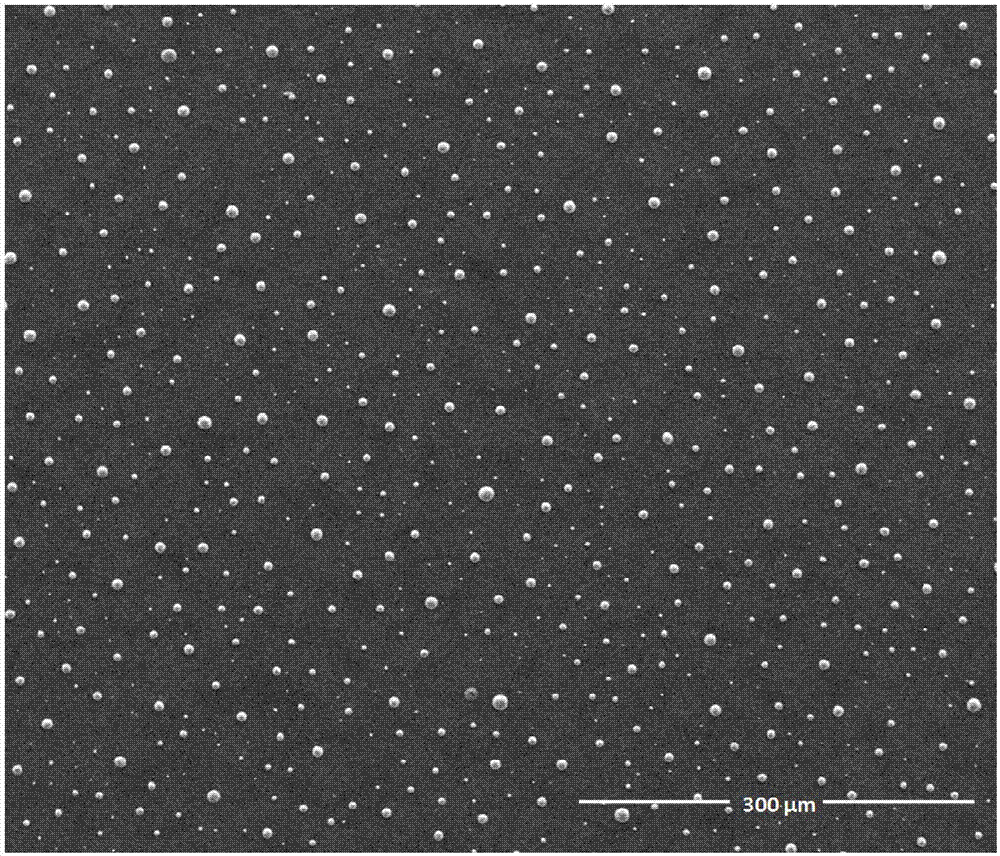

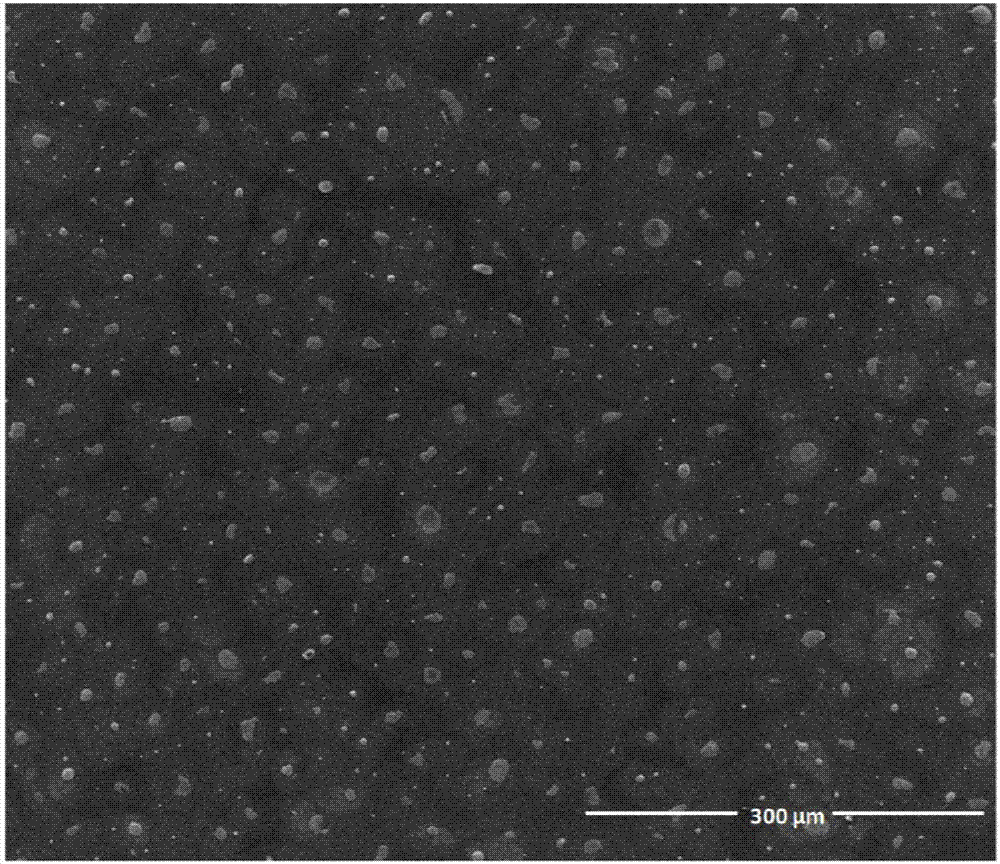

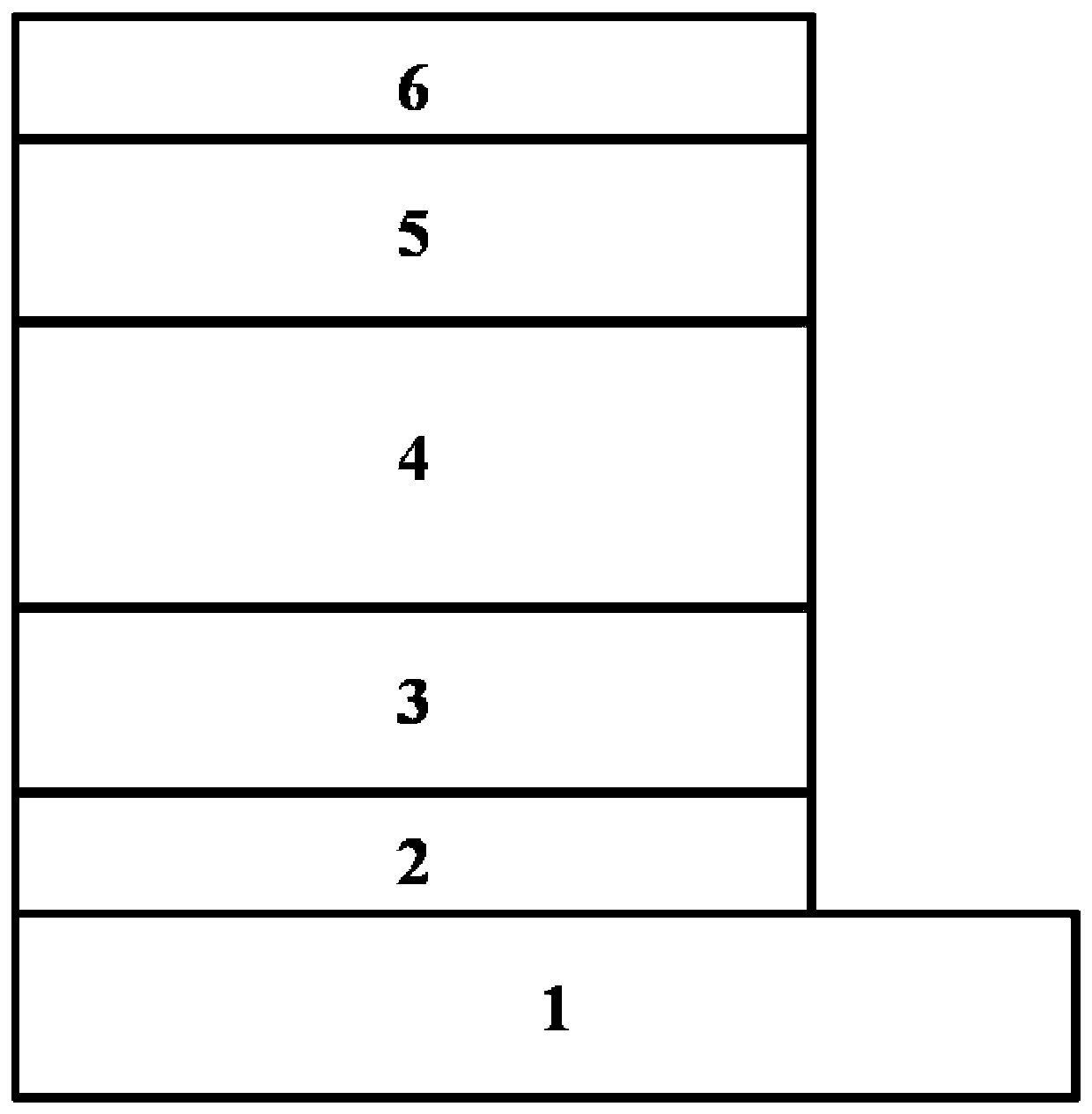

Organic solar cell based on sprayed molybdenum trioxide anode buffer array and preparation method thereof

ActiveCN107369769AImprove performanceReduce chance of recombinationSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellSolar cell

The invention relates to an organic solar cell based on a sprayed molybdenum trioxide anode buffer array. The solar cell, which is of a reciprocal form structure, includes a substrate layer, an ITO transparent conductive cathode layer, a cathode buffer layer, an optical active layer, an anode buffer layer and a metal anode layer in sequence from bottom to top. The anode buffer layer is a molybdenum trioxide array film generated by spraying hyaluronic acid doped ammonium molybdate aqueous solution on the optical active layer and carrying out annealing. The molybdenum trioxide array film includes 0.2-1wt% of ammonium molybdate and 0-0.5 wt% of hyaluronic acid. The invention further discloses a preparation method of the cell. The ammonium molybdate aqueous solution, the precursor of ammonium molybdate, is doped with hyaluronic acid to form a hyaluronic acid layer on the optical active layer. A dangling chemical bond introduced can make the ammonium molybdate layer and the active layer in good ohmic contact. Thus, the performance of the cell is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

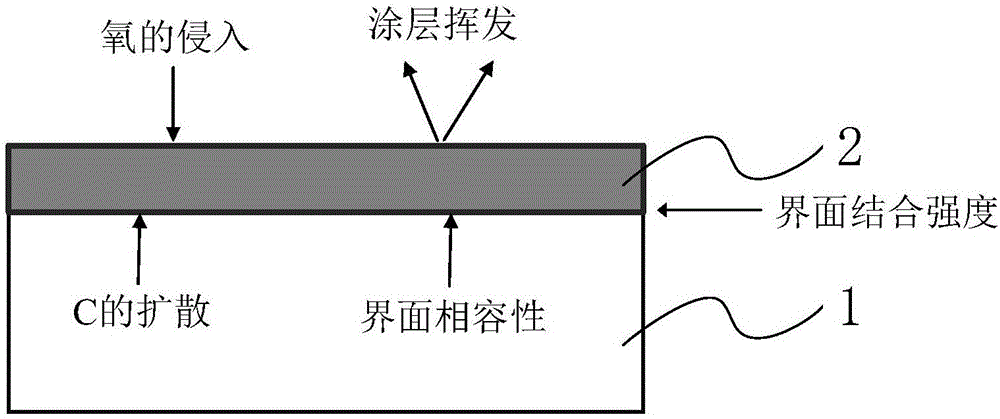

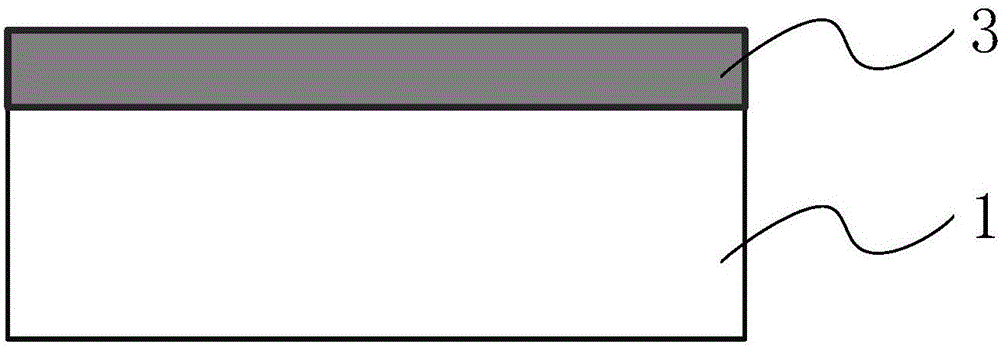

Self-healing anti-oxidation paint for surface of curing blanket and preparation method of self-healing anti-oxidation paint

InactiveCN106752644AImprove antioxidant capacityPrevent slaggingEpoxy resin coatingsSelf-healingHeat conducting

The invention relates to a self-healing anti-oxidation paint for the surface of a curing blanket. The paint is prepared from an antioxidant, a heat-conducting additive and a binder. The paint can be used for anti-oxidation of the surface of the curing blanket, can be sprayed on the surface of the curing blanket through manual brushing or spray gun coating. The self-healing anti-oxidation paint is simple in operation and low in cost; a coating is tightly combined with a matrix material after being dried and curried, and is not easy to peel off; and the problem of residue dropping after high-temperature oxidation of the curing blanket can be effectively solved. Meanwhile, compared with a common paint, the coating has self-healing and anti-oxidation characteristics, and can be used for a high-temperature aerobic environment below 1600 DEG C.

