Patents

Literature

67results about How to "No manual flipping required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

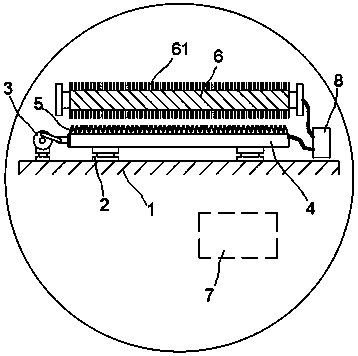

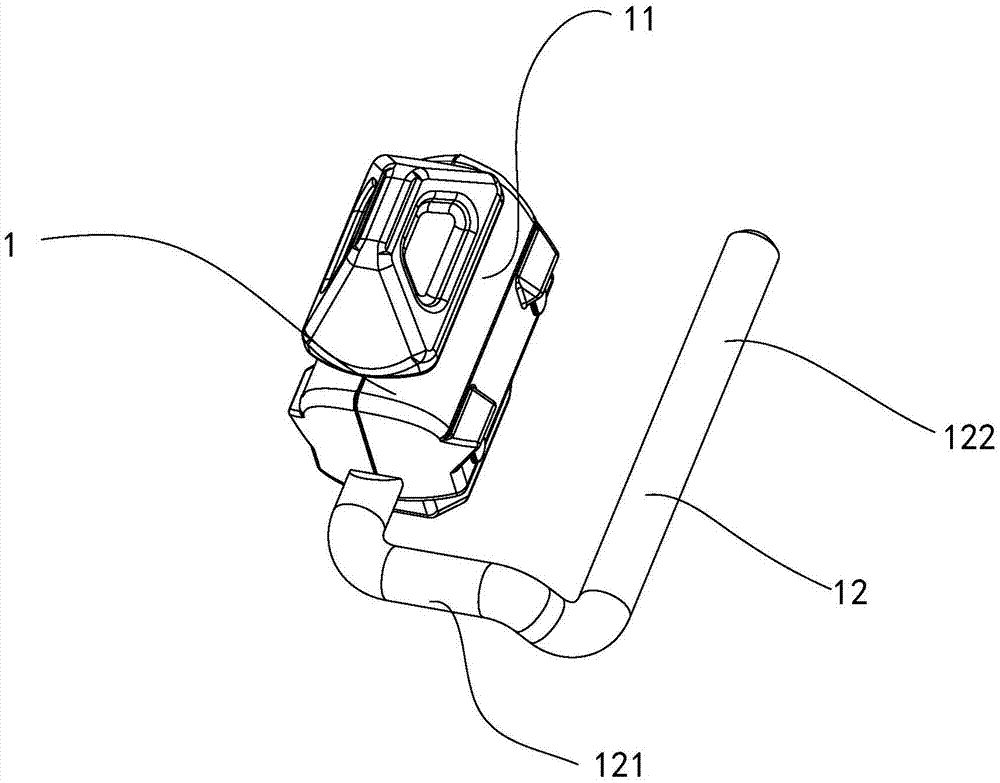

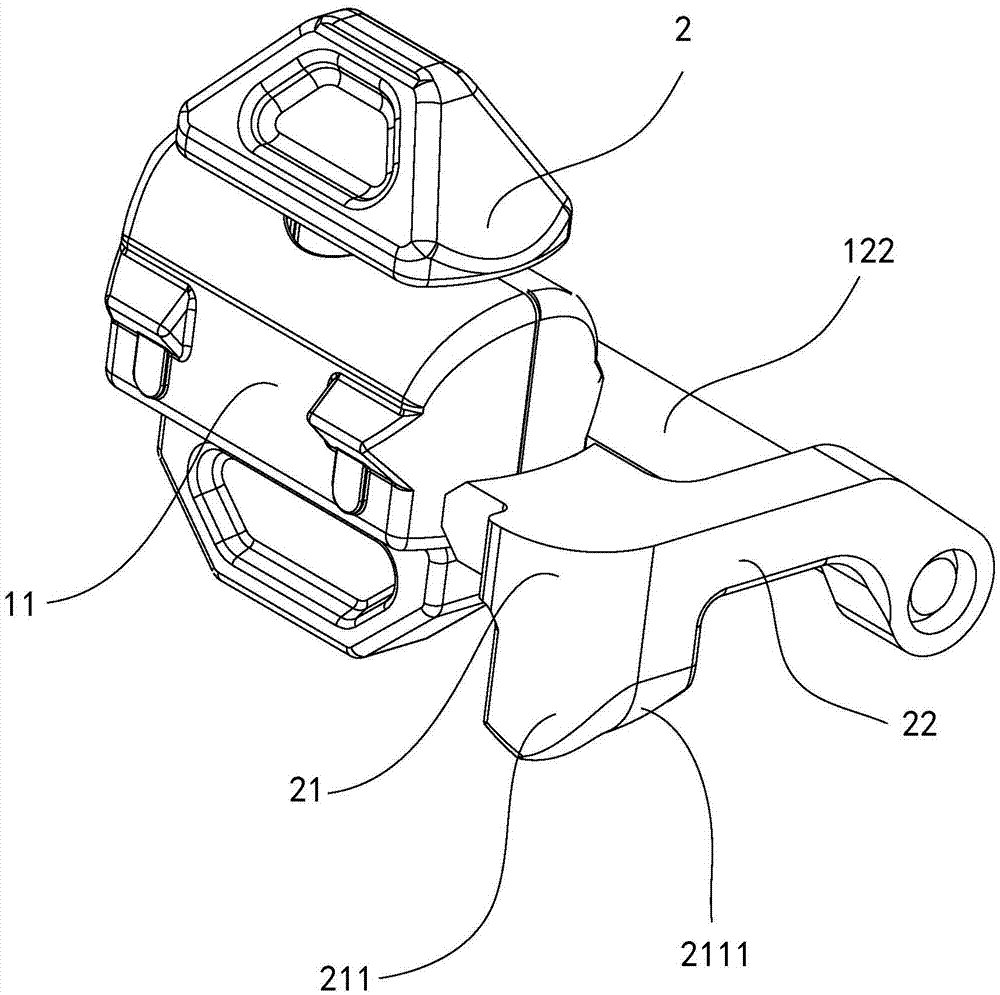

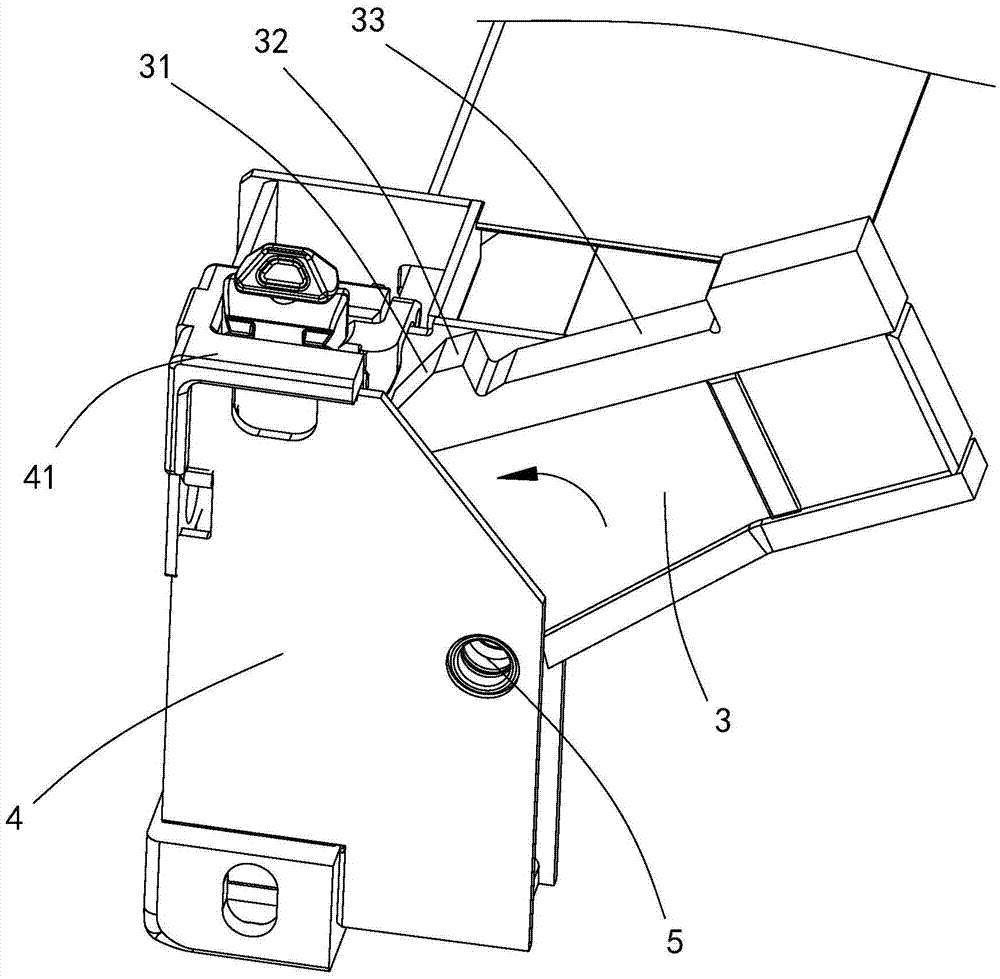

Sweeper anti-winding device

ActiveCN108245084ASmooth rotationAutomate cleaningCarpet cleanersFloor cleanersMechanical engineering

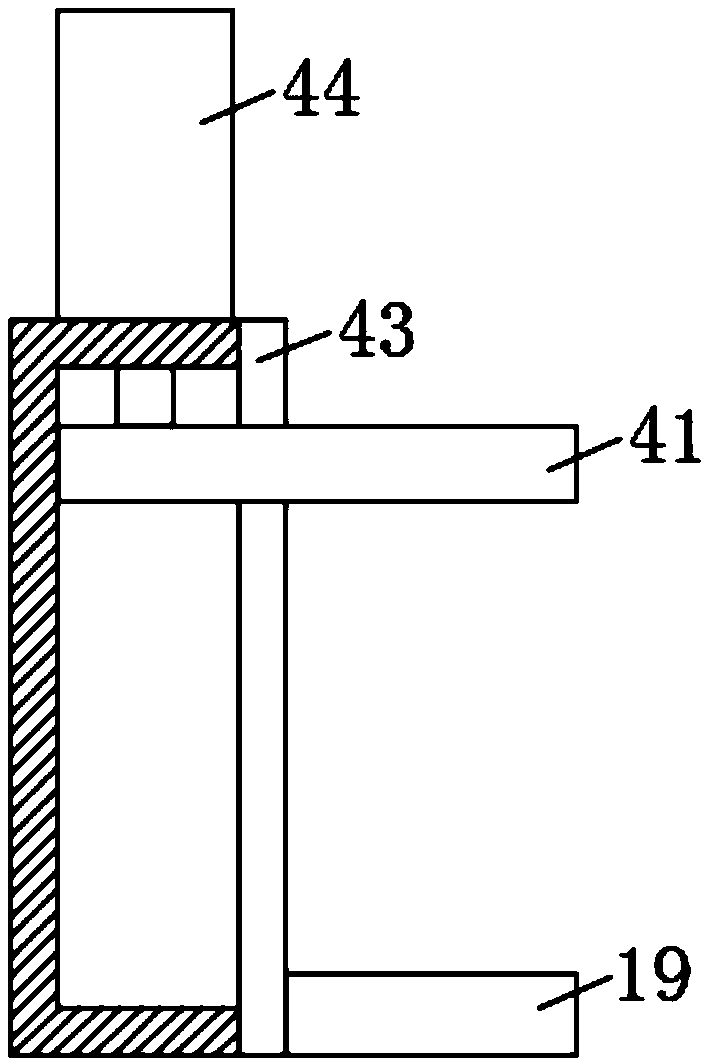

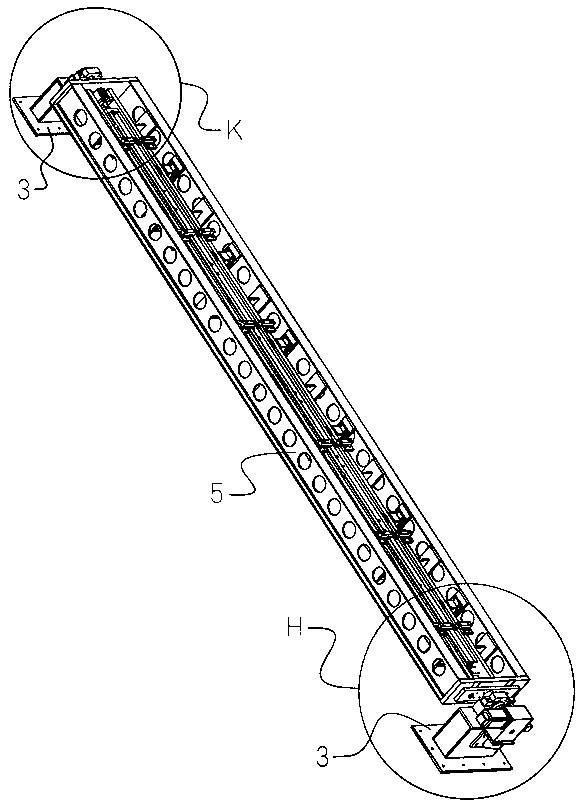

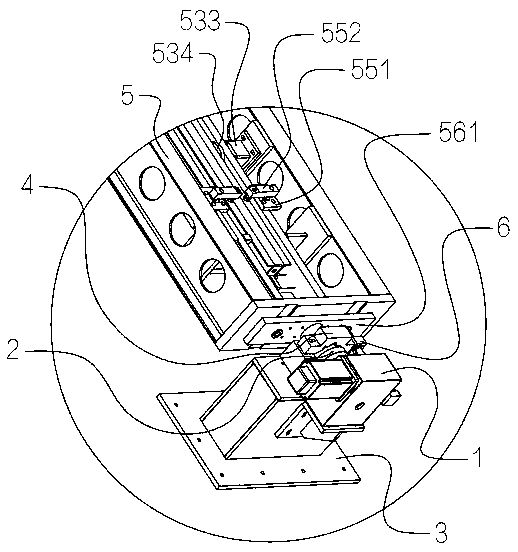

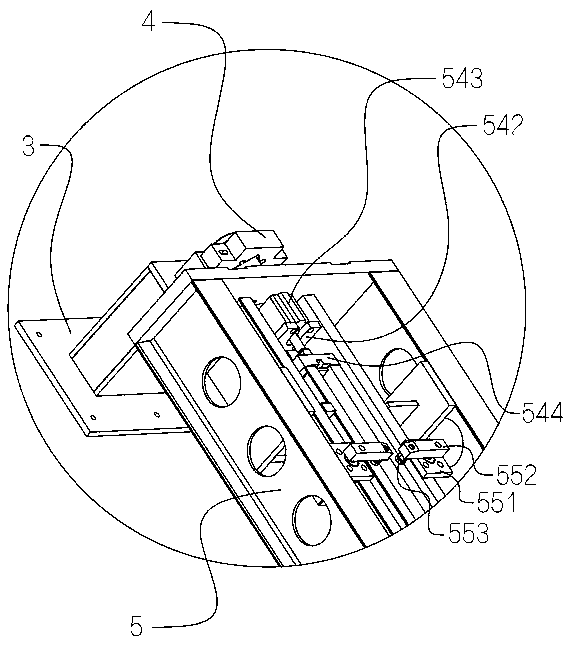

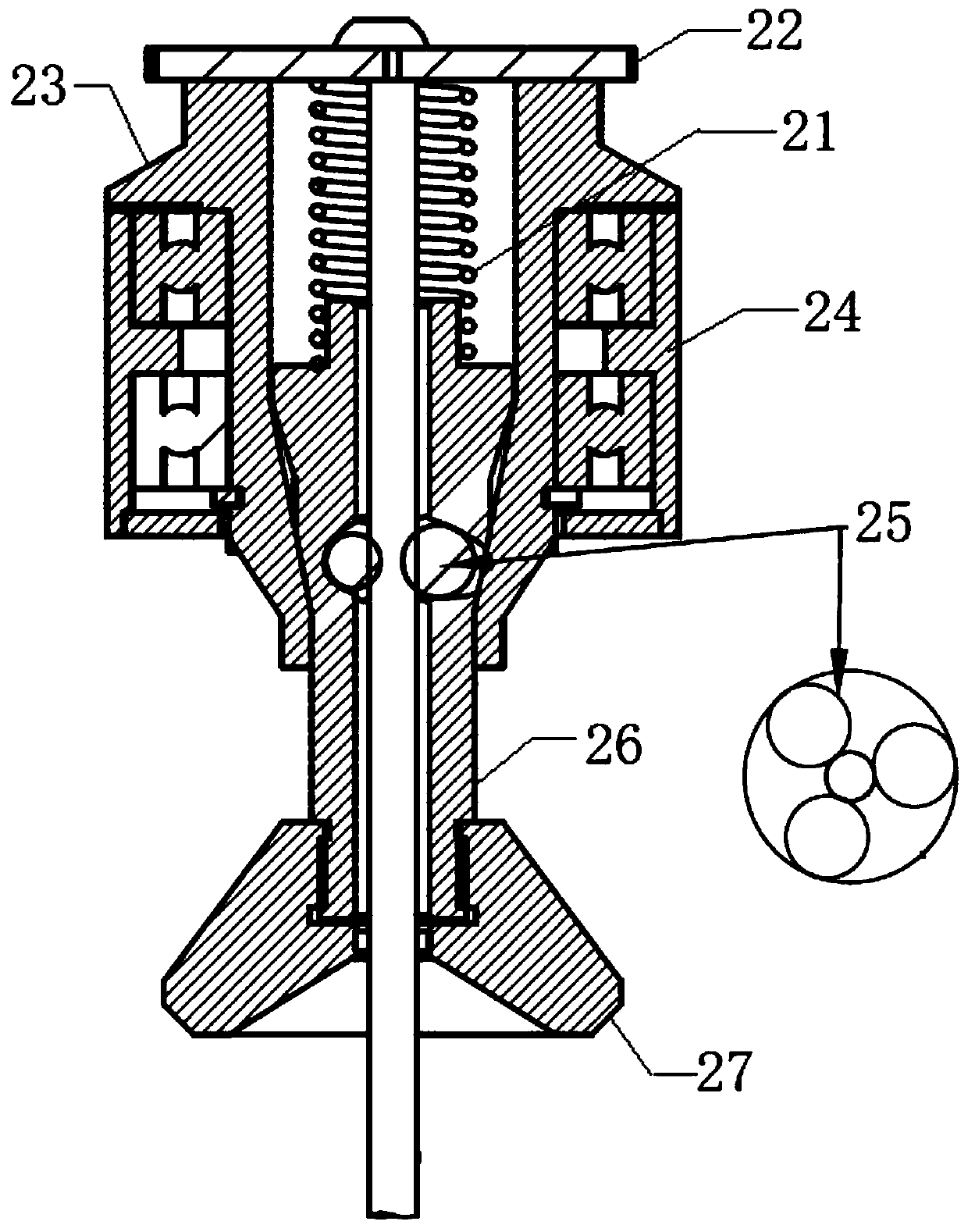

The invention relates to a sweeper anti-winding device which comprises a support seat, telescopic rods, a driver and a cutting device. The driver and the cutting device are connected on the support seat through the telescopic rods, the cutting device comprises a pair of opposite matched cutting strips, the two cutting strips include a driving strip and a driven strip, the driven strip is fixedly connected with the ends of the telescopic rods, the driving strip is slidably connected with the ends of the telescopic rods, the driving strip can reciprocate and translate on the axis of the drivingstrip under driving of the driver, the axes of the two cutting strips are parallel to the axis of a rolling brush, cutting teeth are axially and equidistantly arranged on the cutting strips, and the telescopic rods, the driver and the cutting device are electrically connected with a computer chip in a body. The sweeper anti-winding device is novel and unique in structure, impurities such as hair and thread ends wound on the rolling brush can be efficiently removed, the sweeping effect of a sweeper is ensured, the impurities wound on the rolling brush can be cut off, and the rolling brush is effectively protected.

