Electric double-track wheel type flaw detection car

The technology of a double-track wheeled flaw detection vehicle is applied in the direction of railway inspection vehicles, railway car body parts, railway vehicle shape measuring devices, etc. It can solve the problems of non-adjustable distance, high transportation costs, and non-adjustable angle of the right scanning device. Achieve the effect of easy handling and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A further description will be given below with reference to the drawings and the preferred embodiments of the present invention.

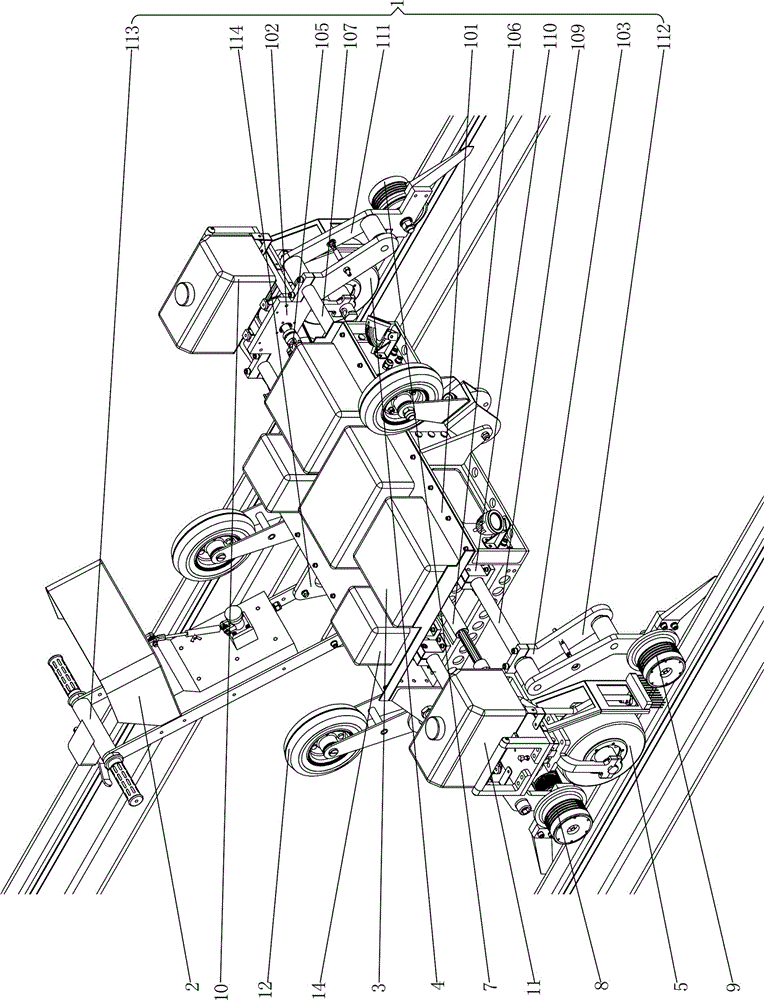

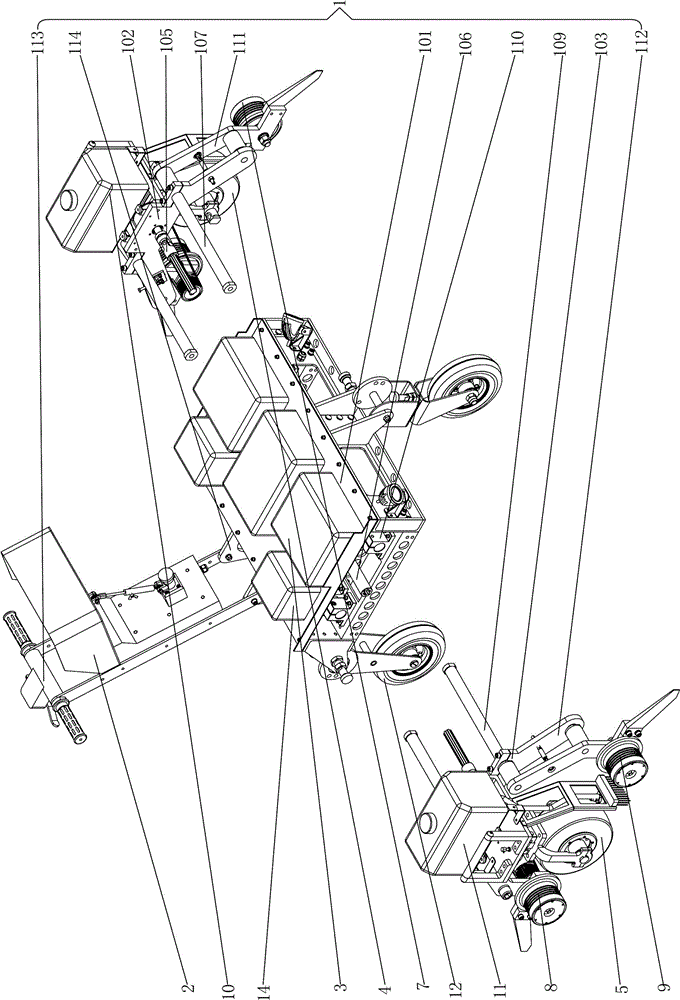

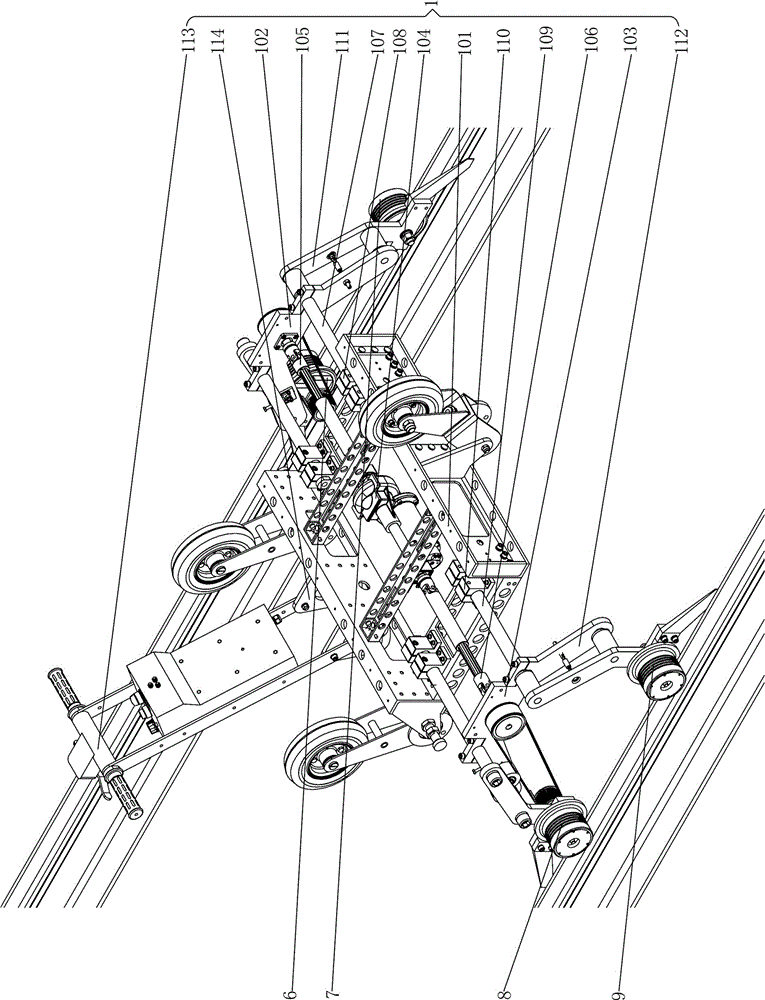

[0037] Such as figure 1 , figure 2 with image 3 As shown, this electric dual-track wheeled flaw detection vehicle includes a frame 1, a detection device 2, a power supply device 3, a left scanning device 4, a right scanning device 5, a left driving wheel 6, a left driven wheel 7, and a right driving wheel 8. Right driven wheel 9, left coupling device 10, right coupling device 11, land travel device 12, lighting device (not numbered in the figure) and accessory box 14; frame 1 includes body 101, left wing 102, right wing 103, motor difference Speed gear assembly 104, left telescopic coupling 105, right telescopic coupling 106, left guide shaft 107, left guide sleeve 108, right guide shaft 109, right guide sleeve 110, left guide device 111 and right guide device 112, The body 101 is also provided with a push frame 113 and a support frame 114....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com