Owner:SHANGHAI TOYO TANSO

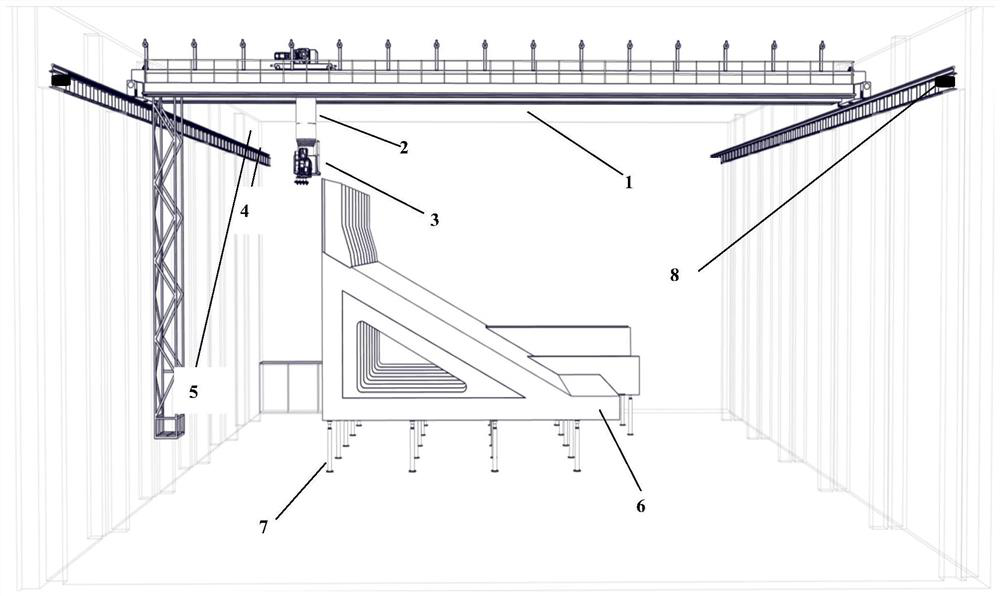

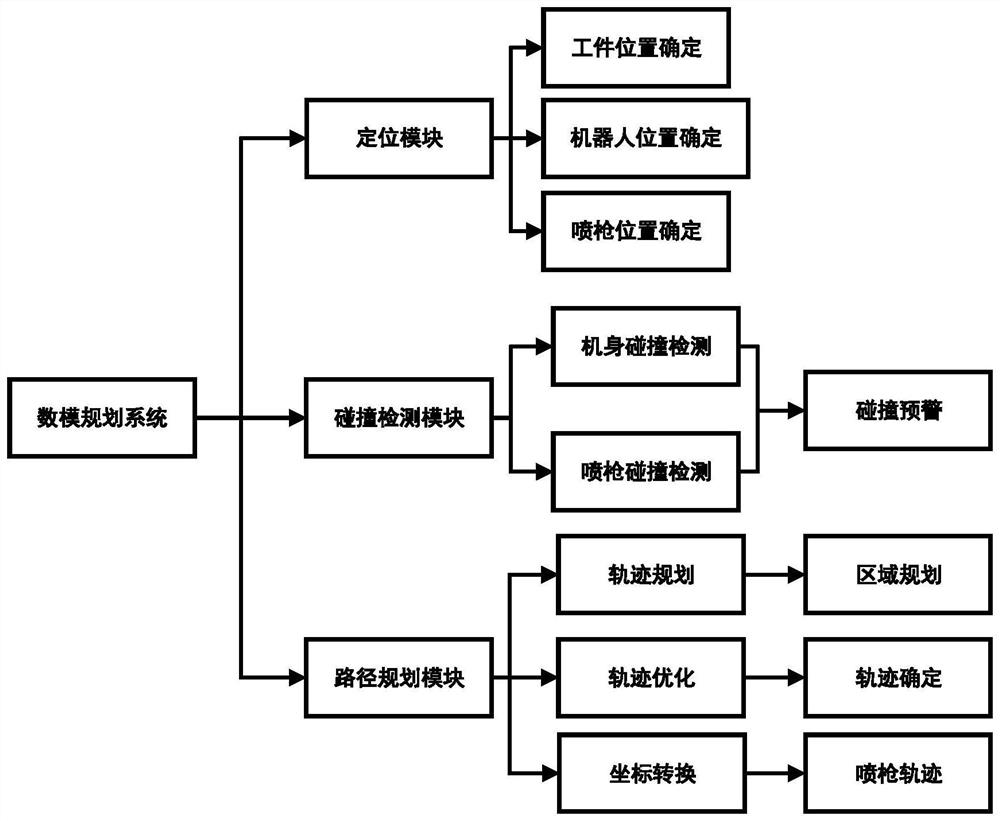

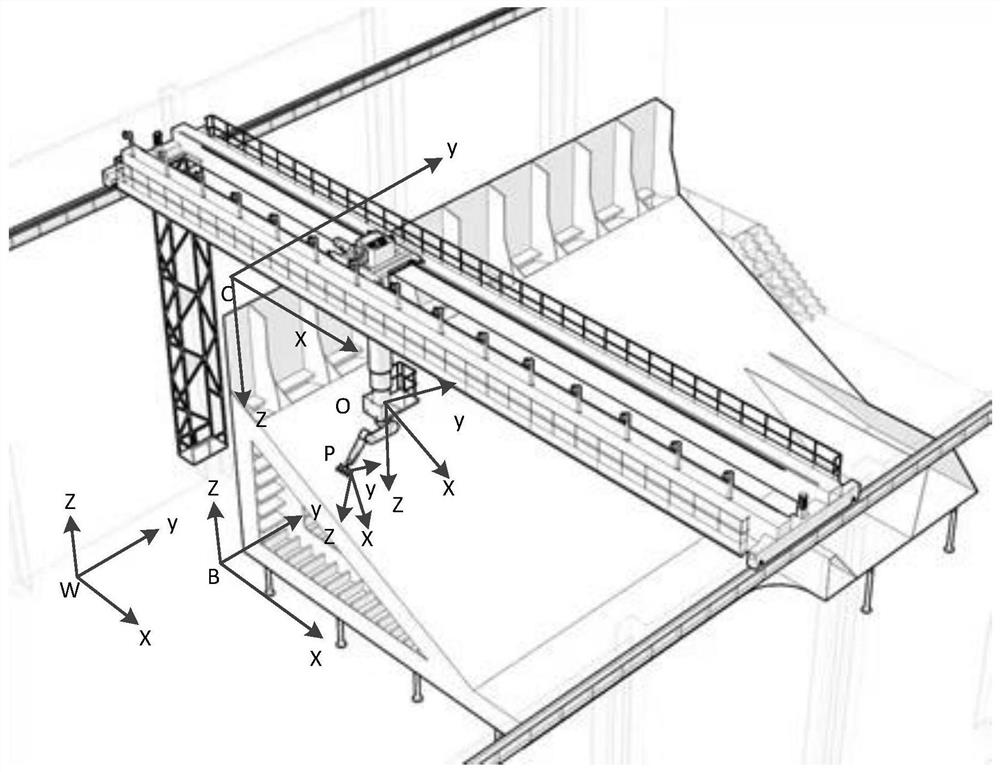

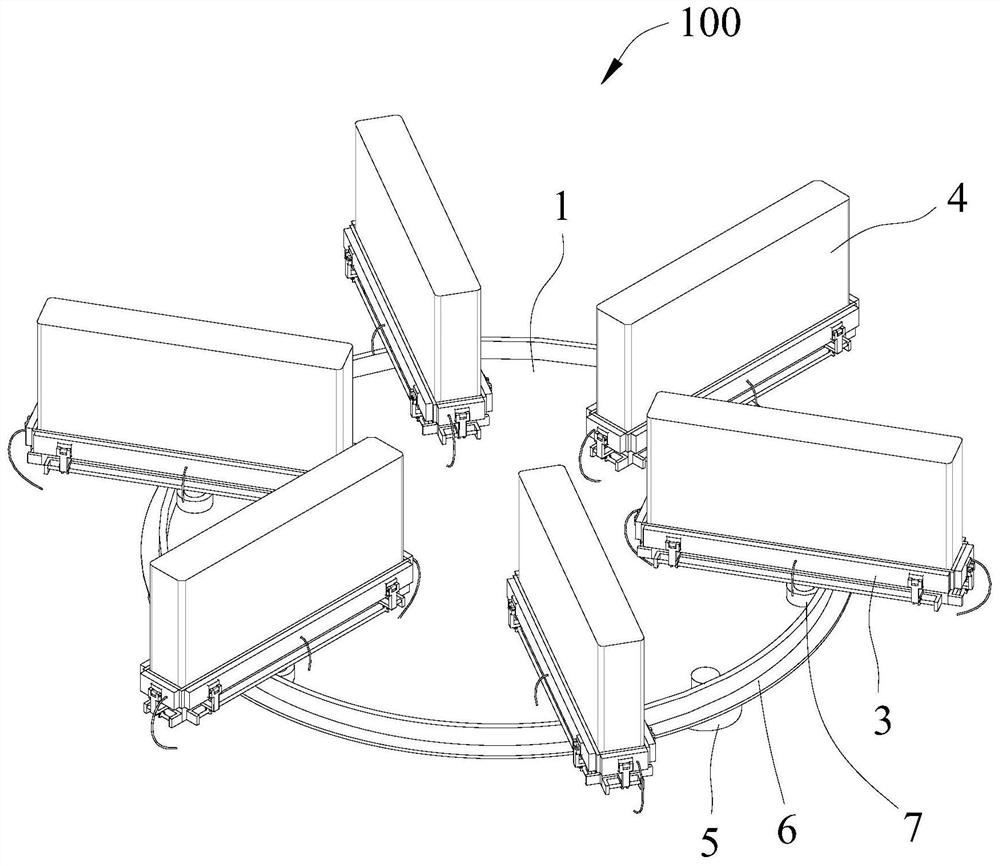

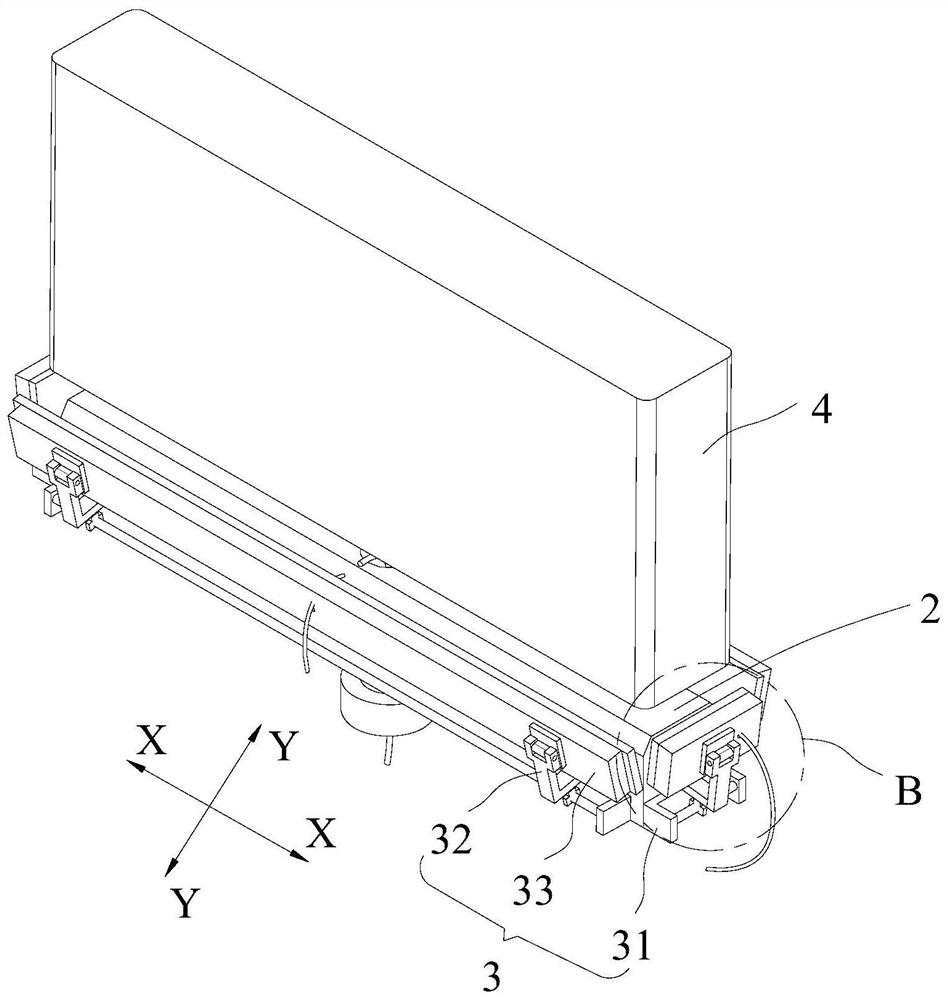

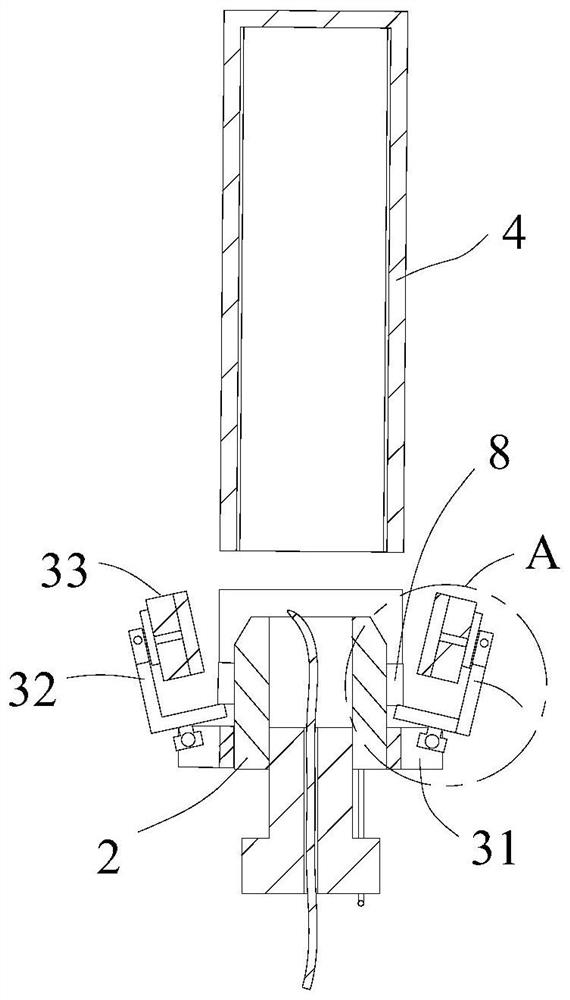

Off-line digital-analog planning system and method for spraying operation of large ship body sections

ActiveCN114082568AAchieve all-round spraying effectRapid Changes in Spraying JobsProgramme-controlled manipulatorSpraying apparatusControl engineeringStructural engineering

The invention discloses an off-line digital-analog planning system and method for spraying operation of large ship body sections. The method comprises the steps that a spraying work station which is the same as an actual spraying site is built in simulation software according to the actual spraying site; a to-be-sprayed segmented ship body model is imported into the simulation work station, and a distance measuring sensor is used for positioning a crown block, a robot, a spray gun and a hull workpiece; to-be-sprayed areas of the segmented ship body are delimited, and path planning is conducted on all the areas through a path planning module; an improved grey wolf algorithm is adopted to optimize transition paths among the areas to obtain a final spraying path; a coordinate conversion module is used for converting spraying paths under a segmented ship body coordinate system B-xyz into path coordinates under a spray gun coordinate system, a spraying robot coordinate system and a crown block coordinate system, and the crown block, the robot and the spray gun move cooperatively; a paint film is detected, and a track is exported. The spraying model can be used for spraying different ship bodies only by building the model for the first time, operation is easy and convenient, and the automation degree is high.

