Patents

Literature

67results about How to "Even sandblasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

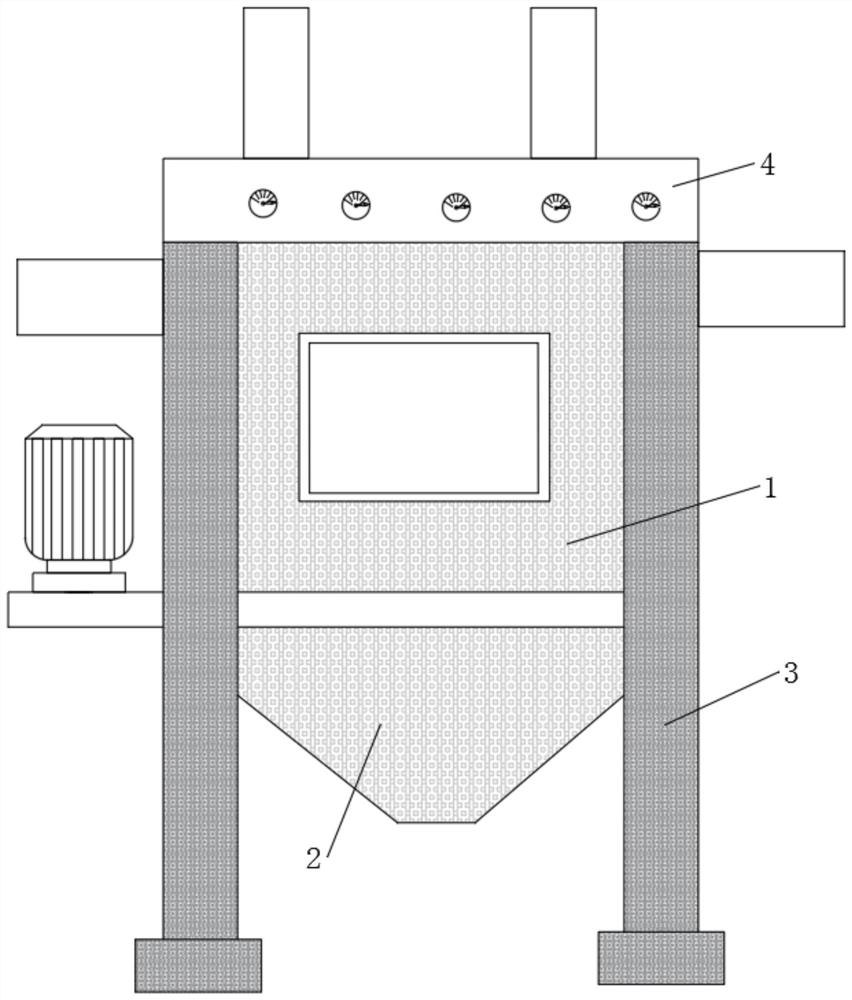

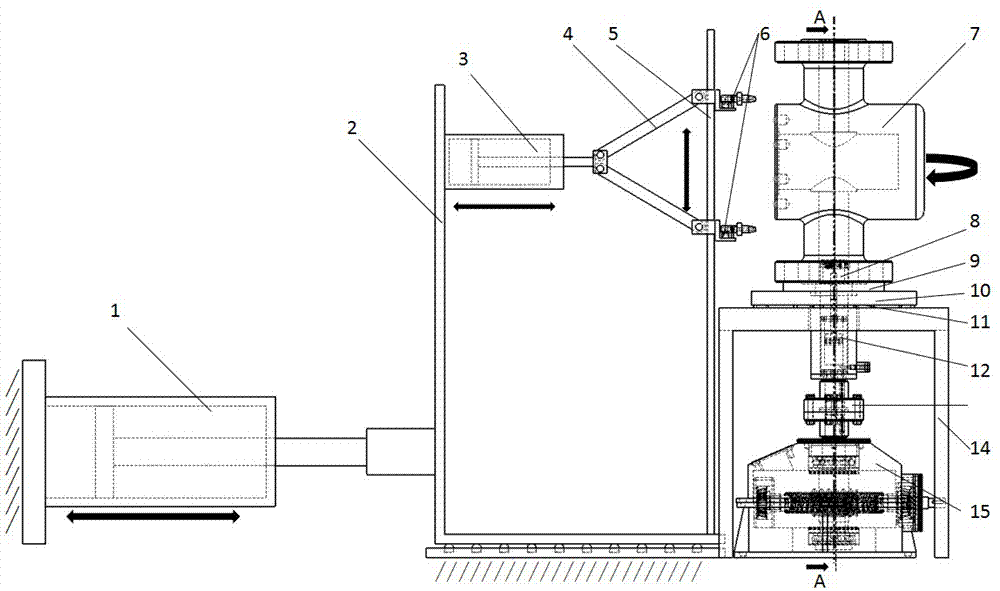

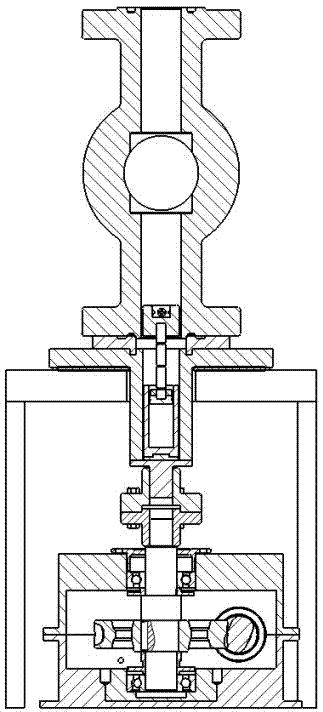

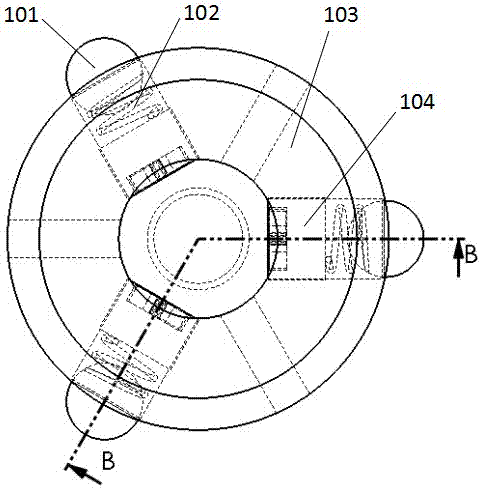

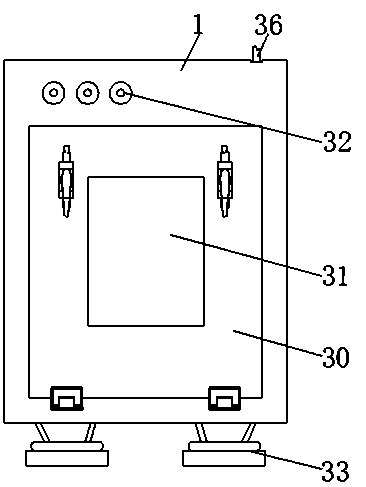

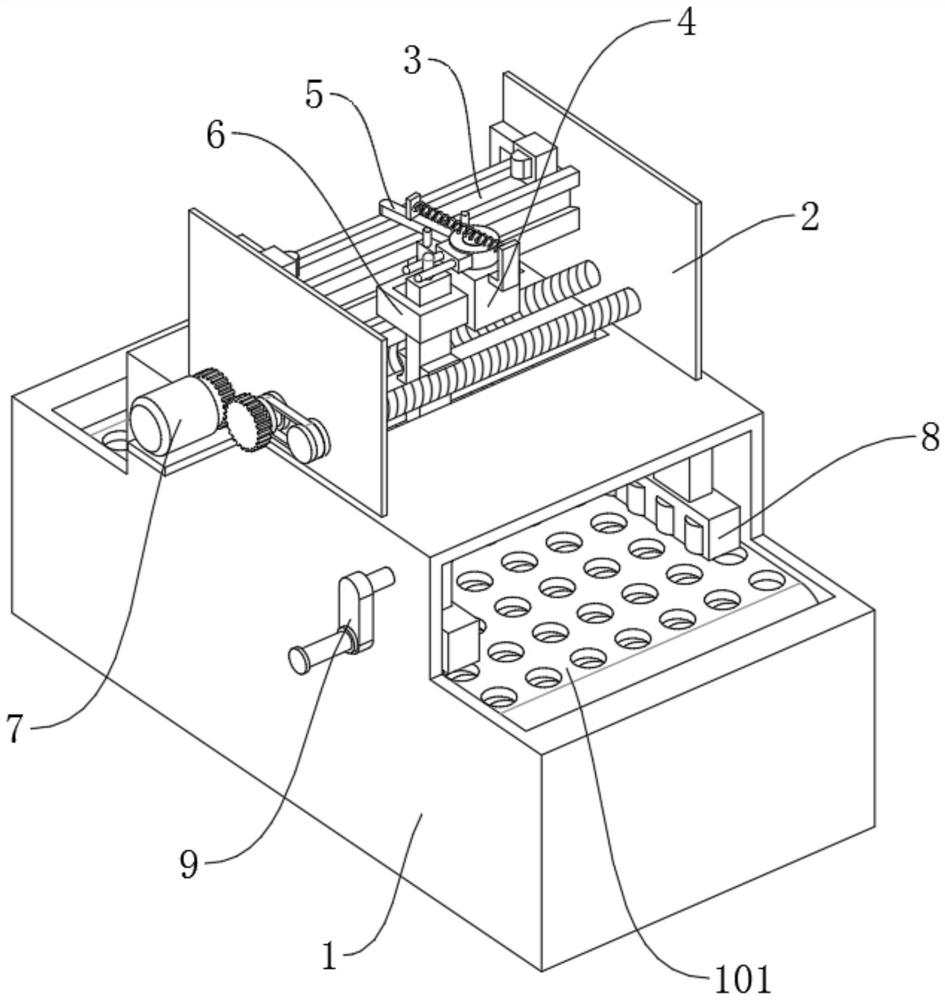

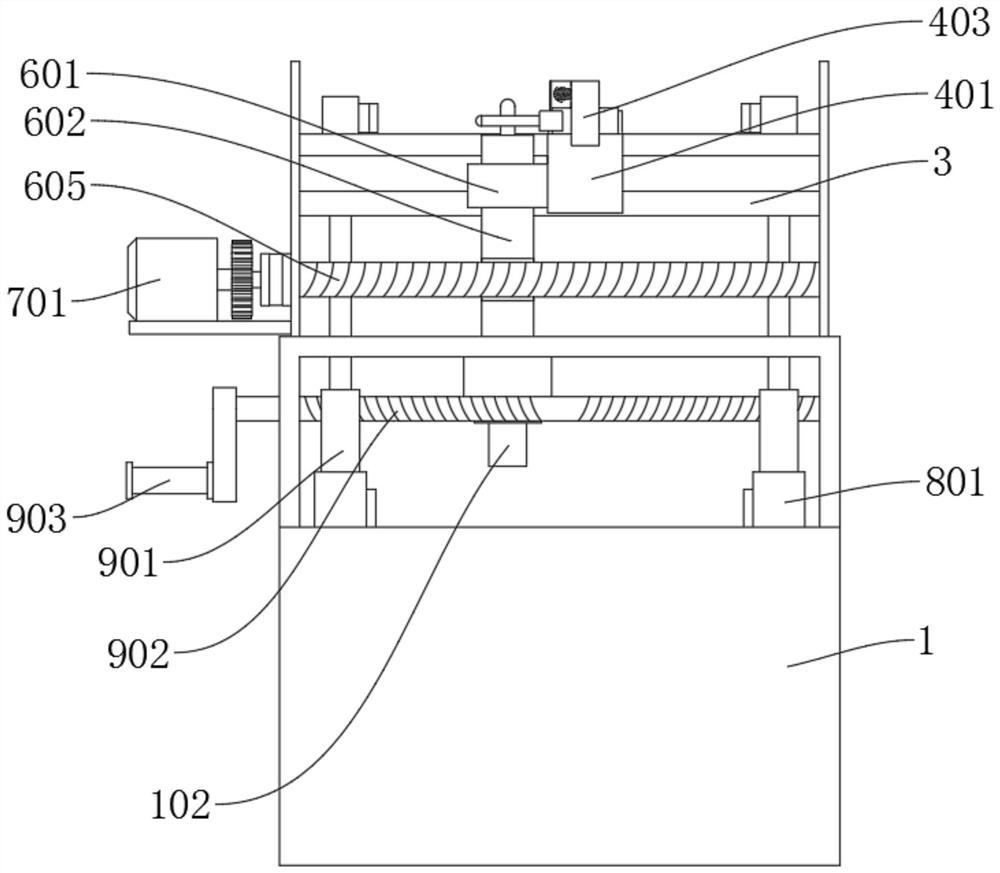

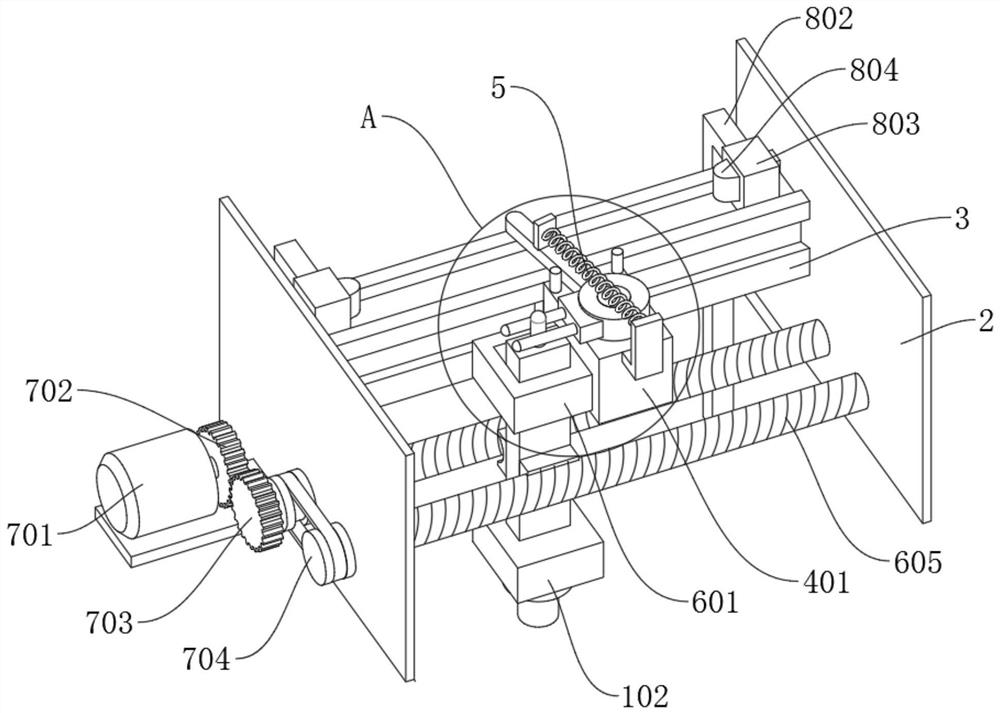

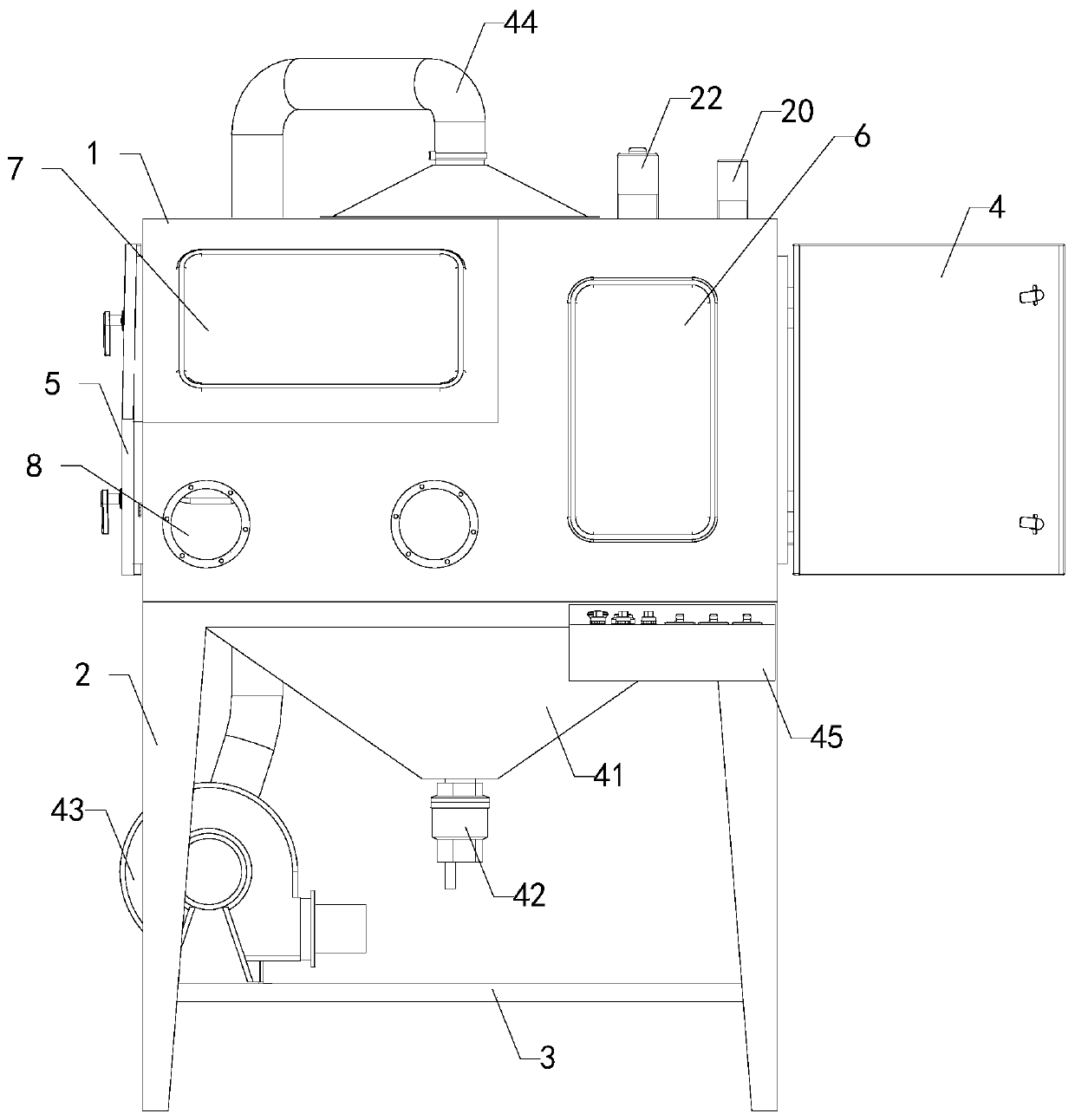

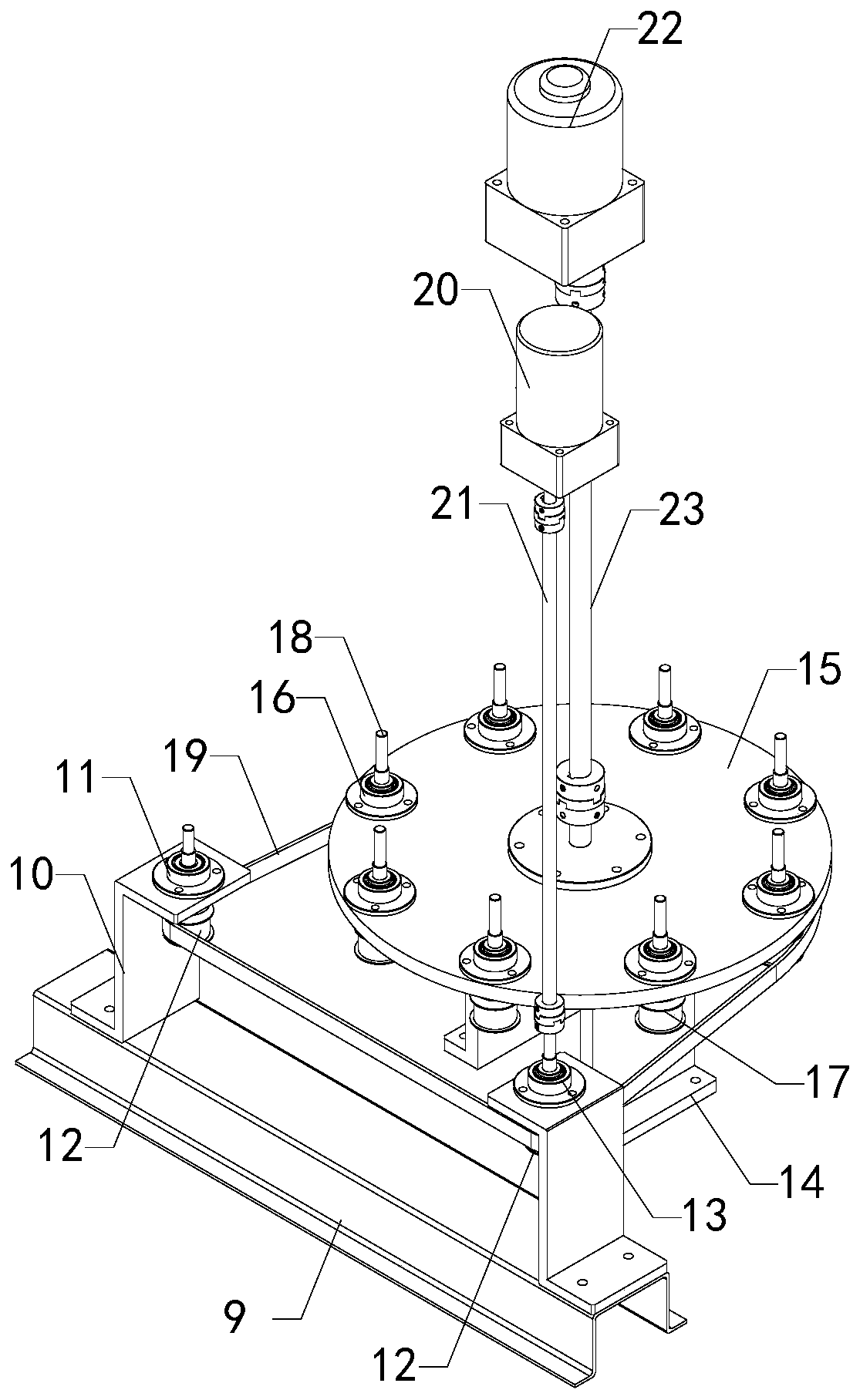

