Molecular adsorption-thermal control bifunctional coating and preparation method thereof

A molecular adsorption and dual-function technology, which is applied in coatings, chemical instruments and methods, and other chemical processes, can solve the problems of small application range, increased self-weight of spacecraft, and low total molecular adsorption of adsorption devices. The effect of being simple and easy to implement and easy to promote on a large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

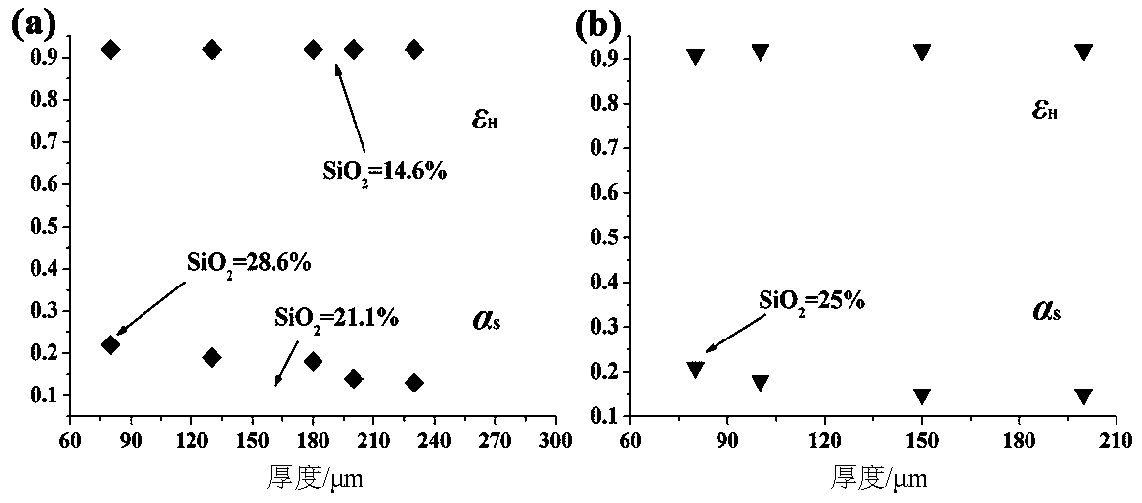

[0055] Accurately weigh 7.5g of inorganic silica sol (concentration is 40%, average particle diameter 30nm), add 12.5g deionized water, magnetically stir for 5 minutes, slowly add 17.5g NaY powder, continue to stir for 4 hours to make it fully mixed, Prepare NaY zeolite slurry. Use a spray gun to spray multiple times on the frosted aluminum substrate. The thickness of a single spraying is 30-50 μm, the interval between two adjacent sprayings is 3 hours, and the spraying atmosphere is air. After the coating was naturally dried in the shade, it was dried at 80°C for 12 hours to obtain NaY zeolite-based molecular adsorption-thermal control dual-functional coating materials (NaY Coatings-40%-14.6%) with different thicknesses.

Embodiment 2

[0057] Accurately weigh 10g of inorganic silica sol (concentration 40%, average particle size 30nm), add 10g deionized water, stir magnetically for 5 minutes, slowly add 15g NaY powder, continue stirring for 4 hours to fully mix, and prepare NaY zeolite slurry. A spray gun was used to spray coating on the frosted aluminum substrate multiple times, and the specific spraying conditions were the same as in Example 1. After the coating was naturally dried in the shade, it was dried at 50°C for 12 hours to obtain NaY zeolite-based molecular adsorption-thermal control dual-functional coating materials (NaYCoatings-40%-21.1%) with different thicknesses.

Embodiment 3

[0059] Accurately weigh 12.5g of inorganic silica sol (concentration is 40%, average particle size 30nm), add 7g deionized water, magnetically stir for 5 minutes, slowly add 12.5g NaY powder, continue to stir for 4 hours to make it fully mixed, and prepare NaY zeolite slurry. A spray gun was used to spray coating on the frosted aluminum substrate multiple times, and the specific spraying conditions were the same as in Example 1. After the coating was naturally dried in the shade, it was dried at 50°C for 12 hours to obtain NaY zeolite-based molecular adsorption-thermal control dual-functional coating materials (NaYCoatings-40%-28.6%) with different thicknesses.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com