Owner:JIANGSU UNIV OF SCI & TECH

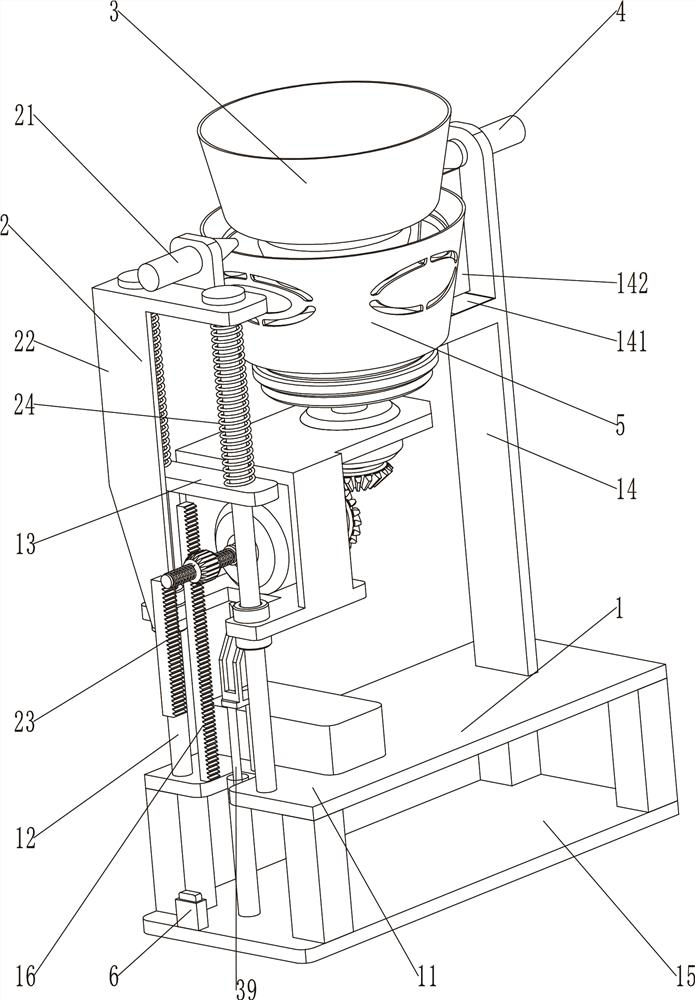

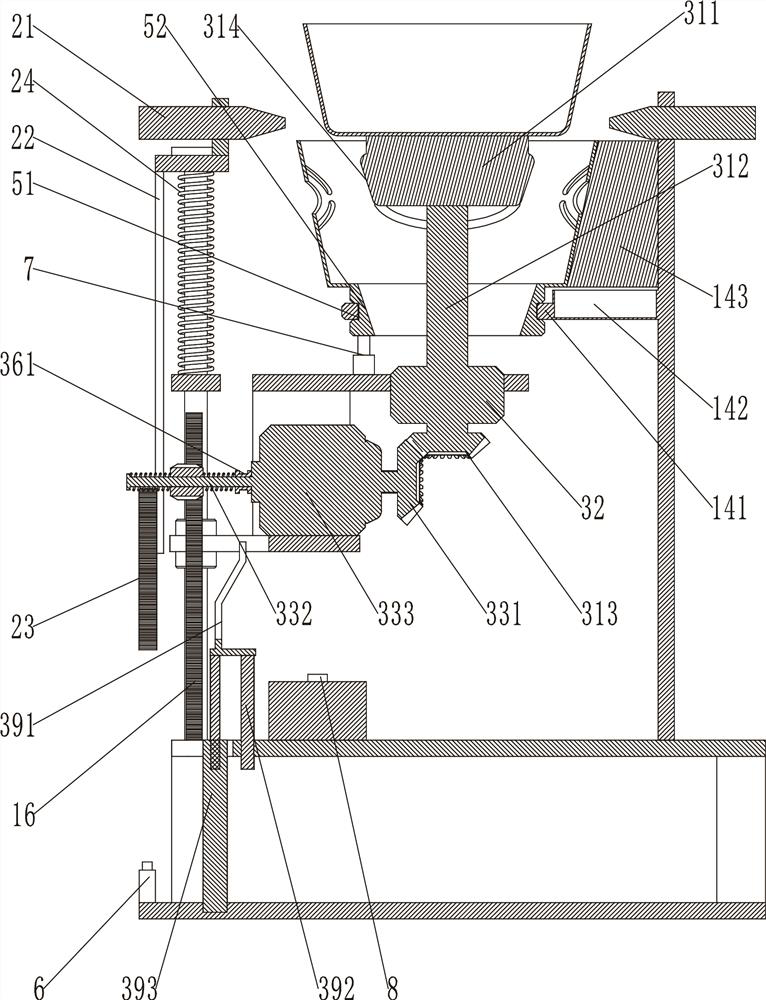

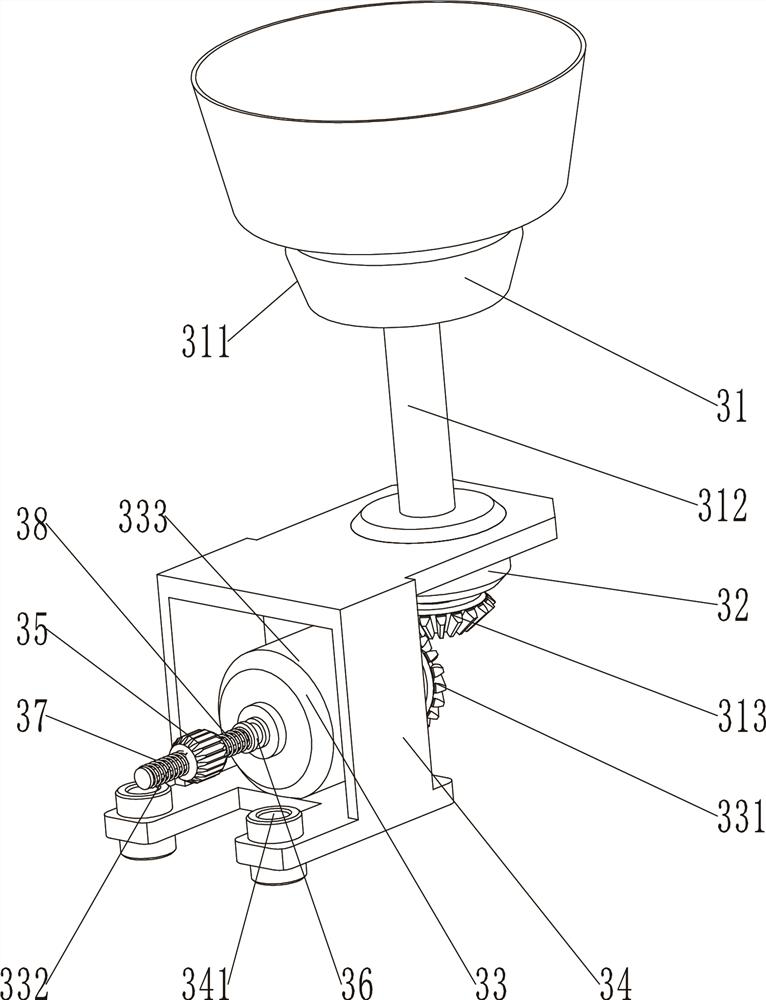

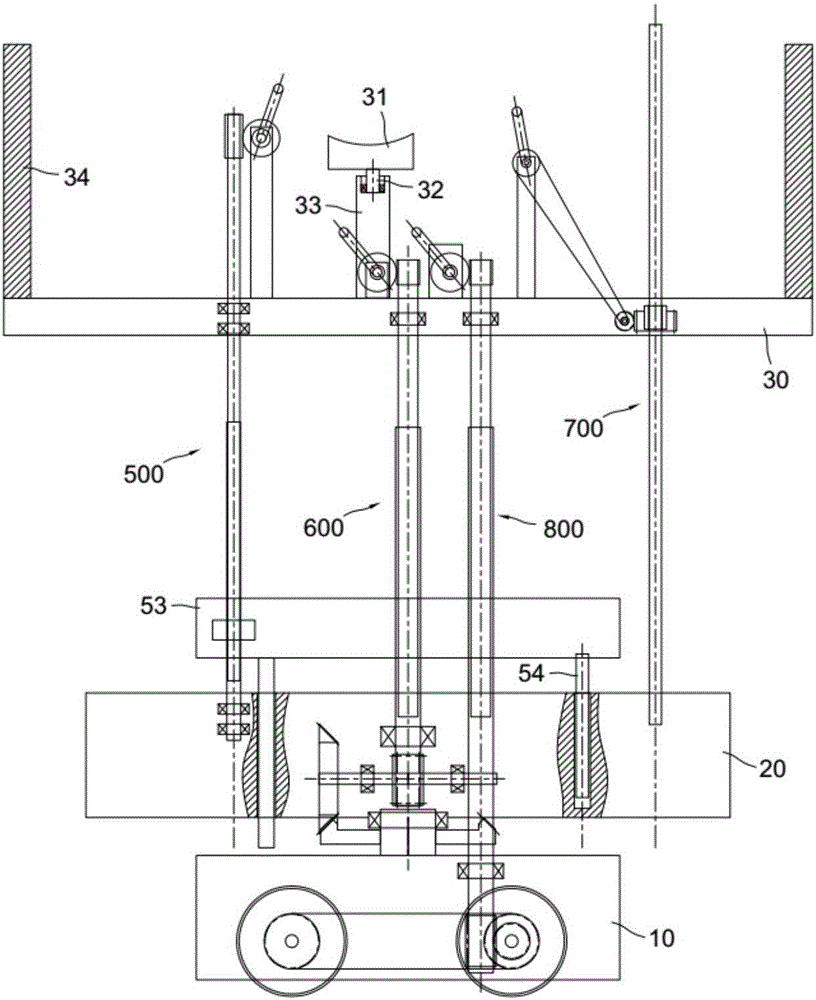

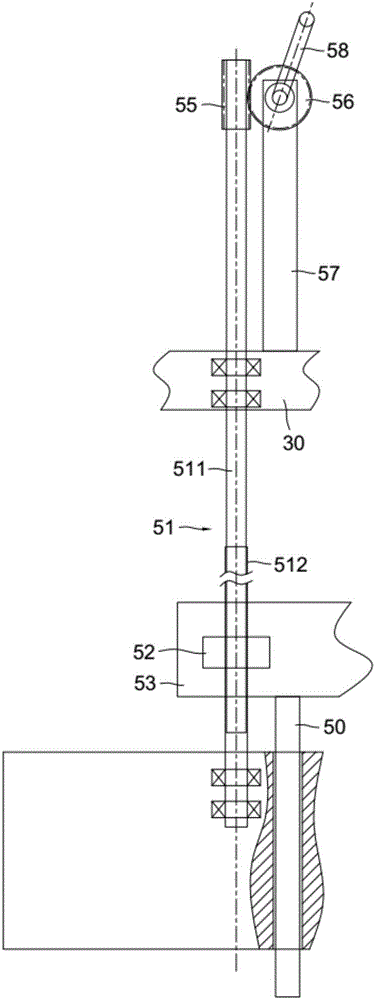

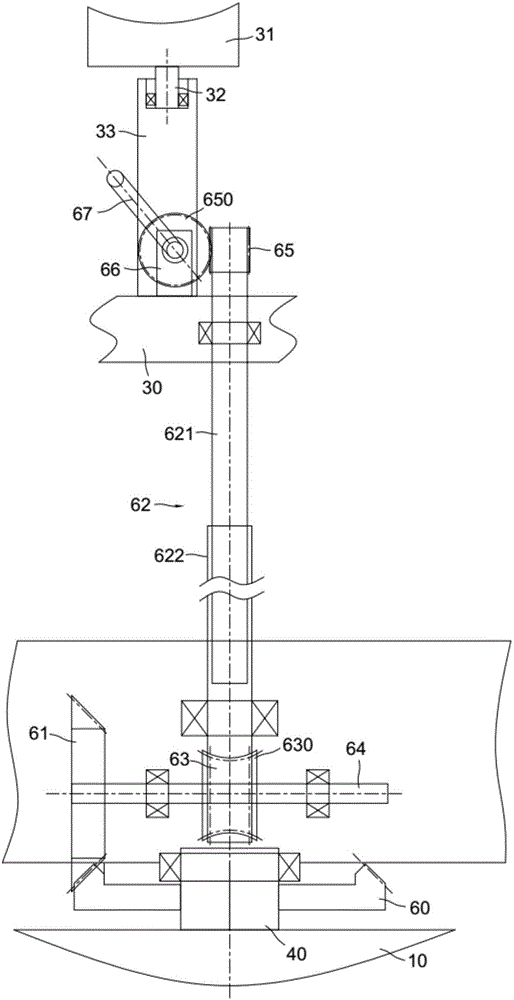

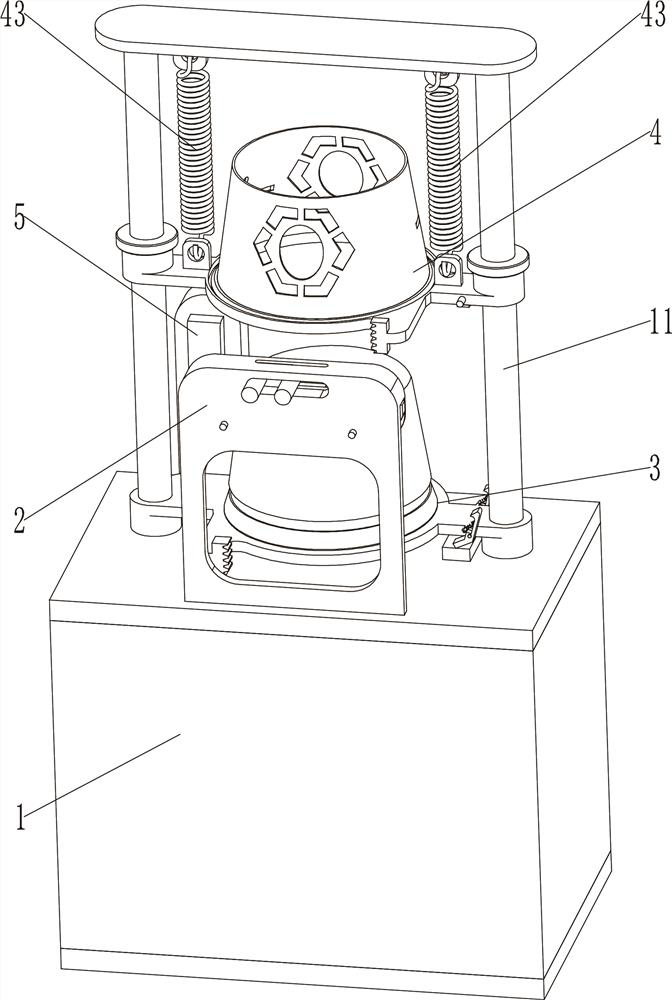

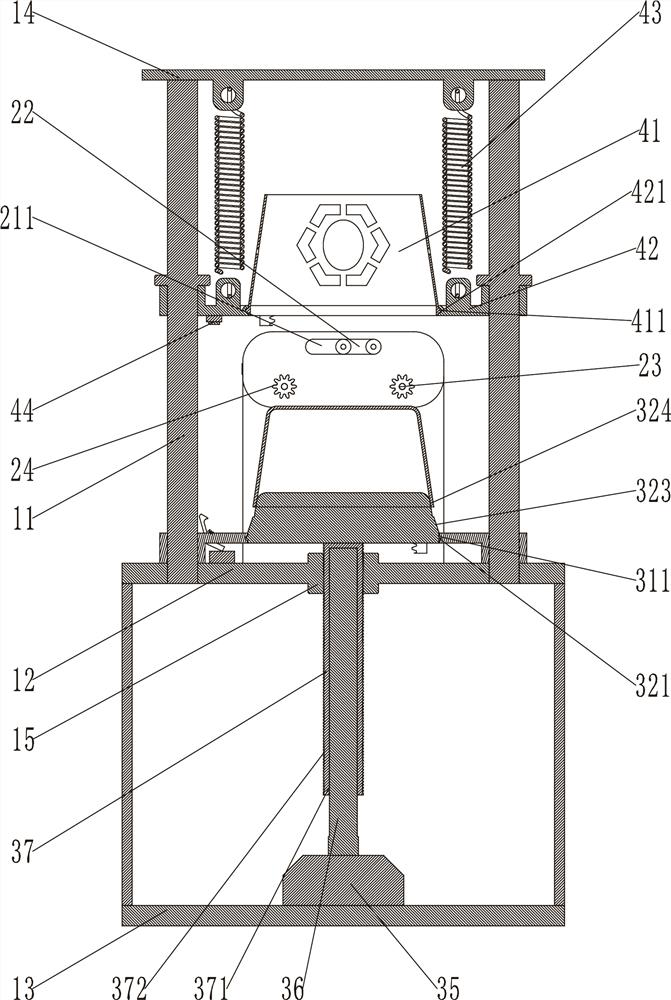

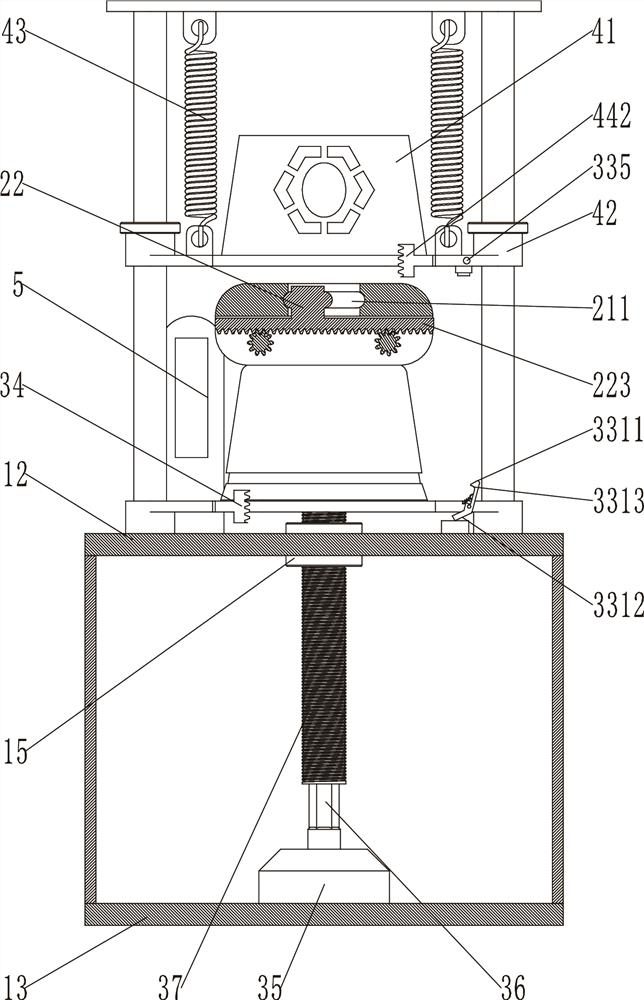

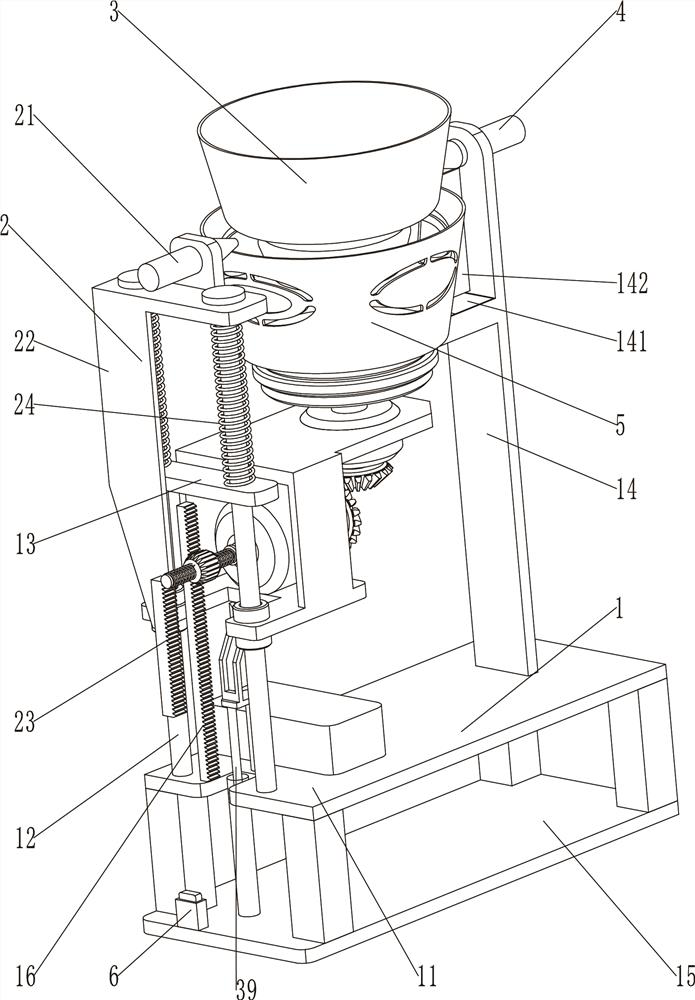

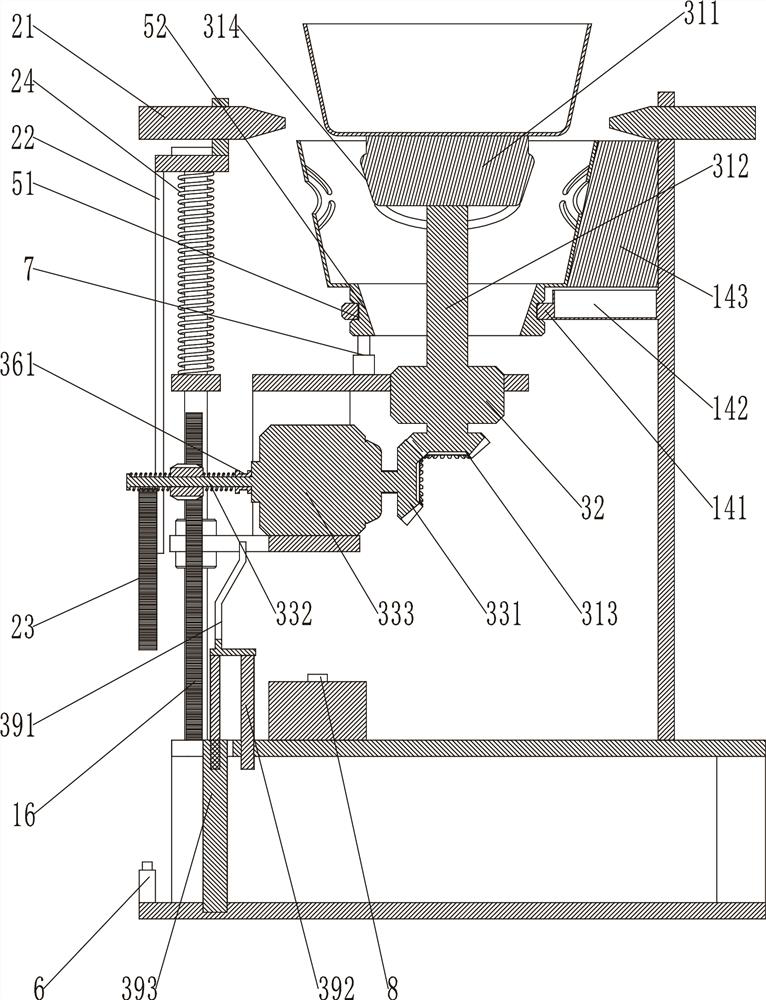

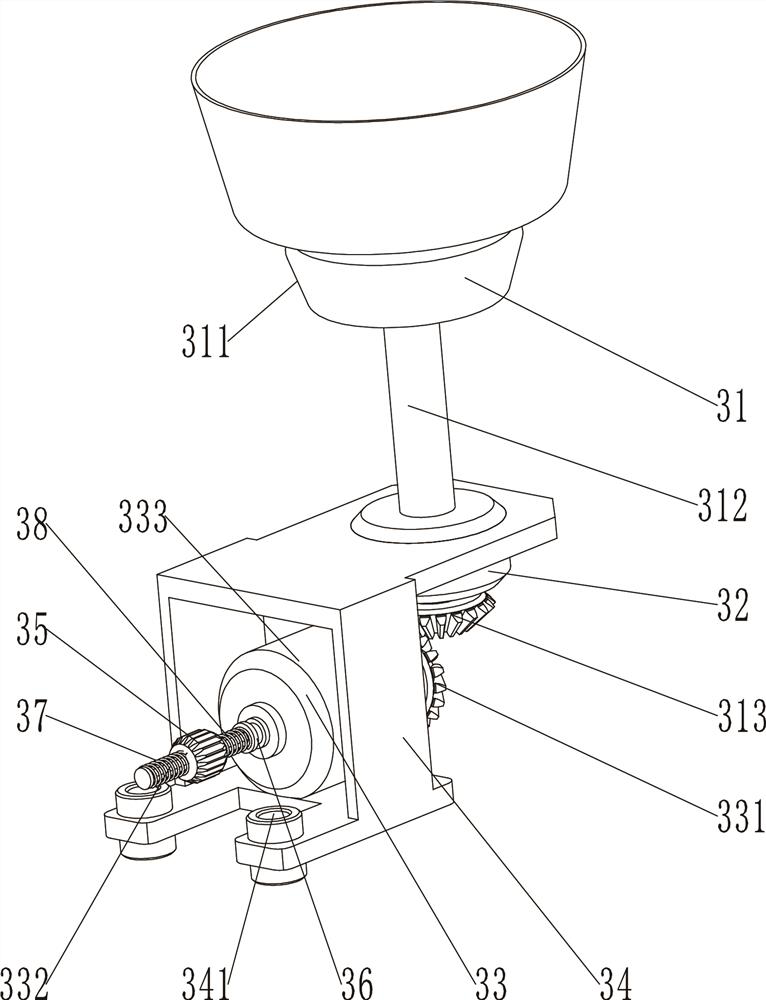

Manufacturing equipment of pot body

ActiveCN113578582AEasy initial stateRestore initial stateSpraying apparatusMachineIndustrial engineering

The invention discloses manufacturing equipment of a pot body. The manufacturing equipment comprises a machine frame, a rotating platform, a shielding part assembly, a first spray gun assembly and a second spray gun assembly, wherein the rotating platform is arranged on the machine frame, an unsprayed pot body is arranged on the rotating platform, the rotating platform drives the pot body to rotate and slide downwards, and the shielding part assembly is arranged on the machine frame; and the rotating platform is matched with the shielding part assembly, and the rotating platform can drive a shielding part on the shielding part assembly to rotate. The invention provides coating equipment capable of spraying different types of pot bodies, and pattern coating can be performed on the pot bodies, so that the spraying operation is automatic, the labor cost is saved, the spraying process is optimized, patterns on the surface of a cooker are more attractive, the ornamental value of the cooker is improved, the competitiveness of the cooker is improved, and the enterprise benefit is improved.

Owner:ZHEJIANG COOKER KING COOKER

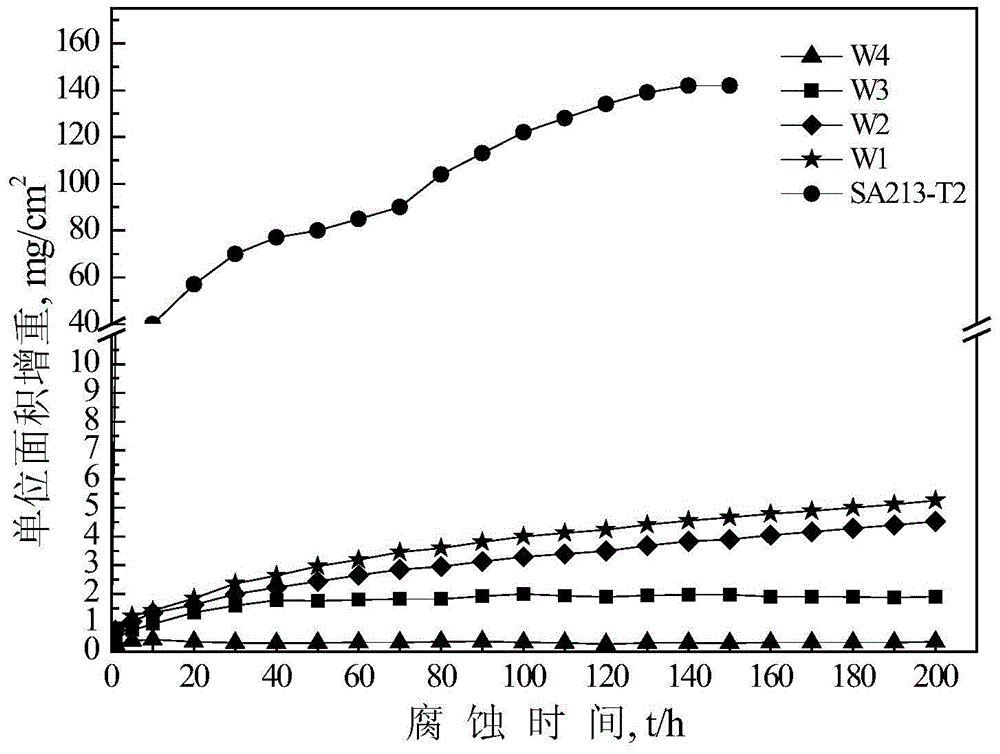

Nickel-based powder core wire and preparation and application of coating

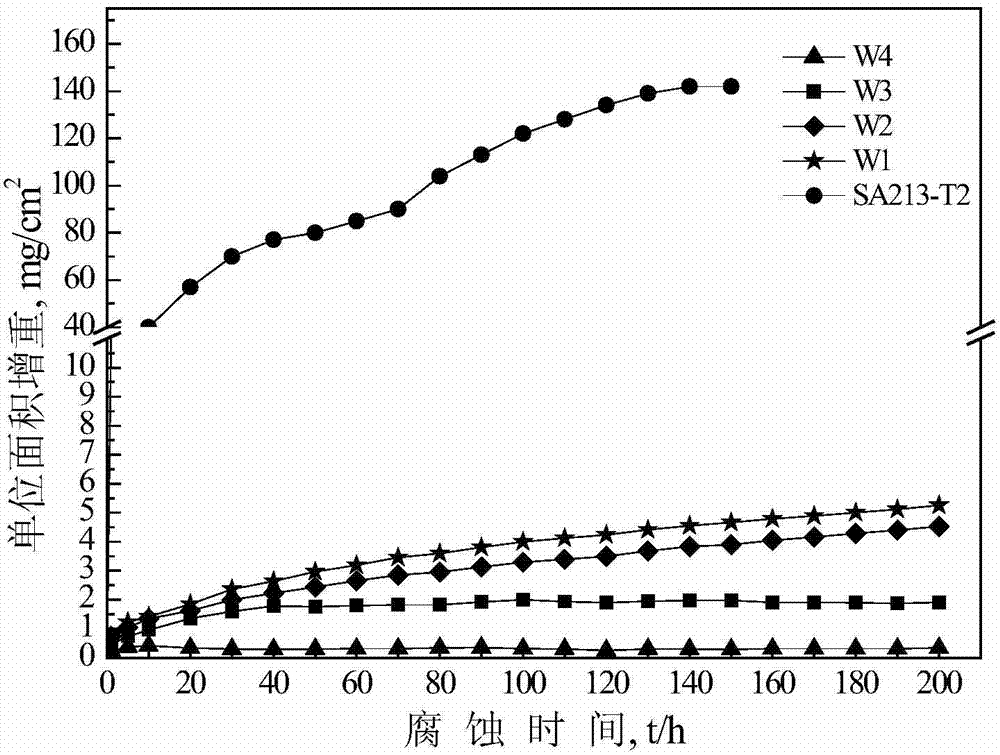

ActiveCN103924183AHigh hardnessGood wear resistanceMolten spray coatingIncinerator apparatusSuperheaterCorrosion resistant

The invention relates to a nickel-based powder core wire and preparation and application of a coating and belongs to the thermal spraying field of material processing engineering. The chemical core comprises the following components in percentage by weight: 20-35% of pure metal chromium powder, 1-4% of pure metal tungsten, 1-30% of nickel boron powder and the balance of nickel. The strip for the outer skin of the powder core wire is 80Ni-20Cr strip. The filling rate of the powder core wire is 32%. When a tungsten-nickel-containing coating is prepared by an electric arc spraying method, a base body is pre-treated first and the spraying process is carried out under following conditions: the voltage is 28-34V, the current is 160-220A, the spraying distance is 190-210mm and the pressure of the compressed air is 0.5-0.6MPa. According to the tungsten-containing corrosion-resistant coating obtained by the invention, the high-temperature corrosion resistance of the coating is increased, and the service stability of a water cooling wall pipe and an over-heater pipe in a waste resourceful WTE (Waste-To-Energy) garbage incinerator is improved.

Owner:唐山宝航机械制造有限公司

Cobalt-containing phosphating agent, metal part and surface phosphating treatment method thereof

InactiveCN112725786AMeticulous structureCompact structureMetallic material coating processesO-Phosphoric AcidMagnesium salt