Owner:ZHEJIANG LANYU INTELLIGENT TECH CO LTD

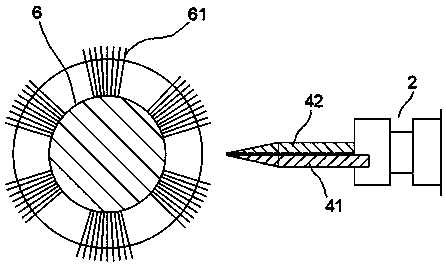

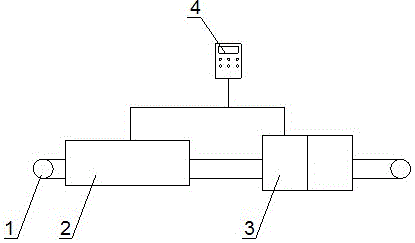

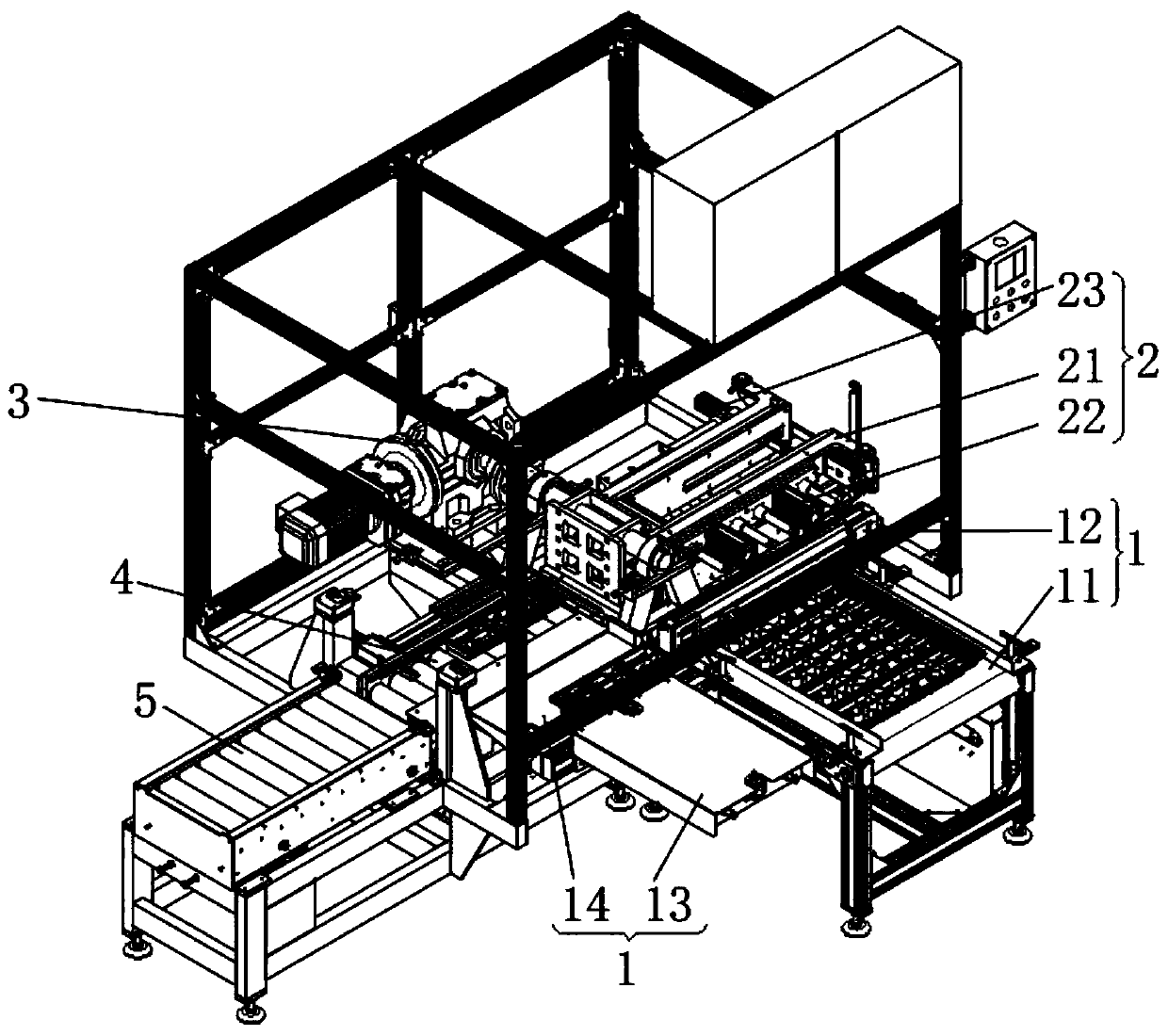

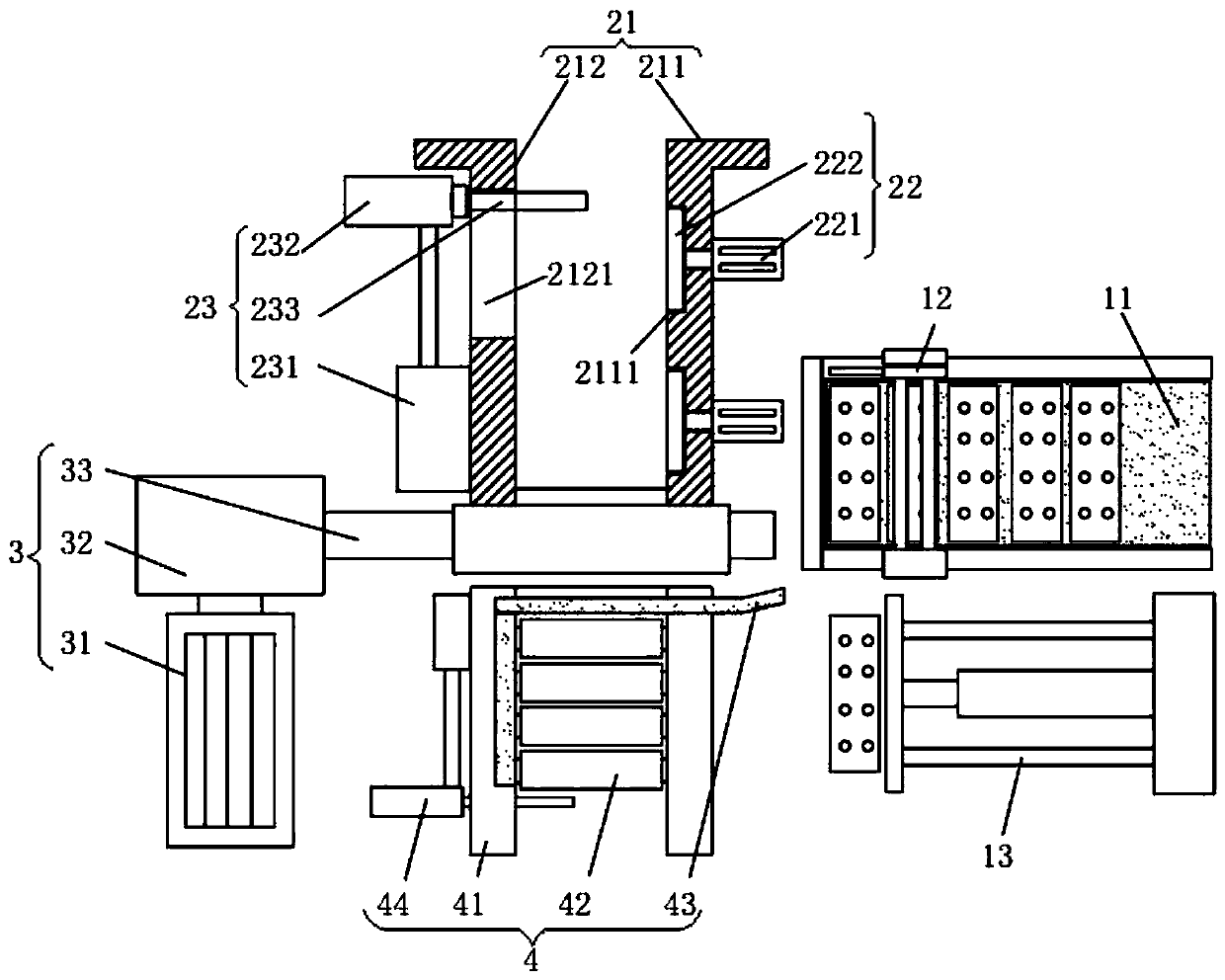

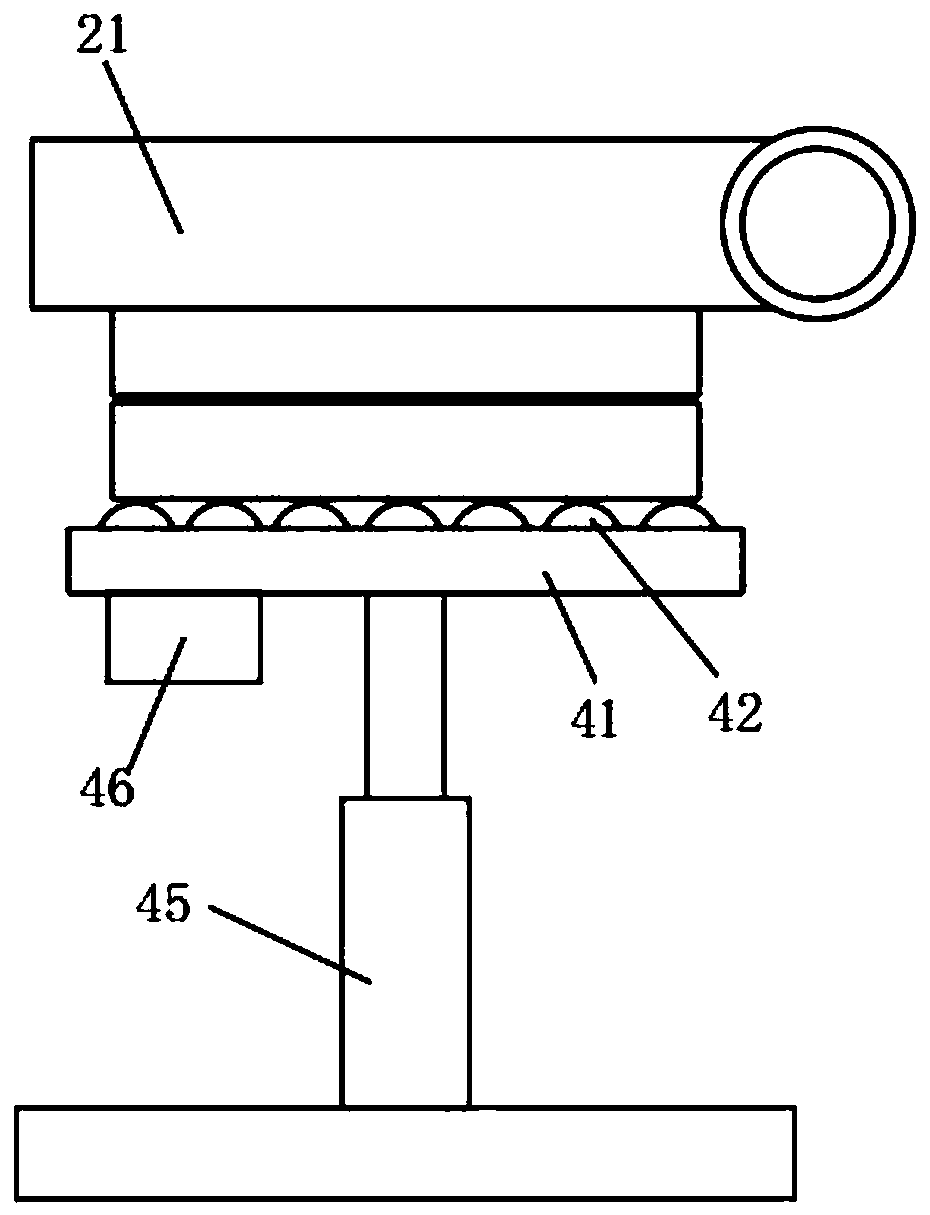

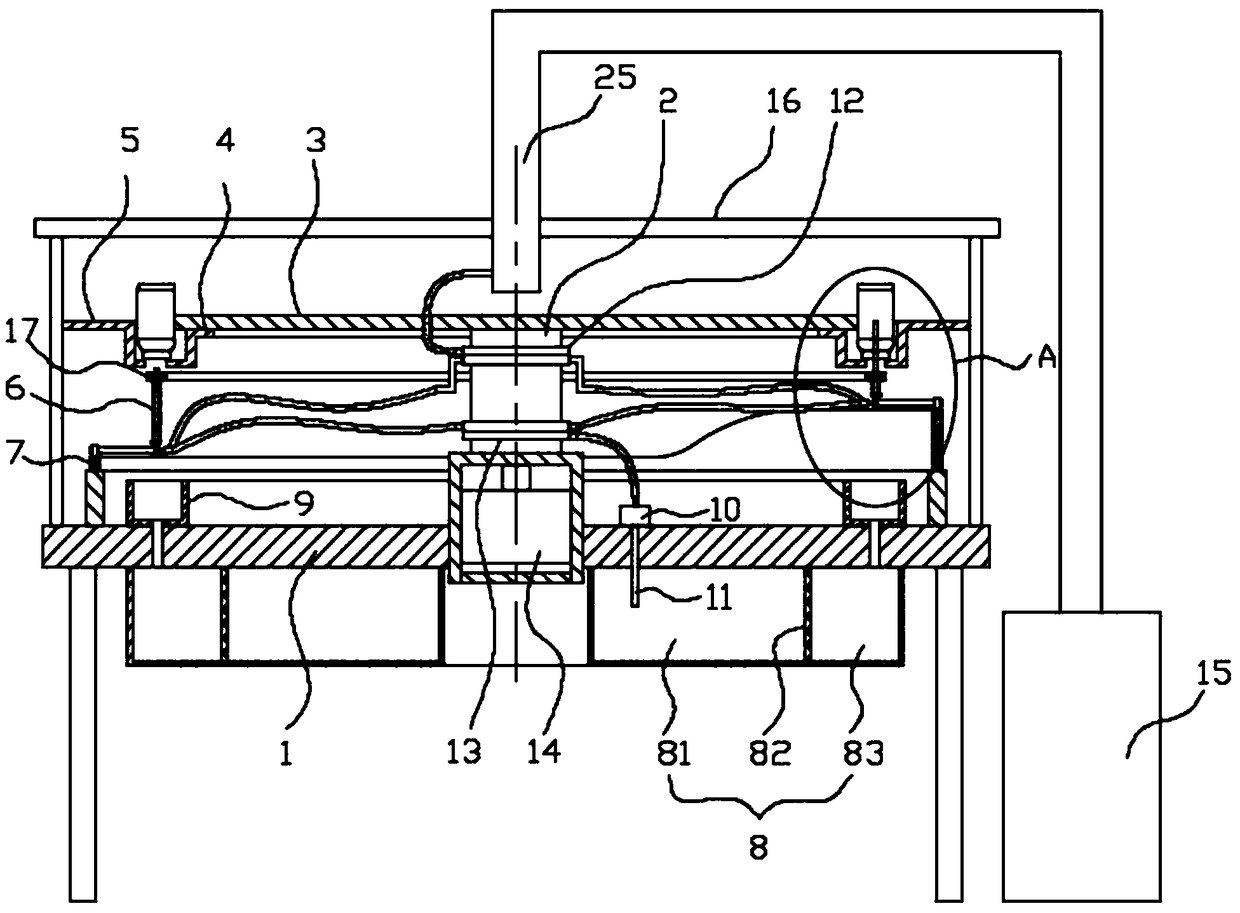

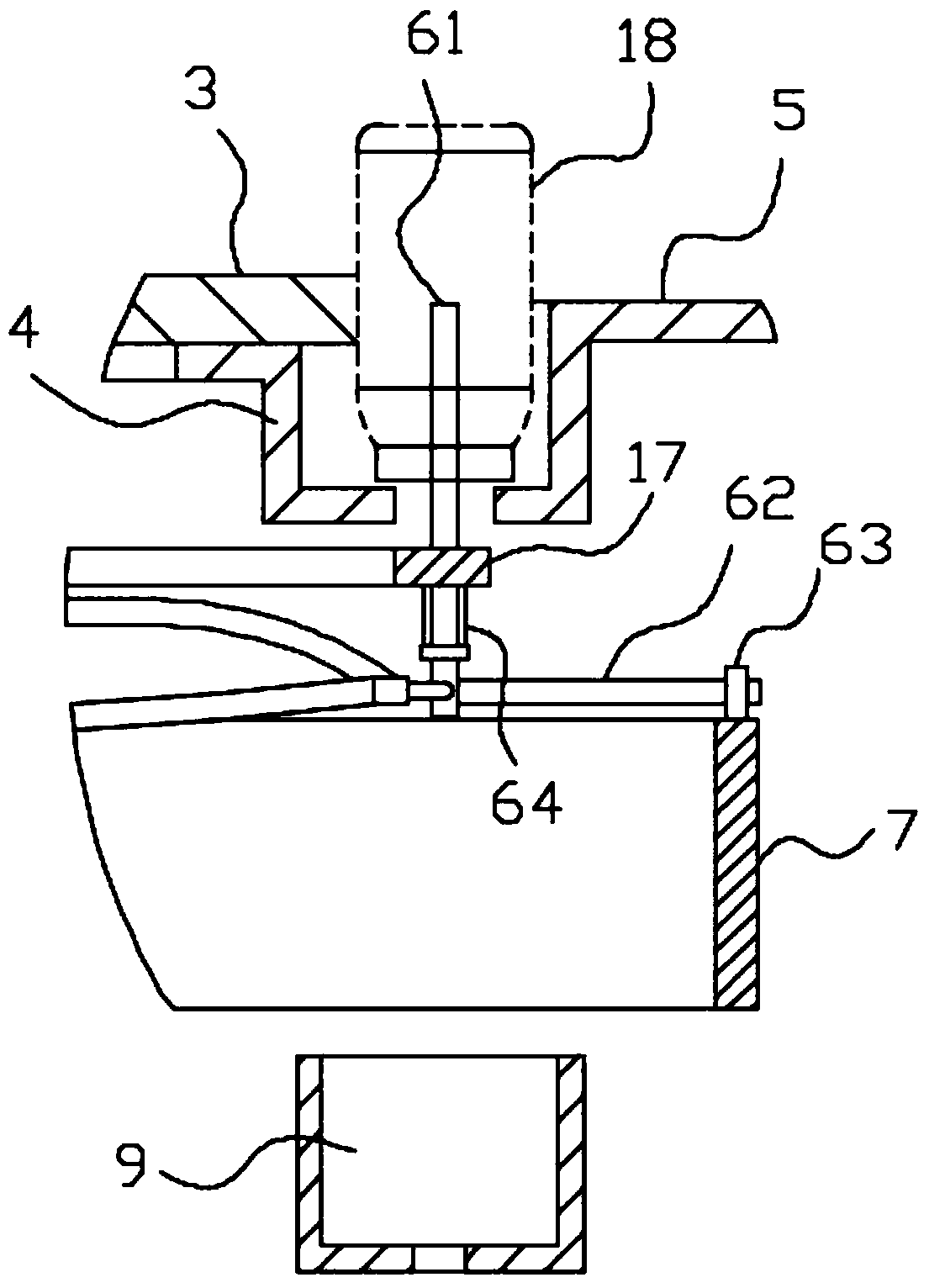

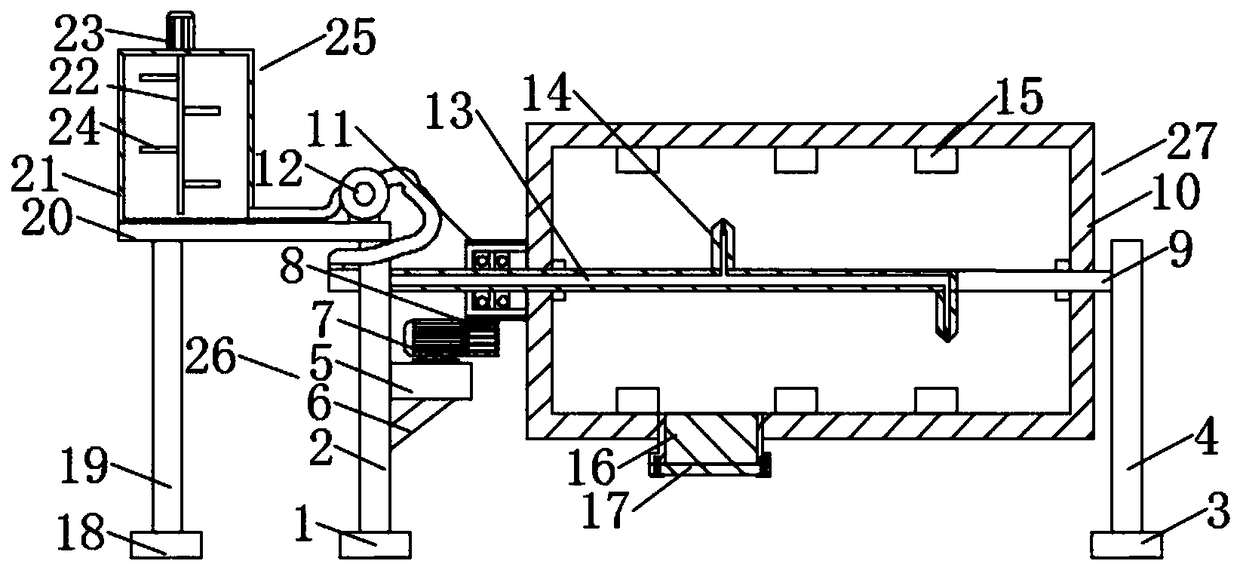

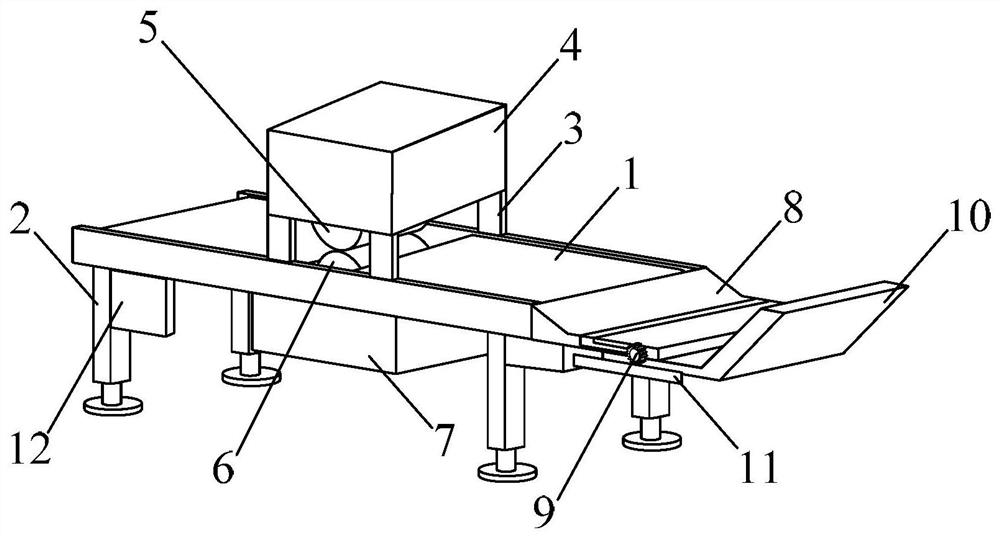

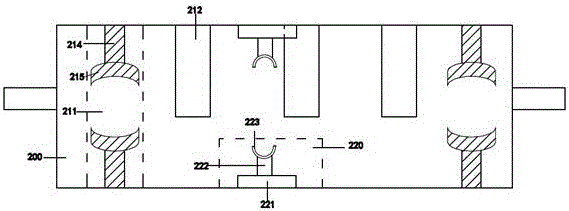

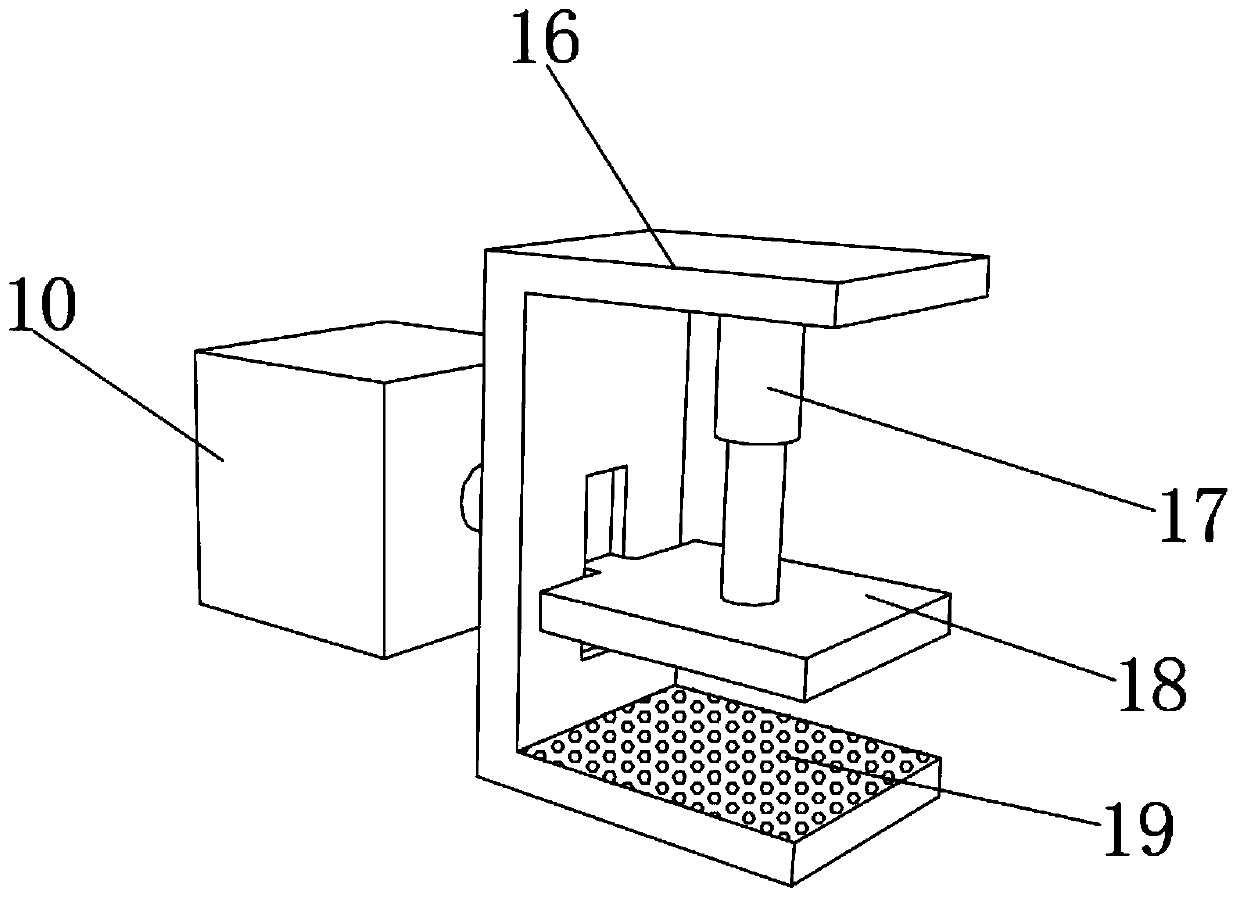

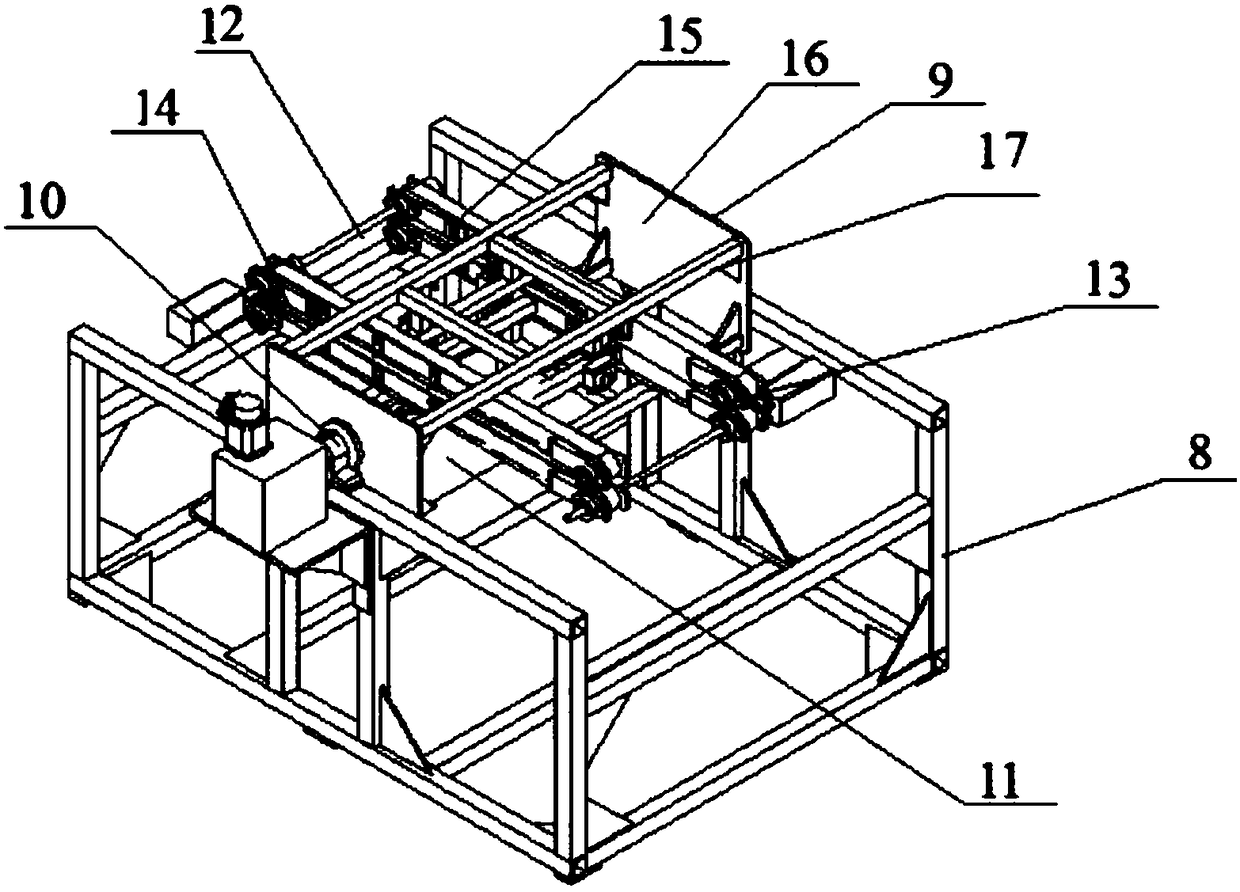

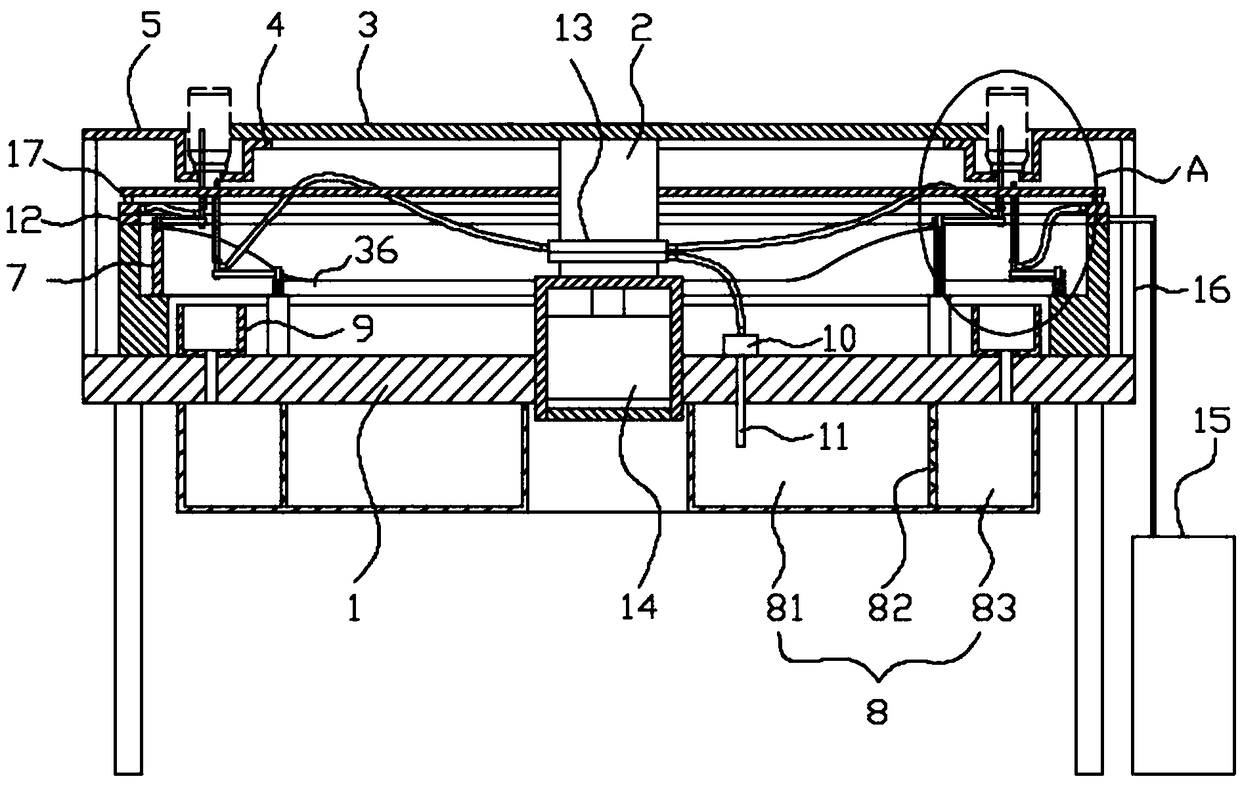

Metal surface rust-removing and sandblasting device

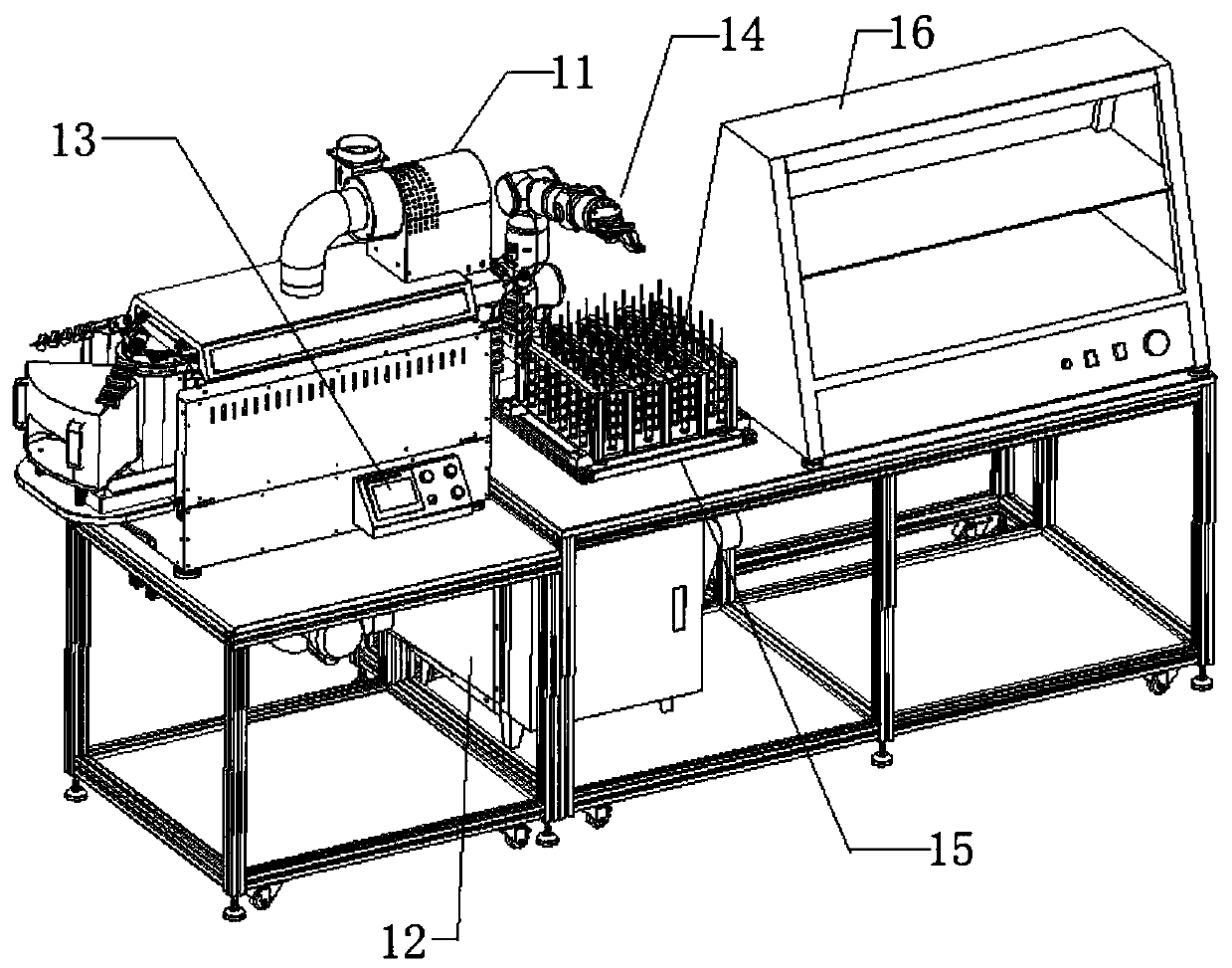

InactiveCN108927737AEasy to useImprove filtering effectAbrasive machine appurtenancesAir purifiersSand blasting