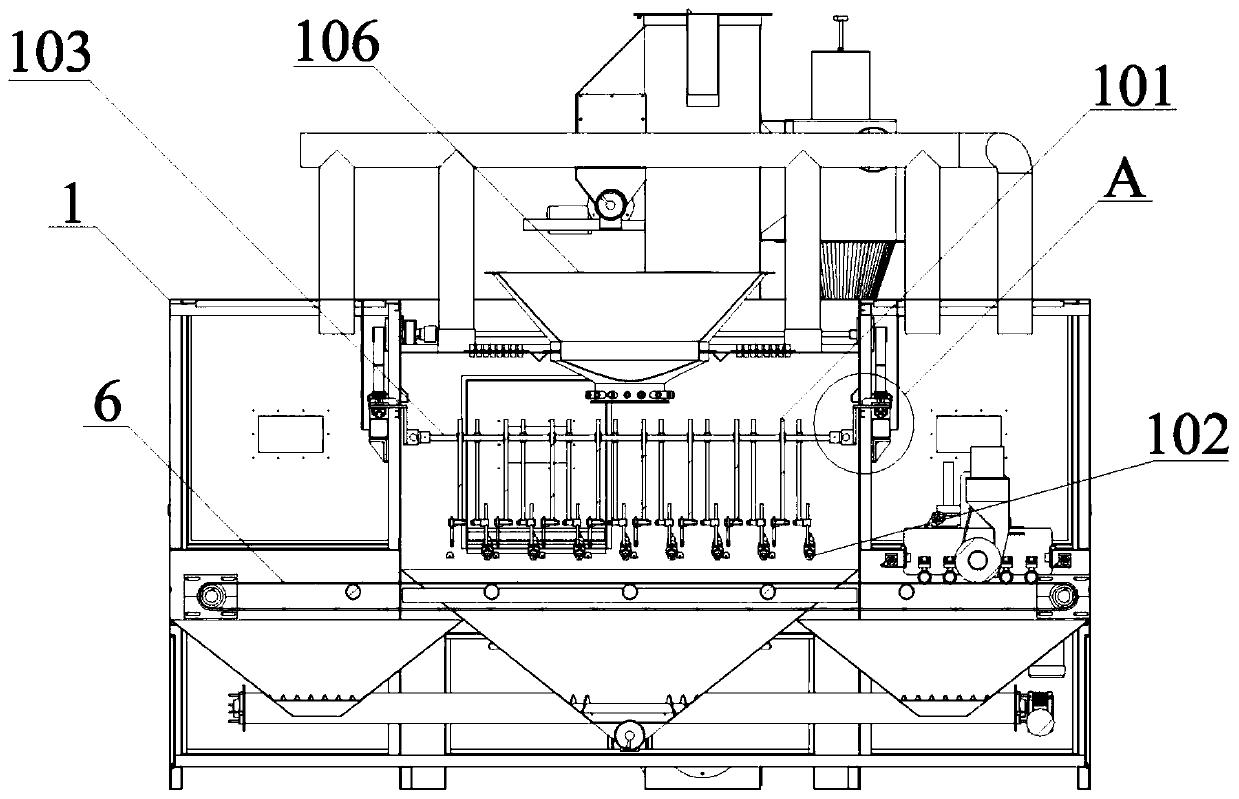

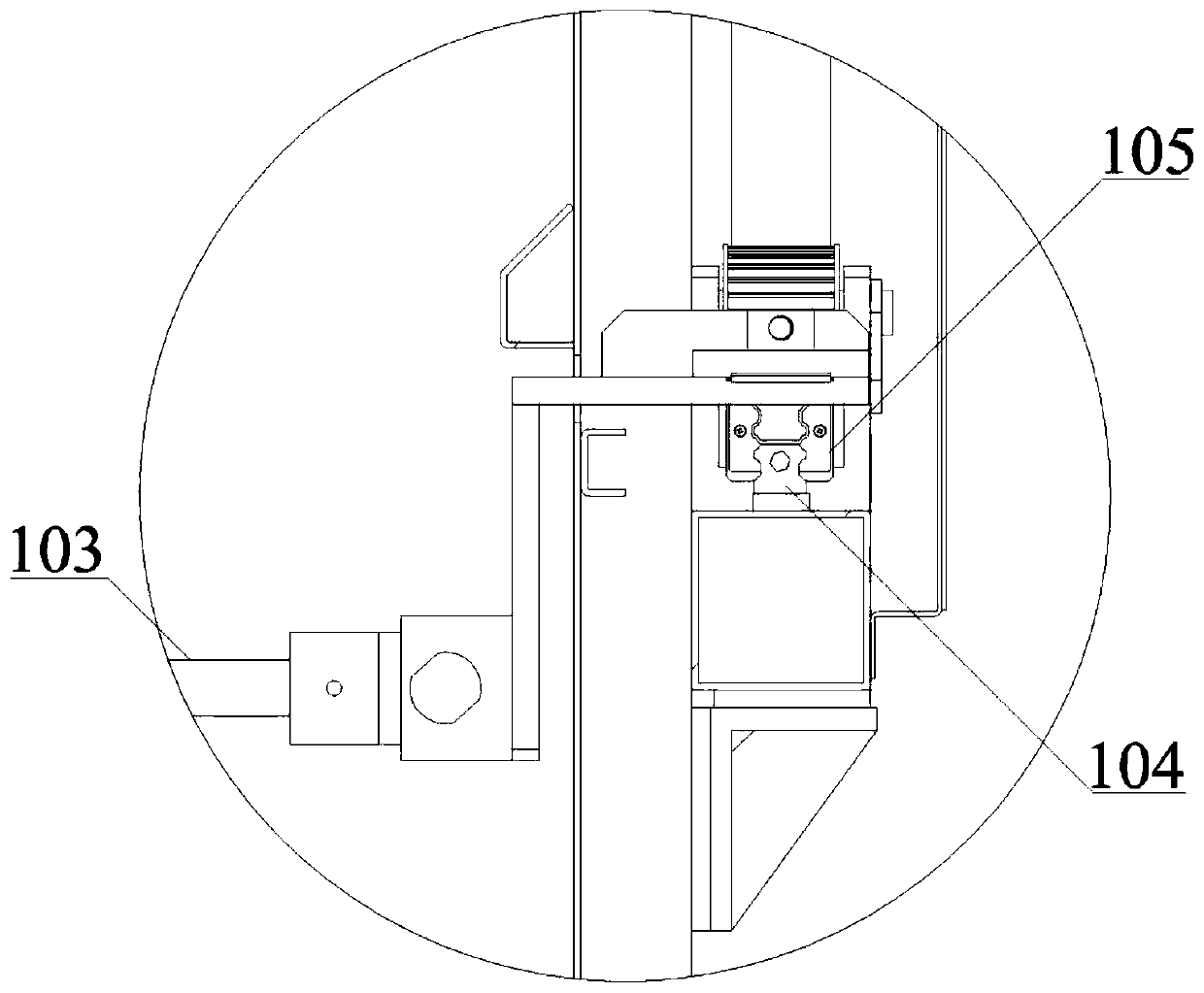

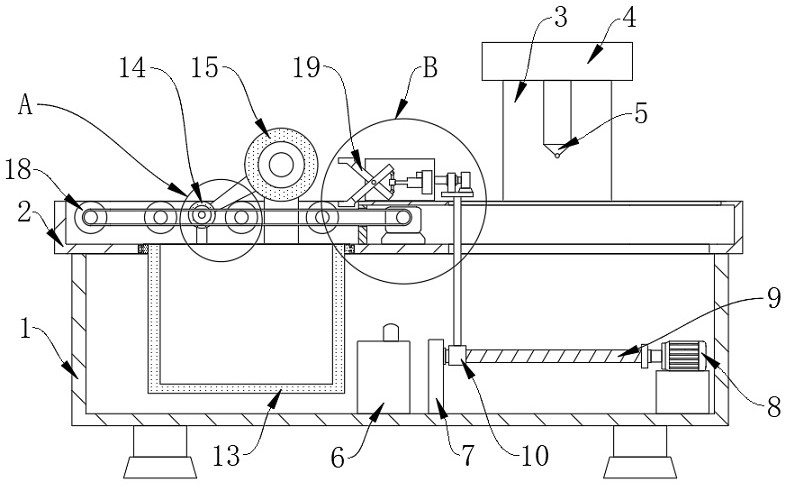

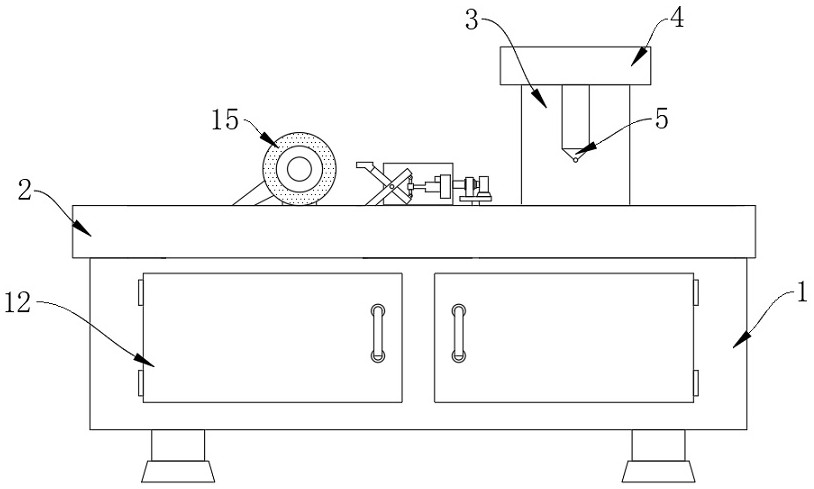

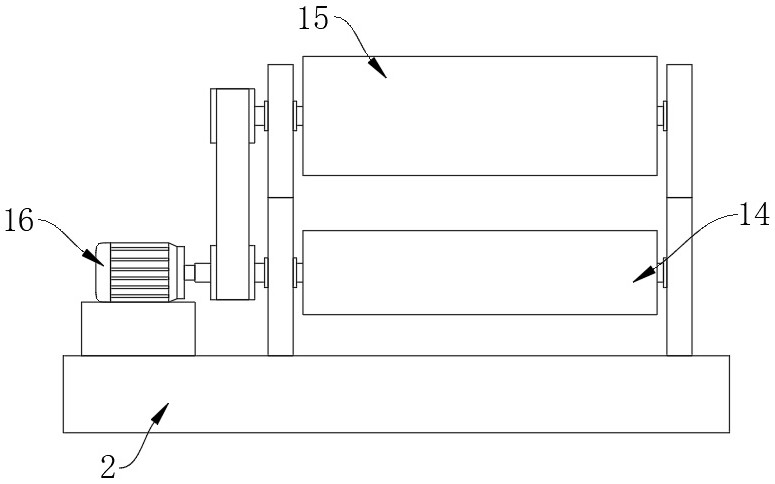

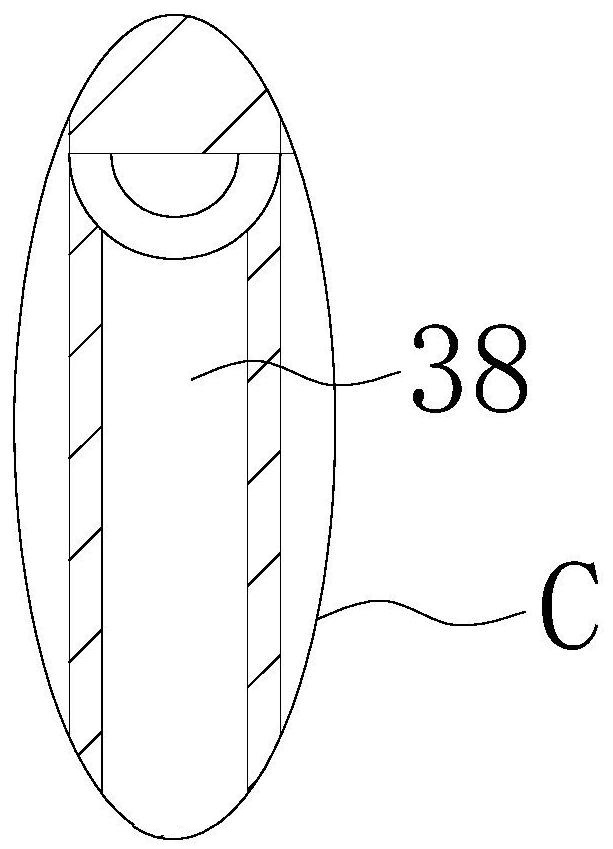

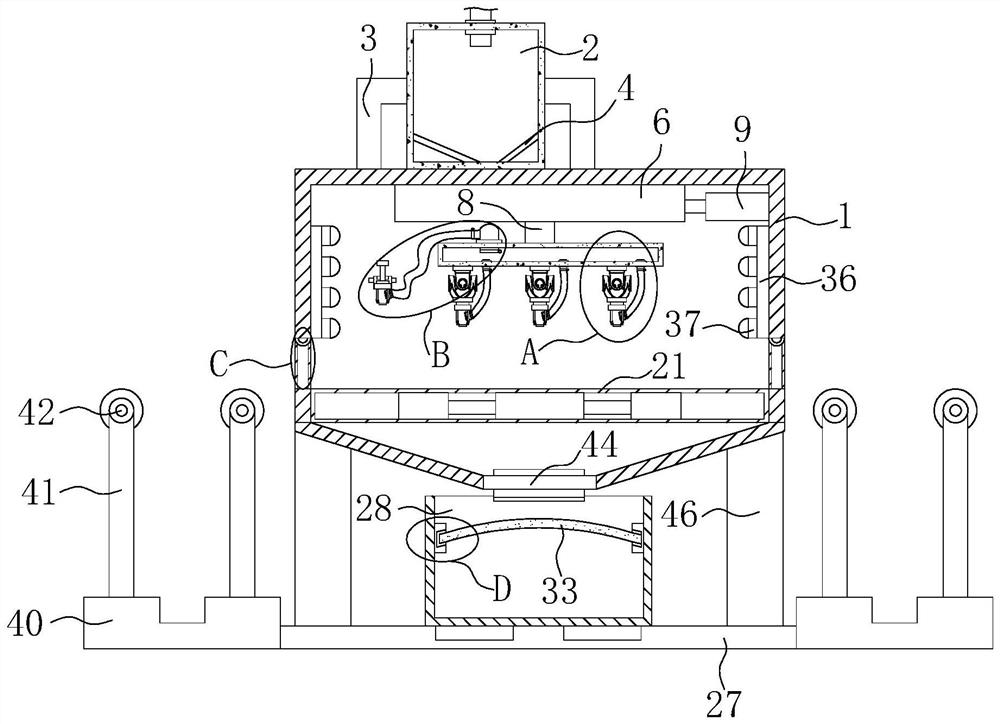

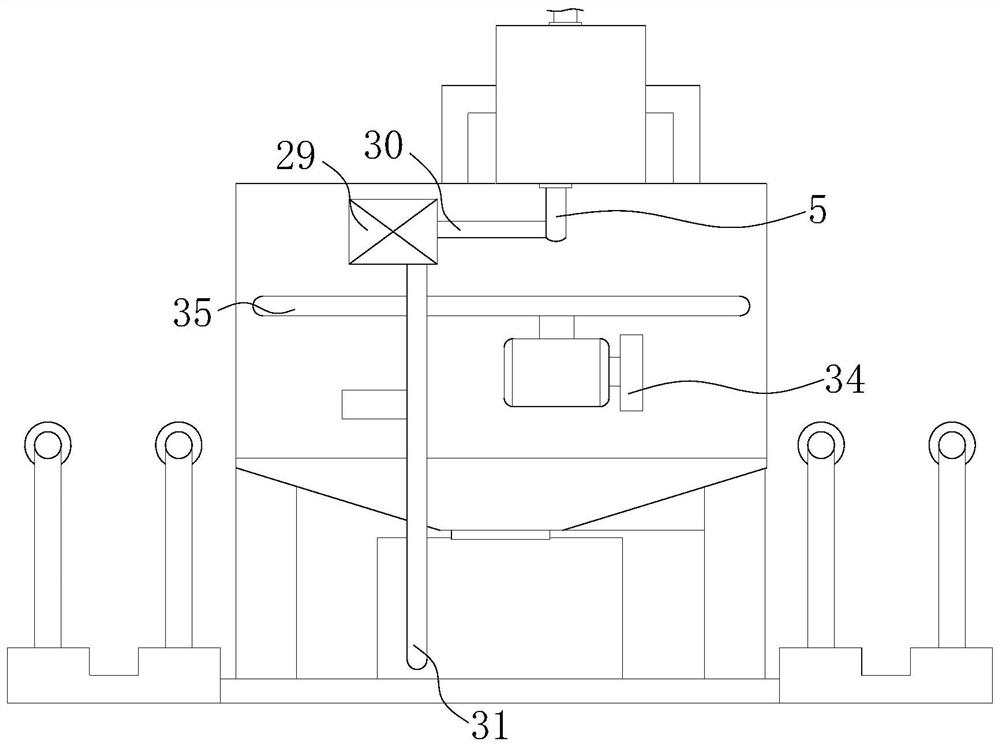

Metal surface rust-removing and sandblasting device

InactiveCN108927737AEasy to useImprove filtering effectAbrasive machine appurtenancesAir purifiersSand blasting