The invention relates to a cobalt-containing phosphating agent, a metal part and a surface phosphating treatment method thereof. The phosphating agent is used for metal part surface pretreatment, and comprises the following components in parts by weight, based on 1000 parts: 5-30 parts of phosphoric acid, 3-10 parts of zinc oxide, 0.5-3 parts of a magnesium salt, 0.5-3 parts of an aluminum salt, 0.5-5 parts of cobalt nitrate and the balance of water. A film layer structure formed by the phosphating agent is compact in structure and firm in adhesion force, and a continuously-even and colored phosphating layer is generated on the surface of the metal part for being applied to phosphating treatment before spraying of steel surfaces such as a cold-rolled plate, a hot-rolled plate and angular steel. A phosphating solution is long in service, is free of wastewater, and can be used for phosphating by brushing, immersing, spraying or a combined way thereof. The phosphating agent can be dried or naturally dried in air at a temperature of 10-50 DEG C, saves energy consumption to a great extent, is short in phosphating time, is free of surface adjustment before use, does not need to add a promoter, and is simple and labor-saving in operation.

Owner:SHENZHEN HENGZHAOZHI TECH CO LTD

Electrical equipment inspection rack

ActiveCN106799721AAchieve rotationSimple welding processWork benchesOther workshop equipmentLocking mechanismPower equipment

The invention discloses an electrical equipment inspection rack. A worker sits on a working chair to operate a first rocking handle manually. A locking mechanism acts. A lifting rod ascends to relieve frictional contact with a top face of a base. A rotary seat and the base can rotate freely. After that, the worker drives a second rocking handle with a foot. A rotation driving mechanism acts. A second bevel gear rotates relative to a bevel gear. A second bevel gear drives the rotary seat to rotate relative to the base. The worker operates a third rocking handle manually. A lifting mechanism acts to realize ascending and descending of a workbench. The worker operates a fourth rocking handle with the foot, a translation mechanism acts. A driving rolling wheel and a driven rolling wheel drive the whole electrical equipment inspection rack to conduct translation along the ground. The inspection rack does multi-dimension motion and is convenient and easy to control.

Owner:吴筱雨

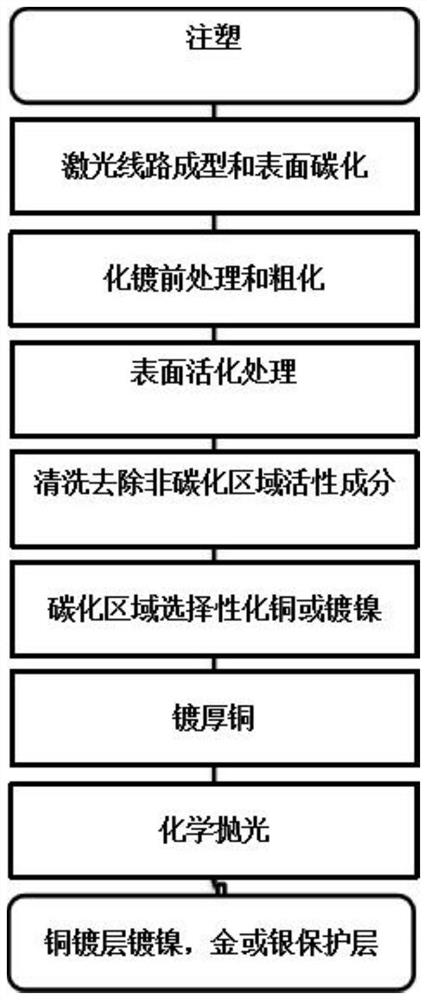

Process for manufacturing three-dimensional circuit through laser etching and plastic surface carbonization

PendingCN113770546AEnsure consistencyImprove the finishWelding/soldering/cutting articlesLaser beam welding apparatusLaser etchingChemical plating

The invention provides a process for manufacturing a three-dimensional circuit through laser etching, plastic surface carbonization and chemical plating, and relates to the technical field of manufacturing of circuits on plastic surfaces. The process comprises the following specific steps that a plastic substrate for bearing the circuit is manufactured through injection molding; a pattern of the circuit is processed on the surface of a plastic part in a laser engraving mode, and the full carbonization effect of a circuit area on the surface of the plastic part is achieved through reasonable selection of a laser light source and optimization of laser parameters while laser is used for processing the circuit; metal is plated in the laser carbonization area through subsequent chemical plating, so that the metal circuit is manufactured on the surface of the plastic; and when the circuit is manufactured on the first-level appearance surface, the smoothness of a plating layer can be fully improved in combination with an optimized special treatment means, and the size of a step between the plating layer and the plastic is reduced, so that the subsequent spraying cost is greatly reduced.