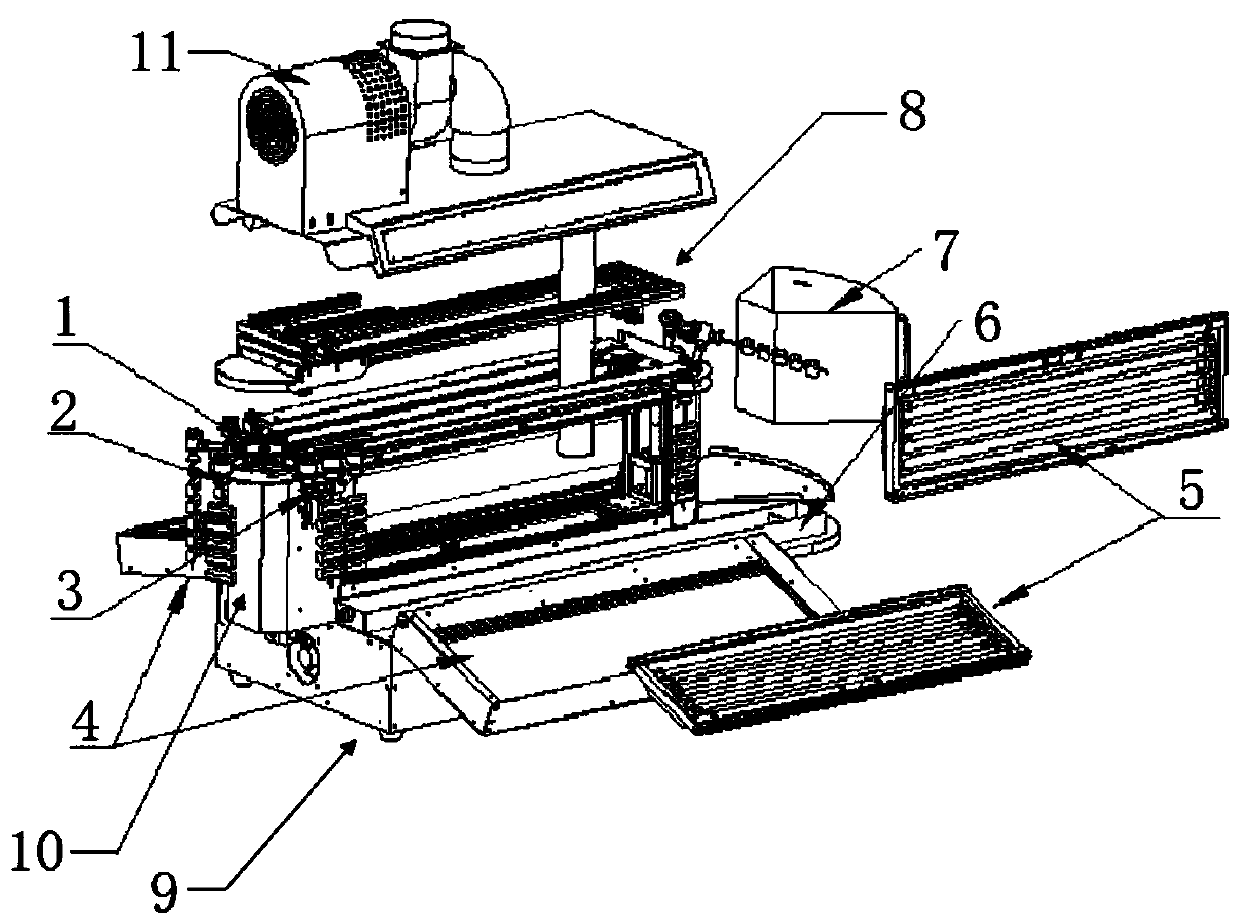

The invention discloses a metal surface rust-removing and sandblasting device, which comprises a sandblasting device body. The sandblasting device body is composed of a work box, an overturn mechanism, an air purifier, a sandblasting mechanism, and an adjusting mechanism. One side of the work box is connected to the overturn mechanism. The interior of the work box is connected to the adjusting mechanism. The structure is compact and thus the device is very convenient for metal rust removing and sandblasting. Due to the overturn mechanism, during sandblasting, the workpiece can be automaticallyoverturned by the overturn mechanism without any artificial intervention, time and labor are saved, the sandblasting becomes more uniform, the rusts can be removed more radically, the work efficiencyis largely improved, the practicality is strengthened; through the adjusting mechanism, the sandblasting becomes omnidirectional, no dead angle exists, due to a sealed space, the blasting sand can berecovered, moreover, the generation of waste gas that pollutes the atmosphere is avoided; the air purifier can purify the exhaust gas, and the work environment is improved for the workers.

