Patents

Literature

63results about How to "Improve solder quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

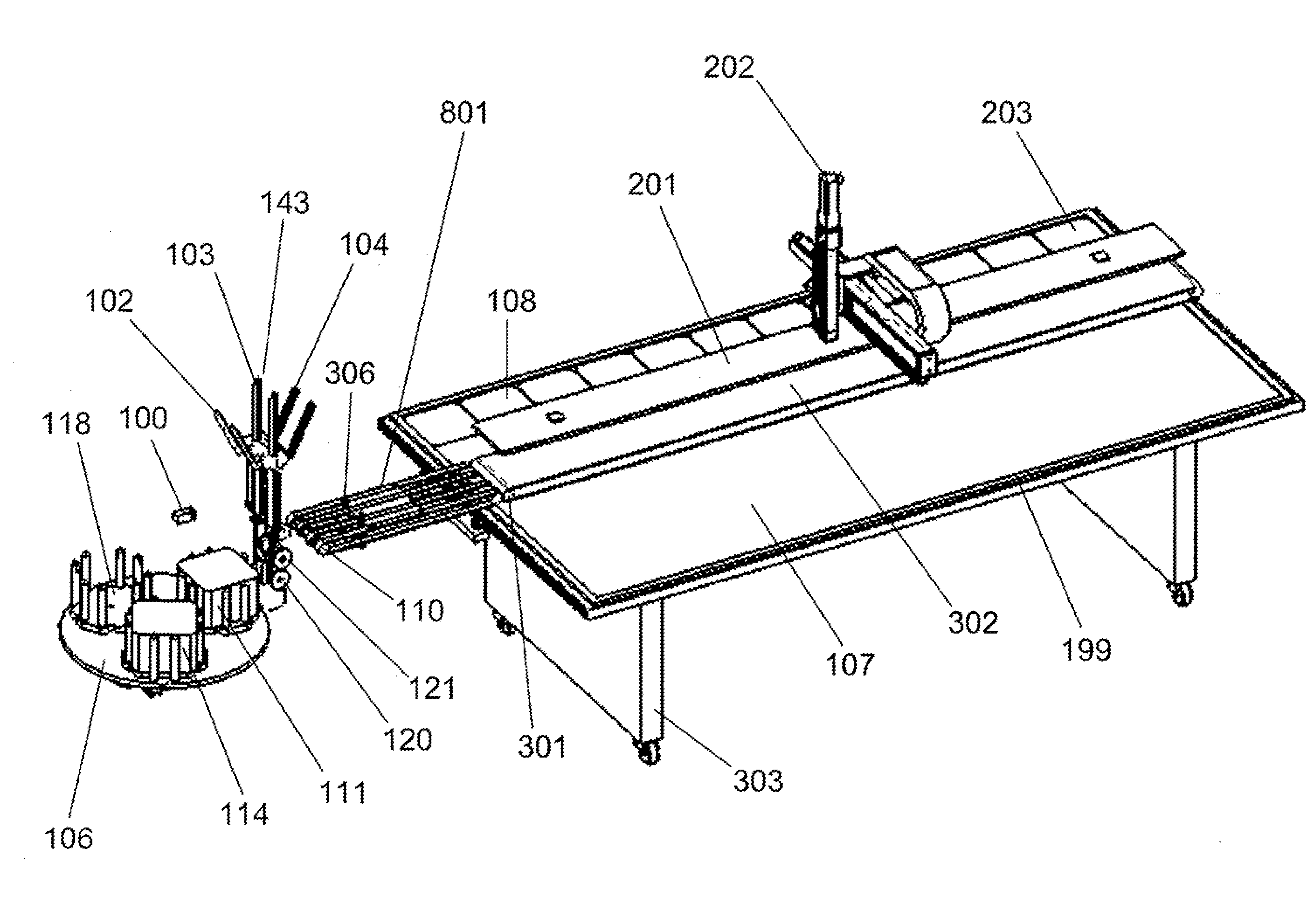

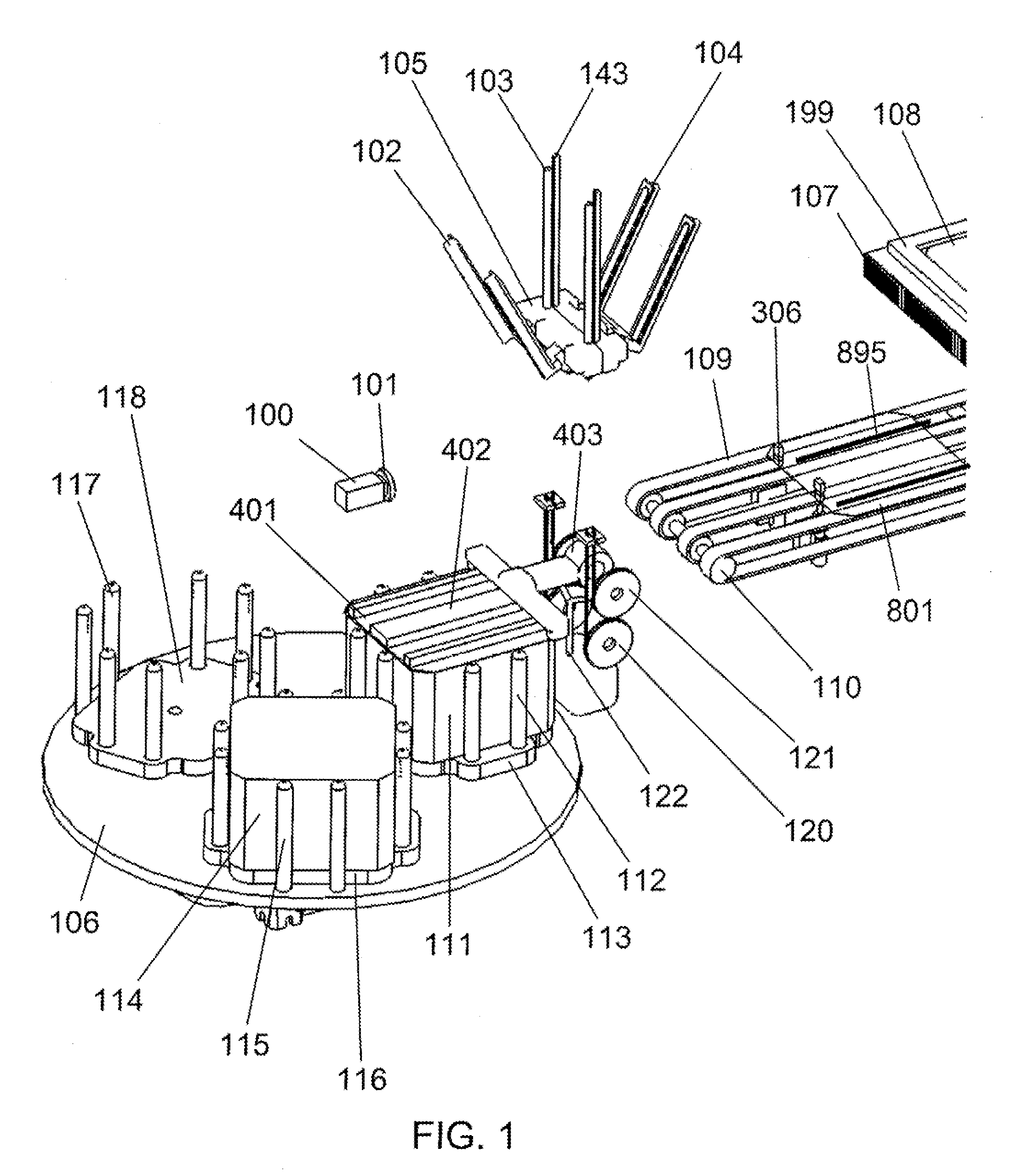

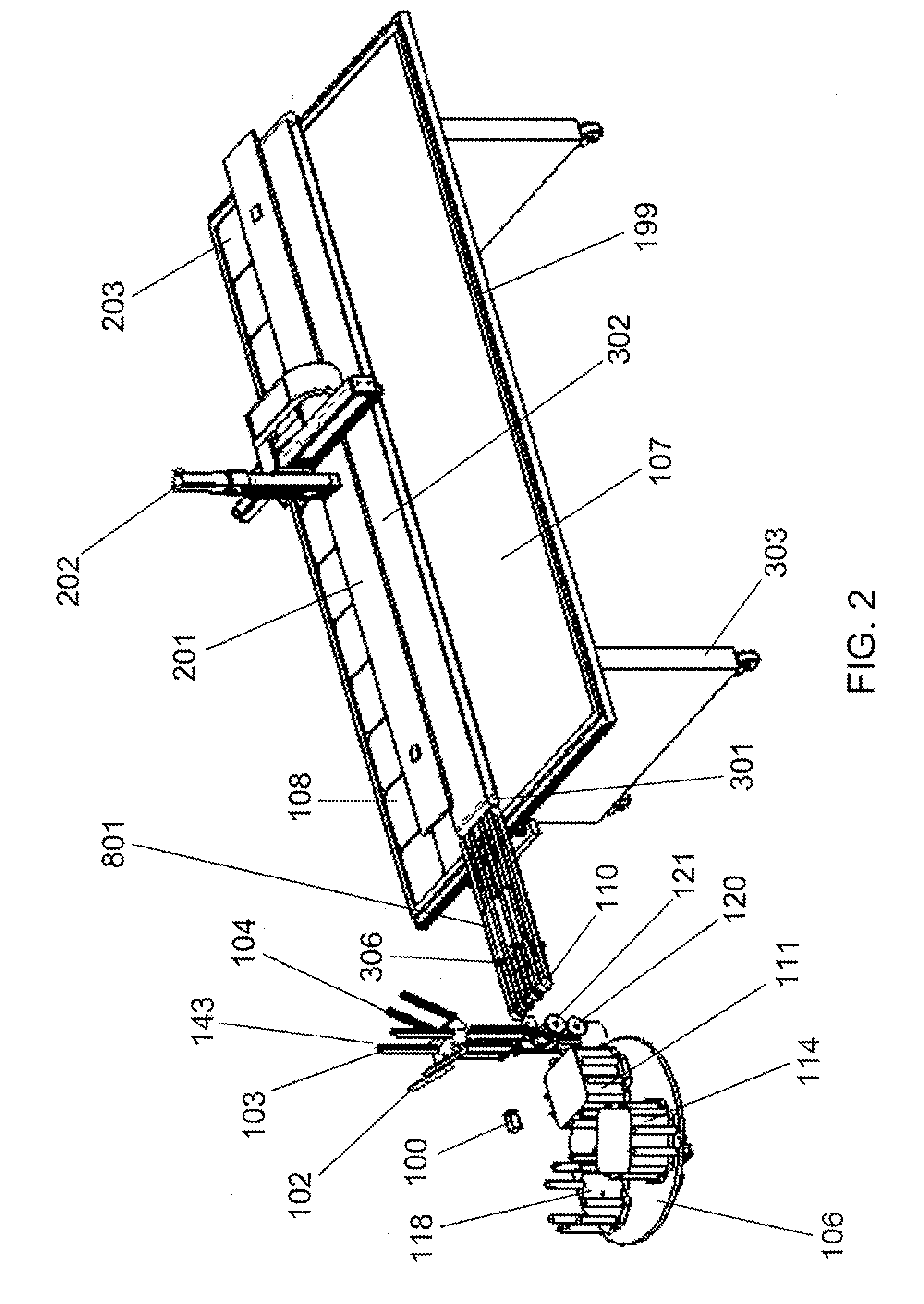

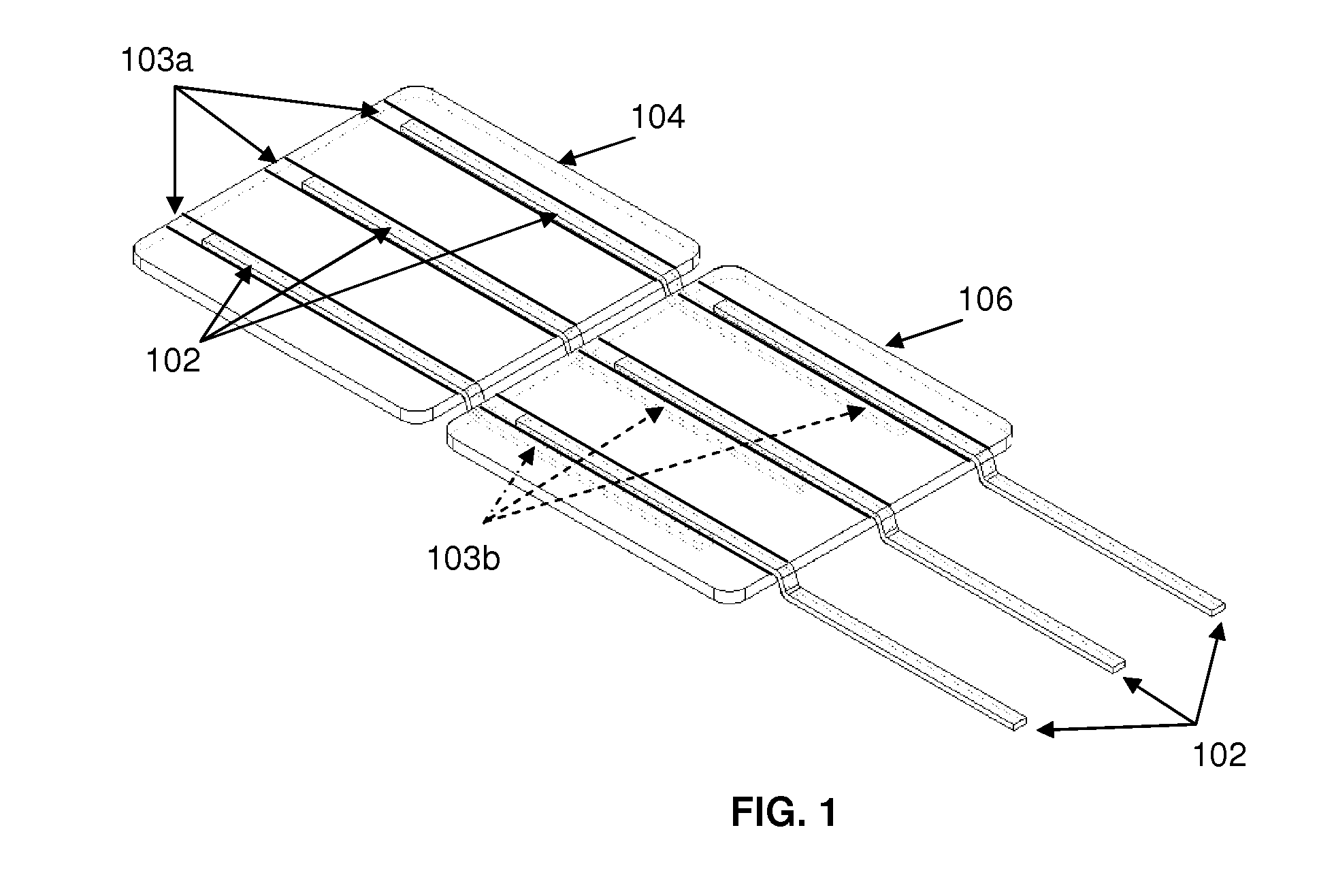

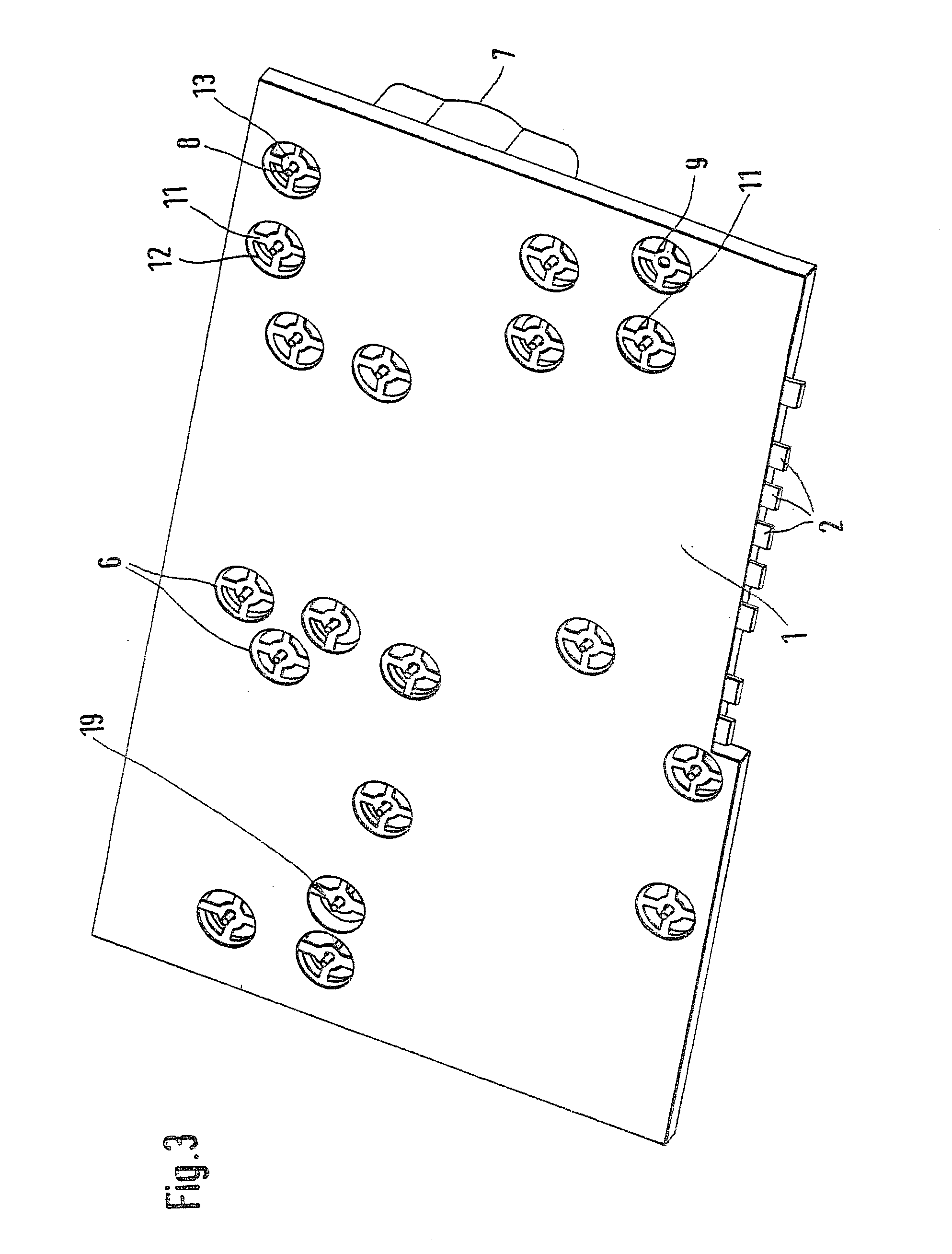

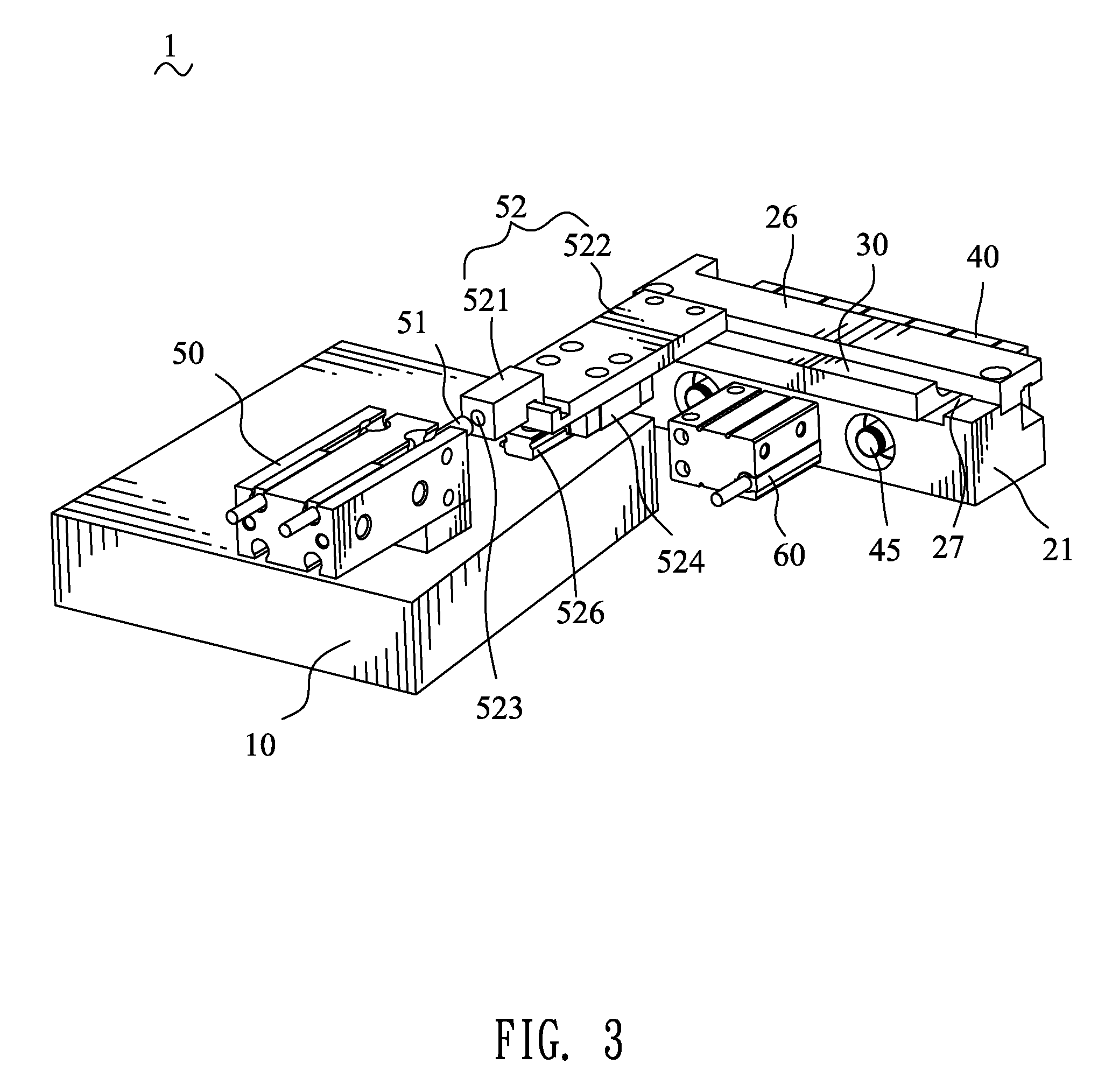

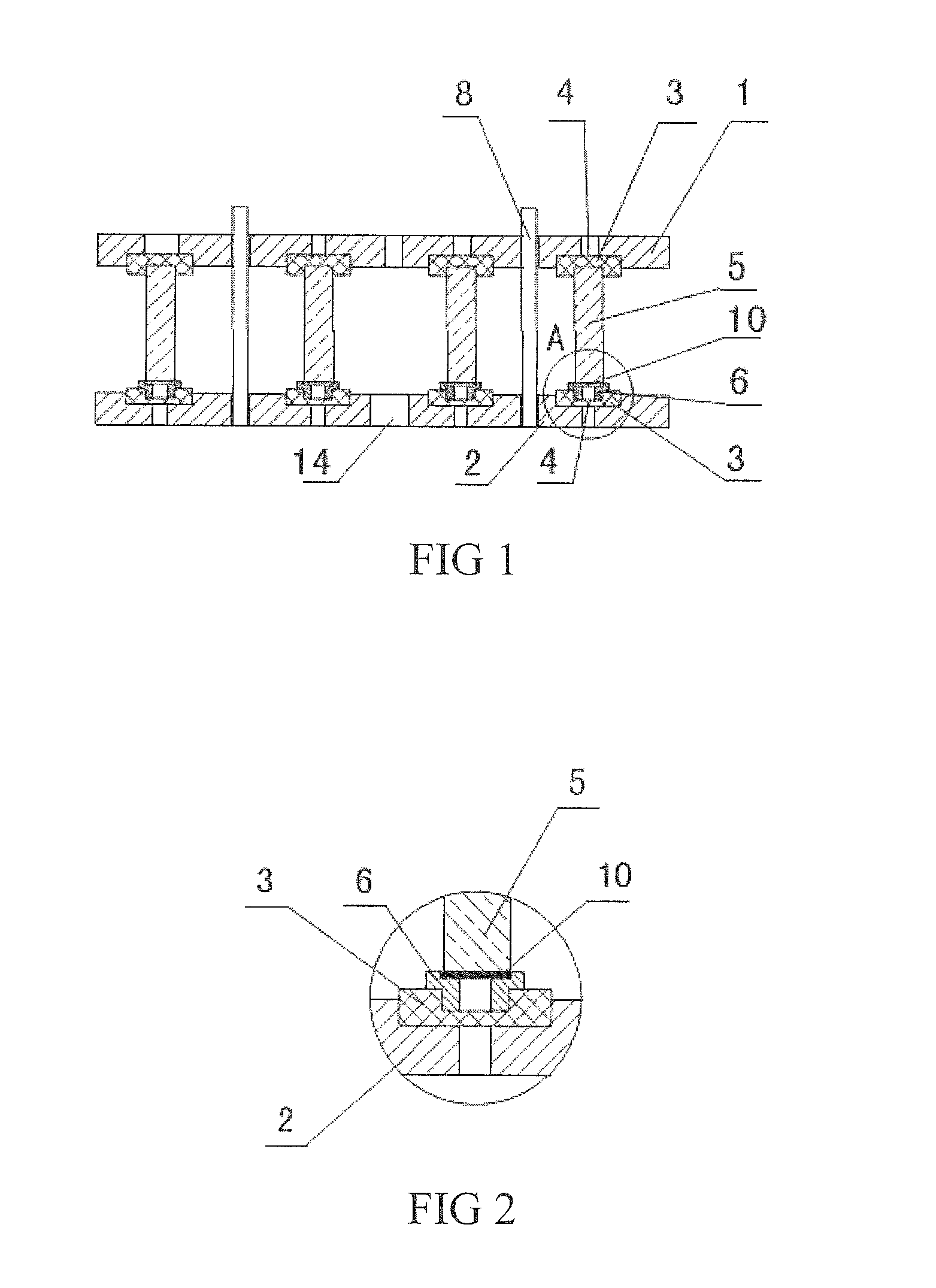

System for simultaneous tabbing and stringing of solar cells

InactiveUS20100037932A1Improve solder qualityQuality improvementPV power plantsMetal-working apparatusEngineeringCell interconnection

A method for stringing photovoltaic (PV) cells together and a system for the combined tabbing and stringing of photovoltaic (PV) cells for assembly into solar cell arrays. Multiple ribbons are first soldered simultaneously (or nearly so) to the front and back surfaces of individual PV cells (tabbing). After tabbing, PV cells are then loaded into a stringer subsystem which solders the front side ribbons of a first PV cell to the back side ribbons of the neighboring PV cell to form strings of PV cells wired in series. The tabber stringer system then loads completed strings into a frame containing a solar cell array being manufactured. The dual-ribbon method of PV cell interconnection reduces the electrical resistance between the cells in a string, thereby raising the solar cell array output power.