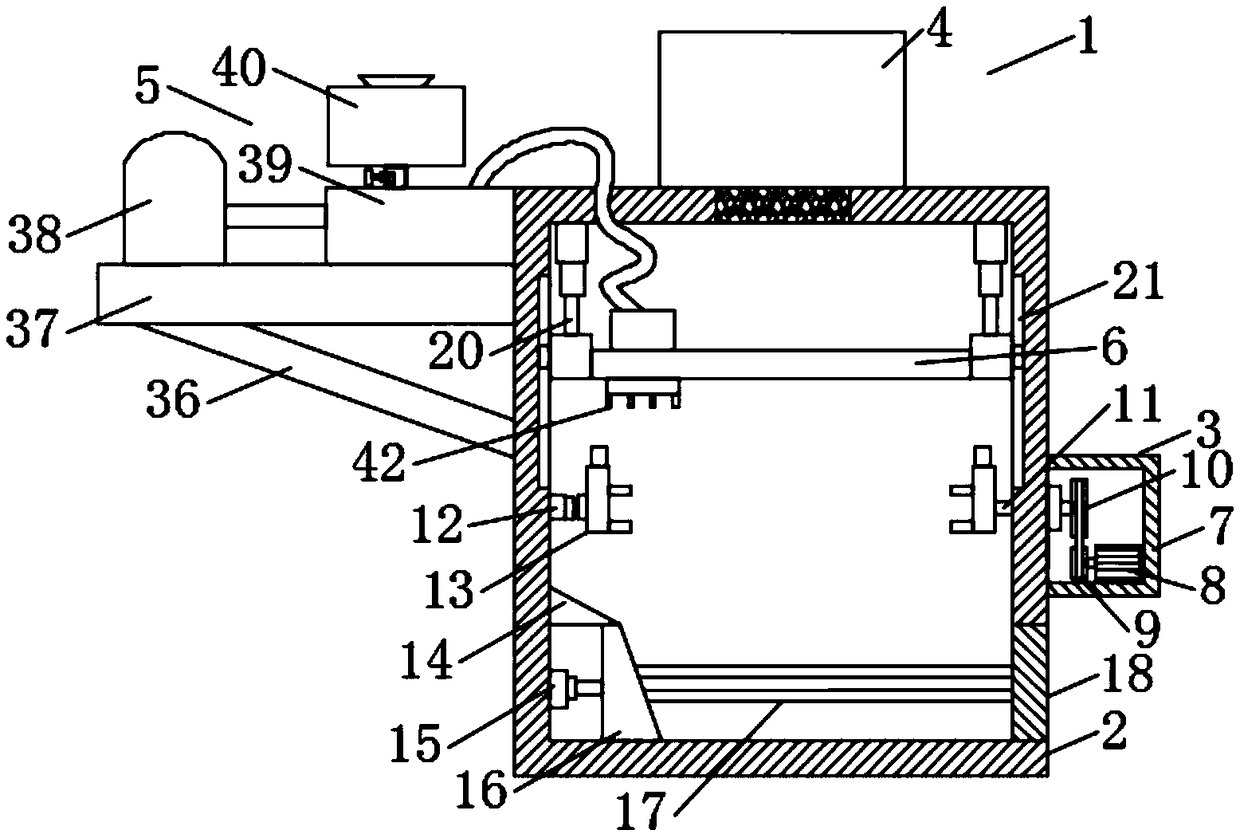

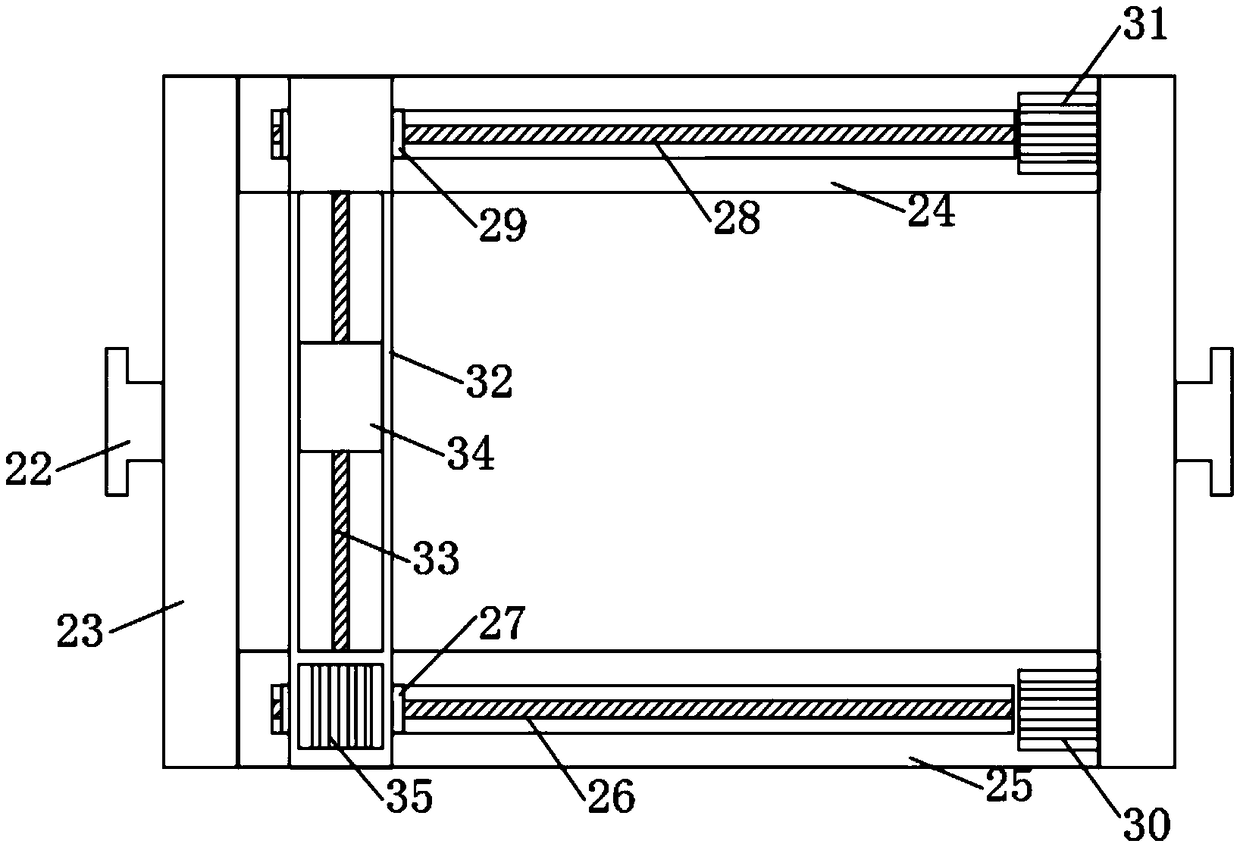

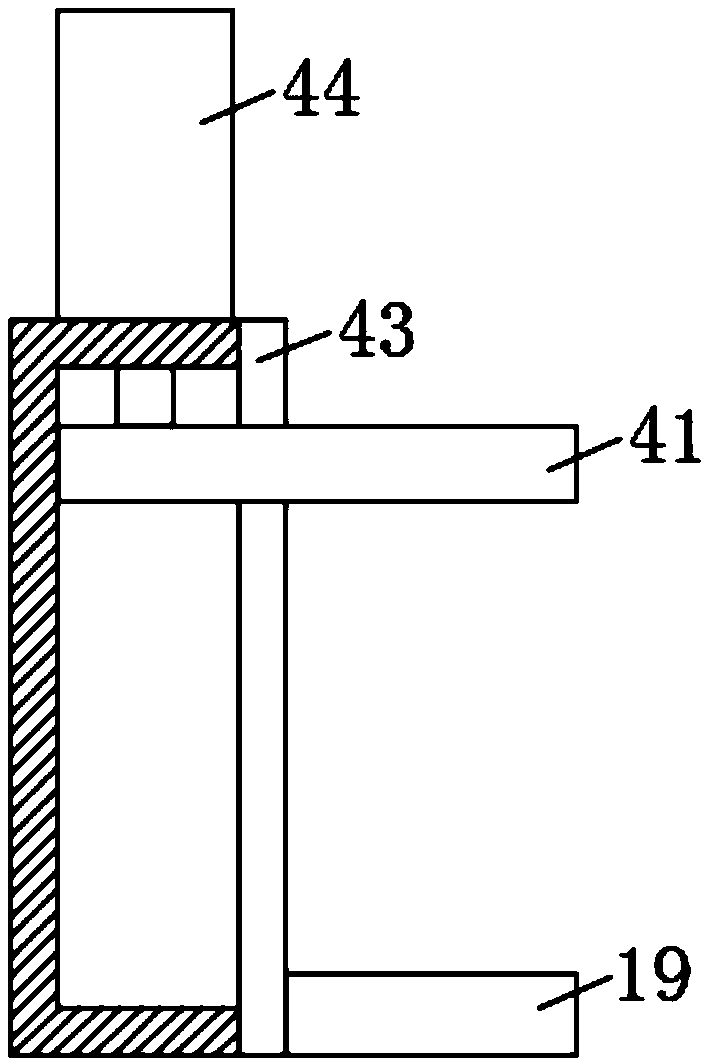

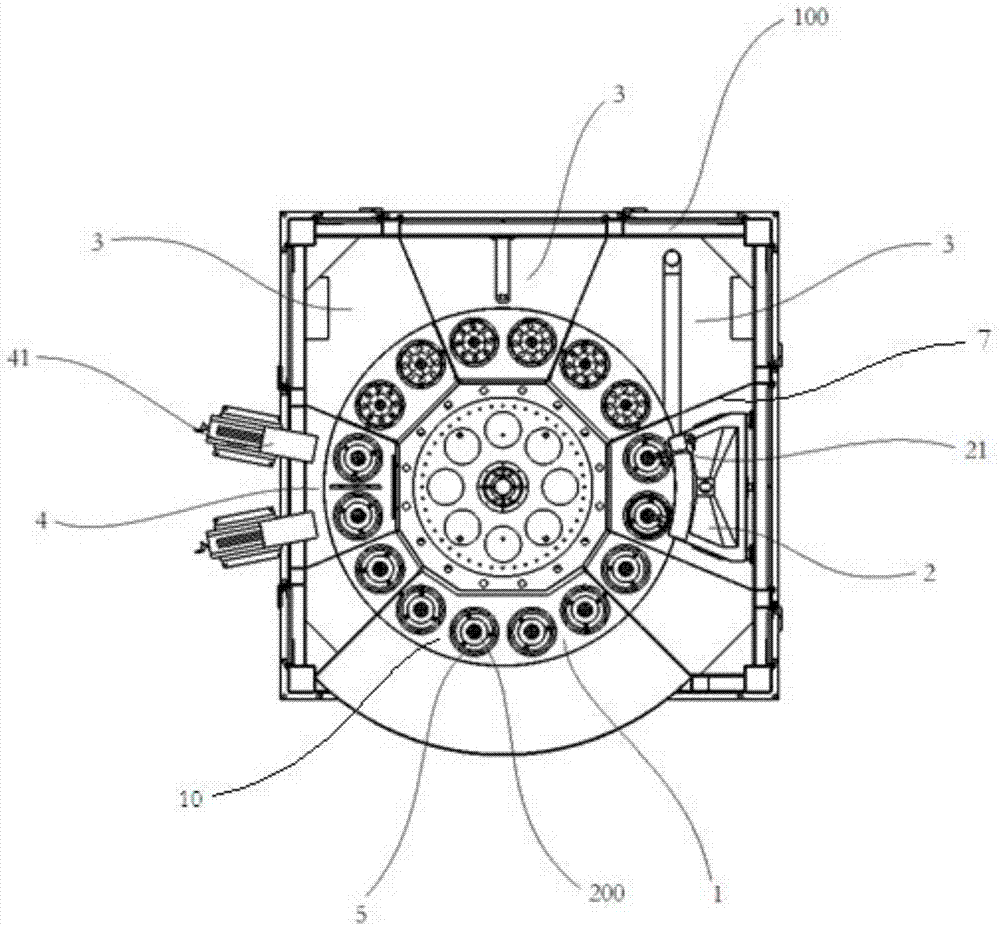

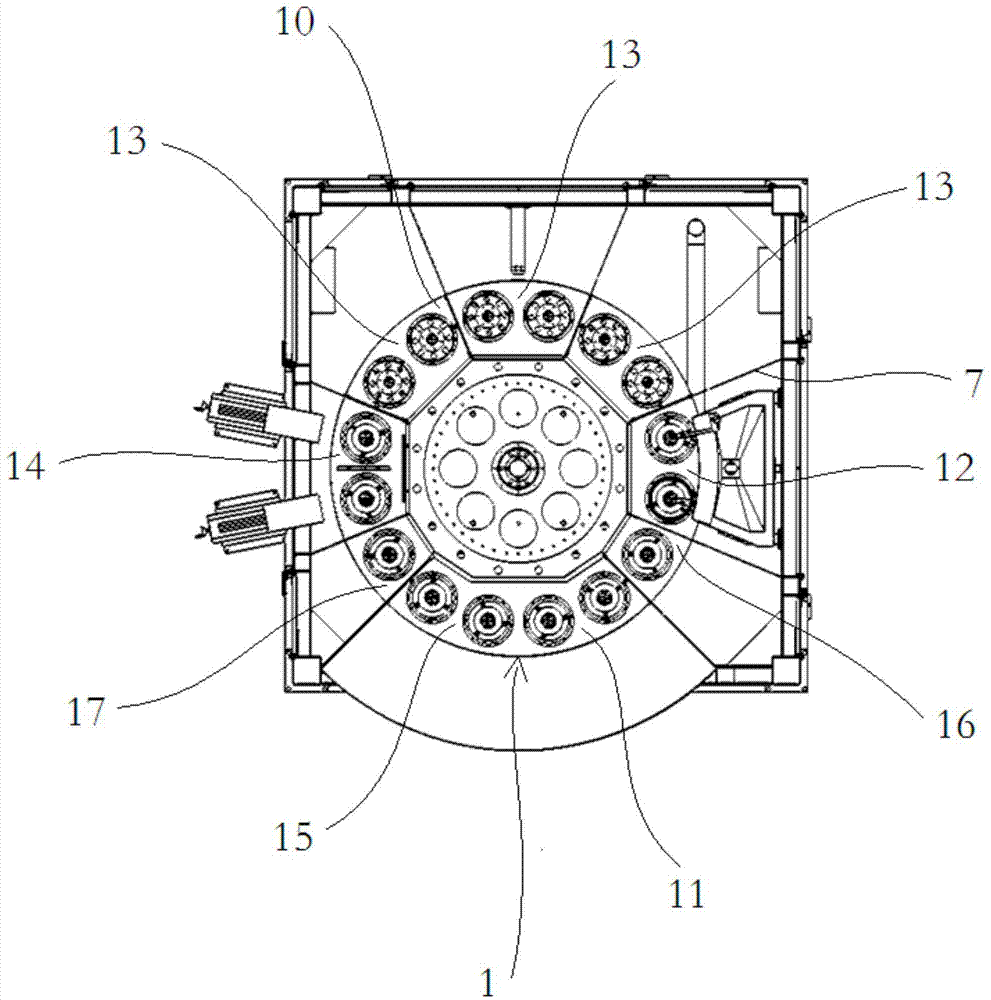

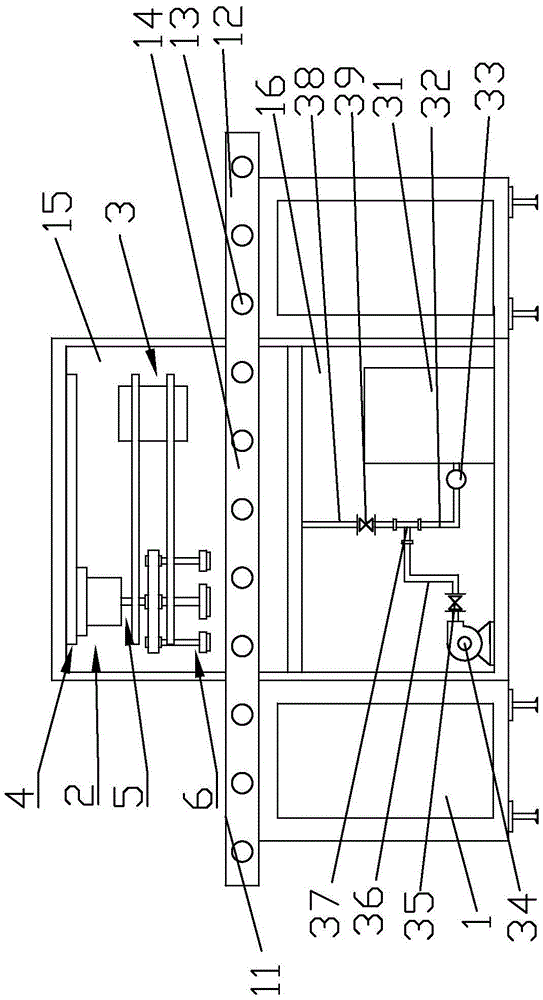

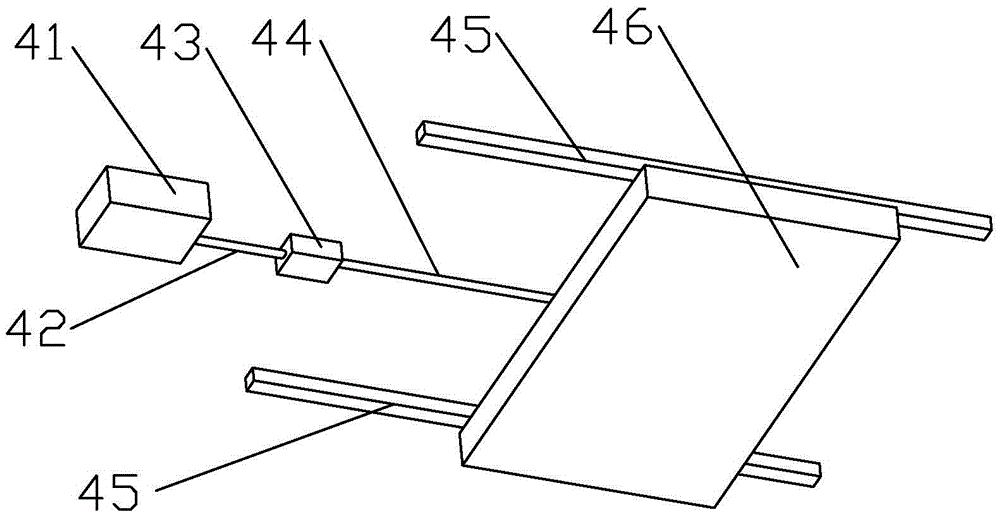

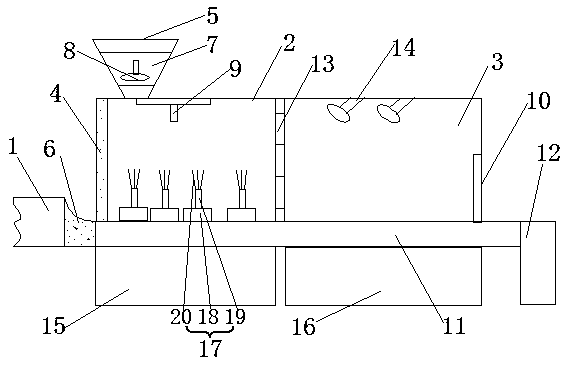

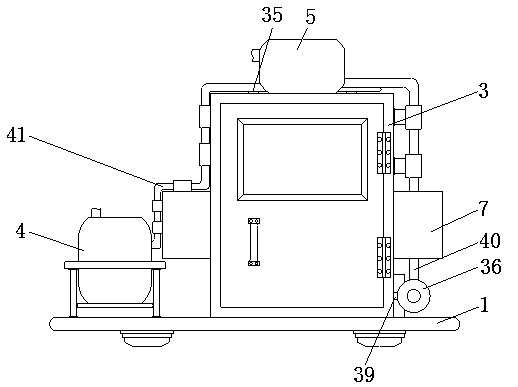

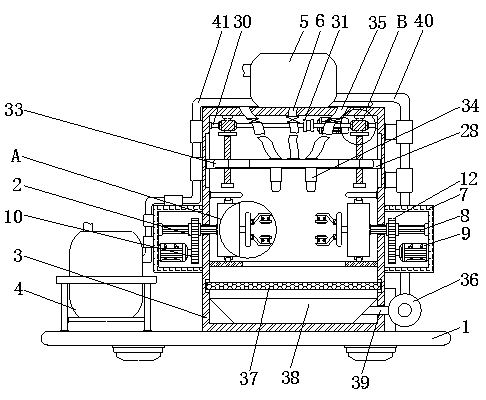

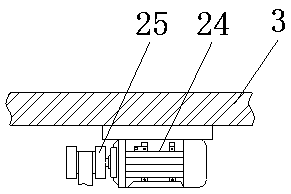

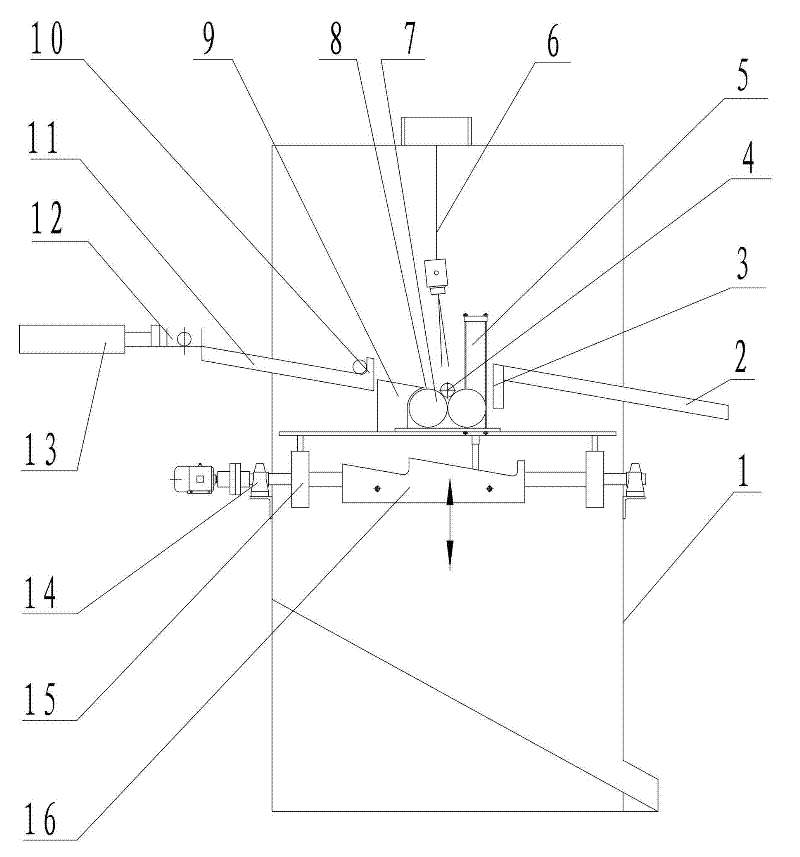

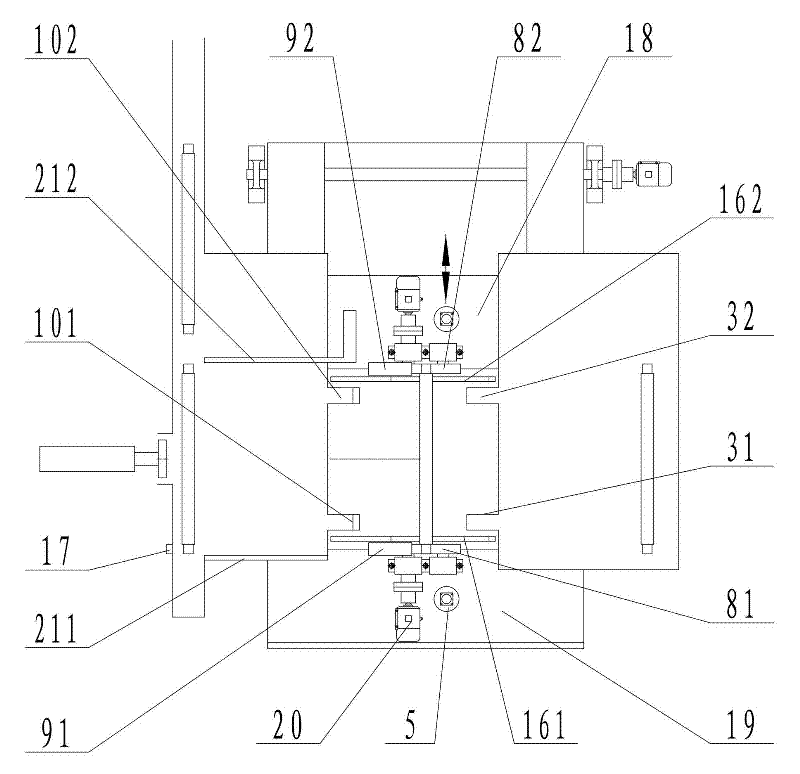

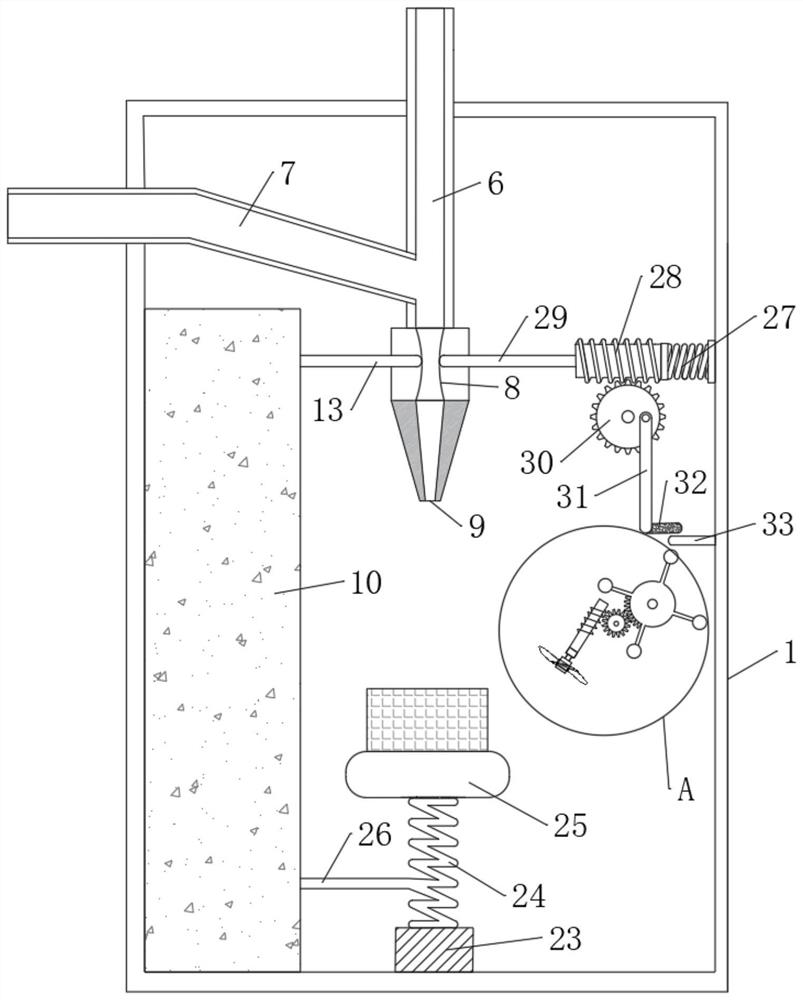

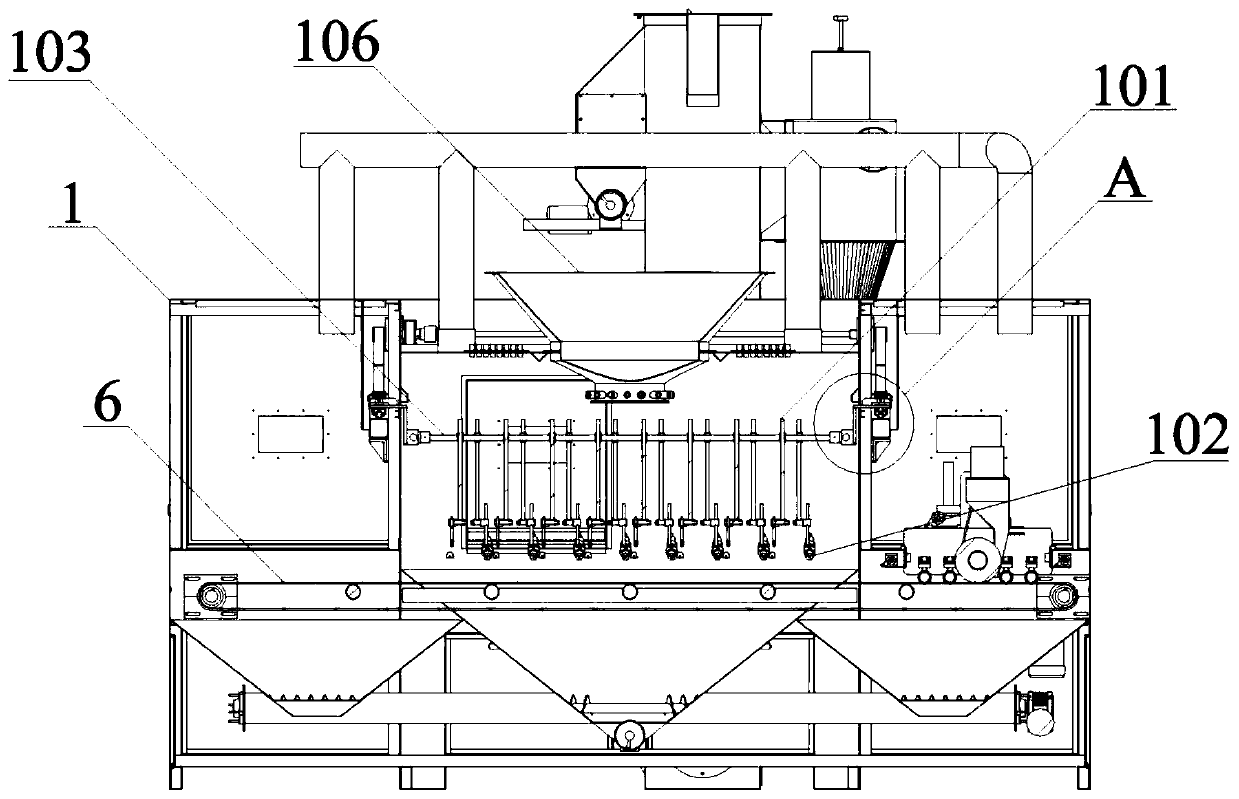

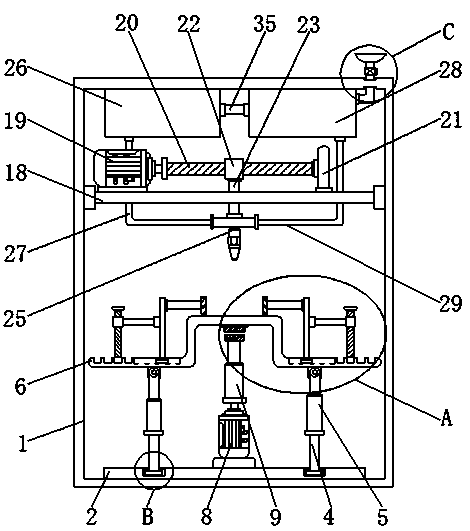

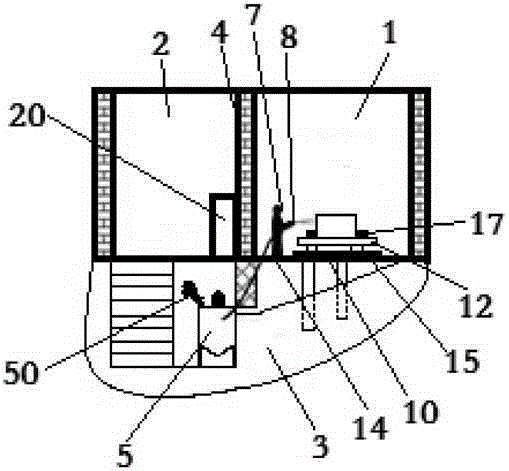

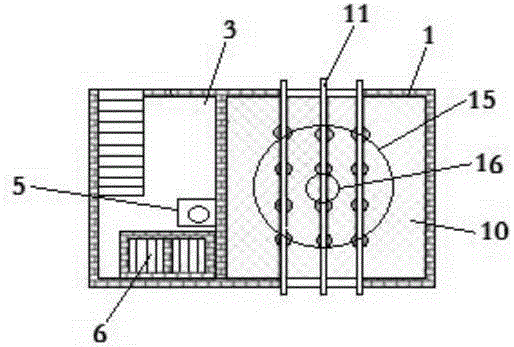

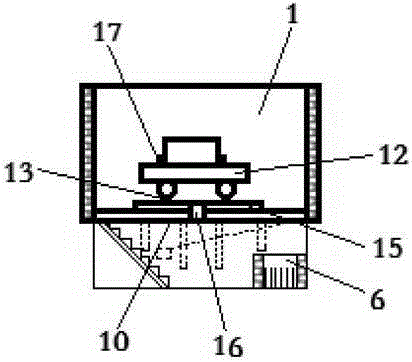

The invention discloses a metal surface rust-removing and sandblasting device, which comprises a sandblasting device body. The sandblasting device body is composed of a work box, an overturn mechanism, an air purifier, a sandblasting mechanism, and an adjusting mechanism. One side of the work box is connected to the overturn mechanism. The interior of the work box is connected to the adjusting mechanism. The structure is compact and thus the device is very convenient for metal rust removing and sandblasting. Due to the overturn mechanism, during sandblasting, the workpiece can be automaticallyoverturned by the overturn mechanism without any artificial intervention, time and labor are saved, the sandblasting becomes more uniform, the rusts can be removed more radically, the work efficiencyis largely improved, the practicality is strengthened; through the adjusting mechanism, the sandblasting becomes omnidirectional, no dead angle exists, due to a sealed space, the blasting sand can berecovered, moreover, the generation of waste gas that pollutes the atmosphere is avoided; the air purifier can purify the exhaust gas, and the work environment is improved for the workers.