Owner:诸葛佳缘

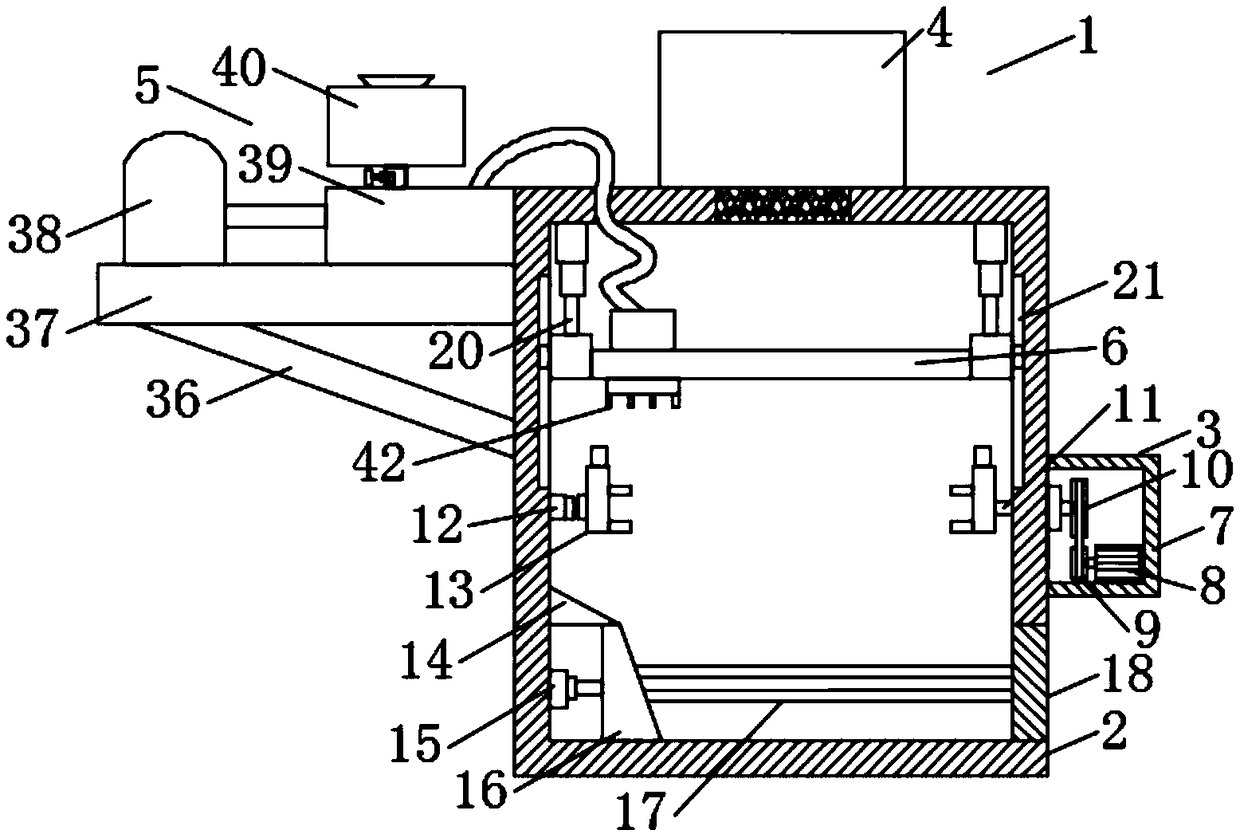

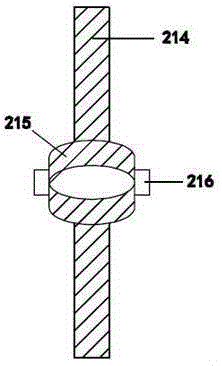

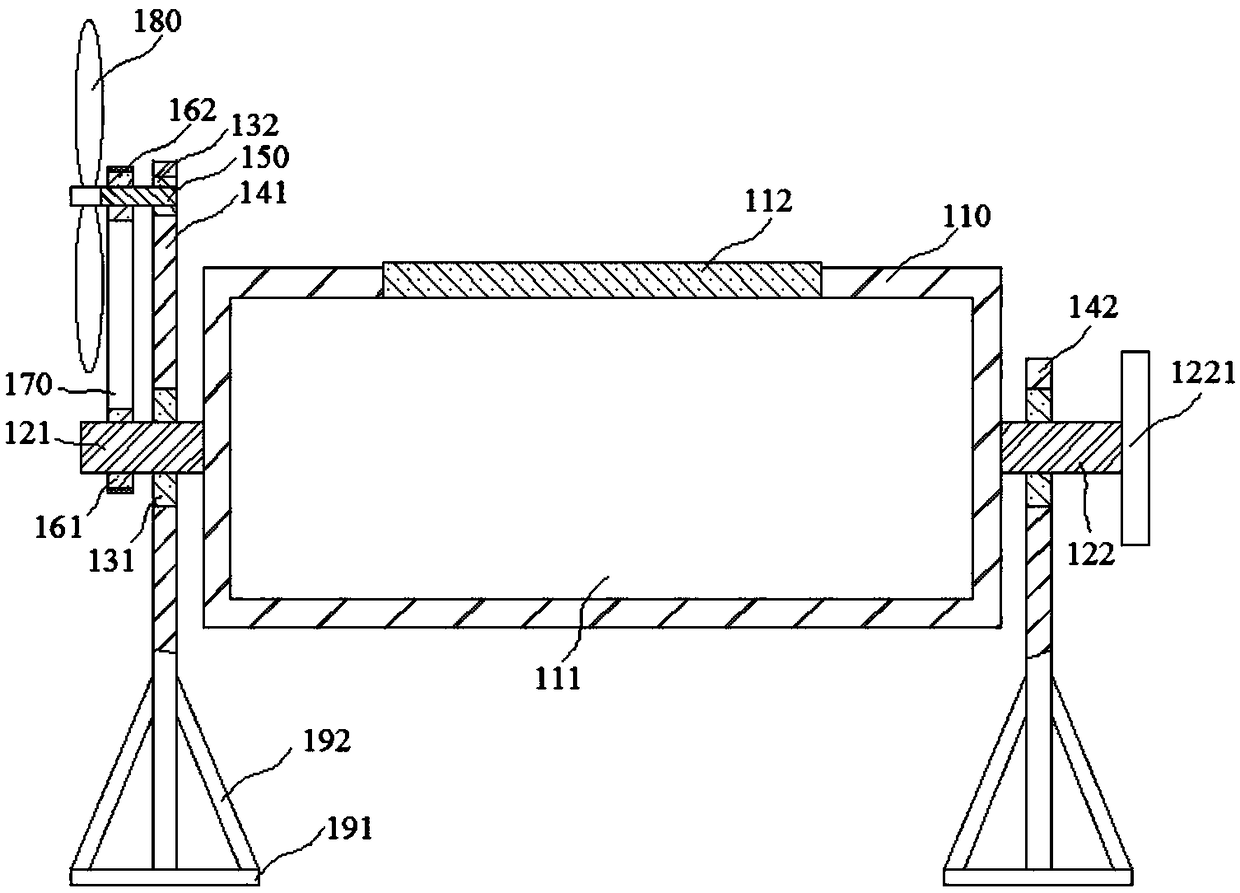

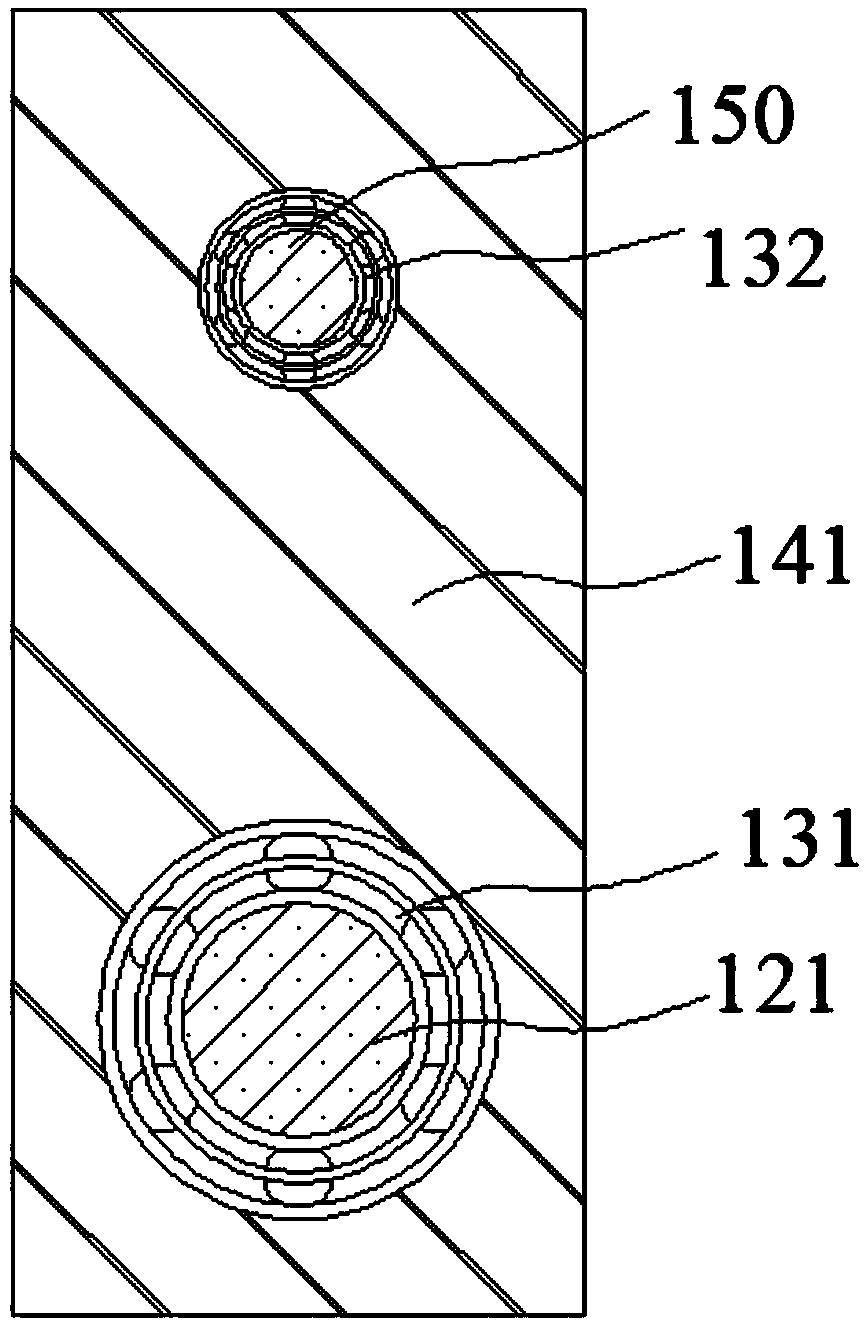

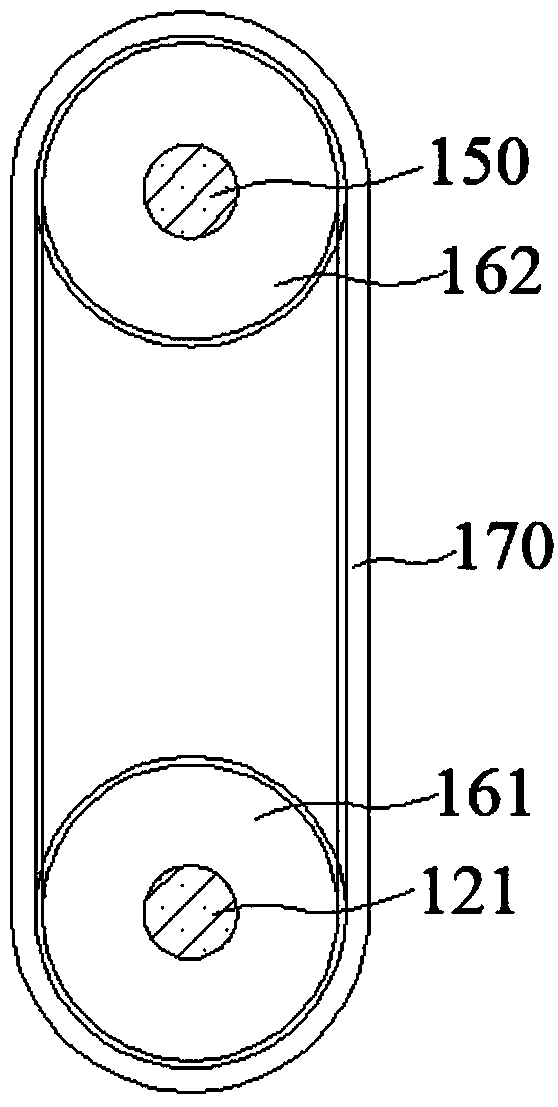

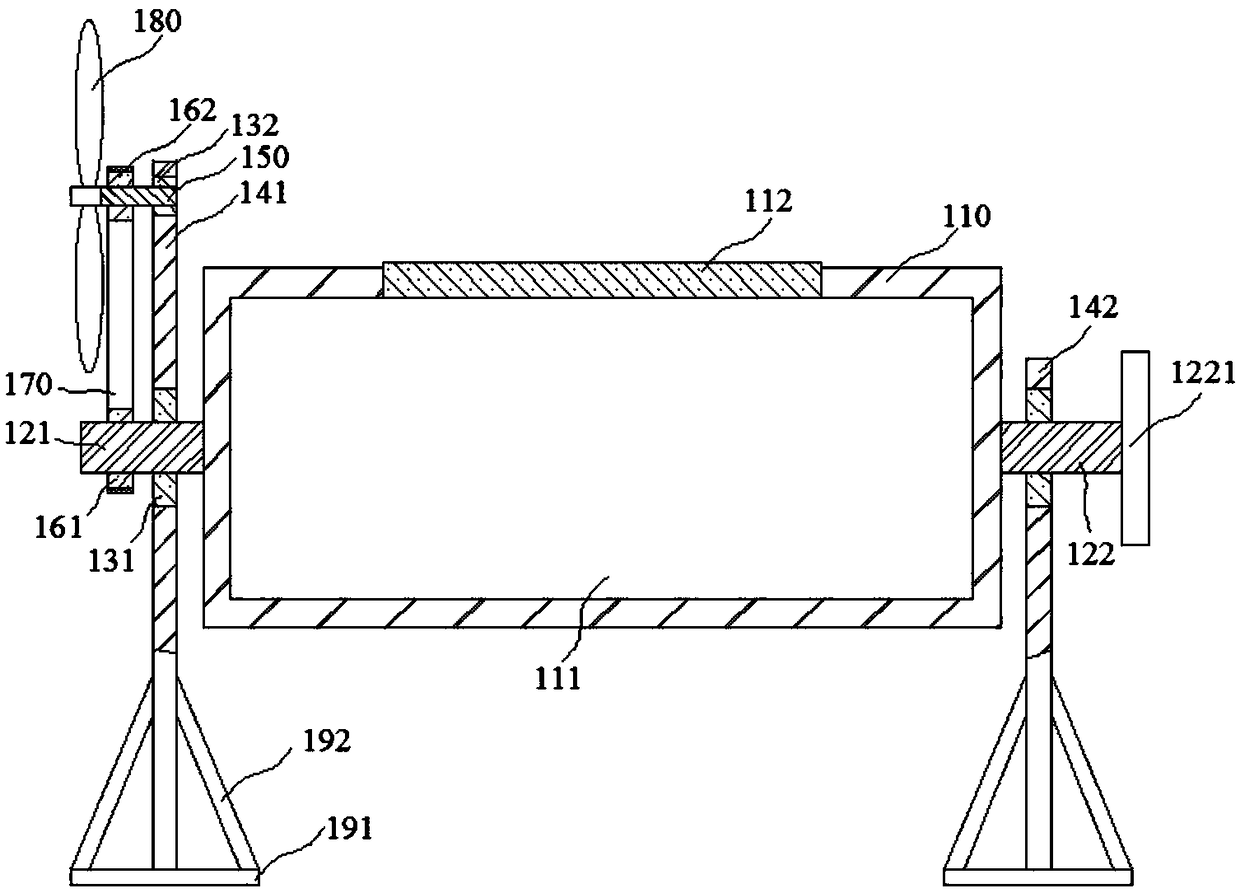

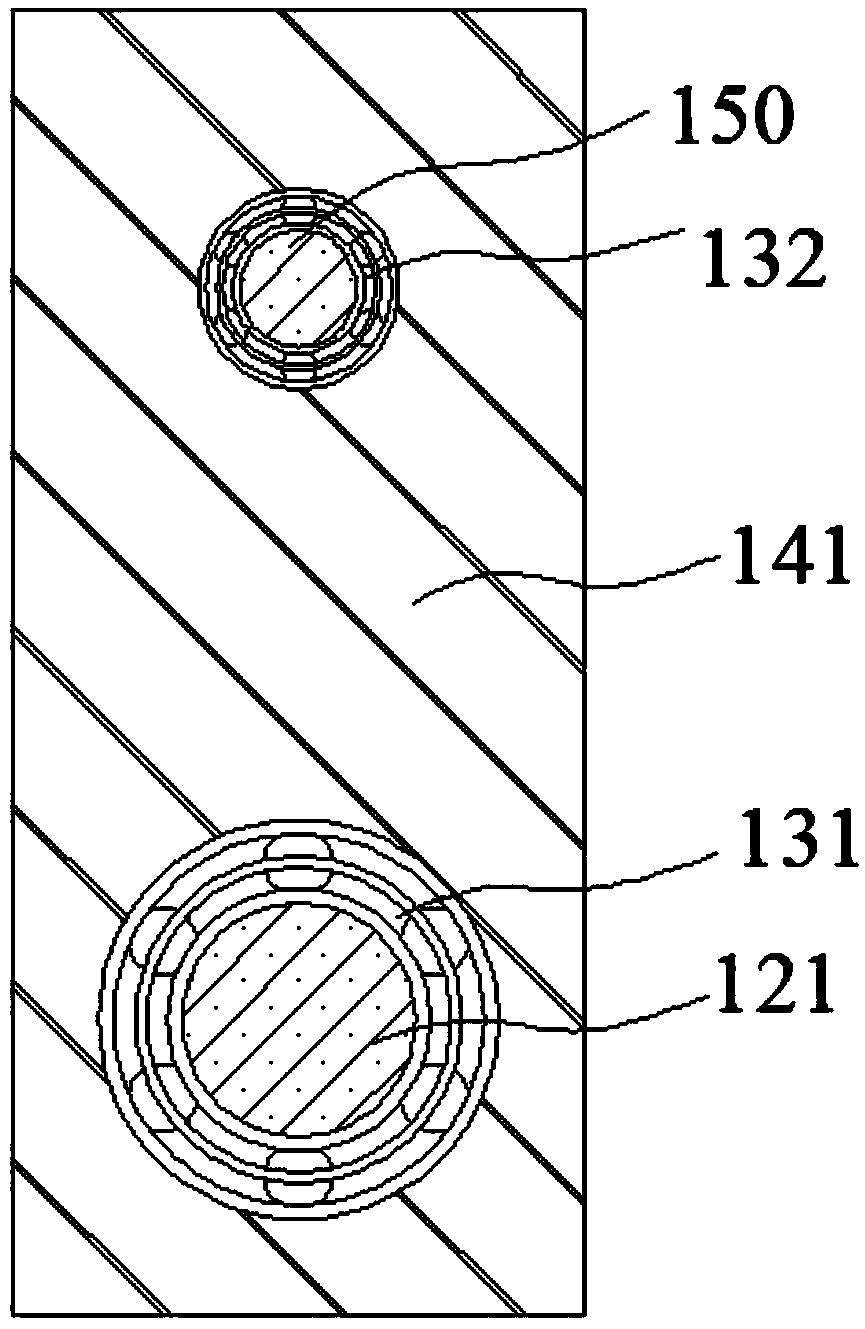

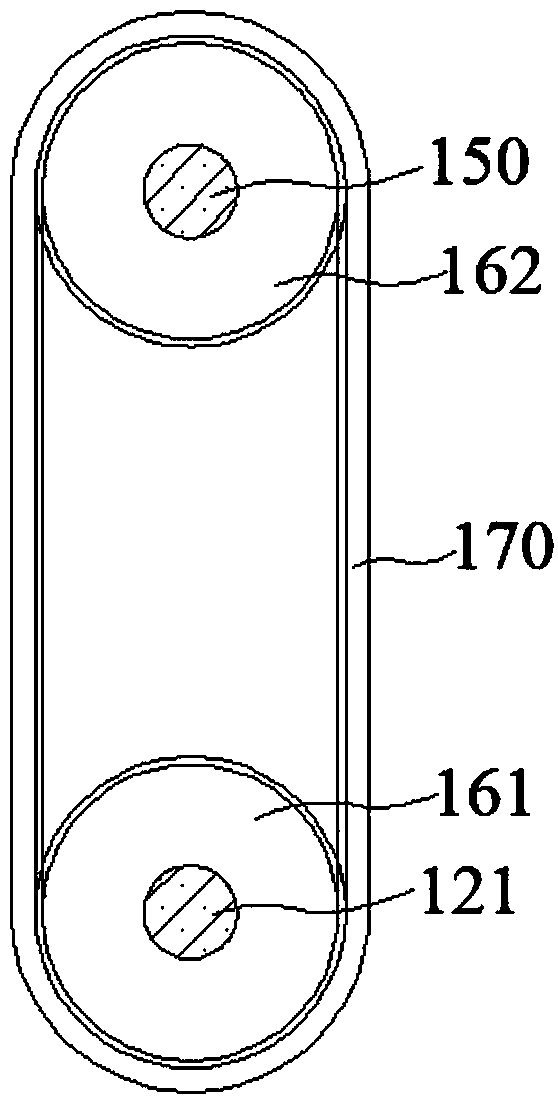

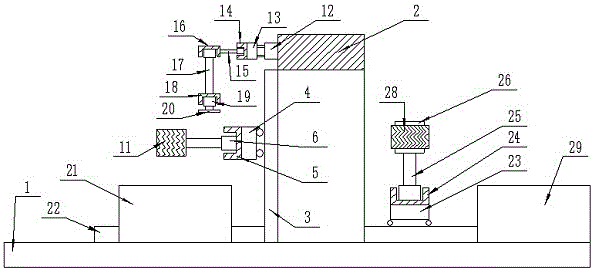

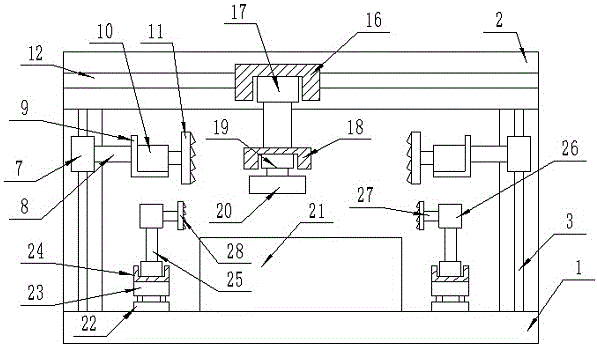

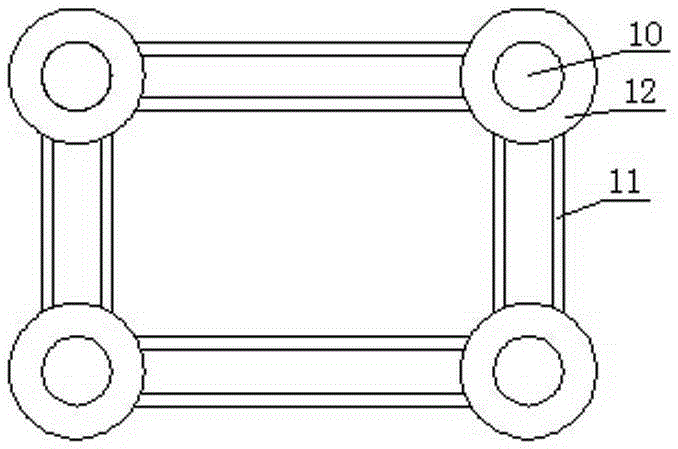

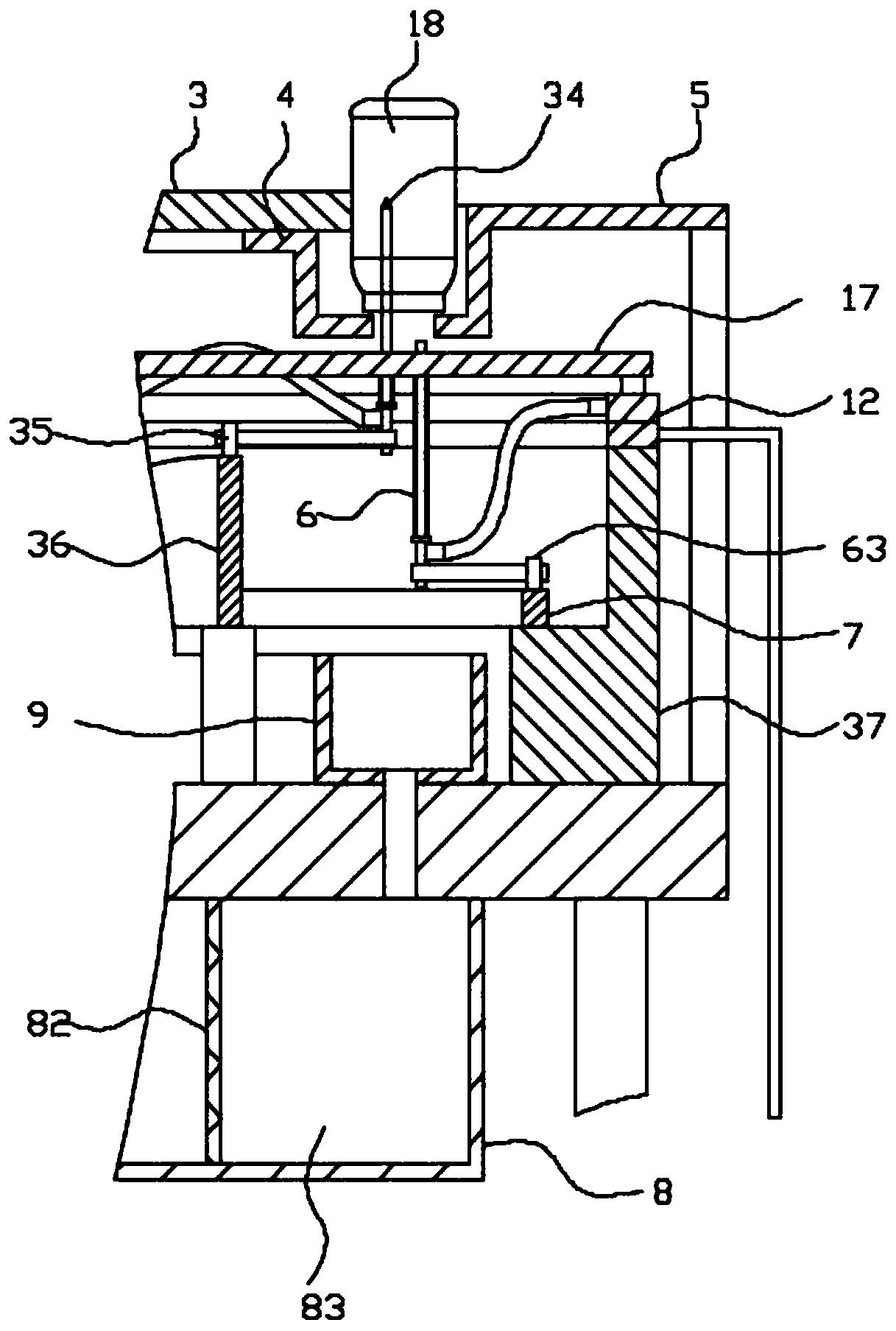

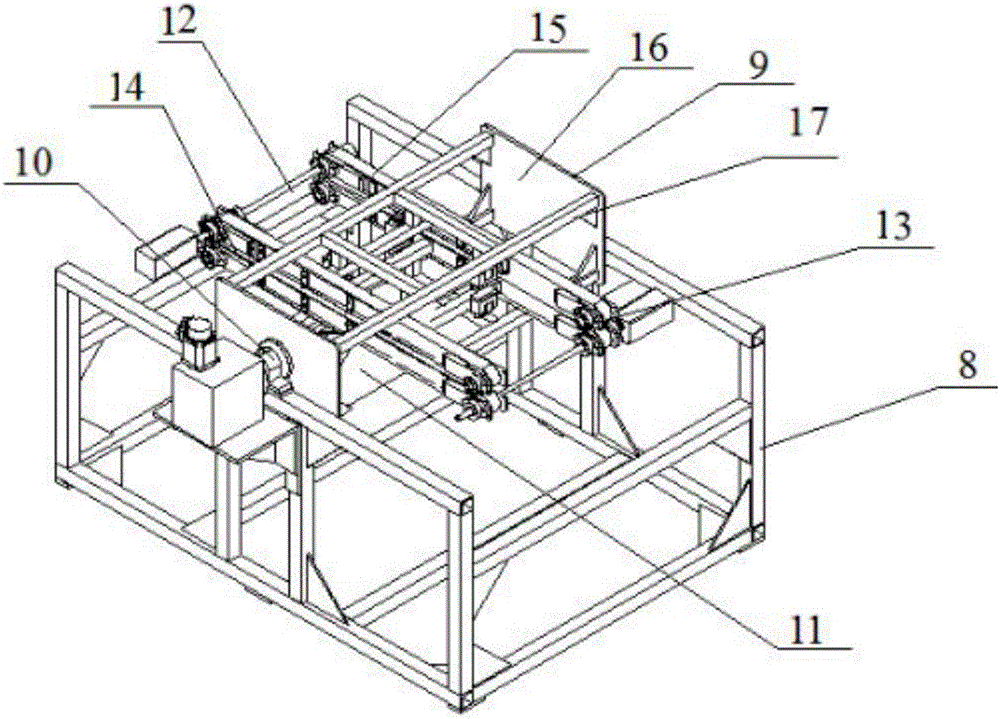

Welding clamp of guide rail of inserted lift scaffold

PendingCN110039236ALow technical proficiency requirementsEliminate destructionWelding/cutting auxillary devicesAuxillary welding devicesAssistive device/technologyEngineering

The invention relates to the technical field of auxiliary equipment for welding and discloses a welding clamp of a guide rail of an inserted lift scaffold. The welding clamp comprises a motor, a rectangular framework and supporting seats; rotary shafts are connected to the two ends of the rectangular framework correspondingly; the two rotary shafts are rotationally connected to the two supportingseats correspondingly; the motor is connected to the supporting seats; the rotary shafts are in transmission connection with output shaft of the motor; and a workpiece station for containing the guiderail and a clamping part for clamping the guide rail are disposed in the rectangular framework. The rectangular framework and the guide rail which is clamped onto the rectangular framework are drivenby the motor to turn over together, automatic over-turning is achieved, the potential safety hazards which exist during manual over-turning are avoided, manpower and time can be greatly saved, over-turning is convenient, operation is simple, the automation degree is high, the requirement for technical proficiency of an operator is low, the production efficiency can be improved, the damage to welding seams during manual over-turning is eliminated, the welding quality is improved, and the welding clamp can cooperate with a welding robot during automatic production for use.

Owner:SENHY CONSTR +1

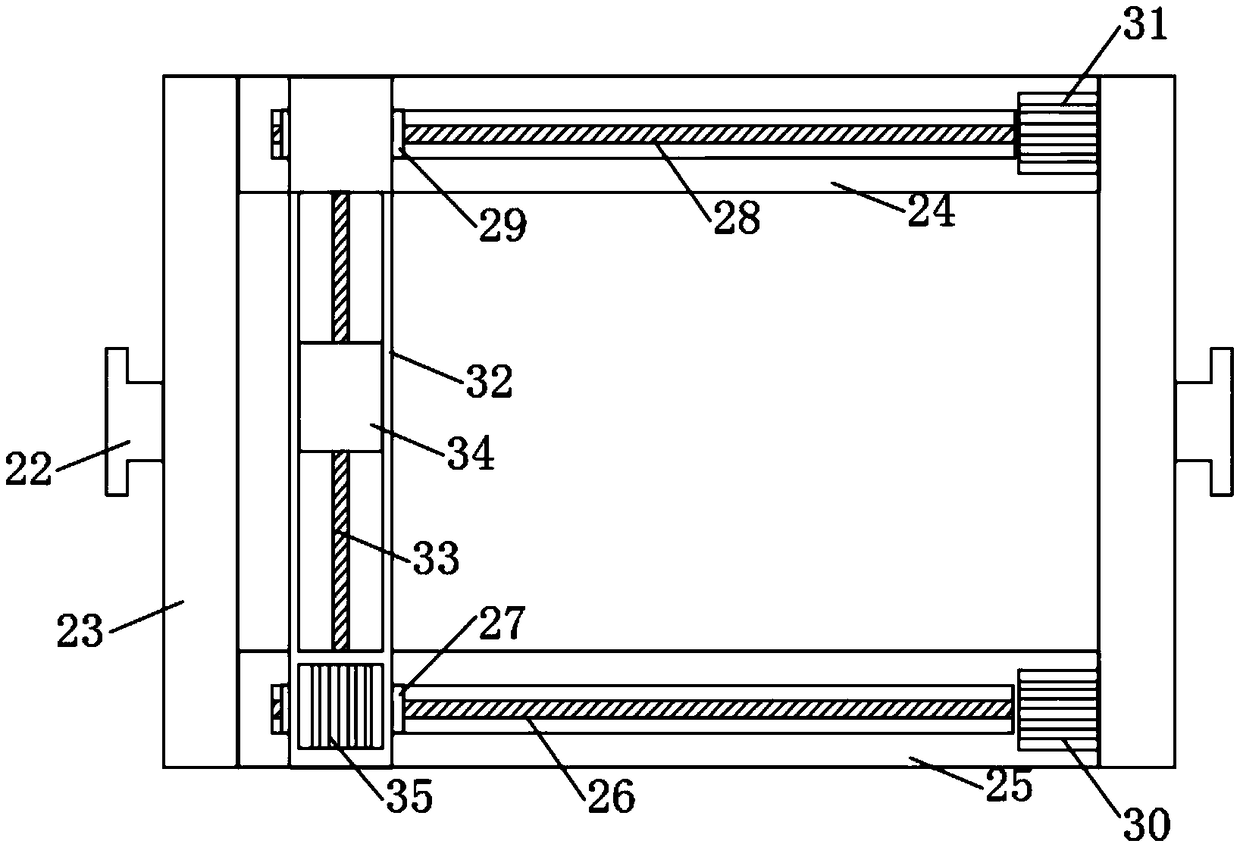

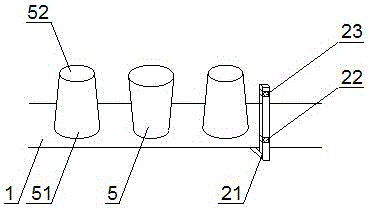

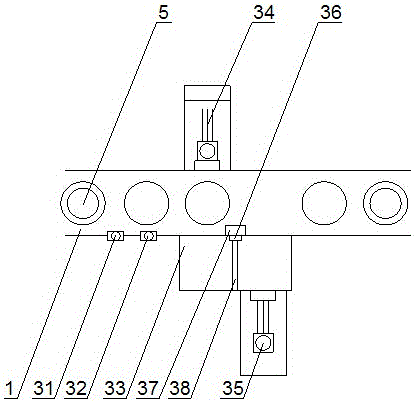

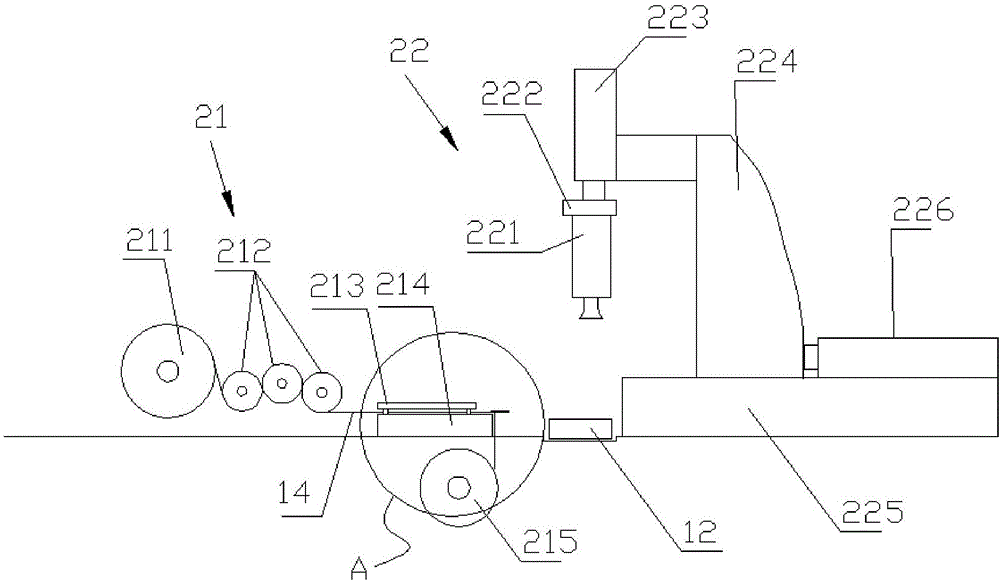

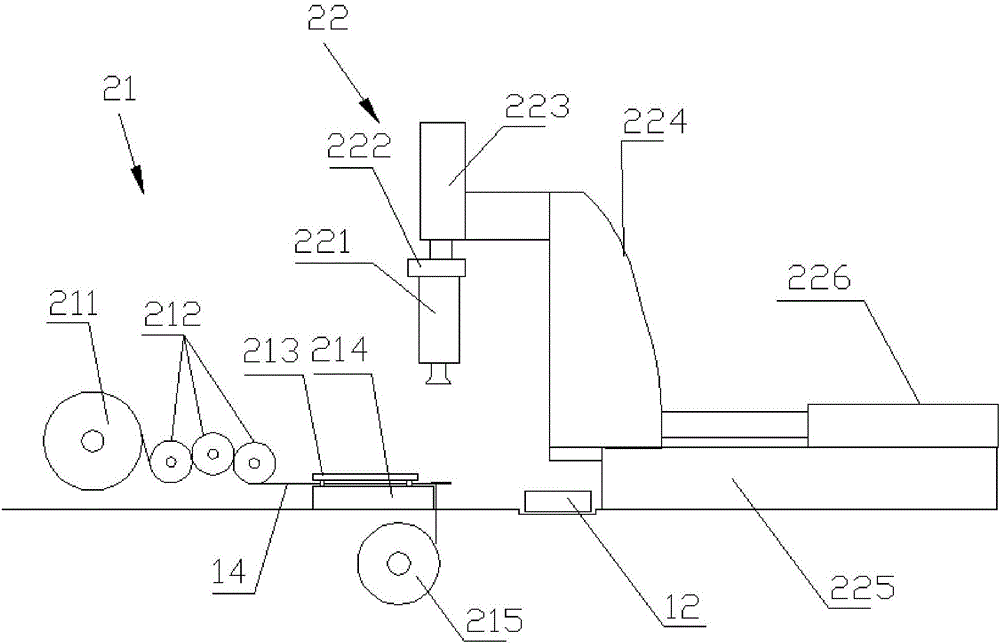

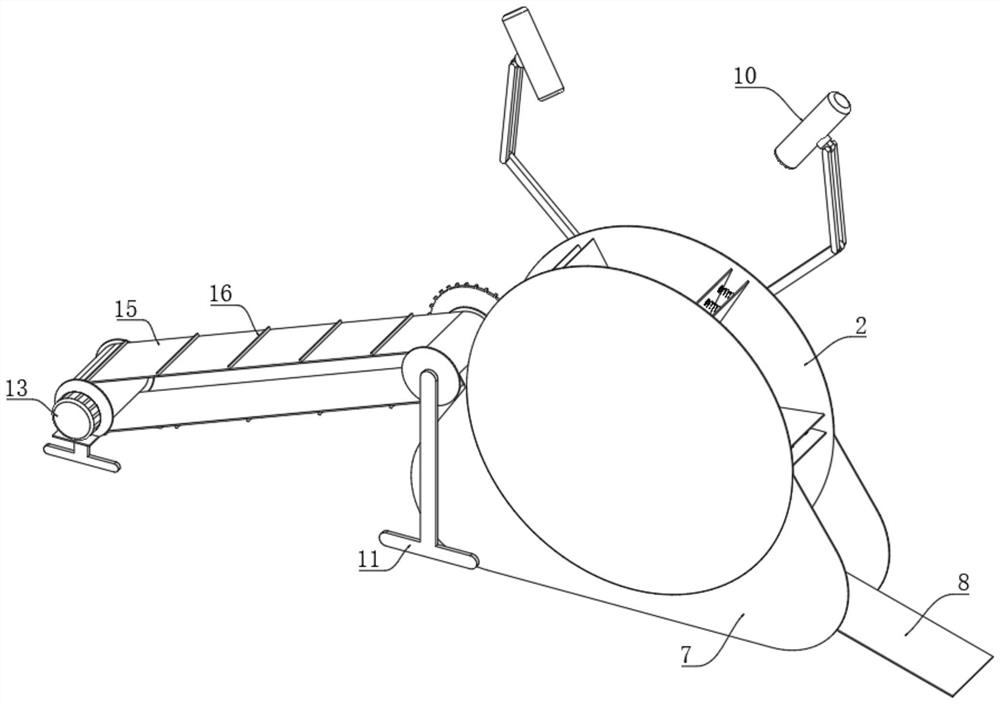

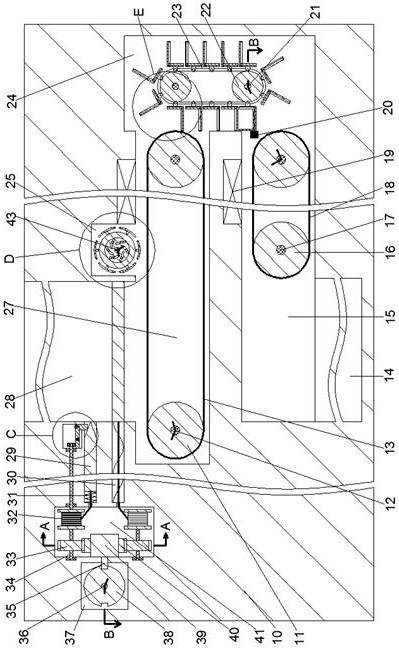

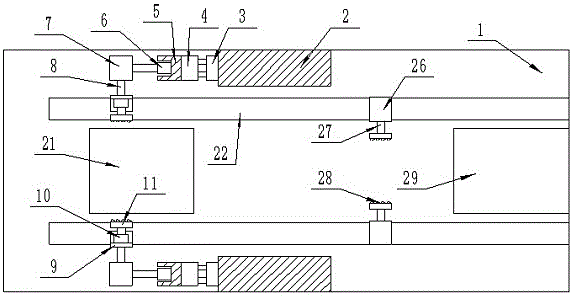

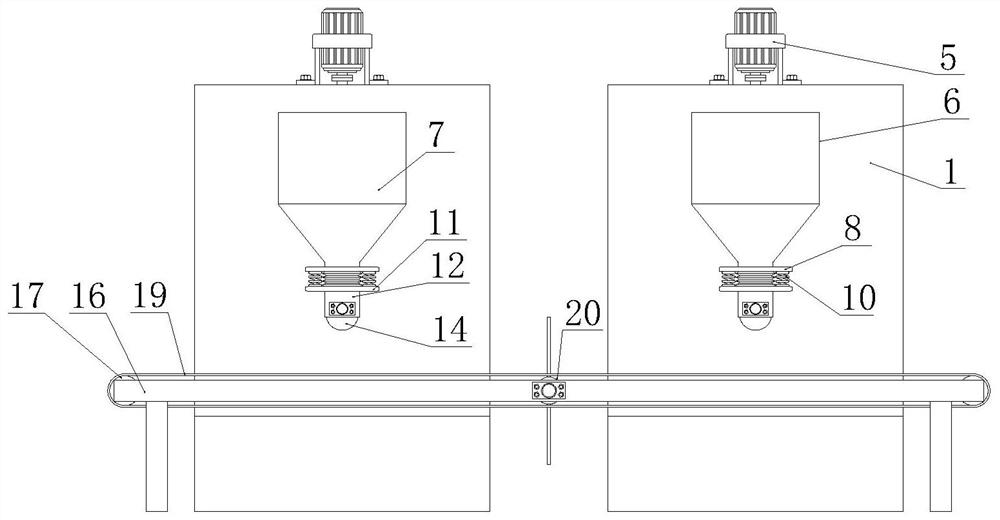

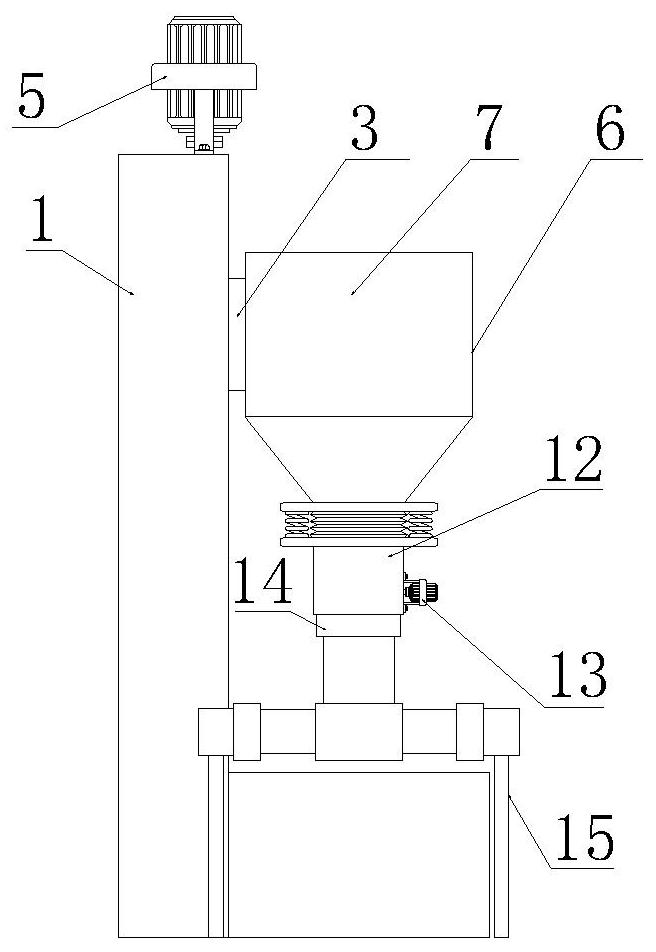

Cone yarn overturning machine and overturning method thereof

InactiveCN105035407AReduce labor intensityHigh degree of automationPackaging automatic controlYarnEngineering

The invention discloses a cone yarn overturning machine and an overturning method thereof. The cone yarn overturning machine comprises a large end and small end detection device and an overturning device which are sequentially installed on a conveying device. The large end and small end detection device and the overturning device are connected with a control device. The positions of a large end and a small end of cone yarn are detected through the large end and small end detection device. The control device judges whether a cone yarn placing mode is correct and then incorrectly-placed cone yarn is overturned through the overturning device so that two pieces of randomly adjacent cone yarn on the conveying device can be arranged in a mutually inverted mode, and an arrangement function is achieved automatically. The labor intensity of workers is low, and the arrangement accuracy is high.

Owner:TAIAN COMPANION MACHINERY

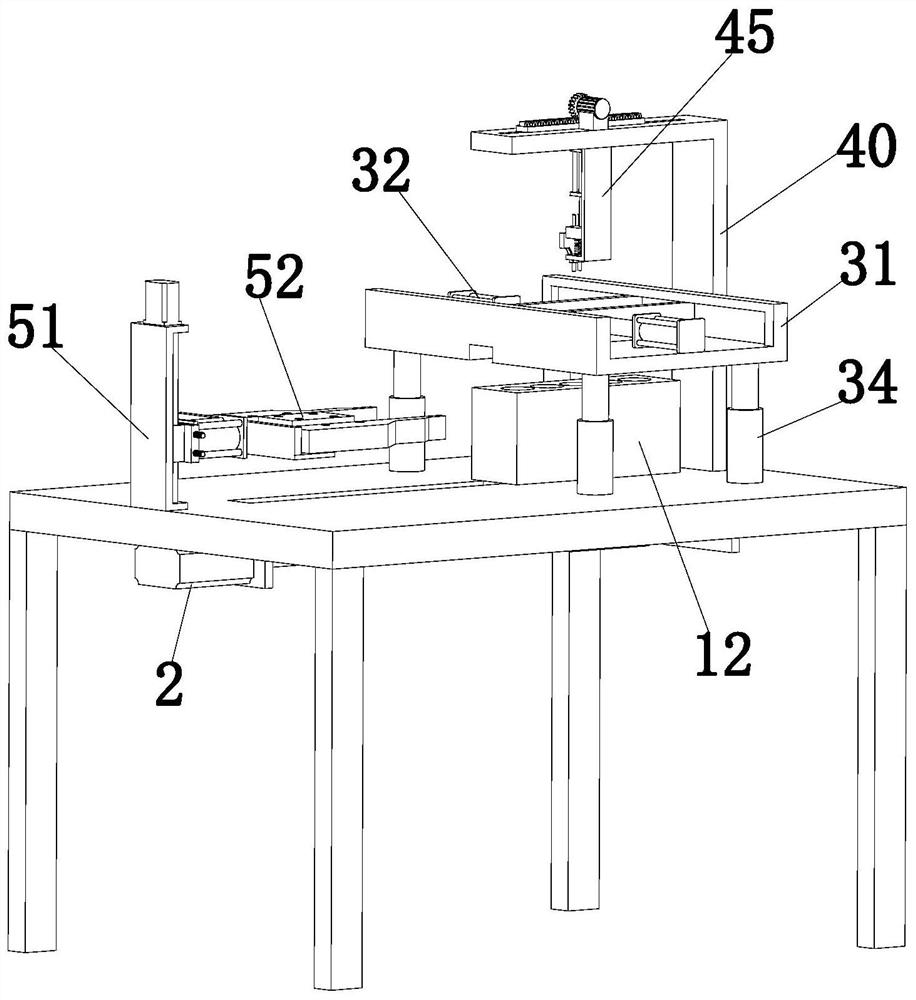

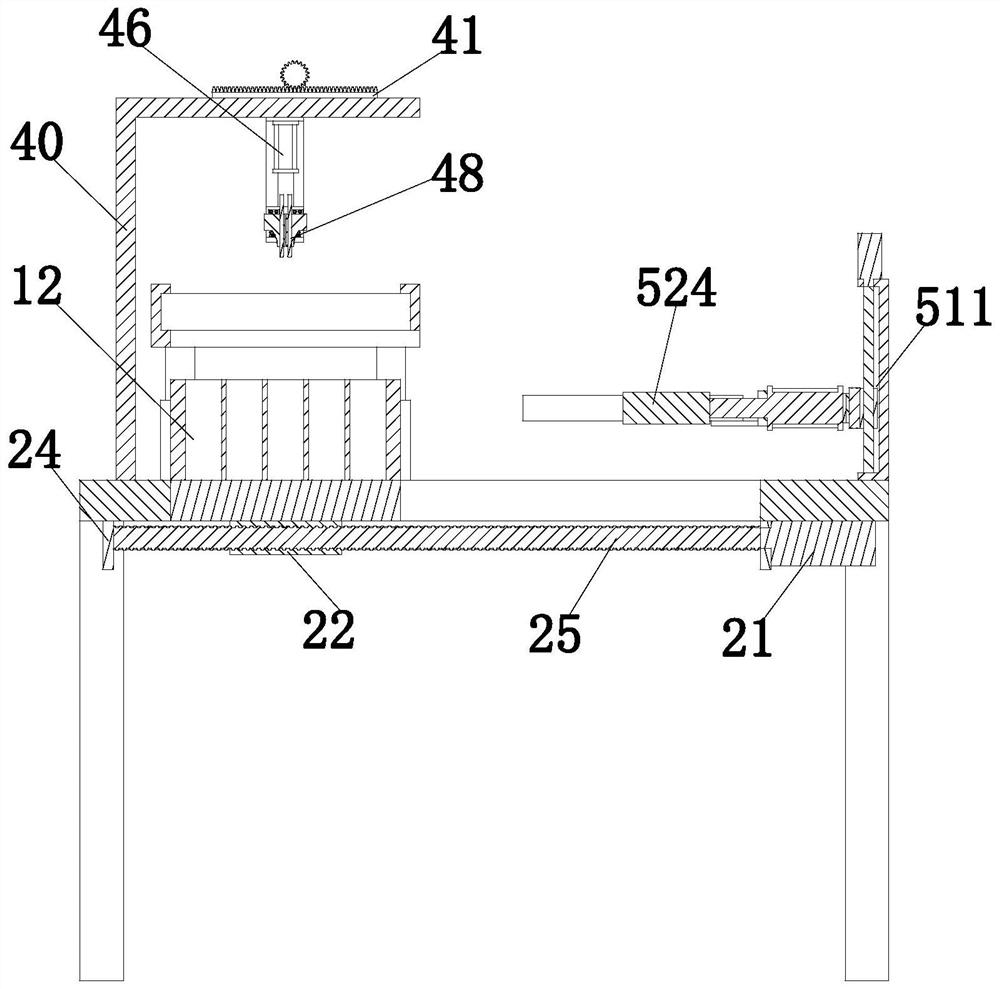

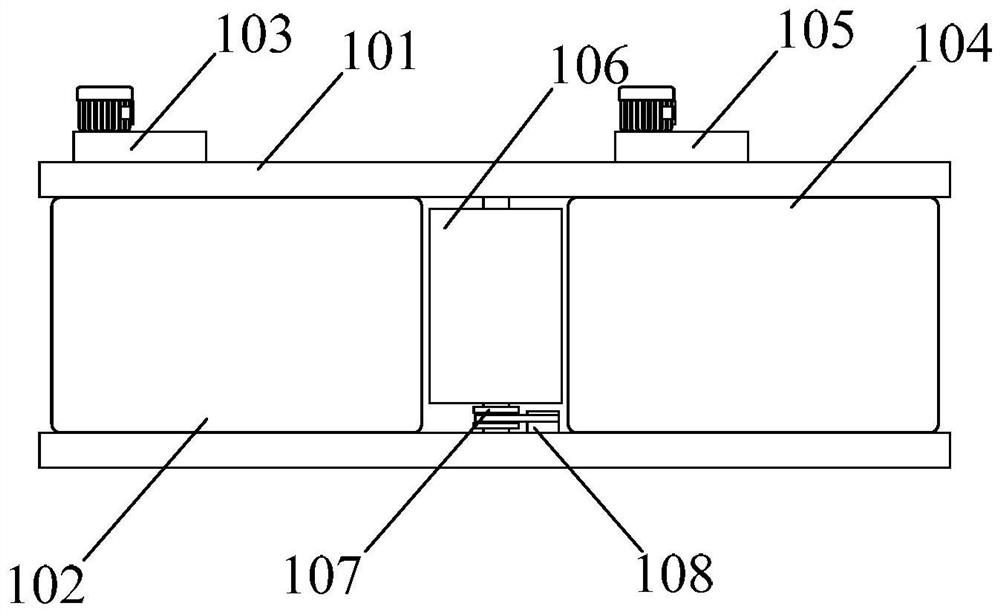

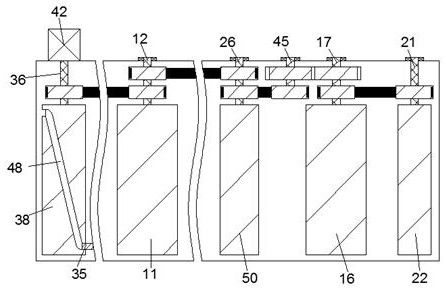

Welding device for lithium ion battery processing

InactiveCN111889937AImprove solder qualityImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering

