Surface spraying method for metal light guiding control panel

A technology for surface spraying and metal panels, which is applied in the direction of surface coating liquid devices, special surfaces, coatings, etc. It can solve the problems of wrinkling and breaking of paint layers, affecting product appearance and optical performance, etc., and achieves high structural strength, The effect of improving product quality and solving the problem of paint layer cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

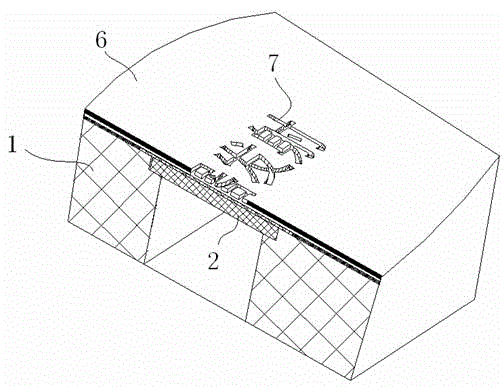

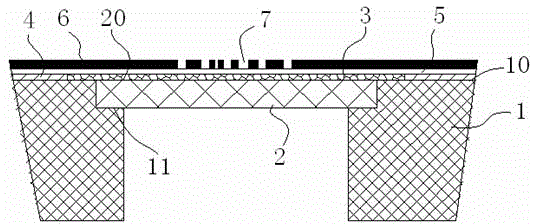

[0025] See figure 1 , 2 And 3, shown in the figure is a kind of surface spraying method for metal light guide control panel, comprises, carries out following steps in sequence,

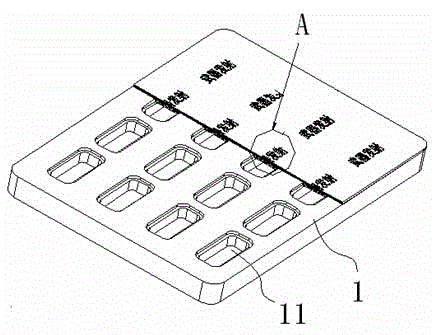

[0026] a) Provide a metal panel 1, the metal panel 1 has an upper surface 10 and a lower surface of the panel opposite to the upper surface 10 of the panel, the upper surface 10 of the panel is formed with a The inlaid counterbore 11 (in the real product, there should be multiple inlaid counterbores distributed on the metal panel, indicating different indicating operation units, but this article only describes one inlaid counterbore as an example for brevity), the inlaid counterbore An insert 2 made of a transparent organic material is housed in the hole 11, wherein the insert 1 has an upper surface 20 of the insert, a lower surface connected to the upper surface of the ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com