A laser micro-textured surface solid lubrication treatment method for friction pairs

A technology of solid lubrication and treatment method, which is applied in the field of surface lubrication of friction pairs, can solve problems such as poor lubrication and anti-friction effects, poor filling effects, etc., and achieve the effects of reducing plastic flow resistance, enhancing bearing capacity, and saving use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

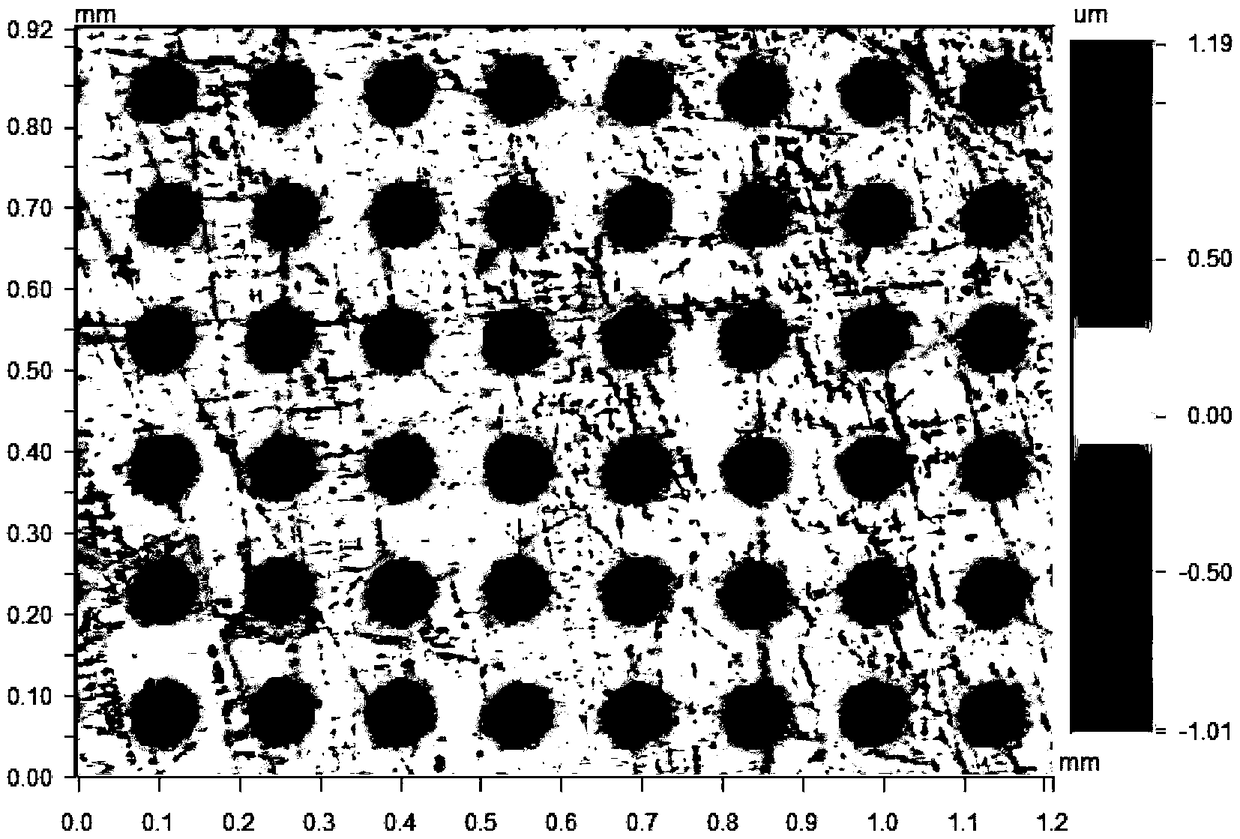

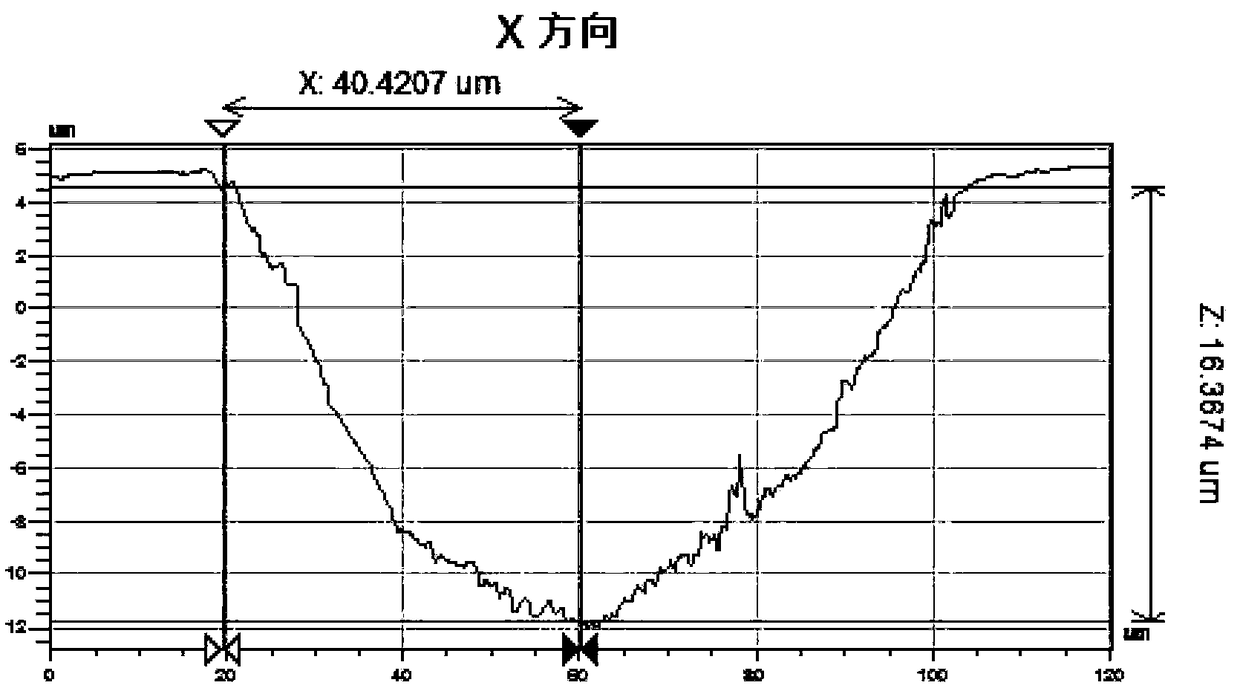

Image

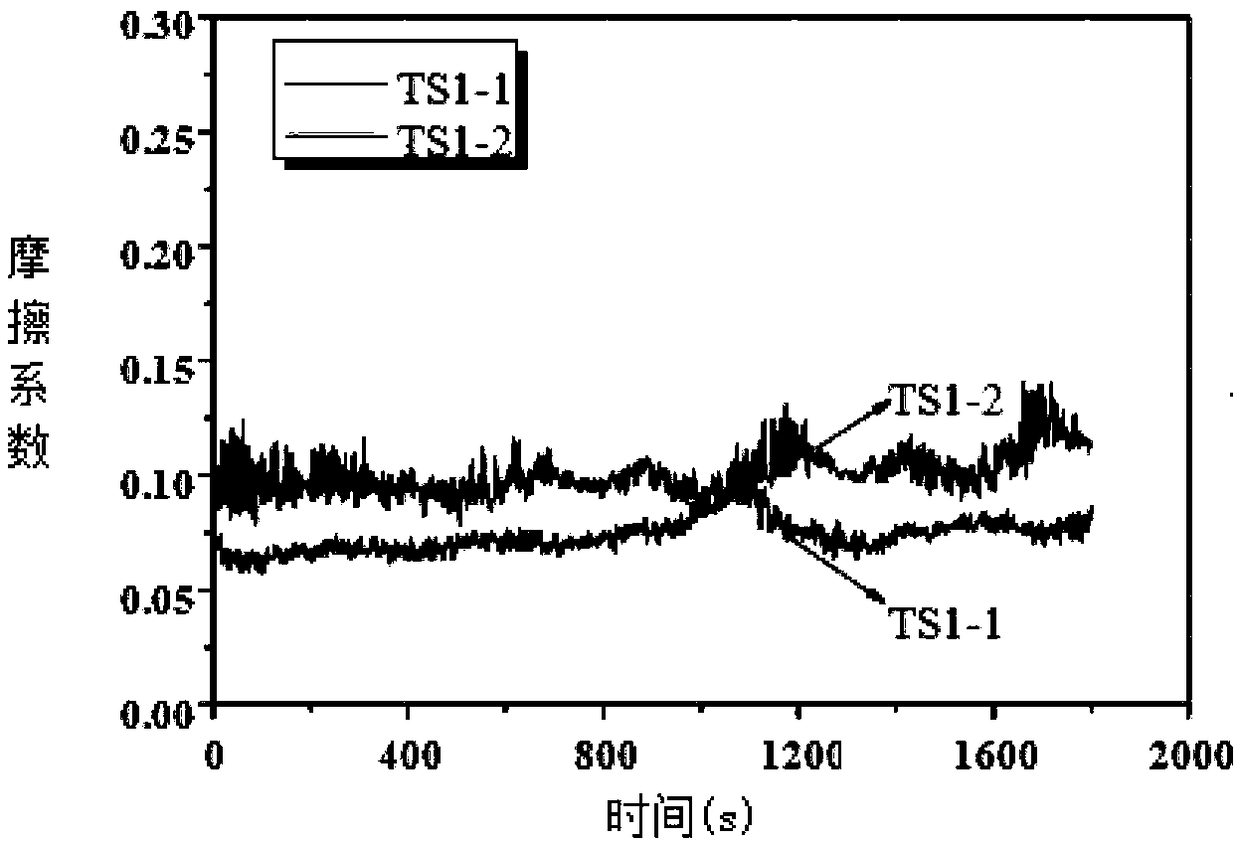

Examples

Embodiment 1

[0041] (1) Same as described in Comparative Example 1.

[0042] (2) Mix the components in the self-lubricating composite material evenly, and dry them at a temperature of 100-130° C. for 2-3 hours until they are dry for later use; the self-lubricating composite material includes the following components in mass percentage: 20% poly Imide (PI) and 80% nano-MoS 2 ;