The invention relates to the technical field of lithium ion battery welding, in particular to a welding device for lithium ion battery processing. The welding device for the lithium ion battery processing comprises a machining table, a moving device, a positioning and fixing device, a welding device and a turnover device, wherein the machining table is arranged on the ground, a rectangular slidinghole is formed in the machining table, a lithium ion battery seat is arranged at the top of the machining table and located on the rectangular sliding hole, the moving device is arranged at the bottom of the machining table, the positioning and fixing device is arranged on the lithium ion battery seat, the welding device is arranged beside the positioning and fixing device and installed at the top of the machining table, the welding end of the welding device is aligned with the positioning and fixing device in a vertical and downward mode, and the turnover device is arranged beside the positioning and fixing device. According to the welding device for the lithium ion battery processing, by means of mutual operation among the moving device, the positioning and fixing device, the welding device and the turnover device, the tin soldering quality of a lithium ion battery is improved, manual assistance is not needed, manpower is saved, and therefore, the whole welding efficiency is improved.

Owner:马程

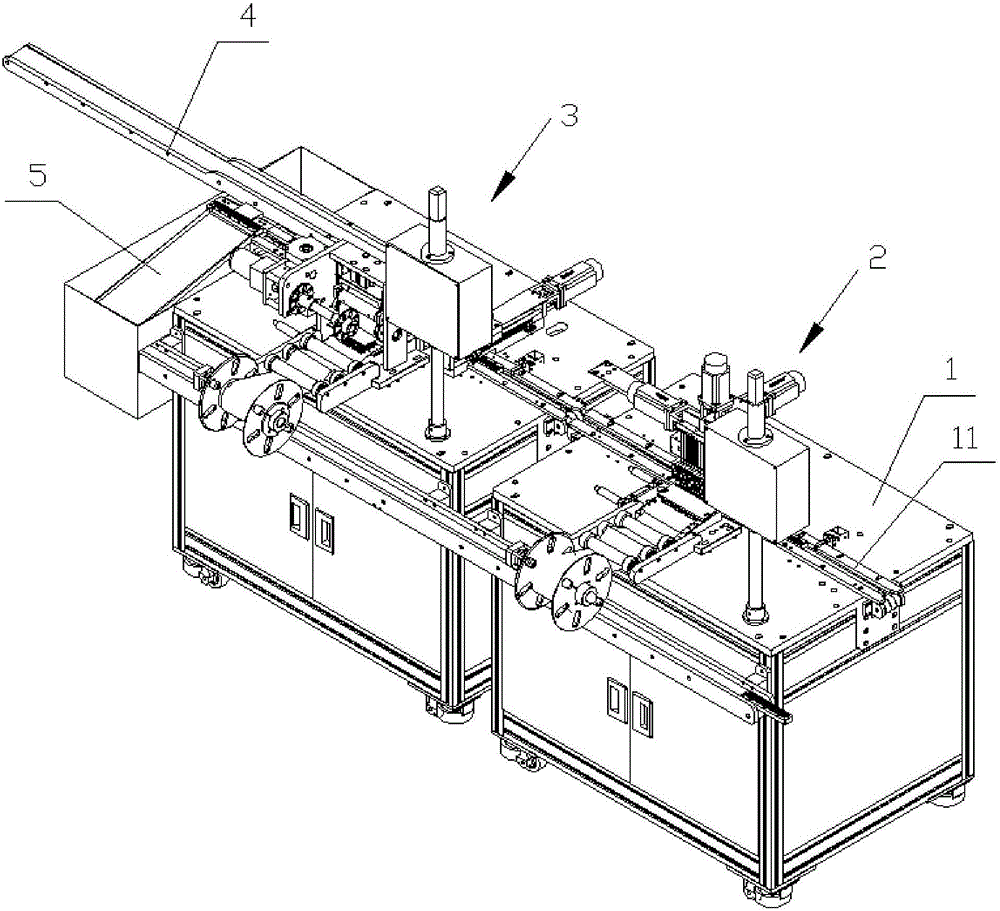

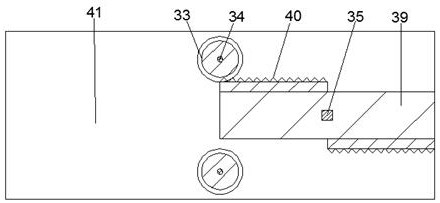

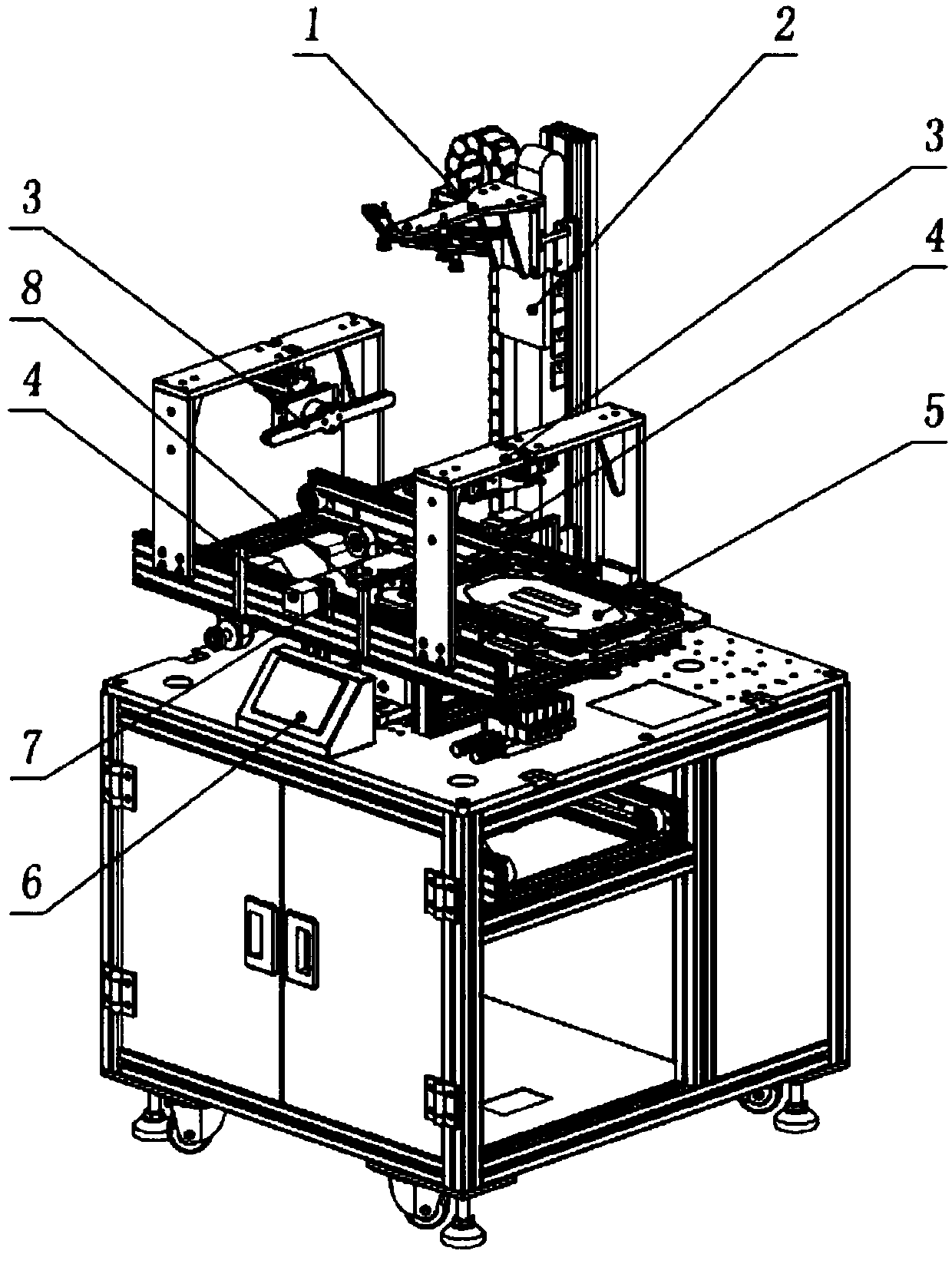

Mobile phone motor double sided adhesive tape and foam pasting unit

The invention provides a mobile phone motor double sided adhesive tape and foam pasting unit. The unit comprises a foam pasting machine and a double sided adhesive tape pasting machine; transfer bars pass through the foam pasting machine and the double sided adhesive tape pasting machine in sequence; and the foam pasting machine separates foams from anti-bonding papers through a separation mechanism, and sucks the foams through a first vacuum absorbing part to send to bond on motors on the transfer bars. The double sided adhesive tape pasting machine separates the anti-bonding papers from the upper sides of double sided adhesive tapes, and is matched with a transfer device to realize pasting of the double sided adhesive tapes at the bottoms of the motors. Compared with the prior art, the foam pasting machine and the double sided adhesive tape pasting machine are arranged on a worktable; the foams (double sided adhesive tapes) are separated from the anti-bonding paper parts by a feeding device, so that the foams (double sided adhesive tapes) are suspended; and the foams are absorbed through the vacuum absorbing part to bond in corresponding positions of the motors, so that the whole flow is high in automation degree, and saves a lot of manpower and time.

Owner:金龙机电(淮北)有限公司

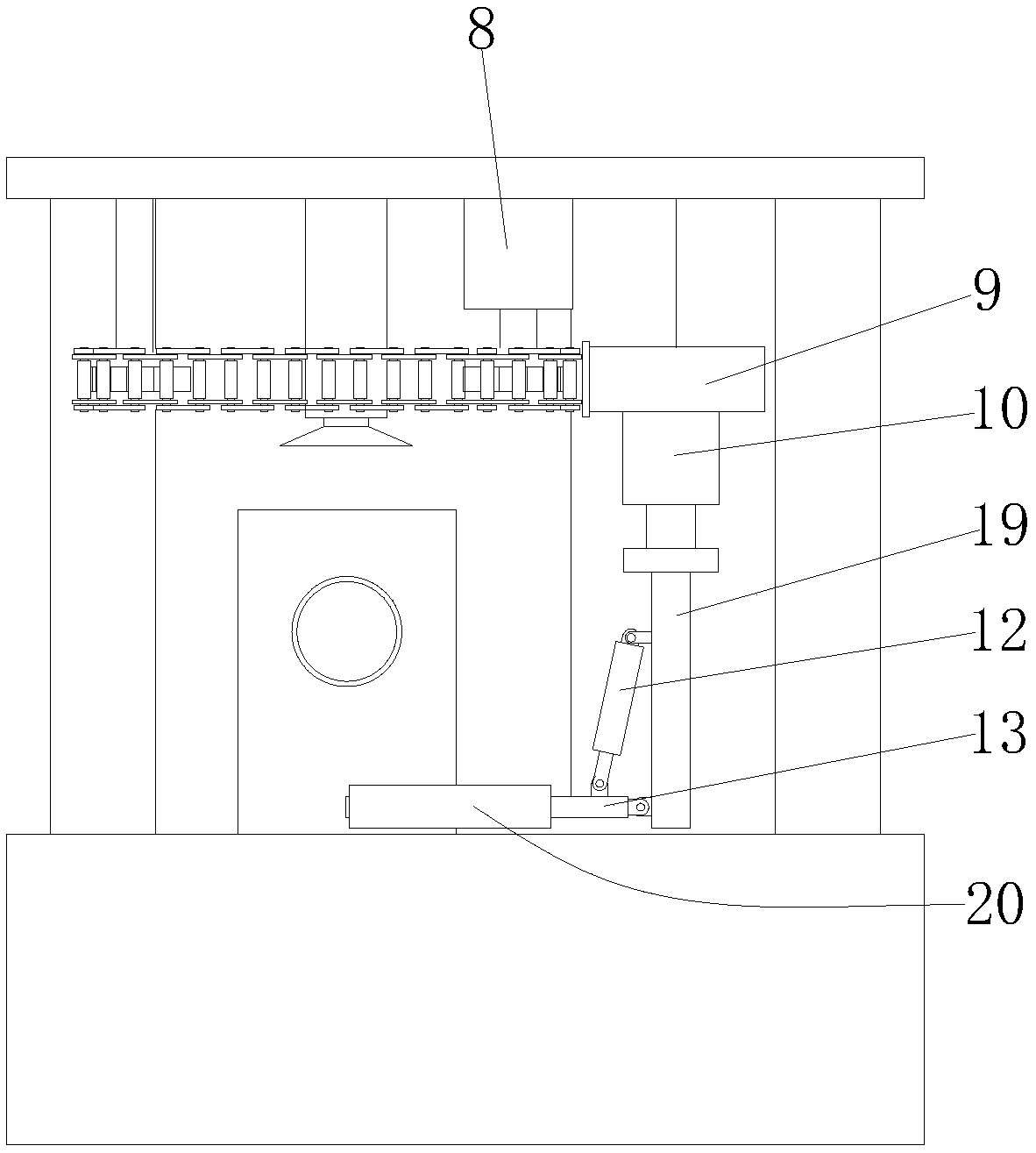

Automatic overturning and capping equipment for lead-acid storage battery

PendingCN111082160AEasy to assembleQuick assemblyAssembling battery machinesFinal product manufactureControl engineeringStructural engineering

The invention discloses automatic overturning and capping equipment for a lead-acid storage battery, which comprises a battery shell feeding mechanism, wherein the battery shell feeding mechanism comprises a battery shell fixing component and an overturning driving mechanism, and the overturning driving mechanism is fixedly connected to a rotating axis of the battery shell fixing component; the battery shell fixing component is used for clamping and fixing a battery shell; the overturning driving mechanism is used for driving the battery shell fixing component to turn over to the top of a conveying wheel; the rotating angle of the overturning driving mechanism is 180 degrees; and a shell cover feeding mechanism is arranged on the longitudinal side of a sealing machining mechanism, the shell cover feeding mechanism is used for conveying a shell cover to the conveying wheel, and the outlet end of the conveying wheel is provided with a discharging conveying wheel. According to the invention, the overturning driving mechanism can drive the battery shell to be inversely arranged at the top of the shell cover in parallel after the battery shell is fixed by the battery shell fixing component, so that manual overturning is not needed, and the battery shell and the shell cover are enabled to be assembled more simply, conveniently and quickly.