Owner:诸葛佳缘

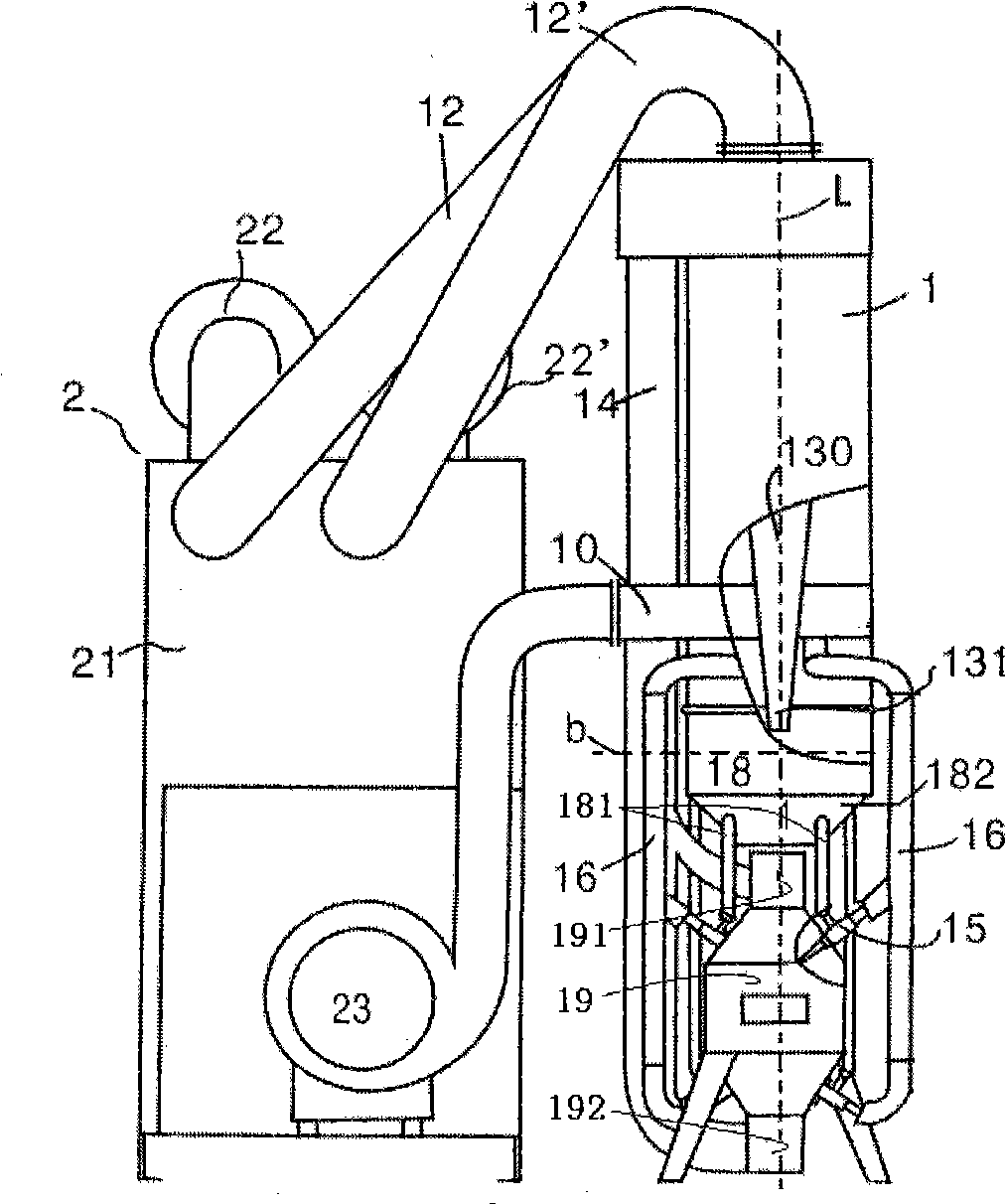

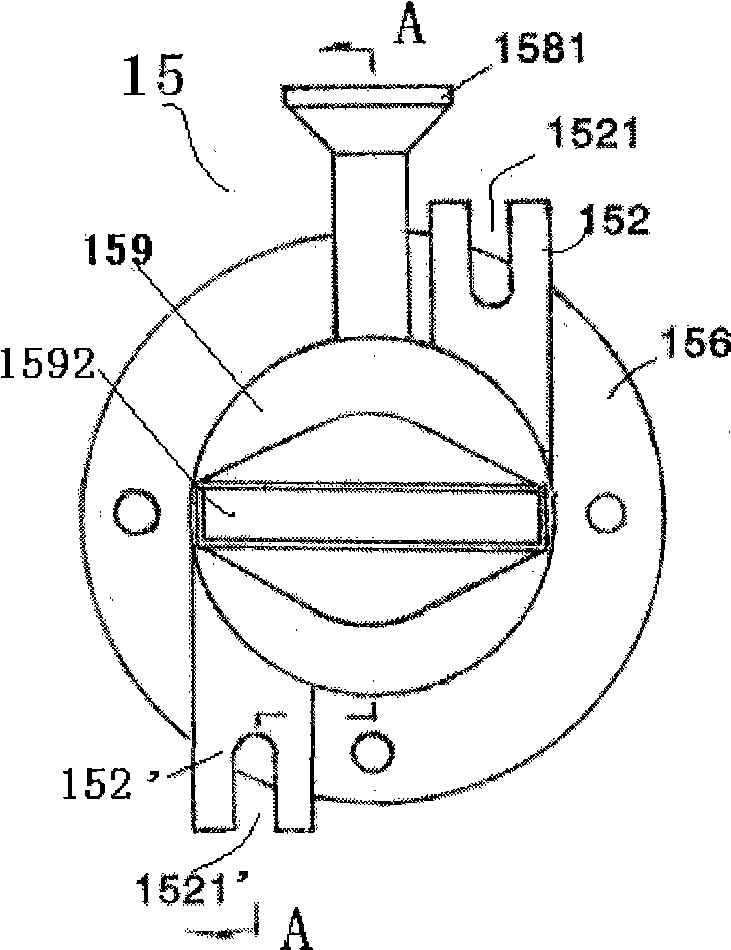

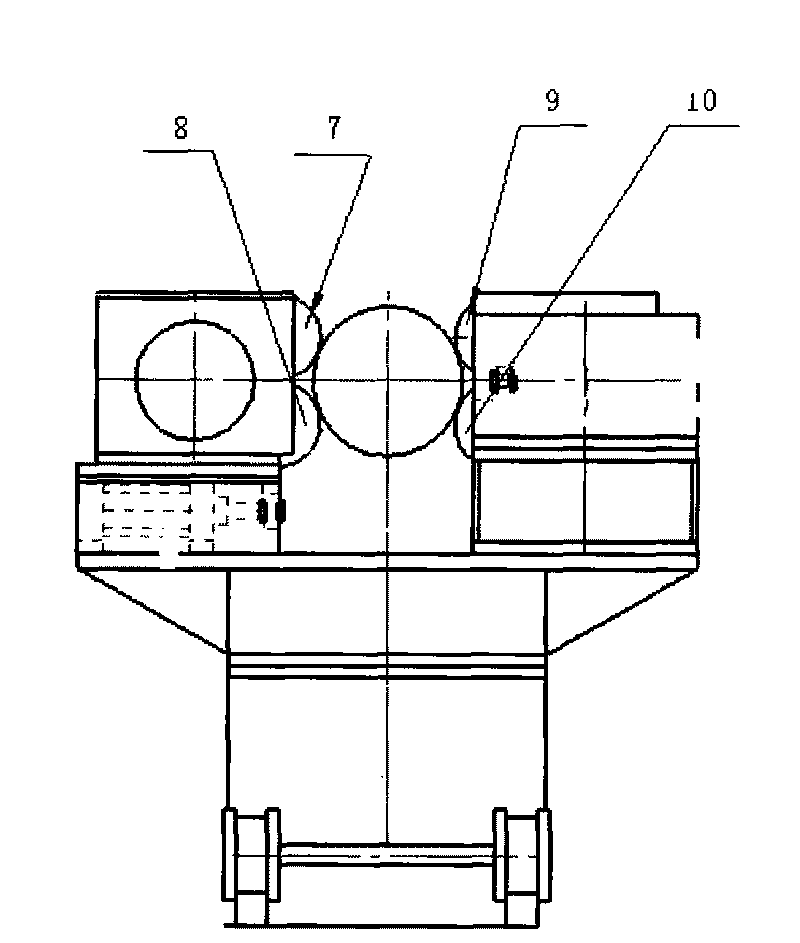

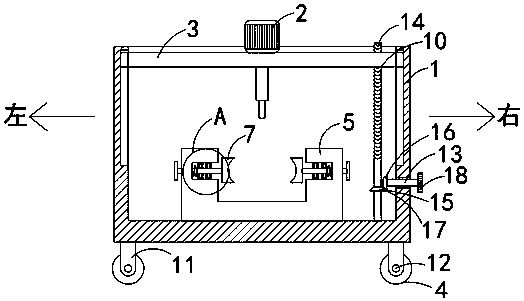

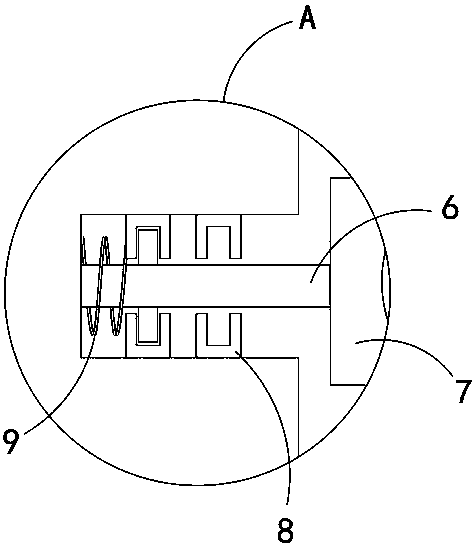

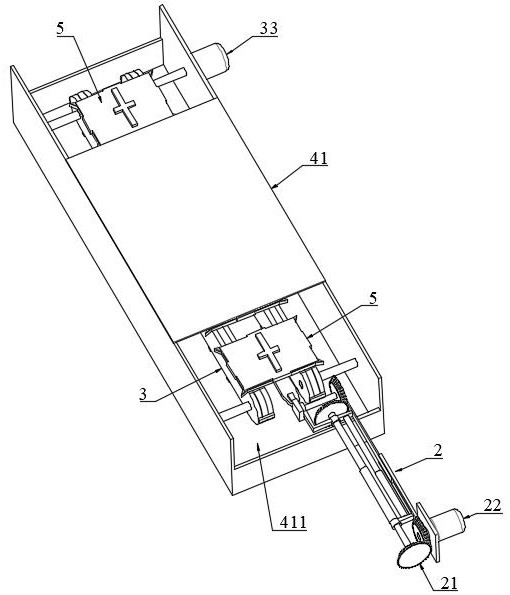

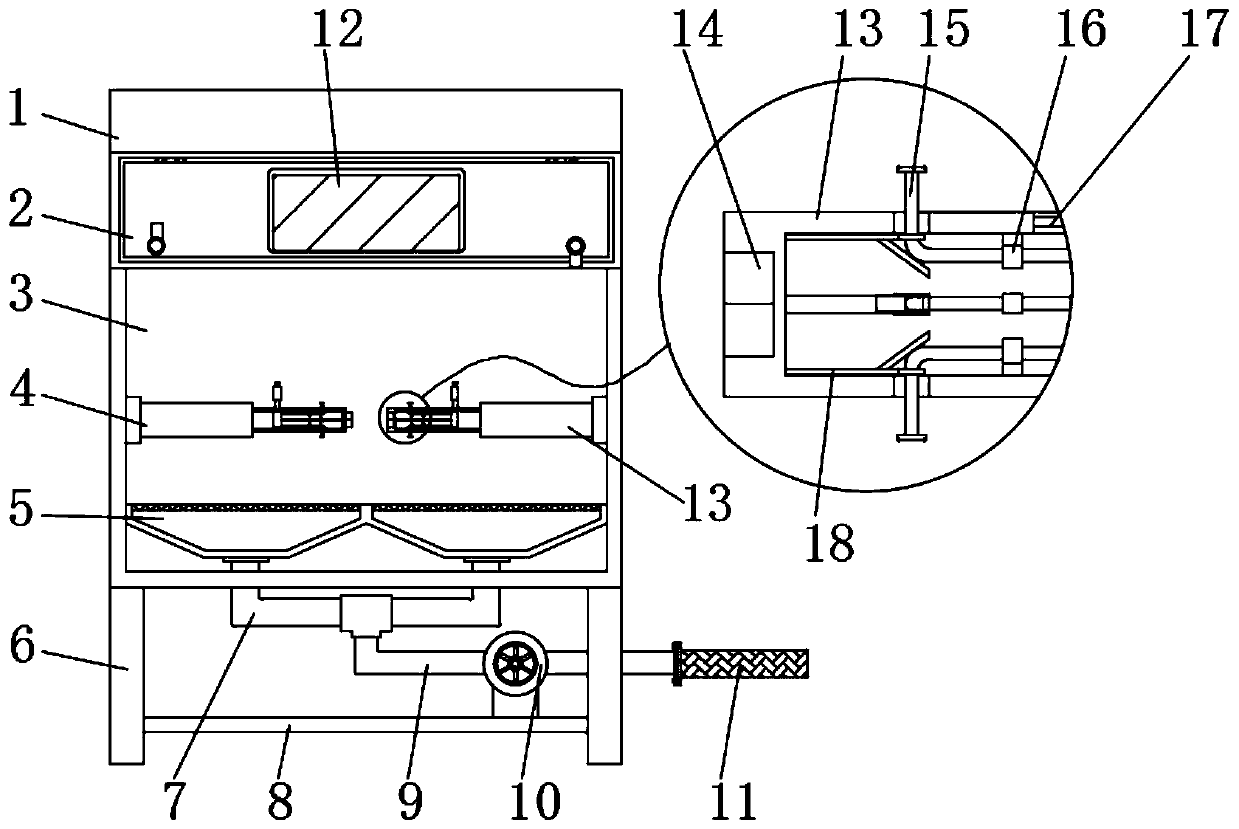

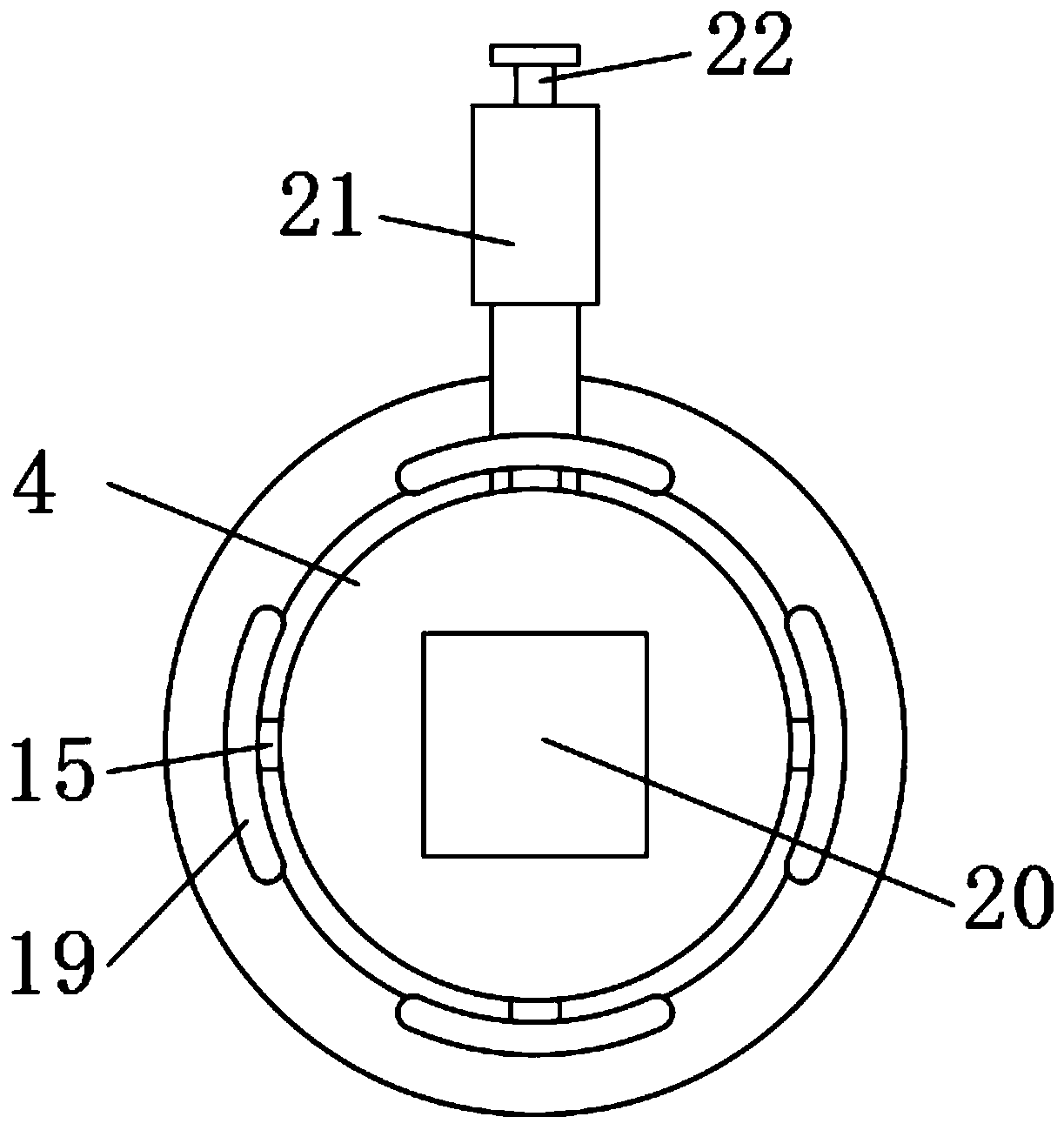

Abrasion blasting head as well as abrasion blasting unit and abrasive blaster thereof

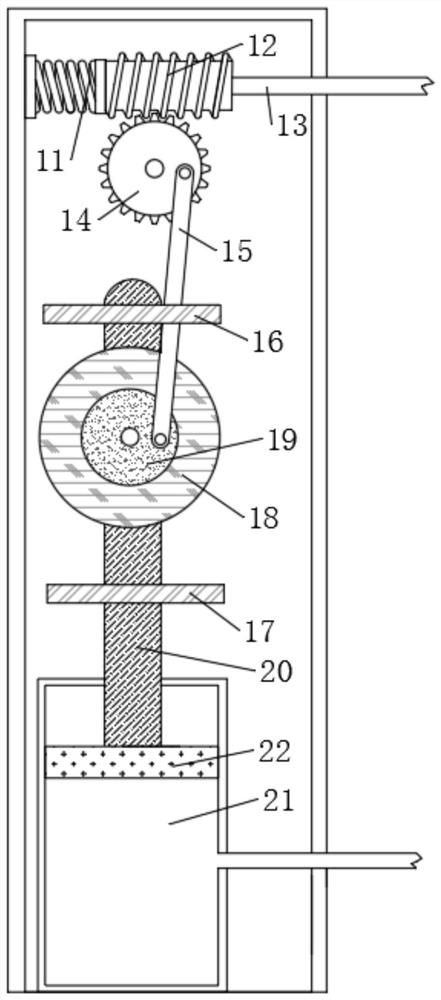

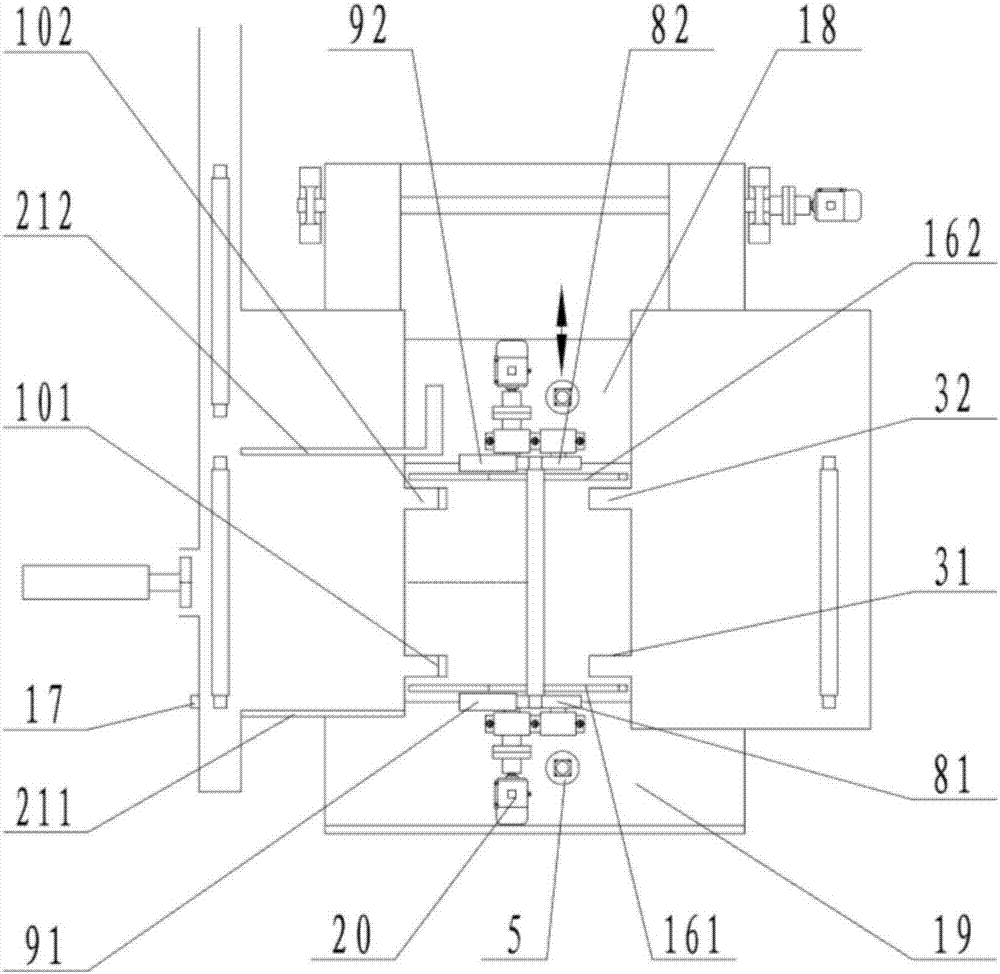

ActiveCN101497180AEven sandblastingNon-overlapping blastingBlast gunsAbrasive machine appurtenancesEngineeringWater tanks

