Crucible bottom coating for full-melting efficient polycrystalline growth as well as spraying process and application of crucible bottom coating

A technology for crucible bottom and polycrystalline growth, which is applied in the field of high-efficiency polycrystalline crucible bottom coating and crucible bottom coating for full-melt high-efficiency polycrystalline growth. It is difficult to control, and the spraying cannot be guaranteed to be completely uniform, etc., to achieve the effect of high density, less impurities, and improved conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

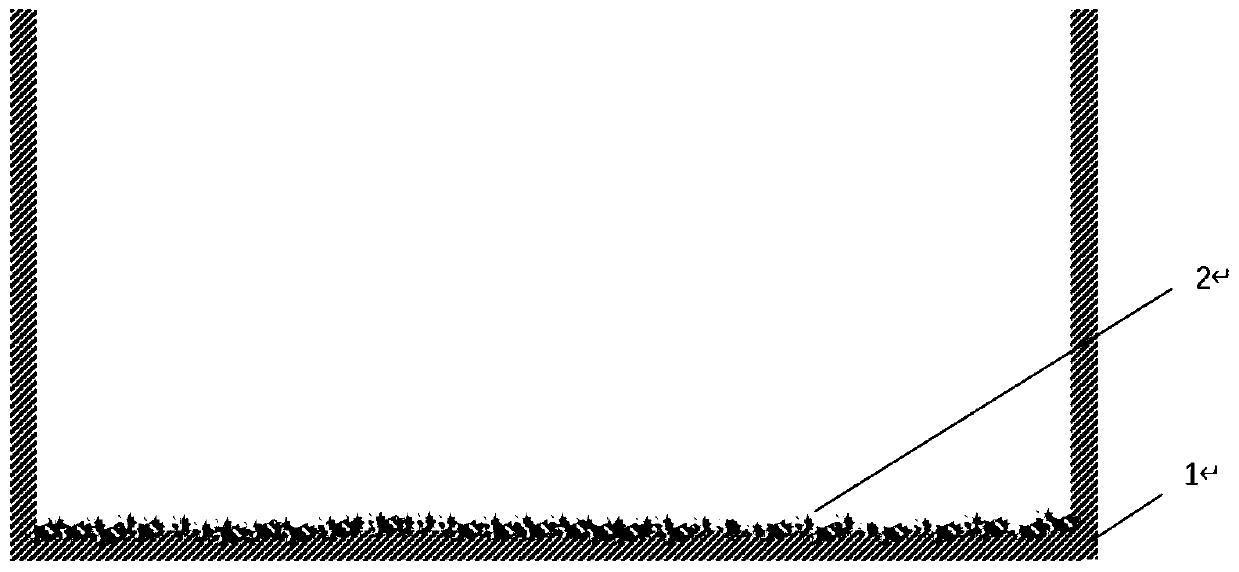

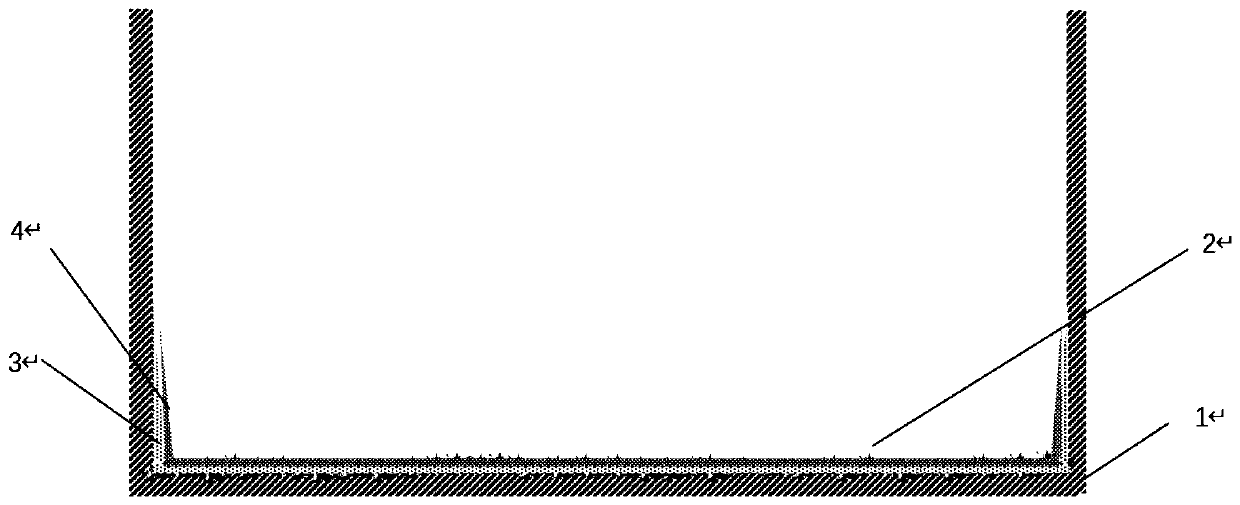

[0028] This embodiment provides a crucible bottom coating for full-melt high-efficiency polycrystalline growth, with a structure such as figure 2 As shown, the coating is covered on the bottom surface of the crucible, the crucible base 1 is provided with quartz sand particles 2, the quartz sand particles 2 are provided with a slurry A coating 3 and a slurry B coating 4, and a slurry B coating 4 On slurry A coat 3 where:

[0029] Slurry A coating is made by spraying slurry A. Slurry A is a mixture of silicon nitride powder, ultrapure water and silica sol. According to the mass ratio, silicon nitride powder: ultrapure water: silica sol=2.5-3 :8-10:1;

[0030] Slurry B coating is made by spraying slurry B. Slurry B is a mixture of silicon nitride powder, ultrapure water, silica sol and mixed powder α. According to the mass ratio, silicon nitride powder: ultrapure water: silica sol : The mass ratio of the mixed powder α is 2.5-3:8-10:1:0.3-0.5, and the mixed powder α is made by...

Embodiment 2

[0034] This embodiment provides the spraying process and application of the bottom coating of the crucible for full-melt high-efficiency polycrystalline growth in Example 1, which specifically includes the following steps:

[0035] (1) Preparation of Slurry A and Slurry B, take a measuring cup and add 540g of ultrapure water and 60g of silica sol and stir, add 150g of silicon nitride powder while stirring, stir for 20-30 minutes and filter to obtain Slurry A For coating slurry A, take another measuring cup and add 360g of ultrapure water and 40g of silica sol and stir, add 100g of silicon nitride powder while stirring, stir for 20-30 minutes and filter, then add 16g of silicon powder of 200 mesh and 0.8 g silicon dioxide powder obtains the slurry B of slurry B coating, for subsequent use;

[0036] (2) Set the atomization pressure of the spray gun to 4.0kgf / cm², and the atomization pressure to 4.2kgf / cm²;

[0037] (3) The starting point and end point of spraying are set on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com