A spraying device for cooking utensils

A technology for spraying devices and cooking utensils, which is applied in the direction of spraying devices, can solve the problems of color and aesthetics that are not as strong as paint, can not be sprayed with patterns, and the singleness of spraying equipment, so as to save labor costs, improve viewing, and enhance The effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

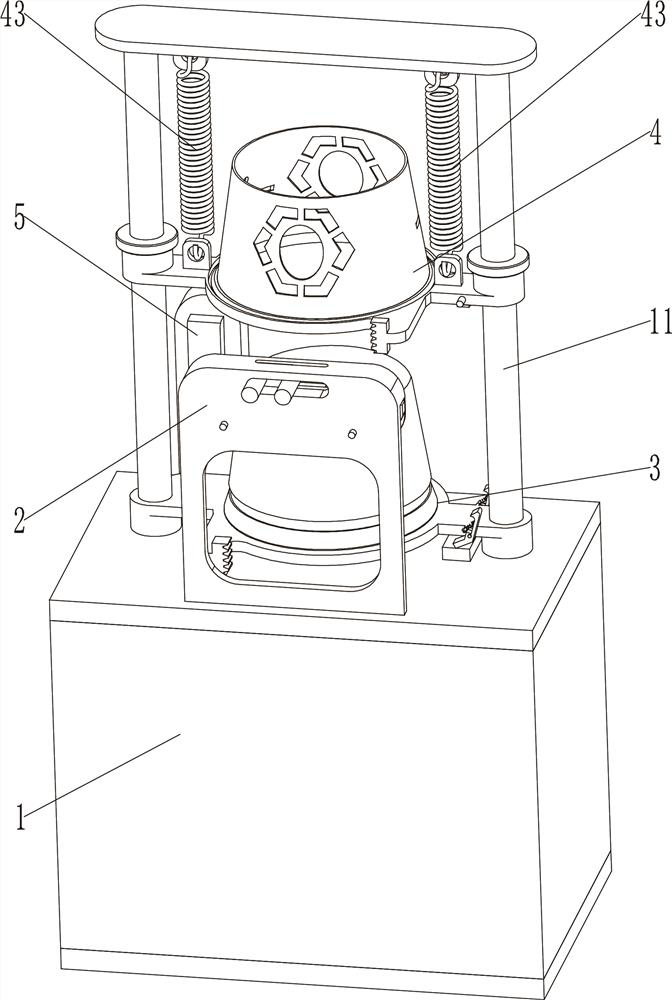

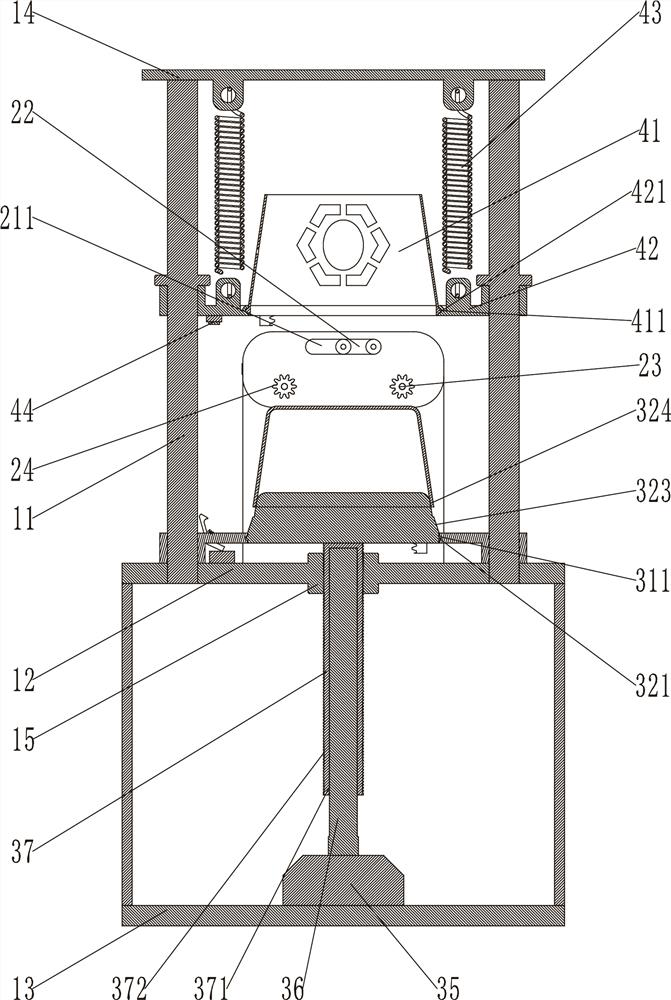

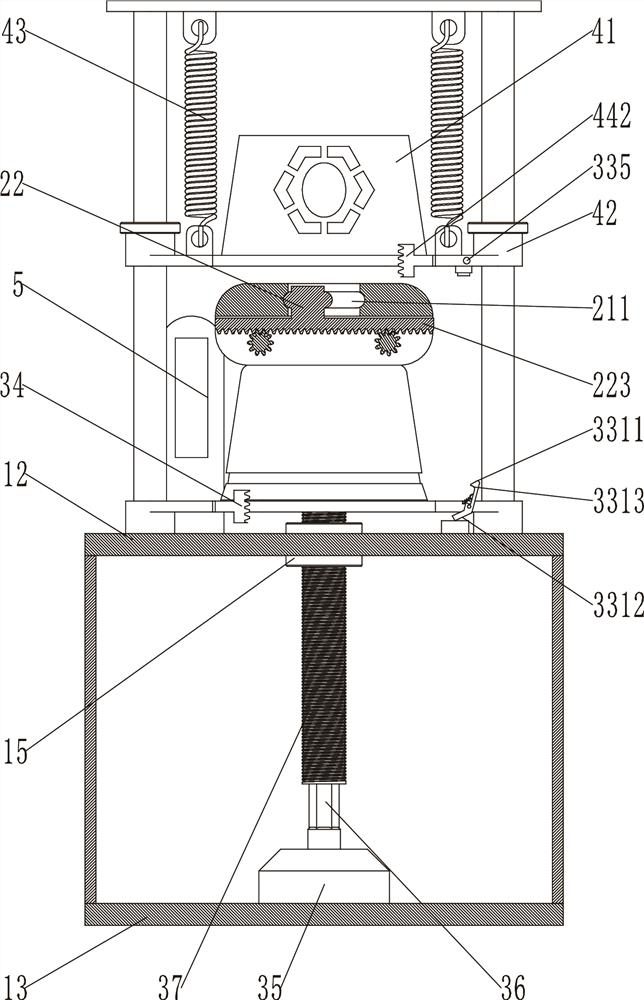

[0028] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 6 , a spraying device for cooking utensils, comprising a base 1 on which a coating part 2, an up and down running part 3, a pattern shielding part 4 and a spray gun start switch 5 are arranged, and the base 1 includes a guide post 11, an intermediate plate 12, a bottom plate 13 and an upper top plate 14, the guide post 11 is arranged on the middle plate 12, and one is arranged on the left and right sides, the upper top plate is arranged on the top surface of the guide post 11, and a threaded sleeve 15 is arranged in the middle of the middle plate 12, The guide post 11 is provided with an upper limit ring 111 .

[0029] Described up and down running part 3 comprises lower slide ring 31, second rack 34, motor 35, hexagonal shaft 36, screw thread mandrel 37, rotating disk 32 and locking device 33, and described motor 35 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com