Epoxy resin spray-coating method and special-purpose epoxy resin spray-coating liquid thereof

A technology of epoxy resin and phenalkamine epoxy resin, which is applied in the field of epoxy resin spraying on amorphous nanocrystalline iron core, can solve the problem that the performance of the iron core is greatly reduced, the amorphous nanocrystalline iron core is not easy to be attached, and the adhesion strength of epoxy resin is small. and other problems to achieve the effect of improving performance and optimizing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, 30 amorphous and nanocrystalline iron cores with a model number of 16 / 21*10 are used as the substrate to spray epoxy resin. oxygen resin.

[0023] The specific operation of spraying epoxy resin is as follows:

[0024] 1. Glue compounding: according to the weight ratio: epoxy resin: curing agent: xylene = 100:30:30 compound glue, mix evenly to get epoxy resin colloid. The curing agent is a phenalkamine epoxy resin curing agent conforming to HG / T3875-2006, and the 7002B curing agent purchased from Boluo Xurisheng Insulation Material Co., Ltd. is used in this embodiment. The above-mentioned epoxy resin is a bisphenol A type epoxy resin in accordance with GB / T13657-1992, and the 7001AG epoxy resin purchased from Boluo County Xurisheng Insulation Material Co., Ltd. is used in this embodiment.

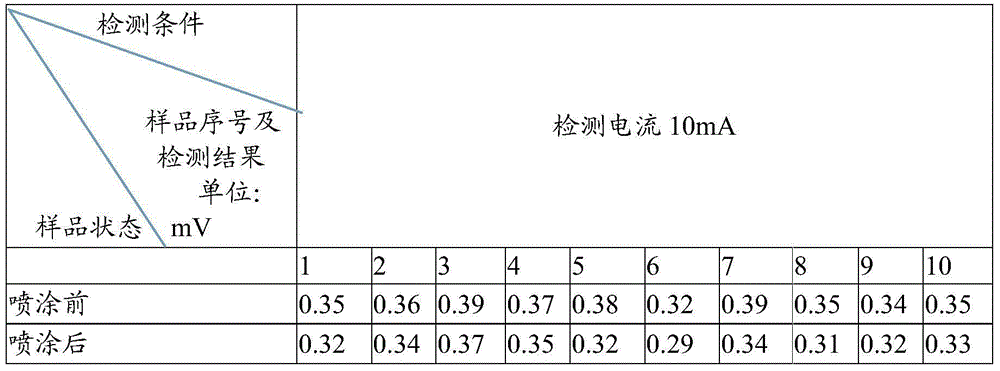

[0025] 2. Use the HT35 iron core measuring instrument to test the bare amorphous iron core of 16 / 21*10. After the bare amorphous iron core of model 16 / 21*10 is ...

Embodiment 2

[0034] In this embodiment, 30 amorphous iron cores with a model number of 16 / 21*10 are used as the substrate to spray epoxy resin. After the heat treatment of the small iron cores, the heat-treated iron cores are directly turned over with a tray, and epoxy resin is sprayed after turning over. .

[0035] The specific operation of spraying epoxy resin is as follows:

[0036] 1. Glue compounding: according to the weight ratio: epoxy resin: curing agent: xylene = 100:30:10 compound glue, mix evenly to get epoxy resin colloid. The curing agent is a phenalkamine epoxy resin curing agent conforming to HG / T3875-2006, and the 7002B curing agent purchased from Boluo Xurisheng Insulation Material Co., Ltd. is used in this embodiment. The above-mentioned epoxy resin is a bisphenol A type epoxy resin in accordance with GB / T13657-1992, and the 7001AG epoxy resin purchased from Boluo County Xurisheng Insulation Material Co., Ltd. is used in this embodiment.

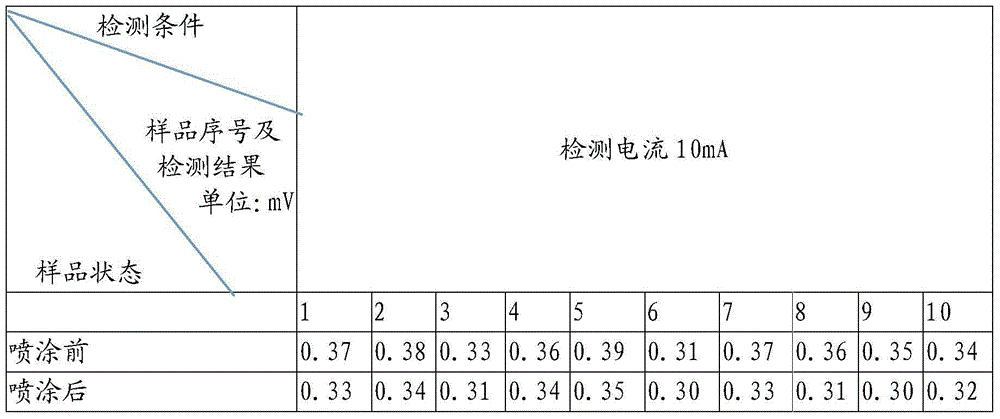

[0037] 2. After the bare amorp...

Embodiment 3

[0046] In this embodiment, 30 amorphous iron cores with a model number of 16 / 21*10 are used as the substrate to spray epoxy resin. After heat-treating the small iron cores, the heat-treated iron cores are turned over directly with a tray, and epoxy resin is sprayed after turning over the plates. .

[0047] The specific operation of spraying epoxy resin is as follows:

[0048] 1. Glue compounding: according to the weight ratio: epoxy resin: curing agent: xylene = 100:30:20 compound glue, mix evenly to get epoxy resin colloid. The curing agent is a phenalkamine epoxy resin curing agent conforming to HG / T3875-2006, and the 7002B curing agent purchased from Boluo Xurisheng Insulation Material Co., Ltd. is used in this embodiment. The above-mentioned epoxy resin is a bisphenol A type epoxy resin in accordance with GB / T13657-1992, and the 7001AG epoxy resin purchased from Boluo County Xurisheng Insulation Material Co., Ltd. is used in this embodiment.

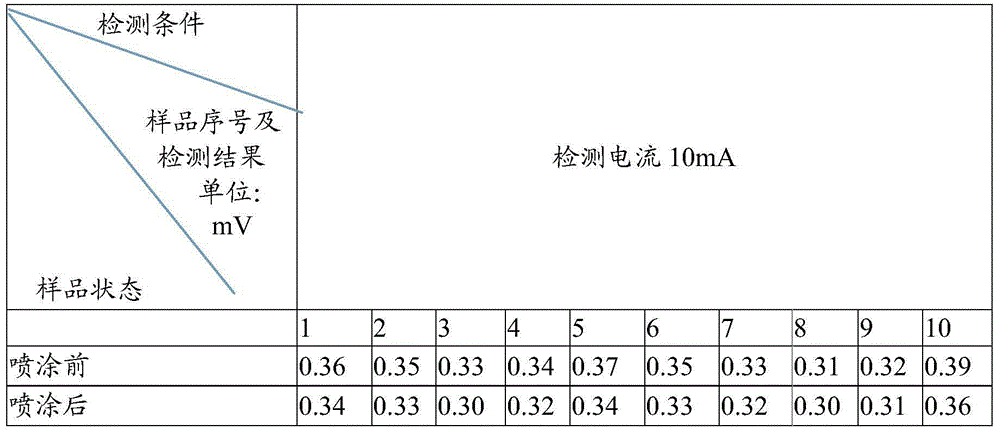

[0049] 2. After the bare am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com