Owner:ANHUI LEOCH POWER SUPPLY

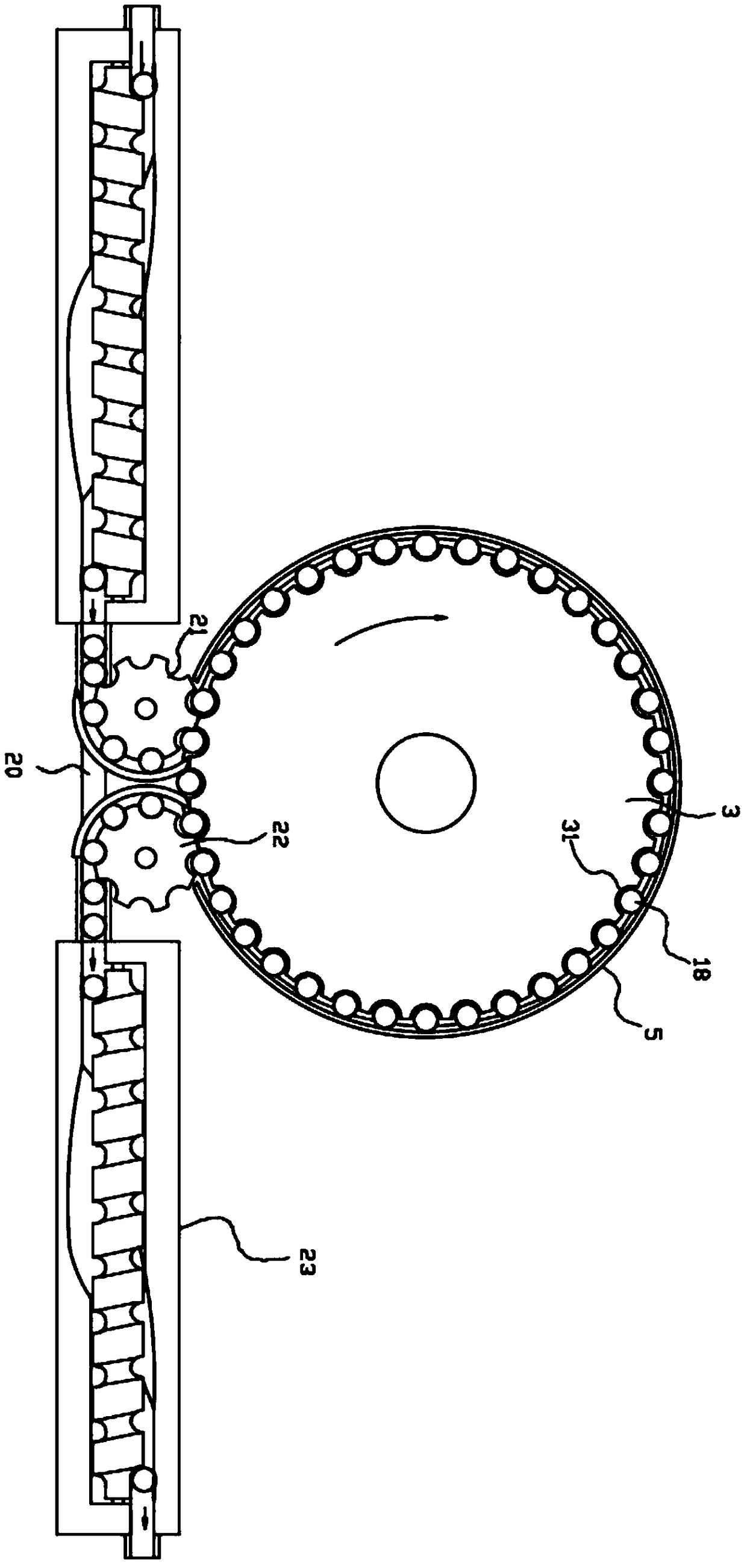

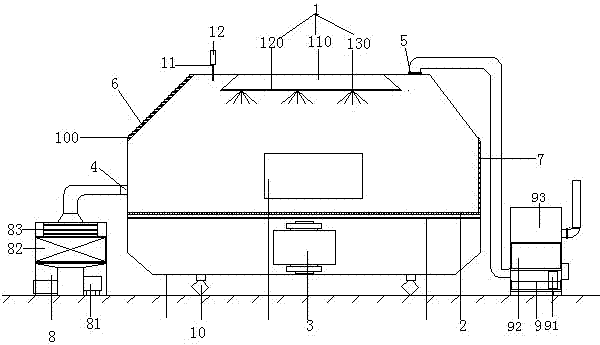

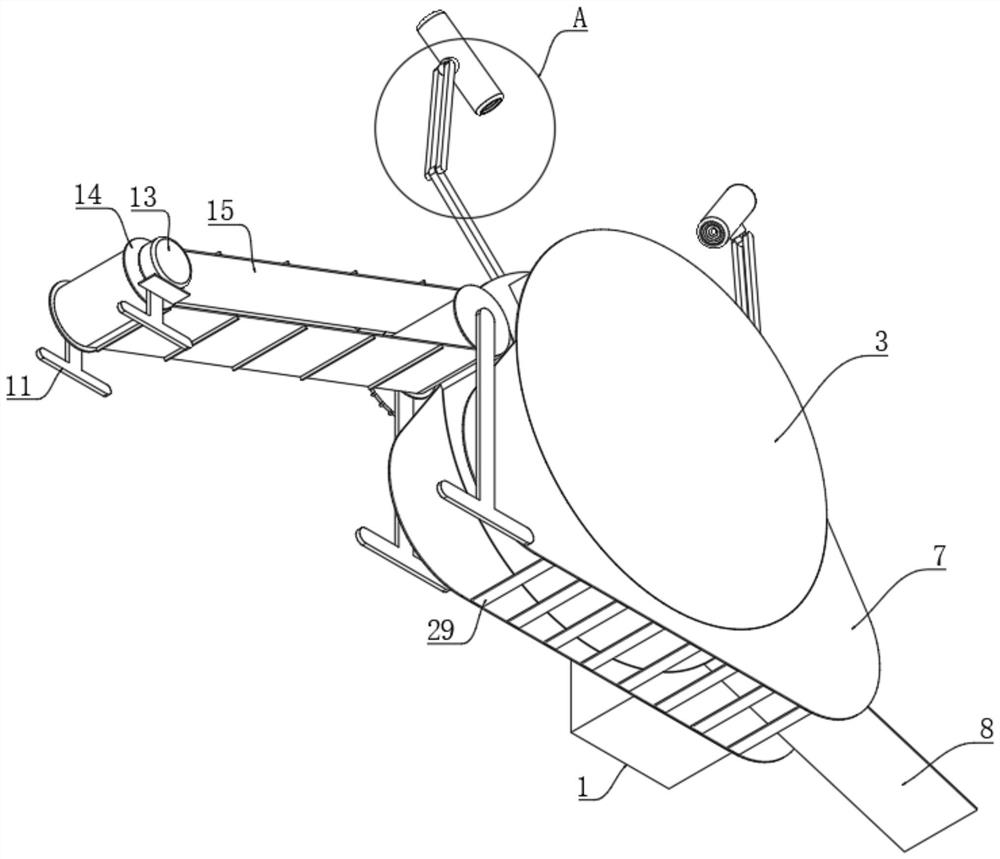

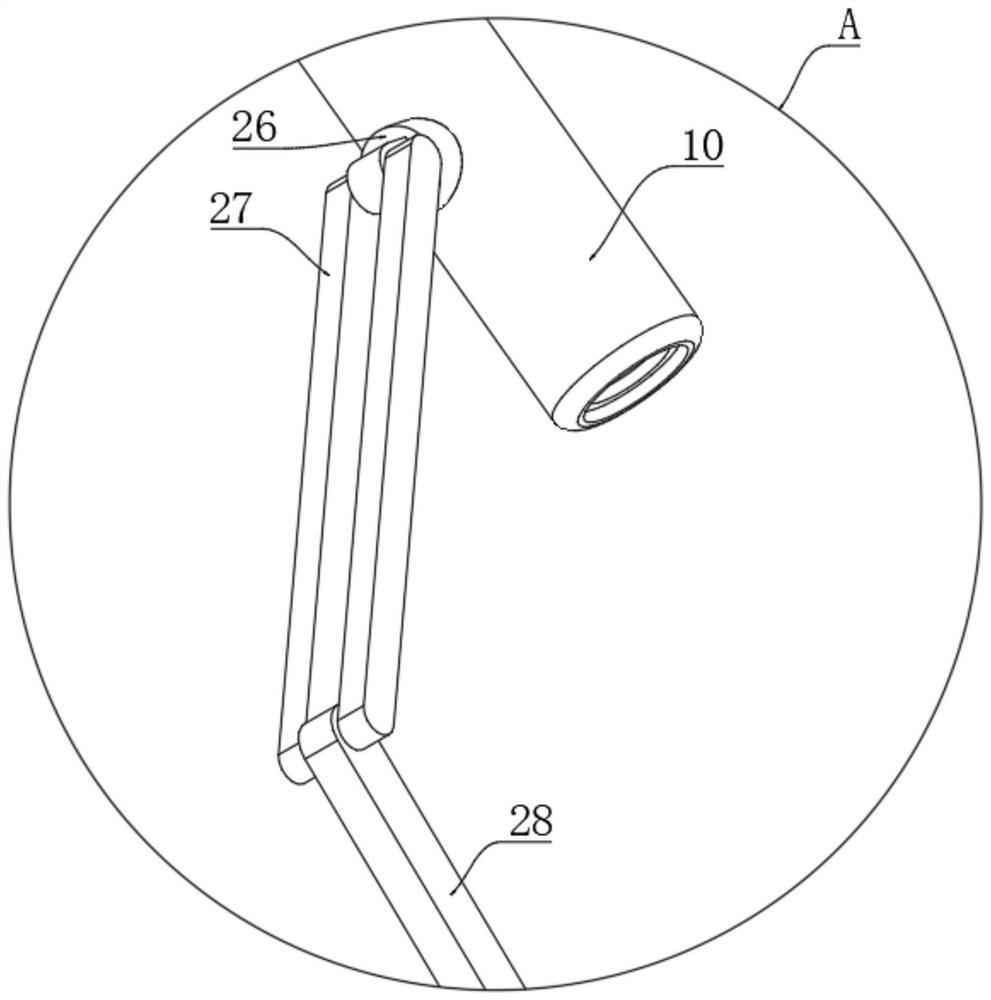

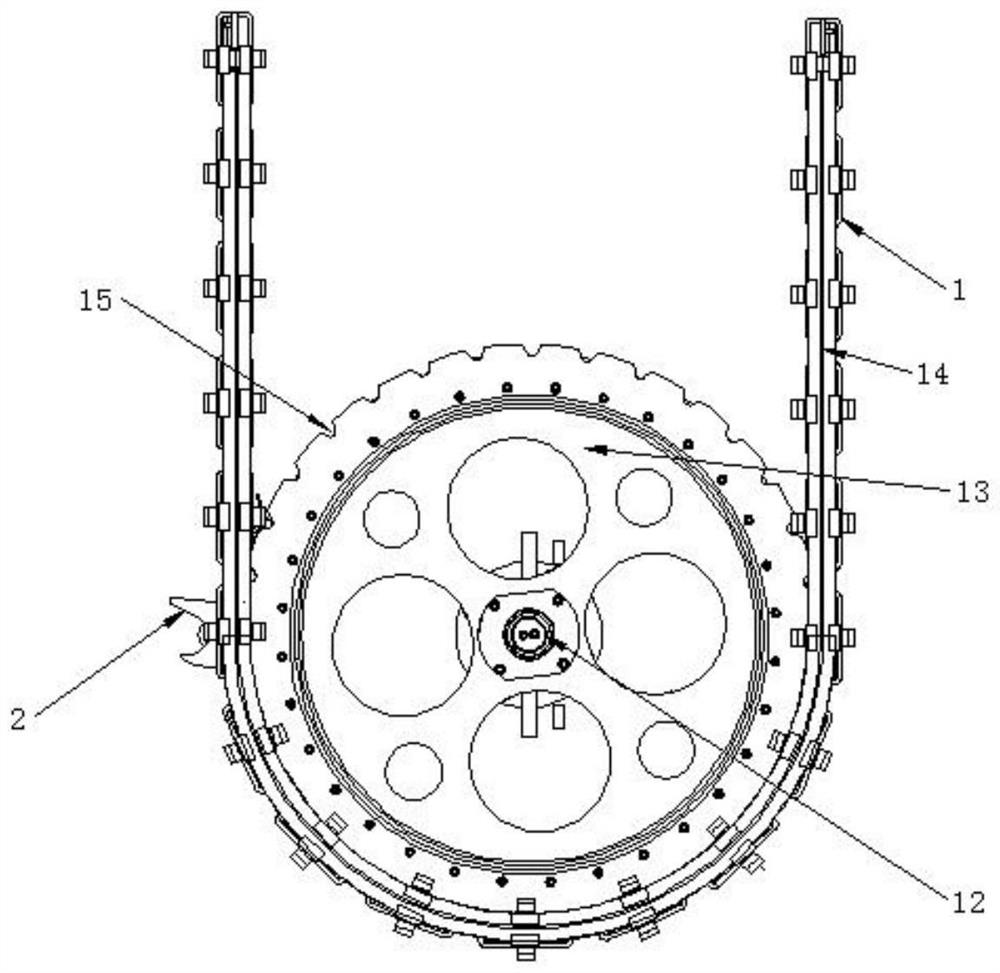

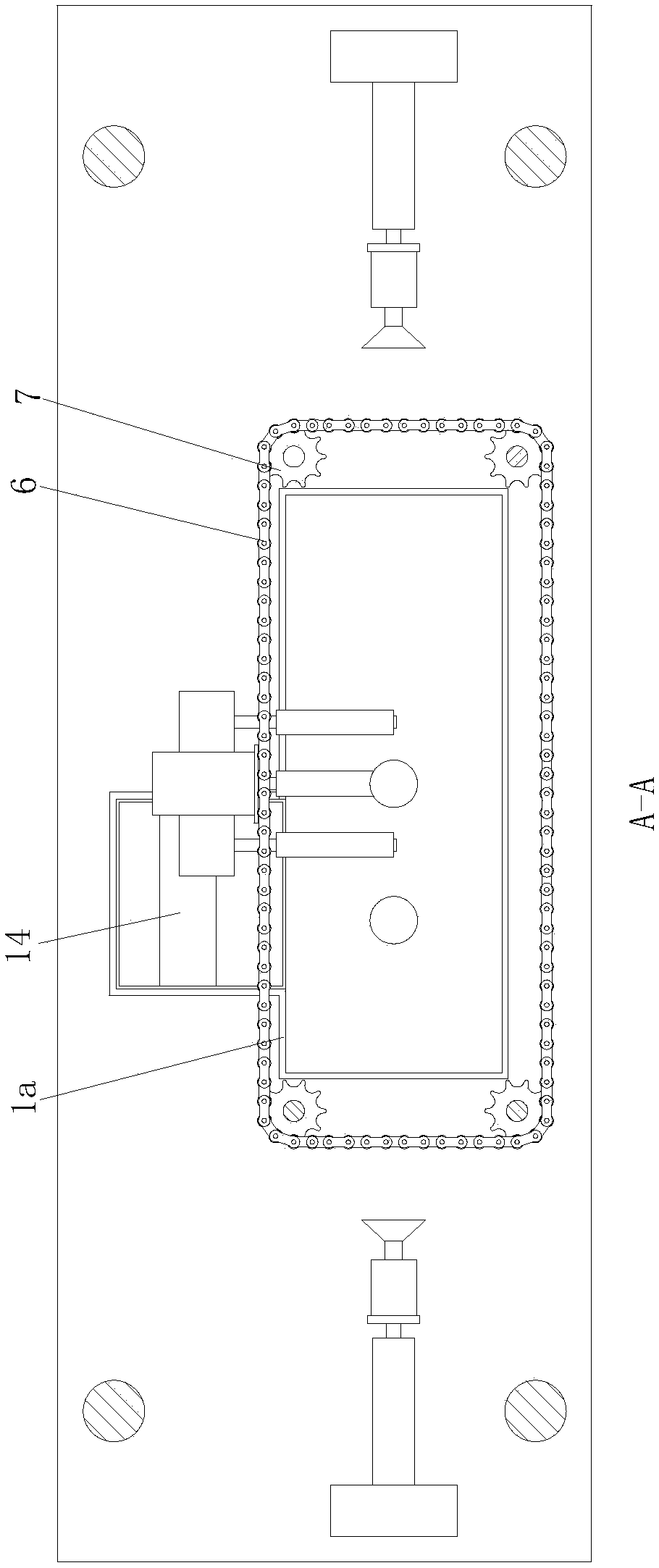

Automatic bottle turning double-pipe synchronous lifting canned bottle inverted rapid circulating and washing system

InactiveCN109332325AImprove cleaning efficiencyHigh degree of automationHollow article cleaningDrying gas arrangementsDouble tubeEngineering

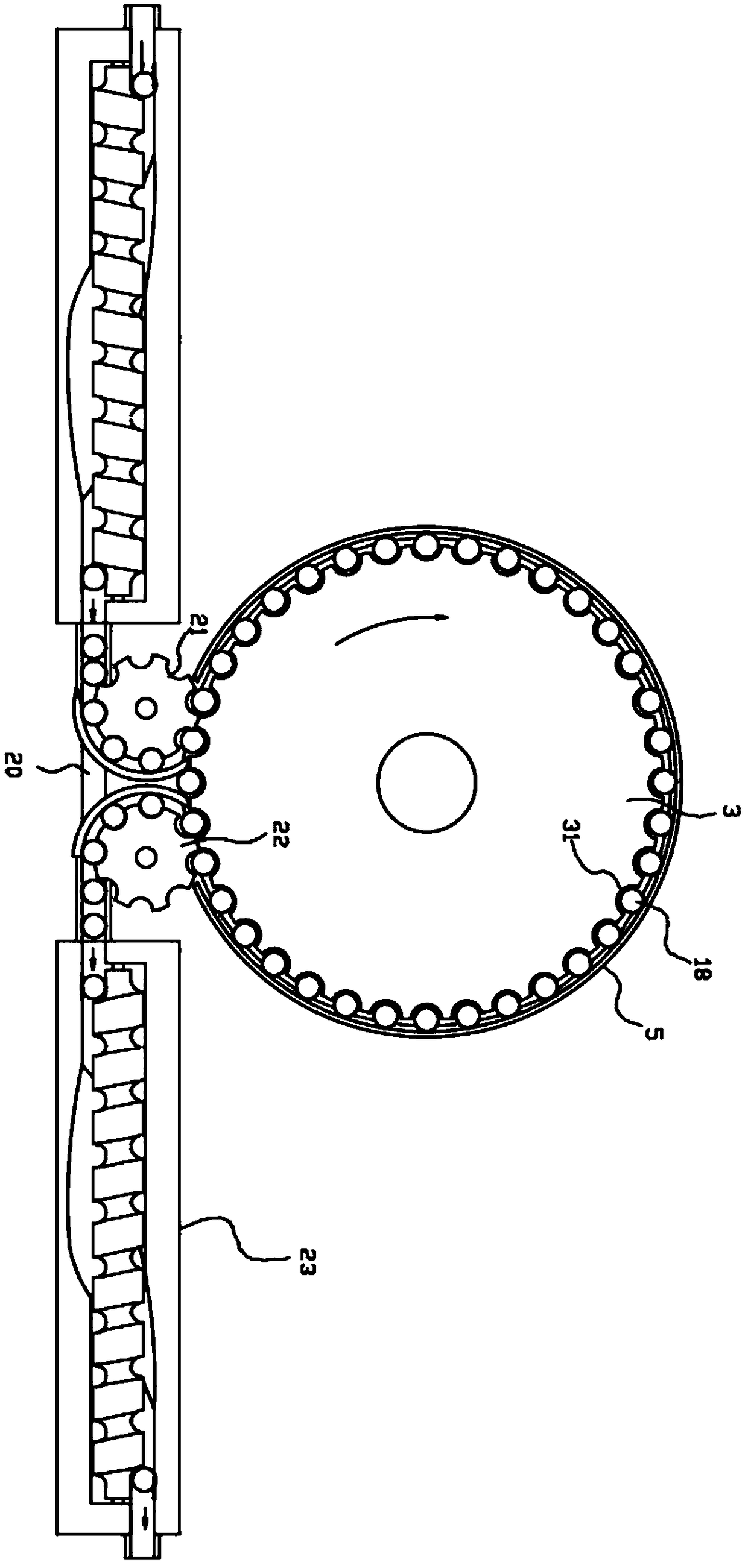

The invention discloses an automatic bottle turning double-pipe synchronous lifting canned bottle inverted rapid circulating and washing system. The system comprises a main poking wheel. A synchronouscarrier rail is arranged on the bottom of the main poking wheel. A ring-shaped fixing carrier rail is arranged on the periphery of the main poking wheel. An installing disc is arranged at the lower end of the main poking wheel. A spraying pipe lifting device is arranged on the installing disc and comprises spraying pipes. Spraying pipe rolling wheels are arranged on the side edges of the sprayingpipes. The spraying pipe rolling wheels are carried on a spraying pipe cam track. Each spraying pipe comprises an air spraying pipe and a liquid spraying pipe. A first rotating connector is connectedto the lower end of each air spraying pipe. A second rotating connector is connected to the lower end of each liquid spraying pipe. The second rotating connectors communicate with a cleaning liquid box through the water pump. A table board is fixedly provided with a ring-shaped liquid falling pool coaxial with the main poking wheel. Each spraying pipe is located above the liquid falling pool. Thebottom of the liquid falling pool communicates with the cleaning liquid box. The first rotating connectors communicate with a hot air fan. According to the system, the full-automatic air and liquid lifting and flushing manner is adopted, canned bottles can be washed continuously without stop, the cleaning liquid is recycled and used, the cleanness degree of washing is high, and the speed is high.

Owner:HUNAN HAILIAN FOOD CO LTD

Tea leaf pile fermentation machine

The invention discloses a tea stacking machine, which comprises a stacking machine tool. The stacking machine tool includes a water vapor distribution device arranged on the upper part of the machine tool, a bed plate arranged in the middle of the machine tool, and a vibration device arranged at the bottom of the machine tool. The water vapor distribution device includes The water steam generator, the air duct connected to the water steam generator, the air duct is provided with a number of air delivery holes; the bed board is provided with diversion holes, and the bottom of the bed board is provided with a dirt collecting tank, and the diversion holes are located above the dirt collecting tank , there is a vibration device under the bed board, and the vibration device adopts a vortex vibration motor; the stacking machine tool is also provided with an air inlet, a material inlet, and a material outlet; the air inlet is located on the left side of the stacker machine tool, and the air inlet is connected to a hot air blower ; There is a shock absorbing device at the bottom of the stacker. Adopting the present invention, the fermentation is rapid, the fermentation effect is good, the fermentation time is shortened, and at the same time, the turning and cooling after the stacking is completed saves time and labor, saves labor costs, and reduces damage to the tea leaves caused by manual turning.

Owner:周会香

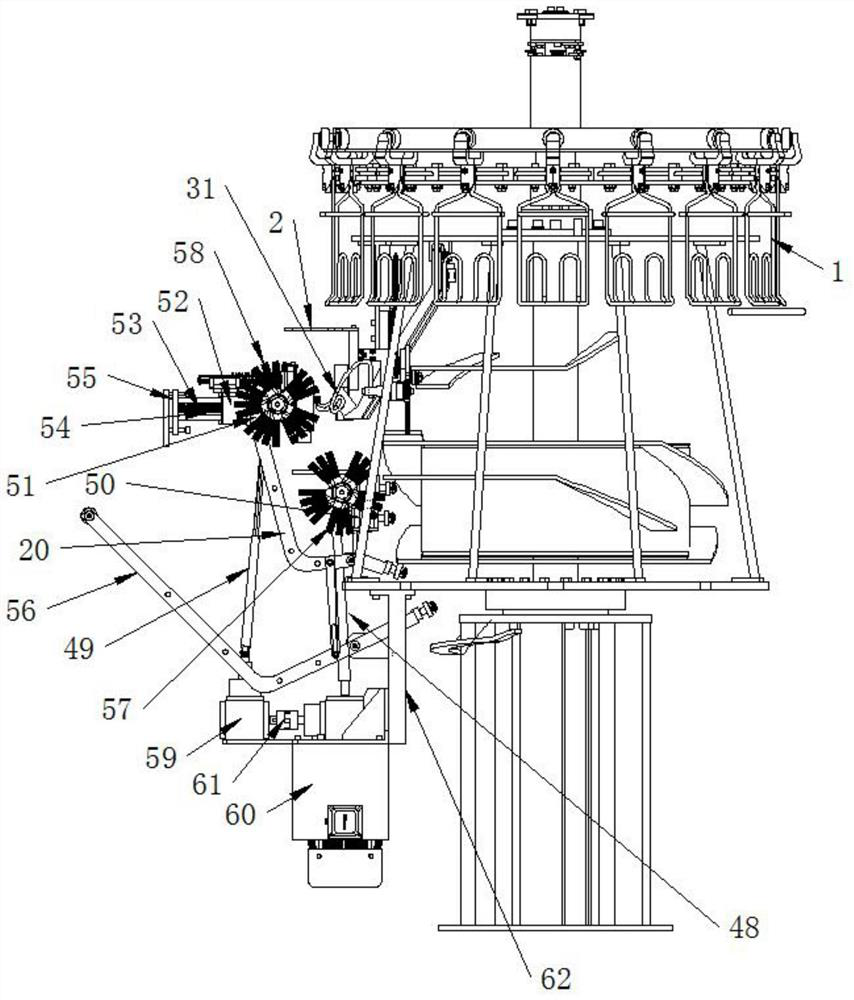

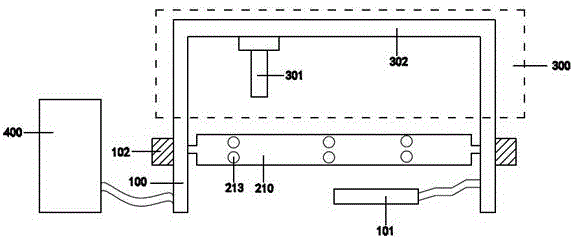

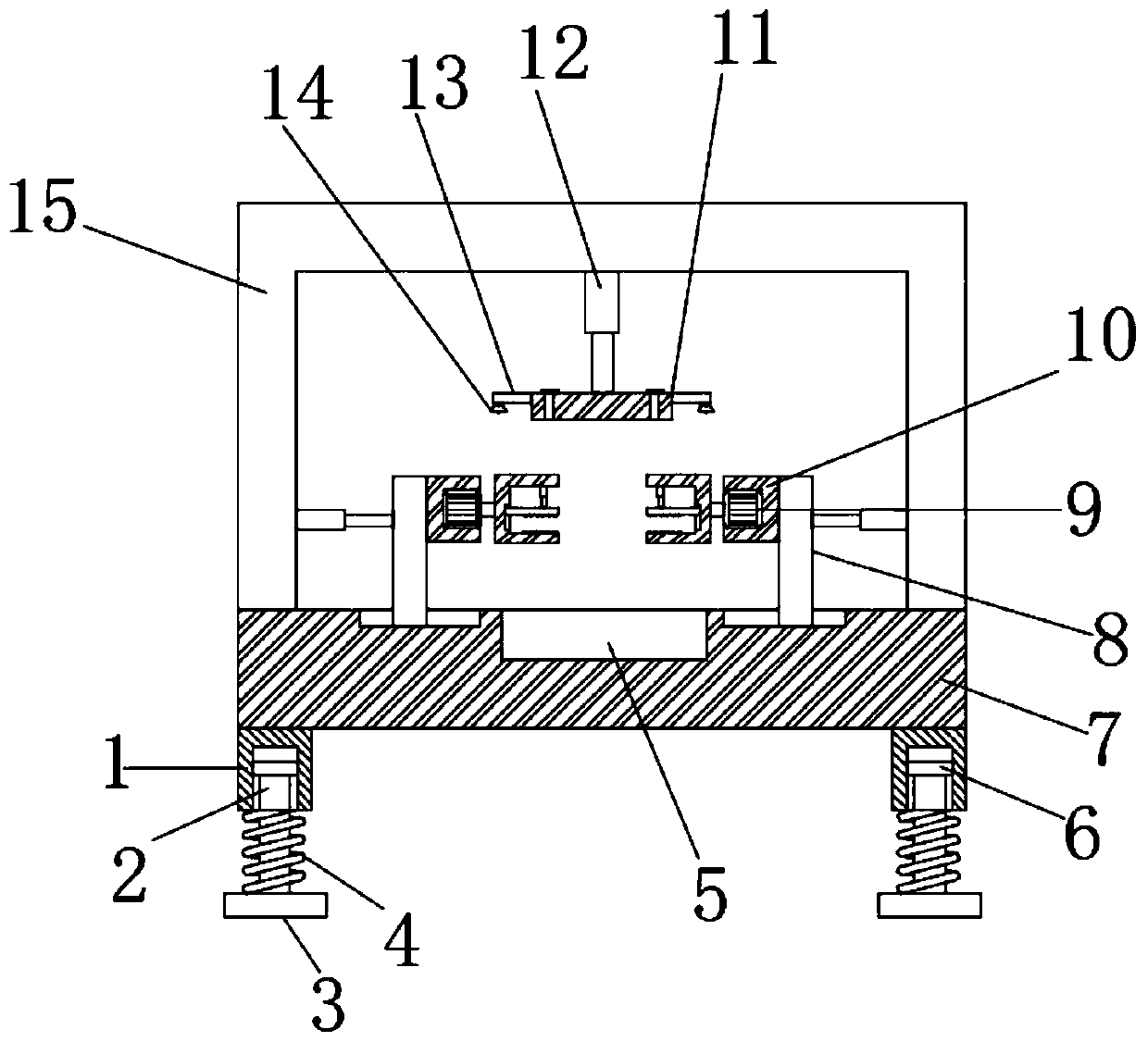

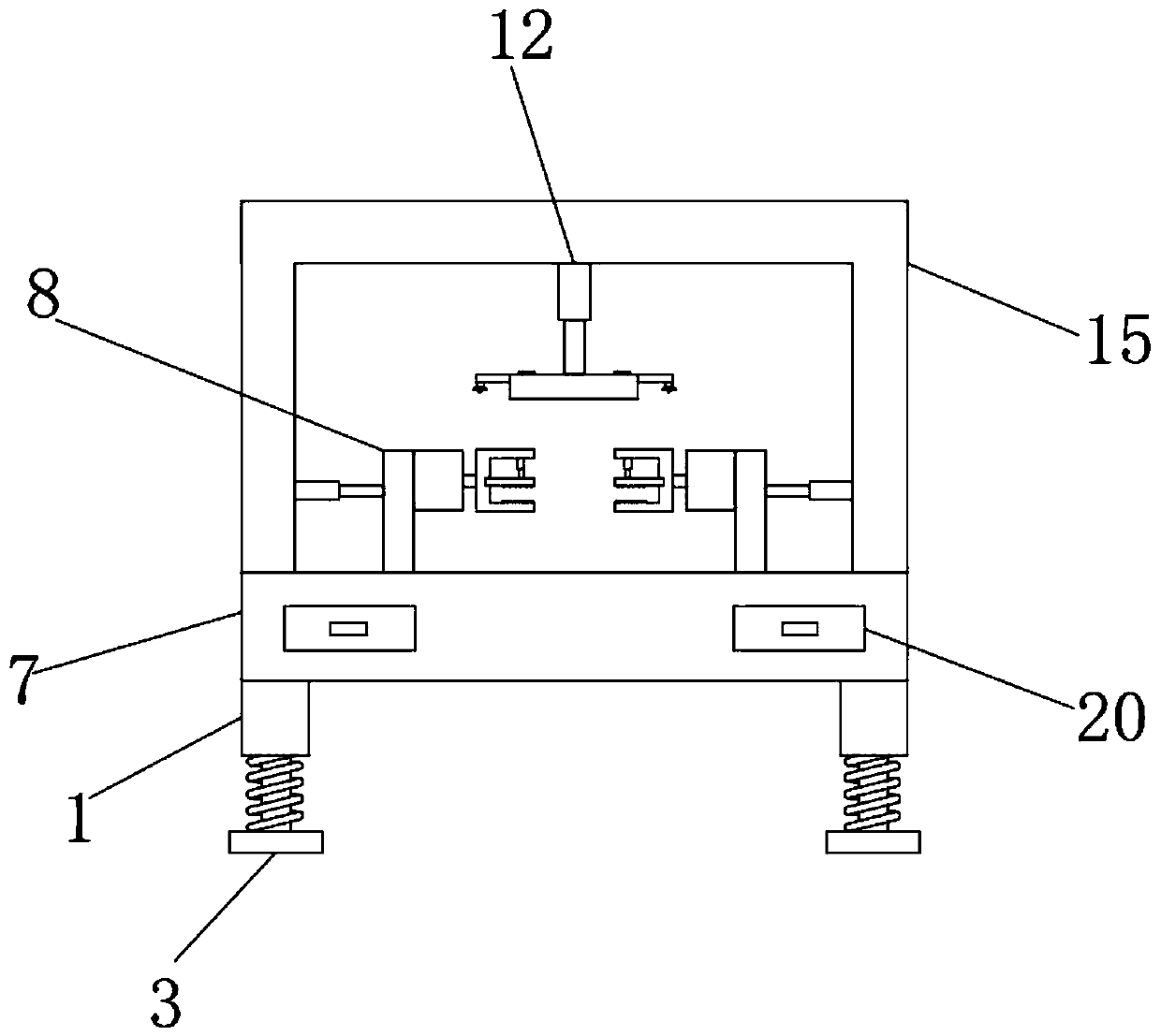

Visual inspection device for computer mainboard

ActiveCN112782185AAvoid damagePlay a shock absorbing effectConveyorsOptically investigating flaws/contaminationVisual inspectionElectric machinery

The invention relates to the technical field of visual inspection, in particular to a computer mainboard visual inspection device, which comprises visual inspection control equipment and two cameras, wherein one side of the visual inspection control equipment is provided with a shell with an upward opening, the shell is fixed on the ground through a supporting mechanism, the cameras are installed above the shell through connecting mechanisms, a rotating shaft is placed in the shell, a plurality of supporting plates are fixed to the outer wall of the rotating shaft in an annular array mode, one end of the rotating shaft is rotationally connected to the center of the inner wall of the shell, the other end of the rotating shaft penetrates through the shell and extends to be fixedly provided with a driving mechanism, a conveying mechanism is arranged on one side of the shell and comprises a first belt wheel, a second belt wheel and a motor, the output shaft of the motor is coaxially connected with the first belt wheel, the outer sides of the first belt wheel and the second belt wheel are jointly sleeved with a belt, and a plurality of separation strips are fixed to the belt at equal intervals. According to the invention, The computer mainboard visual inspection device can detect the two sides of a main board, manual overturning and secondary detection are not needed, and a large amount of detection time is saved.

Owner:昆山合钜泰电子科技有限公司

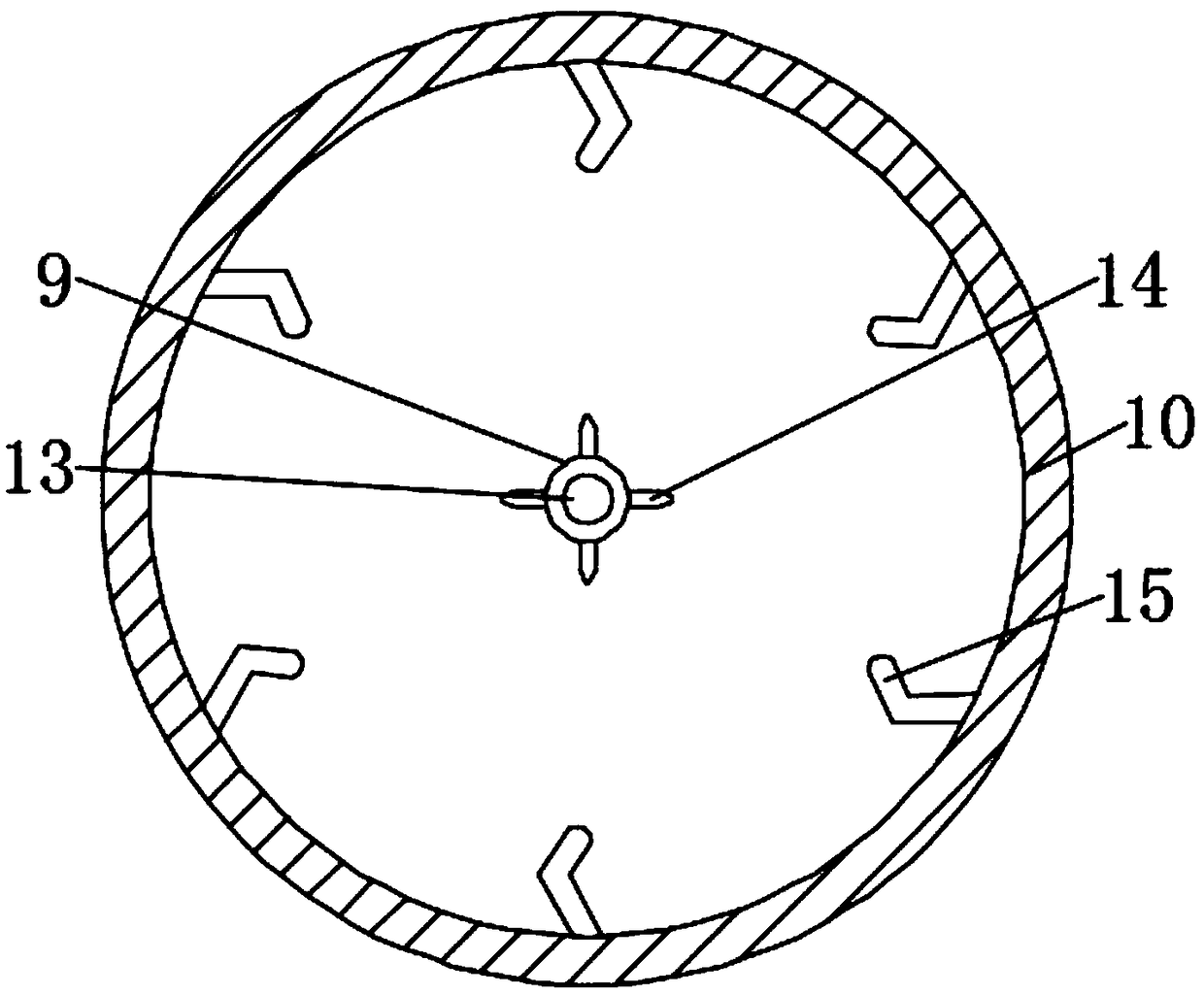

Livestock wing hair removing machine

PendingCN111670937AReduce occupancyOvercoming collision damage issuesPoultry plucking mechanismsPoultry shacklesAnimal scienceAgricultural science

The invention provides a livestock wing hair removing machine, and relates to the technical field of livestock wing hair removing tools. The livestock wing hair removing machine comprises a hanging device, a leading-in device, a positioning device, a wing opening device and a polishing device, wherein the wing opening device comprises wing opening blades which are arranged in a turnover manner andare used for opening duck wings. The livestock wing hair removing machine solves the problems that in the prior art, in the leading-in process of duck bodies, large shaking occurs, the duck wings cannot be accurately removed, the occupied space of a driving component is large, and assembly line processing cannot be realized.