Owner:SHANGHAI SHENZHI OPTOELECTRONICS TECH CO LTD

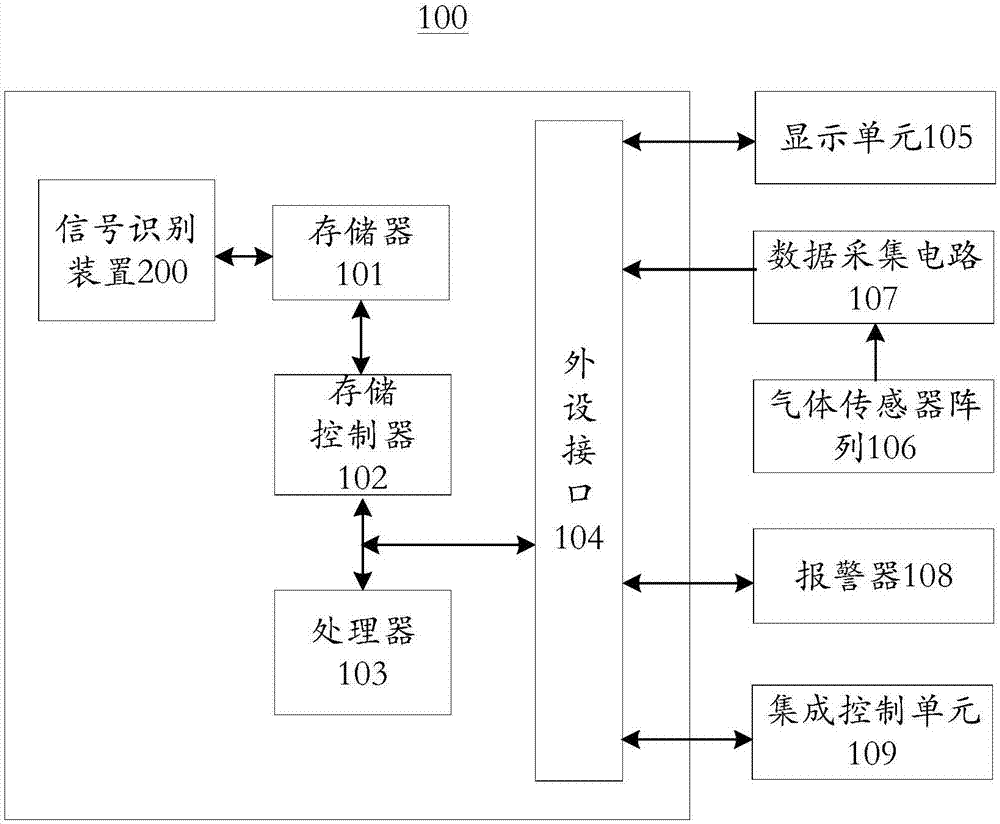

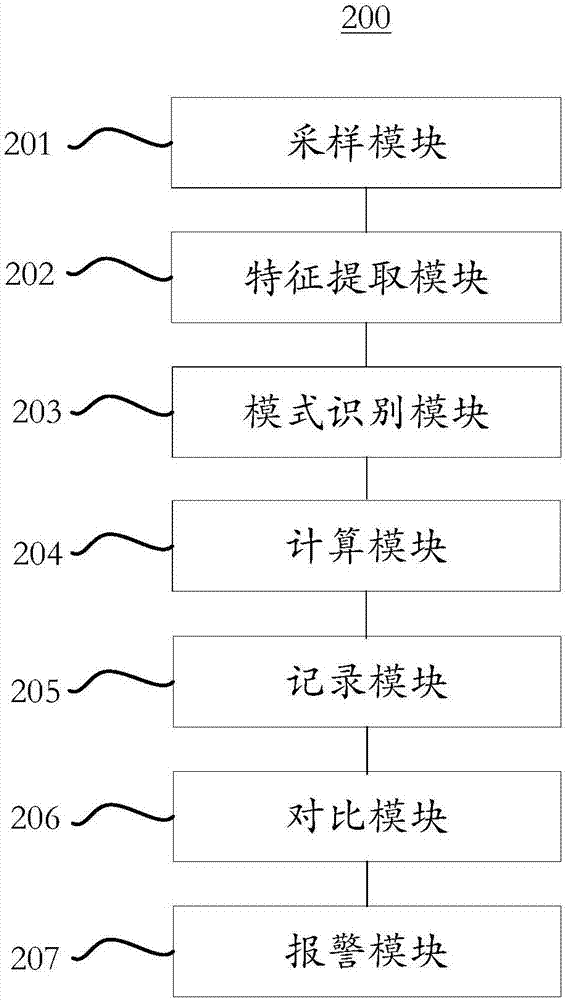

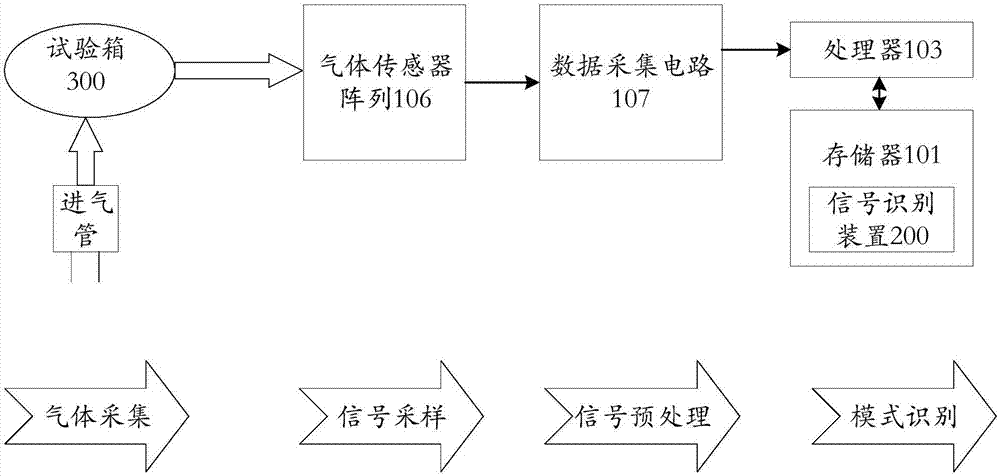

Signal recognition method, signal recognition device and volatile organic compound detection apparatus

InactiveCN107132315AAccurate monitoringEffective Monitoring DataAnalysing gaseous mixturesMaterial electrochemical variablesSensor arrayFeature extraction

The embodiment of the invention provides a signal recognition method, a signal recognition device and a volatile organic matter detection apparatus, and relates to the technical field of air pollutant monitoring. The volatile organic matter detection apparatus is used for carrying out online detection of VOCs, application programs of the signal recognition method and the signal recognition device are stored in the volatile organic matter detection apparatus, the apparatus can collect the VOC pollutants, and a responded signal undergoes preprocessing, sampling, feature extraction, recognition and calculation through the corresponding of a gas sensor array to obtain the kinds of gases contained in the VOCs and the corresponding concentrations in order to rapidly and accurately monitor the VOC pollutants in the spraying process. The method, the device and the apparatus can provide effective monitoring data for environmental monitoring, and also can provide theoretical support for improving the spraying process and technology.

Owner:YANCHENG INST OF TECH

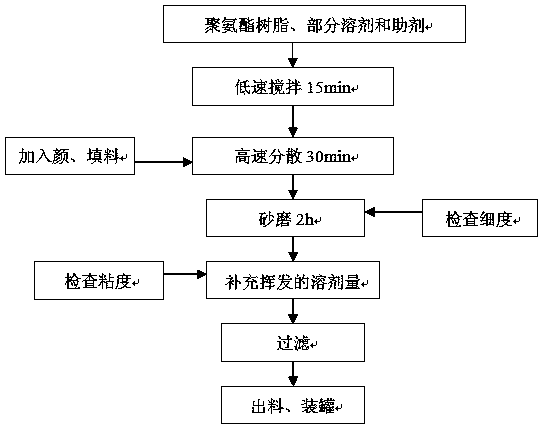

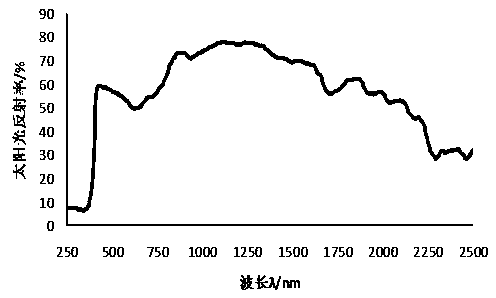

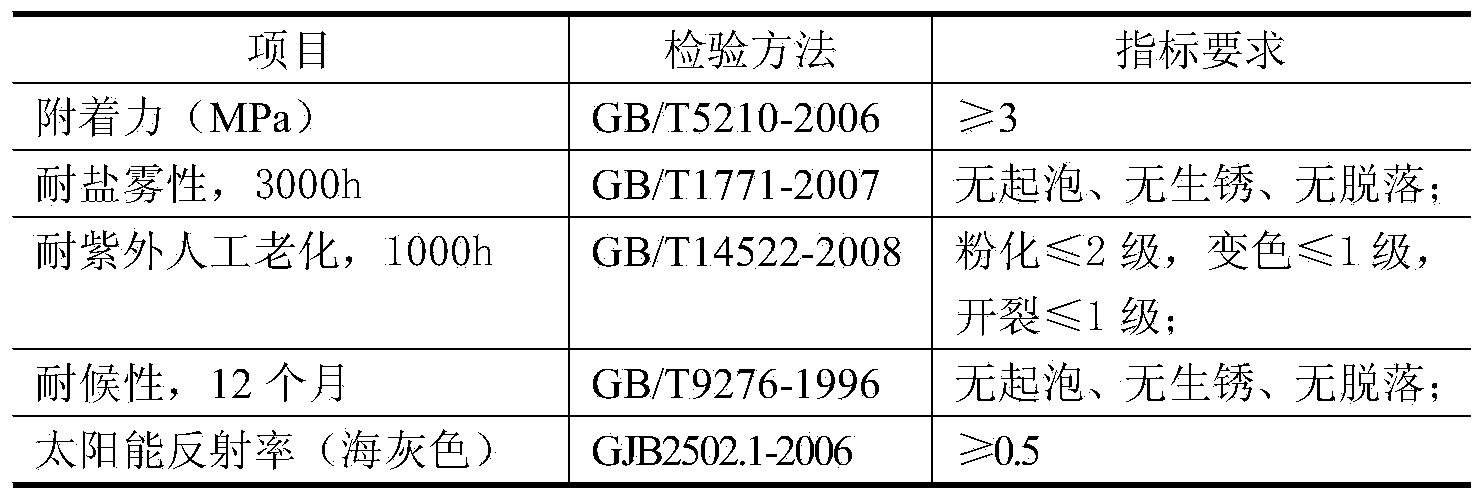

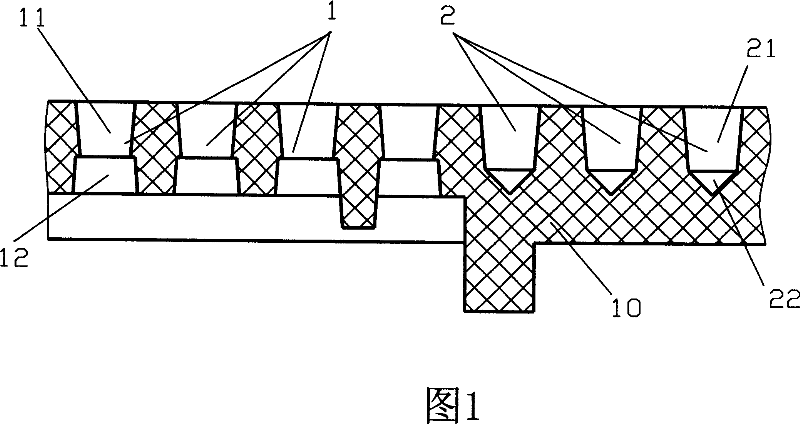

Low-solar absorption energy-saving weather-resistant ocean grey finish paint and preparation method thereof

InactiveCN103881549AHigh transparencyLow absorption ratePolyurea/polyurethane coatingsReflecting/signal paintsSolventChemistry

The invention discloses low-solar absorption energy-saving weather-resistant ocean grey finish paint which consists of a component A and a component B, wherein the component A comprises the following components in percentage by mass: 35-45 percent of polyurethane resin, 25-35 percent of modified titanium dioxide, 5-15 percent of kaolin or calcium carbonate, 0.5-1.5 percent of functional black pigment, 0.1-0.3 percent of functional green pigment, 8-18 percent of solvent and 2-5 percent of aids; the component B comprises the following component in percentage by mass: 10-15 percent of aliphatic polyisocyanate. The low-solar absorption energy-saving weather-resistant ocean grey finish paint is applied to hulls above ship waterlines and outer surfaces of superstructures, adsorption of outer walls of the ships on sunlight illumination energy can be reduced, increase of temperature in the compartment is reduced, the living and working conditions of the crew are improved, and lots of cooling cost is saved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Horn meshwork structure

ActiveCN101043606AReduces chances of sprayingGood appearance consistencyTelevision system detailsColor television detailsEngineeringConoid

The disclosed horn mesh structure comprises: both integrated on the shell, a throughout hole, including a connected top and bottom holes both with circle cross-section and trapezoid longitudinal section; and a blind hole, including a outer hole with circle cross-section and trapezoid longitudinal section and a connected conical inner hole. Wherein, the shape both of the throughout hole and blind hole is calculated by formula with bottom hole diameter A as reference. This invention can eliminate horn black ring on TV shell, and improves production efficiency.