Owner:VSERV TECH CORP

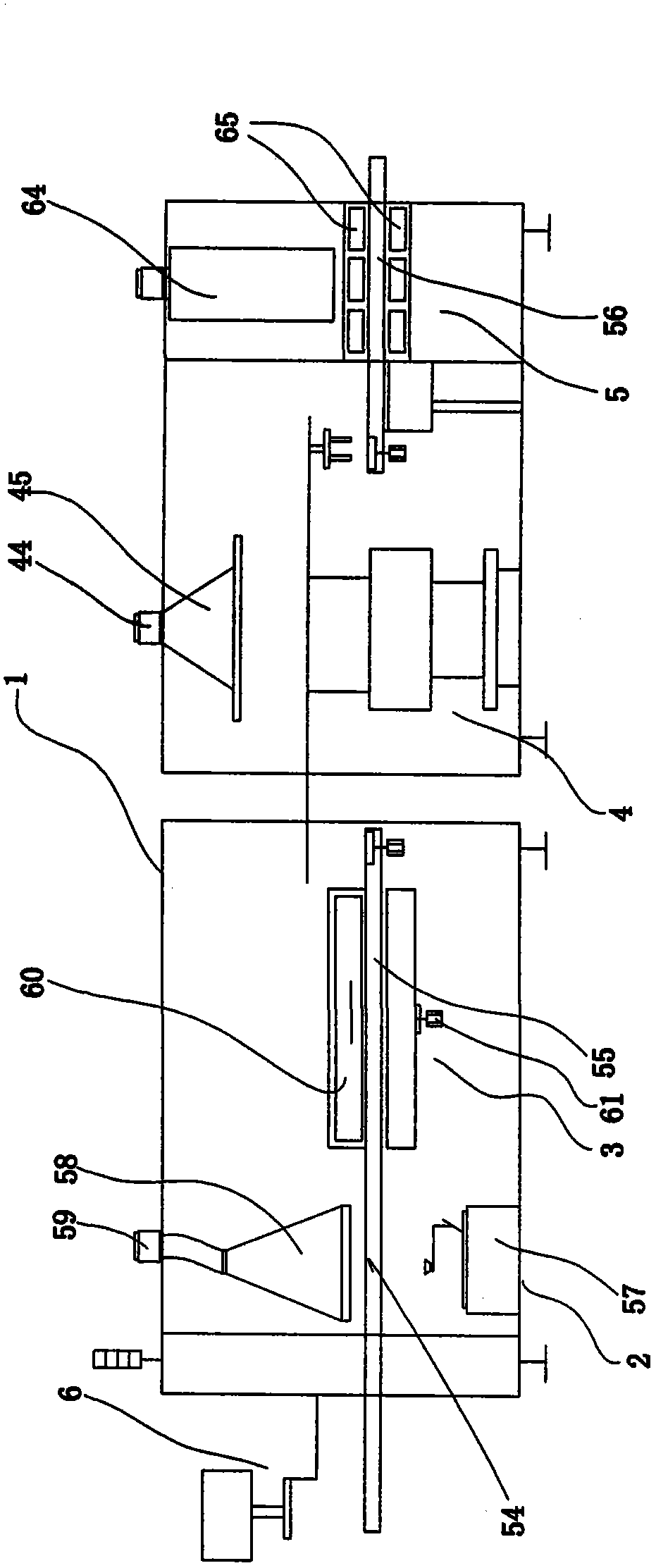

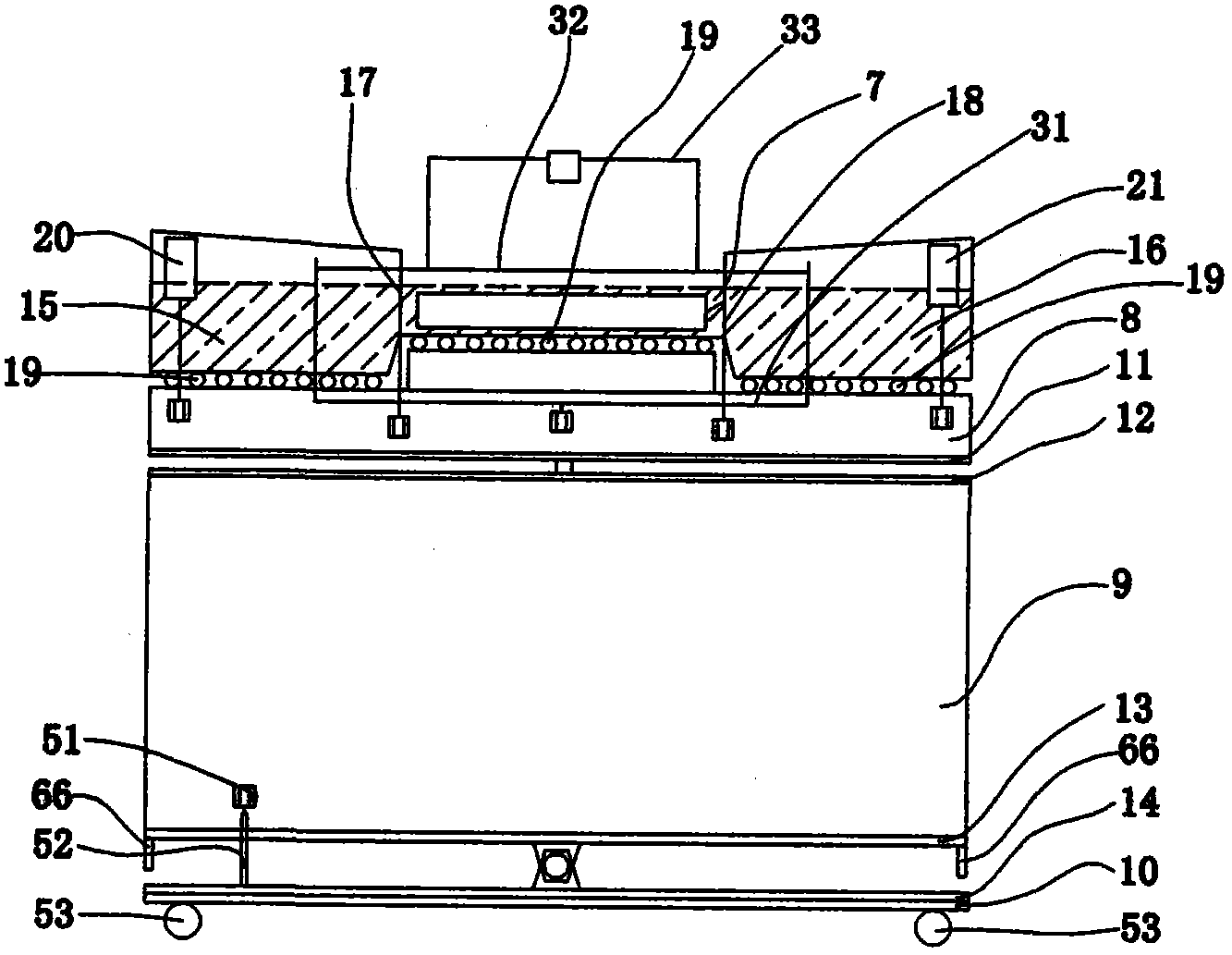

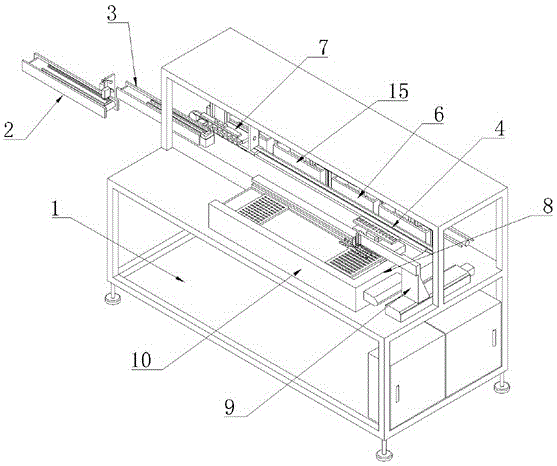

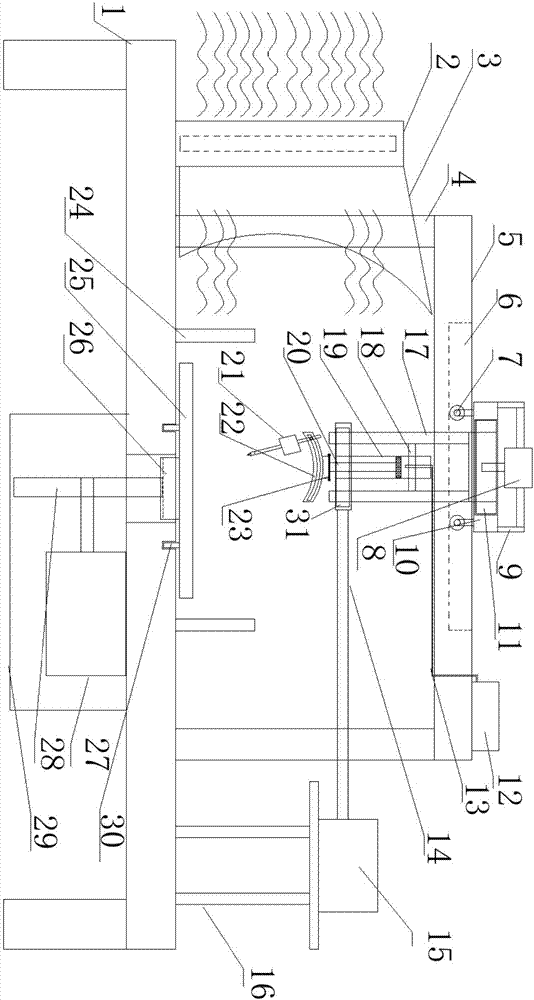

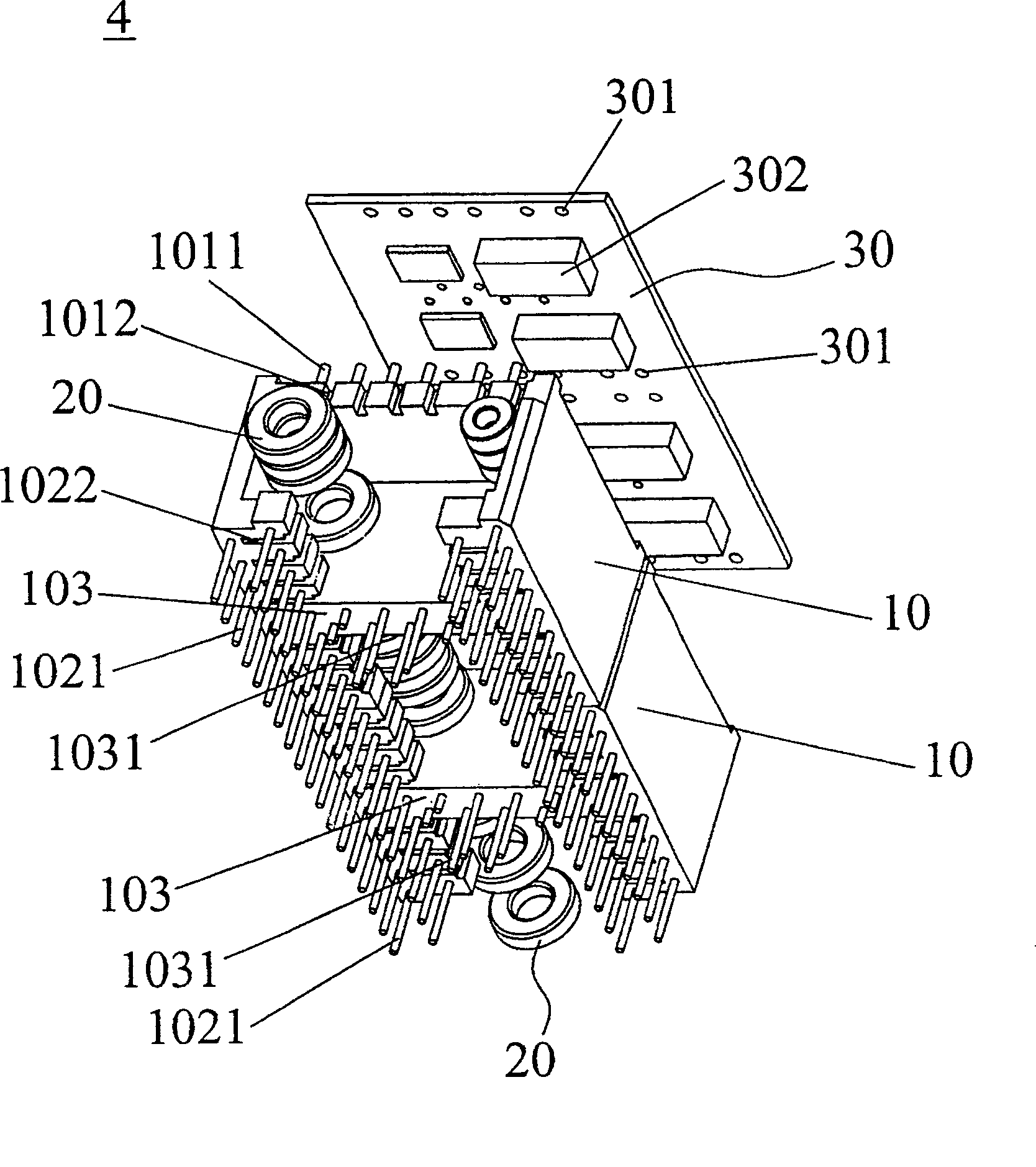

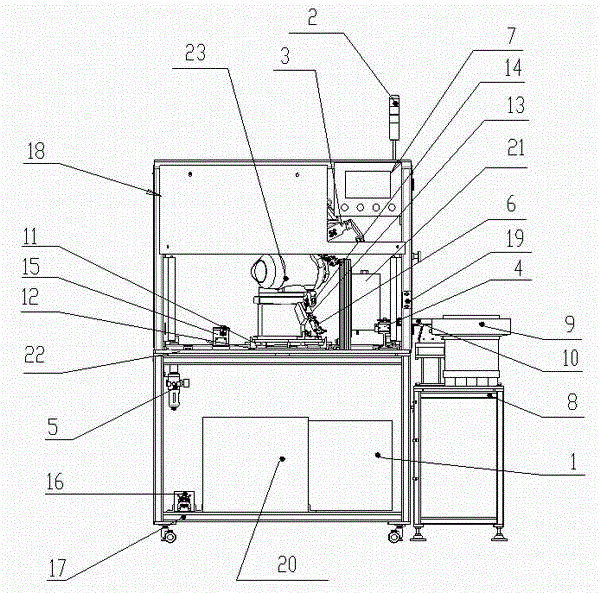

Automatic soldering machine

InactiveCN102689069AMeet different needsAvoid wastingPrinted circuit assemblingMetal working apparatusEngineeringSoldering

The invention discloses an automatic soldering machine which comprises a machine body, a soldering flux spraying device, a preheating device, a soldering furnace assembly, a cooling device and a control assembly. The soldering flux spraying device is mounted in the machine body, the control assembly is mounted at one end of the machine body, and the soldering flux spraying device, the preheating device, the soldering furnace assembly and the cooling device sequentially match with each other. The automatic soldering machine is reasonable in design, can be widely applied to soldering operation of various circuit boards of electronic products, and has a huge market potential and a practical social significance, and various long-term problems of traditional soldering equipment are solved.