Owner:寿光市和益自动化设备有限公司

Tea fermentation method

InactiveCN108719527AImprove filtration efficiencyCompact structurePre-extraction tea treatmentGear driveGear wheel

The invention discloses a tea fermentation method, and a fermentation device. The fermentation device comprises a support mechanism, a fermentation mechanism, and a stirring mechanism; the fermentation mechanism is arranged at the middle part of the support mechanism; the stirring mechanism is arranged on one side of the support mechanism; the support mechanism is composed of a first support plate, a first support, a second support plate, a second support, a supporting seat, an auxiliary support, a rotary motor, and a rotary gear. The fermentation device is compact in structure; an external gear ring and the rotary gear are adopted, so that rotating of a fermentation barrel is realized through rotation of the rotary gear driven by the rotary motor; in the fermentation barrel, tea repeat tumbling is realized using circulation scraper blades, and at the same time, an atomization nozzle is used for spraying fermentation broth onto falling tea; no artificial overturning is needed, both time and labor are saved, labor intensity is reduced greatly, in tea falling process, full contact of fermentation broth with tea is realized, the fermentation broth is uniformly sprayed onto tea surface, problems in the prior art such as nonuniform fermentation caused by nonuniform artificial spraying are solved, and tea fermentation efficiency is increased.

Owner:湖北尖峰茶叶股份有限公司

Printing device for non-woven handbag

InactiveCN112497900AAchieve double-sided embossingImprove printing efficiencyRotary pressesOther printing apparatusTextile printerEngineering

The invention discloses a printing device for a non-woven handbag, which comprises a handbag conveying device, supporting legs, a mounting frame, a protective cover, an upper embossing mechanism, a lower embossing mechanism, a bottom protective box, a handbag transition assembly, a handbag overturning mechanism, an arranging plate, a driving assembly and an industrial personal computer. Accordingto the printing device, through the arrangement of the upper embossing mechanism and the lower embossing mechanism, during usage, the handbag is conveyed to the position between the upper embossing mechanism and the lower embossing mechanism through a first conveying belt, double-face embossing of the handbag can be achieved through the cooperation of the upper embossing mechanism and the lower embossing mechanism at the same time, the printing efficiency of the handbag is effectively improved, and the labor intensity of workers is reduced; through the arrangement of the handbag transition assembly and the handbag overturning mechanism, after printing of the handbag is completed, a second conveying belt conveys the handbag to a transition frame, an overturning frame overturns rightwards and backwards, the bottom of the handbag falls into a groove between the transition frame and the arranging plate, the upper end of the handbag is attached to an inner sidewall of the arranging plate, and the handbag can be integrally and conveniently stored.

Owner:桐城市鸿江包装有限公司

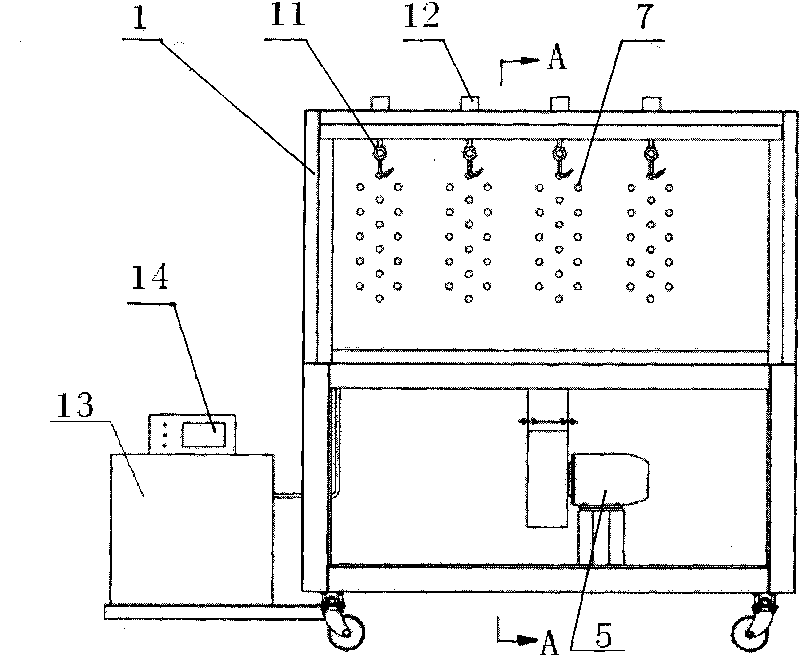

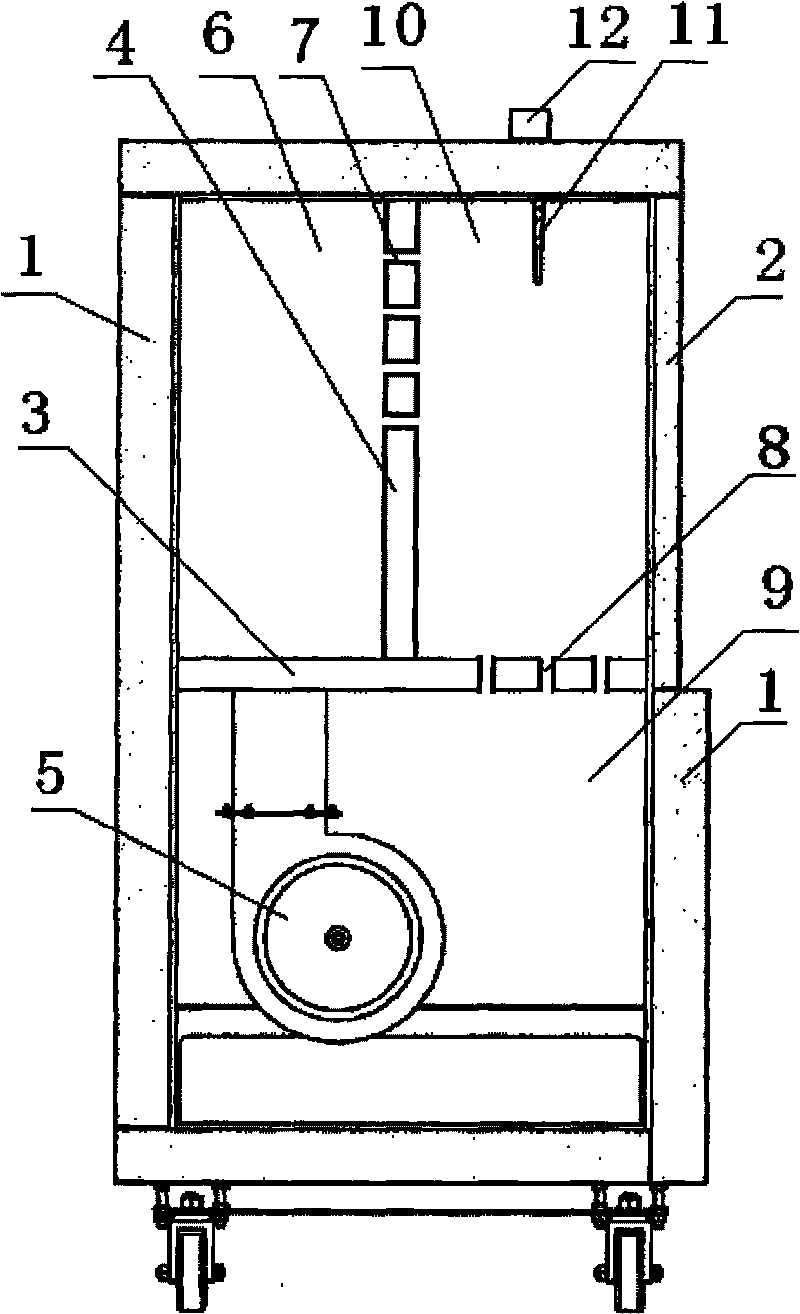

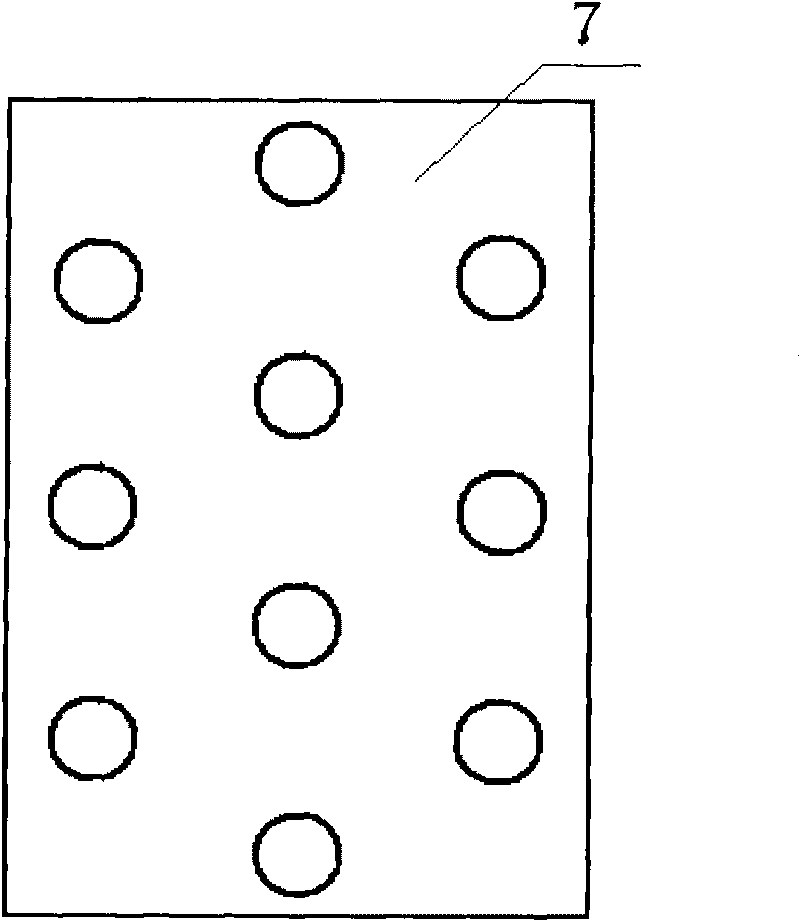

Semi-finished roast duck airing device

InactiveCN101692910AAchieve mechanical propertiesAchieve standardizationMeat/fish preservation by freezing/coolingFood preparationEngineeringRoast duck

The invention discloses a semi-finished roast duck airing device which belongs to the technical field of food processing and is used for unfreezing and dewatering semi-finished roast ducks by airing. The device comprises a box body, an airflow circulation system, a refrigeration system, a hanging system and a control system. A semi-finished roast duck airing room is isolated from the outside by the movable box body with favorable heat-insulating property, a line of semi-finished roast duck hanging hooks are arranged on the top board of the box body in the semi-finished roast duck airing room for hanging the semi-finished roast ducks, and the semi-finished roast ducks are rotated for being aired and dewatered uniformly. The airflow circulation system forces the air in the box to blow onto the semi-finished roast ducks at certain airflow speed, the refrigeration system is used for controlling the airing temperature and ensuring the temperature required for unfreezing and dewatering the semi-finished roast ducks by airing, and the control system controls and adjusts the airing temperature, the airing speed and the rotary speed of the semi-finished roast ducks. The device can set the semi-finished roast duck airing temperature, the airing speed and the rotary speed of the semi-finished roast ducks, prevent the semi-finished roast ducks from being polluted by flies and dust, overcome the influence of weather change and single-direction airflow on the semi-finished roast duck quality, and realizes the mechanization and standardization of unfreezing and dewatering the semi-finished roast ducks by airing.

Owner:CHINA AGRI UNIV

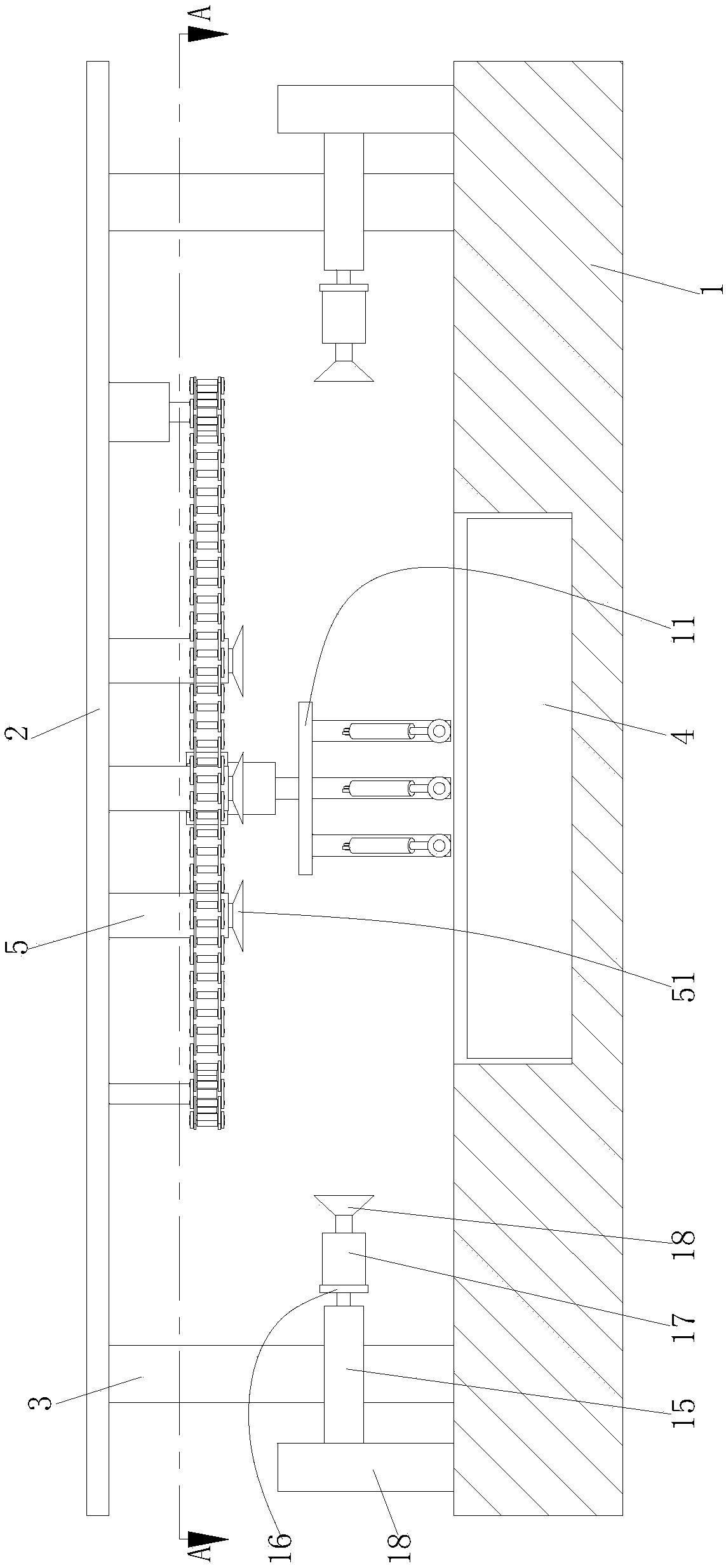

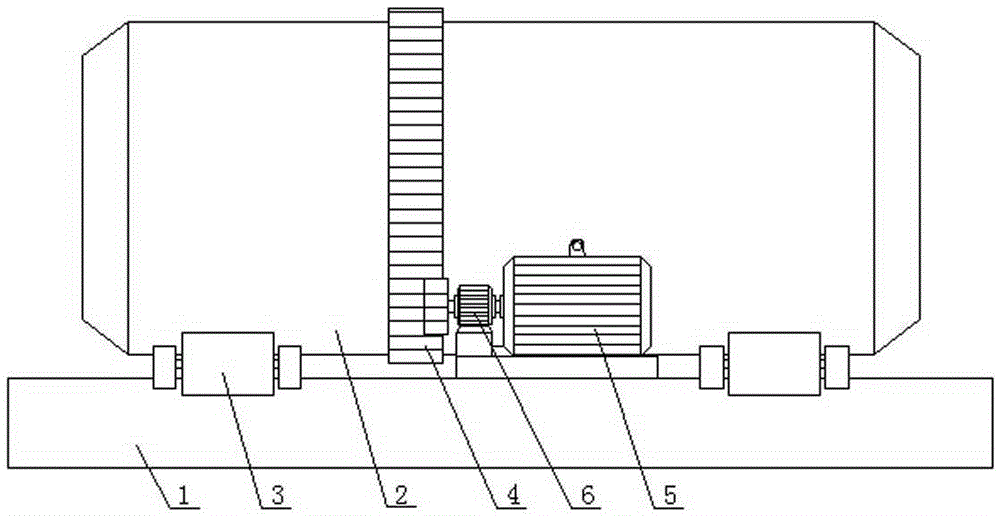

Assembly welding device for axle housing

ActiveCN105108398AGuaranteed unchangedHigh hardnessWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingWelding process

The invention discloses an assembly welding device for an axle housing. The assembly welding device is characterized by comprising a supporting seat, an assembly device, a welding device and an operating platform, wherein the supporting seat comprises a first electric welding device; the assembly device comprises a hollow frame and a plurality of pushing devices; each pushing device comprises a pneumatic pump, a push rod and a mold arm; the welding device comprises one or more movable and retractable second electric welding devices. The assembly welding device for the axle housing can realize spot welding and integral welding by one machine, meanwhile, the frame can rotate automatically, spot welding and integral welding of two sides of the axle housing can be realized, manual turnover is not needed, the position of the axle housing cannot change by the aid of fixing devices and the magnetic mold arms in the turnover process, the whole welding process is more accurate, and errors are reduced.

Owner:TAIZHOU SHENZHOU TRANSMISSION TECH

Drying device for medicinal material processing

InactiveCN112146421ADry evenlyImprove drying effectDrying solid materialsHeating arrangementMedicinal herbsEngineering

The invention discloses a drying device for medicinal material processing. The drying device comprises a main body, wherein a feeding cavity with the upper side communicated with the outside is formedin the main body; a feeding assembly is arranged on the left side of the feeding cavity; a first drying cavity is formed in the lower side of the feeding cavity in a communicated mode; a flattening rotating cavity is formed in the upper side of the first drying cavity in a communicated mode; a flattening assembly is arranged in the flattening rotating cavity; an overturning cavity is formed in the right side of the first drying cavity in a communicated mode; an overturning assembly is arranged in the overturning cavity; a second drying cavity located on the lower side of the first drying cavity is formed in the left side of the overturning cavity in a communicated mode; medicinal materials to be dried are put into a feeding box; the feeding assembly is used for controlling the medicinal materials to be fed intermittently and equivalently; the medicinal materials are flatly laid on a first conveying belt and are flattened through flattening rods; and after one faces of the medicinal materials are dried, the medicinal materials are turned over through the overturning assembly and then are conveyed to a second conveying belt to be dried reversely.

Owner:LINHAI DISA INTELLIGENT TECH CO LTD

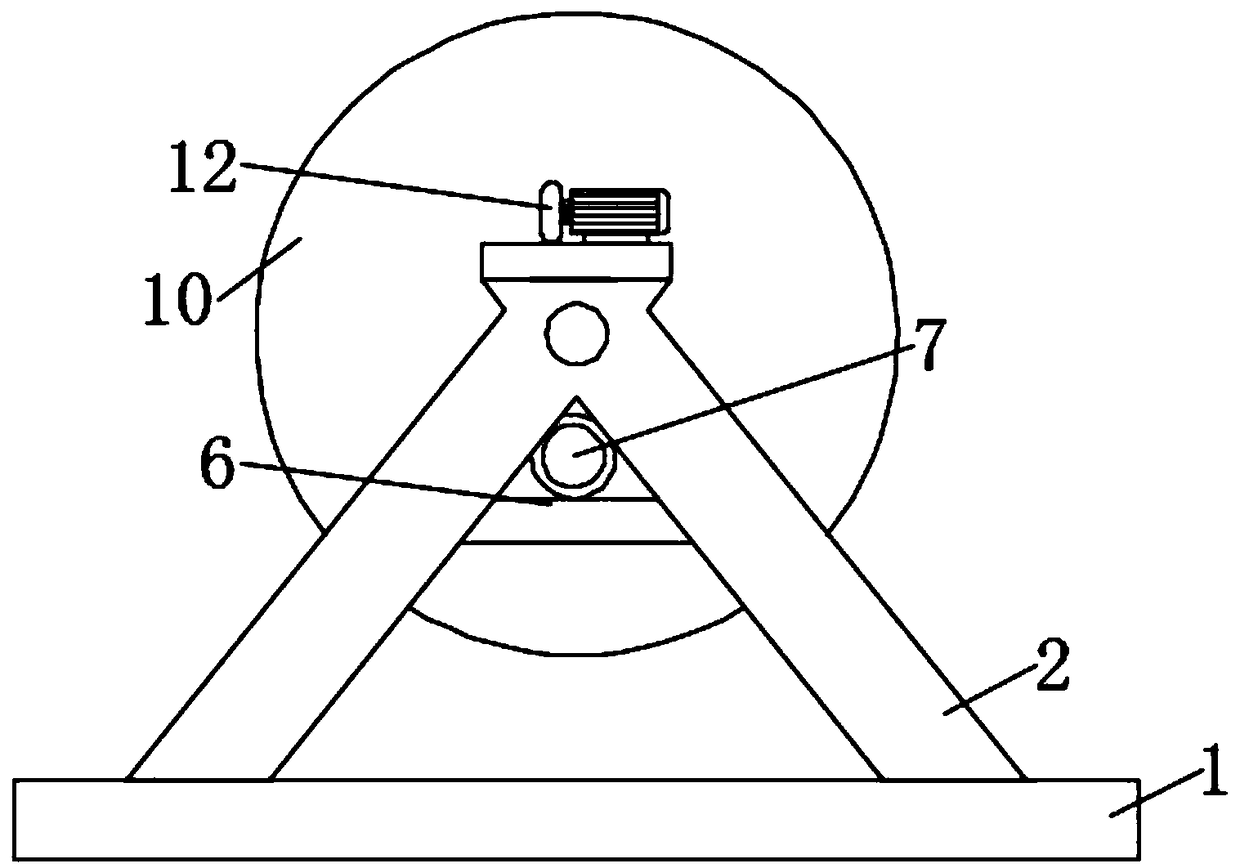

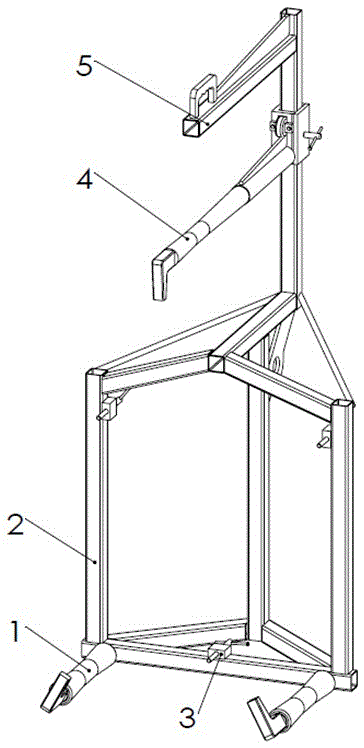

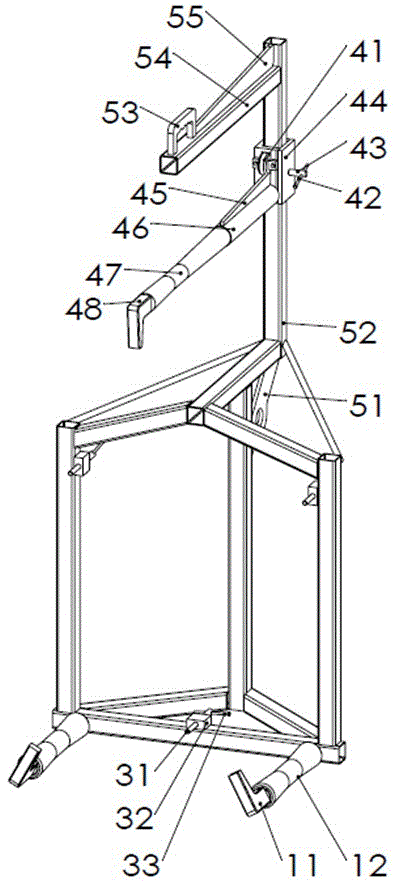

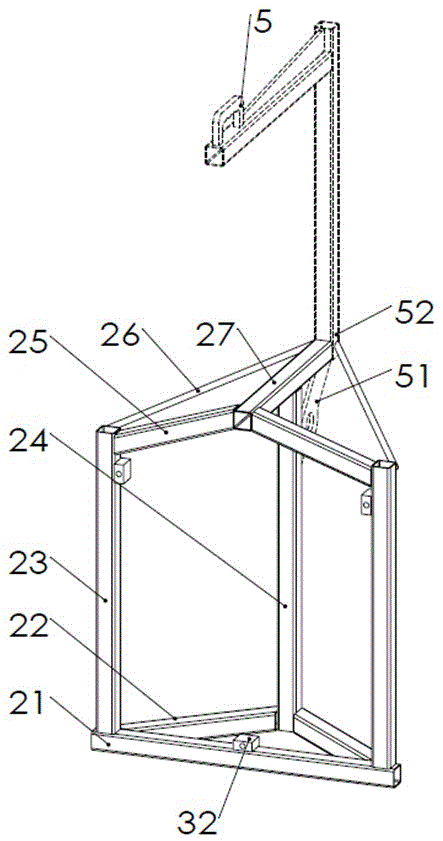

Lifting appliance for assembling heavy forklift tire

ActiveCN106006365AImprove versatilityImprove compatibilityLoad-engaging elementsMechanical engineeringAutomotive engineering

The invention discloses a lifting appliance for assembling a heavy forklift tire. The lifting appliance comprises carrier roller assemblies, a body framework, adjusting mechanisms, a press roller mechanism and a lifting beam mechanism. The lifting appliance is suitable for assembly work of three series and five kinds of tires of a forklift of 12 t to 14 t, a forklift of 16 t to 18 t and a forklift of 20 t to 25 t. Compared with an original assembly method, according to the lifting appliance, convenience and safety of forklift tire lifting are guaranteed; the labor intensity of assembly workers is lowered, and work efficiency is improved by one to two times; and bumping in the process of turning over tires through forklifts in the original assembly method is avoided, and the appearance quality of forklift assembly is effectively improved.

