Elevation type work platform for moving cargo hold of bulk freighter

A working platform and lifting technology, which is applied in the direction of lifting devices, etc., can solve the problems of high cost of occupied materials, long occupation time of door cranes, and high labor intensity of workers, etc., to achieve short occupation time of door cranes, less labor force, and sandblasting and the effect of convenient painting work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

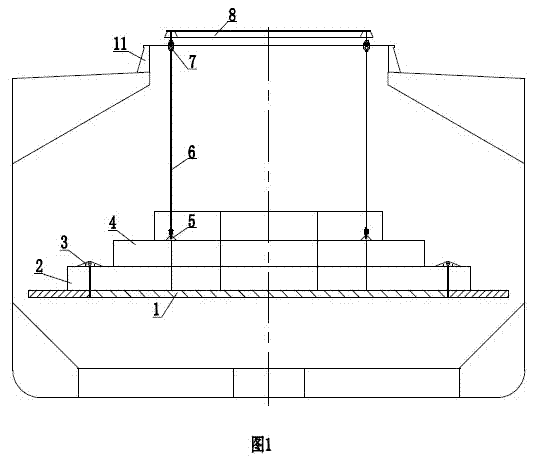

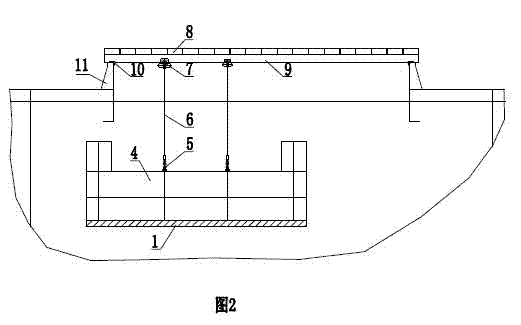

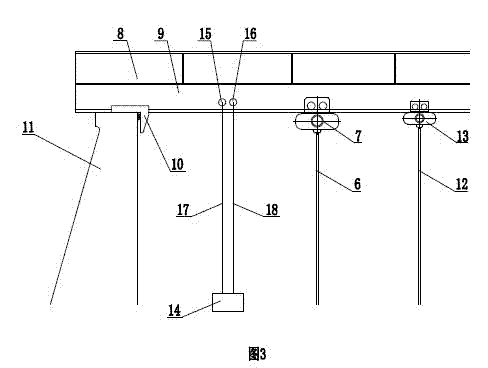

[0013] An embodiment is described with reference to the accompanying drawings. to combine figure 1 , figure 2 , image 3 illustrate.

[0014] The mobile elevating platform for the cargo hold of a bulk carrier includes a working platform 1, a working platform frame 4, and a working platform hanger 5. The working platform and the working platform frame are respectively welded with pipes or profiles to form a truss structure, and the working platform frame is welded on the working platform. , the working platform hanger is welded on the working platform frame, the working platform 1 is provided with a working walkway around it, the structural beam 8 is placed on the hatchway 11 of the cargo hold, the structural beam is welded with steel plates, and the guide rails 9 are welded on both sides below the structural beam, 4 electric hoists A 7 with a lifting capacity of 10 tons are suspended on the guide rails and can move on the guide rails. The control wires of the electric hois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com