Owner:DONGGUAN BABU ELECTRONICS TECH

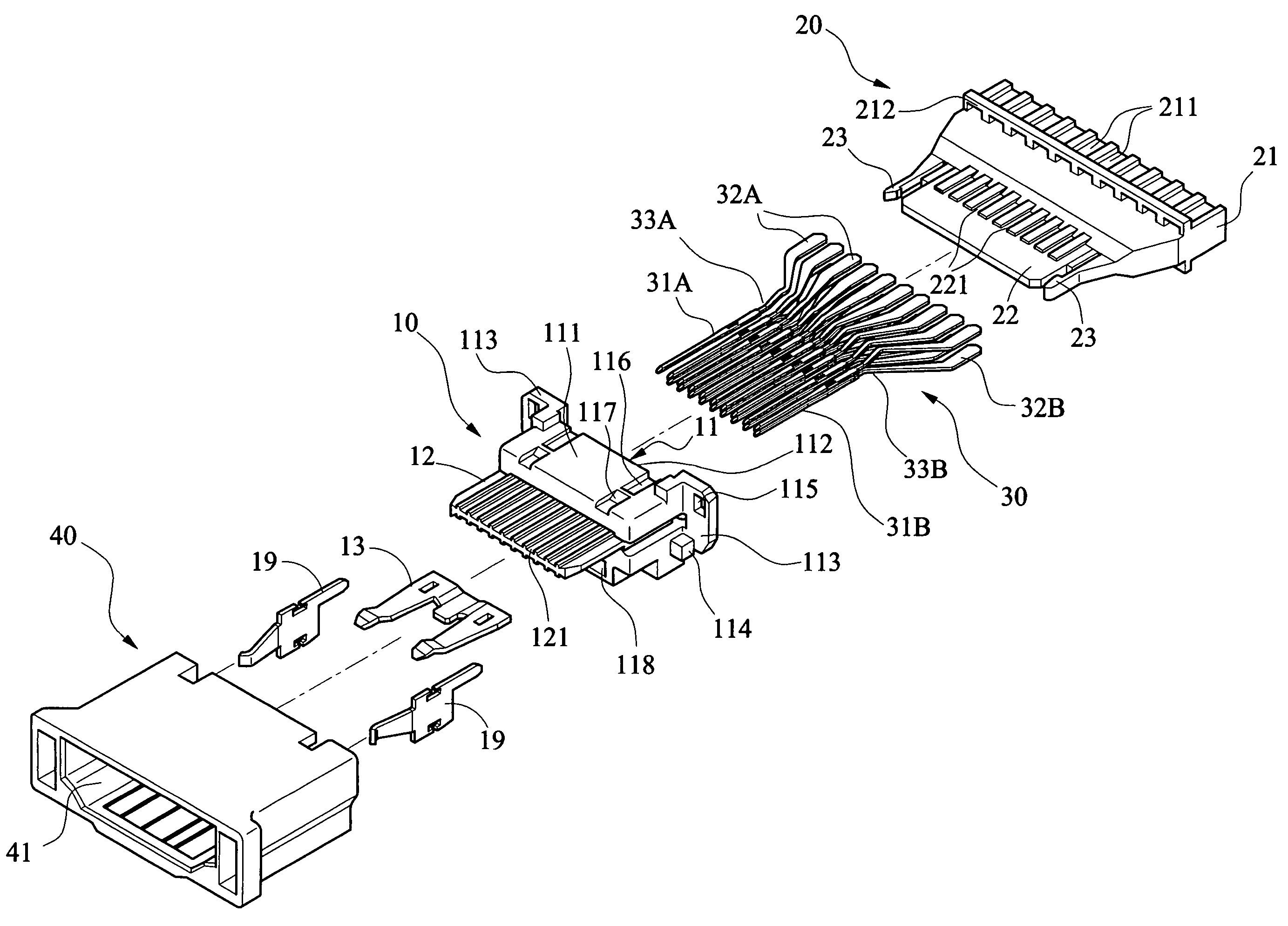

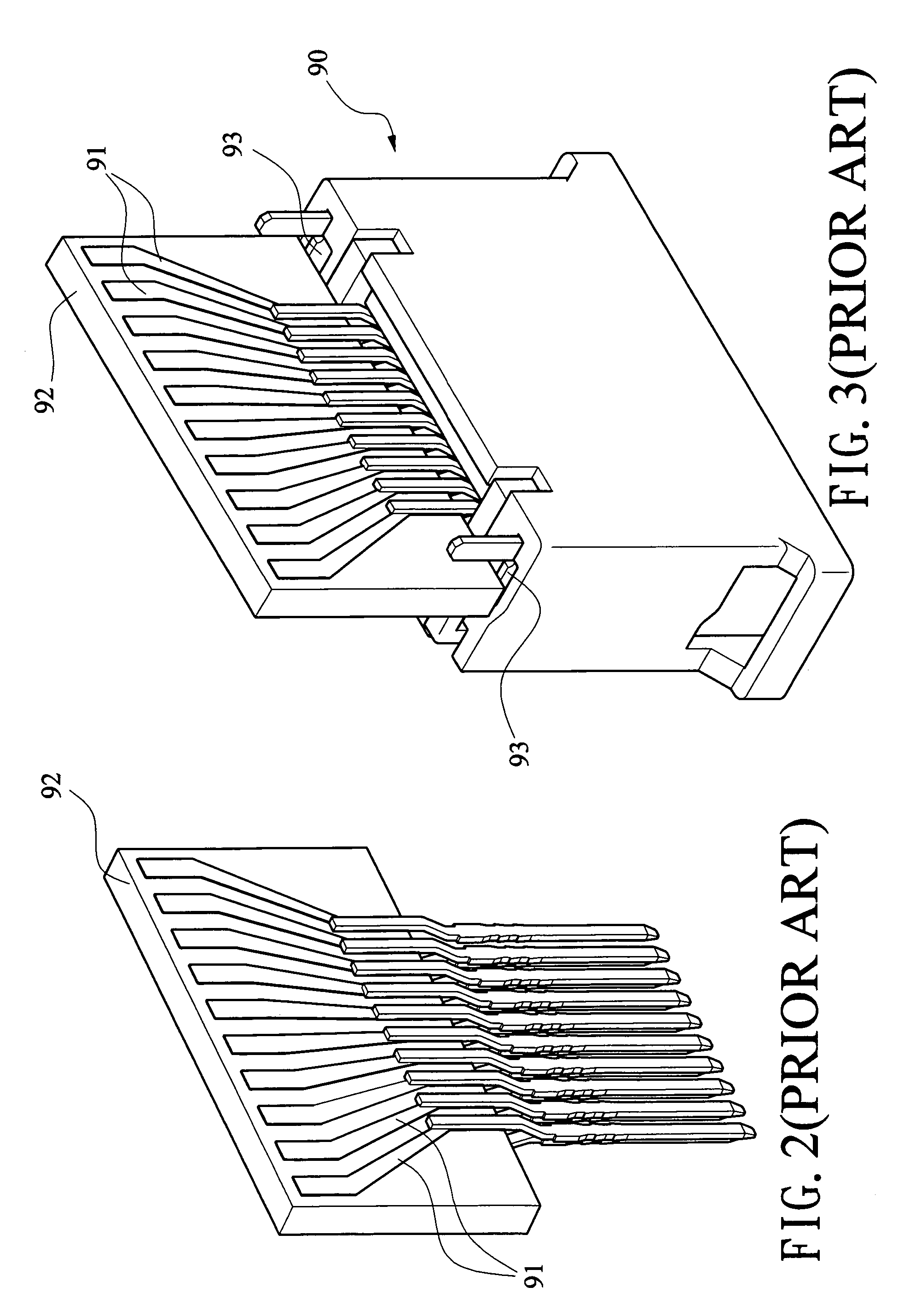

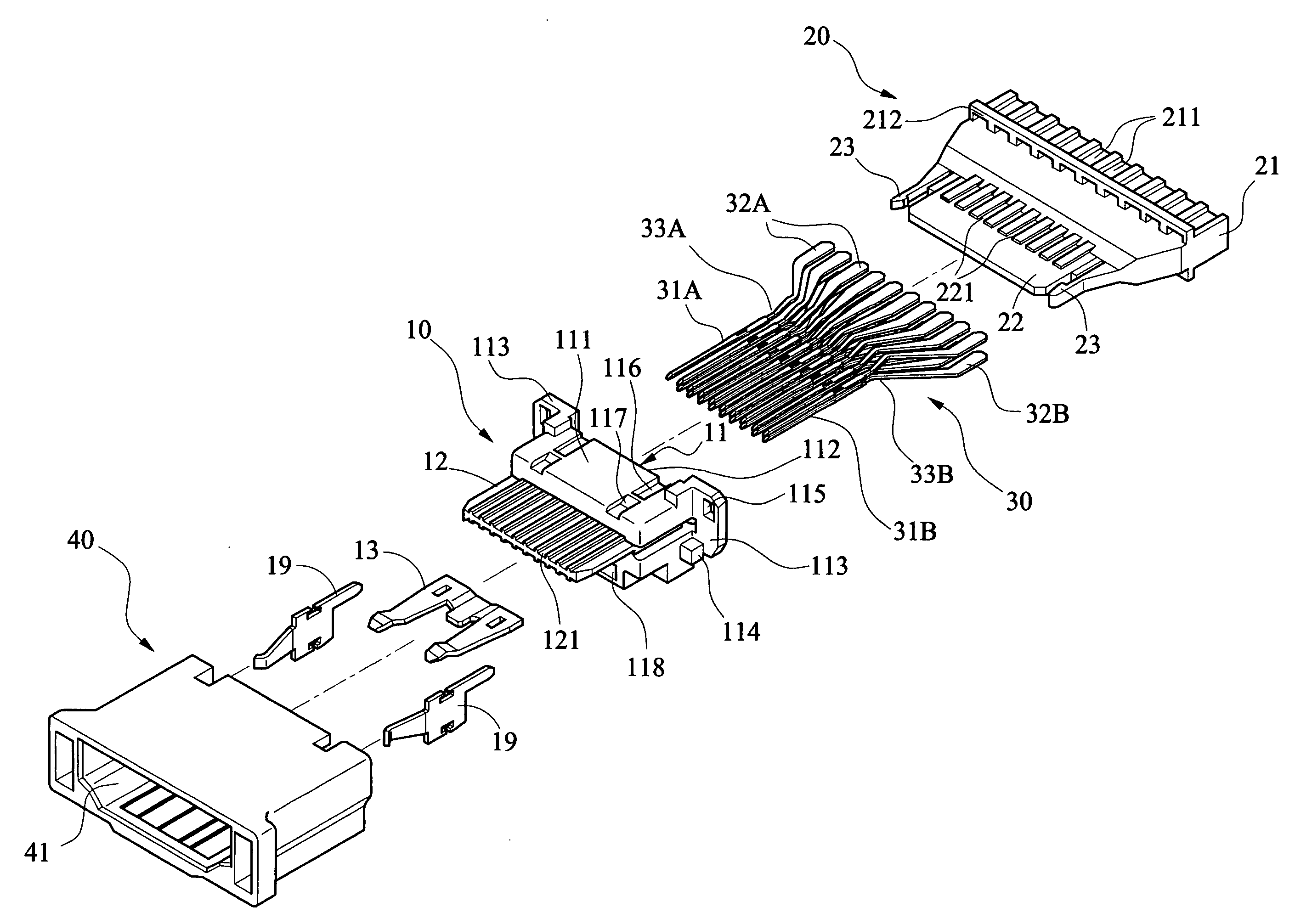

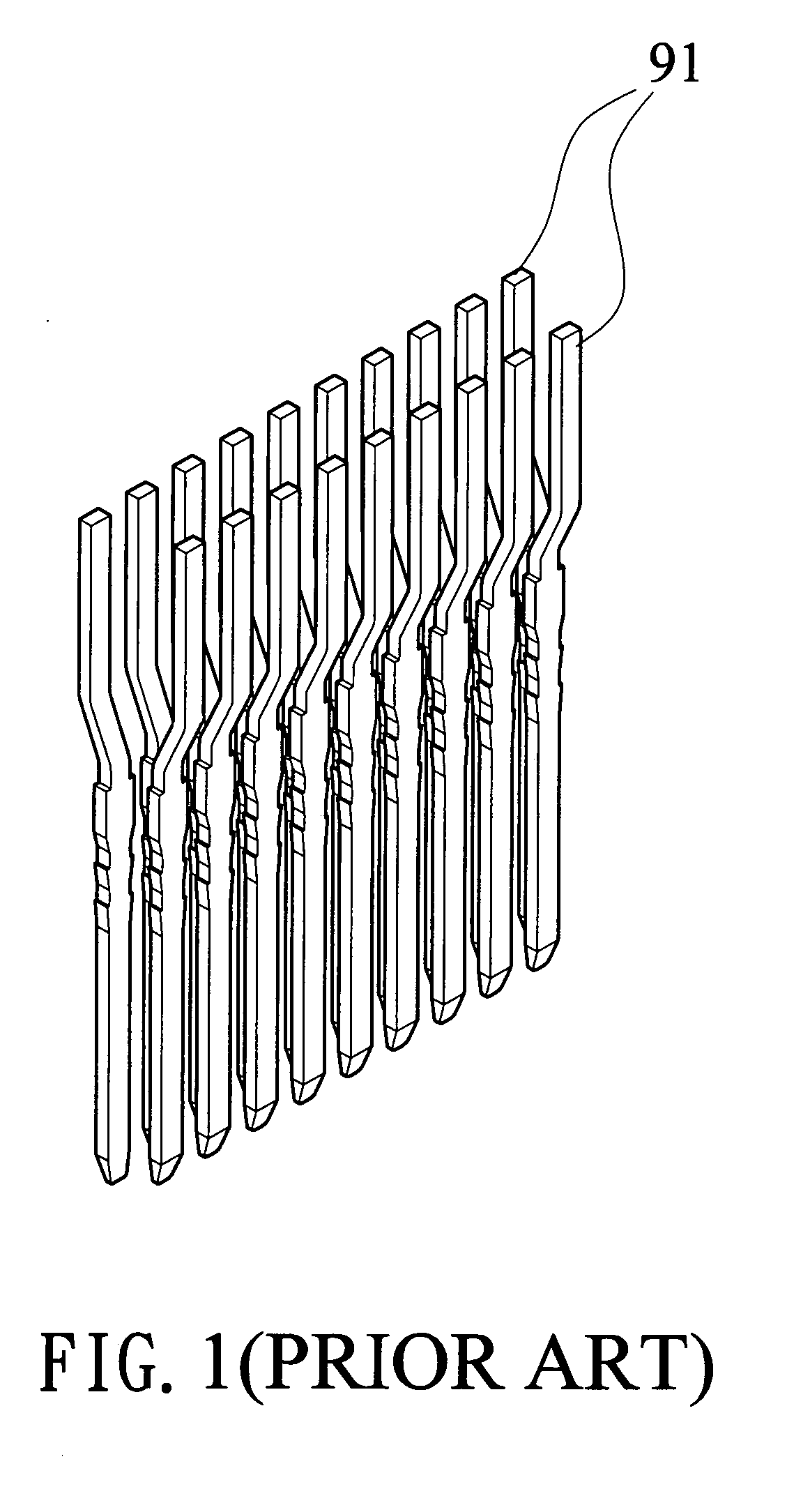

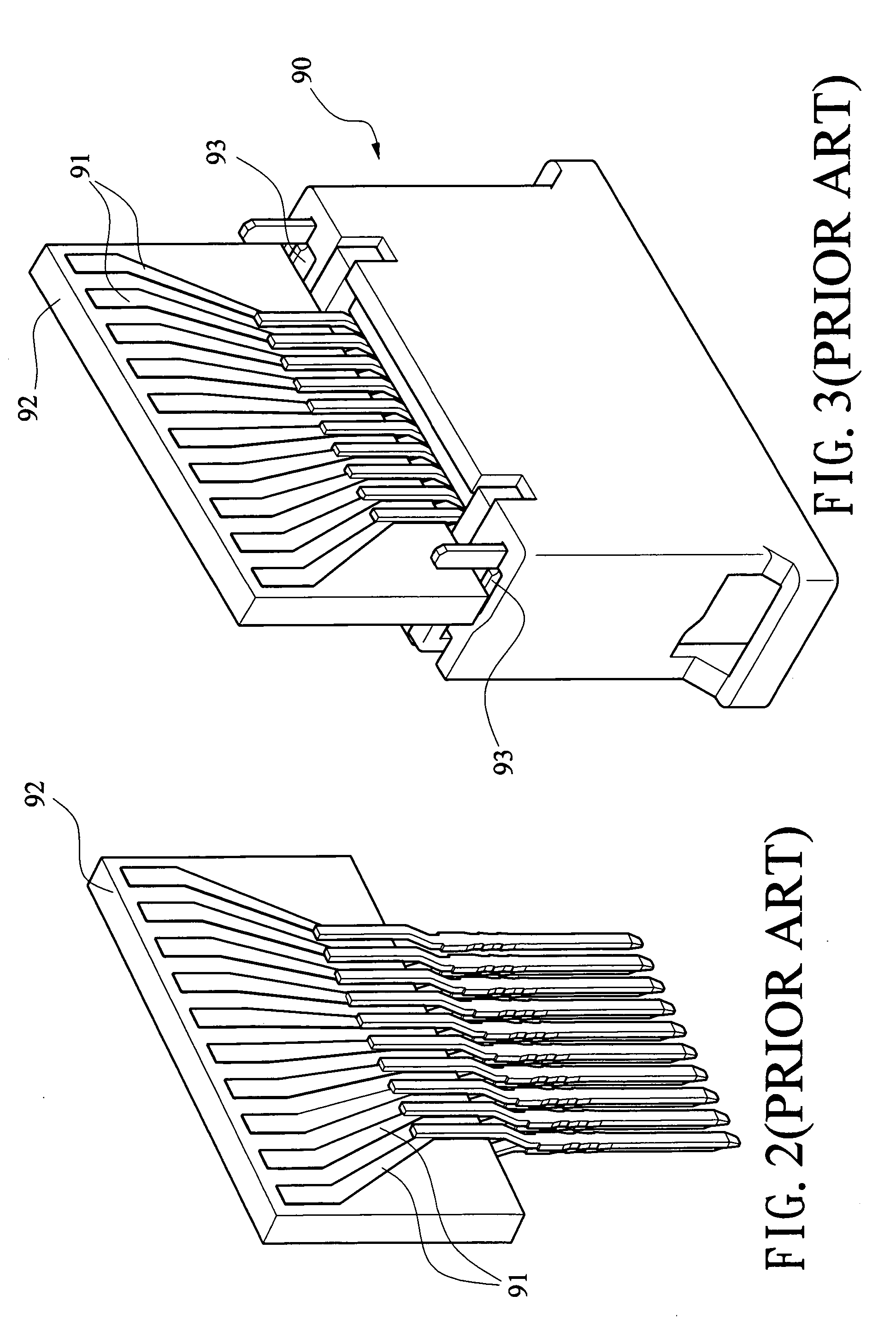

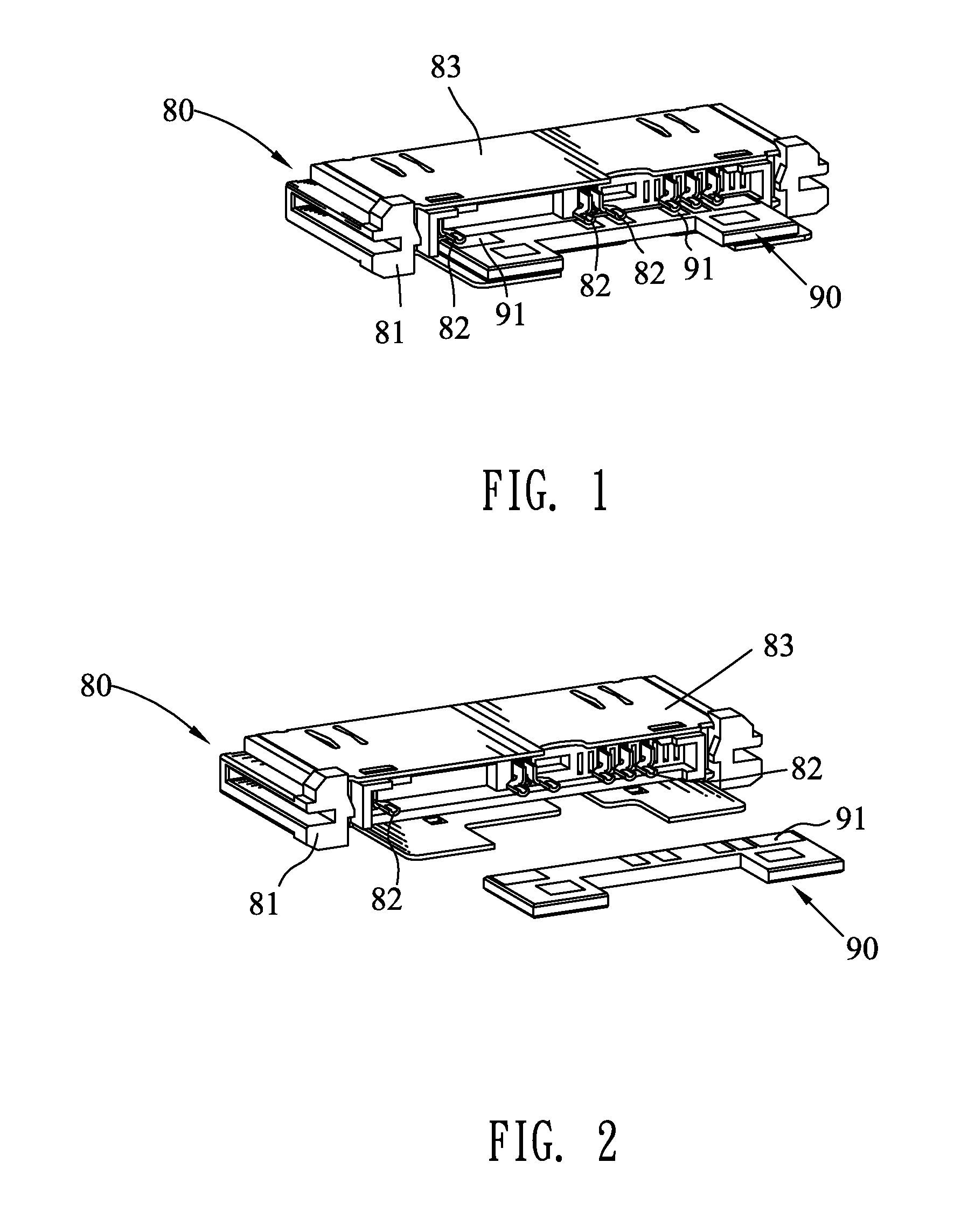

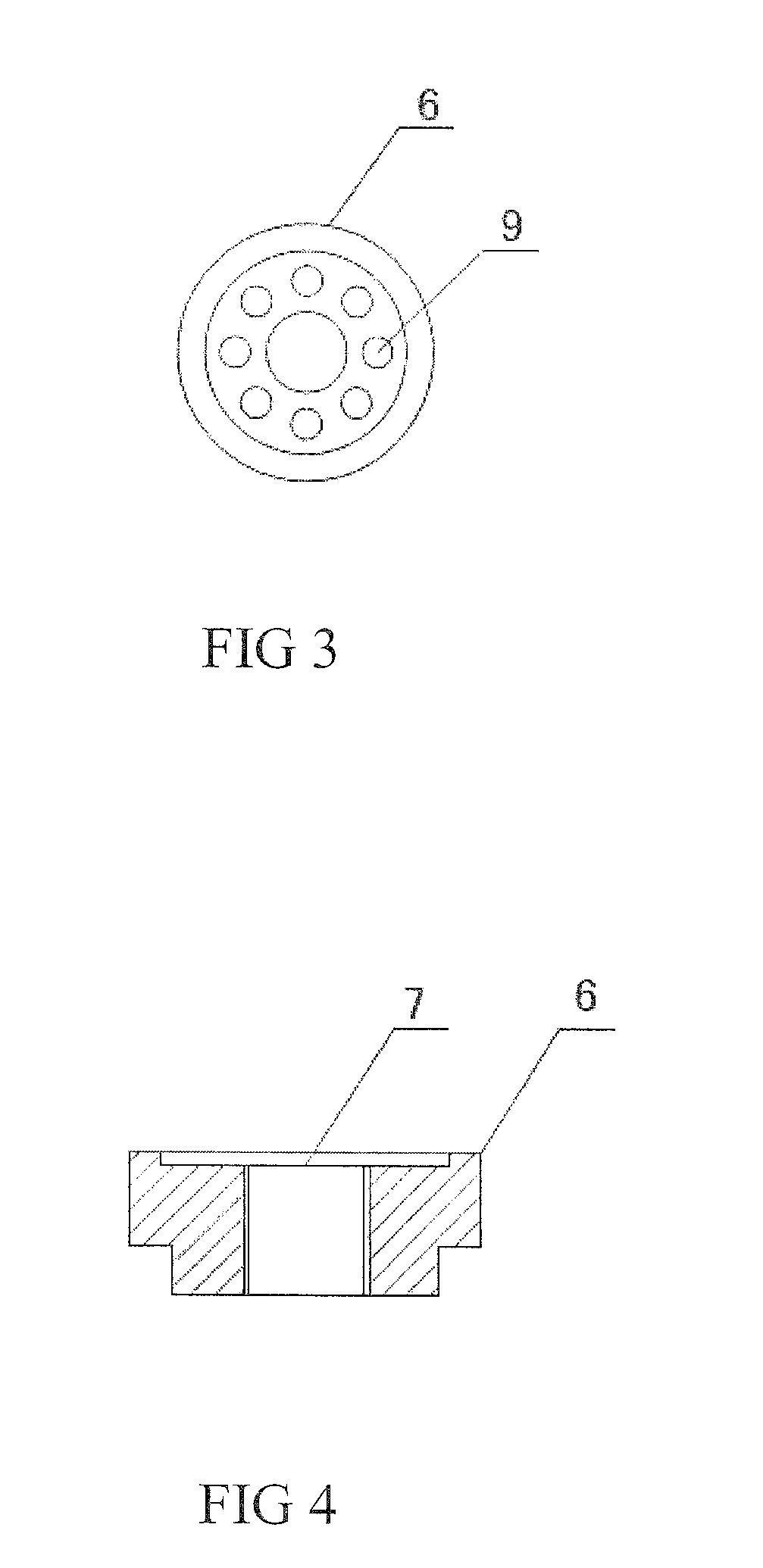

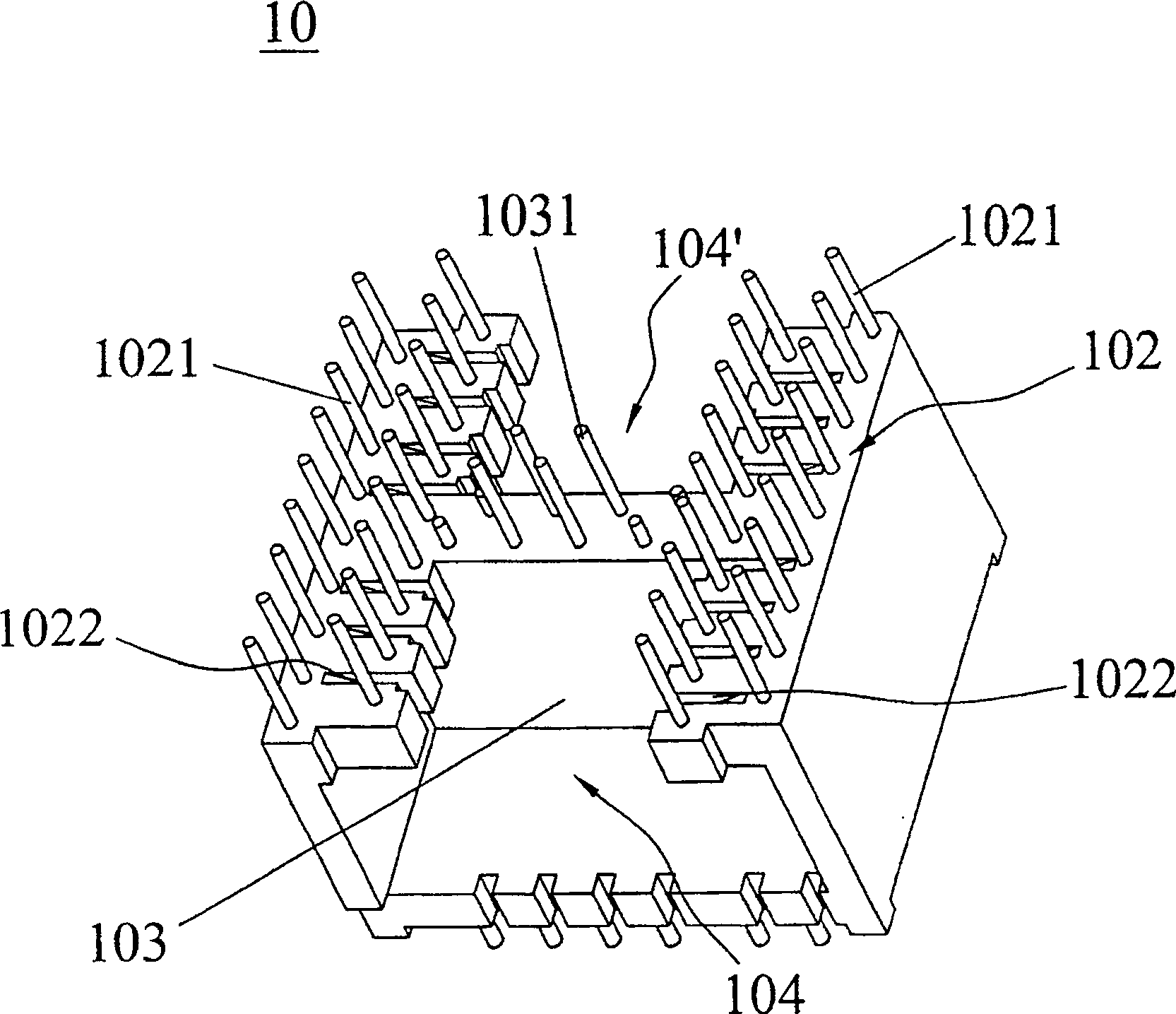

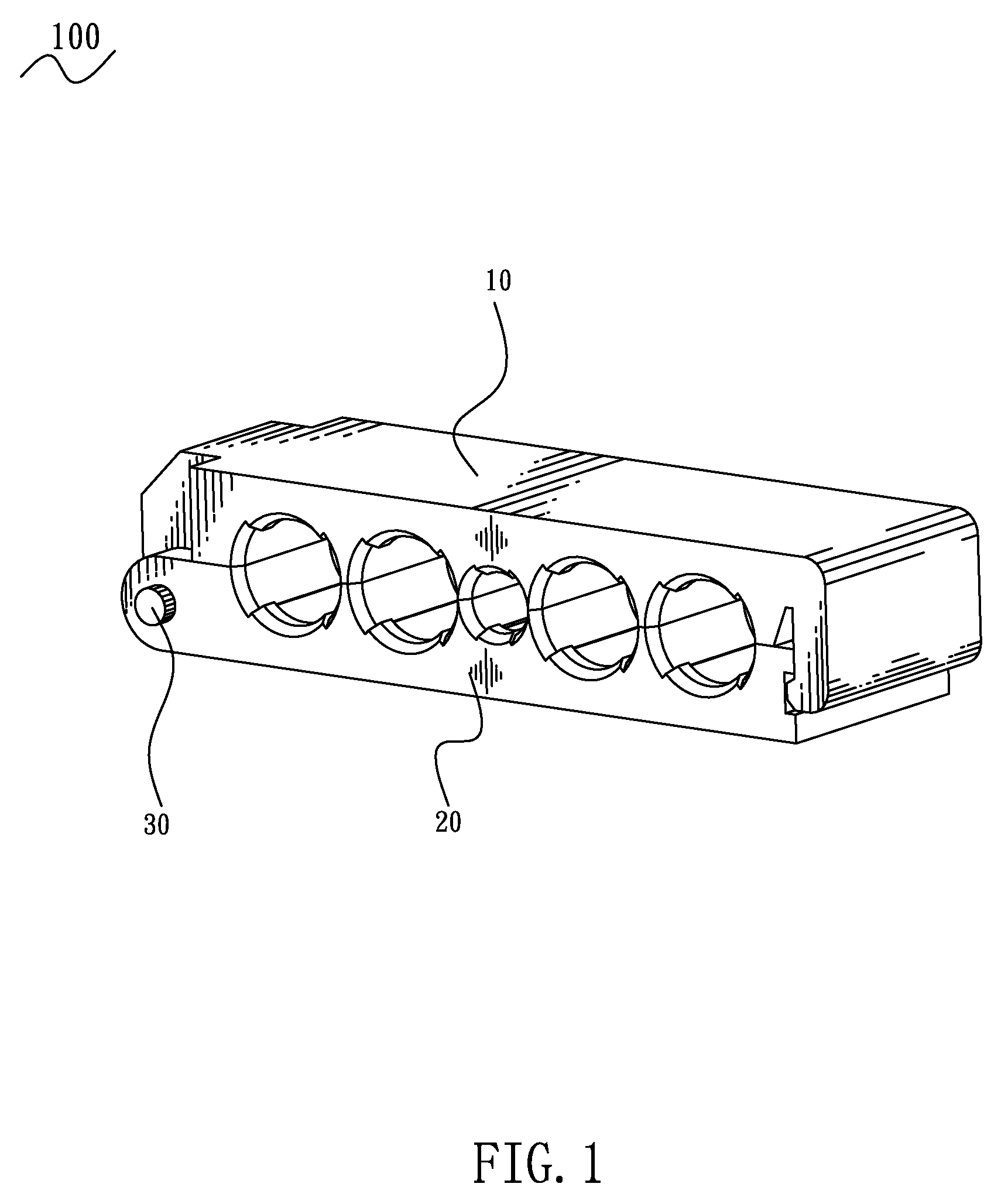

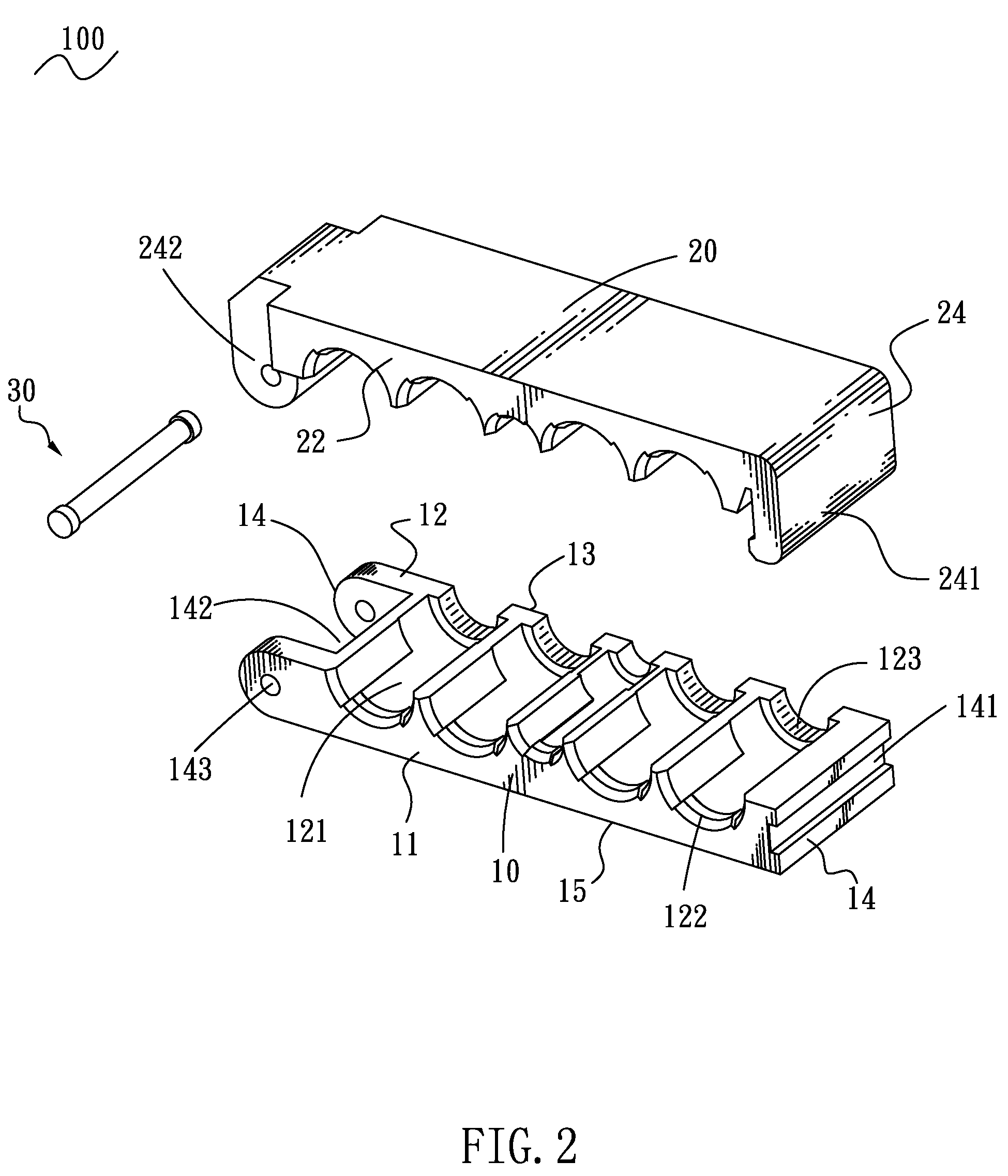

HDMI connector assembly

InactiveUS7210945B1Solder quality be increaseHigh yieldCoupling device detailsPrinted circuitsTransmission performanceHDMI

A HDMI connector assembly includes an insulative body including a body member including a central channel therethrough and parallel grooves on top and bottom of the channel, and a plate including two rows of parallel terminal cavities aligned with the grooves; an insulative seat provided in the channel and including a rear member including parallel furrows on its top and bottom, and a front member including parallel depressions; two rows of conductors provided in the depressions, the furrows, the grooves, and the terminal cavities, each conductor including a front electrical terminal and a rear solder member wherein the solder members of one row and the solder members of the other row are bent in opposite directions; and a housing for receiving the insulative body. The invention has advantages of increased quality and signal transmission performance, and causing no pollution.