Owner:ANHUI HELI CO LTD

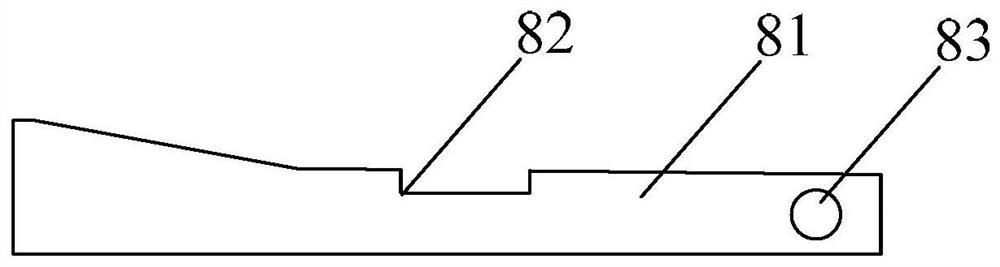

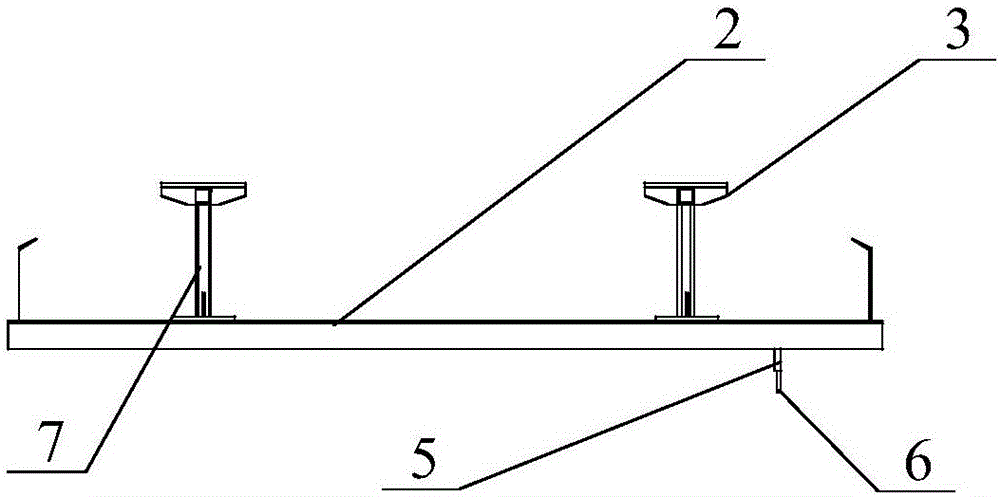

Seed sunning device capable of turning over seeds conveniently

ActiveCN109458808AEasy flipEasy to pourDrying chambers/containersMachines/enginesEngineeringMechanical engineering

Owner:李罡

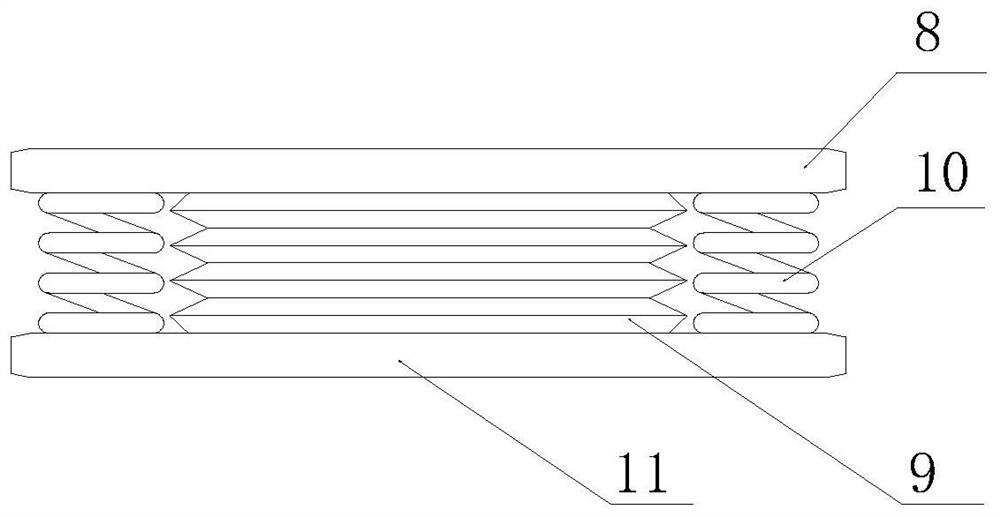

Fixing device for machining automobile beam middle plate

InactiveCN110450118AEasy to processEasy to fixVibration dampersNon-rotating vibration suppressionCouplingArchitectural engineering

The invention discloses a fixing device for machining an automobile beam middle plate. The fixing device comprises a workbench, a portal frame is fixed to the two sides of the outer wall of the top ofthe workbench through screws, electric push rods are fixed to the inner walls of the opposite sides of the portal frame through screws, sliding plates are fixed to one ends of piston rods of the electric push rods through screws, fixing blocks are fixed to the outer walls of the sliding plates through screws, installation grooves are formed in the outer walls of one sides of the fixing blocks, motors are fixed to the inner walls of the installation grooves through screws, output shafts of the motors are connected with U-shaped plates through couplers, hydraulic rods are fixed to the inner walls of the tops of the U-shaped plates through screws, and fixing plates are fixed to one ends of piston rods of the hydraulic rods through screws. According to the fixing device, different surfaces ofthe middle plate can be machined conveniently, manual overturning is not needed, the operation is convenient, the machining efficiency is improved, the practicability is high, the machining positioncan be conveniently pinpointed by a worker, and the machining quality is improved.

Owner:十堰市乾德工贸有限公司

Folding case

The invention discloses a folding case comprising a base frame, end frame arranged at the two ends of the base frame and a hinge device. The hinge device comprises a fixed hinge and a movable hinge. The folding case further comprises a twist lock device comprising a coupling twist lock and a twist lock arm. One end of the twist lock arm is fixedly connected with the coupling twist lock. The other end of the twist lock arm is connected with the base frame in a pivoted mode. The guiding faces / guiding face are / is arranged in the corresponding positions / position of the twist lock arm and / or the moveable hinge. During the period that the end frames are pivoted from folding positions to vertical positions, the guiding face arranged on one of the twist lock arm and the movable hinge makes contact with the other guiding face arranged on one of the twist lock arm and the movable hinge, so that the twist lock device is pivoted from a coupling position to a storage position along with pivoting of the movable hinge from the folding position to the vertical position; and accordingly the movable hinge can apply acting force to the twist lock arm through the guiding face in the pivoting period, and the twist lock arm is made to be pivoted to the storage position without the need for manual turnover of the twist lock device.

Owner:GUANGDONG XINHUI CIMC SPECIAL TRANSPORT EQUIPS +1

Sun-drying device capable of utilizing solar energy and wind energy at same time

ActiveCN109489368ASun seed evenlyImprove utilization efficiencyDrying solid materials with heatDrying machines with non-progressive movementsEngineeringWind power

The invention relates to the technical field of sun-drying devices, in particular to a sun-drying device capable of utilizing solar energy and wind energy at the same time. The sun-drying device comprises a transparent drum, wherein the transparent drum is horizontally arranged. The transparent drum is internally provided with a drum cavity. The side wall of the transparent drum is provided with adrum cover. The left end and the right end of the transparent drum are axially provided with a first driving rod and a second driving rod correspondingly. The first driving rod and the second drivingrod are rotatably connected to a first vertical rod and a second vertical rod correspondingly. The first vertical rod is rotatably connected with a transverse rod. The transverse rod is located abovethe first driving rod and is higher than the transparent drum. Transmission is achieved between the first driving rod and the transverse rod through a toothed belt. Multiple vanes are detachably arranged at one end of the transverse rod. By means of the sun-drying device, seeds can be sun-dried through the solar energy and the wind energy at the same time.

Owner:李罡

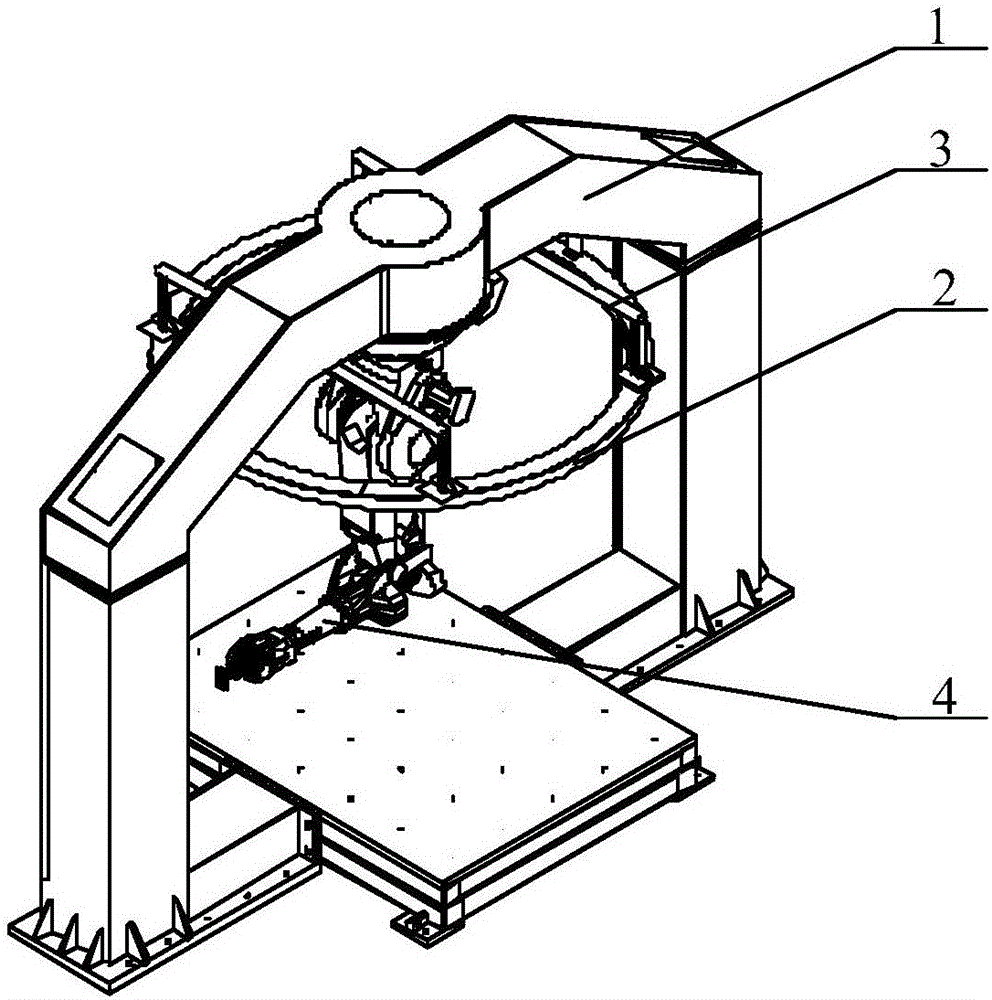

A sheet metal processing equipment

ActiveCN106112545BAvoid entanglementAvoid damageOther manufacturing equipments/toolsLaser cuttingUltimate tensile strength

The invention discloses a sheet metal processing device, and relates to the field of steel plate processing. The device comprises a feed and discharge mechanism, a laser cutting mechanism, a turnover mechanism, a grinding mechanism, a conveying mechanism and a cleaning and drying mechanism, wherein the feed and discharge mechanism, the laser cutting mechanism, the turnover mechanism, the grinding mechanism, the conveying mechanism and the cleaning and drying mechanism are sequentially connected. The laser cutting mechanism comprises a gantry beam and a robot. The robot is fixed to the gantry beam. A circular rail is arranged below the gantry beam. Multiple slide assemblies are arranged at the bottom of the circular rail. Tension balancers are arranged at the bottoms of the slide assemblies. The turnover mechanism comprises a supporting frame. A turnover frame is arranged inside the supporting frame. A steel plate containing area is arranged inside the turnover frame. A steel plate clamping and feeding mechanism is arranged in the steel plate containing area and is fixedly connected with the turnover frame. The tops of feeders are used for containing a steel plate. The feeders are vertically arranged in parallel. Clamps used for clamping the steel plate are arranged on the feeders. By means of the sheet metal processing device, the labor intensity can be lowered, safety is achieved, and the quality of the steel plate can be improved.

Owner:WUHAN TIANQI LASER EQUIP MFG

Timber polishing device

ActiveCN106826519AFast polishingEasy to carryGrinding carriagesPolishing machinesEngineeringUltimate tensile strength

The invention discloses a timber polishing device which comprises a bearing plate. The upper surface of the bearing plate is provided with a polishing mechanism. The timber polishing device has the advantages that the device performs automatic fixed rotation and polishing, the polishing speed is quick, a polished material is directly reasonably placed during polishing, carrying by people is facilitated, manual overturning is not needed, working efficiency is improved, working intensity is reduced, manpower is liberated, and the timber polishing device is convenient to use.

Owner:徐州林域木业有限公司

Double-surface cementing device used for timber

ActiveCN108452994AEasy to glueNo manual flipping requiredLiquid surface applicatorsCoatingsEngineering

Owner:芜湖市夏氏世家家具有限公司

Product overturning mechanism

InactiveCN107585531AAvoid frictionReduce error rateControl devices for conveyorsError ratioEngineering

Owner:广德竹昌电子科技有限公司

Coating covering device for cast product and manufacturing method

PendingCN112495676ATo achieve the effect of paintingImprove coverage efficiencyLiquid surface applicatorsCoatingsStructural engineeringCovers (device)

The invention discloses a coating covering device for a cast product. The coating covering device comprises two lifting frames, wherein smearing mechanisms are arranged on the same sides of the two lifting frames; each smearing mechanism comprises a coating box; the bottom of each coating box is inverted trapezoidal; a discharge pipe is arranged below each coating box; a coating brush is arrangedat the bottom of the inner wall of each discharge pipe; two ends of each coating brush are rotationally connected with the corresponding discharge pipe; a conveying mechanism is arranged below the twosmearing mechanisms; the conveying mechanism comprises two racks; two first transmission rollers are arranged between the two ends of the two racks; the two first transmission rollers are rotationally connected with the racks; and two conveying belts are rotationally connected between the two first transmission rollers. The coating covering device has the beneficial effects that the covering device is provided with the two smearing mechanisms, and a turnover mechanism is additionally arranged between the two smearing mechanisms, so that a workpiece is directly turned over and then smeared again after one surface of the workpiece is smeared, and manual turnover is not needed while the coating covering efficiency is improved.

Owner:江西德辰科技有限公司

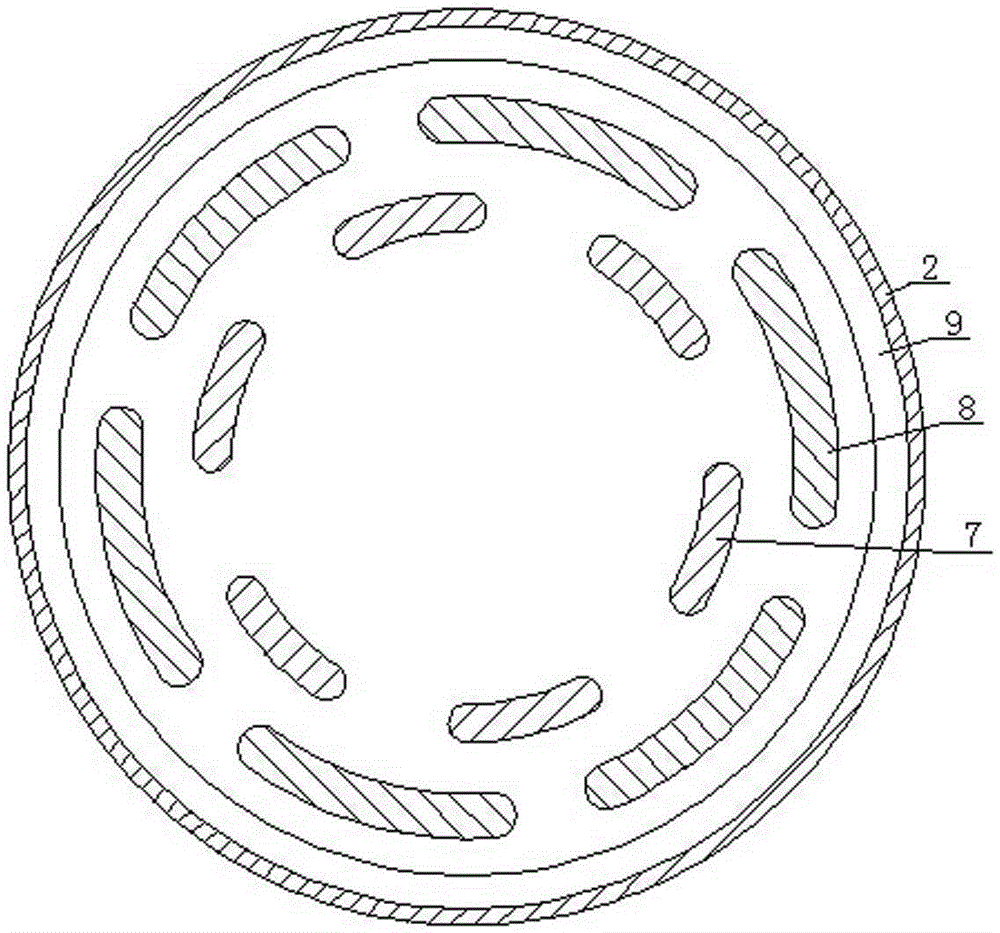

Jasmine tea scenting equipment

The invention belongs to the technical field of jasmine tea making equipment, discloses jasmine tea scenting equipment, and solves the problem that tea processed by the conventional scenting device is poor in quality. The jasmine tea scenting equipment comprises a base, wherein a cylinder body is arranged on the base; a gear ring is arranged on the outer surface of the cylinder body; supporting rollers and a driving motor are arranged on the base; the output shaft of the driving motor is connected with a speed reducer; the output shaft of the speed reducer is connected with a driving gear meshed with the gear ring; a jasmine support used for placing jasmine is arranged inside the cylinder body in the axial direction of the cylinder body; the space between the jasmine support and the cylinder body is used for placing tea leaves; the jasmine support comprises a framework formed by four stainless steel bars; the framework is equipped with a jasmine door capable of being opened and closed; the outer surface of the framework is coated with a screen mesh; the sieve pores of the screen mesh are smaller than the cross section of jasmine in size and larger than the cross sections of the tea leaves in size; the outer surface of each stainless steel bar is coated with a cotton layer.

Owner:四川雅安全义茶树花科技有限公司

Skewer clamping device and smokeless automatic barbecue machine

PendingCN111012196AEvenly heatedReduce manual laborRoasting apparatusRoasters/grillsEngineeringMechanical engineering

The invention discloses a skewer clamping device and a smokeless automatic barbecue machine. The skewer clamping device comprises a first transmission part, a rotating part, an elastic part, a fixingpart and a clamping part, wherein the fixing part is sleeved on the rotating part; one end of the rotating part is fixedly connected with the first transmission part, a mounting hole is formed in theother end of the rotating part, one end of the elastic part and one end of the clamping part are arranged in the mounting hole, one end of the elastic part is connected with the mounting hole, the other end of the elastic part is connected with the clamping part, the clamping part slides in the direction of the mounting hole, and skewer holes are formed in the clamping part in the direction of themounting hole. The clamping part has a tendency of sliding towards the outside of the mounting hole under the elastic action of the elastic part, and the skewer holes are in a tightened state in a mutual extrusion state; overcoming the elastic force effect of the elastic part, the clamping part slides into the mounting hole, and the skewer holes are in a loose state. According to the skewer clamping device, skewers are inserted, locked, pressed and separated, and skewer feeding and skewer discharging are facilitated; the skewers can rotate and be driven to rotate, heating is uniform, manual skewer overturning is not needed, and manual labor is reduced.

Owner:UYJ MACHINERY & EQUIP

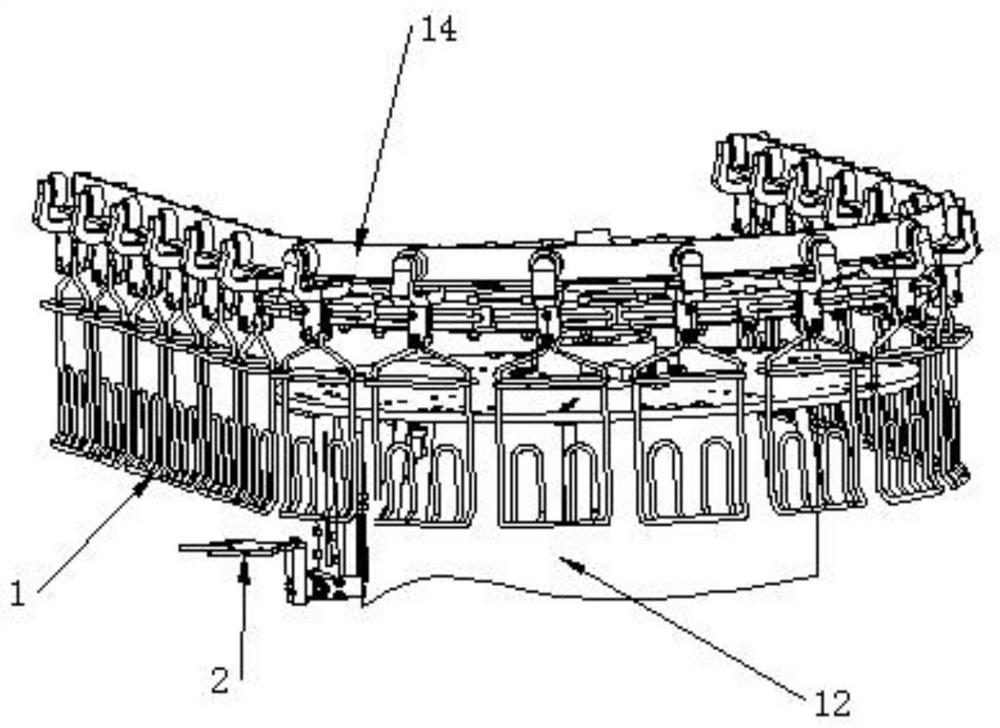

Automatic bottle turnover type double-tube staggered lifting canned bottle circulating cleaning system

InactiveCN109174868AImprove cleaning efficiencyHigh degree of automationHollow article cleaningDrying gas arrangementsDouble tubeAutomatic control

The invention discloses an automatic bottle turnover type double-tube staggered lifting canned bottle circulating cleaning system. The bottom of a main thumb wheel is equipped with a synchronous supporting rail, and the periphery of the main thumb wheel is equipped with a fixed supporting rail; a lifting gas tube and a lifting liquid tube are arranged on a mounting disc at the lower end of the main thumb wheel; a gas tube roller at the side of the lifting gas tube is carried on an outer cam rail; a liquid tube roller at the side of the lifting liquid tube is carried on an inner cam rail; the lifting liquid tube communicates with a cleanout liquid tank through a water pump via a second rotary joint; the cleanout liquid tank is arranged on the bottom of a table board; a liquid dropping tankis arranged on the table board; a gap between the synchronous supporting rail and the fixed supporting rail is positioned above the liquid dropping tank; the bottom of the liquid dropping tank communicates with the cleanout liquid tank; the lifting gas tube communicates with a hot air blower through a first rotary joint; and the two ends of a conveyor belt are equipped with bottle turnover conveying devices. The automatic bottle turnover type double-tube staggered lifting canned bottle circulating cleaning system automatically controls canned bottles to turn over and transmit in an inverted mode, adopts a gas-liquid staggered lifting flushing way, realizes continuously cleaning the canned bottles, circulates the cleanout liquid, is high in cleaning cleanliness, and is high in speed.

Owner:HUNAN HAILIAN FOOD CO LTD

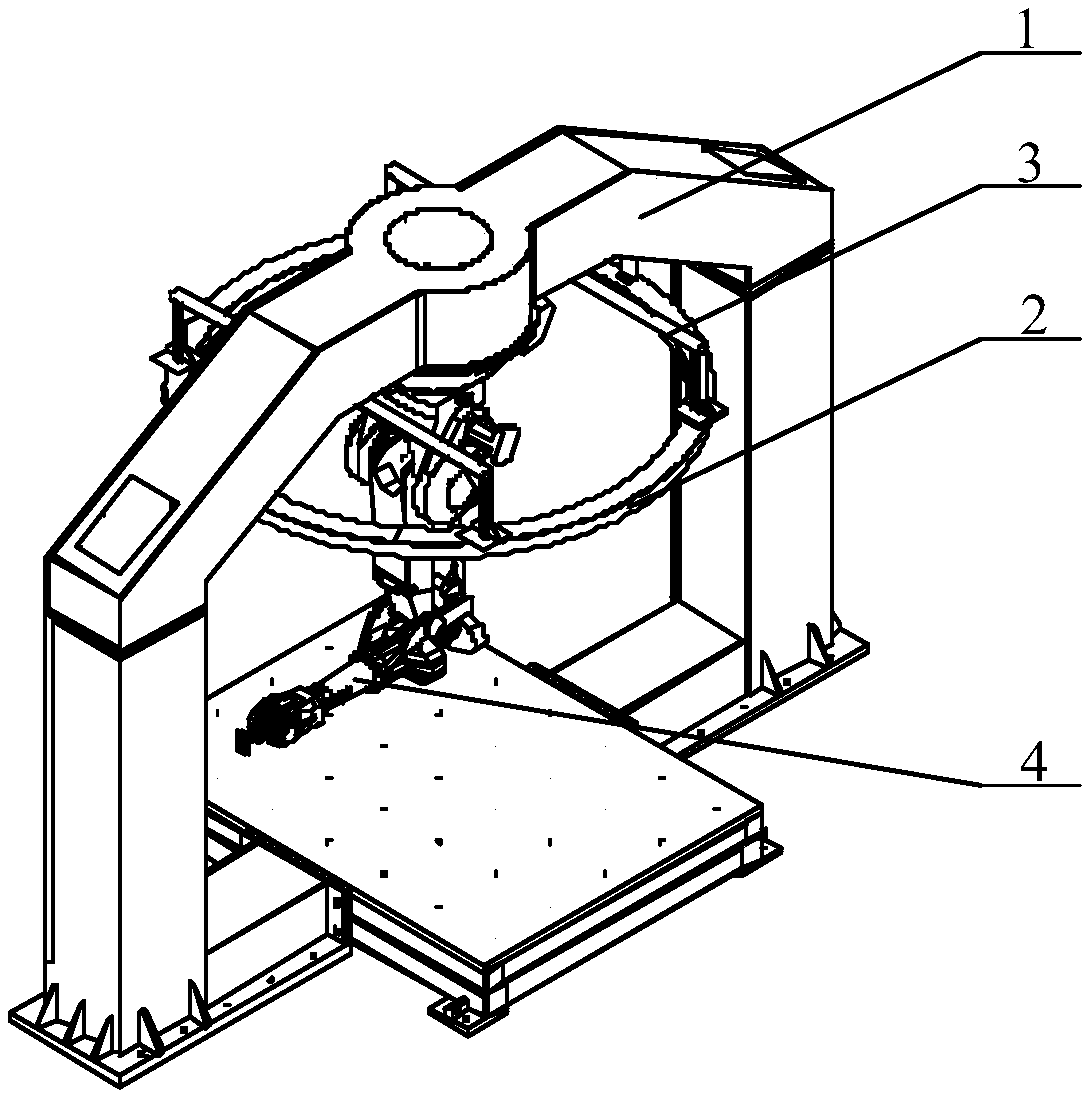

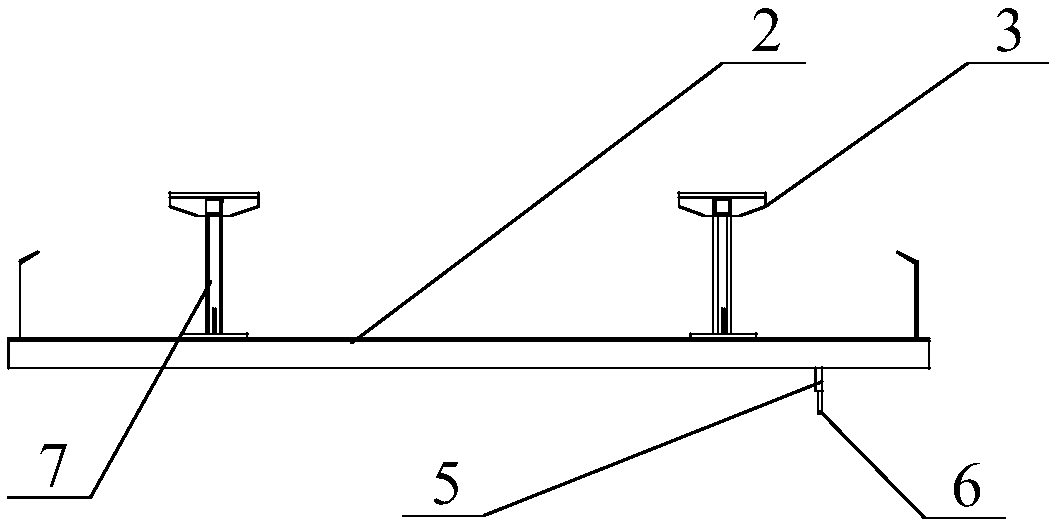

Sheet metal processing device

ActiveCN106112545AAvoid entanglementAvoid damageOther manufacturing equipments/toolsLaser cuttingEngineering

The invention discloses a sheet metal processing device, and relates to the field of steel plate processing. The device comprises a feed and discharge mechanism, a laser cutting mechanism, a turnover mechanism, a grinding mechanism, a conveying mechanism and a cleaning and drying mechanism, wherein the feed and discharge mechanism, the laser cutting mechanism, the turnover mechanism, the grinding mechanism, the conveying mechanism and the cleaning and drying mechanism are sequentially connected. The laser cutting mechanism comprises a gantry beam and a robot. The robot is fixed to the gantry beam. A circular rail is arranged below the gantry beam. Multiple slide assemblies are arranged at the bottom of the circular rail. Tension balancers are arranged at the bottoms of the slide assemblies. The turnover mechanism comprises a supporting frame. A turnover frame is arranged inside the supporting frame. A steel plate containing area is arranged inside the turnover frame. A steel plate clamping and feeding mechanism is arranged in the steel plate containing area and is fixedly connected with the turnover frame. The tops of feeders are used for containing a steel plate. The feeders are vertically arranged in parallel. Clamps used for clamping the steel plate are arranged on the feeders. By means of the sheet metal processing device, the labor intensity can be lowered, safety is achieved, and the quality of the steel plate can be improved.

Owner:WUHAN TIANQI LASER EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com