[0043] (3) After the mold surface is pretreated, the self-lubricating composite material described in the step (2) is pre-filled to the micro pits on the surface of the friction pair described in the step (1) with the mold hot pressing solidification filling method; The press pressurizes the self-lubricating composite material for pressure-holding and hot-pressing solidification and filling; the hot-pressing and solidification filling part of the mold is the same as that described in Comparative Example 1, and then the upper and lower sets of nuts of the simple mold pressurization device that have been tightened are ...

Embodiment 2

[0051] (1) Same as described in Comparative Example 1.

[0052] (2) Mix the components in the self-lubricating composite material evenly, and dry them at a temperature of 100-130° C. for 2-3 hours until they are dry for later use; the self-lubricating composite material includes the following components in mass percentages: 10-15 % Polyimide (PI), 74-80% Nano MoS 2 , 0-12% carbon nanotube additive (CNTs), 0-5% binder;

[0053] (3) After the mold surface is pretreated, the self-lubricating composite material described in the step (2) is pre-filled to the micro pits on the surface of the friction pair described in the step (1) with the mold hot pressing solidification filling method; The press pressurizes the self-lubricating composite material for pressure-holding and hot-pressing solidification and filling; this step (3) is the same as in Example 2.

[0054] (4) Heat the friction pair filled in step (3) at a temperature of 250°C for 20 minutes, and then heat it under 99.9% N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com