An organic solar cell based on a spray-coated molybdenum trioxide anode buffer array and its preparation method

A technology of solar cells and molybdenum trioxide, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as carrier transmission and separation obstruction, anode buffer layer interface roughness, high carrier recombination probability, etc., to achieve Reduce the chance of recombination, reduce the coffee ring effect, optimize the effect of spraying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

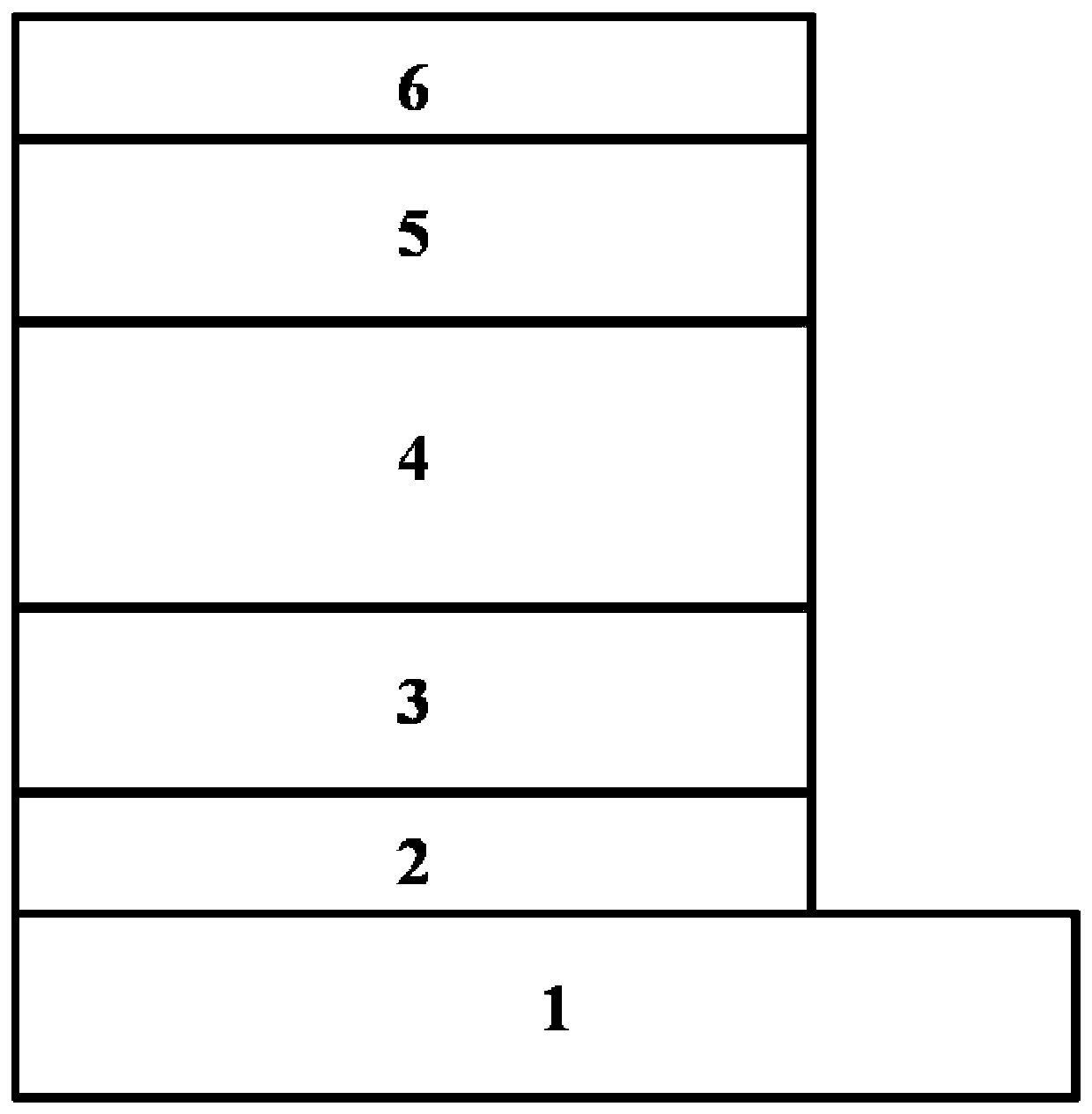

[0028] Such as figure 1 As shown, an organic solar cell based on a spray-coated molybdenum trioxide anode buffer array, the solar cell adopts an inverted structure, including a substrate layer 1, ITO (ITO, English name Indium Tin Oxides, oxidized Indium tin) transparent conductive cathode layer 2, cathode buffer layer 3, photoactive layer 4, anode buffer layer 5, metal anode layer 6;