Owner:YING WAN FA

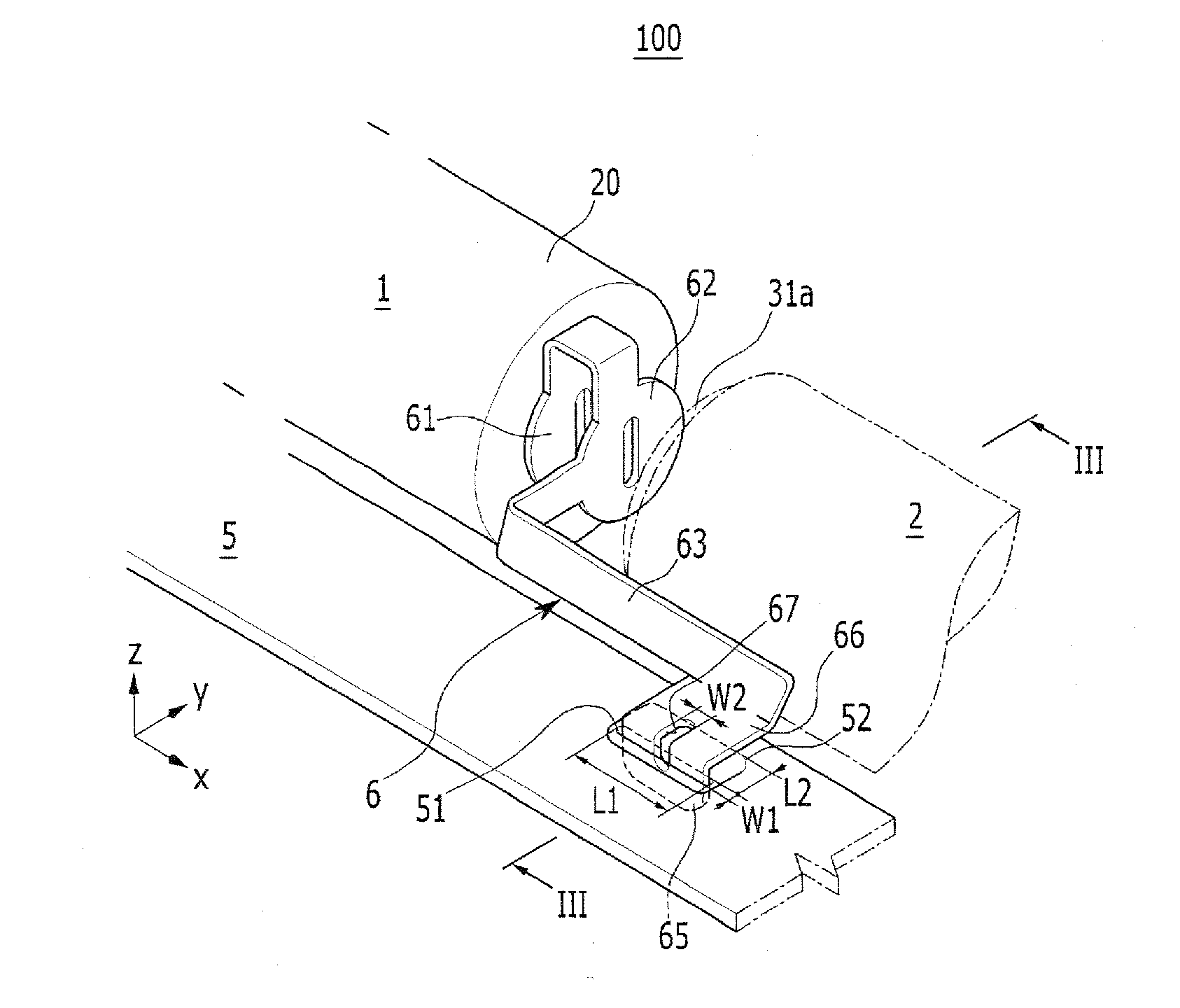

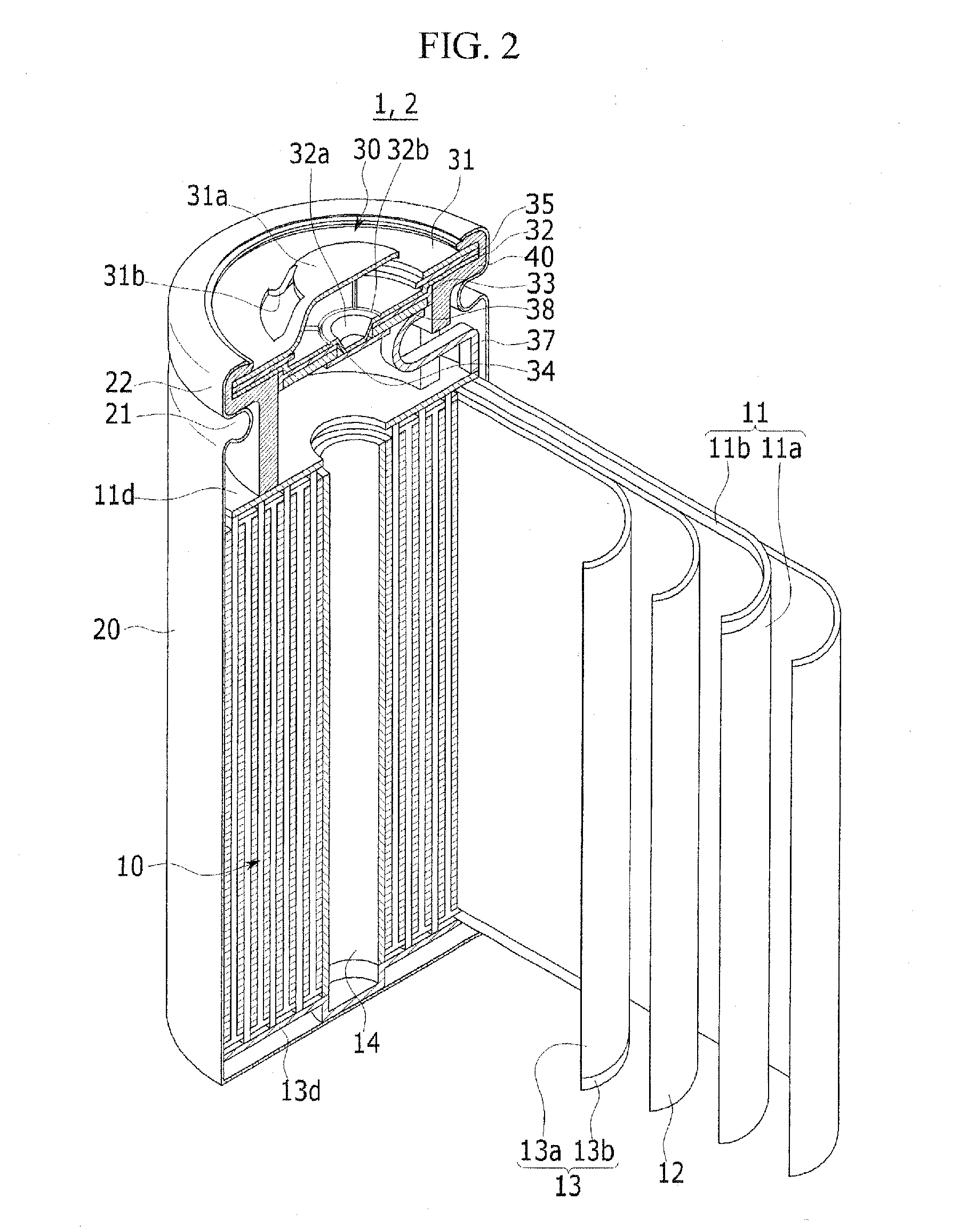

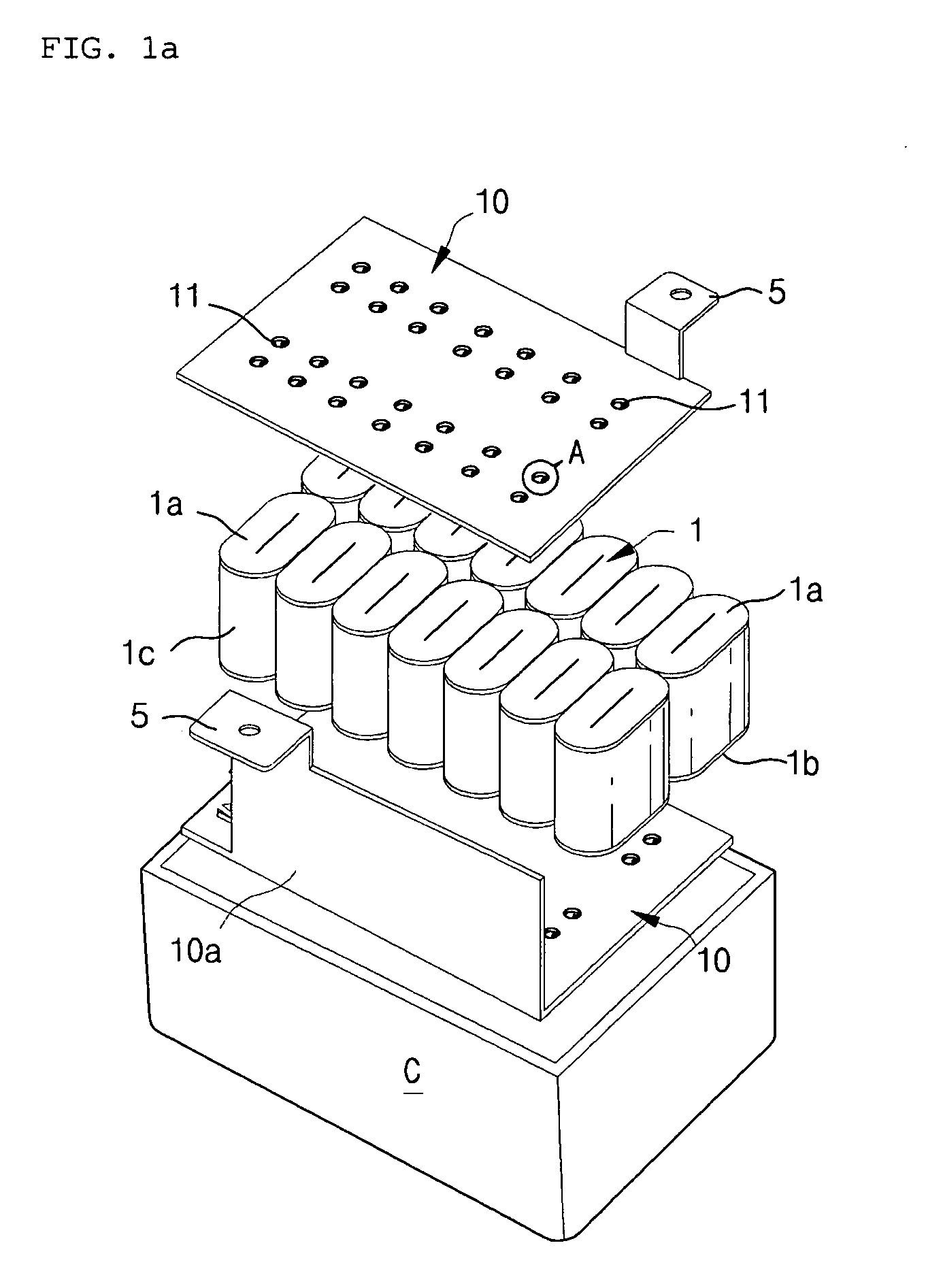

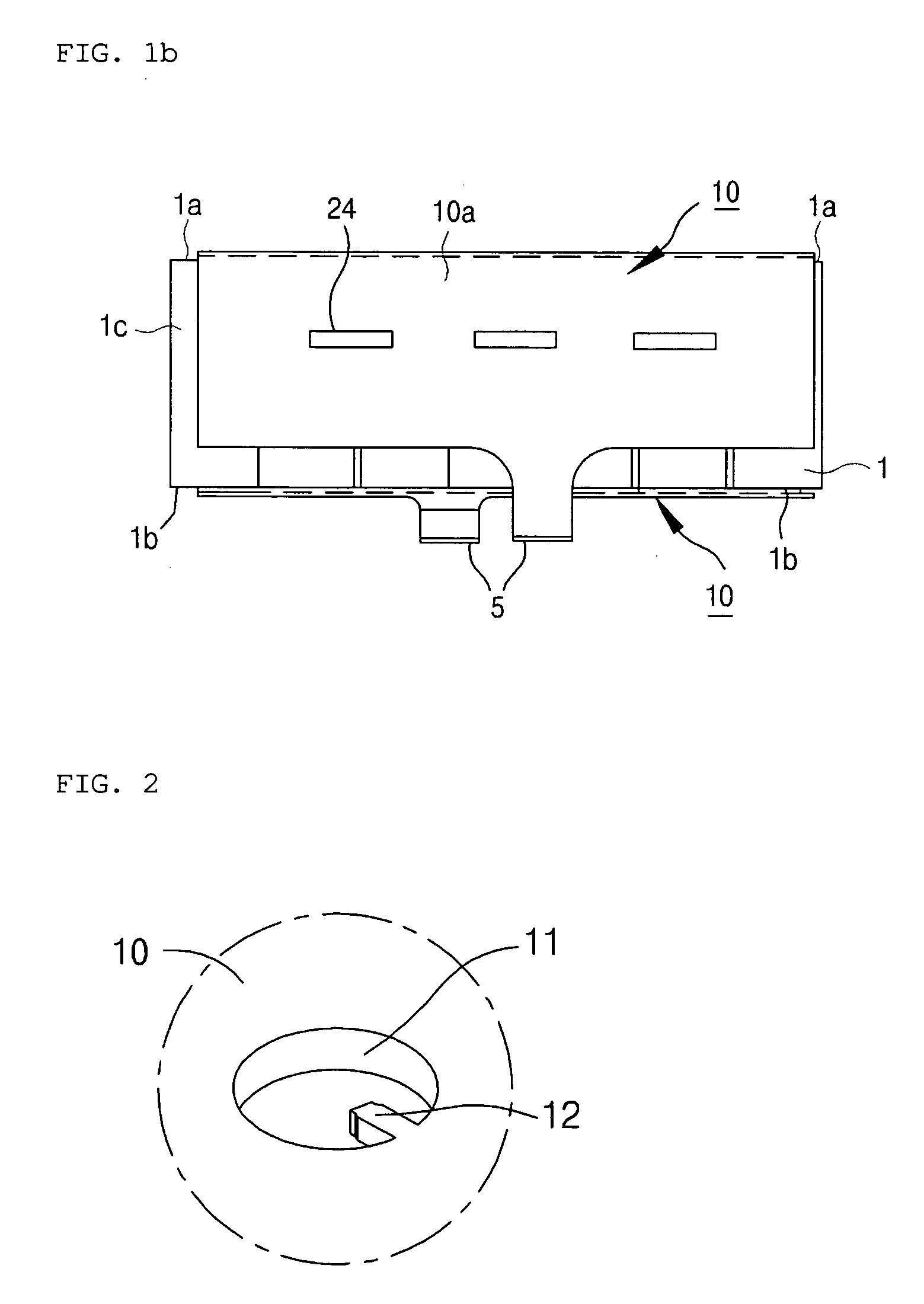

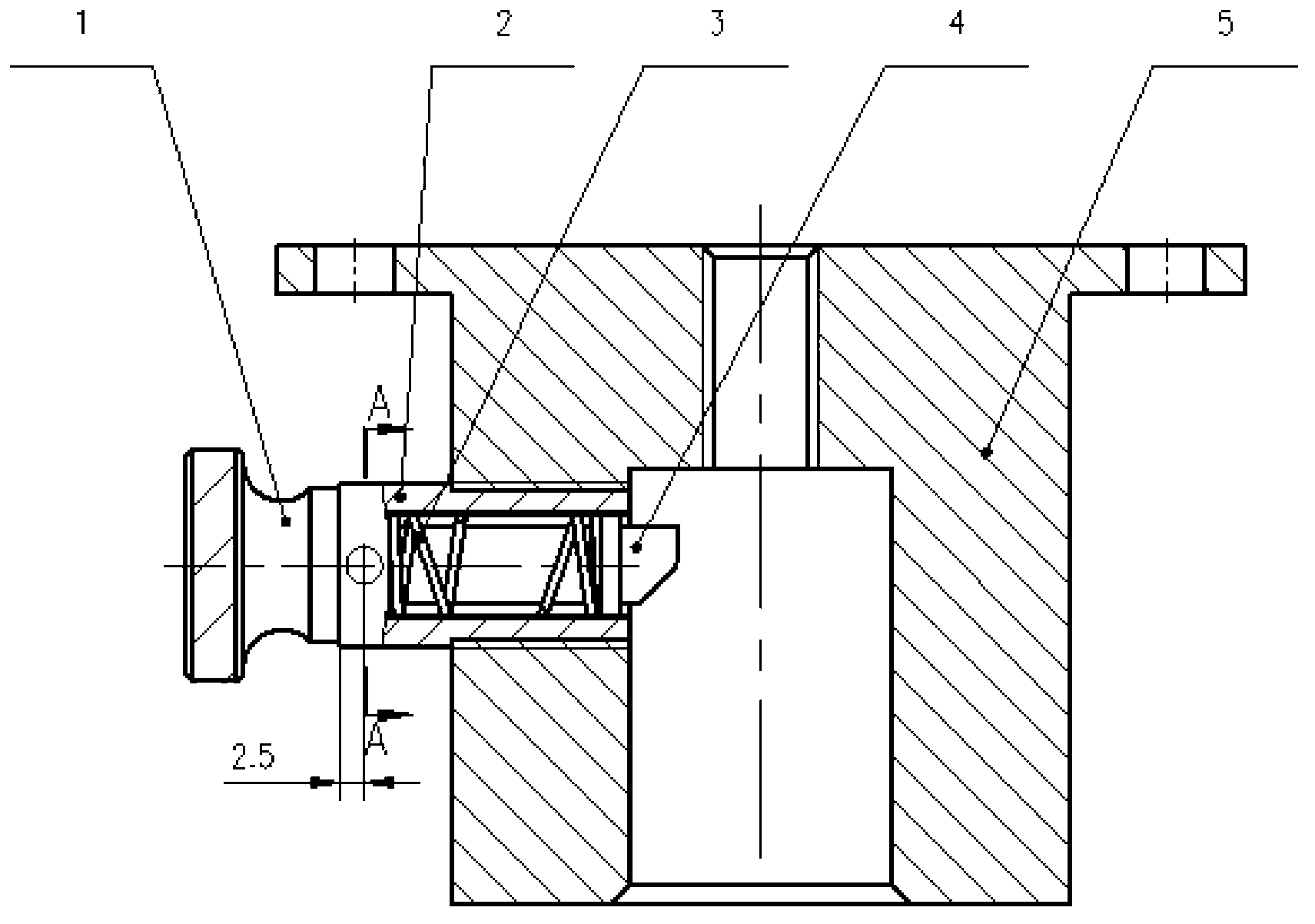

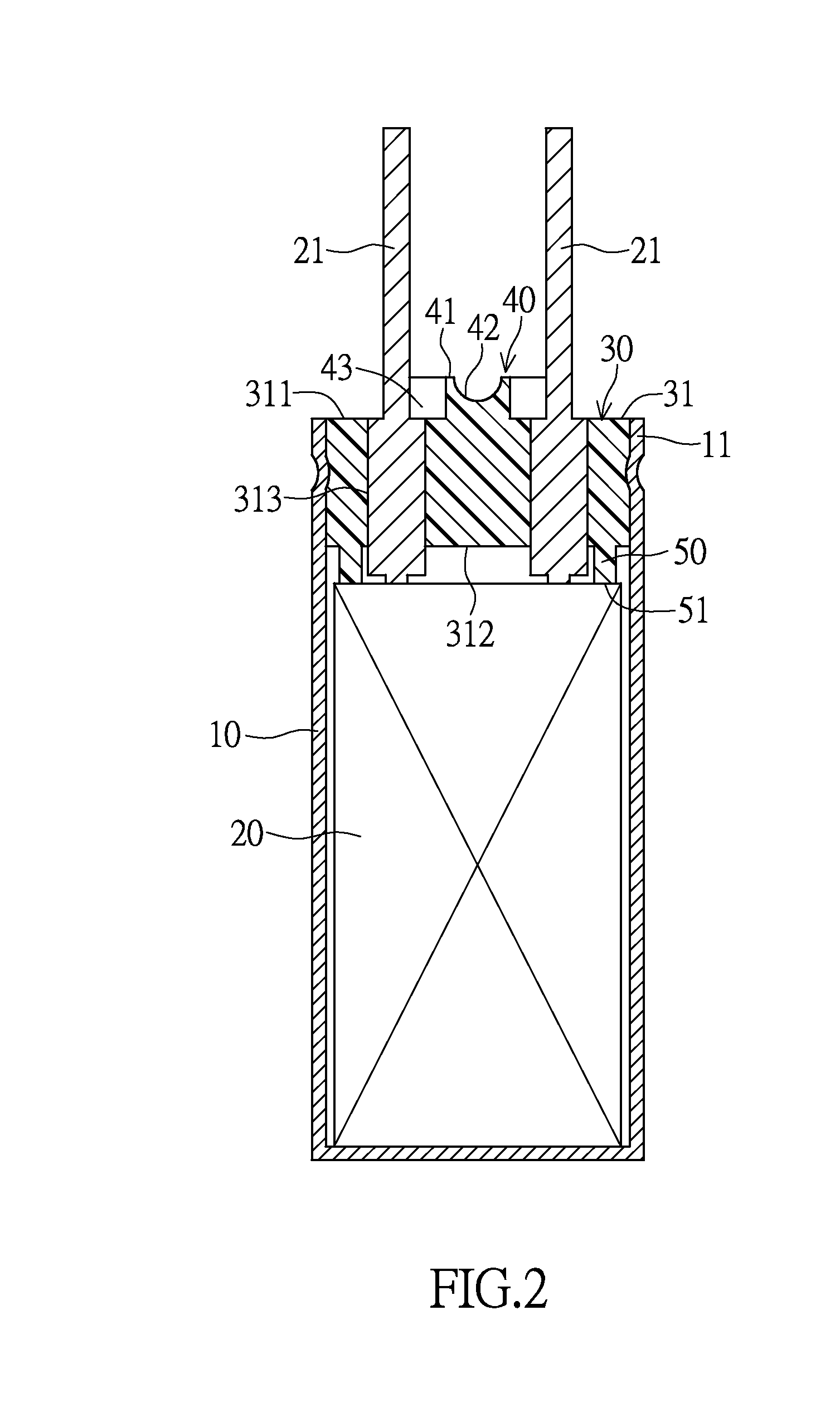

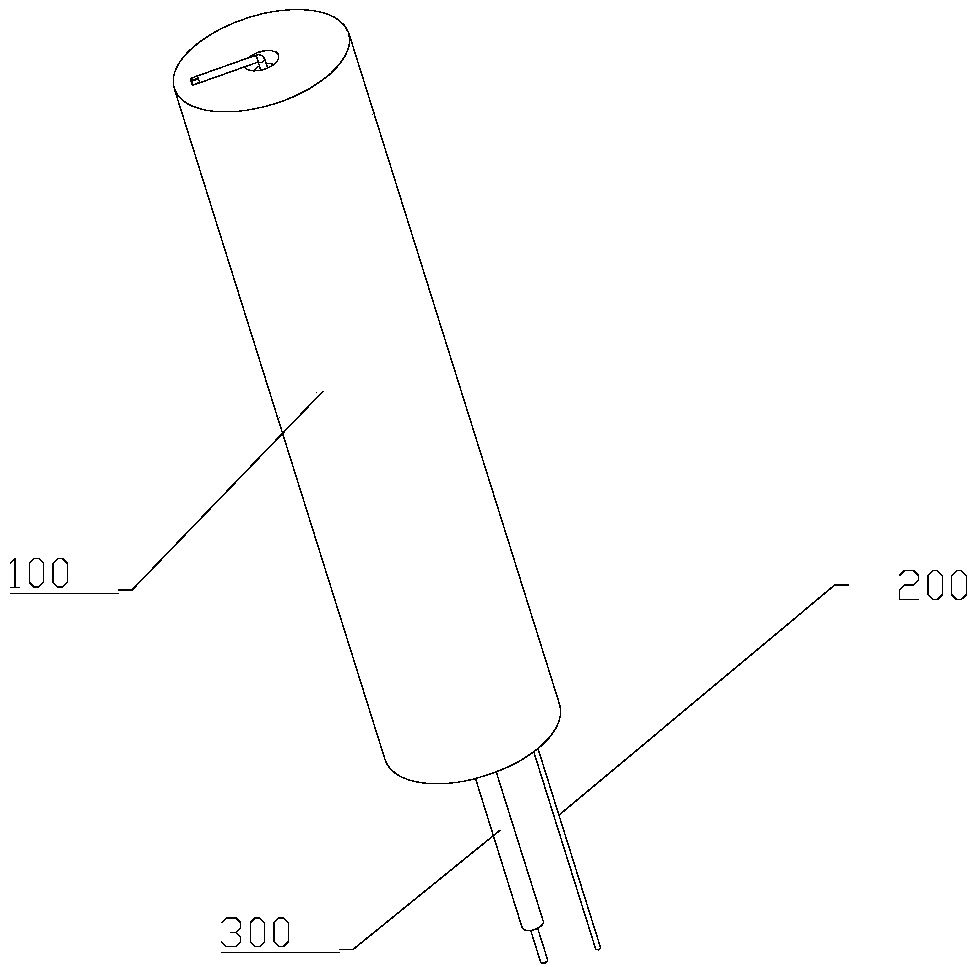

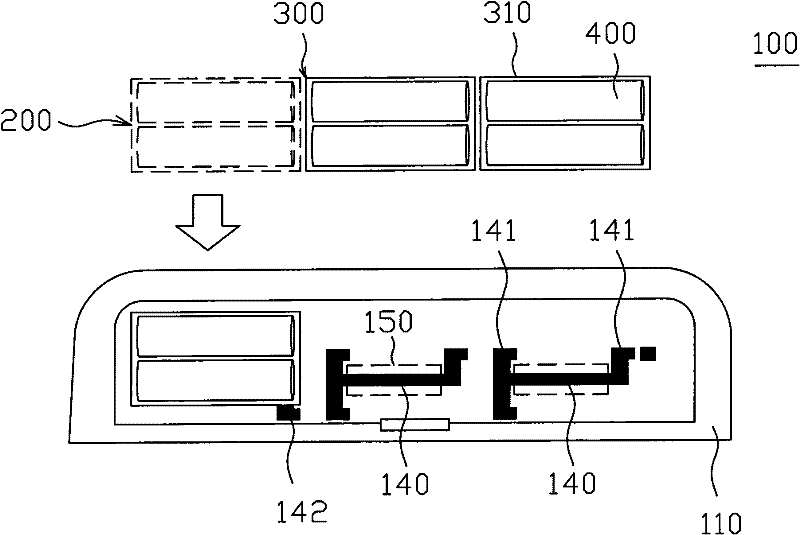

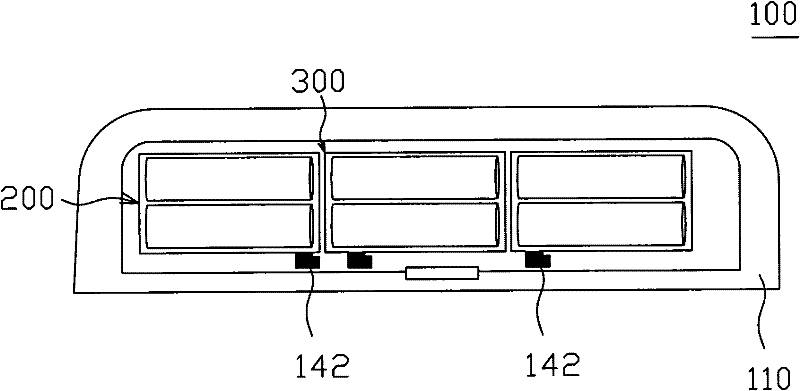

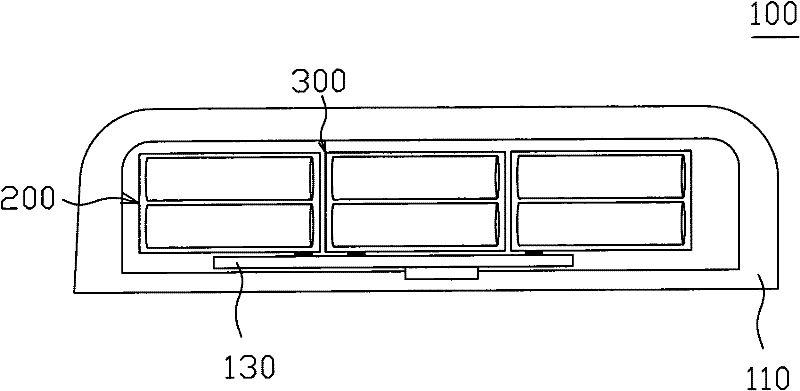

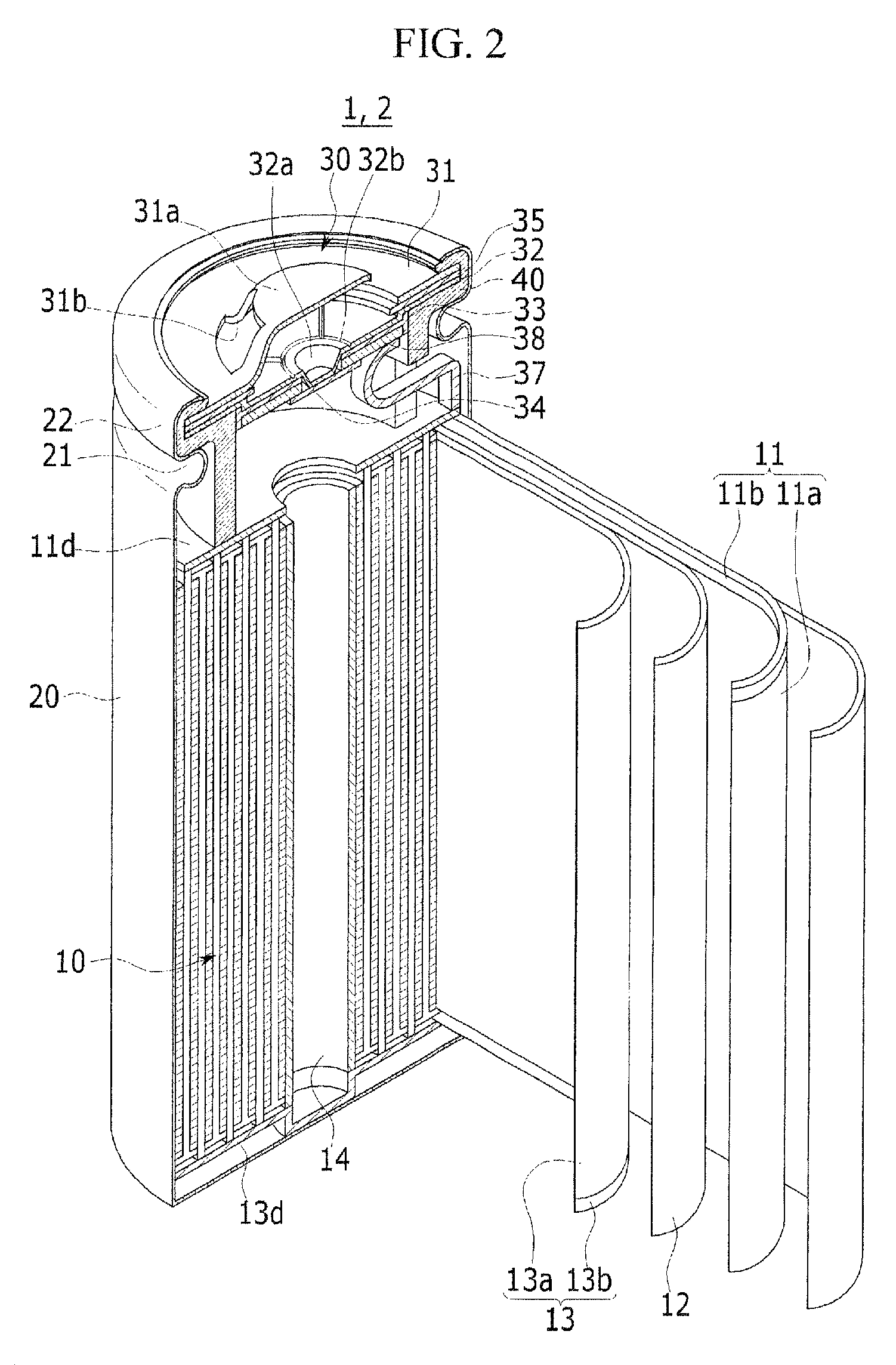

Rechargeable battery pack

InactiveUS20120052332A1Strong and more resilient electrical connectionAccurately fixes connectionCells structural combinationCell component detailsElectricityElectrical battery

A rechargeable battery pack that accurately fixes connection locations of a connection tab and a first pad and strengthens the impact resistance of a connection unit. A rechargeable battery pack according to an exemplary embodiment includes: a first unit cell and a second unit cell formed by a rechargeable battery; a connection tab electrically connecting the first unit cell and the second unit cell to each other; and a protection circuit module (PCM) where a aperture in the PCM is formed in a first pad connected to the connection tab, wherein the connection tab includes a first portion inserted into the aperture in the PCM and a second portion bent and connected to the first portion and overlapped with the first pad and including an aperture in second portion of connection tab.

Owner:SAMSUNG SDI CO LTD

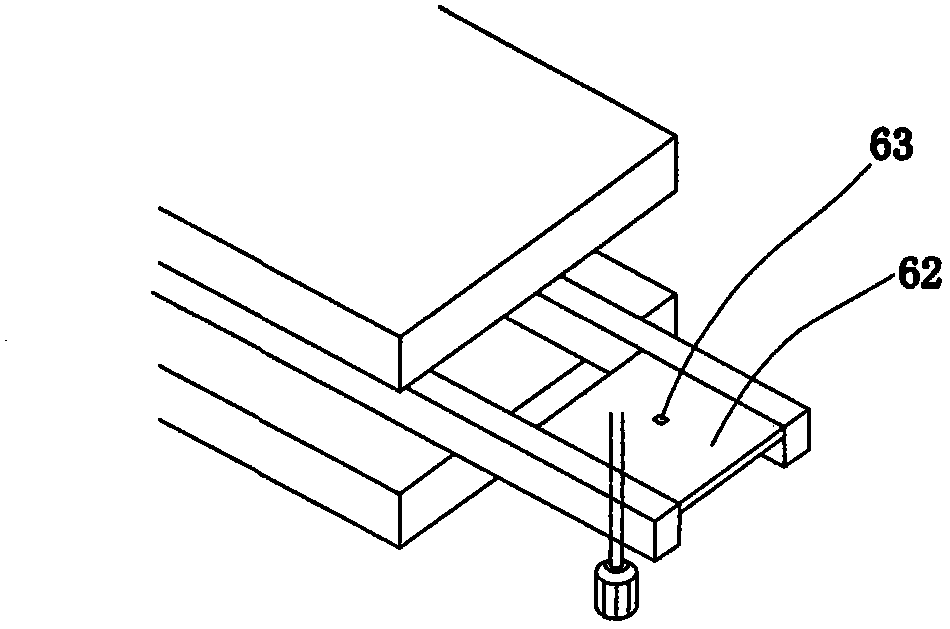

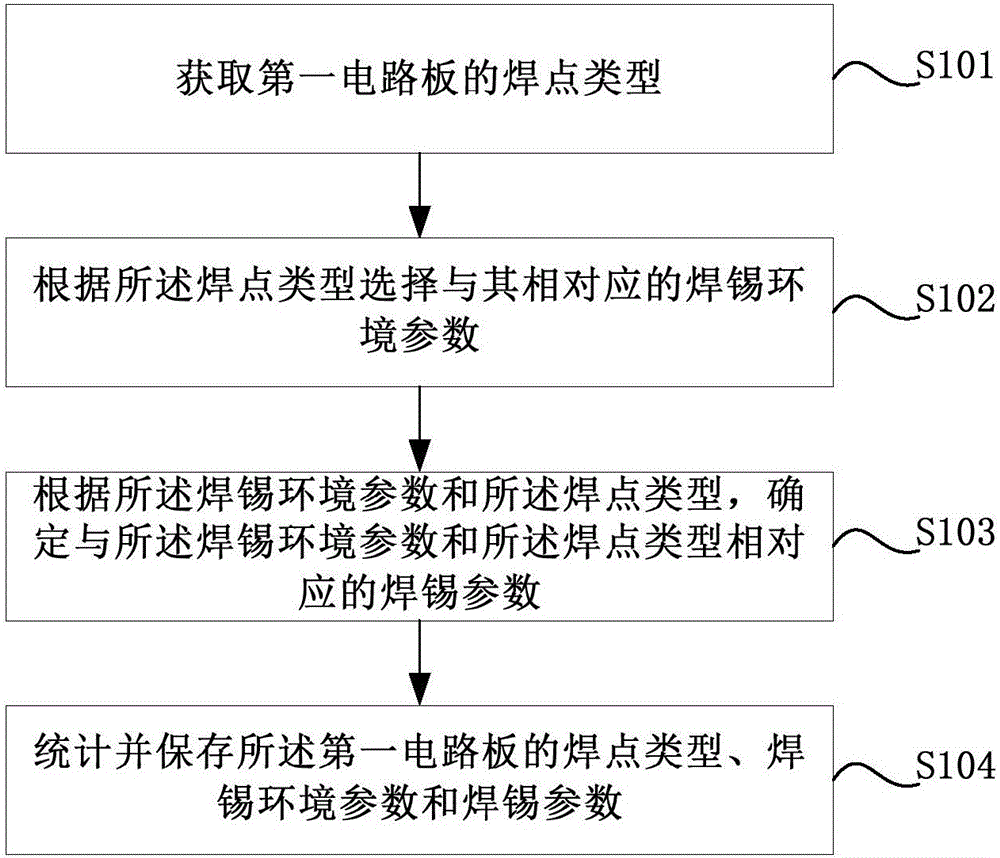

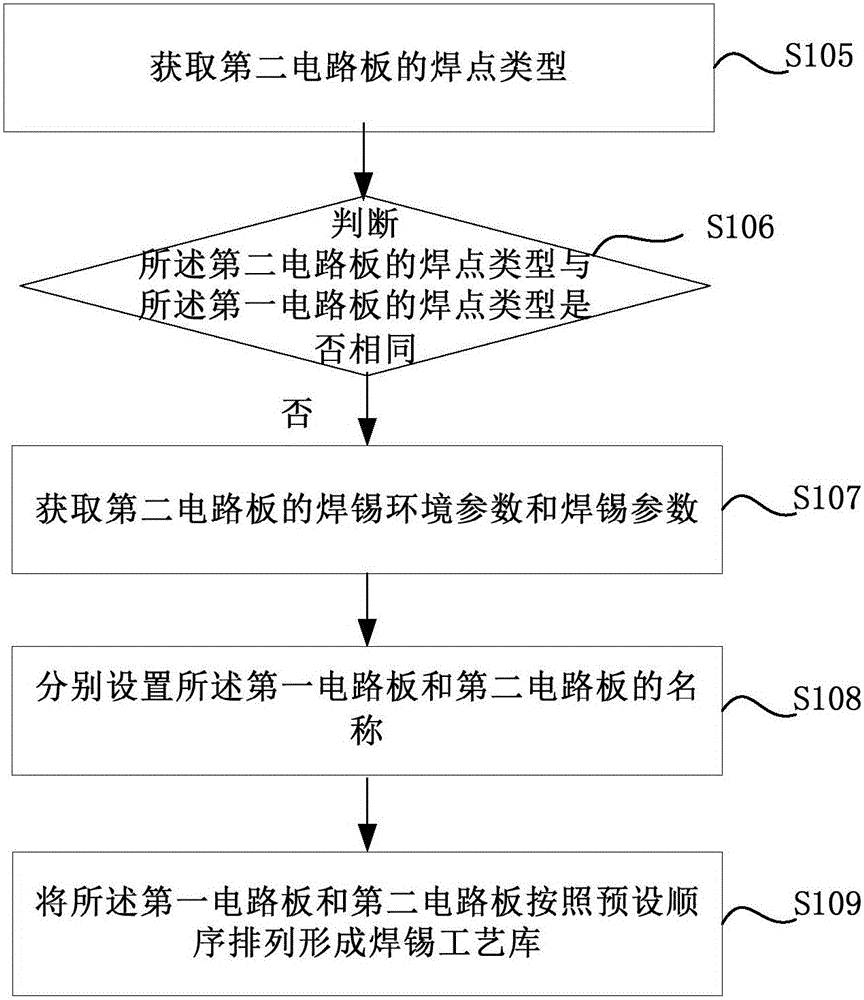

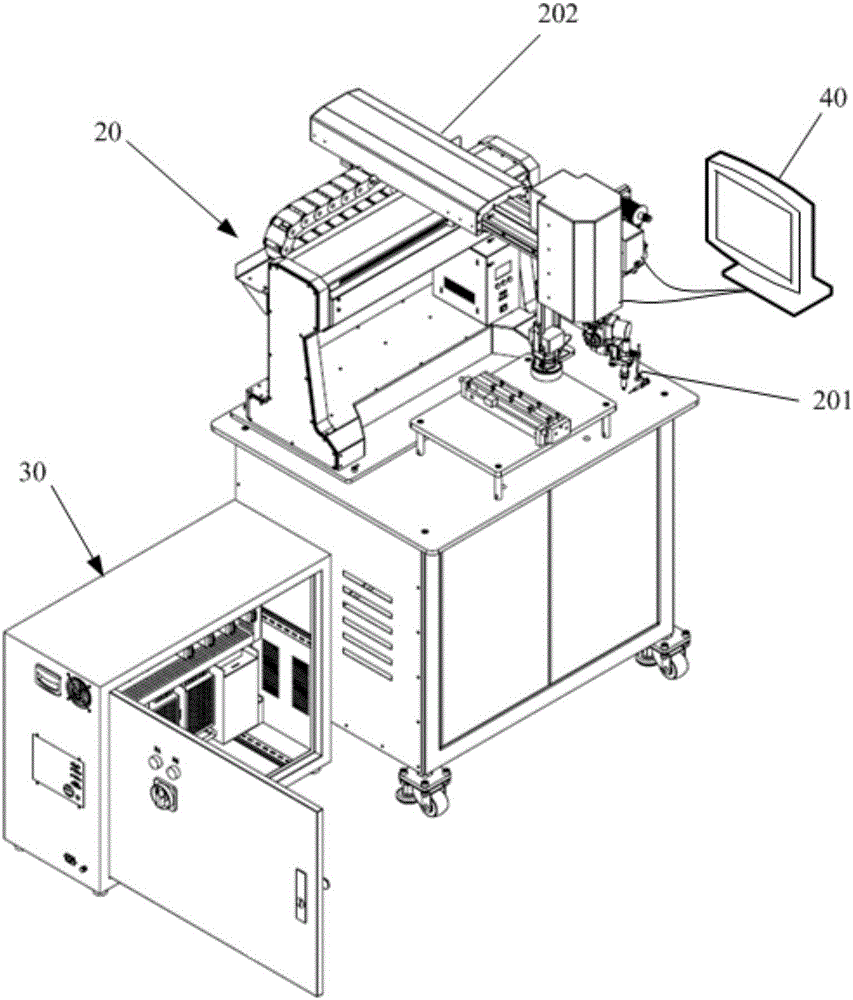

Method for establishing tin soldering process libraries and system applied to same

InactiveCN105729475AAvoid settingShorten the timeProgramme-controlled manipulatorMetal working apparatusJoints typesEngineering

An embodiment of the invention discloses a method for establishing tin soldering process libraries and a system applied to the same. The method includes acquiring solder joint types of first circuit boards, selecting tin soldering environmental parameters according to the solder joint types and determining tin soldering parameters according to the tin soldering environmental parameters and the solder joint types; counting and storing the solder joint types of the first circuit boards, the tin soldering environmental parameters and tin soldering parameters. The solder joint types include pin parameters and pad parameters of components on the first circuit boards, and the tin soldering environmental parameters correspond to the solder joint types. The tin soldering parameters correspond to the tin soldering environmental parameters and the solder joint types and include tin feeding speeds, tin feeding lengths, preheating time and tin-soldered stagnation time. The method and the system have the advantages that tin soldering can be carried out by the aid of the tin soldering parameters in the tin soldering process libraries when the tin soldering process libraries contain the solder joint types of the circuit boards to be subjected to tin soldering and the tin soldering environmental parameters, accordingly, the tin soldering parameters do not need to be manually set one by one, and the tin soldering efficiency can be improved.