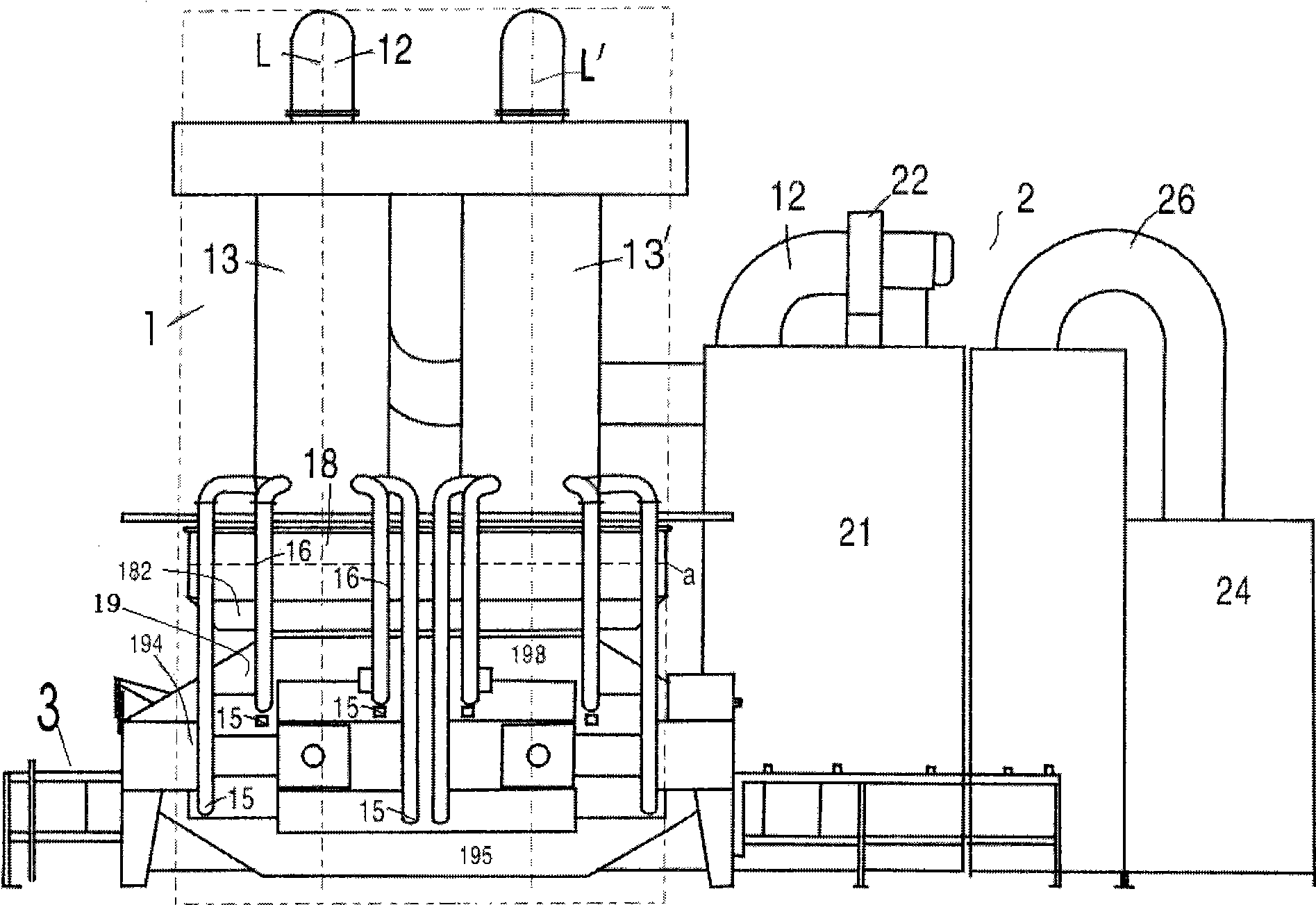

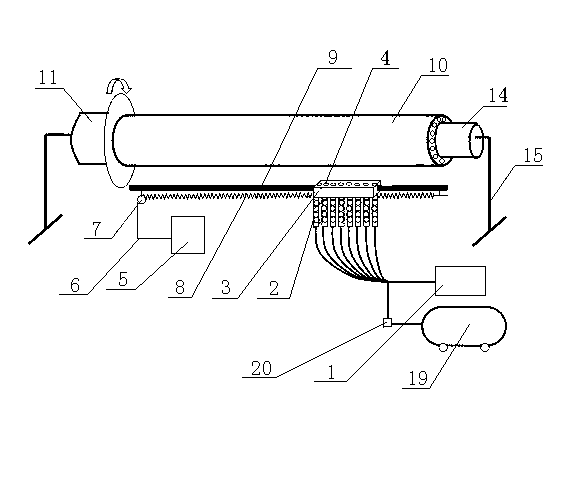

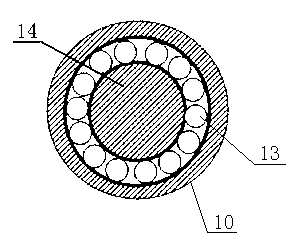

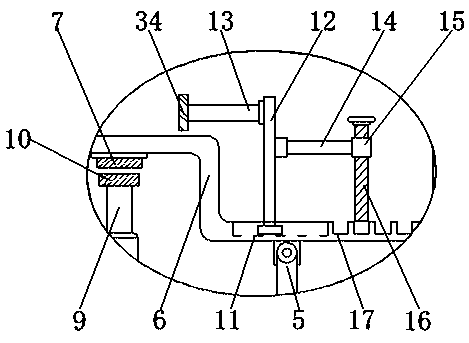

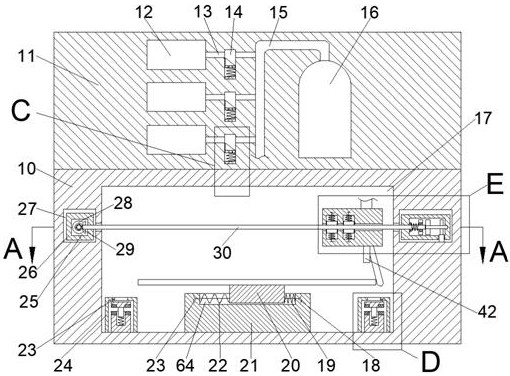

The invention relates to a sand spraying head, a sand spraying unit and a sand sprayer. An air inlet element of the sand spraying head is sleeved and folded in a sand inlet element, and a sand storage inner chamber is formed between the air inlet element and the sand inlet element; the air inlet element and the sand inlet element are configured in a mode allowing for the adjustment of advancing and withdrawing of the air inlet element through a thread connection part and the sand inlet element is provided with a nozzle capable of extending into a sand spray chamber; a sand storage chamber of the sand spraying unit has a rectangular inner cavity and a first tower body and a second tower body are arranged above the sand storage chamber; and a dust removing mechanism of the sand sprayer has a dust collection body and a dust removal water tank, and the water tank is connected by a dust removing pipeline in a mode allowing for wet dust removal. The two-tower sand spraying unit and the improved sand spraying head can improve the sand spraying efficiency and two-stage dust removal configuration of the dust collection body and the dust removal water tank makes the device more environmentally-friendly and more acceptable to users.

Owner:吴楹

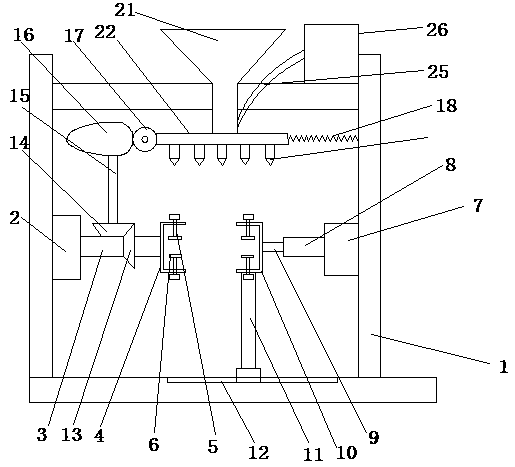

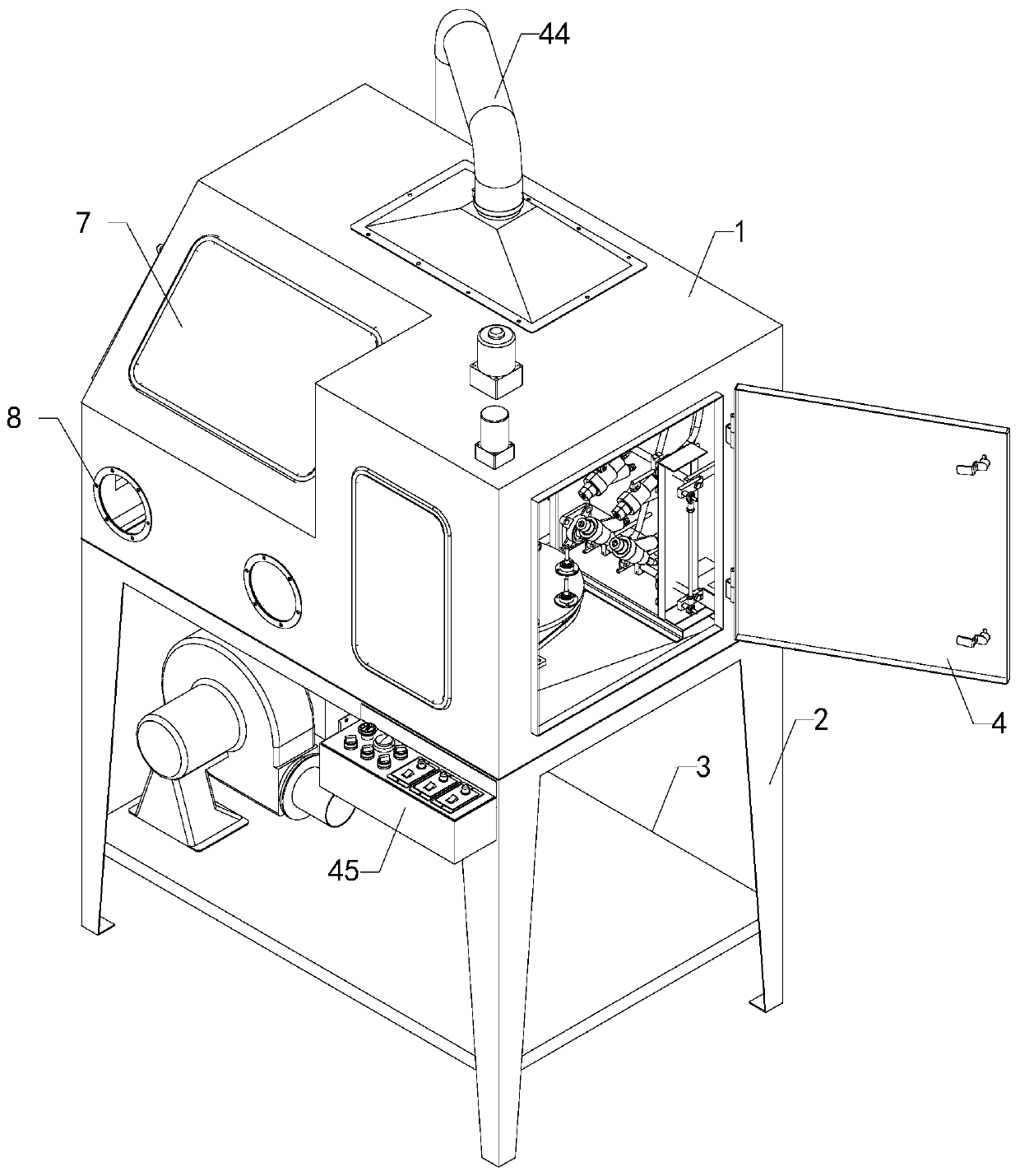

Improved sand-blasting machine

PendingCN108673349AReduce outflowReduce contentAbrasive feedersAbrasive machine appurtenancesSand blastingCam

The invention discloses an improved sand-blasting machine, and belongs to the technical field of machinery. The improved sand-blasting machine comprises a machine frame, a motor, a first rotating shaft, a first guide sleeve, a clamping plate, a driving air cylinder, a rotating rod, and a second guide sleeve. The first rotating shaft is in key connection with a first bevel gear; the first bevel gear meshes with a second bevel gear; the number of teeth of the second bevel gear is twice that of the first bevel gear; a second rotating shaft is in key connection with the upper portion of the secondbevel gear; the second rotating shaft is in connection with a cam; the cam is in contact with a rolling wheel in a matched mode; a plurality of sand-blasting devices are in fixed connection with theother end of the rolling wheel; a spring is in connection with the other end of the sand-blasting devices; the spring is fixedly arranged on the lateral wall of the machine frame; the sand-blasting devices are connected with a feed opening by material sending pipelines; and the feed opening is connected with a sand-storage tank. Automatic sand-blasting is achieved, and omnidirectional sand-blasting is achieved to a workpiece during sand-blasting process, and sand-blasting efficiency is high.

Owner:湖北省麻城市和丰精密机械有限公司

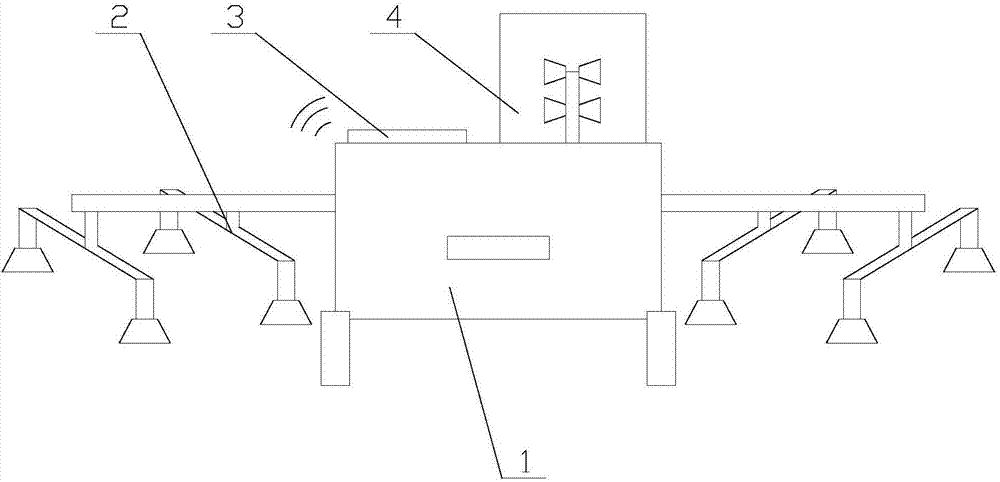

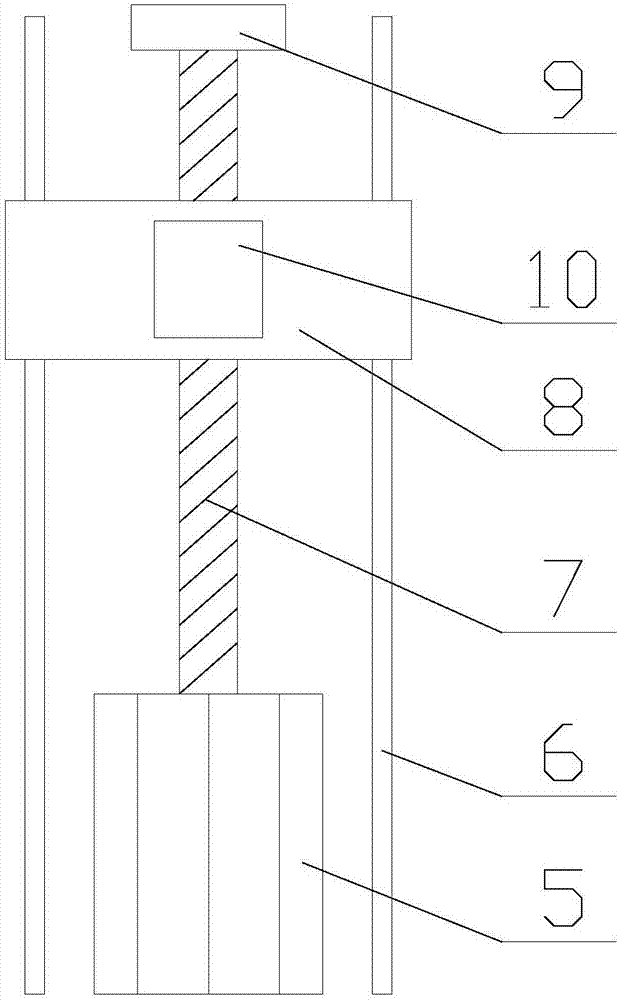

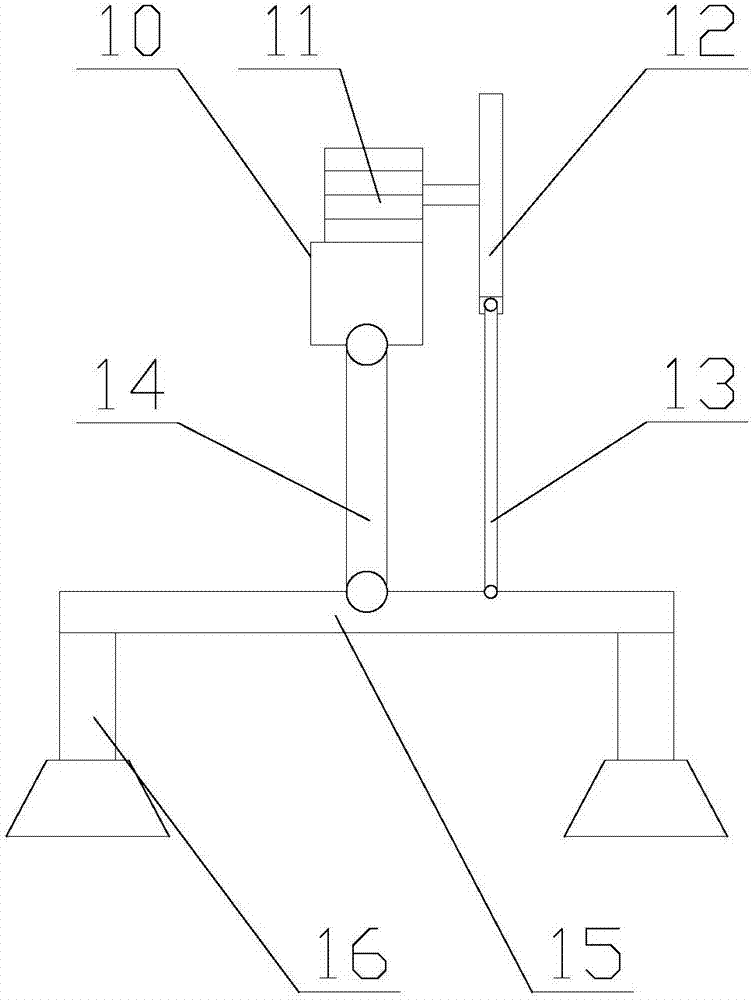

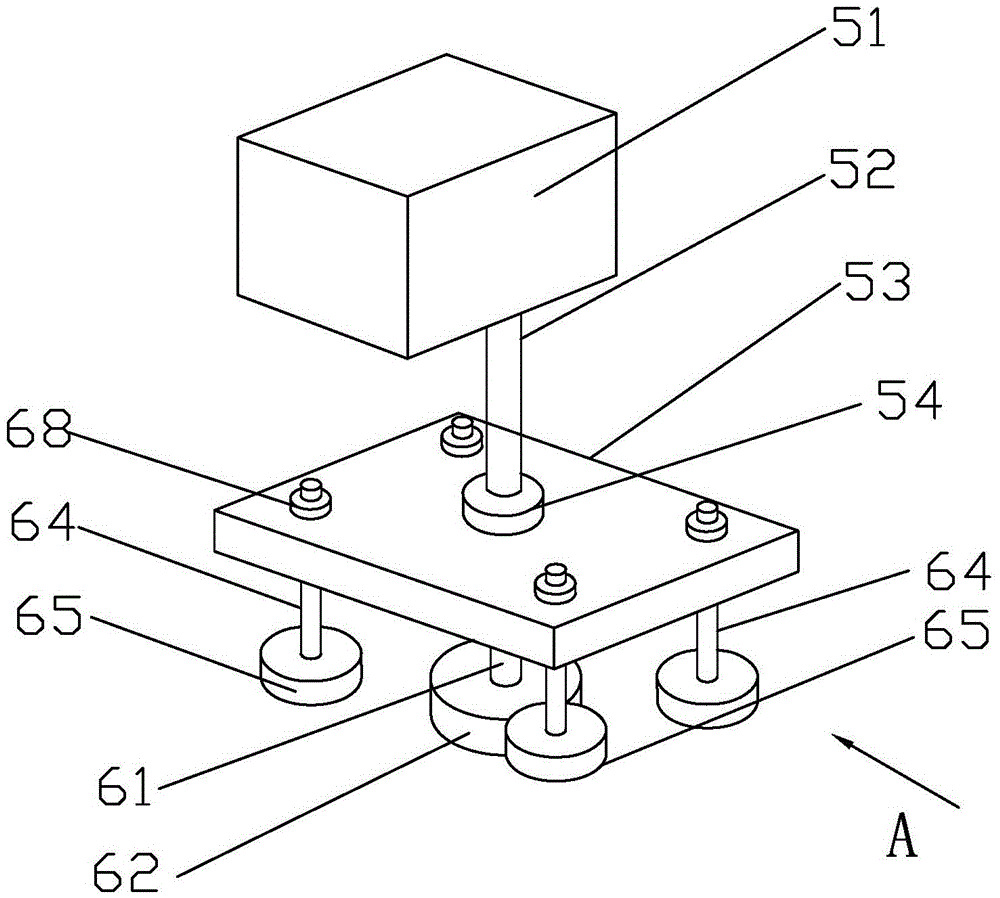

Intelligent robot which is based on internets of things and is applicable to agricultural irrigation

InactiveCN107318603ASpray evenlyEven sandblastingTransportation and packagingRotary stirring mixersAgricultural irrigationAgricultural engineering

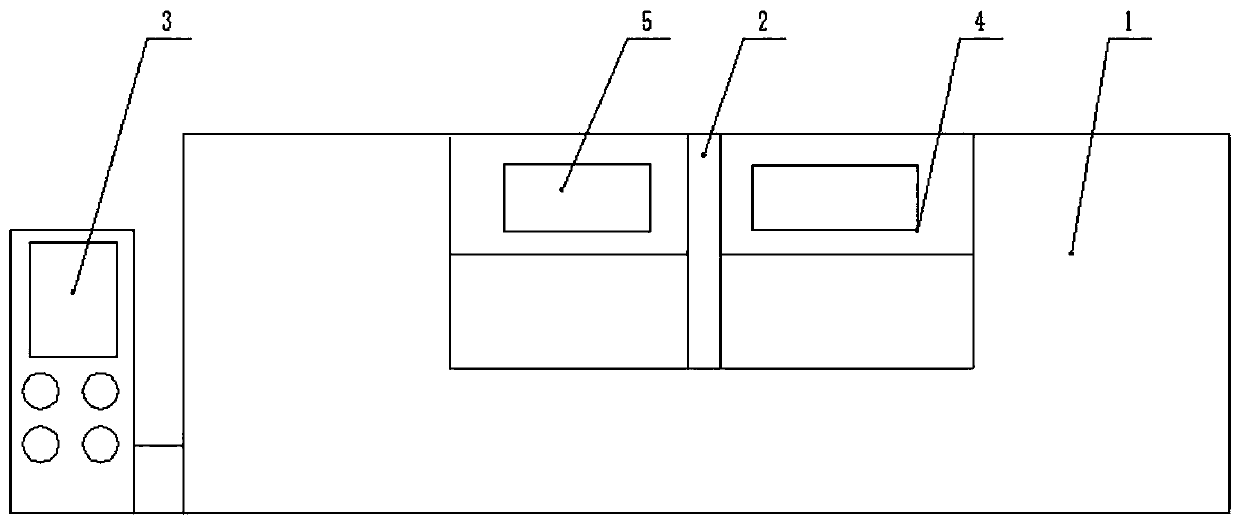

The invention relates to an intelligent robot which is based on internets of things and is applicable to agricultural irrigation. The intelligent robot comprises a body, a lifting mechanism, spraying mechanisms, a moving and stirring mechanism and a center control mechanism. The spraying mechanisms comprise shaking assemblies and rotary assemblies, the shaking assemblies comprise driving units and shaking units, the rotary assemblies comprise water pumps, connecting pipes, fan blades, rotary shafts, waterproof blocks and spray nozzles, the moving and stirring mechanism comprises a moving assembly and a stirring assembly, the moving assembly comprises a third motor, a second driving shaft and a moving wheel, and the stirring assembly comprises a worm, a second gear, a bearing block, a stirrer and a stirring tank. The intelligent robot which is based on the internets of things and is applicable to agricultural irrigation has the advantages that spraying at different altitudes can be carried out by the aid of the lifting mechanism, the spray nozzles can be shaken by the spraying mechanism, and accordingly the intelligent robot is uniform in spraying range; the spraying mechanism and the lifting mechanism are matched with each other, and accordingly water can be saved; liquor can be sufficiently mixed by the aid of the moving and stirring mechanism, precipitation can be prevented, and accordingly the practicality of the intelligent robot can be greatly improved.