[0029] in,

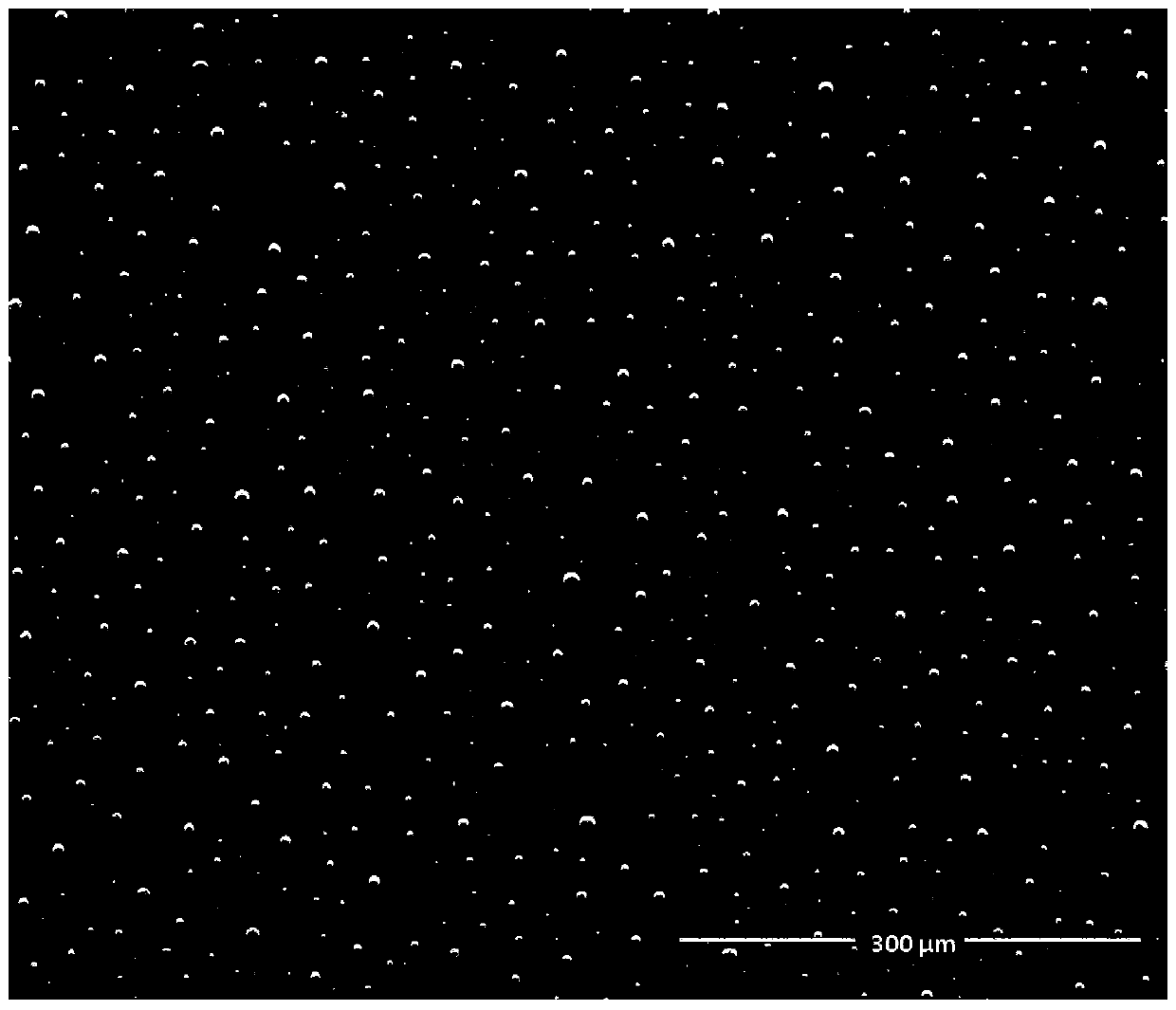

[0030] The anode buffer layer 5 is a molybdenum trioxide array film formed by spraying an aqueous ammonium molybdate solution mixed with hyaluronic acid on the photoactive layer 4 and annealing; in the molybdenum trioxide array film, the mass fraction of hyaluronic acid and ammonium molybdate They are:

[0031] Ammonium molybdate 0.2-1wt%;

[0032] Hyaluronic acid 0-0.5wt%.

[0033] Preferably, the photoactive layer 4 is mainly composed of electron donor material P3HT and electron acceptor material PC 61 A solid film prepared from a mixed solution of BM;

[0034] in,

[0035]...

specific Embodiment

[0054] Control group 1

[0055] 1. Clean the substrate composed of a transparent substrate layer 1 and an ITO transparent conductive cathode layer 2 with a surface roughness less than 1 nm, and dry it with nitrogen after cleaning;

[0056] 2. Spin-coat ZnO nanoparticles on the surface of the ITO transparent conductive cathode layer 2 (working parameters: rotating speed 5000rpm, time 40s, thickness 50nm, the same below, no further description) to prepare the cathode buffer layer 3, and conduct the formed film at low temperature Baking (working parameters: temperature 30°C, time 20min);

[0057] 3. Prepare P3HT: PC by spraying on the cathode buffer layer 3 61 BM (mass ratio 1:0.9, concentration 5mg / ml, the same below, no further description) photoactive layer 4 (airflow 15L min-1, solvent 0.075ml min -1 300nm, the same below, no further explanation);

[0058] 4. Spray ammonium molybdate aqueous solution (airflow 10L min on the surface of photoactive layer 4 -1 , solvent 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com