Owner:XIAMEN PRIMA TECH

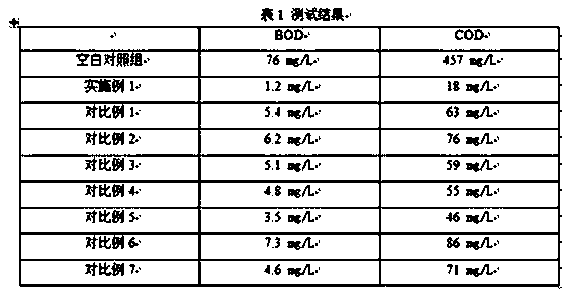

Preparation method of modified aerogel for sewage treatment

InactiveCN109351294AImprove contact effectGood sewage treatment effectOther chemical processesAerogel preparationBENZYL ALCOHOL/WATERPolystyrene

The invention provides a preparation method of modified aerogel for sewage treatment. The preparation method has the advantages that low-crosslinking polystyrene serves as an aerogel matrix, a certainamount of tetrabutyl titanate is added during dissolution, and silica, bentonite, polydopamine, vinyltriethoxysilane and benzyl alcohol are used for spraying, so that the excellent adsorption effectis achieved; experimental results show that the modified aerogel prepared by the preparation method has excellent treatment ability for oil-rich sewage, and has remarkable adsorption effect on the sewage, so that the application of the polystyrene aerogel in the water treatment field is promoted.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

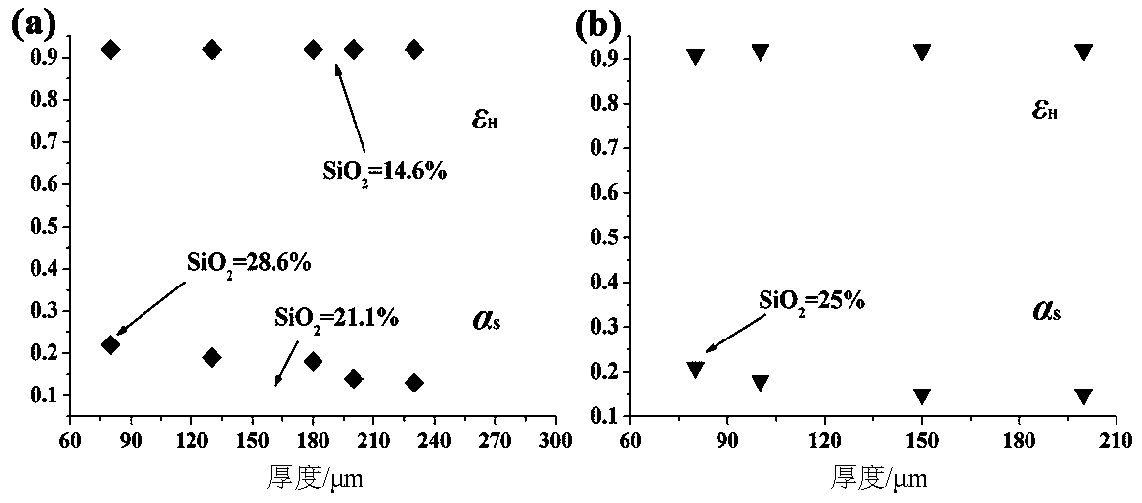

Molecular adsorption-thermal control bifunctional coating and preparation method thereof

InactiveCN110499047ASimple manufacturing methodEasy to operateOther chemical processesAluminium silicatesBifunctionalMolecular adsorption

The invention discloses a molecular adsorption-thermal control bifunctional coating and a preparation method thereof. The raw materials of the molecular adsorption-thermal control bifunctional coatingcomprise a Y-type zeolite and an inorganic silica sol, wherein the mass percentage content of the Y-type zeolite is 60-90%, and the inorganic silica sol is distributed around zeolite crystals in theform of a three-dimensional porous reticular SiO2 chain. The molecular adsorption-thermal control bifunctional coating has a simple structure, saves the cost, does not need to additionally construct athermal control coating, avoids the use of a thermal control material with a multilayer film structure, integrates the molecular adsorption performance with the thermal control performance, has a saturated adsorption capacity of 130 mg / g, and can be used as a functional coating with a high emission value and a high adsorbability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Surface spraying method for metal light guiding control panel

InactiveCN104624453AOptimize the spraying processImprove structural strengthSpecial surfacesCoatingsSize changeSpray method

The invention relates to a surface spraying method for a metal light guiding control panel. The method comprises the following steps that firstly, the metal panel is provided, an insert counter bore is formed in the metal panel, an insert is contained in the insert counter bore, the insert is provided with an insert upper surface, and a panel upper surface is flush with the insert upper surface; secondly, the panel upper surface and the insert upper surface are cleaned; thirdly, a composite film is provided and provided with a surface insulating layer and a surface adsorption layer, and the surface adsorption layer is attached to the insert upper surface and the panel upper surface; fourthly, primer is sprayed; fifthly, the surface insulating layer is removed, and the transparent colorless surface adsorption layer is retained; sixthly, the light transmitting white paint is sprayed; seventhly, the shading finishing coat is sprayed; eighthly, a light guiding illumination character is etched. Thus, the size change produced in a joint due to the temperature change is offset through superelasticity of the composite film, and it is avoided that a paint layer is tensioned and fractured by stress.

Owner:SHANGHAI AVIATION ELECTRIC

A laser micro-textured surface solid lubrication treatment method for friction pairs

InactiveCN105782243BImprove carrying capacityOptimize the spraying processShaftsBearing componentsMicro textureHigh pressure

The invention provides a solid lubrication treatment method for a friction pair laser micro-texture surface. The method comprises the steps that a micro-pit shape is machined on the surface of a friction pair through the laser surface texturing technology; all components in a self-lubrication composite are evenly mixed and dried to be used later; the surface micro-pit in a pre-treated die is filled with the self-lubrication composite through a die hot-press curing filling method; pressure maintaining hot-press curing filling is conducted through a hot press; then, the filled friction pair is heated for 20 min at the temperature of 250 DEG C and then protected by 99.9% of N2 to be heated for 30 min at the temperature ranging from 370 DEG C to 385 DEG C, insulating sintering is conducted for 0.5 h-1.0 h, and sintering forming is conducted after cooling; and solid lubrication can be finished after surface posttreatment. According to the method, the high-temperature sliding friction performance of the self-lubrication surface of a micro-texture can be improved, a good lubricating effect can be achieved under the conditions such as the high temperature and the high pressure, the bearing capability of a nanometer composite solid lubricating agent is effectively improved, and the nanometer composite solid lubricating agent can be applied under some complex and strict work conditions.

Owner:JIANGSU UNIV

An organic solar cell based on a spray-coated molybdenum trioxide anode buffer array and its preparation method

ActiveCN107369769BImprove performanceReduce chance of recombinationSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellOhmic contact

The invention relates to an organic solar cell based on a spray-coated molybdenum trioxide anode buffer array. The solar cell adopts an inverted structure, including a substrate layer, an ITO transparent conductive cathode layer, a cathode buffer layer, and a photoactive layer arranged in sequence from bottom to top. , anode buffer layer, metal anode layer; the anode buffer layer is a molybdenum trioxide array film formed by spraying an ammonium molybdate aqueous solution mixed with hyaluronic acid on the photoactive layer and annealing; in the molybdenum trioxide array film, hyaluronic acid The mass fractions of ammonium molybdate and ammonium molybdate are: 0.2-1wt% ammonium molybdate; 0-0.5wt% hyaluronic acid. The invention also discloses the preparation method of the battery; the invention forms a hyaluronic acid layer on the photoactive layer by adding hyaluronic acid into the ammonium molybdate aqueous solution, the precursor of molybdenum trioxide, and the introduced hanging chemical bonds can make The molybdenum trioxide layer forms a good ohmic contact with the active layer, which improves the performance of the battery.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Crucible bottom coating for full-melting efficient polycrystalline growth as well as spraying process and application of crucible bottom coating

InactiveCN111518422AHigh purityImprove compactnessPolycrystalline material growthPretreated surfacesCrucibleSILICONE DIOXIDE

The invention discloses a crucible bottom coating for full-melting efficient polycrystalline growth as well as a spraying process and application of the crucible bottom coating. The coating covers thesurface of the bottom of a crucible and comprises a slurry A coating and a slurry B coating. The slurry A coating is made of a mixture of silicon nitride powder, ultrapure water and silica sol, and the mass ratio of the silicon nitride powder to the ultrapure water to the silica sol is (2.5-3): (8-10): 1. The slurry B coating is made of a mixture of silicon nitride powder, ultrapure water, silicasol and mixed powder alpha, the mass ratio of the silicon nitride powder to the ultrapure water to the silica sol to the mixed powder alpha is (2.5-3): (8-10): 1: (0.3-0.5), and the mixed powder alpha is prepared by mixing silicon powder of 200-300 meshes and silicon dioxide powder. The coating material is high in purity and few in impurities, the formed coating is high in compactness and good inbarrier effect, and the spraying process is simple and easy to implement.

