Hydraulic mechanical planetary reversible transmission device and method

A technology of hydraulic machinery and transmission device, applied in the field of transmission, can solve the problems of large structure, inconvenient adjustment, difficult starting, etc., and achieve the effect of small structure and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

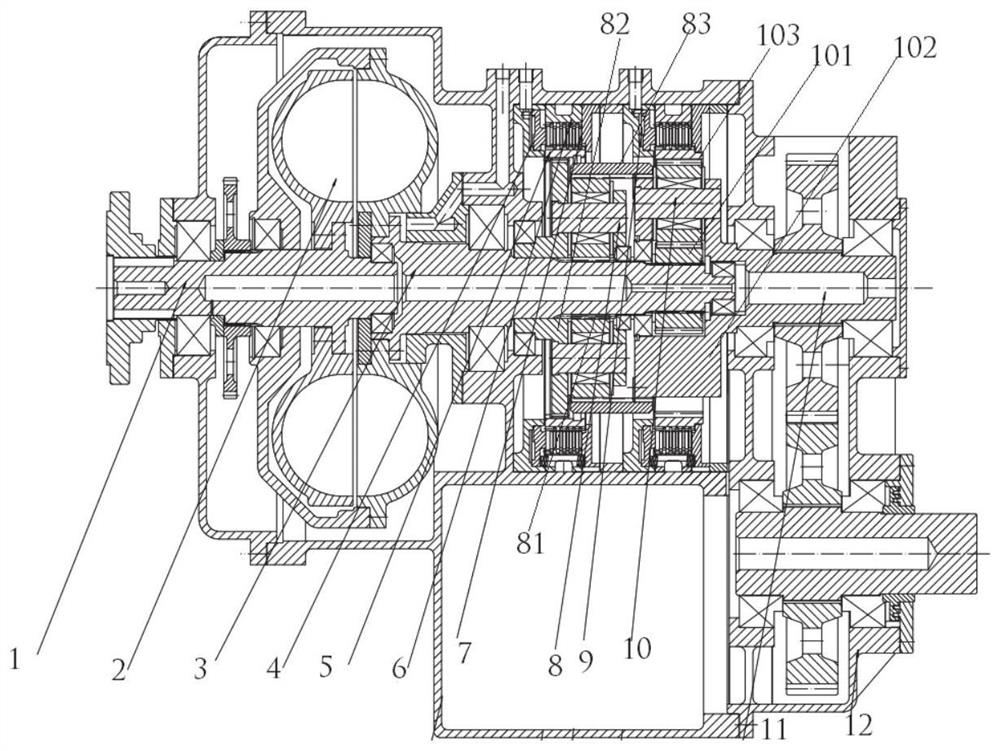

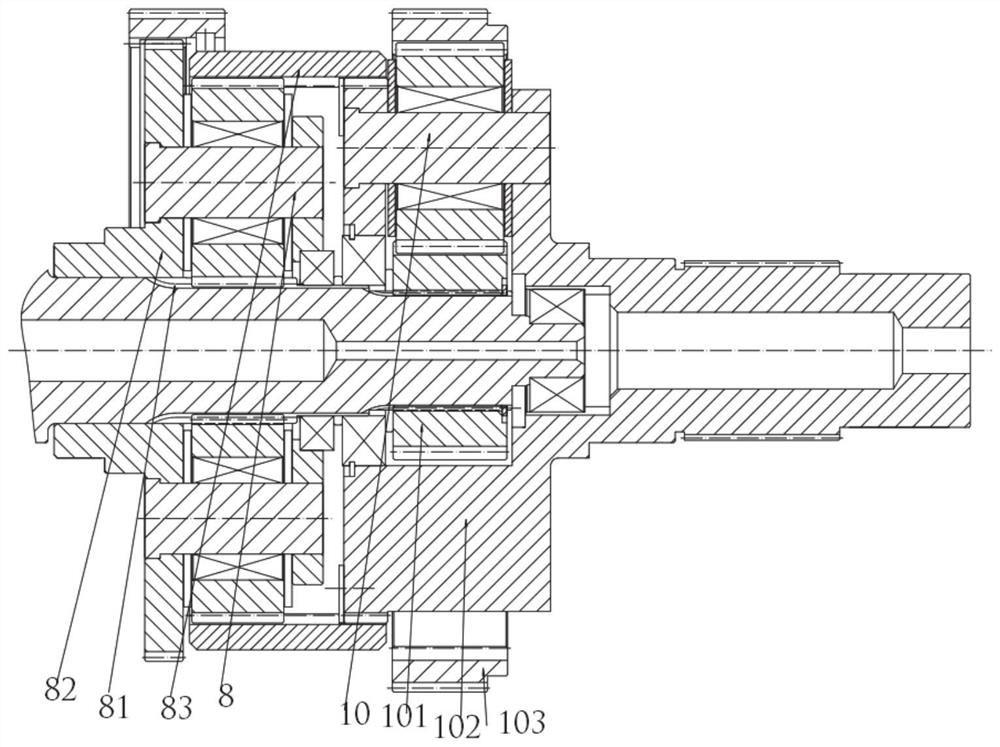

[0030] See how Figure 1-2 , the present invention relates to a hydromechanical planetary reversing transmission device, including a casing 12, and a pump wheel shaft 1, a hydraulic transmission part 2, a turbine shaft 3, a forward clutch 4, and a brake ring gear in the casing 12 5. Clutch support seat 6, friction plate 7, forward gear planetary pair 8, reverse gear clutch 9, reverse gear planetary pair 10, fixed shaft type single-stage gear transmission mechanism 11. The hydraulic transmission part 2 can adopt a hydraulic coupling or a hydraulic torque converter, depending on the specific implementation conditions.

[0031] Hydraulic transmission parts, turbine shaft 3, forward clutch 4, brake ring gear 5, clutch support seat 6, friction plate 7, forward gear planetary pair 8, reverse gear planetary pair 10, fixed shaft single-stage gear transmission mechanism 11 They are all installed on the box body 12, the pump wheel shaft is used as the input end of the whole hydromechan...

Embodiment 2

[0047] The present invention also relates to a hydromechanical planetary reversing transmission method, based on a hydraulic mechanical planetary reversing transmission device in Embodiment 1, to realize the switching output of forward gear, neutral gear and reverse gear, and the specific steps are as follows:

[0048] When the forward gear needs to be realized, the pump wheel shaft drives the turbine shaft to rotate through the hydraulic transmission; when the forward gear clutch is filled with oil, the brake ring gear is locked and braked, driving the forward gear planet carrier 82 to brake, and the power passes through the forward gear sun gear 81 input, the forward gear ring gear 83 and the forward gear sun gear 81 reverse output, and the forward gear ring drives the reverse gear planetary carrier 102 to output in the same direction. to power transmission;

[0049] When the reverse gear needs to be realized, the pump wheel shaft drives the turbine shaft to rotate through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com