Owner:SHENZHEN XIAOKONG COMM TECH CO LTD

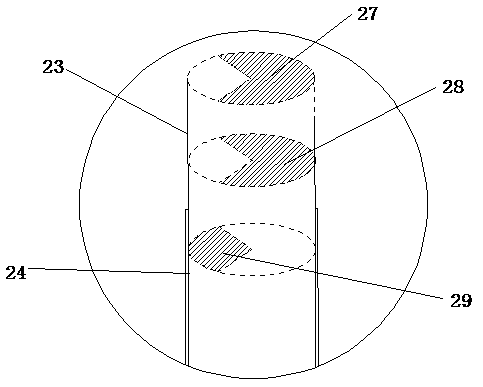

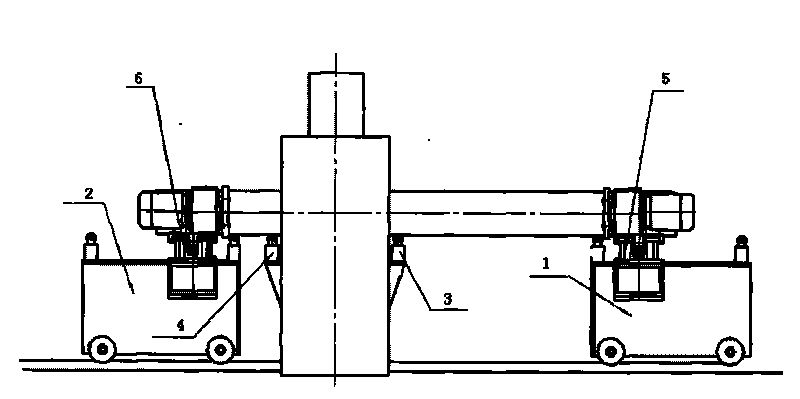

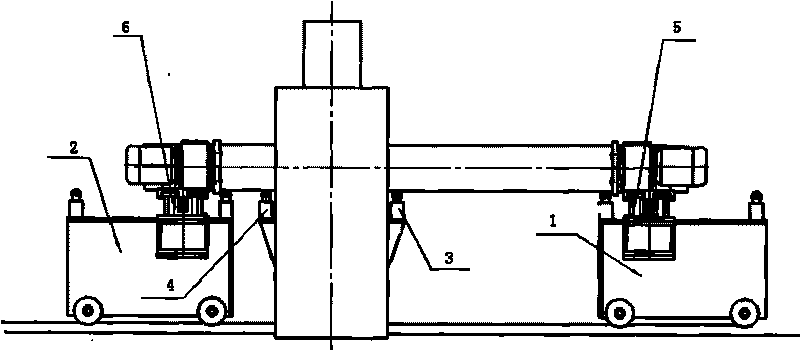

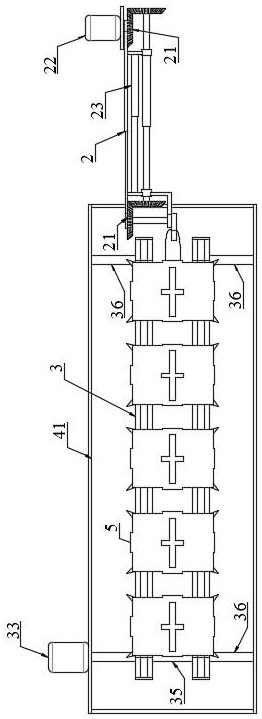

Sand blasting equipment for outer wall of steel pipe

InactiveCN101758460AEven sandblastingAbrasive machine appurtenancesAbrasive blasting machinesSand blastingMaterials science

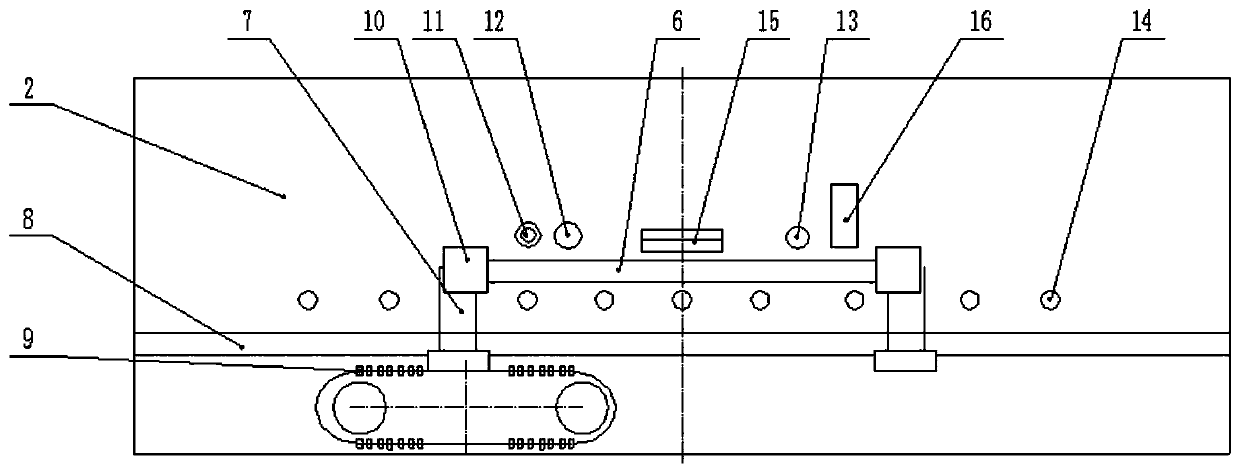

The invention relates to sand blasting equipment for the outer wall of a steel pipe, which comprises a transportation support component and a sand blasting component, wherein the transportation support component comprises trolleys (1) and (2) and support posts (3) and (4), and the sand blasting component comprises a sand blasting machine and a sand blasting box. The invention is characterized in that the steel pipe is pushed to enter the sand blasting component through the trolleys, the sand blasting machine carries out sand blasting, a friction wheel of the sand blasting box drives the steel pipe to rotate at the constant speed, and the goal of controlling the uniform sand blasting on the surface of the steel pipe is reached.

Owner:TIANJIN GENERAL PRINCIPLE MACHINERY NEW TECH

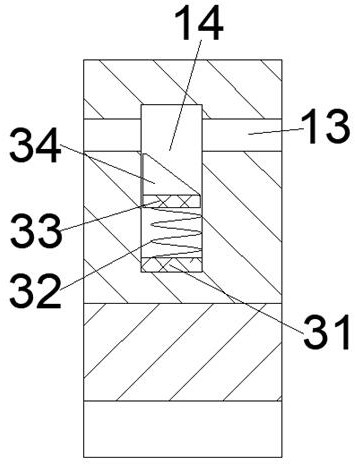

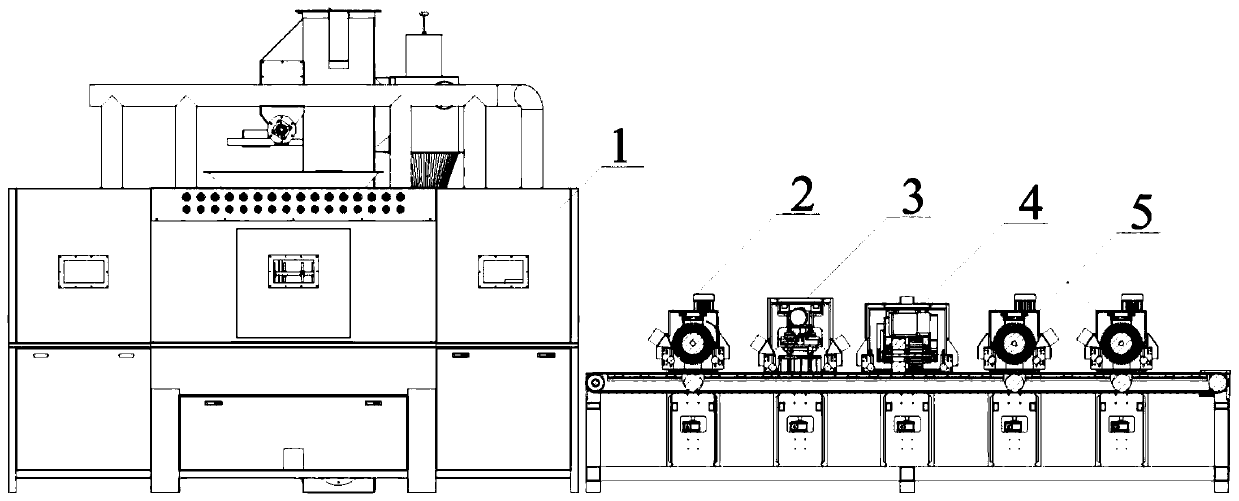

Isolation structure on spraying device for surface treatment and sandblasting and spraying integrated machine

ActiveCN104841602AAvoid influenceAvoid secondary clampingLiquid surface applicatorsSpraying apparatusAbrasive blastingEngineering

The invention discloses an isolation structure on a spraying device for surface treatment and a sandblasting and spraying integrated machine comprising the isolation structure, and belongs to the technical field of surface treatment. The isolation structure comprises a lower cover and an upper cover, wherein the lower cover and the upper cover are respectively arranged above a workpiece bearing device and below the workpiece bearing device; the upper cover moves to a combination position and is combined with the lower cover positioned at a treatment workstation to form an isolation cavity; and the workpiece bearing device is sealed in the isolation cavity. The sandblasting and spraying integrated machine comprises a rack, a sandblasting device, a blowing-off device, a spraying device, the workpiece bearing device, a conveying device and the isolation structure. The technical problems that a surface spraying treatment operation always disturbs other operations, the existing sandblasting operation affects the spraying operation easily, and sandblasting and spraying are difficultly carried out in the same machine continuously are solved. The isolation structure has the advantages that other surface spraying treatment operations cannot be disturbed, the spraying effect of workpieces cannot be affected, occupied area is saved, and the work efficiency is high.

Owner:RIAMB (BEIJING) TECH DEV CO LTD

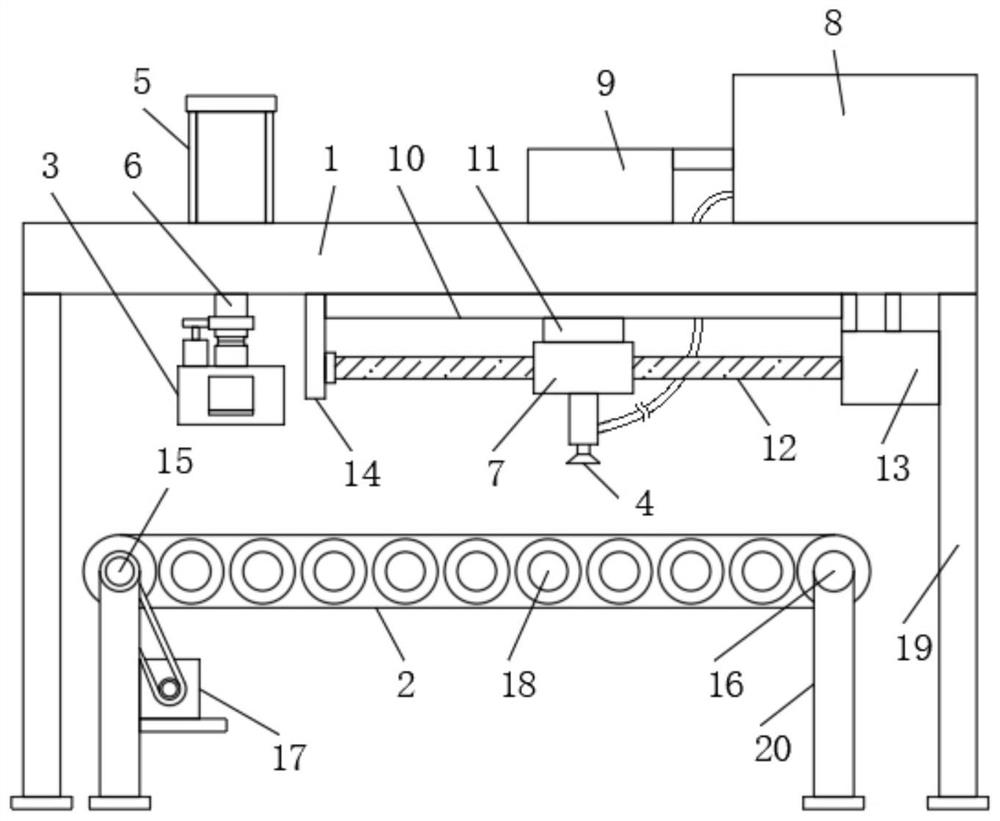

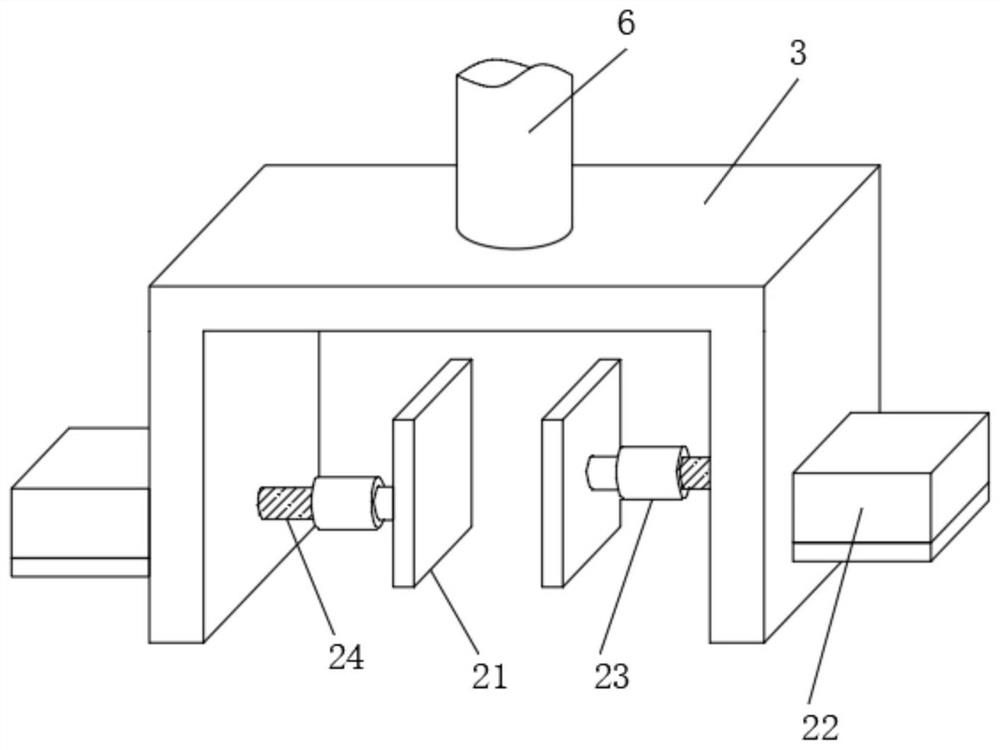

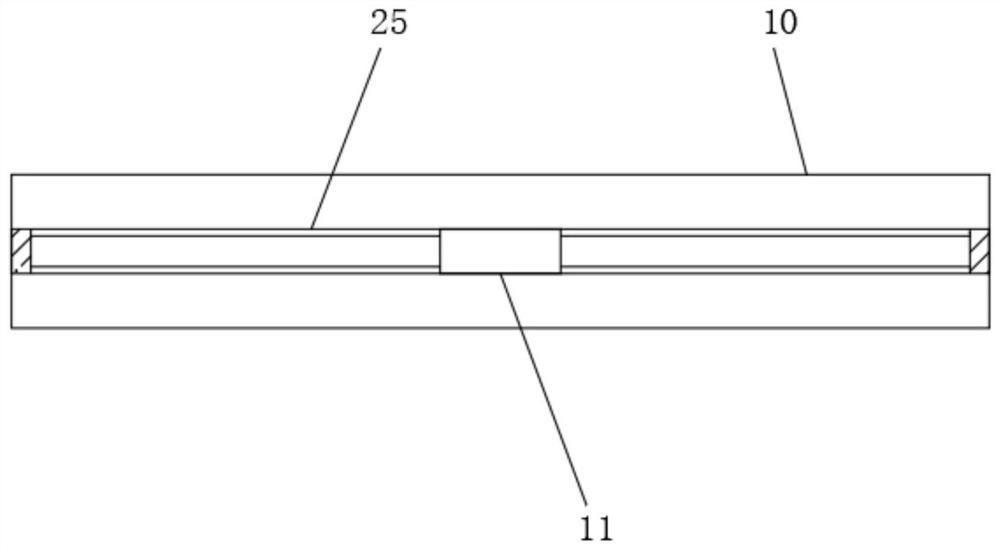

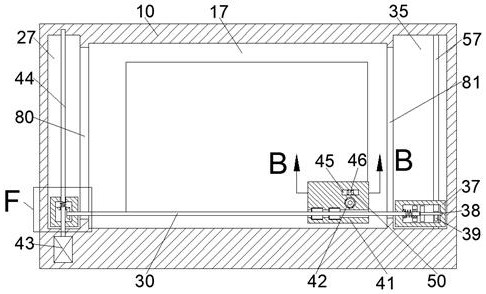

Full-automatic sand blasting machine applied to aluminum plate surface treatment

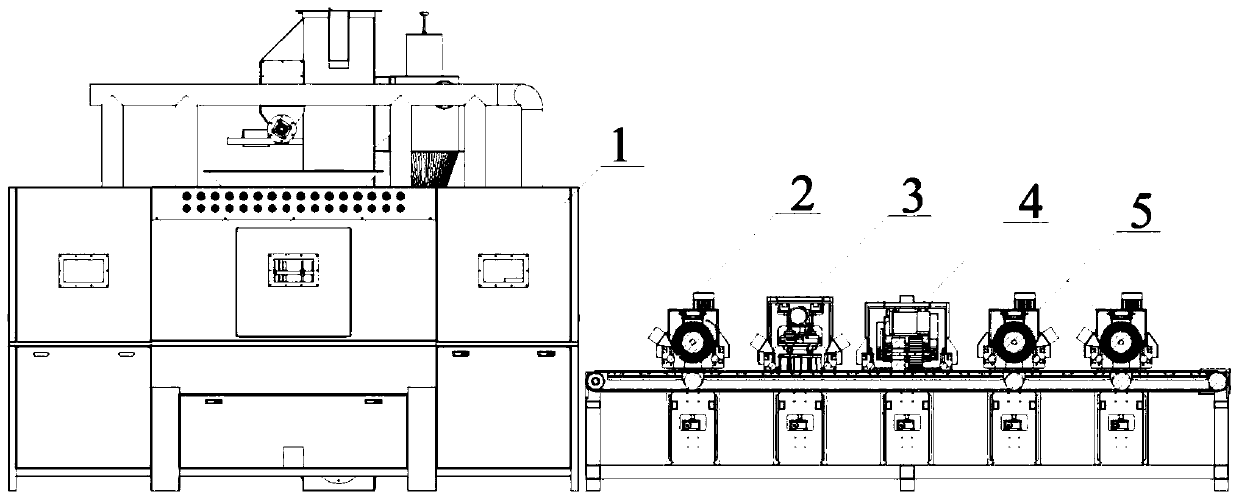

InactiveCN105538165ASolve Sandblasting ProblemsSimple structureAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention discloses a full-automatic sand blasting machine applied to aluminum plate surface treatment. The full-automatic sand blasting machine comprises a rack. A sand blasting chamber is arranged on the rack. A conveying device is arranged on the rack and penetrates through the sand blasting chamber. The conveying device comprises a conveying frame and conveying rollers. A suction cup device is arranged above the conveying rollers and comprises a suction cup assembly, a lifting adjustment mechanism and a horizontal movement mechanism. The horizontal movement mechanism is installed at the top of the sand blasting chamber. The lifting adjustment mechanism is arranged at the lower end of the horizontal movement mechanism and connected with the suction cup assembly. A sand blasting device is arranged on the side wall of the sand blasting chamber and comprises sand blasting assemblies, spray gun movement mechanisms and spray gun rotation mechanisms. The spray gun movement mechanisms are installed on the side walls of the sand blasting chamber and connected with the spray gun rotation mechanisms. The sand blasting assemblies are arranged on the spray gun rotation mechanisms. The full-automatic sand blasting machine is simple in structure, scientific, convenient to use, high in automation degree and work efficiency and even in sand blasting, and sand blasting of the aluminum plate surface treatment is well achieved.