Owner:江苏美科太阳能科技股份有限公司

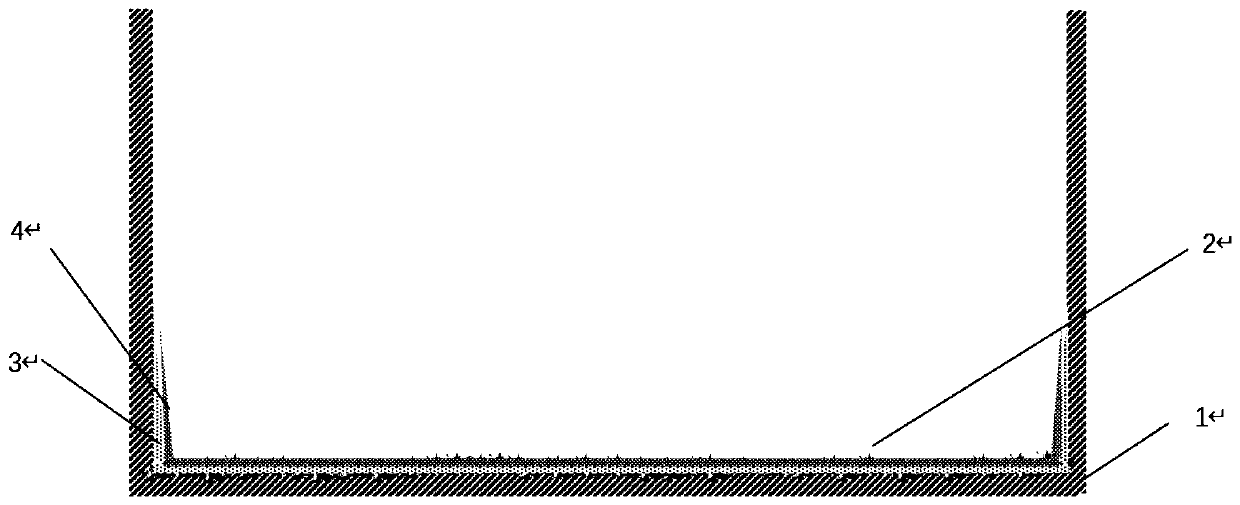

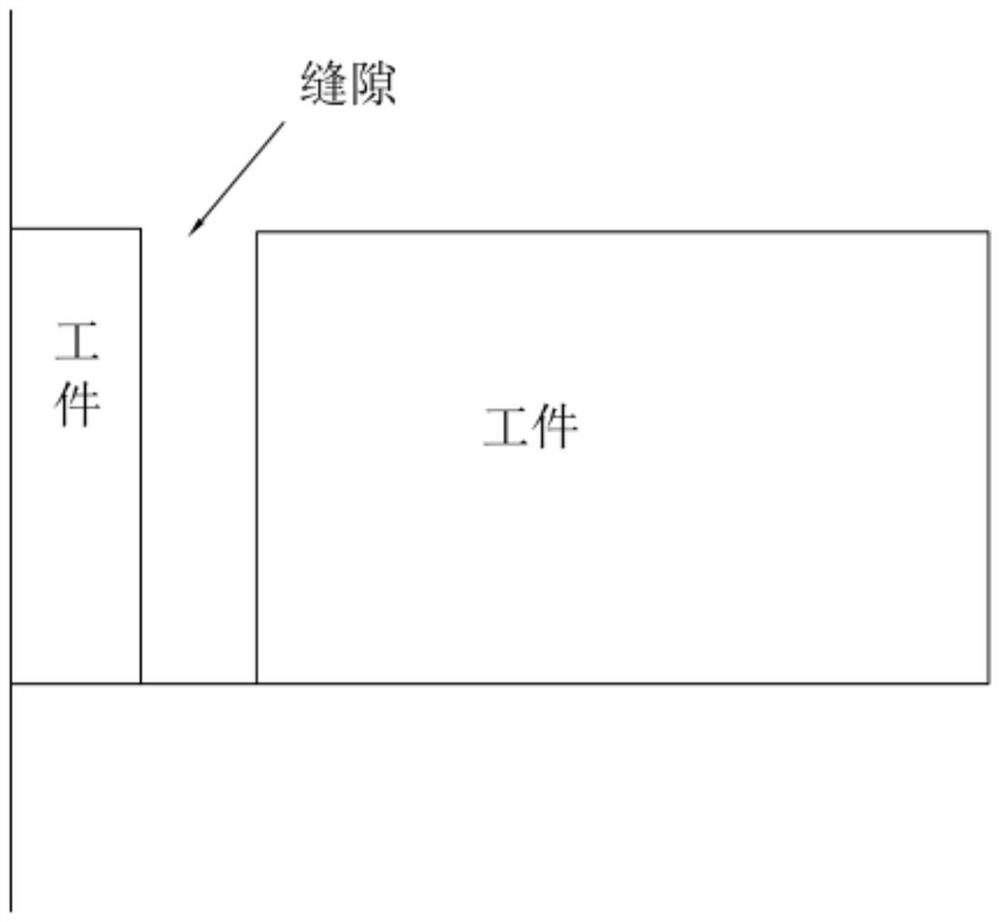

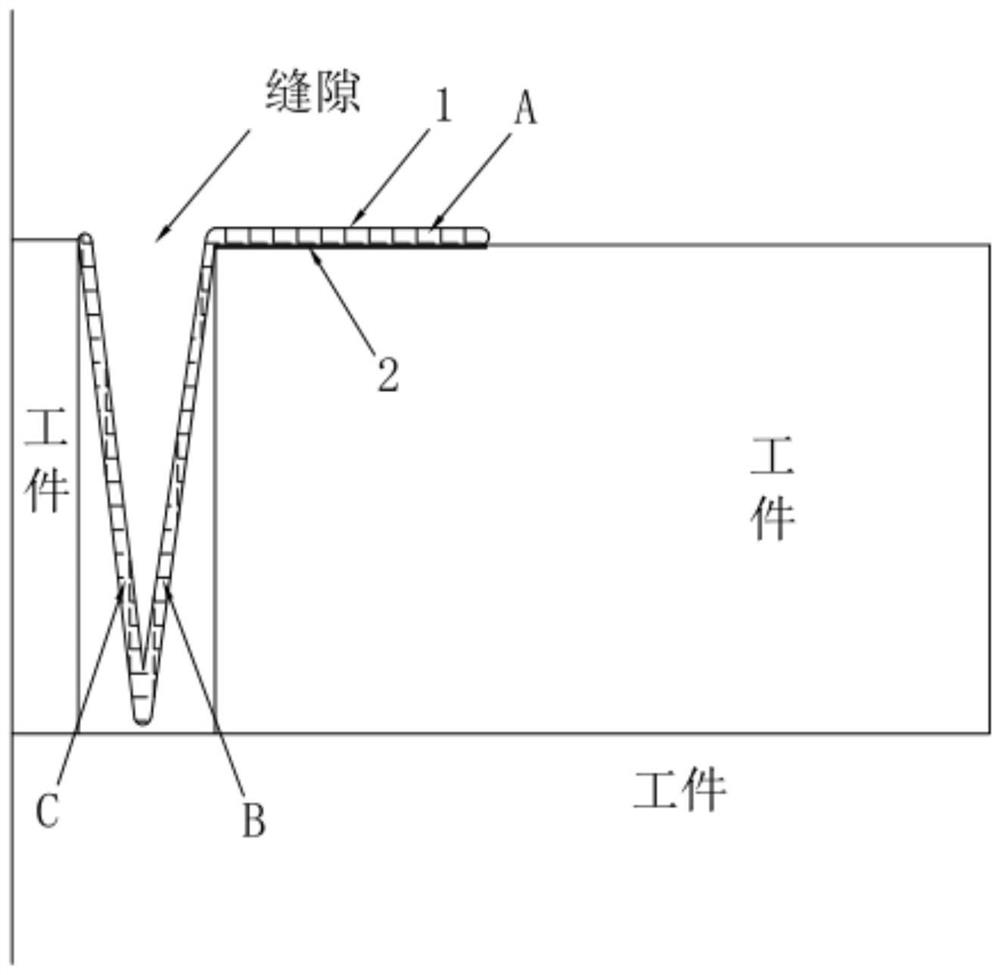

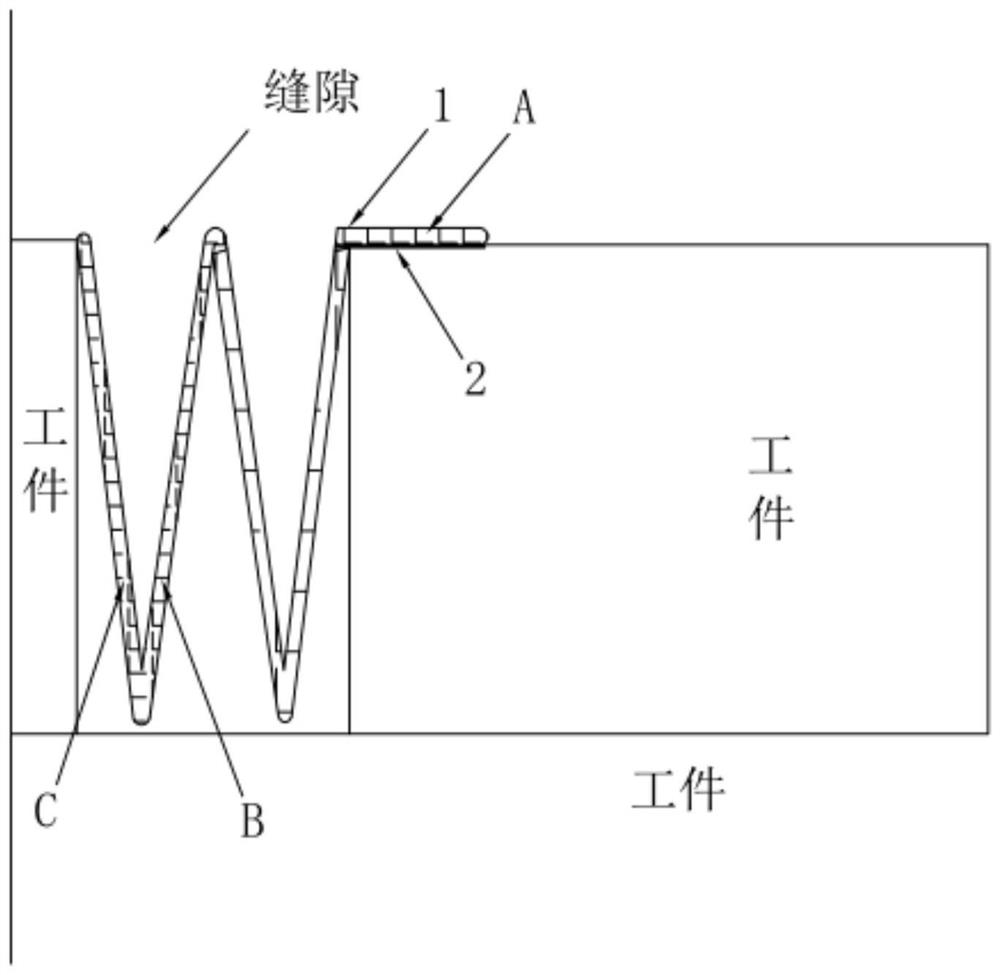

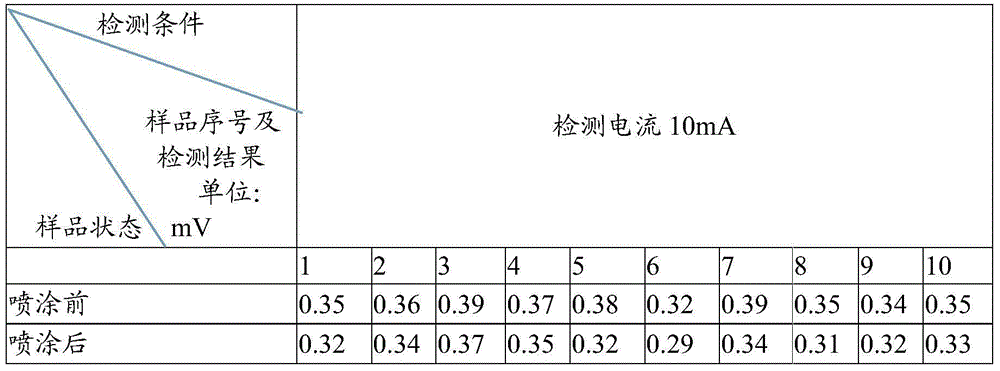

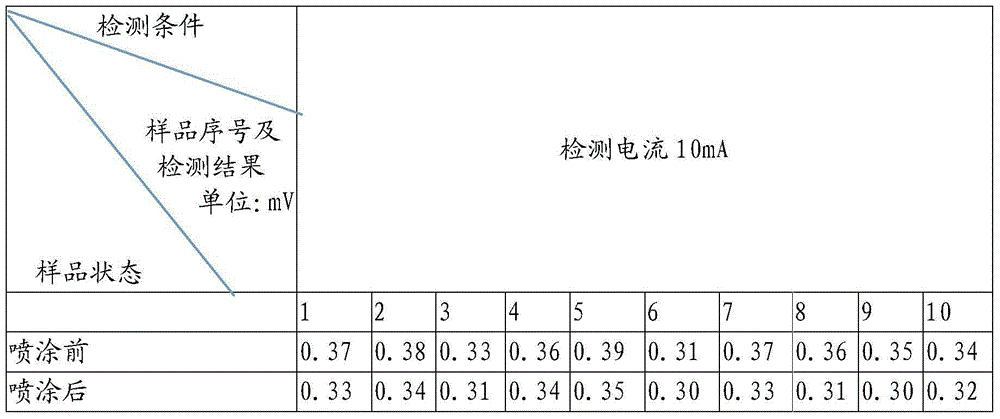

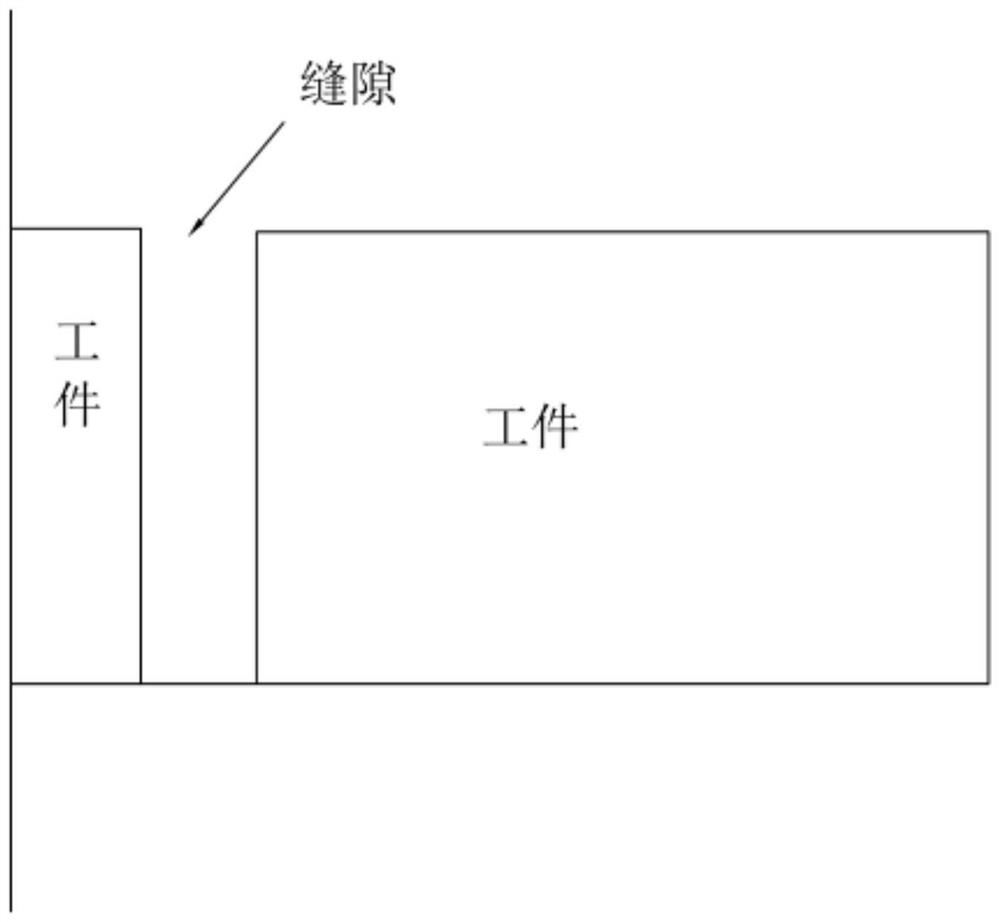

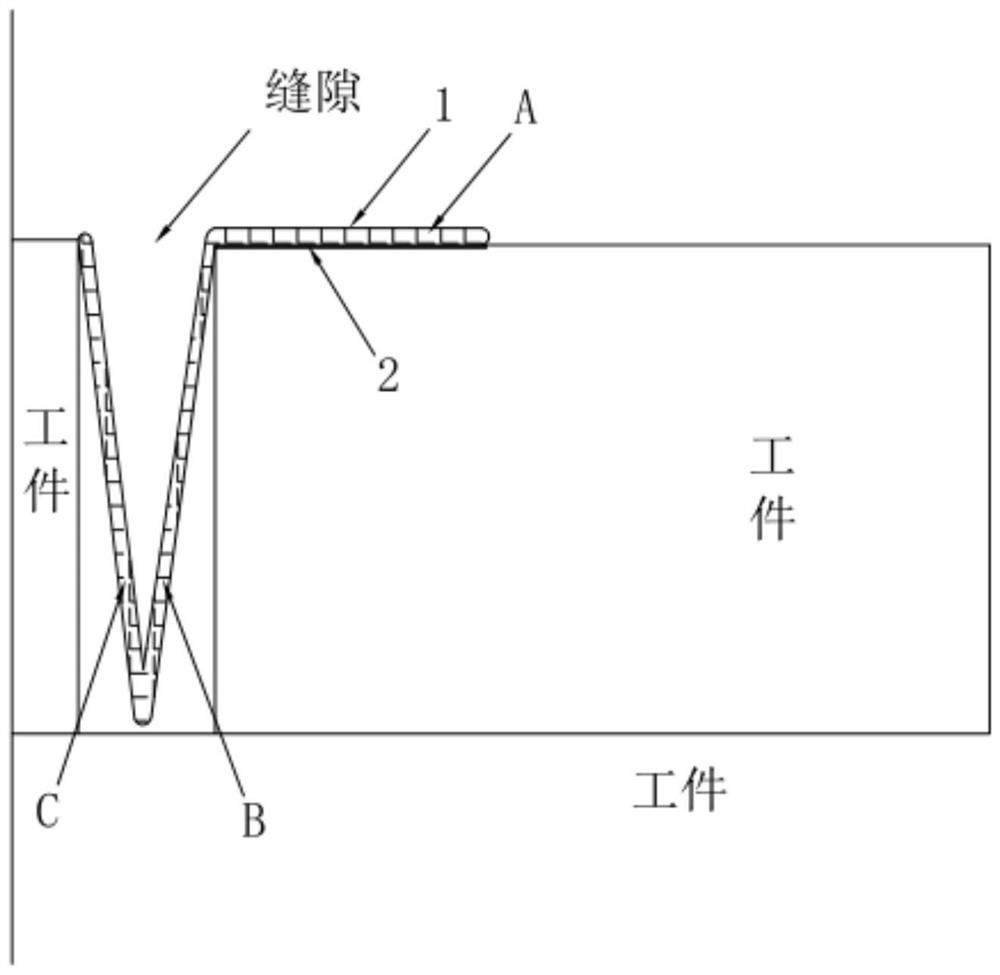

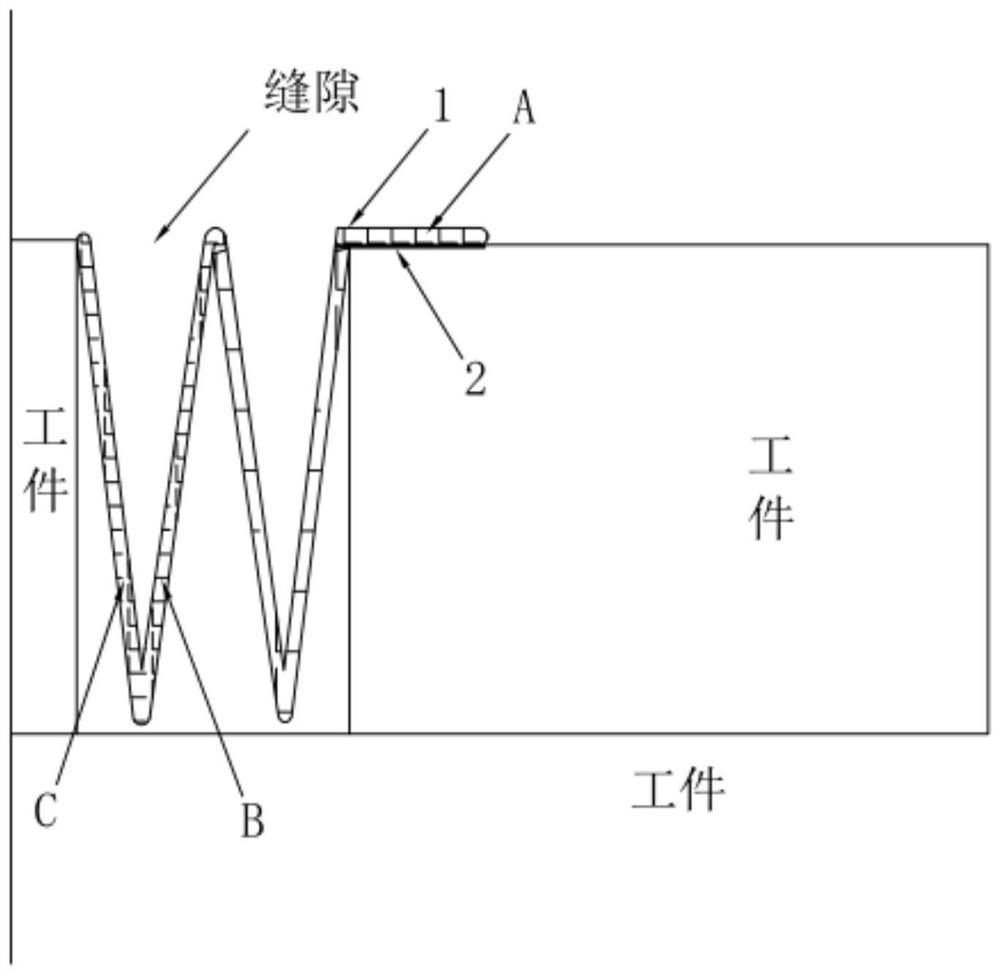

Sand blasting or spraying method for slit workpiece

The invention relates to the technical field of mechanical workpiece machining, discloses a sand blasting or spraying method for a slit workpiece, and solves the technical problems existing in two traditional methods of high-temperature adhesive tape shielding and iron sheet shielding. The method comprises the following steps that S1, a shielding material is selected; S2, the shielding material is formed into a V shape; S3, the formed shielding material is uniformly inserted into the gaps of the workpiece; S4, a supporting structure is arranged between the part B and the part C of the shielding material; S5, sand blasting or spraying operation is started; and S6, the supporting structure is dismantled, the shielding material is dismantled, and sand blasting or spraying operation is completed. According to the sand blasting or spraying method for the slit workpiece, the V-shaped shielding material with suspension wings is designed to shield the gaps of the workpiece, and the V-shaped shielding material is convenient to mount and dismount, high in efficiency and good in quality, so that the purpose of optimizing the sand blasting or spraying process of the workpiece is achieved.

Owner:HUANENG GRP R&D CENT CO LTD +2

Titanium-containing phosphating agent, metal part and surface phosphating treatment method of metal part

InactiveCN112708878AMeticulous structureCompact structureMetallic material coating processesO-Phosphoric AcidMagnesium salt

The invention relates to a titanium-containing phosphating agent, a metal part and a surface phosphating treatment method of the metal part. The phosphating agent is used for metal part surface pretreatment and comprises the components of, in parts by weight in 1000 parts, 5-30 parts of phosphoric acid, 3-10 parts of zinc oxide, 0.5-3 part of magnesium salt, 0.5-3 part of aluminum salt, 0.5-5 part of fluotitanic acid and the balance water. A film layer formed by the phosphating agent is fine in structure and firm in adhesive force, a continuous, uniform and colorful phosphating layer can be generated on the surface of the metal part, and the titanium-containing phosphating agent, the metal part and the surface phosphating treatment method of the metal part are applied to phosphating treatment before spraying of the surfaces of steel such as cold-rolled plates, hot-rolled plates and angle steel. The phosphating solution has the advantages of long service life and no wastewater generation, and can be used for phosphating in a brushing, soaking, spraying or combination mode, the adopted temperature is 10-50 DEG C, drying and natural airing can be achieved, energy consumption is reduced to a great extent, phosphating time is short, surface conditioning and accelerant adding are not needed before use, and operation is easy and time-saving.

Owner:SHENZHEN HENGZHAOZHI TECH CO LTD

Epoxy resin spray-coating method and special-purpose epoxy resin spray-coating liquid thereof

InactiveCN105623462ARaise the ratioOptimize the spraying processPretreated surfacesEpoxy resin coatingsEpoxySpray coating

The invention discloses an epoxy resin spray-coating method and a special-purpose epoxy resin spray-coating liquid thereof. The epoxy resin spray-coating liquid comprises, by weight, 100 parts of epoxy resin, 30 parts of a curing agent and 10-30 parts of xylene. The method comprises 1, spray-coating one side of a base, which is baked at a temperature of 110 DEG C for 15min and is to be spray-coated, with the epoxy resin spray-coating liquid, 2, baking the spray-coated base at a temperature of 100-120 DEG C for 15-30min, and 3, turning over the base baked through the step 2 and spray-coating the other side of the base through the steps 1 and 2. The epoxy resin spray-coating method accelerates amorphous nanometer crystal iron core package treatment time, reduces an amorphous nanometer crystal iron core package cost and improves performances of the amorphous nanometer crystal iron core spray-coated with epoxy resin.

Owner:山东海源光电科技有限公司

A spraying device for cooking utensils

ActiveCN113634396BUninterrupted power transmissionBeautiful surface patternSpraying apparatusSurface patternEngineering

The invention discloses a spraying device for cooking utensils, which comprises a base on which a coating part, an up and down running part, a pattern shielding part and a spray gun start switch are arranged, and the up and down running part drives the cooker to slide up and down, and during the sliding Rotate, when it goes up to the highest position, it combines with the pattern shielding part, drives the pattern shielding part to go down and rotate together, and in the process drives the painting part to realize the conversion of the nozzle. The spray gun start switch is set in cooperation with the up and down running part, Controls the start and stop of the spray gun. The invention provides a variety of paint spraying equipment that can spray patterns and patterns, so that the spraying operation can be automated, labor costs can be saved, the spraying process can be optimized, the surface patterns of cookware can be more beautiful, the ornamental value of cookware can be improved, and the competitiveness of cookware can be improved. , so as to enhance enterprise efficiency.

