Electrical equipment inspection rack

A technology for electrical equipment and maintenance benches, applied in workshop equipment, workbenches, manufacturing tools, etc., can solve problems such as difficult handling by maintenance personnel and difficult work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

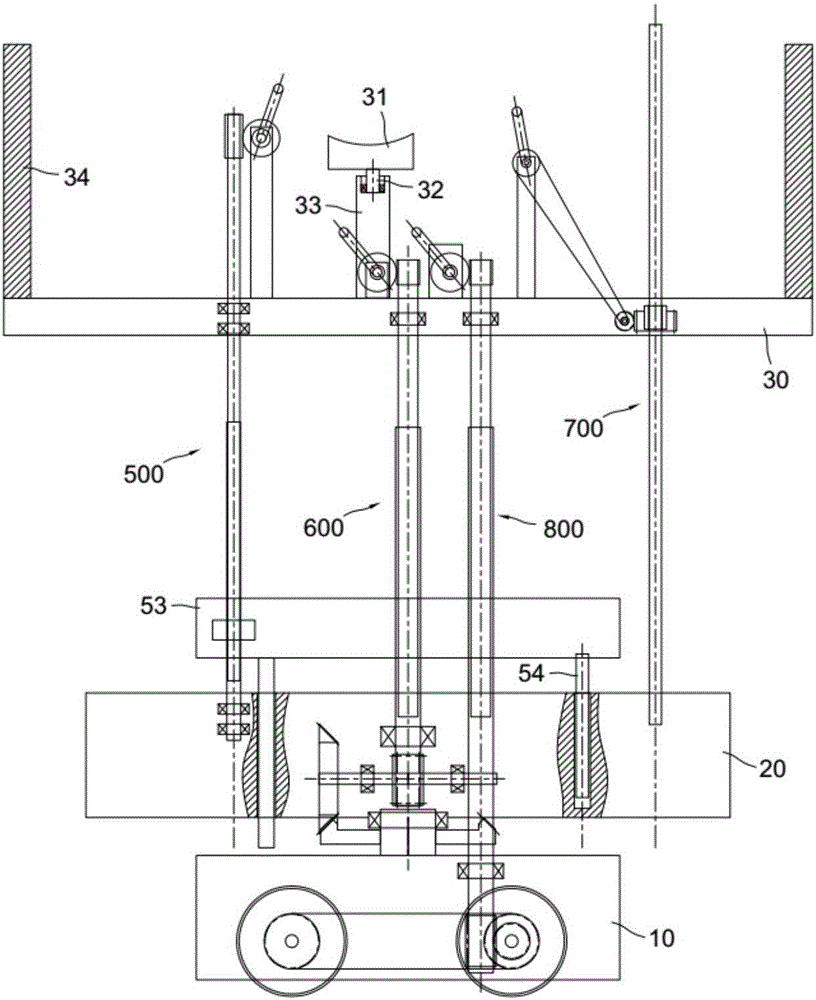

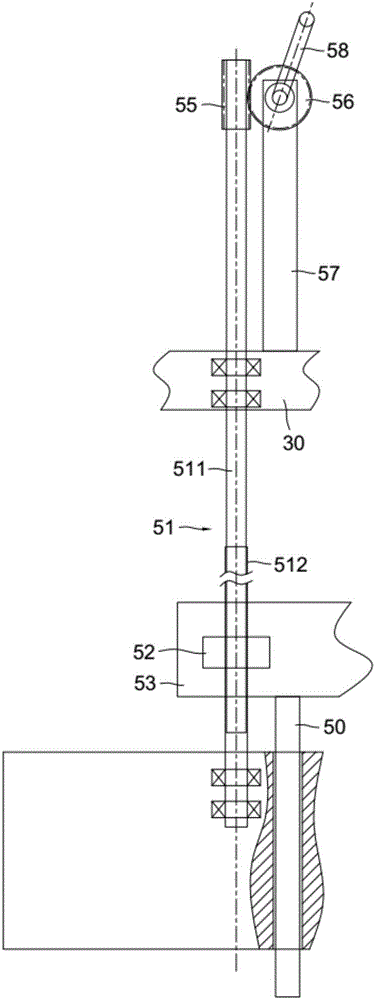

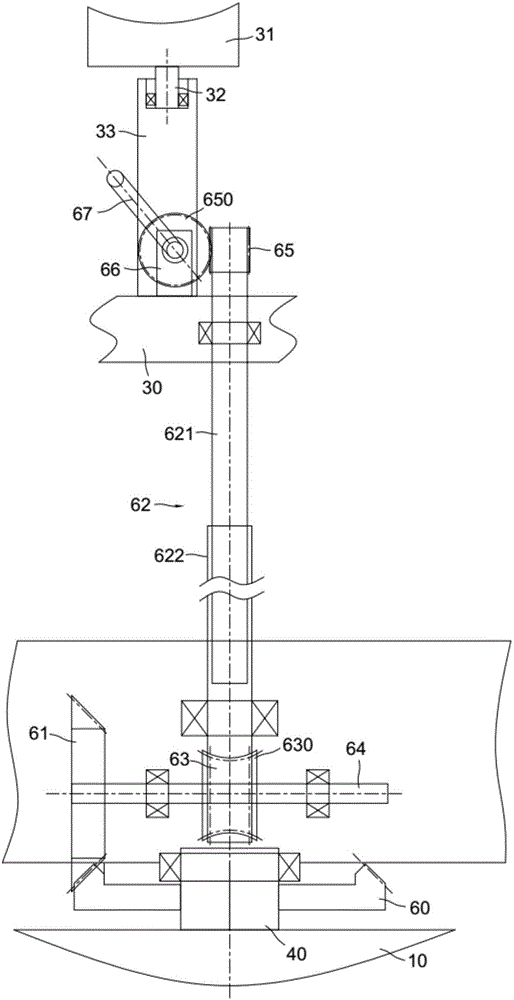

[0031] Refer to the following specific implementation methods Figure 1 to Figure 5 .

[0032] An electric equipment maintenance platform includes a rotating base 20 pivotally connected to a base 10 and a workbench 30 mounted on the rotating base, and the rotating base is pivotally connected to the base through a rotating shaft 40 .

[0033] The maintenance platform for electrical equipment is provided with a locking mechanism 500 for locking the rotating base 20 on the base 10 .

[0034] The maintenance platform for electrical equipment is provided with a rotation drive mechanism 600 that drives the rotation base 20 to rotate relative to the base 10 .

[0035] The power equipment maintenance platform is provided with a lifting mechanism 700 for driving the workbench 30 up and down.

[0036] The power equipment maintenance platform is provided with a translation mechanism 800 that drives the entire power equipment maintenance platform to move linearly along the ground.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com