Heat dissipation module spraying redundant part removal method and treatment device

A technology of heat dissipation module and processing equipment, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of inconvenient spraying, unfavorable shielding device, complex structure, etc., and achieve the effect of improving spraying accuracy and optimizing spraying process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

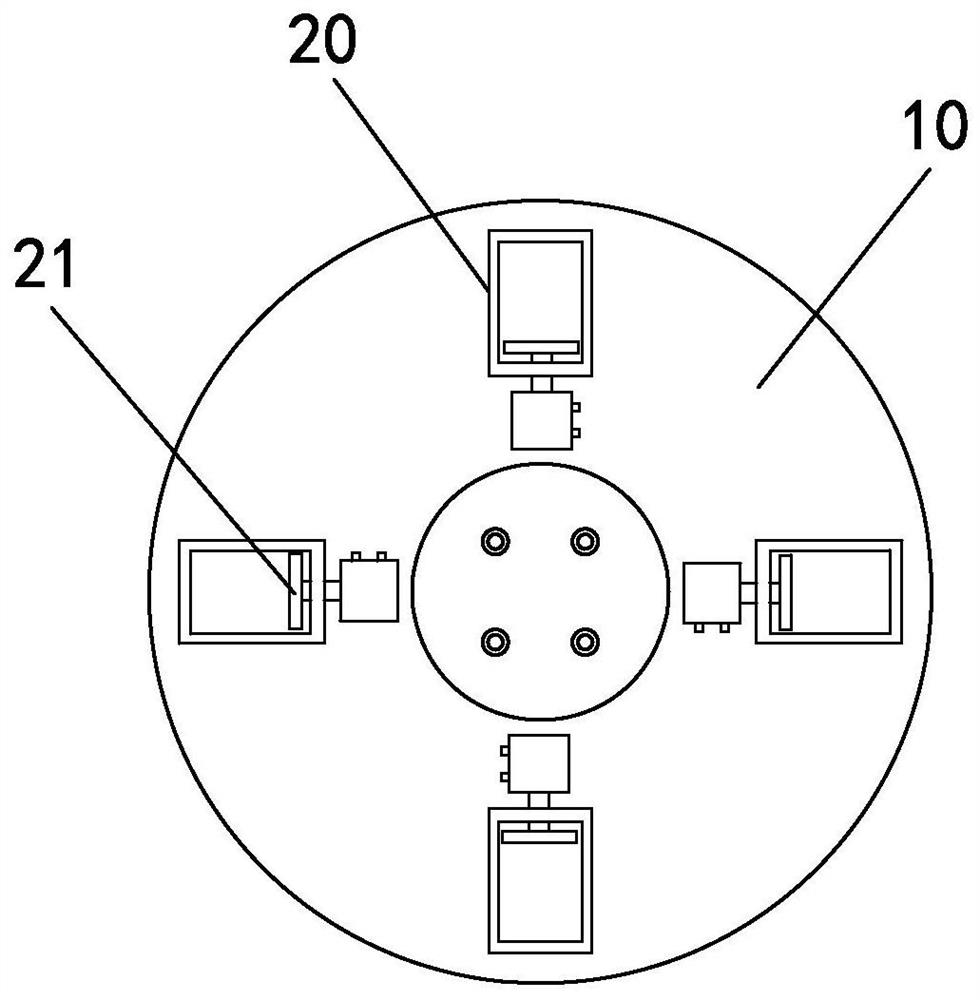

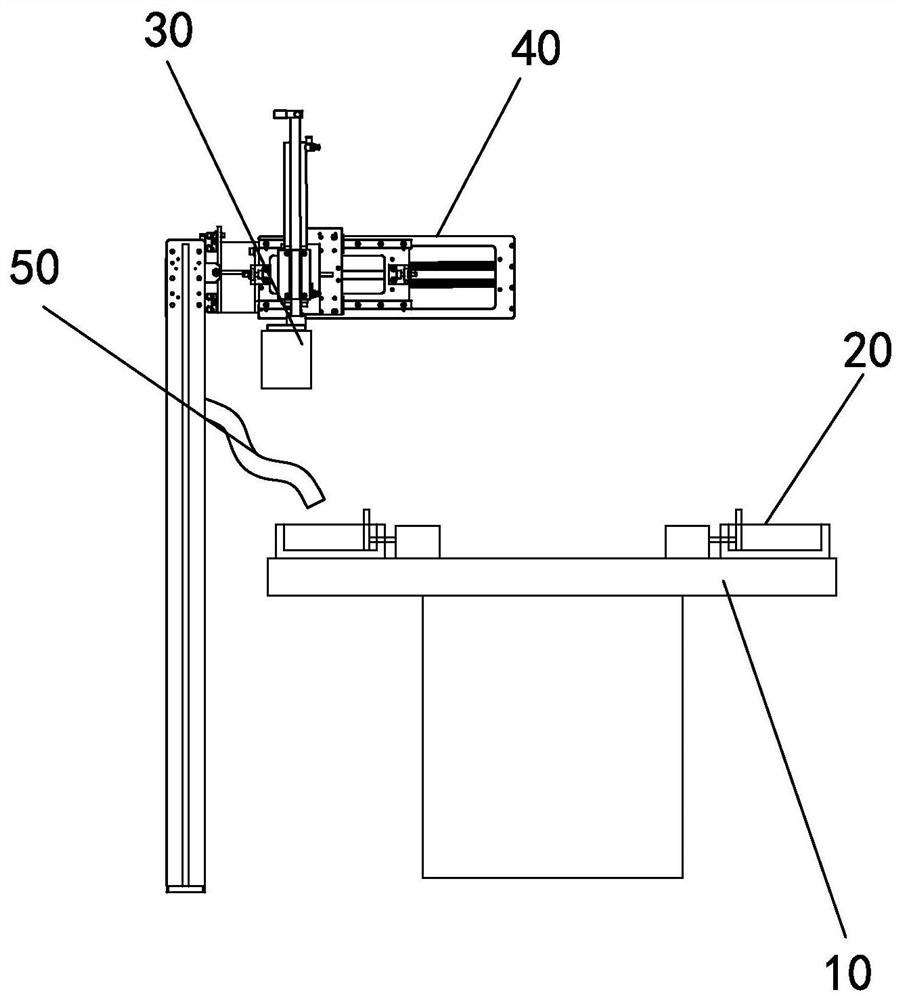

[0020] A heat dissipation module spraying excess part processing equipment includes a four-station turntable 10, and a loading manipulator, a laser device, a wiping device and a material-discharging manipulator arranged beside the four-station turntable. A jig 20 is installed on each station plate of the four-station turntable, and the jig includes a jig plate and a pneumatic side pushing block 21. A positioning profiling cavity is arranged in the jig plate, and the pneumatic side pushing block is installed on the positioning imitation block. inside the cavity. The wiping device comprises an alcohol tube and a wiping cotton, and the alcohol tube and the wiping cotton are connected by a pipeline. The laser device includes a laser head 30 and a three-axis displacement mechanism 40, and the laser head is arranged on the Z axis of the three-axis displacement mechanism. Both the feeding manipulator and the unloading manipulator use suction cups as the grabbing tooling for grabbing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com