Owner:ZHEJIANG COOKER KING COOKER

Preparation and application of a nickel-based powder core wire material and coating

ActiveCN103924183BOptimize the spraying processHigh hardnessMolten spray coatingIncinerator apparatusMaterials processingHigh-temperature corrosion

The invention relates to a nickel-based powder core wire and preparation and application of a coating and belongs to the thermal spraying field of material processing engineering. The chemical core comprises the following components in percentage by weight: 20-35% of pure metal chromium powder, 1-4% of pure metal tungsten, 1-30% of nickel boron powder and the balance of nickel. The strip for the outer skin of the powder core wire is 80Ni-20Cr strip. The filling rate of the powder core wire is 32%. When a tungsten-nickel-containing coating is prepared by an electric arc spraying method, a base body is pre-treated first and the spraying process is carried out under following conditions: the voltage is 28-34V, the current is 160-220A, the spraying distance is 190-210mm and the pressure of the compressed air is 0.5-0.6MPa. According to the tungsten-containing corrosion-resistant coating obtained by the invention, the high-temperature corrosion resistance of the coating is increased, and the service stability of a water cooling wall pipe and an over-heater pipe in a waste resourceful WTE (Waste-To-Energy) garbage incinerator is improved.

Owner:唐山宝航机械制造有限公司

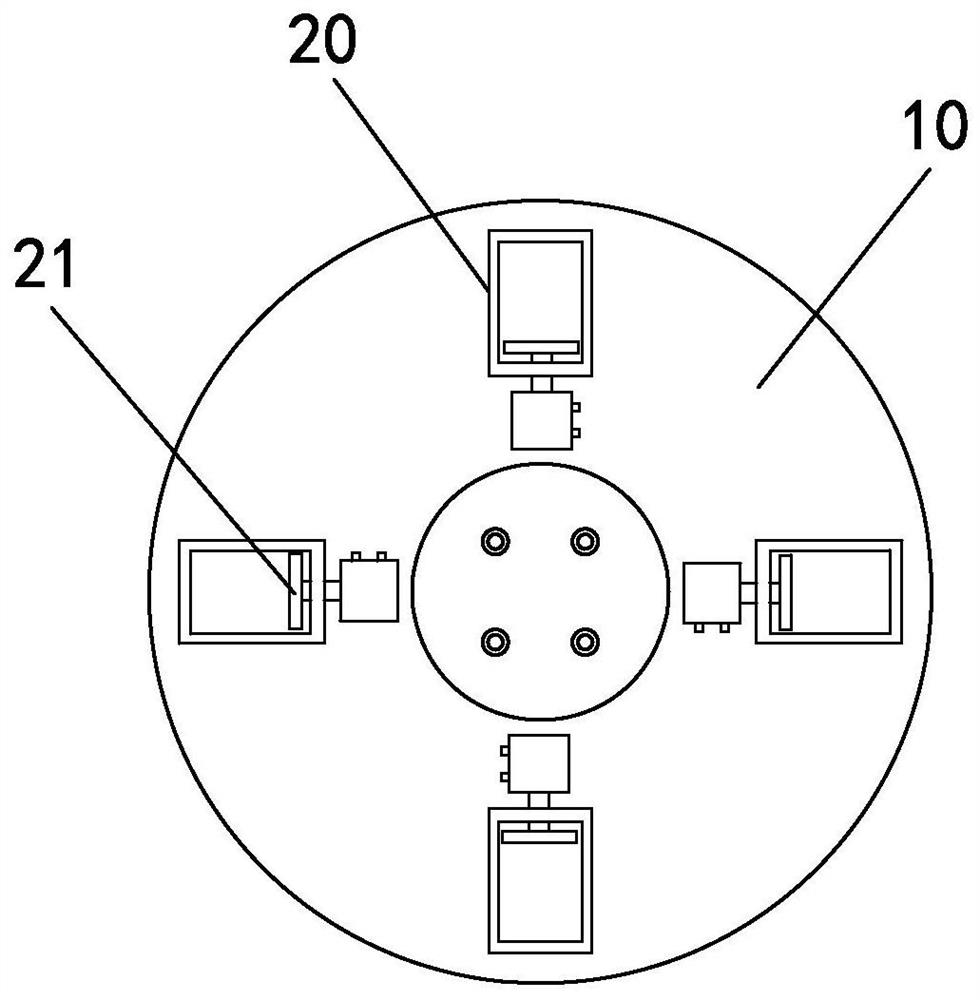

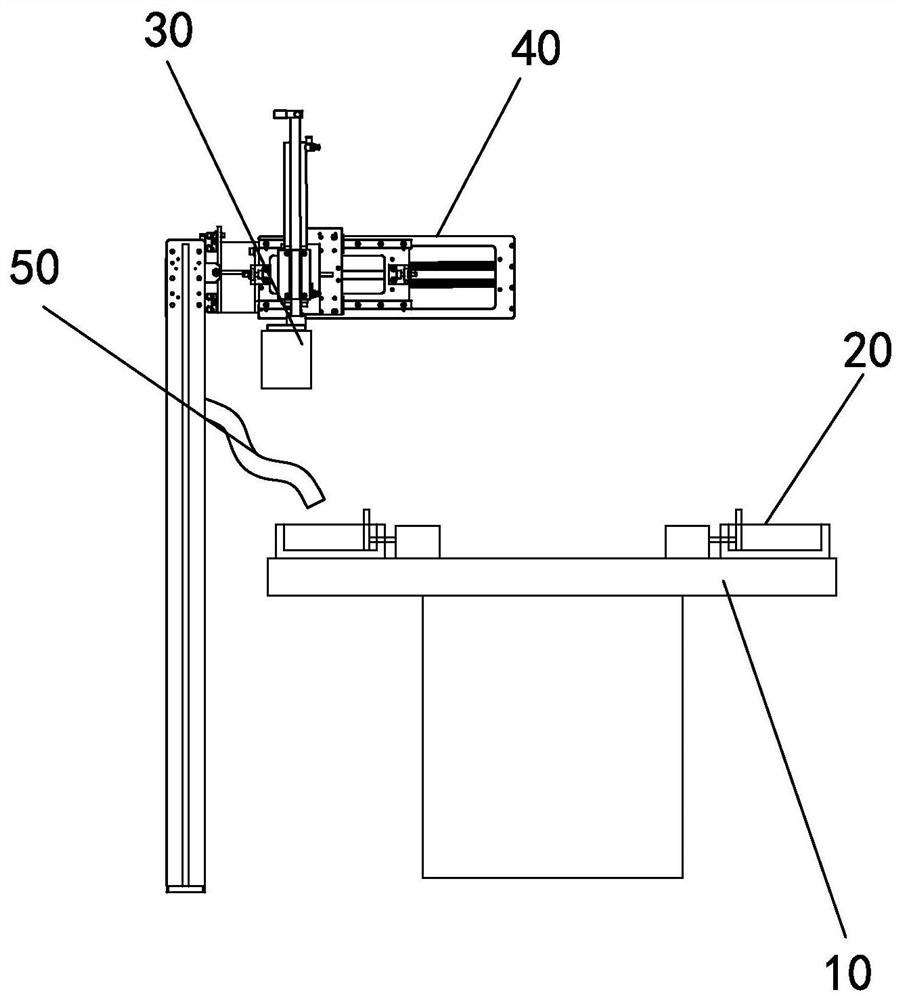

Heat dissipation module spraying redundant part removal method and treatment device

PendingCN112643208AOptimize the spraying processImprove spraying accuracyLaser beam welding apparatusRobot handEngineering

The invention provides a heat dissipation module spraying redundant part removal method and treatment device. The removal method comprises the following steps that firstly, a heat dissipation module is placed below a laser head, and redundant parts are removed through a laser process; and secondly, a wiping device wipes a laser area back and forth twice. The treatment device comprises a four-station rotary disc, and a feeding mechanical hand, a laser device, the wiping device and a discharging mechanical hand which are arranged beside the four-station rotary disc. A jig is installed on each station plate of the four-station rotary disc. A dust suction pipe is arranged beside the laser device. The redundant spraying parts on a scattering module are removed through the laser method, and in this way, the heat dissipation module does not need to be shielded in the spraying stage, the spraying process of the heat dissipation module is optimized, and the spraying precision is improved.

Owner:昆山宏宏泰电子科技有限公司

A kind of pot manufacturing equipment

ActiveCN113578582BEasy initial stateRestore initial stateSpraying apparatusIndustrial engineeringCooker

The invention discloses a pan body manufacturing equipment, which includes a frame, a rotating platform, a shield assembly, a first spray gun assembly and a second spray gun assembly, the rotary platform is set on the frame, and the unsprayed pan body is set on the On the rotating platform, it drives the pot body to rotate and slide down. The shutter assembly is arranged on the frame, and the rotating platform is arranged in cooperation with the shutter assembly. The rotating platform can drive the shutter assembly The cover rotates. The invention provides a pot body coating equipment capable of spraying different types, and can carry out pattern coating on the pot body, so that the spraying operation can be automated, labor costs can be saved, the spraying process can be optimized, the surface pattern of the cooker can be more beautiful, and the cooker can be improved. It can enhance the competitiveness of cooking utensils, thereby enhancing the benefits of enterprises.

Owner:ZHEJIANG COOKER KING COOKER

Manufacturing method of wear-resistant cylinder liner based on surface treatment

ActiveCN110777321BImprove wear resistanceExtended service lifeMolten spray coatingNitrogen oxidesCeramic coating

The invention discloses a method for manufacturing a wear-resistant cylinder liner based on surface treatment, and relates to the technical field of diesel engine accessories. The invention comprises the following steps: pretreatment of the cylinder liner substrate, spraying a 0.03-0.045mm thick TiN bonding layer, preheating, spraying a 0.23-0.26mm thick Cr3C2-NiCr ceramic coating, and heat-treating the workpiece after spraying . The invention uses the wear-resistant surface treatment technology of the alloy to spray ceramic coating on the surface of the cylinder liner substrate, reasonably improves the spraying process, improves the wear resistance of the cylinder liner, prolongs the service life of diesel engine parts, and improves fuel efficiency. The efficiency reduces the emission of sulfur oxides and nitrogen oxides in the exhaust gas of diesel engines, protects the environment and reduces the cost of use.

Owner:福建汇华集团东南汽车缸套有限公司

Spraying auxiliary device

ActiveCN112295777AAvoid pollutionOptimize the spraying processSpraying apparatusElectrical batteryElectrical polarity

The invention relates to the technical field of spraying tools, in particular to a spraying auxiliary device. The spraying auxiliary device comprises a base, a positioning piece and a clamping and protection assembly; the positioning piece is arranged on the base and is used for positioning the inner side of a battery shell; the clamping and protection assembly comprises a clamping unit and a protection unit; the clamping unit is connected to the positioning piece, and the clamping unit can clamp the outer side of the battery shell; the protection unit is arranged on the inner side of the clamping unit, and the protection unit can be in pressing connection to and cover the outer side of the end part, close to the base, of the battery shell when the clamping unit is in a clamping state; andthe protection unit is connected with a power supply and used for generating a charge induction area in the covered area of the battery shell. The spraying auxiliary device is provided with the clamping and protection assembly, and after the protection unit is electrified, an electrified area with the same polarity as electric charge carried by spraying powder is generated, so that no powder is adhered to the electrified area, the battery shell is prevented from being polluted by the powder, and the spraying process is optimized.

Owner:CONTEMPORARY AMPEREX TECH CO

Sandblasting or spraying method for slit workpiece

The invention relates to the technical field of machining of mechanical workpieces, and discloses a sandblasting or spraying method for slit workpieces, which solves the technical problems existing in the two methods of traditional high-temperature tape shielding and iron sheet shielding, and includes the following steps: Step S1, selecting shielding material; step S2, forming the shielding material into a V-shape; step S3, inserting the formed shielding material into the gap of the workpiece evenly; step S4, setting a support between the B part and the C part of the shielding material structure; step S5, start sandblasting or spraying operation; step S6, dismantle the support structure, and remove the shielding material to complete the sandblasting or spraying operation. According to the above technical solutions, the present invention designs a V-shaped shielding material with cantilever wings to shield the workpiece gap, and the V-shaped shielding material is easy to install and disassemble, and has good efficiency and high quality, so as to achieve spraying on the workpiece. For sand or spray process optimization purposes.

Owner:HUANENG GRP R&D CENT CO LTD +2

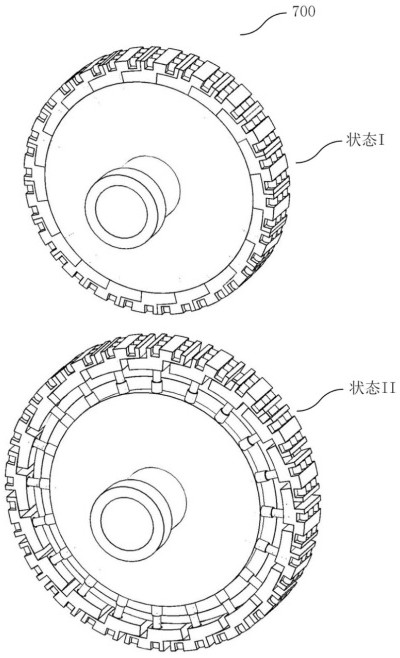

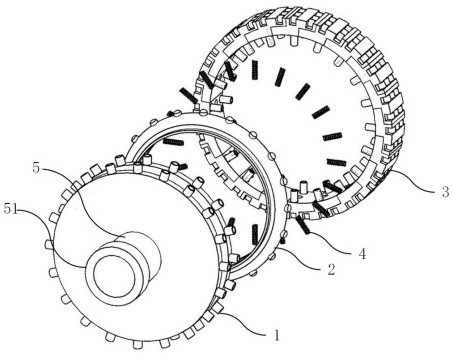

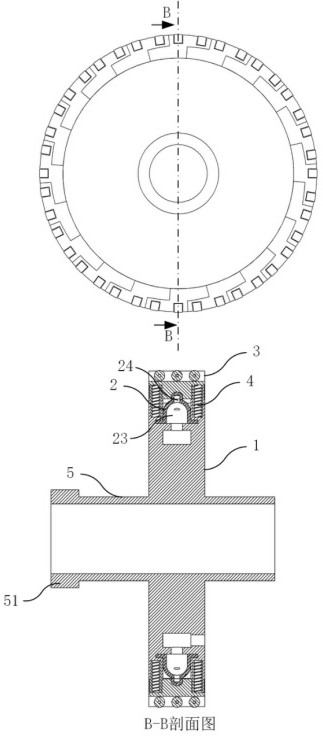

Pipeline construction device and pipeline waterproof anti-corrosion polyurea spraying construction method

ActiveCN114148051AReasonable structureEasy to useSpraying apparatusLaminationStructural engineeringMechanical engineering

The invention relates to the technical field of pipeline water prevention and corrosion prevention, in particular to a pipeline construction device and a pipeline water prevention and corrosion prevention polyurea spraying construction method.The pipeline construction device comprises a center disc, radial expansion pieces and a pressing ring, the radial expansion pieces are fixedly arranged on the outer circumference of the center disc, and the radial outer sides of the radial expansion pieces are connected with the pressing ring; the pressing ring is connected with the center disc through a spring, a communicating pipe is arranged in the center of the center disc in the axial direction, and a spray head assembly fixing base is arranged at one end of the communicating pipe. The pipeline construction device is compact and reasonable in structure and good in use stability, the technological process of pipeline waterproof and anti-corrosion spraying construction can be simplified, and the spraying quality and the construction efficiency are effectively improved.

Owner:山东安博瑞工程科技有限公司

A kind of preparation method of modified airgel for sewage treatment

InactiveCN109351294BEasy to handleImprove contact effectOther chemical processesAerogel preparationTriethoxysilanePolystyrene

The invention provides a method for preparing modified airgel for sewage treatment. The invention uses polystyrene with a low degree of crosslinking as the airgel matrix, and adds a certain amount of tetrabutyl titanate during the dissolution process. Afterwards, it was sprayed with silica, bentonite, polydopamine, vinyltriethoxysilane and benzyl alcohol, and an excellent adsorption effect was achieved. Experimental results show that, for the sewage rich in oil, the modified airgel prepared by the method of the present invention has excellent treatment capacity, and the modified airgel prepared by the present invention has remarkable adsorption effect in sewage, which promotes Application of polystyrene airgel in the field of water treatment.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com