Vortex exhaust structure of automobile engine

An automotive engine, eddy current technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as dead ends of airflow, difficult exhaust gas discharge, and increased pressure, so as to speed up flow, improve fuel injection combustion rate, and improve Smooth air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

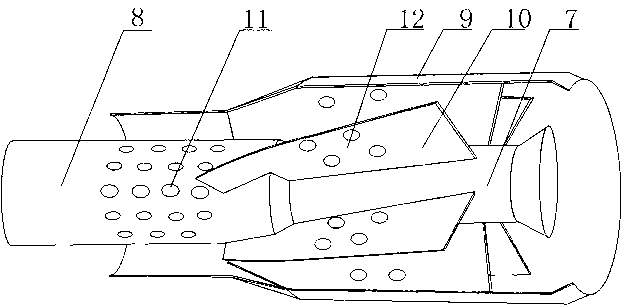

[0017] Such as figure 1 Shown, the present invention is installed on the exhaust pipe of engine, comprises a flow regulating cylinder 7, and one end of flow regulating cylinder 7 is connected on the air-inducing cylinder 8, and air-inducing cylinder 8 is as the part that is connected with the output end of exhaust pipeline, and flow rate The regulating cylinder 7 has an exhaust structure, and can adjust its exhaust volume. On the side wall of the air-inducing cylinder 8, a plurality of air distribution holes 11 are arranged, and a cladding 9 is also included. The structure of the cladding 9 is cylindrical as a whole. , its two ends are arc-shaped or tapered, and the cladding 9 covers the air distribution holes 11, and six drainage plates 10 are installed between the cladding 9 and the flow regulating cylinder 7, and the six drainage plates 10 are evenly distributed in the flow regulating 7, and extend to the outside of the air-inducing tube 8, six baffles 10 are arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com