Owner:湖州金丰新材有限公司

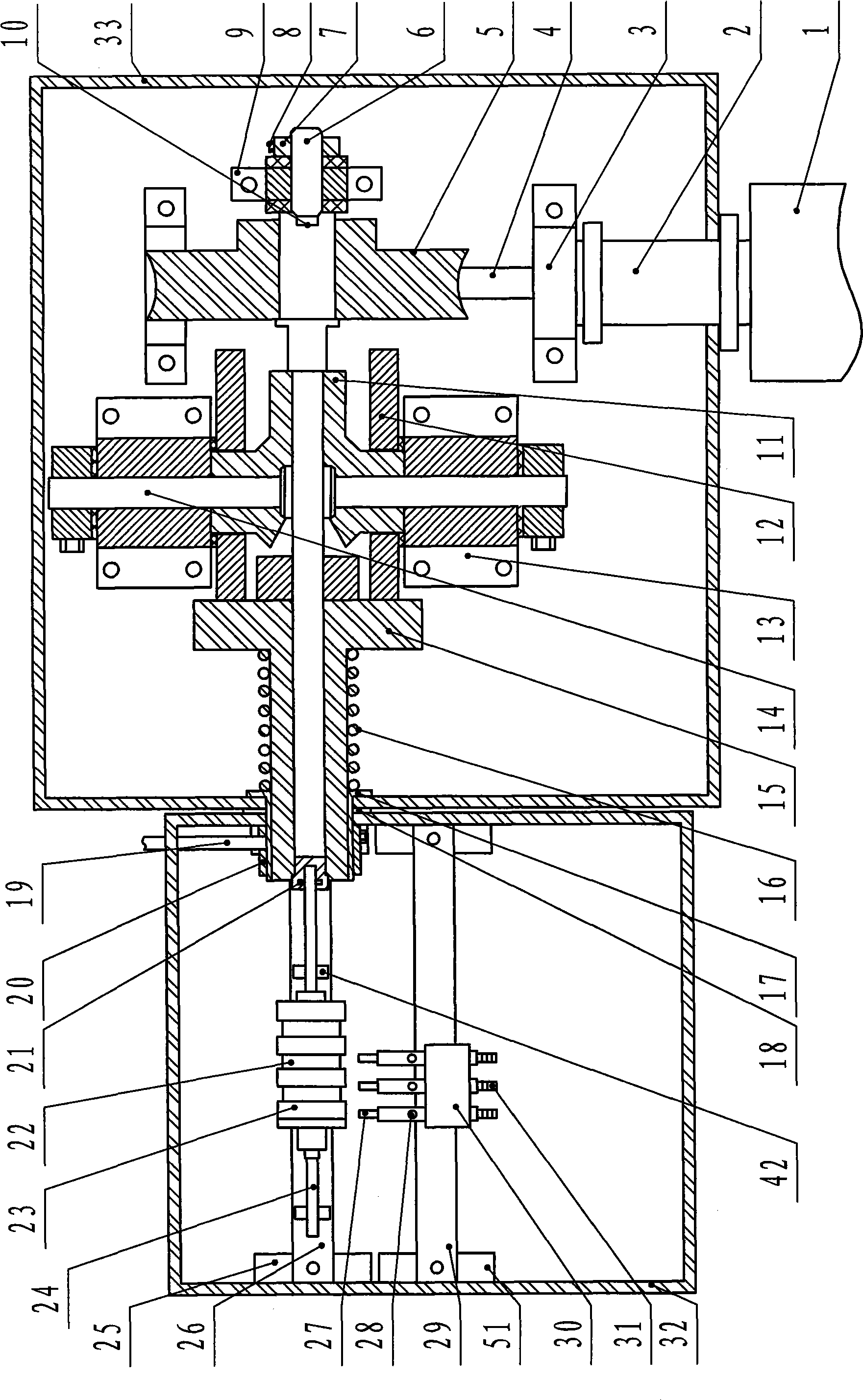

Automatic sand-blasting machine for combing roller

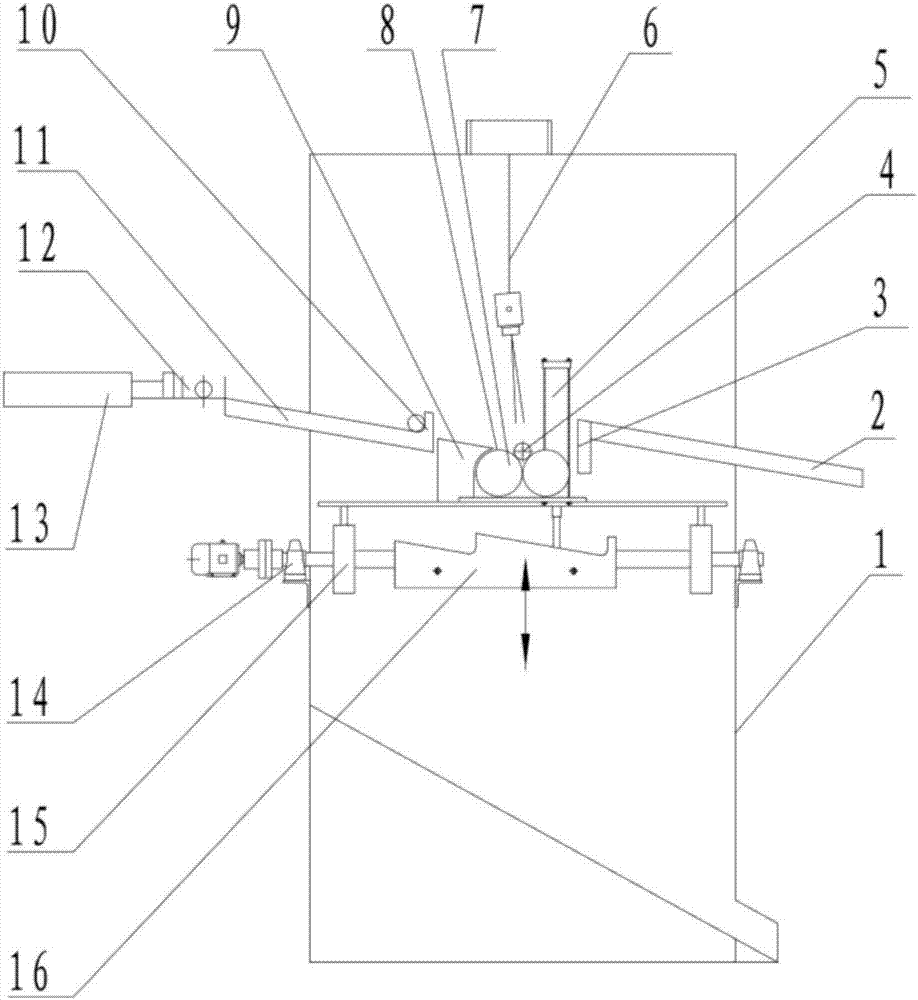

InactiveCN101486168ANo hanging phenomenonEven sandblastingBlast gunsAbrasive machine appurtenancesTransmitted powerGear wheel

The invention discloses an opening roller automatic sand blasting machine, which belongs to equipment for processing opening rollers. The sand blasting machine comprises a motor, a transmission device and a sand blasting device, wherein the motor is connected with the transmission device. The sand blasting machine is characterized in that the transmission device is connected with a roller spindle; the roller spindle is provided with an opening roller clamping device; and the sand blasting device consists of a base and a blast gun arranged on the base. The sand blasting machine comprises the following working process that: the opening roller with blurs is arranged on the roller spindle; the motor is started; the motor rotates to drive a worm and a turbine to reduce the rotation speed to 50 rounds and drive a transmission shaft to rotate at a constant speed; at the same time, a turbine shaft transmits power to eccentric wheels at two sides through bevel gears for the eccentric wheels to rotate; outer circles of the eccentric wheels drive the transmission shaft and the roller spindle to move reciprocally; and the blasting device blasts sand onto the surface of the opening roller with blurs with uniform sand blasting and complete blur treatment. The opening roller processed by the machine is free from pattern hanging during use.

Owner:SHANXI SCENERY MACHINE MFG

Part sand blasting machine

InactiveCN108942691AEven sandblastingEasy to recycleAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention discloses a part sand blasting machine. The part sand blasting machine comprises a material placing table, a sand blasting chamber, a discharging chamber and a processing center, an automatic sensing door is arranged between the material placing table and the sand blasting chamber, a feeding hopper is arranged above the sand blasting chamber, a storage chamber is arranged in the feeding hopper, a stirring device is arranged inside the storage chamber, and materials can be effectively prevented from being condensed into blocks; a first waste collecting box is arranged at the lowerend of the sand blasting chamber, a second waste collecting box is arranged at the lower end of the discharging chamber, clamping devices are arranged in the sand blasting chamber, the clamping devices can move in a telescopic mode, and the clamping devices comprise clamping drive devices, telescopic rods and clamping claws; and a conveying device is arranged at the lower end of the sand blastingchamber and the lower end of the discharging chamber, and the conveying device comprises a grid conveying belt and a conveying belt drive device. According to the part sand blasting machine, parts are clamped through the clamping devices capable of moving telescopically, then the parts can uniformly undergo sand blasting, and the defective rate of sand blasting is reduced; and the grid conveyingbelt is adopted, redundant blasted sand in the sand blasting process can enter the first waste collecting box, so that the recovery of the materials is facilitated, and resources are saved.

Owner:HEFEI PNT ELECTRONICS

Automatic sand blasting device for outer surface of bushing

InactiveCN102836809ARealize automatic sandblastingEven sandblastingLiquid surface applicatorsCoatingsLine tubingSand blasting

The invention relates to an automatic sand blasting device for an outer surface of a bushing. A sand box of the automatic sand blasting device for the outer surface of the bushing is connected with a sand blaster through a sand grain conveying pipeline; an air compressor is connected with the sand grain conveying pipeline through an air line; the sand blaster consists of a single-grain sand loading pipe, a sand grain nozzle and a sand blasting movable seat; the single-grain sand loading pipe is positioned outside the sand blasting movable seat; the sand grain nozzle is arranged in the sand blasting movable seat; the single-grain sand loading pipe is connected with the sand grain nozzle; the sand blasting movable seat is arranged on a sliding polished rod in a penetrating way; a transmission lead screw of a sand blasting feeding mechanism is in threaded connection with the sand blasting movable seat; the bushing is arranged on a rotary bracket; one end of the bushing is in threaded connection with an electric rotary disc of the rotary bracket, and the other end of the busing is arranged together with a bearing and a bearing fixing rod of the rotary bracket; and the sand blaster is arranged close to the bushing and can be used for blasting sand grains to the bushing. According to the automatic sand blasting device, automatic sand blasting of an oil field bushing is realized, the entire process is automatically realized, uniform sand blasting in an entire sand blasting process can be guaranteed, and the degree of standardization is high.

Owner:NORTHEAST GASOLINEEUM UNIV

Sand blasting device for speed changing box suspension support

InactiveCN109500749AEasy to useImprove surface qualityAbrasive machine appurtenancesAbrasive blasting machinesSand blastingFixed frame

The invention discloses a sand blasting device for a speed changing box suspension support, and relates to the technical field of sand blasting equipment. A bottom plate and a movable block are included. A box is fixedly connected to the top of the bottom plate. The part, located on one side of the box, of the top of the bottom plate is fixedly connected with an air source pump through a supporting frame. A storage barrel is fixedly connected to the top of the box. The bottom of the storage barrel communicates with a discharging pipe. The bottom end of the discharging pipe penetrates through the box and extends into the box. Fixing frames are fixedly connected to the two sides of the box. One side of the inner wall of each fixing frame is rotationally connected with a spline shaft througha bearing, wherein one end of the spline shaft penetrates through the box and extends into the box. According to the sand blasting device for the speed changing box suspension support, uniform sand blasting treatment can be conducted on the surface of the speed changing box suspension support, the function of improving the support surface quality is achieved, work intensity of work personnel is relieved as well, and good conditions are created for later normal usage of the support.

Owner:江苏圣金特汽车配件有限公司

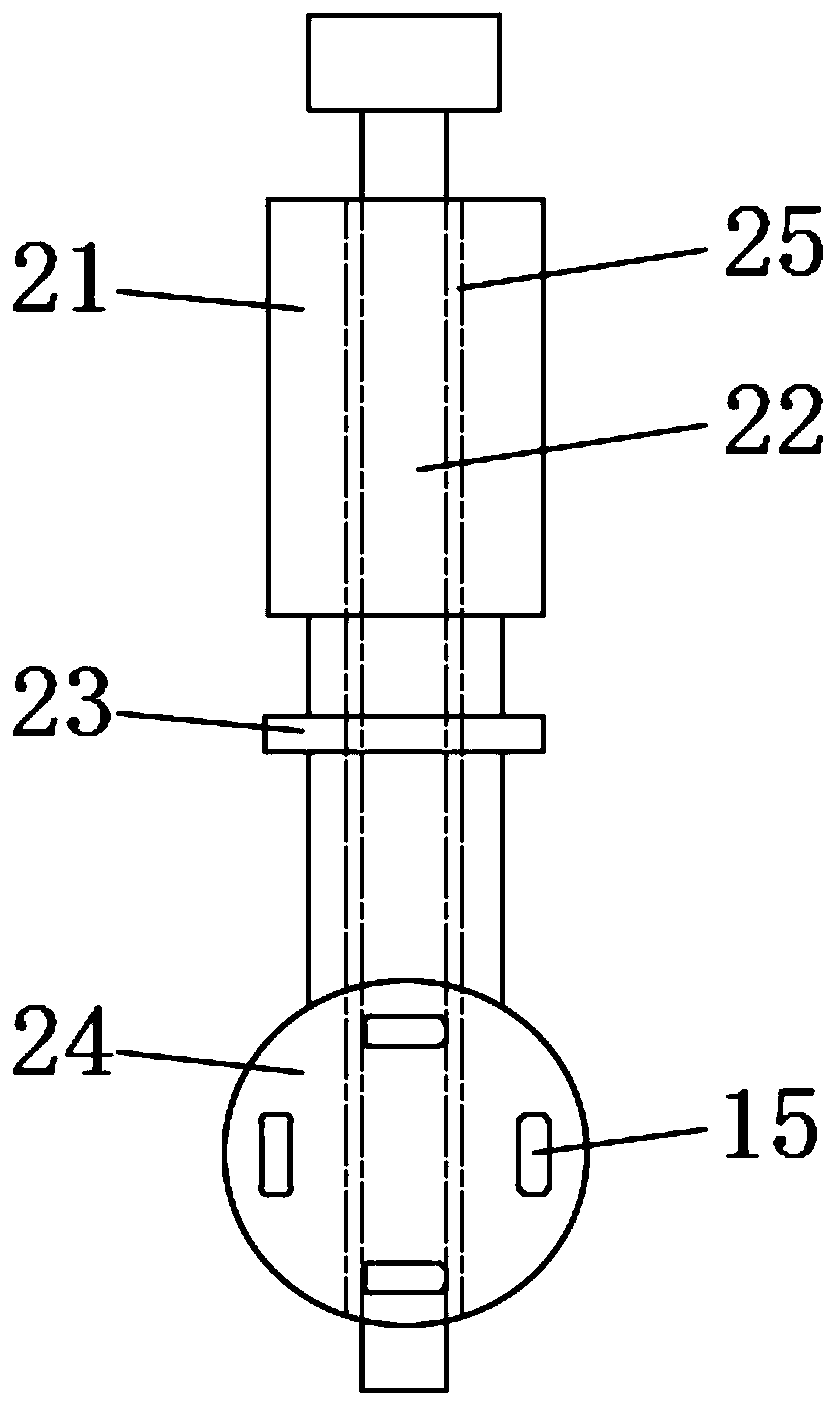

Sand spraying machine for transmission shaft

The invention discloses a sand spraying machine for a transmission shaft. The sand spraying machine comprises a machine frame and a sand spraying mechanism which is arranged on the machine frame; two groups of poisoning assemblies for placing the transmission shaft are placed below the sand spraying mechanism; the distance between two groups of poisoning assemblies is equal to the distance between splines at two ends of the transmission shaft; each group of the positioning assemblies comprises two rotation pieces which are opposite to each other; and a distance is reserved between two rotation pieces and is smaller than the diameter, at the spline, of the transmission shaft. The sand spraying machine has a simple structure, can spray sand uniformly, and avoid the phenomenon that the splines at two ends of the transmission shaft can be prevented from being impacted by an adhesive.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

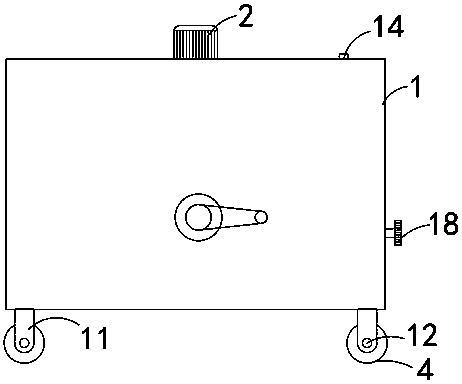

Sand blasting device

InactiveCN109202742APlay a limiting effectAvoid affecting the sandblasting effectAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention discloses a sand blasting device. The sand blasting device comprises a box body, a sand blasting machine body and a cross board, the two ends of the cross board are slidably connected with the left side wall and the right side wall of the box body respectively, the sand blasting machine body is fixedly connected to the cross board, a walking mechanism is arranged on the lower end ofthe box body, a fixing block is fixedly connected with the bottom of the interior of the box body, the upper end of the fixing block is provided with a first groove, the left side wall and the right side wall of the first groove are provided with second grooves respectively, a movable rod penetrates through the bottoms of the second grooves, a fixing board is fixedly connected with the end, closeto the first groove, of the movable rod, a plurality of connection blocks are arranged on the side walls of the interiors of the second grooves, limiting grooves are arranged on the opposite side walls of the plurality of connection blocks, a plurality of limiting blocks matched with the limiting grooves are arranged on the movable rod, the parts, located in the second grooves, of the movable rodare sleeved with springs, and an adjusting mechanism used for adjusting the cross board is arranged on the right side wall of the box body. The sand blasting device can adjust the sand blasting machine body, can limit to-be-processed pieces, and is easy to operate.

Owner:江苏纽克光谱科技有限公司

Machining device and method for sharpness of antenna target plate

ActiveCN113878500ALow mechanical strengthEven sandblastingAbrasive machine appurtenancesSuperimposed coating processSand blastingElectric machinery

The invention discloses a machining device and method for the sharpness of an antenna target plate. The machining device comprises a target plate transferring mechanism, a conveying mechanism, a sand blasting mechanism and a protective shell. The protective shell comprises a target plate bottom support and a target plate upper cover, the target plate upper cover is buckled on the target plate bottom support, and the protective shell is used for placing a target plate; the target plate transferring mechanism is used for transferring the protective shell to the conveying mechanism; the sand blasting mechanism comprises a sand blasting pool and a plurality of sand nozzles, and the sand nozzles are used for blasting sands to the target plate; and the conveying mechanism comprises two groups of conveying plates which are oppositely arranged, two conveying chains and a second motor, each group of conveying plates comprises an outer plate and an inner plate which are oppositely arranged, one conveying chain is located between the outer plate and the inner plate, and the conveying chains are used for placing the protective shell and enabling the protective shell to move from one end of the sand blasting mechanism to the other end of the sand blasting mechanism. By using the machining device and method disclosed by the invention, uniform sand blasting can be independently conducted on bulges, so that the mechanical strength of each bulge is weakened; and after etching treatment, an antenna with the sharpness smaller than 20 microns can be obtained.

Owner:四川英创力电子科技股份有限公司

Full-automatic multi-axis linkage conveying type sand blasting device based on quartz crucible production

The invention discloses a full-automatic multi-shaft linkage conveying type sand blasting device based on quartz crucible production. The full-automatic multi-axis linkage conveying type sand blasting device based on quartz crucible production comprises a fixing frame and a conveying device, the conveying device is arranged at the lower end of the fixing frame, an air cylinder is arranged at the left end of the top of the fixing frame, the bottom of the air cylinder penetrates through the fixing frame to be connected with an air pressure rod, a movable shaft is arranged at the lower end of the air pressure rod, a positioning mechanism is fixedly arranged at the bottom of the air pressure rod, a first gear rotating disc is arranged at the upper end of the air pressure rod, electric push rod devices are arranged at the outer side ends of the positioning mechanism, push rods are connected to the inner side ends of the electric push rod devices, third motors are fixedly arranged at the inner side ends of the push rods, the inner side ends of the third motors are connected with clamping plates through a rotating shaft, and a spray gun is arranged at the right end of the bottom of the fixing frame. According to the full-automatic multi-axis linkage conveying type sand blasting device based on quartz crucible production, the positioning mechanism is positioned on the exterior of a quartz crucible, and therefore the sand blasting efficiency is improved, the uniform sand blasting effect is achieved, and the automation performance is high.

Owner:XINYI ZHONGXIN OPTOELECTRONICS TECH CO LTD

Sand blasting machine capable of automatically adjusting to achieve uniform sand blasting

InactiveCN112059920AUniform thicknessReduce distortionBlast gunsAbrasive feedersSand blastingAir spring

The invention relates to the technical field of sand blasting machines, and discloses a sand blasting machine capable of automatically adjusting to achieve uniform sand blasting. The sand blasting machine comprises a sand blasting chamber, a sand blasting gun is fixedly installed in the sand blasting chamber, an arc-shaped wall is arranged in the sand blasting gun, the bottom of the arc-shaped wall is connected with a muzzle, adjusting modules are installed on the inner walls of the left and right sides of the sand blasting chamber, a fixing block is installed below the sand blasting gun, thetop of the fixing block is connected with an air spring, and the top of the air spring is connected with a workbench. According to the sand blasting machine capable of automatically adjusting to achieve uniform sand blasting, pressure on the arc-shaped wall is transmitted to a first common spring through a first pressure rod, the first common spring is contracted or stretched through the pressure,a first gear, a first disc, a second disc, a sliding rod, a piston plate and the air spring are driven to move in a matched mode, and a workbench is made to move downwards or upwards; and therefore,the distance between the muzzle of the sand blasting gun and a workpiece on the workbench is increased or decreased, and the thickness of sand sprayed to the surface of the workpiece is uniform.

Owner:刘西杰

Sanding and grinding process of wood product

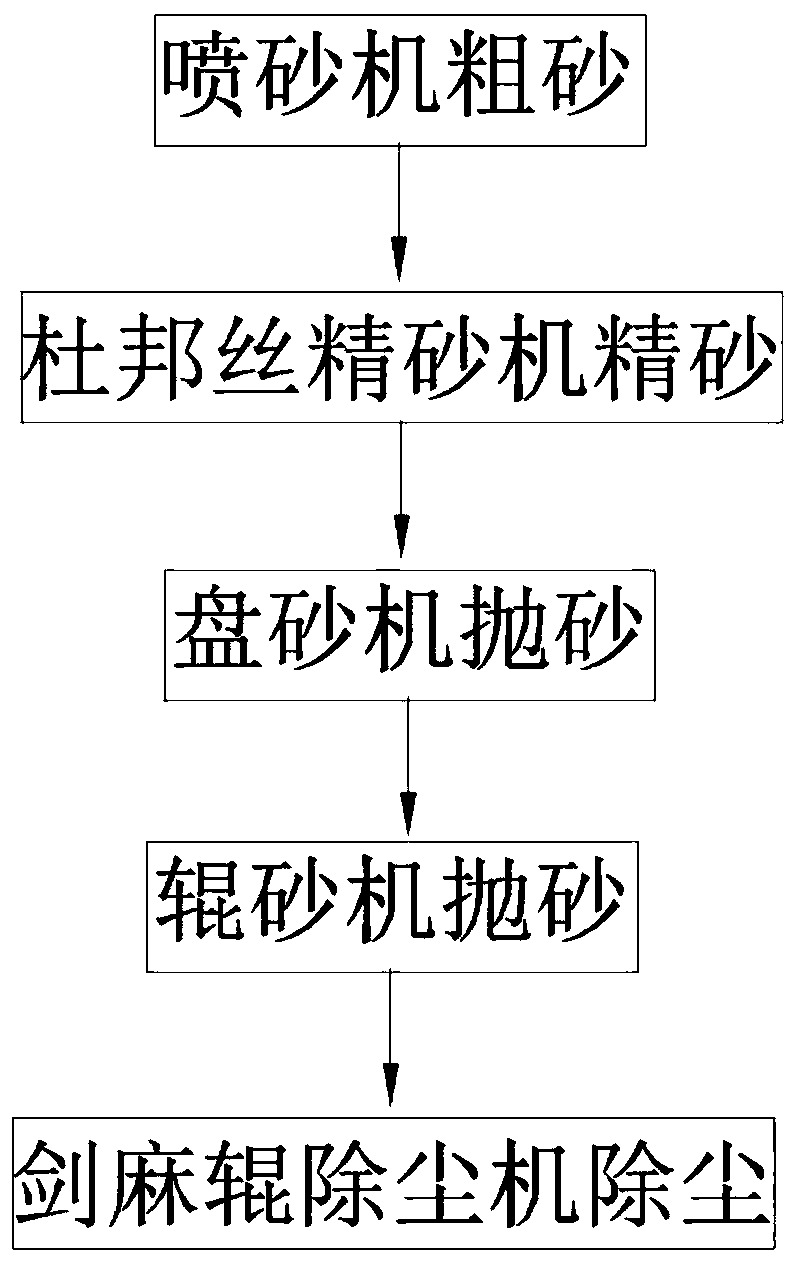

ActiveCN110834227AGuaranteed matte effectGood matte effectBlast gunsAbrasive feedersSand blastingDust control

The invention relates to the technical field of wood product processing, and discloses a sanding and grinding process of a wood product. The wood product is sequentially subjected to the following steps that (1) a sand-blasting machine carries out rough sanding, the surface of the wood product achieves the matt effect, the sand-blasting machine can sand dark faces (cannot be sanded by existing special-shaped sand) of workpieces, and the dark faces of the workpieces also achieve a good matt effect; (2) a Dupont line fine sanding machine carries out fine sanding, sand grains left by sand blasting are removed, and sand marks left by sand blasting are covered; (3) a disc sanding machine and a roller sanding machine carry out sand blasting, sand marks of Dupont lines are covered, the workpieceshave hand feelings, and the workpieces can meet the requirement for surface roughness in the next procedure; and (4) sisal hemp roller dust removal machines remove dust, atomization spray guns sprayand wet sisal hemp roller wires with dust removed, sisal hemp rollers keep wet, dust absorption devices and hot air blow-drying devices are combined to adsorb dust left on the surfaces of the workpieces and blow away water left on the surfaces of the workpieces, and the workpieces meet the requirement of finishing coat spraying.

Owner:佛山市晟瑞兴智能设备有限公司

Sand blasting machine for transmission shaft

InactiveCN107116475AAvoid collisionCompact structureAbrasive machine appurtenancesAbrasive blasting machinesSand blastingDrive shaft

The invention discloses a sand blasting machine for a transmission shaft. The sand blasting machine comprises a machine frame and a sand blasting mechanism arranged on the machine frame, wherein two sets of positioning assemblies allowing the transmission shaft to be placed are arranged under the sand blasting mechanism; the distance between the two sets of positioning assemblies is equal to that between splines arranged at two ends of the transmission shaft; each set of positioning assembly comprises two rotating parts which are oppositely arranged; a spacing is reserved between the two rotating parts, and is smaller than the diameter of a position wherein the spline is formed, of the transmission shaft. The sand blasting machine disclosed by the invention is simple in structure, and uniform in sand blasting; and the situation that splines at two ends of the transmission shaft are impacted by grinding materials can be avoided.

