Dual-cutter cutting machine for liquid crystal glass and cutting method

A liquid crystal glass and cutting machine technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low efficiency of liquid crystal display, easy cracking of glass, leakage of liquid crystal, etc., to avoid leakage of liquid crystal, improve Production efficiency and yield, the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

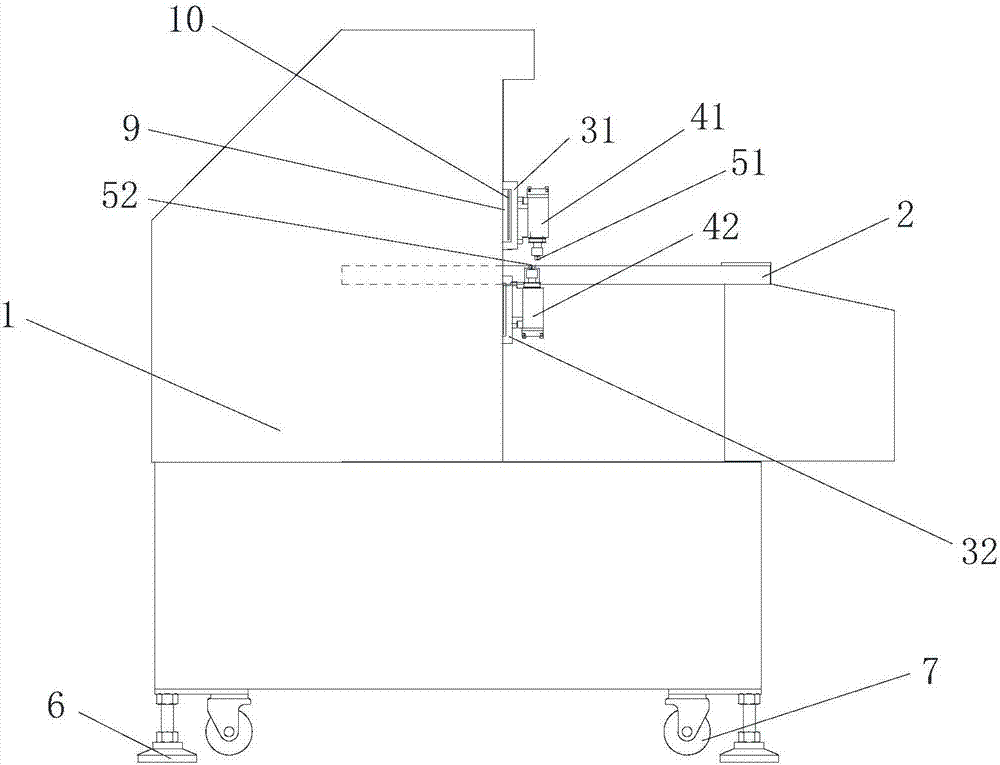

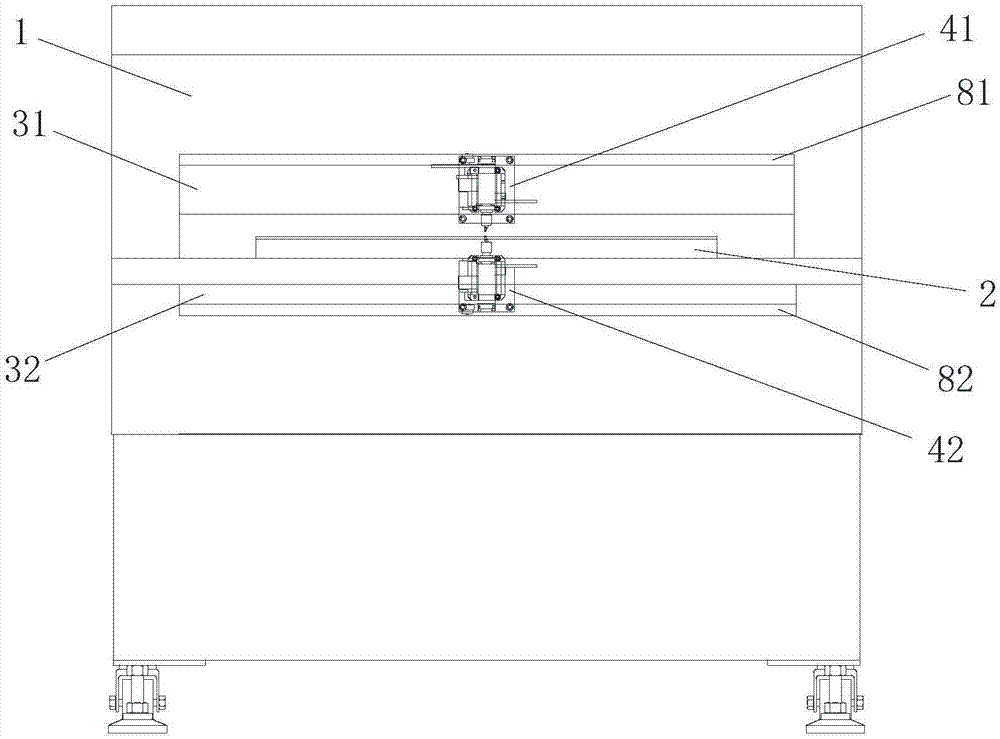

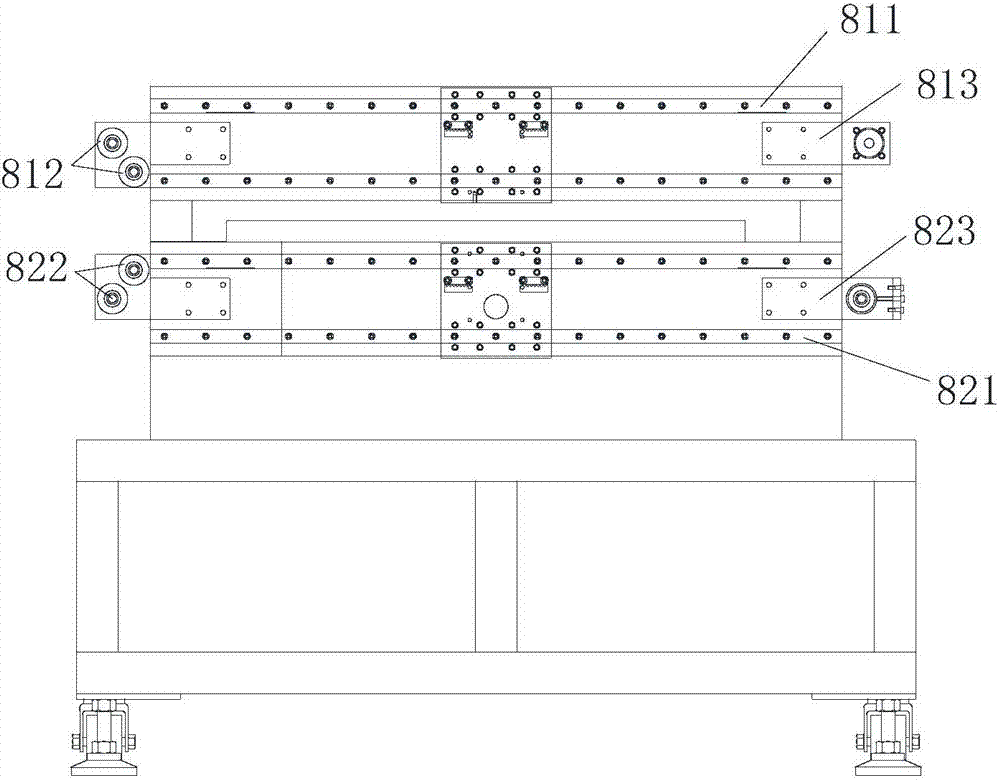

[0034] Please also refer to Figure 1 to Figure 3 , as shown in the figure, a liquid crystal glass double-knife cutting machine includes a frame 1, a work surface 2 arranged on the frame 1, a positioning plate arranged on the work surface 2, a cutting knife frame installed on the positioning plate, The cutting head that is installed on the knife rest, the positioning plate includes the upper positioning plate 31 that is arranged on the work table top and the lower positioning plate 32 that is arranged on the work table below, and the cutting knife frame includes the upper positioning plate that is installed on the upper positioning plate 31 Cutting knife rest 41 and the following cutting knife rest 42 installed on the lower positioning plate 32, the cutting knife head includes the upper cutting knife head 51 installed on the upper cutting knife rest 41 and the lower cutting knife head 52 installed on the lower cutting knife rest 42, The upper cutting head 51 and the lower cutt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com