Owner:迈力(北京)机器人科技有限公司

Bus-bar for jointing capacitor

ActiveUS8018712B2Inferiority rate can be reducedImprove welding efficiencyMultiple fixed capacitorsLiquid electrolytic capacitorsEngineeringSoldering

A bus-bar for assembling a capacitor device is disclosed, which is capable of improving the environment of a soldering operation for the bus-bar being soldered to a capacitor device, reducing the inferior rate of the capacitor device while improving the quality of the capacitor device, and reducing the weight of the capacitor module, in soldering the bus-bar to capacitor devices. The lead frame attached to polar plates by soldering is formed thinner than the other parts of the bus-bar, and opening parts having an oval or polygonal shape are formed on a surface of the bus-bar so that two adjoining capacitor devices can be exposed. The lead frame is formed in the opening in order for soldering with the polar plates of the capacitor device.

Owner:NUINTEK

HDMI connector assembly

InactiveUS20070111564A1Improve solder qualityHigh yieldCoupling device detailsPrinted circuitsElectrical conductorHDMI

A HDMI connector assembly includes an insulative body including a body member including a central channel therethrough and parallel grooves on top and bottom of the channel, and a plate including two rows of parallel terminal cavities aligned with the grooves; an insulative seat provided in the channel and including a rear member including parallel furrows on its top and bottom, and a front member including parallel depressions; two rows of conductors provided in the depressions, the furrows, the grooves, and the terminal cavities, each conductor including a front electrical terminal and a rear solder member wherein the solder members of one row and the solder members of the other row are bent in opposite directions; and a housing for receiving the insulative body. The invention has advantages of increased quality and signal transmission performance, and causing no pollution.

