Off-line digital-analog planning system and method for spraying operation of large ship body sections

A hull, off-line technology, used in spraying devices, manipulators, program-controlled manipulators, etc., can solve the problems of low degree of automation in coating production, unstable quality, and different sizes of spraying surfaces, and improve spraying efficiency and spraying quality. , Reduce the link and personnel settings, the effect of rapid spraying job changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings.

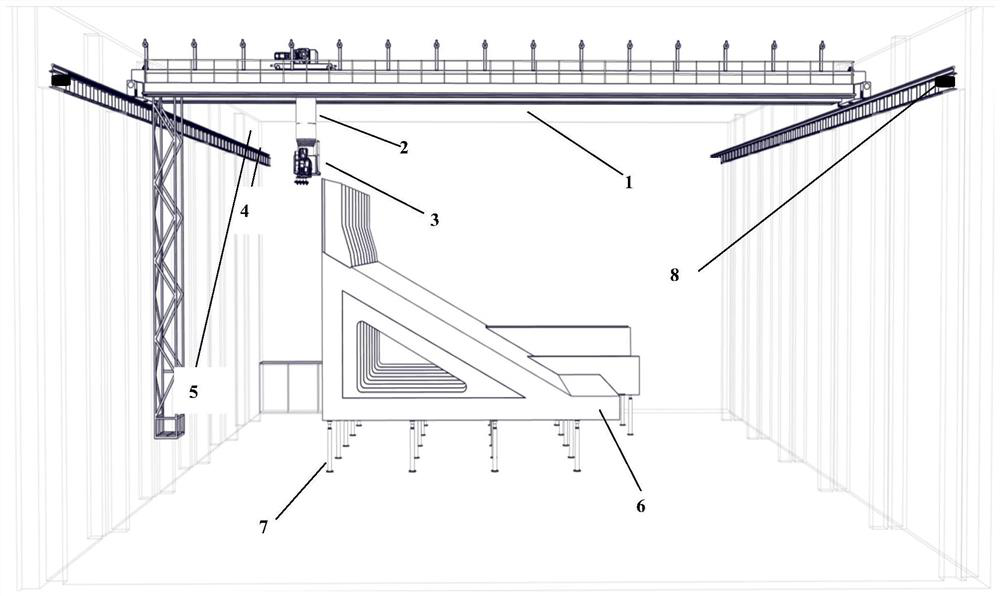

[0059] figure 1 It is a schematic diagram of the spraying operation of a spraying workstation of a large hull according to an embodiment of the present invention. Such as figure 1 As shown, the three-degree-of-freedom mobile crane platform composed of the crane 1 and the multi-stage telescopic arm 2 can carry the six-degree-of-freedom spraying robot 3 along the X, Y, and Z directions, select a specific spray gun 4 and install it at the end of the robot, and the distance measuring sensor 5 Installed on the fuselage of the spraying robot 3, it is used to measure the distance between the robot and the hull during the spraying process of the robot, and compare the measured distance with the set minimum safe distance to prevent collisions. The hull 6 to be sprayed is placed in a large storage On the frame 7, a positioning device 8 is installed around the spray b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com