Automatic sand blasting device

A sandblasting device, an automatic technology, is used in explosion generating devices, used abrasive processing devices, spray guns, etc., and can solve problems such as human harm, inconvenient positioning, and complex clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

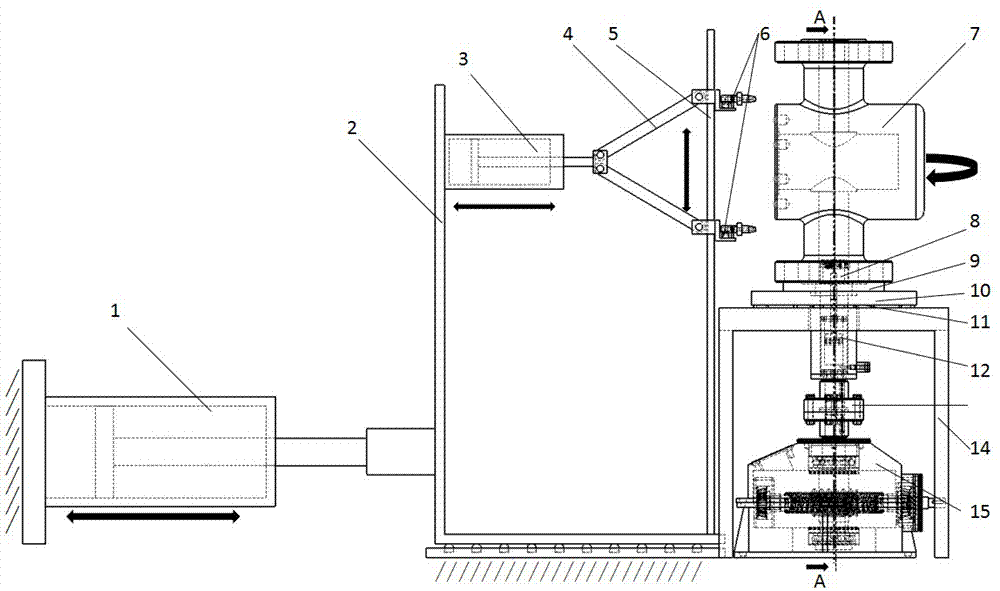

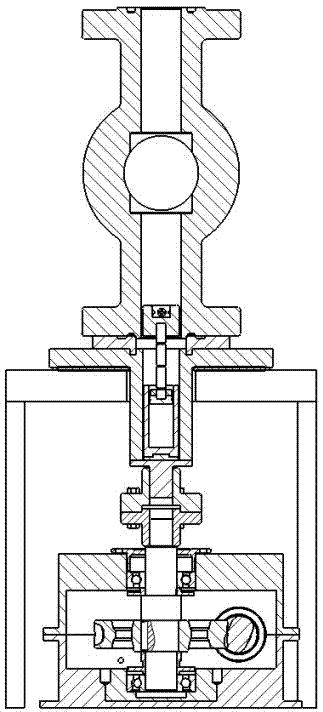

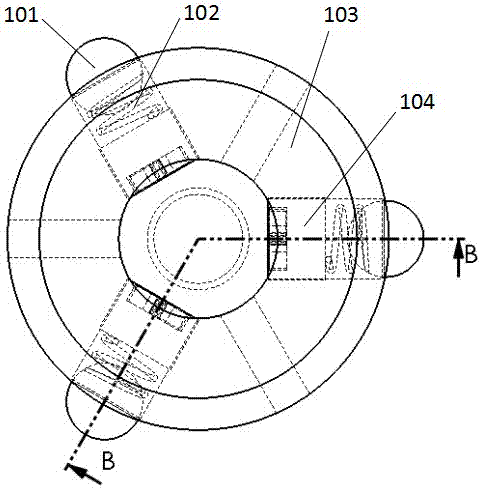

[0028] The following structural drawings further illustrate the technical solution of the present invention.

[0029] Such as figure 1 , 2 As shown, the automatic sandblasting device includes a rotating table and a pneumatic sandblasting mechanism that cooperate with each other; the pneumatic sandblasting mechanism is composed of a No. 1 pneumatic cylinder 1, an L-shaped fixed plate 2, a No. , guide rail 5 and sand blaster 6, rollers are installed under the base plate of L-shaped fixed plate 2, guide rail 5 is vertically installed above the base plate of L-shaped fixed plate 2, and the cylinder rod of No. 1 pneumatic cylinder 1 is connected to the L-shaped fixed plate On the side plate of 2, the No. 2 pneumatic cylinder 3 is installed on the side plate of the L-shaped fixed plate 2, and one end of the two connecting rods 4 is installed on the cylinder rod of the No. 2 pneumatic cylinder 3 through the connecting block, and the two connecting rods 4 The other end of the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com