Sand blasting device and method for surface post-treatment of cast valve body

A sandblasting device and sandblasting technology are applied in the direction of used abrasive processing devices, explosion generating devices, spray guns, etc., which can solve the problem of difficult to meet the comprehensive sandblasting requirements of the valve body, areas that are difficult to be sandblasted, and the inner wall of the valve cannot be solved. Coverage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

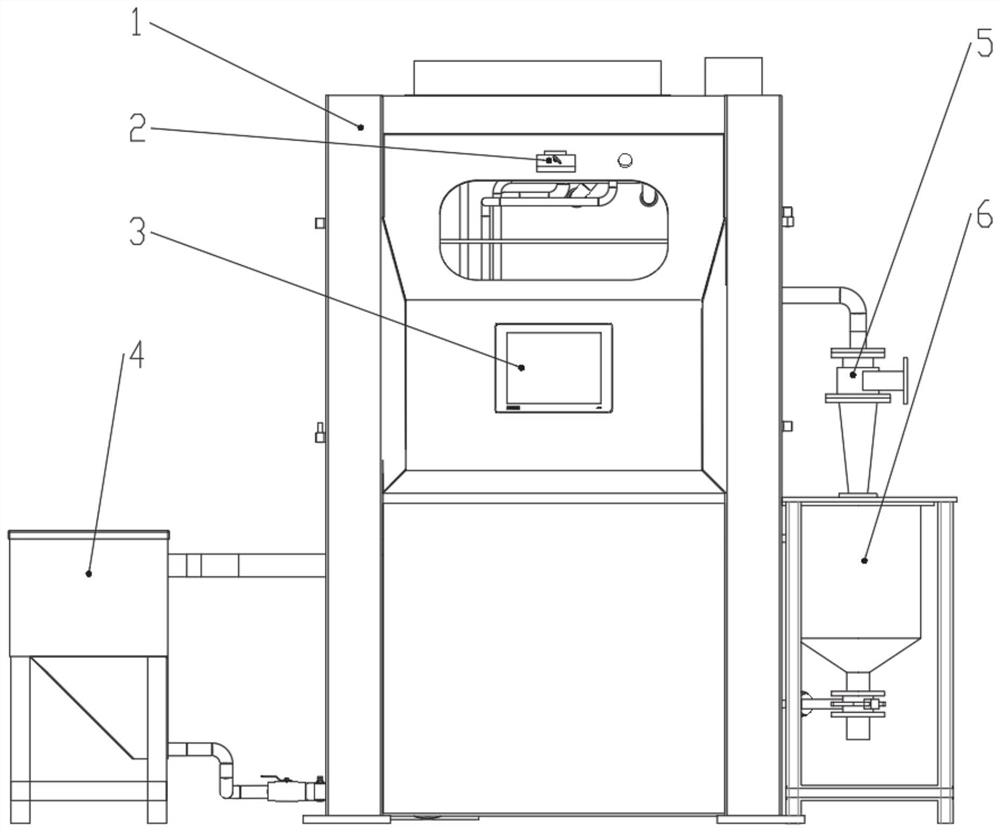

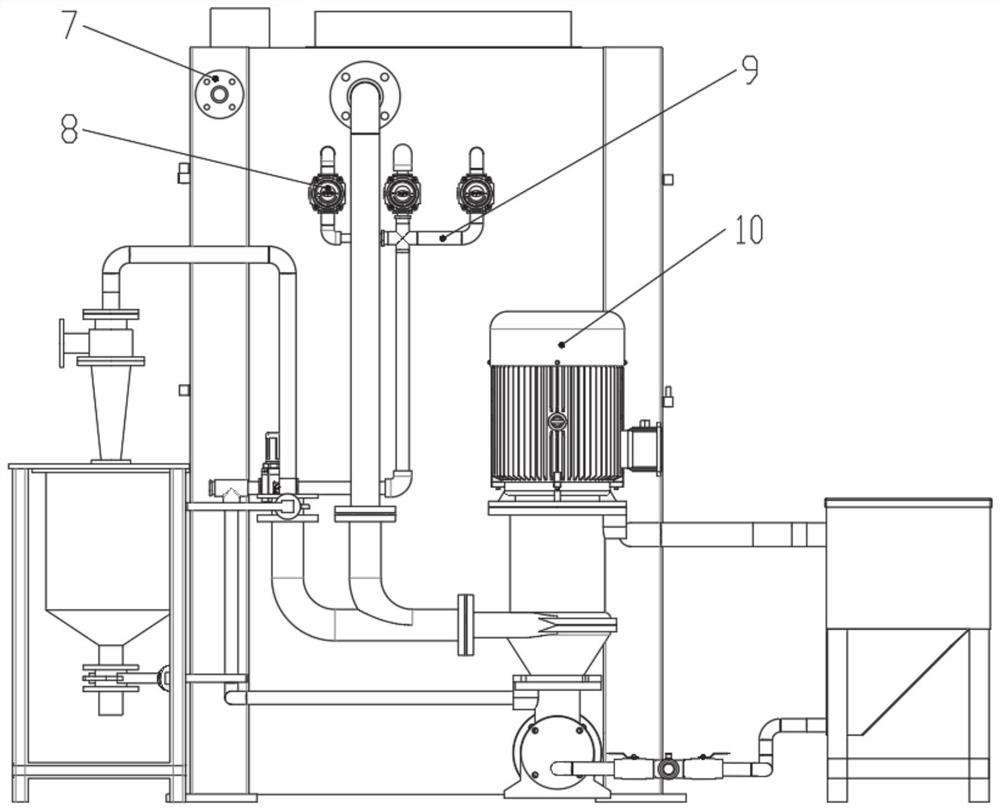

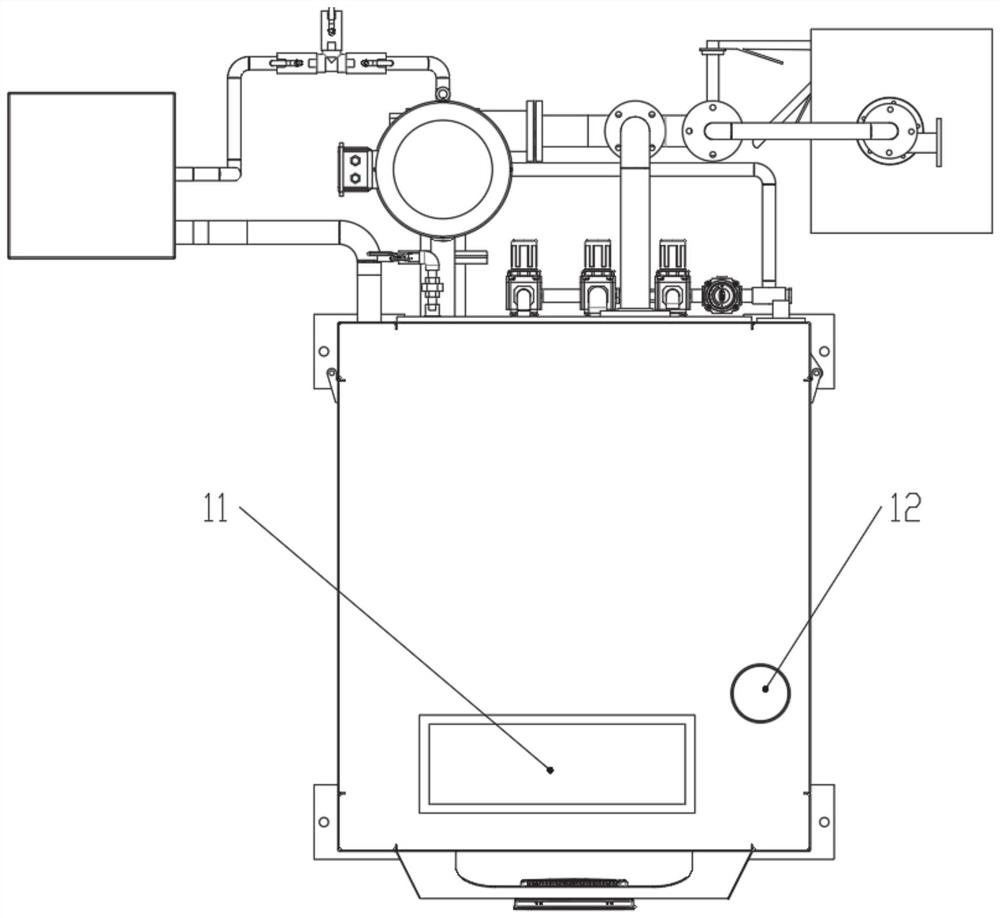

[0037] In a typical implementation of the present disclosure, such as Figure 1-Figure 7 As shown, a sandblasting device for post-treatment of the surface of a cast valve body is provided.

[0038] It includes a sandblasting mechanism, a sandblasting supply mechanism, a working cabin 1, a three-axis motion mechanism and a fixture turntable 19;

[0039] The sandblasting supply mechanism passes through the outer wall of the working cabin 1 to communicate with the sandblasting mechanism inside the working cabin 1. The three-axis motion mechanism and the fixture turntable 19 are located in the working cabin 1. The fixture turntable 19 is arranged opposite to the sandblasting mechanism. The mechanism faces the workpiece on the fixture turntable 19, and outputs sand flow to sandblast the workpiece. A reflow box 20 is provided below the turntable 19 to receive the recycled sand flow.

[0040] Based on the characteristics of the most common three-opening valve body parts (such as top...

Embodiment 2

[0068] In another typical implementation of the present disclosure, such as Figure 1-Figure 7 As shown, a sandblasting method for the post-treatment of the surface of the cast valve body is proposed, using the sandblasting device for the post-treatment of the surface of the cast valve body as described in Example 1.

[0069] Include the following steps:

[0070] Mixed blasting material:

[0071] Put the sand into the grinding liquid return tank 20 through the hatch, add water to the interior of the working cabin 1 through the water inlet pipe, and then initially mix the grinding liquid. The reflux box 20 realizes uniform mixing of water and sand.

[0072] Sandblasting:

[0073] After the sandblasting materials are mixed evenly, the abrasive liquid pump 10 starts the external circulation of the abrasive liquid. At this time, the abrasive liquid pump 10 is used to provide the feeding power, and the abrasive liquid is transported to the three sandblasting hose spray guns 13 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com