Pipeline construction device and pipeline waterproof anti-corrosion polyurea spraying construction method

A pipeline construction and pipeline technology, applied in lamination devices, spray devices, chemical instruments and methods, etc., can solve problems such as affecting waterproof and anti-corrosion effects, uneven thickness of polyurea coating, and improve spraying quality and construction efficiency. Good tightness and shock absorption, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0054] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of structure, change of proportional relationship or adjustment of size shall fall within the range covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. within range.

[0055] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

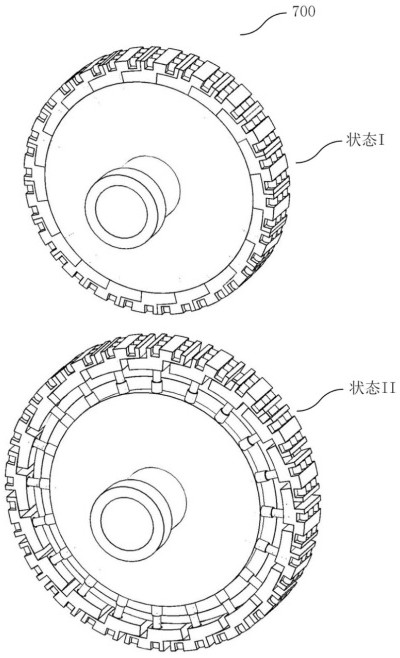

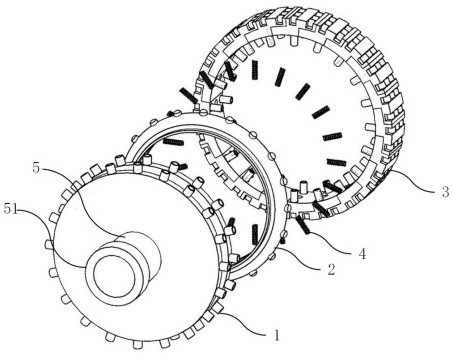

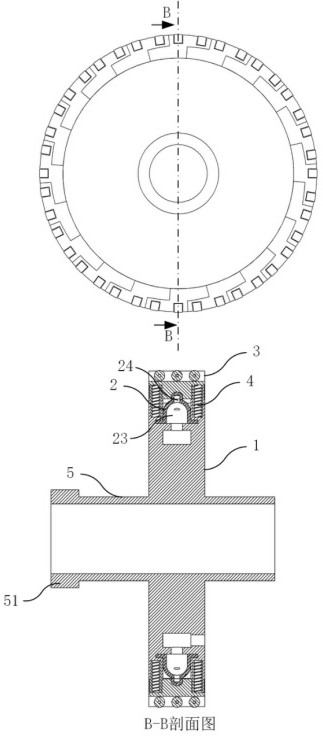

[0057] combined with Figures 1 to 14 , this embodiment provides a pipeline construction device 700, including a central disk 1, a radially expanding member 2 and a pressure ring 3, the outer circumference of the central disk 1 is fixed with a radially expanding member 2, and the radially expanding member 2 is connected to the pressure ring 3 on the radially outer side, and the pressure ring 3 is connected to the central disk 1 through a spring 4. A connecting pipe 5 is arranged axially at the center of the central disk 1, and one end of the connecting pipe 5 is provided with The spray head assembly fixing seat 51.

[0058] Among the above technical solutions, refer to figure 2 and Figure 12 The spray head assembly 600 used for polyurea spraying can be fixed on the spray head assembly fixing seat 51 of the connecting pipe 5, and various pipelines connected to the spray head assembly 600 can be placed inside the connecting pipe 5, such as for connecting the delivery materia...

Embodiment 2

[0071] In this embodiment, on the basis of Embodiment 1, the structures of the radial expansion member 2 and the flange insertion groove 121 are optimized, and the specific technical solutions are as follows, as Figure 6As shown, the intersection of the arc portion 211 and the flange 212 is provided with an arc-shaped fourth groove 213, and the upper end surface of the flange 212 is a first arc-shaped curved surface 214 that protrudes upwards. The flange 212 is provided with a third through hole 216 communicating with the first cavity 23 and an annular third cavity 215 communicating with the third through hole 216, and the flange insertion groove 121 is provided with The arc-shaped second protrusion 122 corresponding to the four grooves 213 and the second arc-shaped curved surface 123 corresponding to the first arc-shaped curved surface 214 .

[0072] In the above technical solution, when high-pressure fluid is injected into the first cavity 23, the fluid enters the third cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com