Fabricated building steel structure

A steel structure and prefabricated technology, applied in the field of steel structure, can solve the problems affecting the use of steel structure, affecting the beauty of steel structure, unskilled technology, etc., to achieve the effect of easy control, strong practicability and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

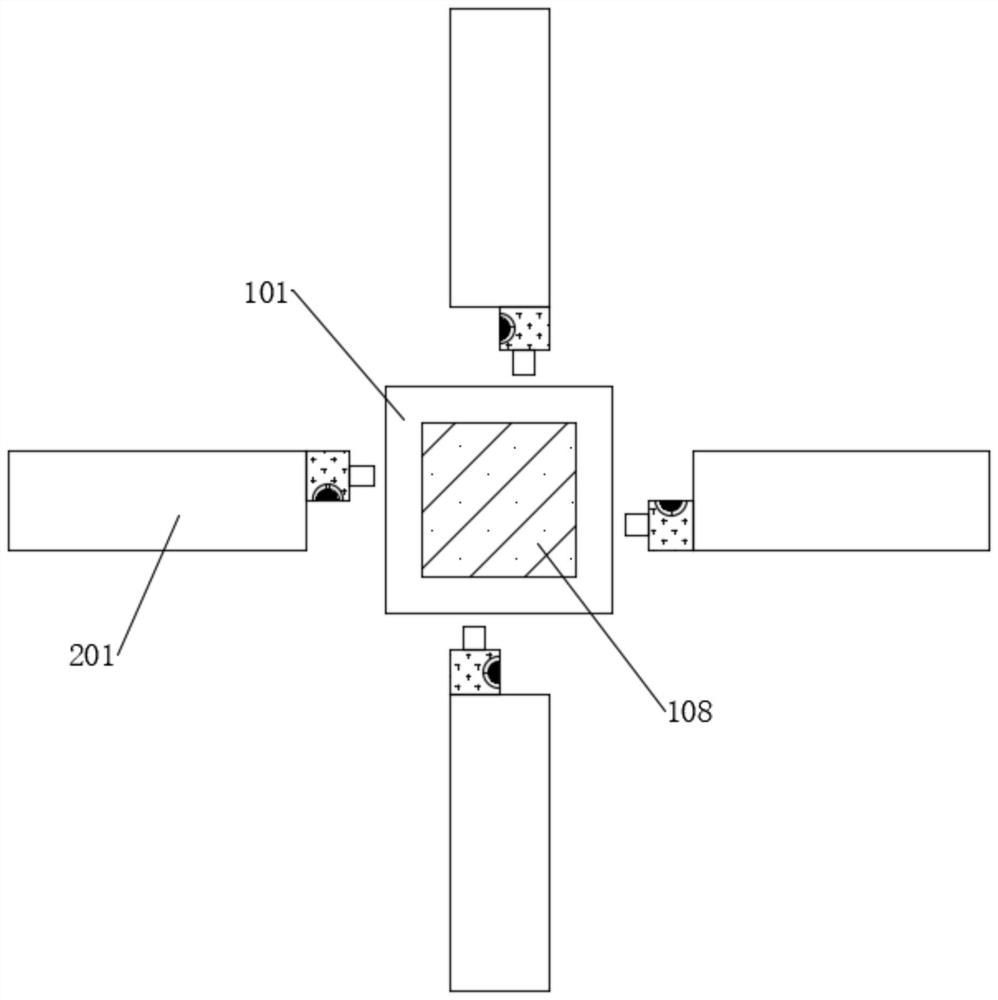

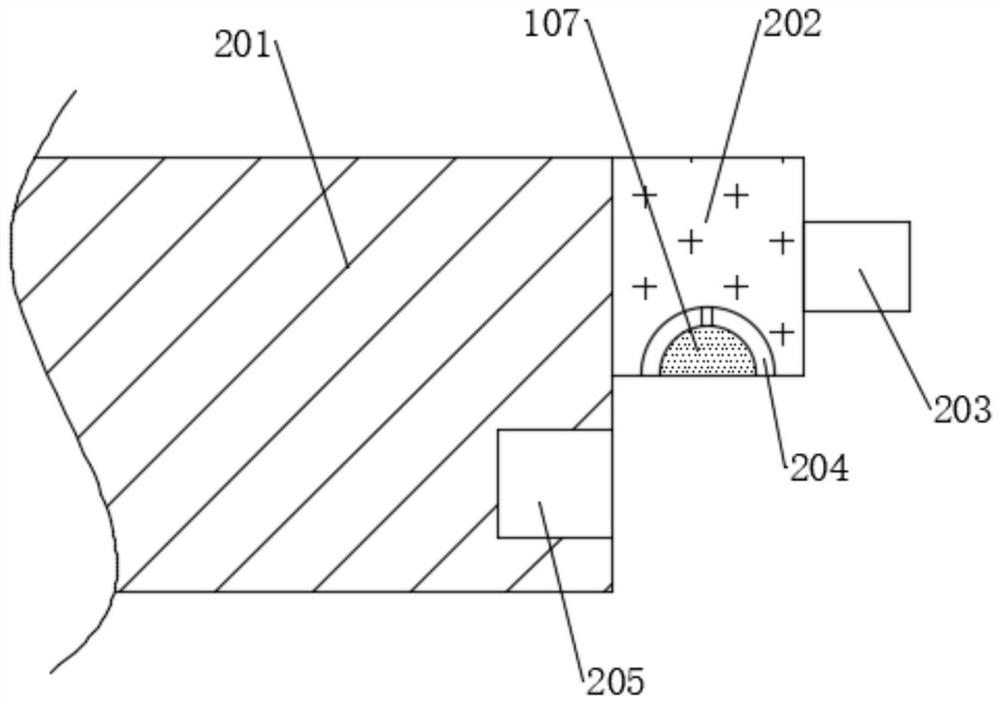

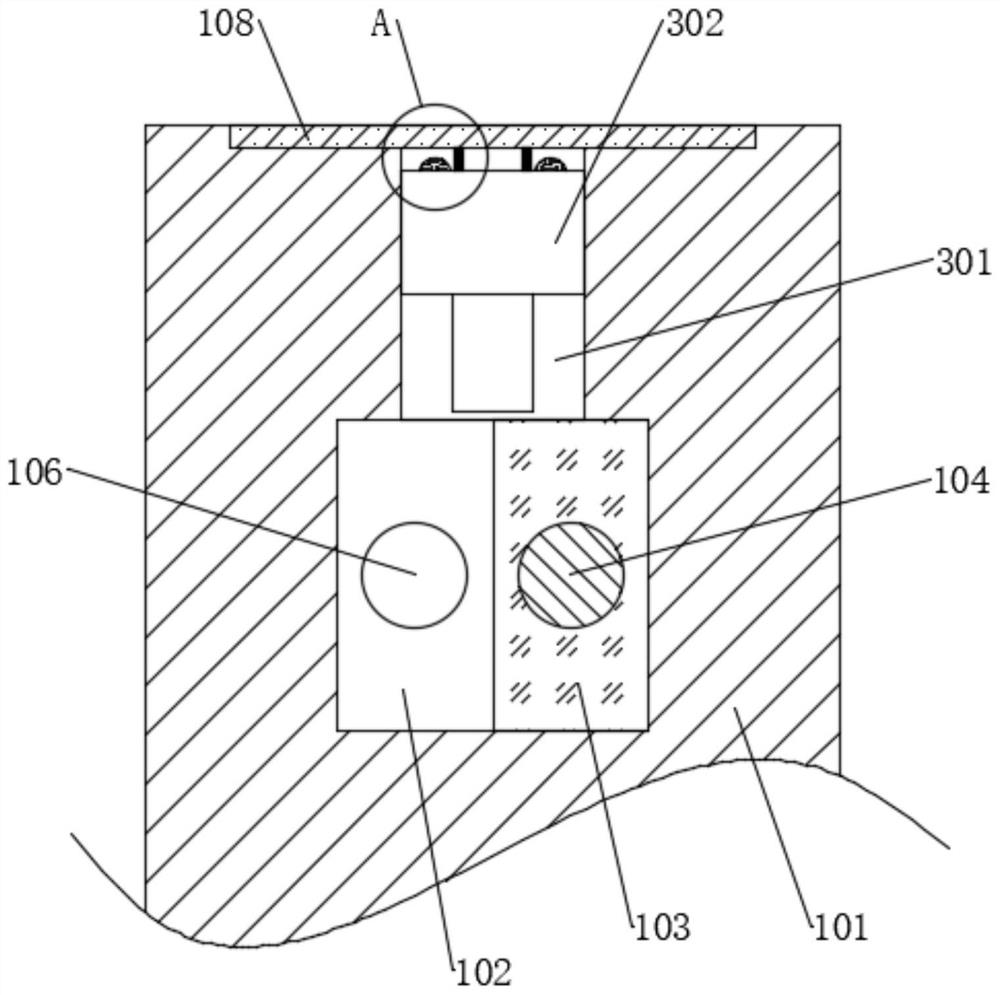

[0036] see Figure 1-9 , a prefabricated building steel structure, including a prefabricated assembly column 101 and a plurality of prefabricated assembly beams 201. The outer wall of the prefabricated assembly column 101 is provided with a plurality of assembly grooves 102 that match the prefabricated assembly beams 201. The assembly grooves 102 are provided with There are post-mortise and tenon assemblies, one end of the prefabricated assembly beam 201 is provided with a beam-mortise and tenon assembly, and a mortise and tenon drive connection assembly is provided above each assembly groove 102. A storage box 302 is fixedly connected to the inner wall of the groove 301 , an elastic sealing film 303 is connected with an opening on the outer wall of the bottom end of the storage box 302 , and a mortise and tenon pin 304 is fixedly connected to one side of the elastic sealing film 303 . An elastic convex bag 305 is connected to the top outer wall of the storage box 302 , the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com