Owner:肇庆市端州区图恩斯科技有限公司

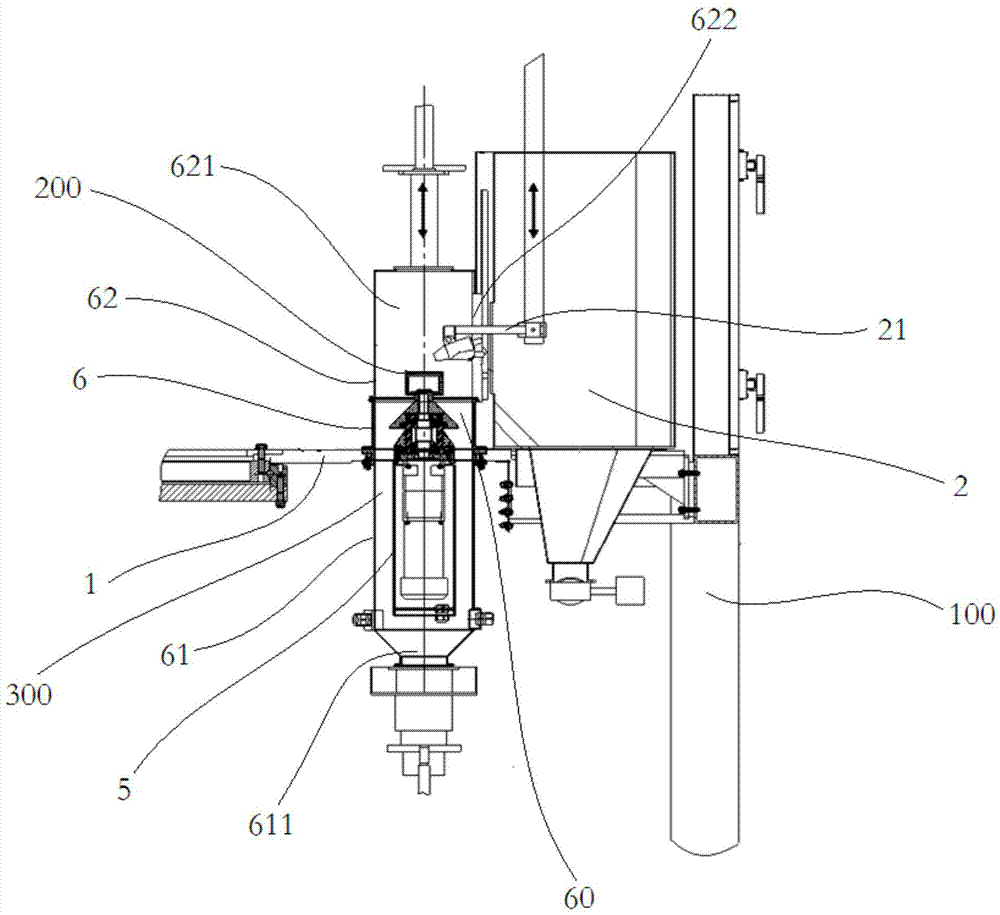

Automatic sand blasting device

PendingCN106926141AAchieve full sandblastingAvoid collisionBlast gunsAbrasive machine appurtenancesMachine partsSand blasting

The invention discloses an automatic sand blasting device. The automatic sand blasting device comprises a rotating workbench and a pneumatic sand blasting mechanism which are matched with each other. The rotating workbench can rotate a machined part on the rotating workbench. The pneumatic sand blasting mechanism can achieve sand blasting while moving a nozzle up and down, front and back and rotating the nozzle by 90 degrees on the plane according to the position and angle change of the machined part. The automatic sand blasting device is intelligent and self-adaptive, one-time complete sand blasting of the machined part can be completed, the sand blasting efficiency is improved, the labor intensity of workers is relieved, and the phenomenon that the workers work in a severe environment is avoided; and the degree of automation is high, controlling is sensitive and fast, and safety and reliability are high.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Sandblasting device for torsion rod bracket machining

InactiveCN109397110AEven sandblastingQuality improvementAbrasive machine appurtenancesAbrasive blasting machinesEngineeringMachining

The invention discloses a sandblasting device for torsion rod bracket machining, and relates to the technical field of workpiece sandblasting. The sandblasting device comprises a box; the bottom of aninner cavity of the box is fixedly connected with a bottom plate; a circular arc groove is formed in the top of the bottom plate, and the two sides in the circular arc groove are slidably connected with sliding blocks correspondingly; the tops of the sliding blocks are fixedly connected with first hydraulic telescopic rods; and the top ends of the first hydraulic telescopic rods are movably connected with operating plates through movable pipes. According to the sandblasting device for torsion rod bracket machining, the horizontal angle and the height of a to-be-sandblasted bracket can be adjusted, meanwhile, the to-be-sandblasted bracket can be rotated, the side face of the bracket with the irregular shape can be very conveniently sandblasted, a nozzle can move left and right, thus the to-be-sandblasted bracket can be evenly sandblasted, the sandblasting quality is improved to a good extent, the to-be-machined bracket is fixed well, and during device operation, the internal structureof the device is very stable.

Owner:江苏圣金特汽车配件有限公司

Novel automated sand blasting and nickel plating machine

InactiveCN110355691AEven sandblastingSave materialMolten spray coatingVacuum evaporation coatingAutomatic controlNickel plate

The invention discloses a novel automated sand blasting and nickel plating machine. A spraying bin is internally provided with a sand blasting gun and a nickel plating gun and further provided with adeduster, a grinding device and a thickness detection device, after sand blasting is completed, the grinding device can be automatically controlled by a system to grind a base pipe treated after sandblasting, burrs of the surface of the base pipe treated after sand blasting are removed, then the deduster is used for dedusting the spraying bin, after dedusting, the system automatically controls the nickel plating gun to conduct nickel plating on the base pipe, the thickness detection device can monitor the thickness of the surface of the base pipe, after the set thickness is achieved, the machine automatically stops operating, the two processes of sand blasting and nickel plating can be completed just through one machine for processing treatment, the operation is easily and conveniently conducted, and the production cost is reduced.

Owner:FAKETE TECH JIANGSU

Workpiece rotation type wet type sand blasting room

InactiveCN105269468AImplement auto-rotationEven sandblastingAbrasive feedersAbrasive machine appurtenancesSand blastingEngineering

The invention discloses a workpiece rotation type wet type sand blasting room. The workpiece rotation type wet type sand blasting room comprises a sand blasting chamber, a maintenance chamber and a treatment chamber. A partition plate is arranged between the sand blasting chamber and the maintenance chamber. A grid floor, tracks and a workpiece transport cart are arranged in the sand blasting chamber. A fixing device, a support and a rotating platform are arranged on the grid floor. The rotating support is connected with the grid floor through a rotation contactor. The fixing device is arranged on the rotating platform. The workpiece transport cart is provided with a workpiece fixing clamping base fixed to the fixing device. The maintenance chamber is provided with a control cabinet. An abrasive material supply system and a recycling system are arranged in the treatment chamber. The transverse position and the longitudinal position of the workpiece fixing clamping base can be adjusted. According to the workpiece rotation type wet type sand blasting room, injection is carried out after sand materials and water are mixed, the workpiece transport cart is arranged on the rotating platform, the automatic rotation of a workpiece is achieved, and the purposes that sand blasting on the surface of the workpiece is even, the finish degree and strength of the surface of the workpiece are effectively improved, and the pollution to the environment is reduced are achieved.

Owner:重庆明治百通机械制造股份有限公司

Automatic sand blasting device for surface of large flat mechanical part

InactiveCN111958498AImprove operational safetyAvoid harmAbrasive machine appurtenancesAbrasive blasting machinesMechanical componentsSand blasting

The invention discloses an automatic sand blasting device for the surface of a large flat mechanical part. The automatic sand blasting device comprises a main box, a sand blasting cavity is formed inthe main box, the left side of the sand blasting cavity is communicated with a left-axis sliding cavity, the left side of the left-axis sliding cavity is communicated with a transmission box sliding cavity, the right side of the sand blasting cavity is communicated with a right-axis sliding cavity, the right side of the right-axis sliding cavity is communicated with a stepping box sliding cavity,a transmission bevel gear box is in slidable and matched connection in the transmission box sliding cavity, and a transmission bevel gear cavity is arranged in the bevel gear box. According to the device, automatic sand blasting is conducted instead of manual sand blasting, the sand blasting efficiency is greatly improved, the harm, caused by the dust generated during sand blasting, to the human body is prevented, and the operation safety of operators is improved. Because sand blasting operation is carried out in the closed sand blasting cavity, the dust and waste gas generated during sand blasting cannot pollute the working environment of workers, and sand is more uniformly blasted to the surface of the part due to fixed-distance sand blasting, the problems of repeated blasting and blasting missing are solved, and the sand blasting effect is greatly improved.

Owner:台州市凯规机械科技有限公司

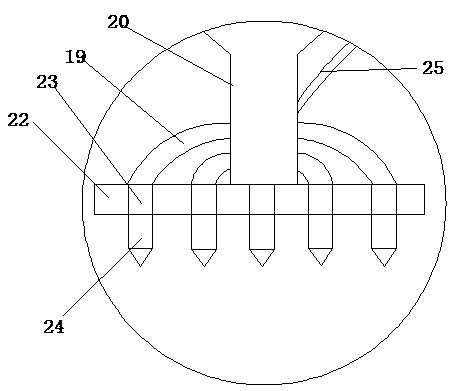

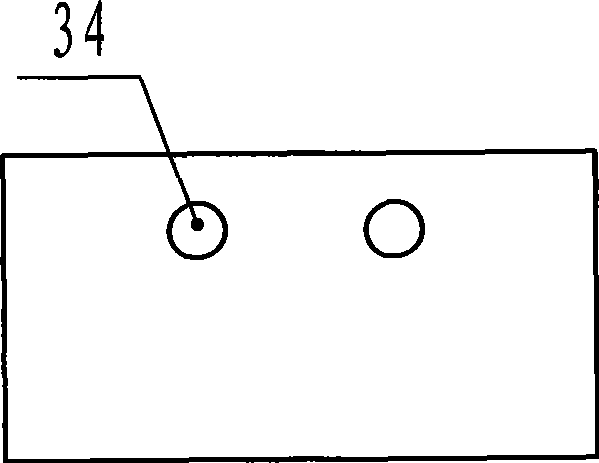

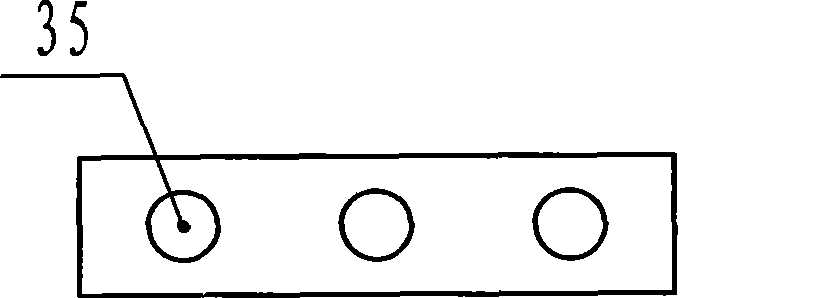

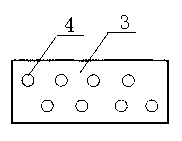

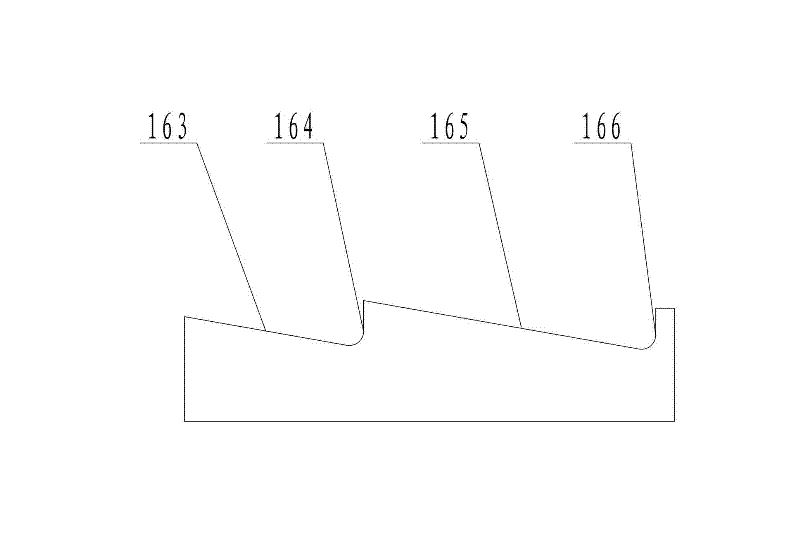

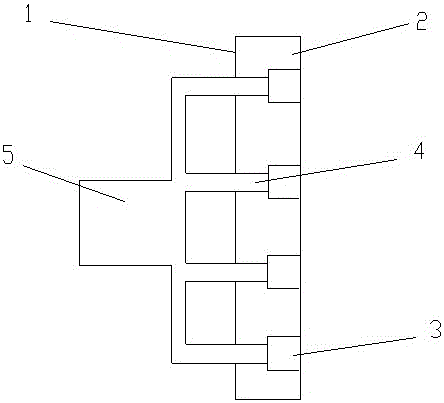

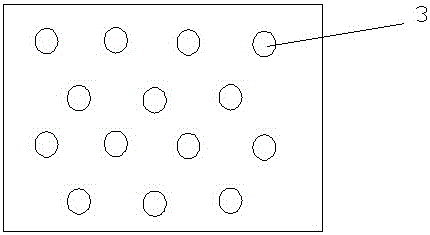

Spray head of sand-blasting machine with sand-blasting openings arranged in array staggered mode

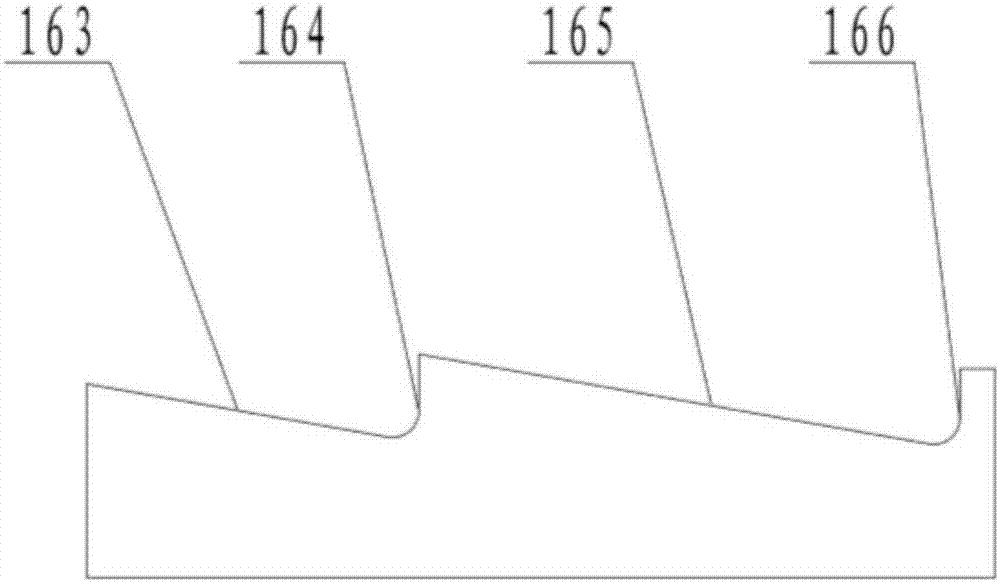

InactiveCN105150119AAvoid uneven thicknessUniform and fine sandblastingBlast gunsSand blastingGuide tube

The invention discloses a spray head of a sand-blasting machine with sand-blasting openings arranged in an array staggered mode. The spray head comprises a spray head body, wherein a sand-blasting table-board is arranged at the front end of the spray head body; a plurality of rows of sand-blasting openings, which are arranged in the form of an array, are formed in the sand-blasting table-board; the upper-row sand-blasting openings and the low-row sand-blasting openings in the sand-blasting table-board are arranged up and down in a staggered mode; distances among the sand-blasting openings are the same; the rear ends of the sand-blasting openings are connected with a sand-blasting guide tube; and the rear end of the sand-blasting guide tube is connected on a spraying discharge header tube by virtue of a connecting tube. In this way, the spray head can carry out sand-blasting treatment in a relatively uniform and fine mode; after being sprayed out by the sand-blasting discharge header pipe, the sand-blasting material is dispersed into each sand-blasting opening for being sprayed out, so that the sand-blasting is more uniform, and therefore, the sand-blasting thickness of the material surface is prevented from being uneven.

Owner:JIANGSU HONGLIAN ENVIRONMENTAL PROTECTION TECH CO LTD

Surface treatment device for aluminum profile machining

ActiveCN114800291AAvoid wastingEven sandblastingAbrasive machine appurtenancesAbrasive blasting machinesSand blastingStructural engineering

The surface treatment device for aluminum profile machining comprises a sand blasting machine body, a conveying belt used for conveying plates is arranged in the sand blasting machine body, a spray head used for sand blasting is arranged in the sand blasting machine body, fixing plates are welded to the two ends of the top of the sand blasting machine body, and a sliding rail is welded between the fixing plates; a sliding mechanism is arranged on the front side of the sliding rail, a shifting mechanism is arranged on the top of the sliding mechanism, a reciprocating mechanism is arranged on one side of the sliding mechanism, and the spray head is connected to the bottom of the reciprocating mechanism. The device has the following beneficial effects that the limiting mechanism can be adjusted according to the size of the aluminum alloy plate, so that the moving range of the reciprocating mechanism is adjusted through cooperation of the shifting mechanism and the limiting mechanism, the reciprocating mechanism only moves in the top area of the aluminum alloy plate, it is guaranteed that sand blasting is uniform, and the working efficiency is improved. And waste of resources can be avoided, the device is suitable for aluminum alloy plates of different sizes, and practicability is improved.

Owner:山东瑞高铝业有限公司

Roller sand blasting equipment

InactiveCN111331519AEven sandblastingImprove practicalityBlast gunsAbrasive machine appurtenancesSand blastingTransmission belt

The invention relates to the technical field of rollers, in particular to roller sand blasting equipment. The roller sand blasting equipment enables sand blasting treatment on the surface of a rollerto be more uniform and improves practicability. The roller sand blasting equipment comprises a sand blasting box, a first sealing door, a first base, two sets of mounting frames, a first bearing seat,two sets of first belt wheels, a second bearing seat, a second base, a rotary disc, a plurality of sets of third bearing seats, a plurality of sets of second belt wheels, a transmission belt, a firstmotor, a first connecting shaft, a second motor, a second connecting shaft and a spraying device. A cavity is formed inside the sand blasting box, four sets of supporting legs are arranged at the bottom end of the sand blasting box, a bottom plate is arranged at the bottoms of the four sets of supporting legs, a first glass window capable of observing the interior of the cavity of the sand blasting box is arranged on the right portion of the front end of the sand blasting box, and an opening communicating with the cavity of the sand blasting box is formed in the right end of the sand blastingbox; and the rear end of the first sealing door is rotationally and vertically installed at the opening of the right end of the sand blasting box, the first base is fixedly installed at the bottom end of the cavity of the sand blasting box, and the two sets of mounting frames are symmetrically installed at the top end of the first base.

Owner:辽宁兆金重型装备制造有限公司

Ornament prototype surface sandblasting equipment

InactiveCN110788761AImprove stabilityEven sandblastingAbrasive machine appurtenancesAbrasive blasting machinesStructural engineeringMechanical engineering

The invention discloses ornament prototype surface sandblasting equipment which comprises a sandblasting machine, and a sandblasting cavity is arranged in the sandblasting machine. According to the ornament prototype surface sandblasting equipment, a jewelry ring to be subjected to sandblasting is arranged on object loading blocks of a first telescopic sleeve rod and a second telescopic sleeve rodin a sleeve manner, then the first telescopic sleeve rod and the second telescopic sleeve rod are stretched in opposite directions, connecting columns of quadrangular structures and connecting grooves are in butt joint, adjusting handles on the surfaces of the first telescopic sleeve rod and the second telescopic sleeve rod slide to promote supporting discs at the bottom ends of the adjusting handles to push multiple plastic strips to move under the sleeving, connecting and supporting actions of a fixed sleeve, and therefore the plastic strips penetrate through avoiding holes of the first telescopic sleeve rod and the second telescopic sleeve rod and through grooves in a support plate to outwards extend, in cooperation with the guide effect of guide strips, the supporting scope of the object loading blocks of the multiple arc-shaped structures is enlarged, the multiple object loading blocks are promoted to support and carry an inner ring of the jewelry ring to be processed, and the ornament prototype surface sandblasting equipment is suitable for fixing and supporting jewelry rings with different diameters.

Owner:义乌市傅宝仙饰品有限公司

Wood product sanding and grinding system

PendingCN110757312AGuaranteed matte effectGood matte effectBlast gunsGrinding drivesEnvironmental geologyManufacturing engineering

The invention relates to the technical field of wood products and discloses a wood product sanding and grinding system. The wood product sanding and grinding system comprises a conveying belt used forconveying a wood product; the conveying belt is sequentially provided with a sand sprayer, a Dupont line fine sanding machine, a disc sanding machine, a roller sanding machine and at least one sisalroller dust remover. The coarse sand of the sand sprayer guarantees a haze effect of the surface of the wood product and can be used for sanding the dark side of a workpiece. The Dupont line fine sanding machine can be used for implementing secondary clearing on the dark side of the workpiece, and meanwhile sand particles embedded into the surface of the workpiece are thrown out and cover the sanding marks remaining after sand is sprayed. The disc sanding machine and the roller sanding machine are used for throwing sand to cover the sanding marks of a Dupond line so that the workpiece is endowed with hand feeling and meets the surface roughness requirement of the next step. The sisal roller dust remover is used for removing dust; an atomizing spray gun is used for wetting a dust-removed sisal roller wire in a spraying manner so that a sisal roller is kept wet; a combined dust collecting device and a hot air blow-drying device are correspondingly used for adsorbing dust remaining on thesurface of the workpiece and drying the moisture remaining on the surface of the workpiece in a drying manner; and thus the workpiece meets the requirements of spraying of a finish paint.

Owner:广东顺德泓涂机械有限公司

Large stainless steel workpiece surface sand blasting device and process

ActiveCN111872855AEven sandblastingCleaning using toolsAbrasive machine appurtenancesMetallurgySand blasting

The invention discloses a large stainless steel workpiece surface sand blasting device which comprises a main box, an operation platform box is fixedly connected to the upper surface of the main box,a sand blasting machine body is fixedly connected to the upper surface of the operation platform box, and a mounting base is fixedly connected to the upper surface of the sand blasting machine body. The invention further provides a large stainless steel workpiece surface sand blasting process which comprises the following step that S1, a stainless steel workpiece is placed on the upper surface ofthe operation platform box, a fourth motor is started, a roller is driven by a chain to rotate, and therefore the stainless steel workpiece moves rightwards. According to the large stainless steel workpiece surface sand blasting device, by arranging a second motor, a mounting plate can rotate, by arranging a clamping rod and an electric telescopic rod, the stainless steel workpiece can be clampedby a clamping plate, and by arranging the sand blasting machine body and a nozzle, sand blasting can be conducted on the stainless steel workpiece; and therefore, the effect of uniform sand blasting of the large stainless steel workpiece surface sand blasting device is achieved.

Owner:温州鹏象管件有限公司

Sandblasting operation device for producing and processing wooden products

ActiveCN111922923APrevent leakageEasy loadingAbrasive machine appurtenancesAbrasive blasting machinesUniversal jointSand blasting

The invention discloses a sandblasting operation device for producing and processing wooden products and relates to the technical field of wooden product production. The sandblasting operation devicefor producing and processing the wooden products comprises a work box, and a sand storage box is fixedly arranged on the outer surface of the top of the work box. According to the sandblasting operation device, through cooperative use of a connecting plate, a first electric push rod, a second electric push rod, a magnetic mounting block, sand separation boxes, cross universal joints, thread bushes, coupling hoses and spray guns, the sandblasting operation can be uniformly and automatically performed on timber without the need of carrying out the sandblasting operation by hand holding, the condition that the staff take time and energy but the efficiency is not high is avoided on one hand, and on the other hand, rough material surface caused by inhomogeneous manual sandblasting is avoided; and the danger during manual operation is avoided, the working efficiency is effectively improved, the labor intensity of the staff is reduced, the safety of the device is improved, and the practicality is enhanced.

Owner:浙江金隆木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com