Welding clamp of guide rail of inserted lift scaffold

A technology for lifting scaffolding and welding fixtures, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. The effect of saving manpower and time and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

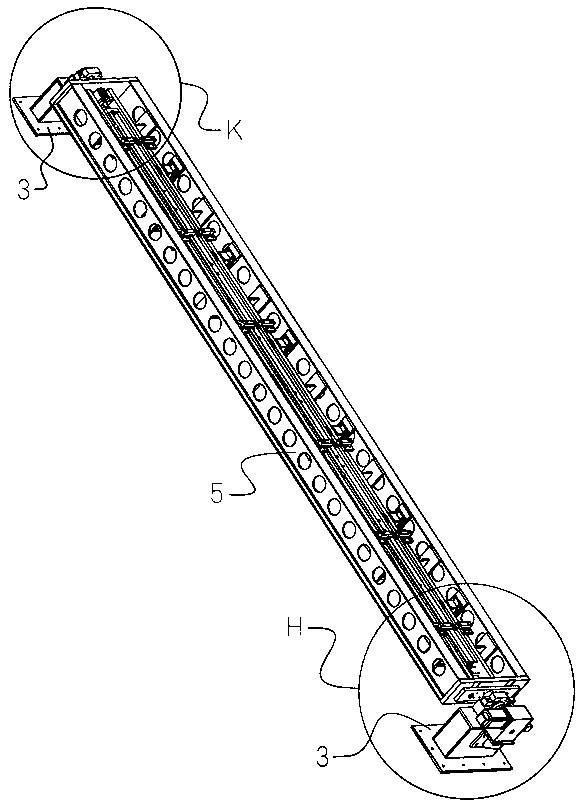

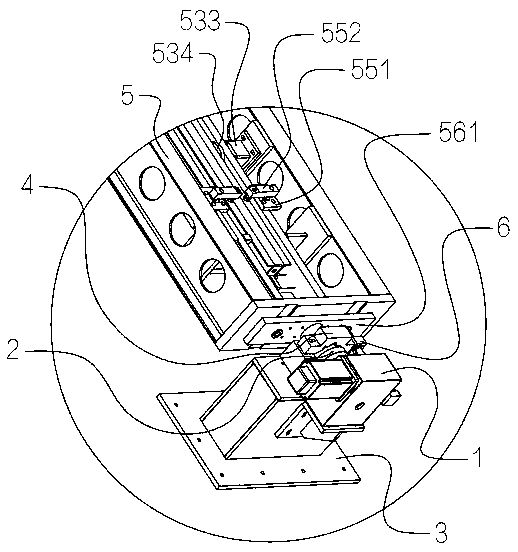

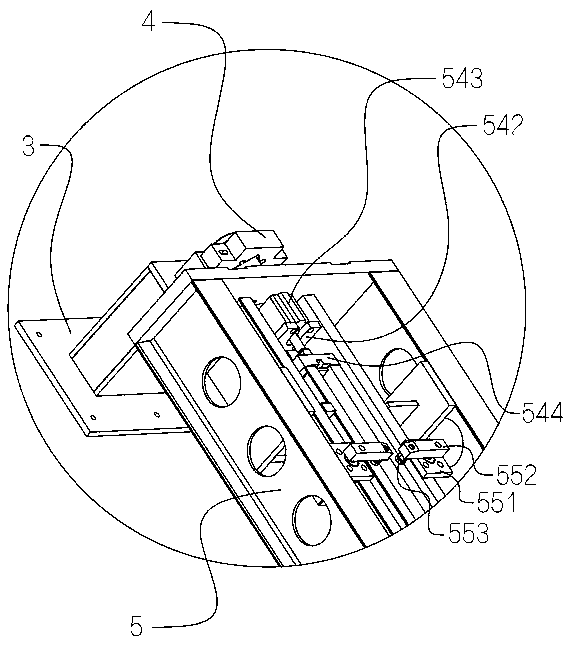

[0035] Such as figure 1 , figure 2 , image 3 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a welding fixture for the guide rail of an attached lifting scaffold includes a geared motor 1 , a rectangular frame 5 and two support seats 3 . The guide rail aimed at in this embodiment includes two channel steel rail bodies arranged back to back, between the two channel steel rail bodies along the length direction of the channel steel rail bodies, there are several circular retaining rods and some back plates evenly arranged, and the two channel steel rail bodies are located at End plates are respectively arranged at the two ends. The circular retaining rod, the back plate and the end plate are all welded together with the channel rail body to form a guide rail weldment, and the welding fixture of this embodiment is used to assist in completing these welding tasks.

[0036] Such as figure 2 , Figure 4 , Figure 5 , Figure 6 , Figure 8 and Figure 11 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com