Owner:YING WAN FA

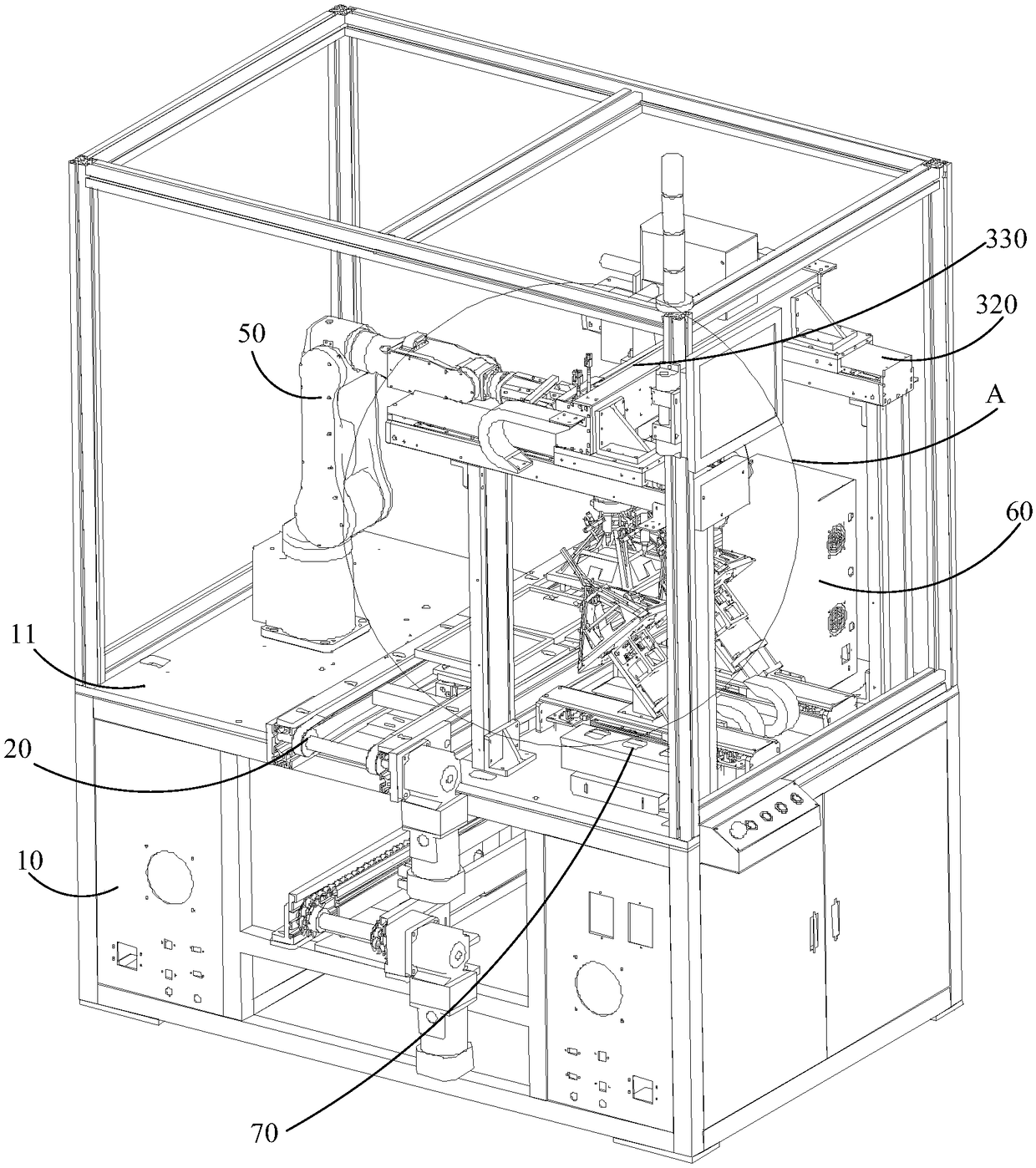

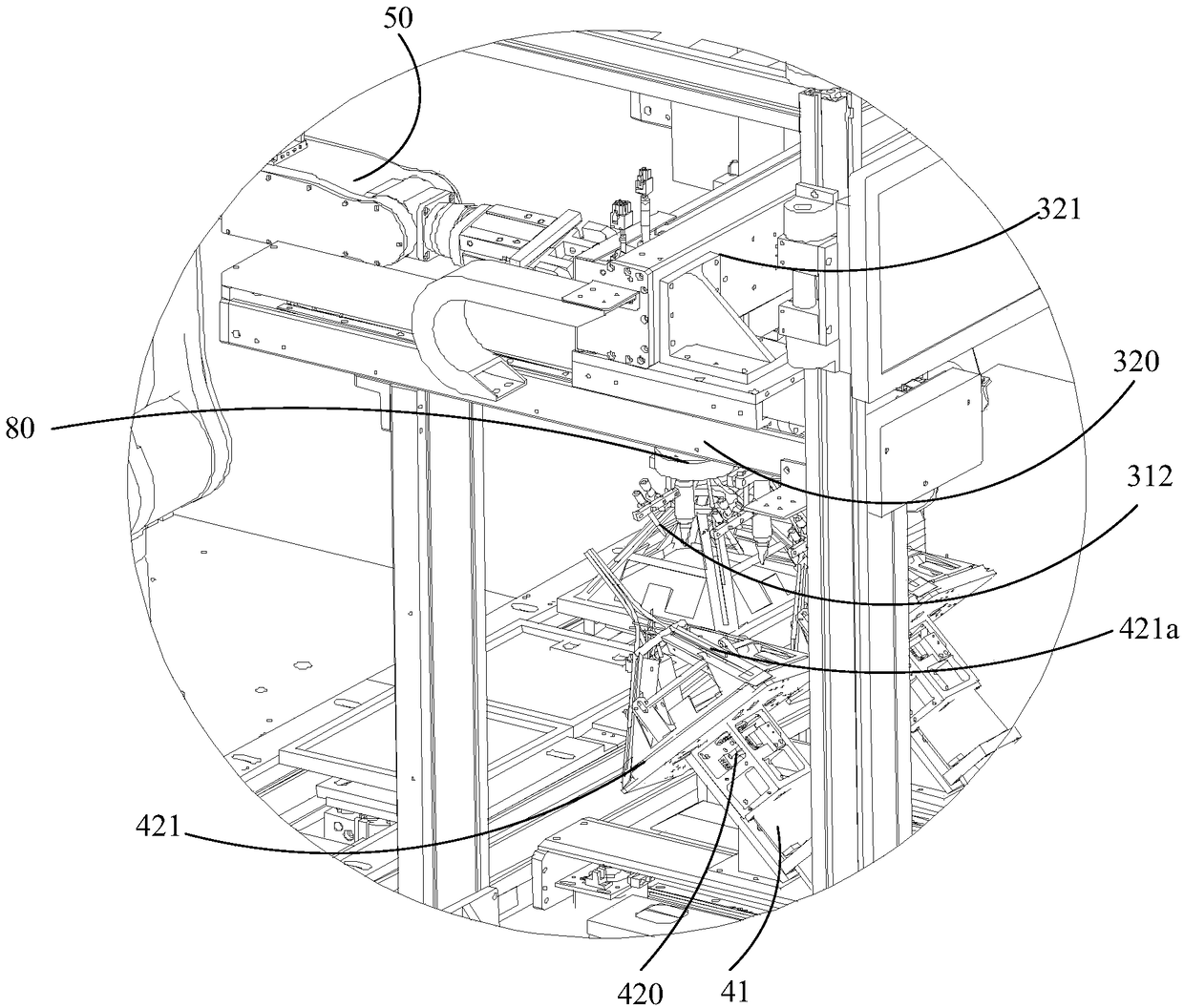

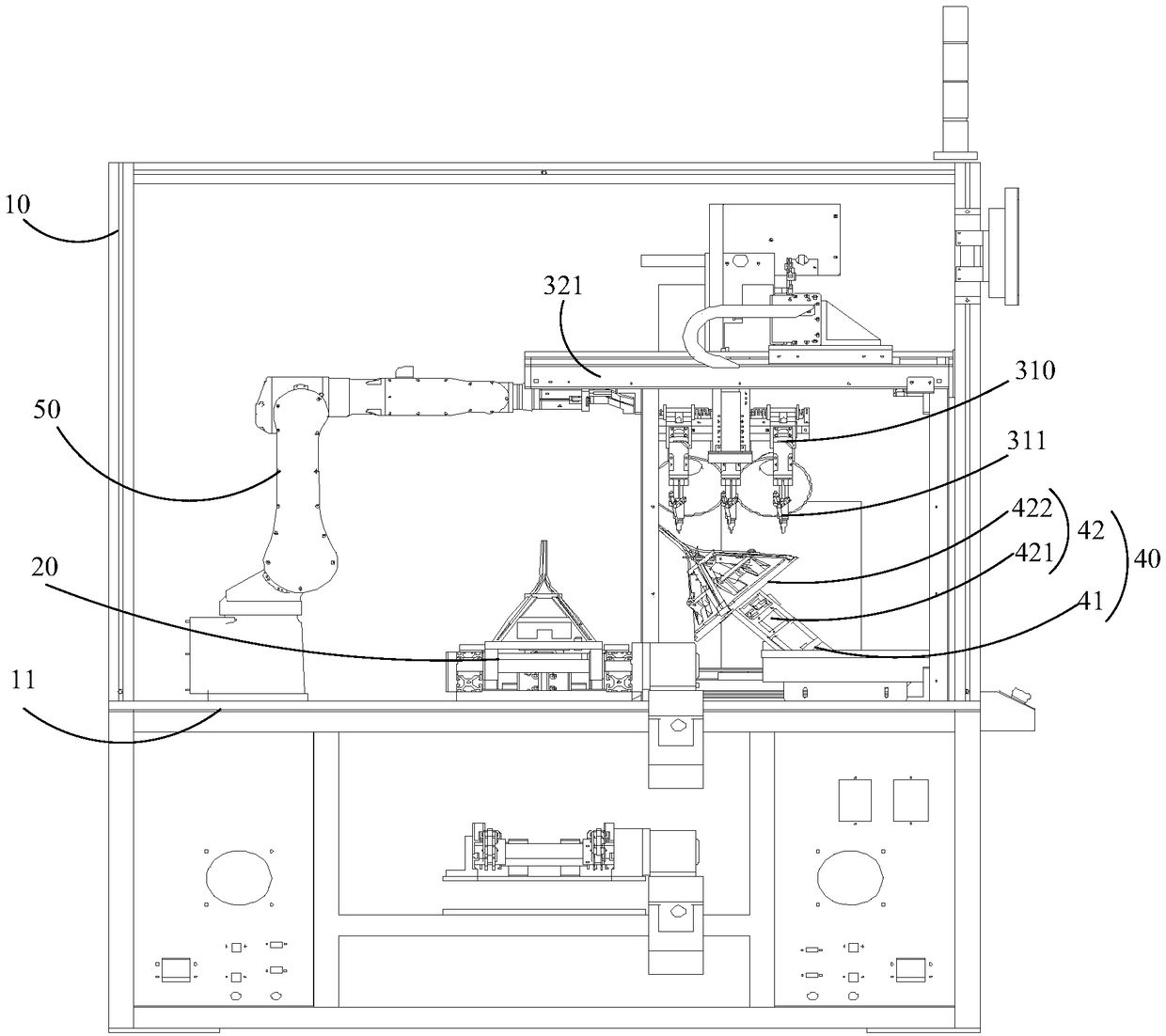

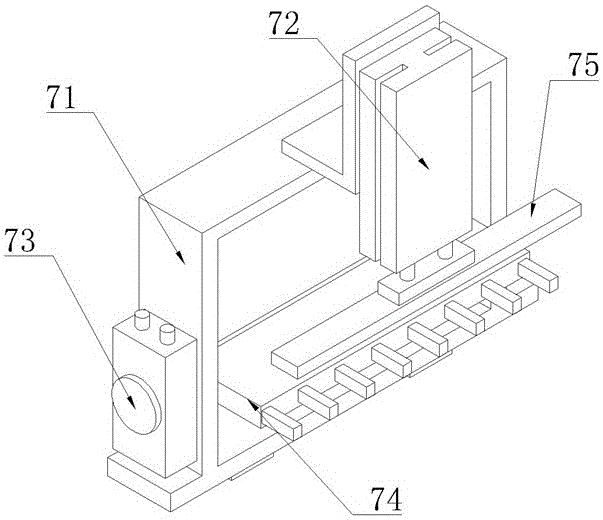

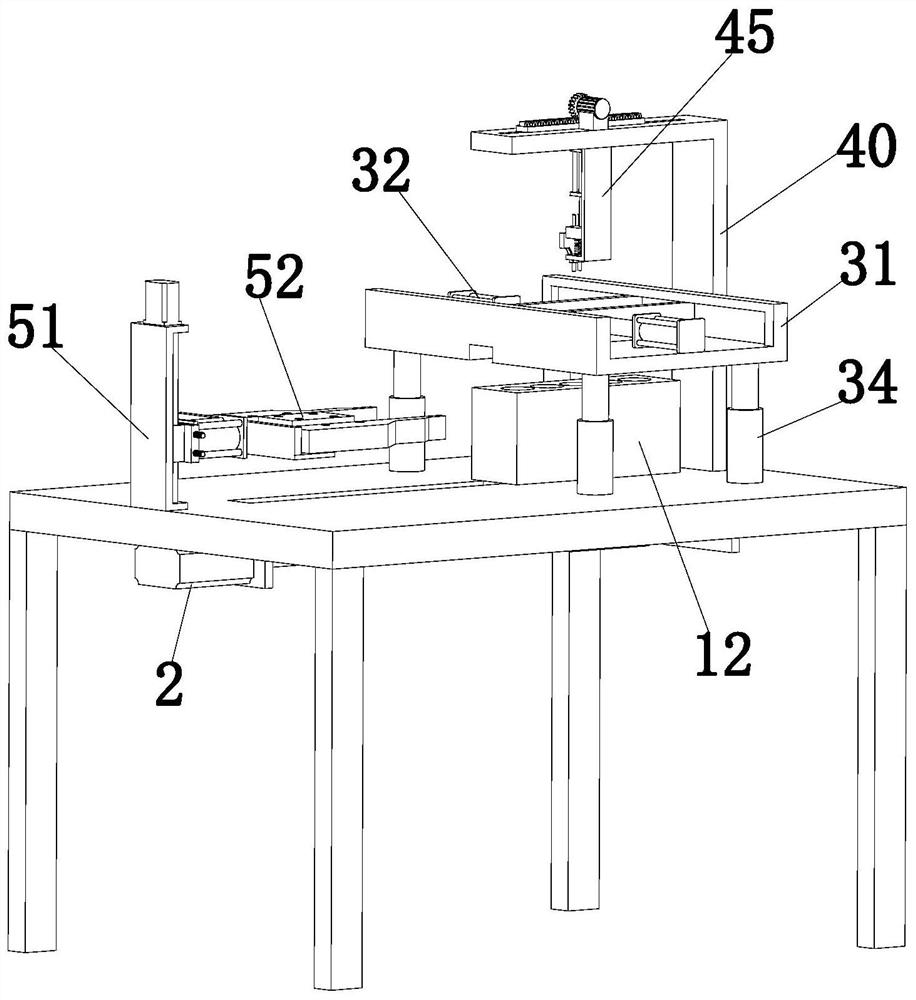

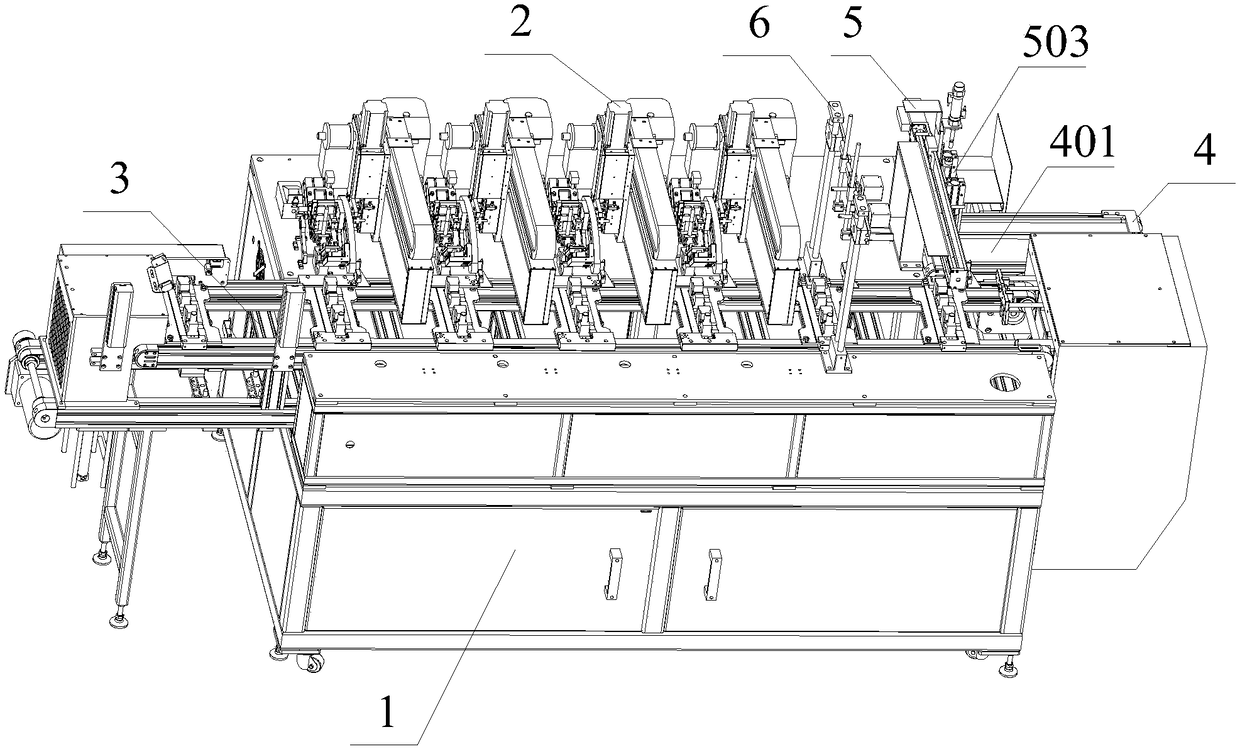

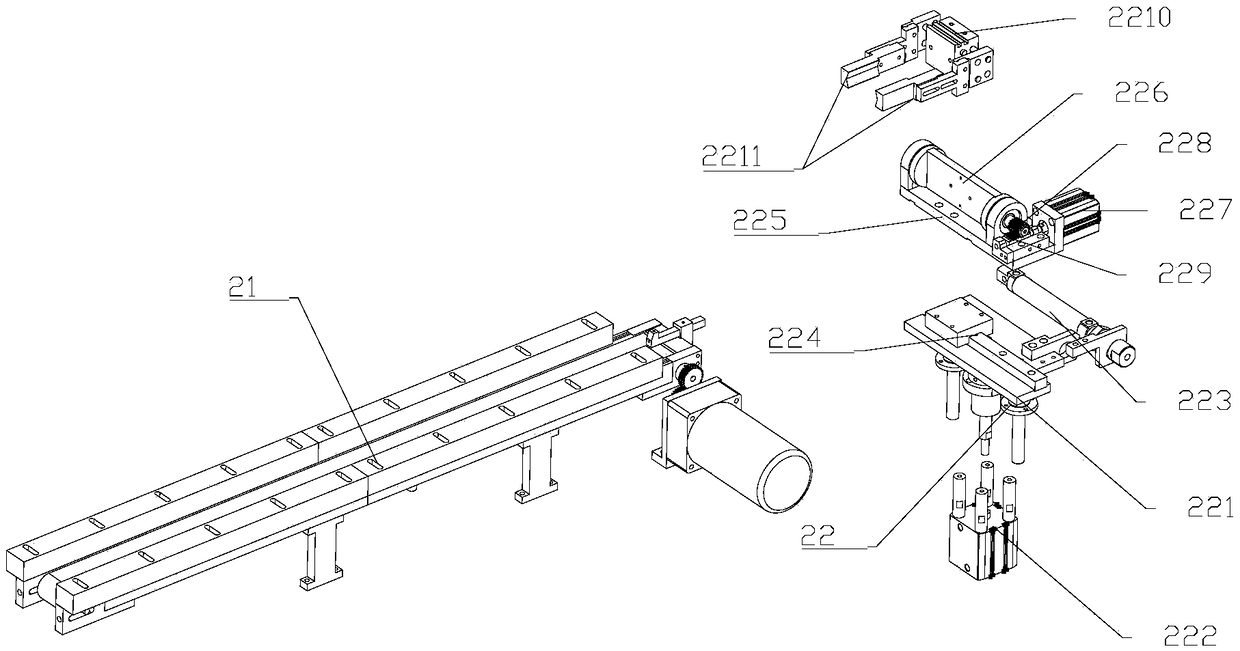

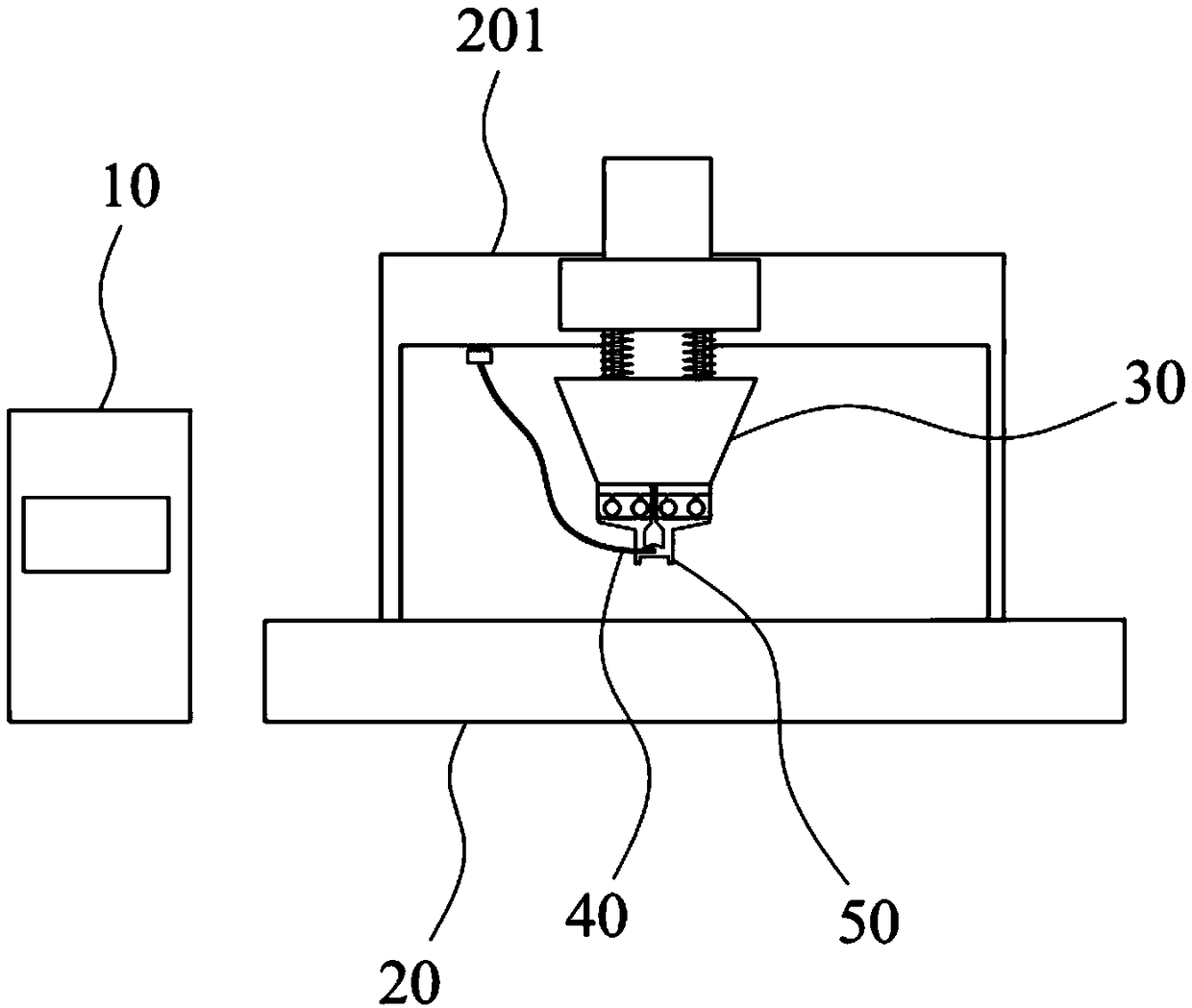

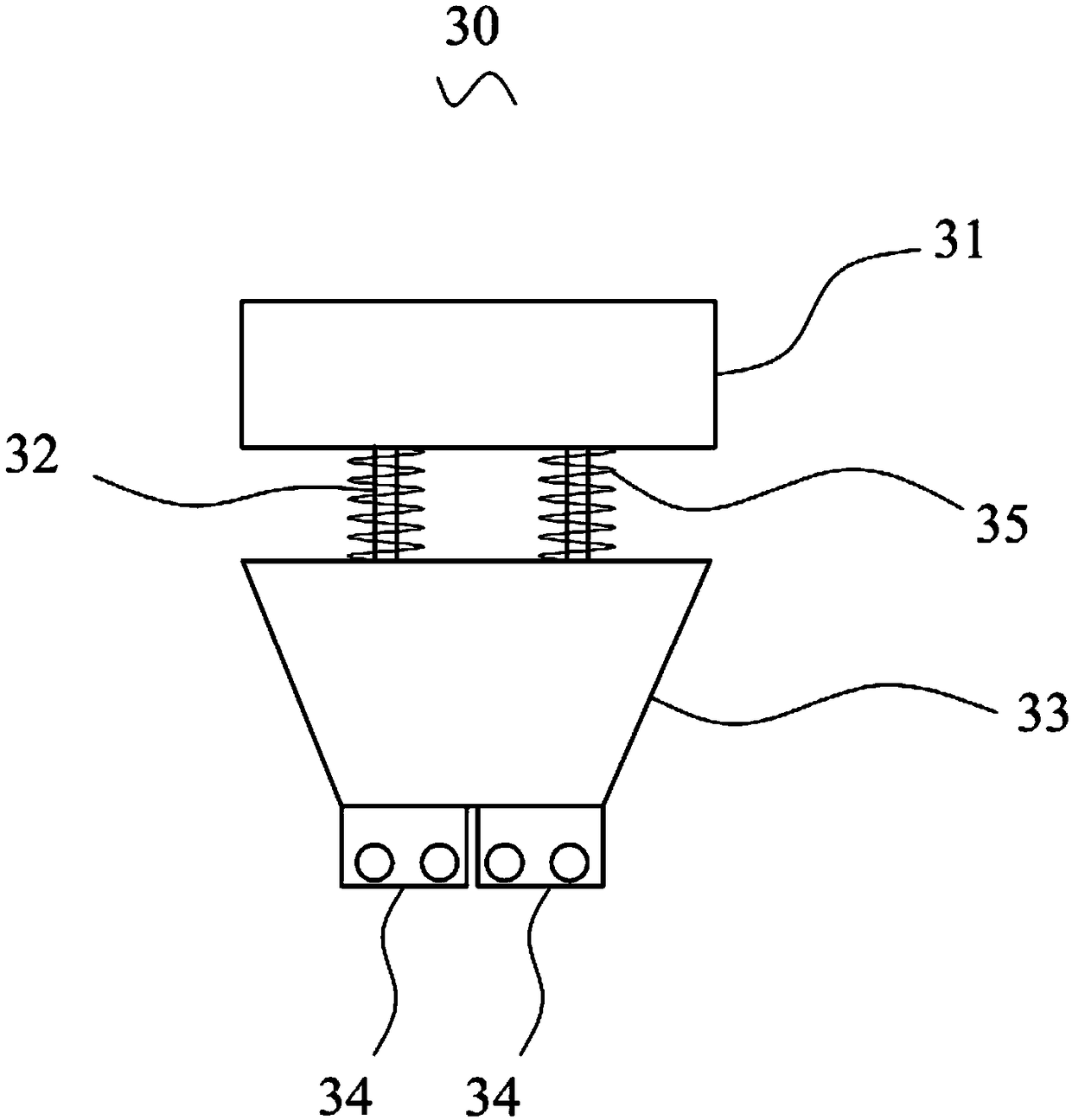

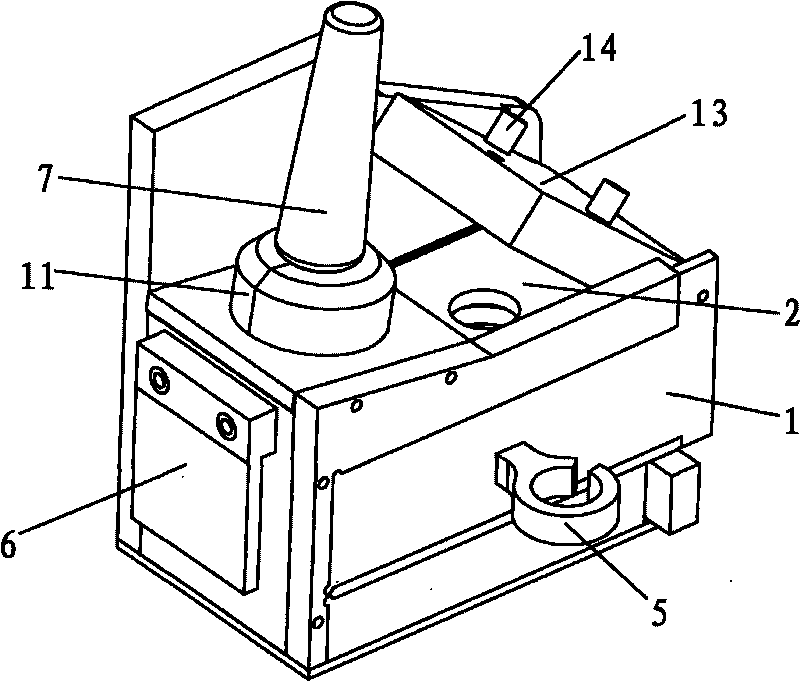

Ring vibrator automatic soldering robot and control method thereof

PendingCN108941826AMove preciselyImprove solder qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering

The invention discloses a ring vibrator automatic soldering robot and a control method thereof. The ring vibrator automatic soldering robot is characterized by comprising a rack, a conveying device, asoldering device, a workpiece fixing device and a manipulator, wherein a workbench is arranged on the rack; the conveying device is arranged on the workbench and used for conveying workpieces to be machined; the soldering device comprises a soldering assembly and a driving assembly for driving the soldering assembly to move; the soldering assembly is arranged on the driving assembly; the drivingassembly is arranged on the workbench; the workpiece fixing device comprises a supporting frame arranged on the workbench and a rotary support arranged on the supporting frame; the rotary support is used for rotating the workpieces to be machined; the manipulator is arranged on the workbench and used for grabbing the workpieces to be machined from the conveying device to the rotary support. Through the technical scheme, the ring vibrator automatic soldering robot achieves the functions of full-automatic feeding and discharging, locating and soldering and then improves the soldering quality andthe soldering efficiency of ring vibrators.

Owner:锐驰机器人(深圳)有限公司

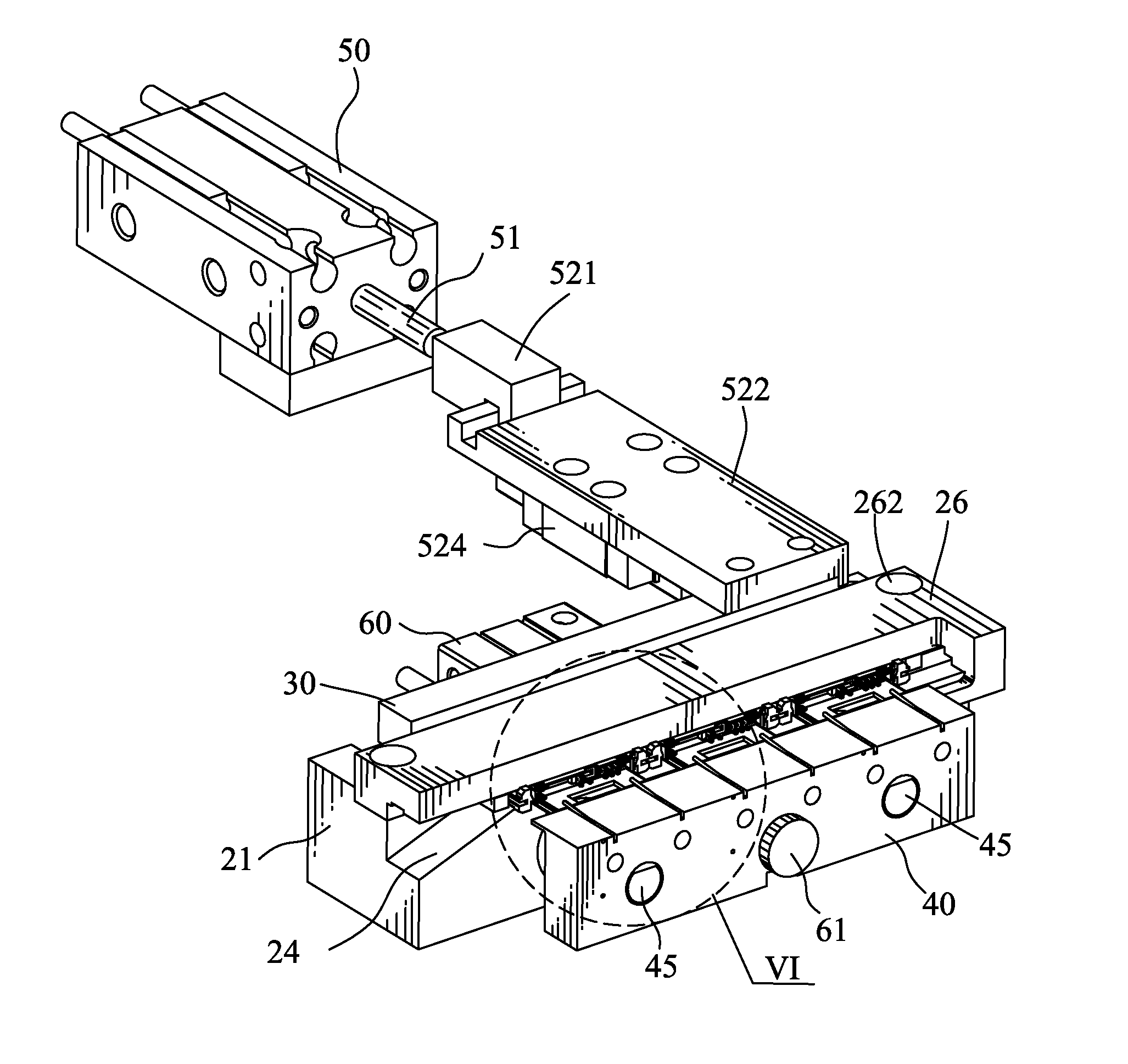

Linear automatic tin soldering device

ActiveCN105127537AImprove securitySave human effortMetal working apparatusSoldering auxillary devicesTransformerHeating furnace

The invention discloses and provides a linear automatic tin soldering device capable of simultaneously completing various motor skills, saving labor and time, relieving labor intensity, improving labor efficiency, guaranteeing the safety of staff and improving the tin soldering quality and yield of products. The linear automatic tin soldering device comprises a rack and a conveying mechanism fixedly arranged on the rack. A feeding mechanism and a linear positioning mechanism are further arranged on the conveying mechanism. A first tin soldering station, a second tin soldering station and a discharging mechanism are further sequentially arranged on the rack. The first tin soldering station and the second tin soldering station each comprise a scaling powder mechanism and a tin furnace which are fixedly arranged on one side of the linear positioning mechanism, the tin furnaces are further provided with high-temperature glue protection devices, a tin soldering mechanism is further arranged on the linear positioning mechanism, the linear positioning mechanism drives the tin soldering mechanism to sequentially pass through the first tin soldering station and the second tin soldering station, and then double-tin-soldering procedures are completed. The linear automatic tin soldering device is suitable for the field of transformer production.

