Livestock wing hair removing machine

A poultry and duck wing technology, applied in poultry plucking machines, poultry processing, poultry restraints, etc., can solve the problems of inability to realize assembly line processing, inability to accurately remove hair from duck wings, and large space occupied by driving parts, so as to overcome collisions Damage problem, overcoming electronic failure, effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

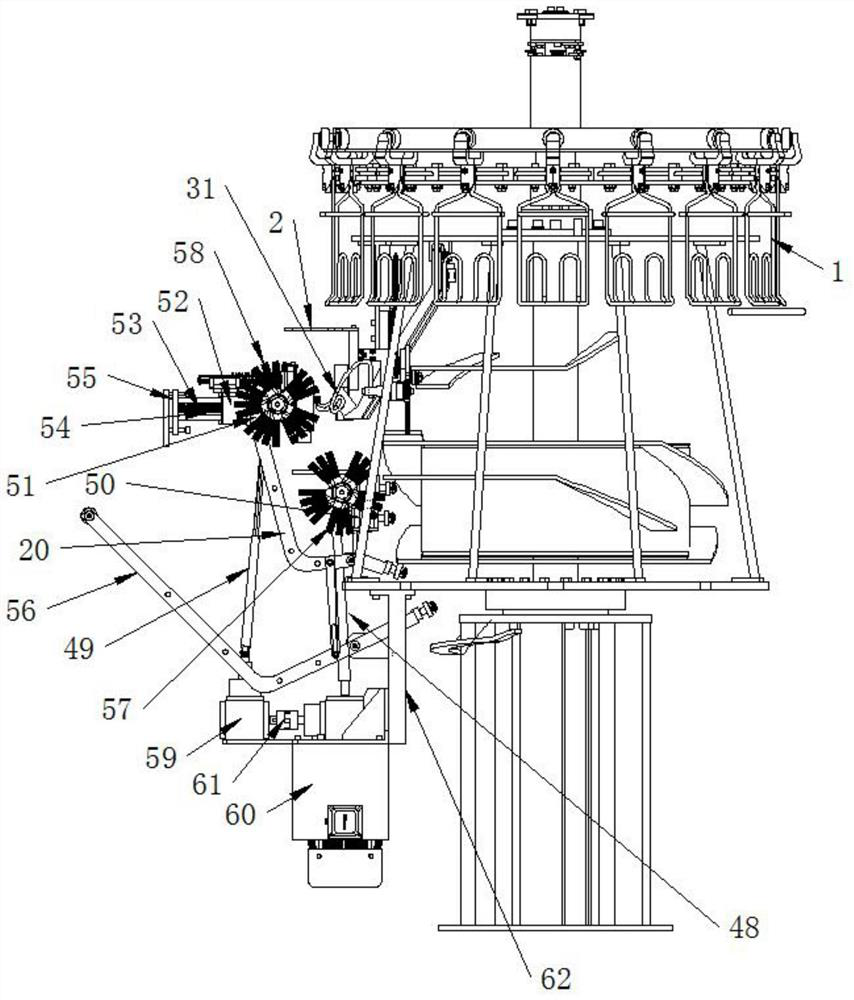

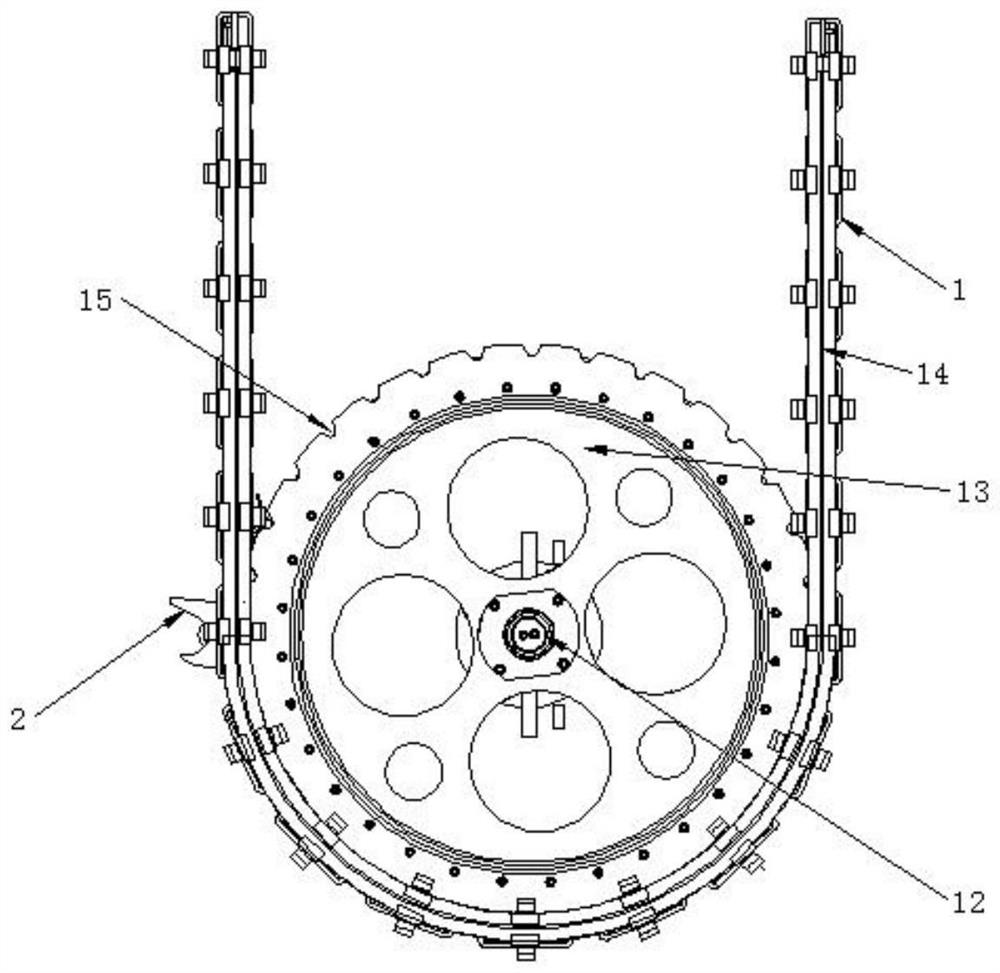

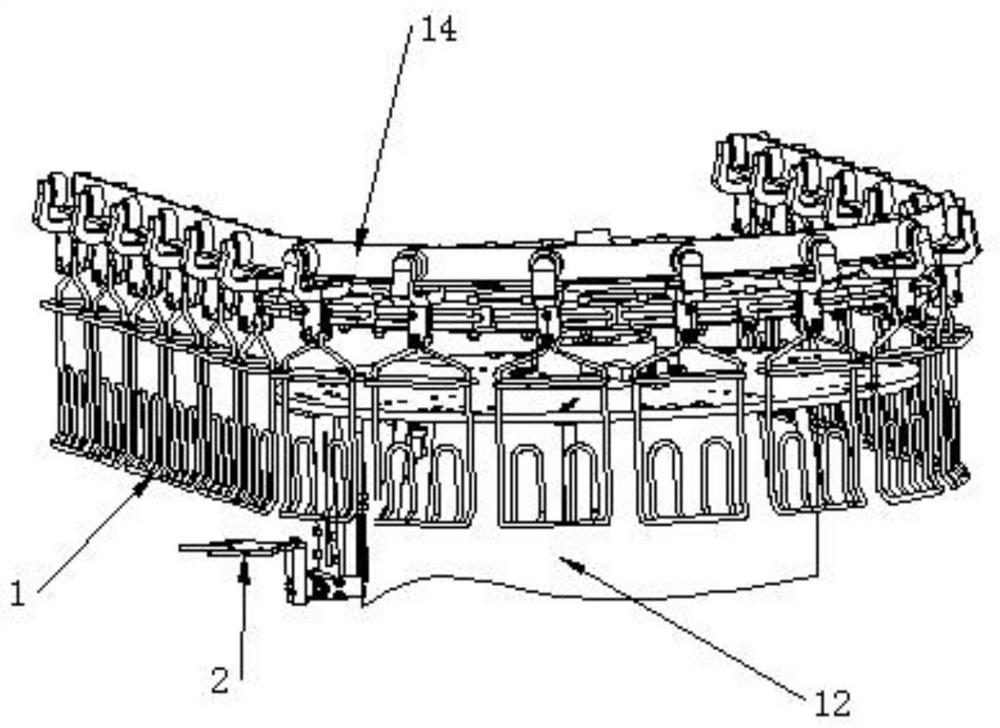

[0063] Such as Figure 1 to Figure 20 As shown, the poultry wing hair machine includes a suspension device, an introduction device, a positioning device, a wing opening device and a polishing device, and the wing opening device includes wing opening blades that are turned over to open the duck wings.

[0064] The suspension device includes a hook frame 1 for hooking two duck feet and a positioning plate 2 positioned below the hook frame 1 for positioning the distance between the two duck legs.

[0065] There are a plurality of hook racks 1, which are cyclically rotated along the feeding channel, and a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com