Self-healing anti-oxidation paint for surface of curing blanket and preparation method of self-healing anti-oxidation paint

An anti-oxidation coating and self-healing technology, which is applied in the field of thermal insulation materials, can solve the problems of thermal insulation performance degradation, oxidized matting, etc., and achieve the effects of easy operation, prevention of slag drop, and good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

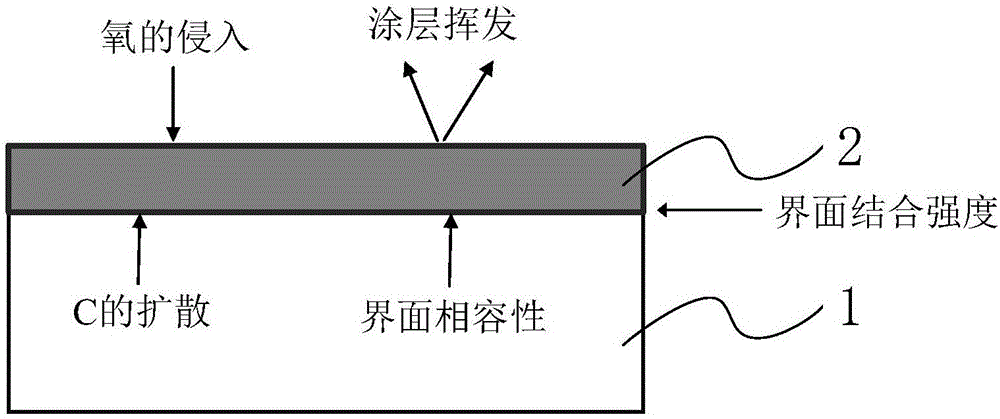

Problems solved by technology

Method used

Image

Examples

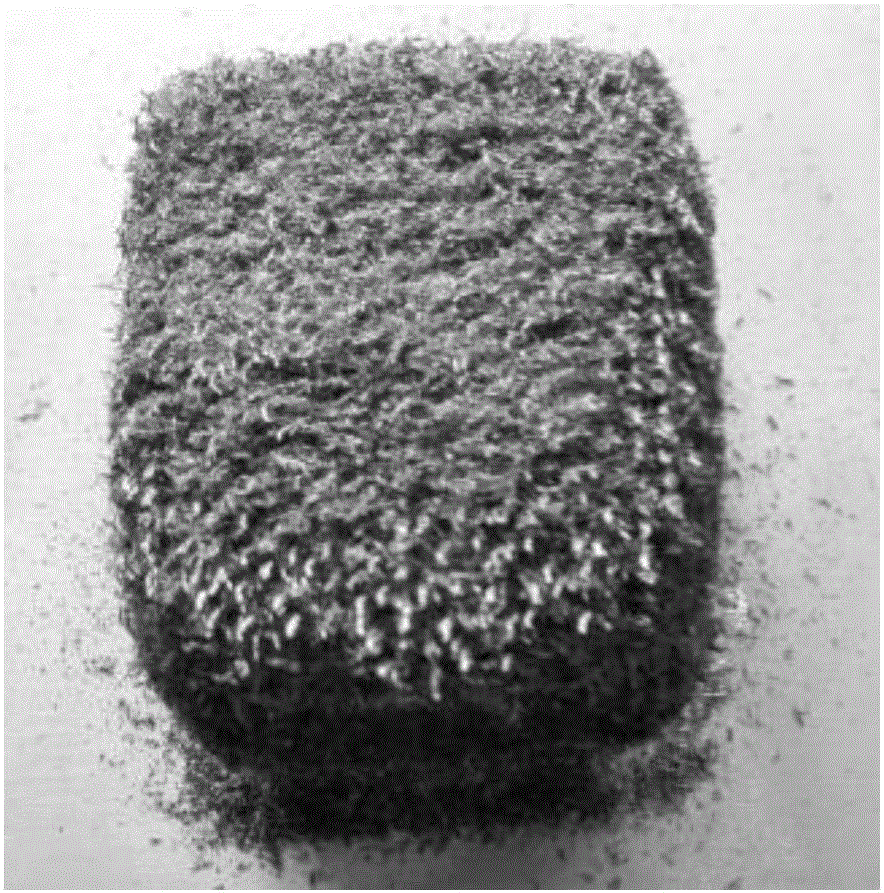

Embodiment 1

[0031] SiC powder 100g (particle size ≤ 5μm), B 4 C powder 30g (particle size ≤ 3μm), silicon powder 10g (particle size ≤ 5μm), graphite powder 20g (particle size ≤ 5μm) were placed in a V-type mixer and mixed for 0.5h, after fully mixing, the mixture was taken out and waited use. Take 20g of phenolic resin, dissolve it in 100g of ethanol, ultrasonically disperse it evenly, stir it with a mixer for 20min, and control the speed at 200-300r / min to make a resin solution. Then add the mixture into the resin solution, and continue stirring with the mixer for 30 minutes to make a self-healing anti-oxidation coating.

Embodiment 2

[0033] SiC powder 100g (particle size ≤ 5μm), B 4 C powder 30g (particle size ≤ 3μm), silicon powder 10g (particle size ≤ 5μm), graphene powder 5g (average number of layers 2-3 layers) were placed in a V-type mixer and mixed for 0.5h, after fully mixing, put The mixture is taken out for use. Take 20g of phenolic resin, dissolve it in 80g of ethanol, ultrasonically disperse evenly, stir with a mixer for 20min, and control the speed at 200-300r / min to form a resin solution. Then add the mixture into the resin solution, and continue stirring with the mixer for 30 minutes to make a self-healing anti-oxidation coating.

Embodiment 3

[0035] SiC powder 82g (particle size ≤ 5μm), B 4 C powder 40g (particle size ≤ 3μm), graphite powder 22g (particle size ≤ 5μm) were placed in a V-type mixer and mixed for 0.5h. After fully mixing, the mixture was taken out for use. Take 26g of epoxy resin, dissolve it in 80g of acetone, disperse it evenly by ultrasonic, stir it with a mixer for 20min, and control the speed at 200-300r / min to make a resin solution. Then add the mixture into the resin solution, and continue stirring with the mixer for 30 minutes to make a self-healing anti-oxidation coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com