Power-ceaseless gear transmission

A technology of gear transmission and transmission, which is applied in the direction of gear transmission, belt/chain/gear, transmission, etc., which can solve the problems of mechanical shock, incapable of carrying large load power transmission, power interruption of shifting, etc., to avoid mechanical shock Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

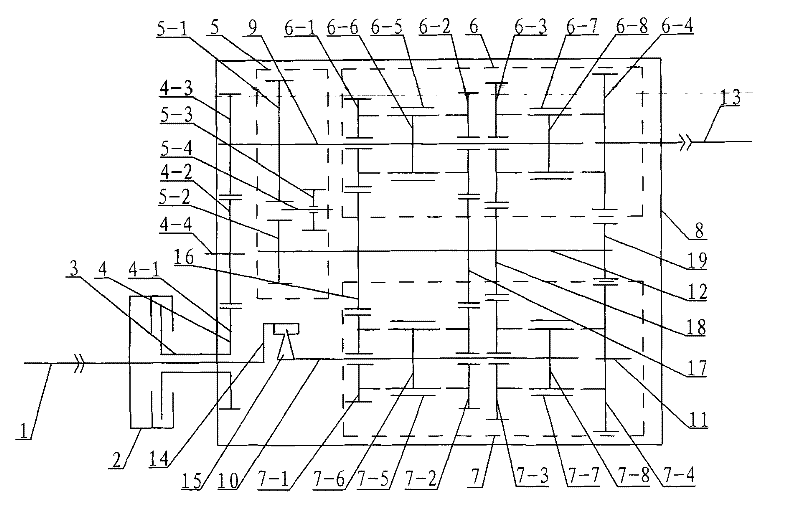

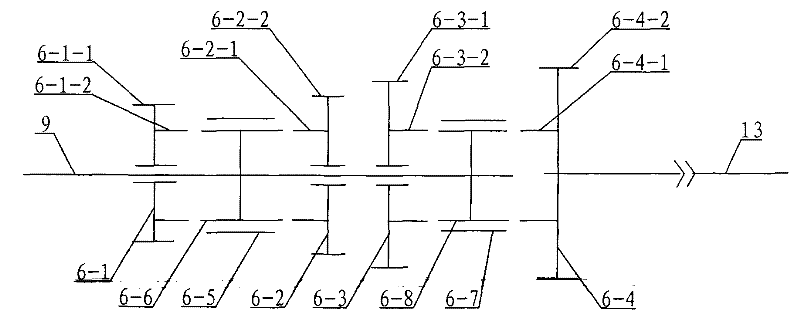

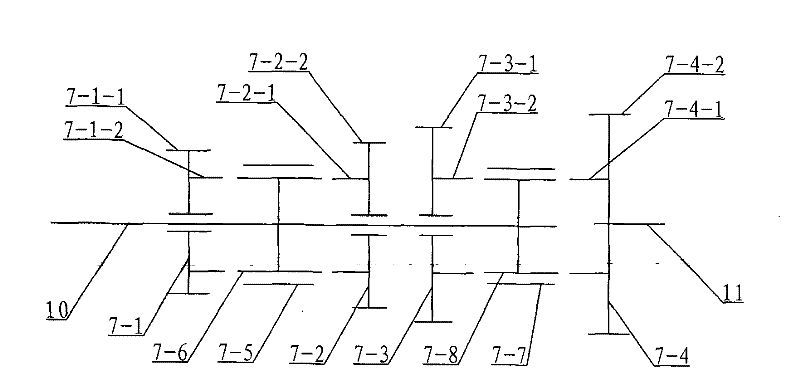

[0008] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment includes input end gear mechanism 4, reverse gear mechanism 5, box body 8, drive shaft 1, clutch 2, bushing 3, main drive gear mechanism 6, secondary drive gear mechanism 7, the first Transmission shaft 9, second transmission shaft 10, second output shaft 11, third transmission shaft 12, first output shaft 13, one-way wheel input shaft 14, one-way wheel 15, first transmission gear 16, second transmission gear 17. The third transmission gear 18 and the fourth transmission gear 19, the one-way wheel input shaft 14 is located at the output end of the drive shaft 1, and the one-way wheel input shaft 14 is integrated with the drive shaft 1, and the sleeve 3 is set on the drive shaft 1, the input end of the drive shaft 1 is located outside the box body 8, and the bushing 3 is arranged on the box body wall of the box body 8 through bearings, the input end of the clutch 2 is...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, the input end gear mechanism 4 of this embodiment is made up of input end driving gear 4-1, input end intermediate gear 4-2, input end driven gear 4-3 and input end intermediate shaft 4-4, the input end The passive gear 4-3 is fixed on the input end of the first transmission shaft 9, the input end driving gear 4-1 is fixed on the output end of the shaft sleeve 3, and the input end intermediate gear 4-2 is connected with the input end driving gear 4 at the same time. -1 meshes with the driven gear 4-3 at the input end, the intermediate gear 4-2 at the input end is fixed on the intermediate shaft 4-4 at the input end, and the intermediate shaft 4-4 at the input end is arranged on the box body wall of the box body 8 through bearings . The input end driving gear 4-1 has the same pitch circle diameter and the same number of teeth as the input end intermediate gear 4-2, and the pitch circle diam...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment, the reverse gear mechanism 5 of this embodiment is made up of reverse gear driving gear 5-1, reverse gear passive gear 5-2, reverse gear intermediate gear 5-3 and reverse gear intermediate shaft 5-4, reverse gear The driving gear 5-1 is fixed on the first transmission shaft 9, the reverse gear driven gear 5-2 is fixed on the third transmission shaft 12, and the reverse intermediate gear 5-3 is located between the reverse driving gear 5-1 and the reverse gear. At the side end face of the driven gear 5-2, the reverse intermediate gear 5-3 is fixedly mounted on the reverse intermediate shaft 5-4 through bearings, and the two ends of the reverse intermediate shaft 5-4 are respectively arranged on the ribs of the casing 8 through the bearings. board. The reverse gear intermediate gear 5-3 can mesh with the reverse gear driving gear 5-1 and the reverse gear driven gear 5-2 simultaneously, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com