Owner:珠海科德电子有限公司

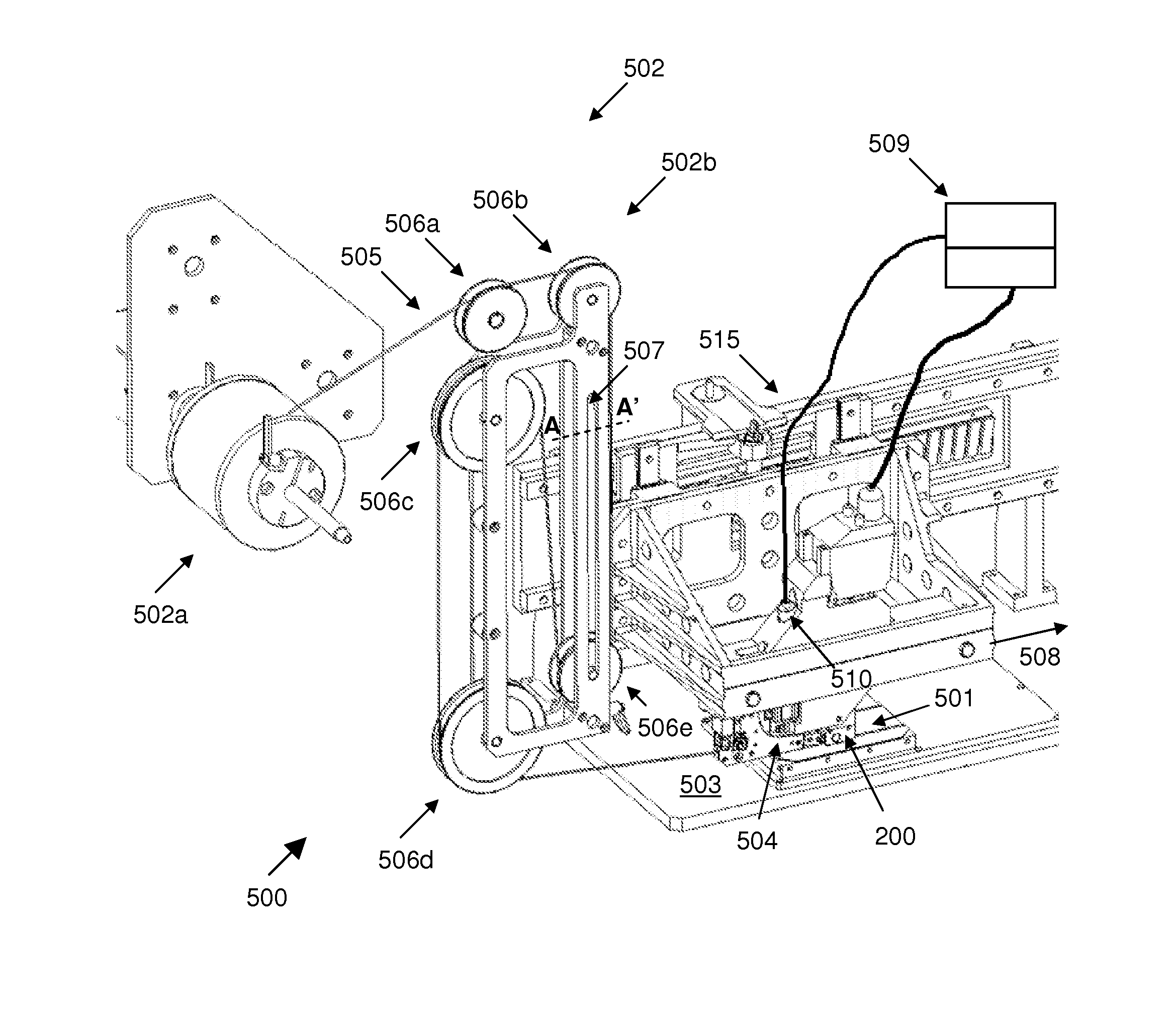

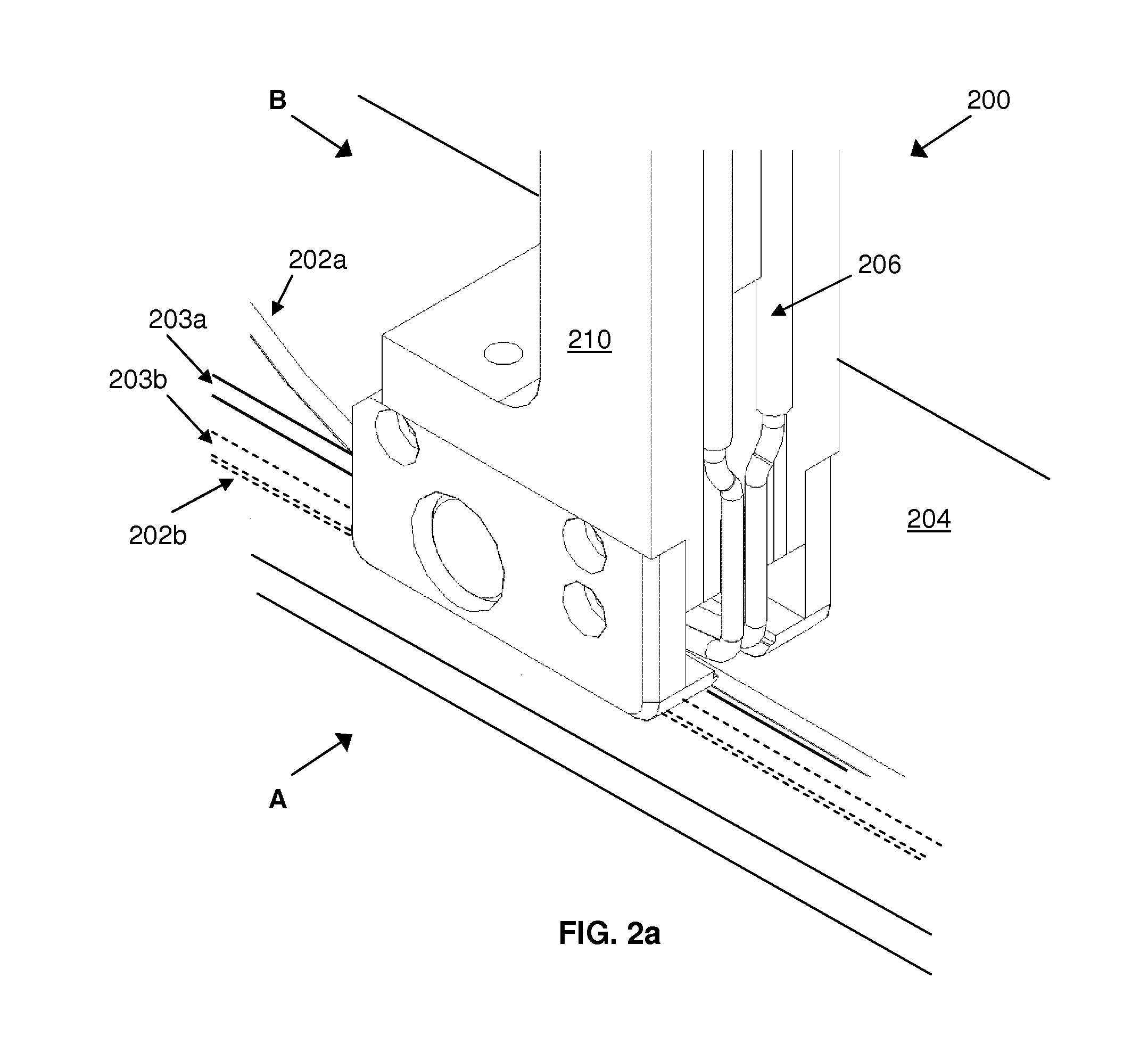

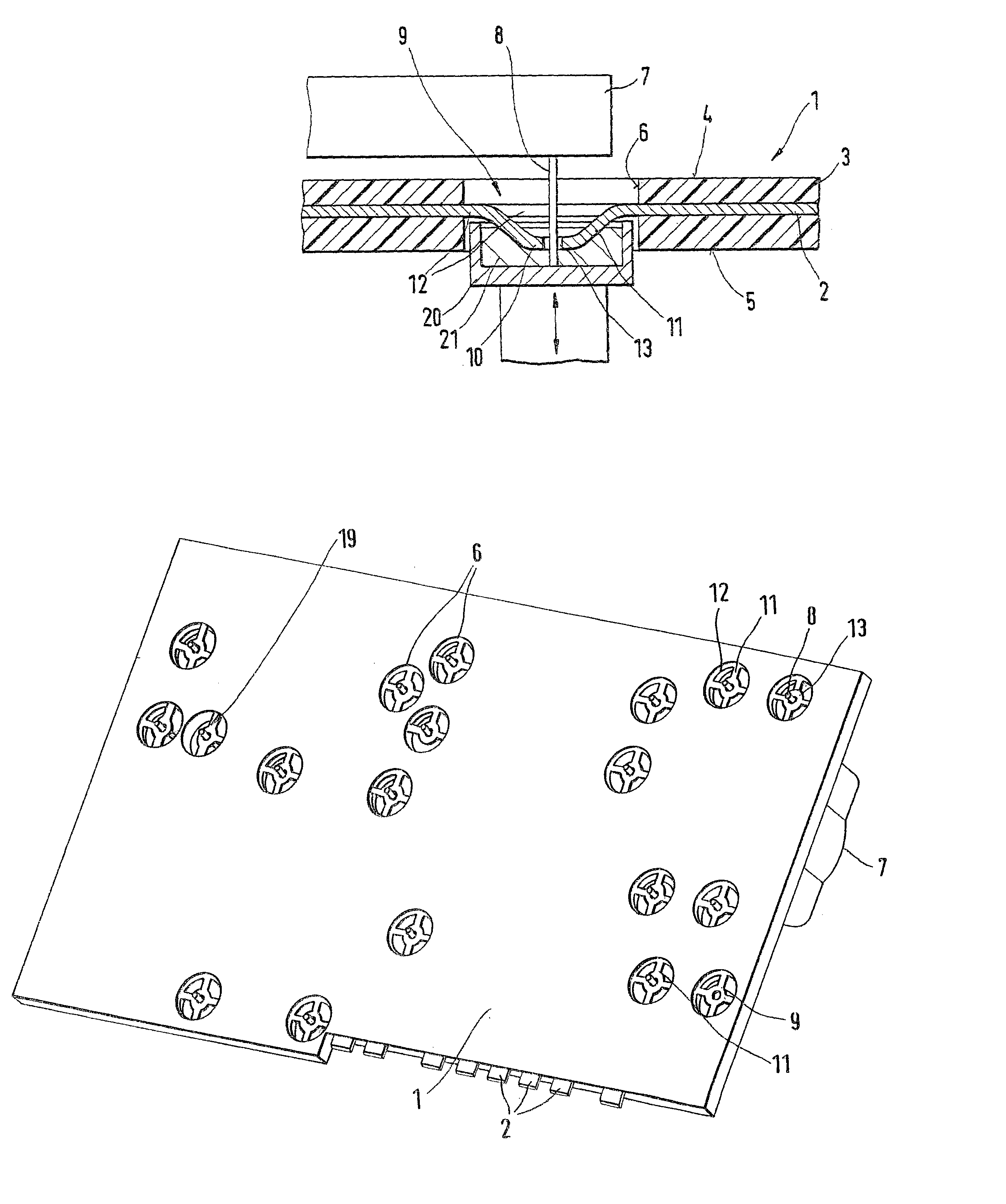

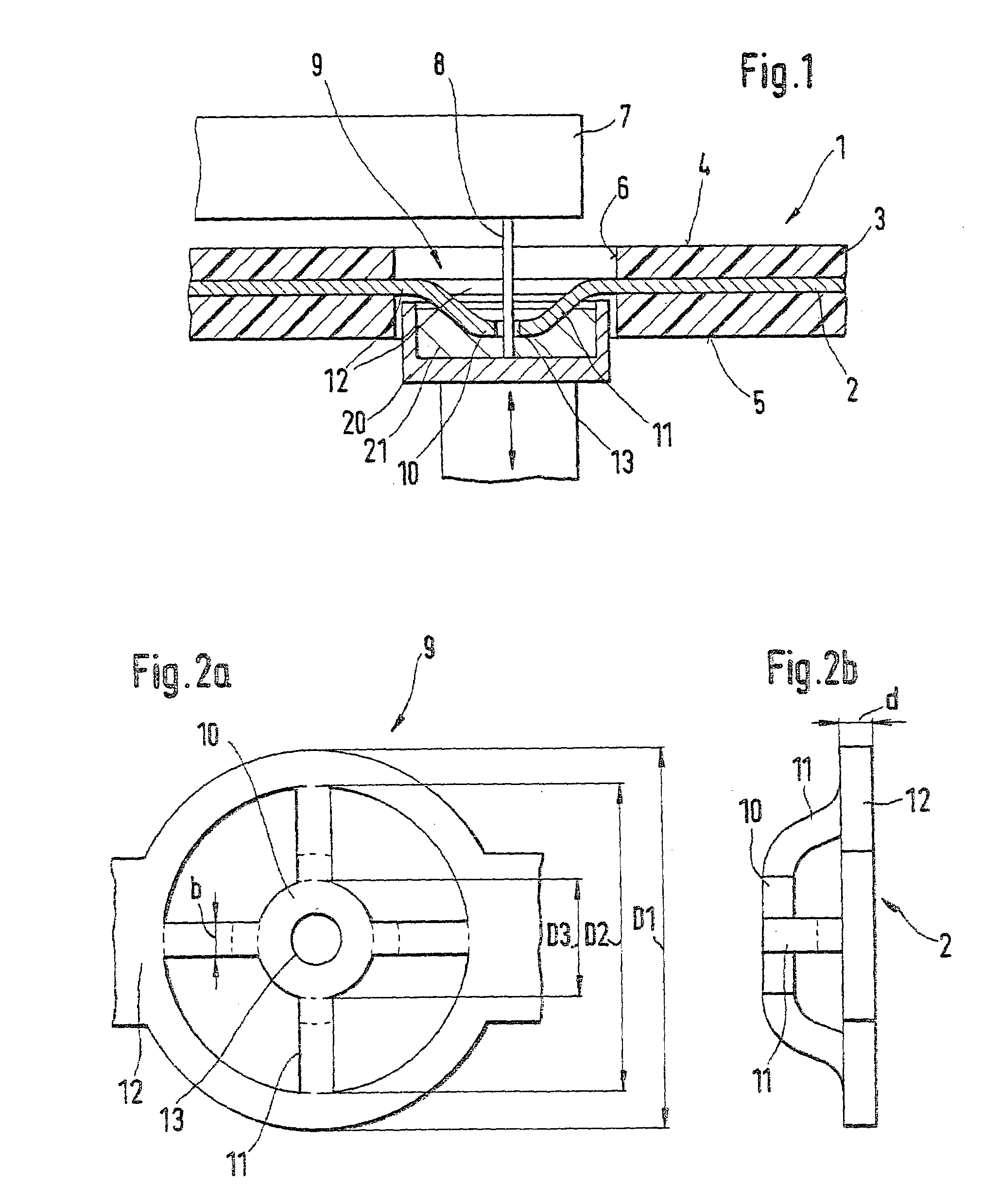

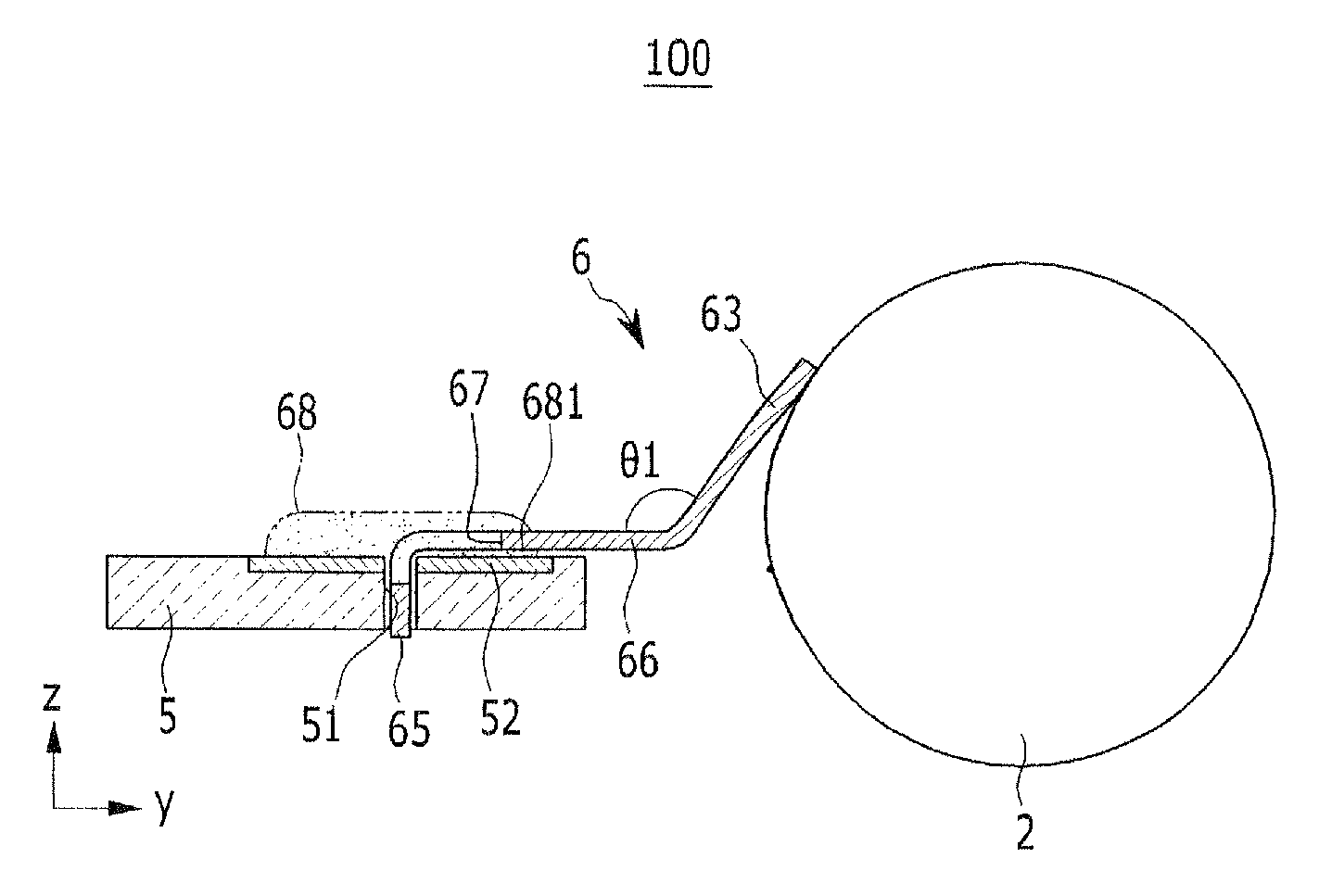

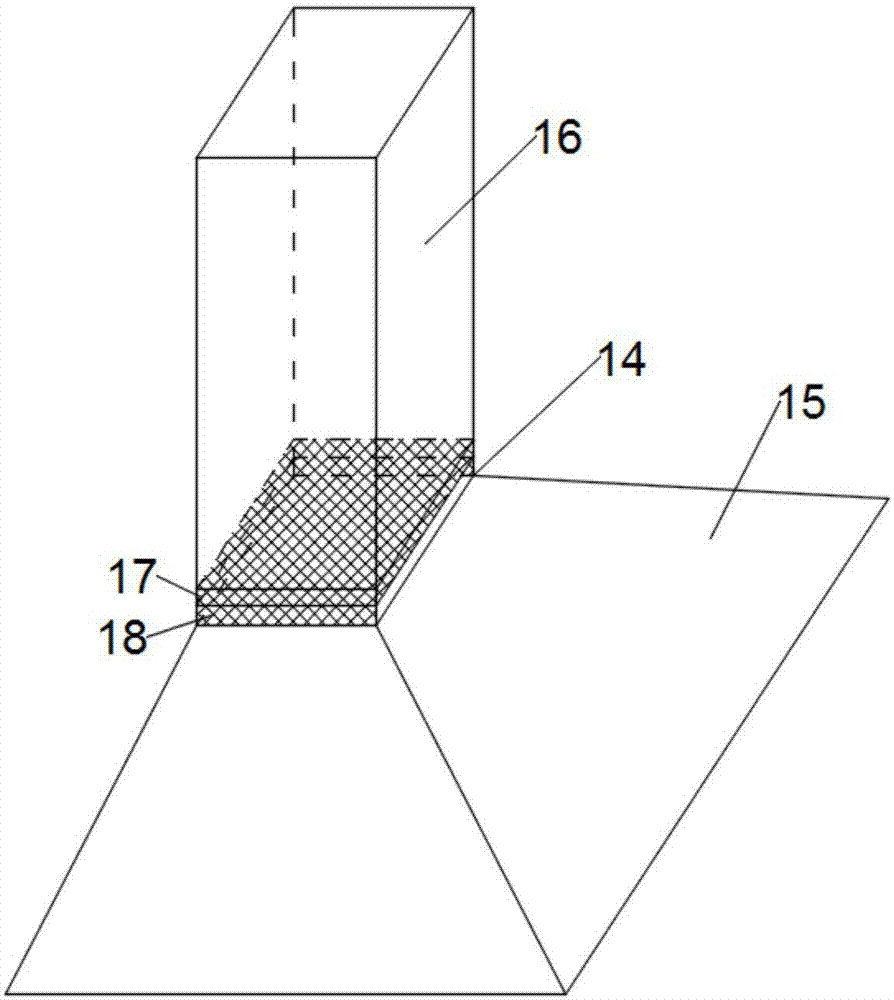

Apparatus and method of interconnecting a plurality of solar cells

InactiveUS20130277361A1Minimizes the effect of the thermal mismatch in the CTEImprove solder qualityCooking-vessel materialsAutomatic control devicesElectricityElectrical conductor

Disclosed is an apparatus for electrically interconnecting a plurality of solar cells. The apparatus comprises: i) a roller operative to roll along a solar cell to press an electrical conductor against an electrical contact of the solar cell, the electrical conductor being for electrically interconnecting the solar cell with one or more other solar cells; and ii) a heat-generating device arranged and configured to provide heat for soldering the electrical conductor to the electrical contact of the solar cell while the roller is pressing the electrical conductor against the electrical contact of the solar cell. A method of electrically interconnecting a plurality of solar cells, and a mechanism for laying and soldering an electrical conductor onto a solar cell, are also disclosed.

Owner:ASM TECH SINGAPORE PTE LTD

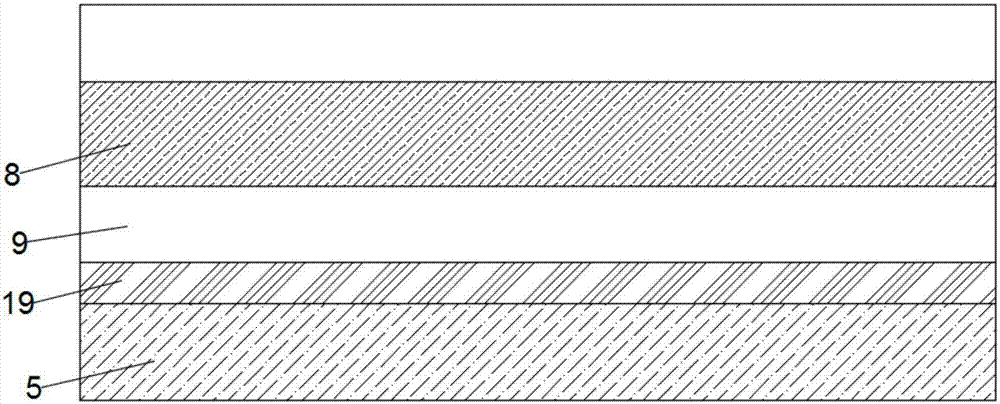

Process method for carrying out integral soldering on armature

InactiveCN102837094AImprove solder qualityImprove adhesionSoldering apparatusTinningTemperature control

The invention relates to a process method for carrying out integral soldering on an armature. Before the armature is subjected to integral soldering, a commutator pre-tinning process is added; a spiral wound gasket is used for replacing an asbestos cord; the spiral wound gasket is placed between a tin pan and the armature; the tin pan is made of titanium alloy; and a PID (Proportion Integration Differentiation) intelligent control instrument is adopted to carry out temperature control and maintenance. The commutator pre-tinning process is designed from the economy, the practicality and the manufacturability and takes an important effect in the process method for carrying out integral soldering on the armature. After the pre-tinning is carried out, the reliability of the integral soldering of the armature is improved, the pseudo soldering and the missing soldering are avoided, the repair rate of the armature is reduced and the motor quality is fundamentally improved. According to the method, the armature soldering efficiency is improved for dozens of times; the temperature control and constant temperature effects are good; the liquidity of molten tin, the welding strength and the welding reliability are improved; and the integral soldering quality of the armature is improved.

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

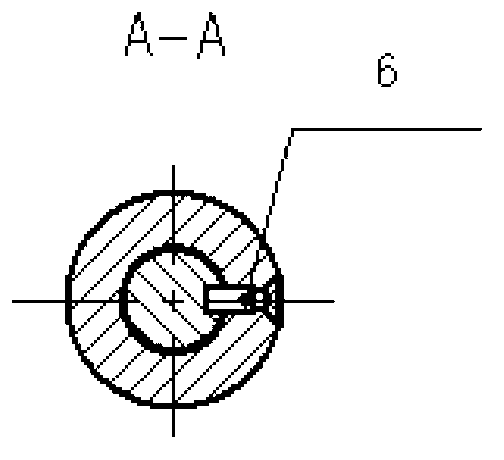

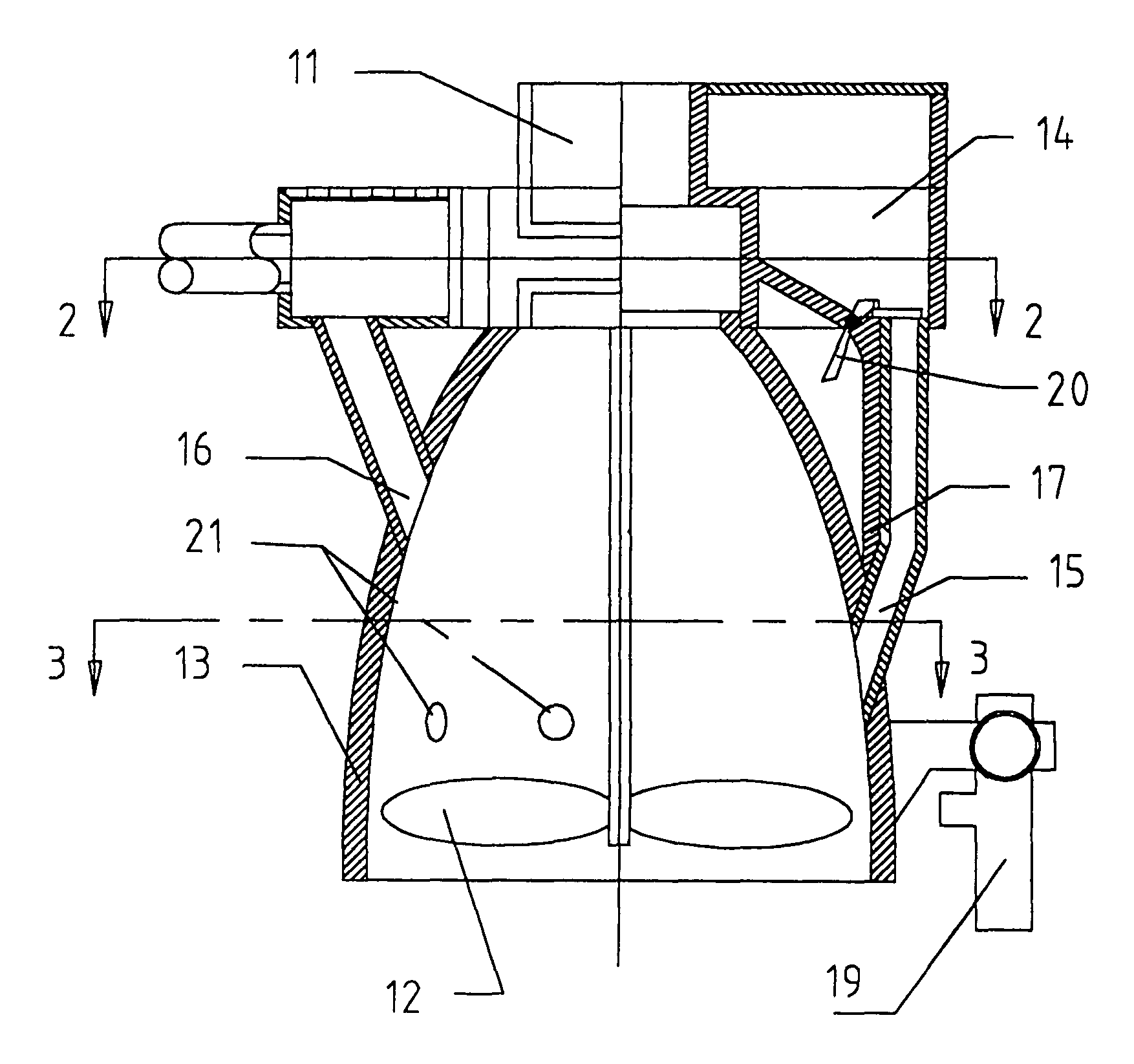

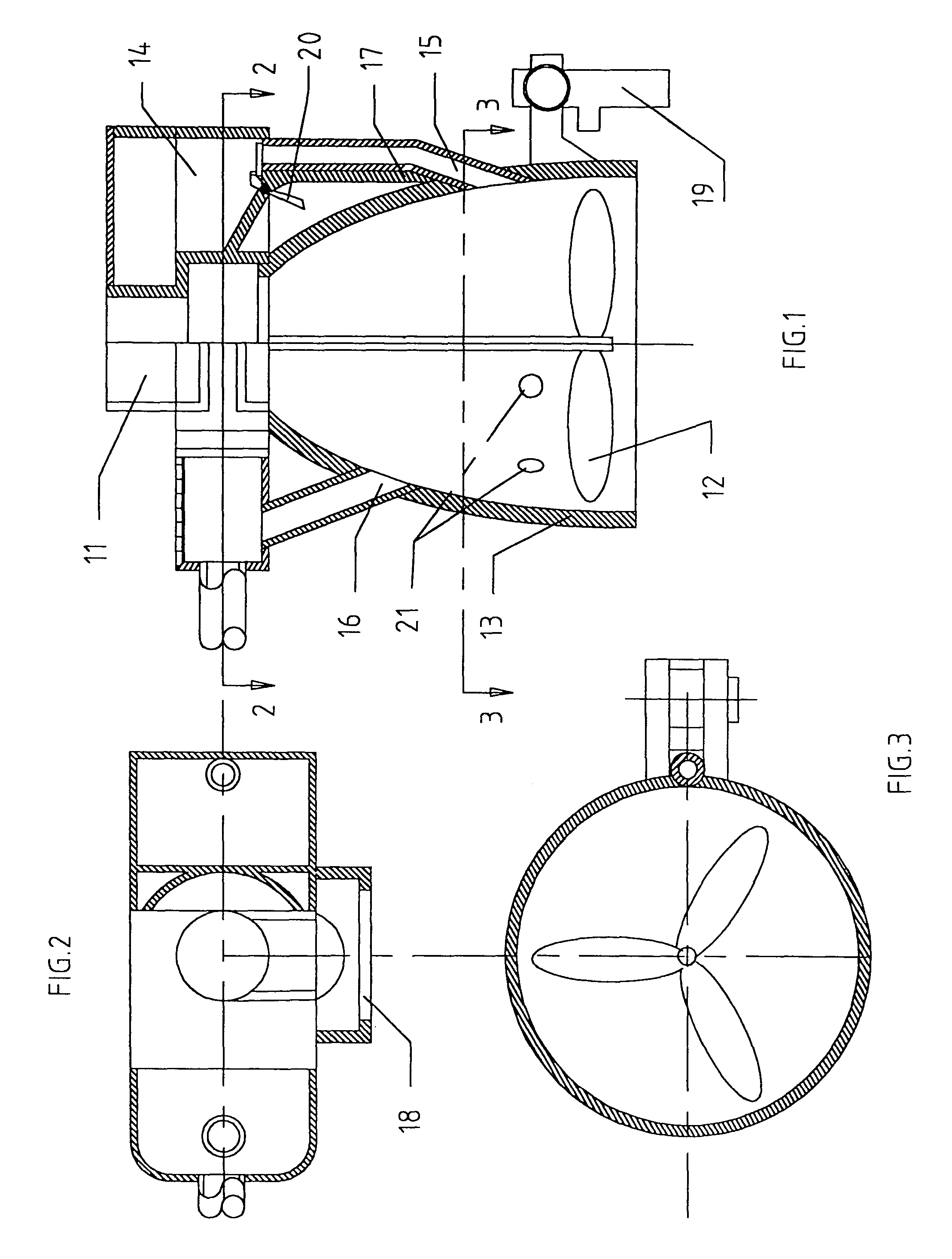

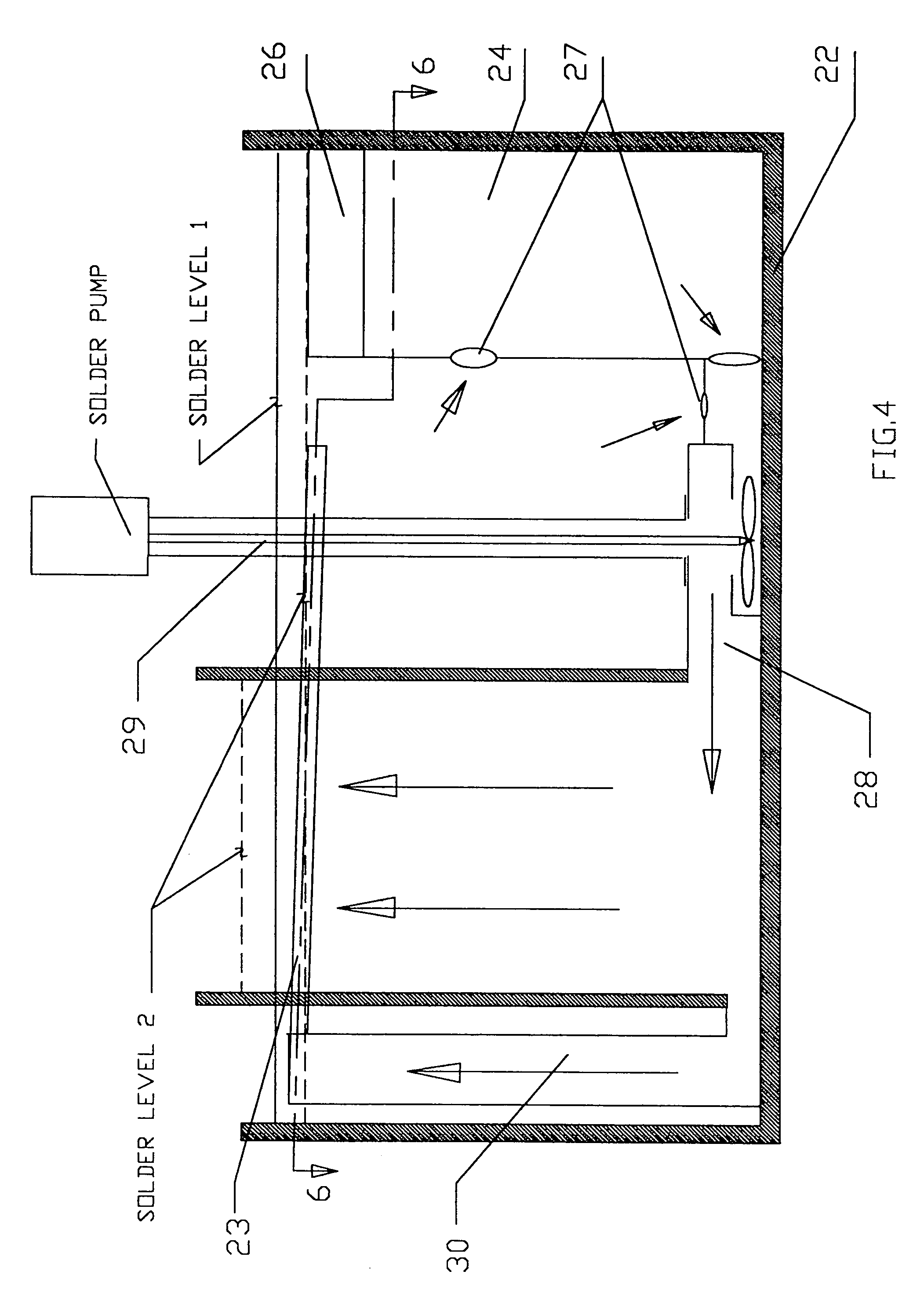

Apparatus and method for recycling of dross in a soldering apparatus

InactiveUS6942791B1Reduce traffic problemsReduce chanceSemi-permeable membranesFatty/oily/floating substances removal devicesImpellerEngineering

An apparatus and method for eliminating dross in a solder pot of a soldering machine by converting the dross into usable solder. The conversion apparatus is comprised of an impeller, a shroud, an electric motor for driving the impeller, a vacuum source operatively connected to the shroud, an arrangement of guides immersed in the solder pot for recirculating liquid solder and a chemical de-oxidizing agent. The impeller and shroud are adjacent to a free surface of the dross which forms at the top portion of the liquid solder. The method includes the steps of adding a measured amount of de-oxidizing agent to the solder pot, agitating and recirculating the liquid solder / de-oxidizer mixture with the impeller to break-up the dross into smaller particles and separate the solder from the dross, and removing a residue of the dross by suction as the recirculating mixture passes beneath the shroud.

Owner:PETROV RADKO G +1

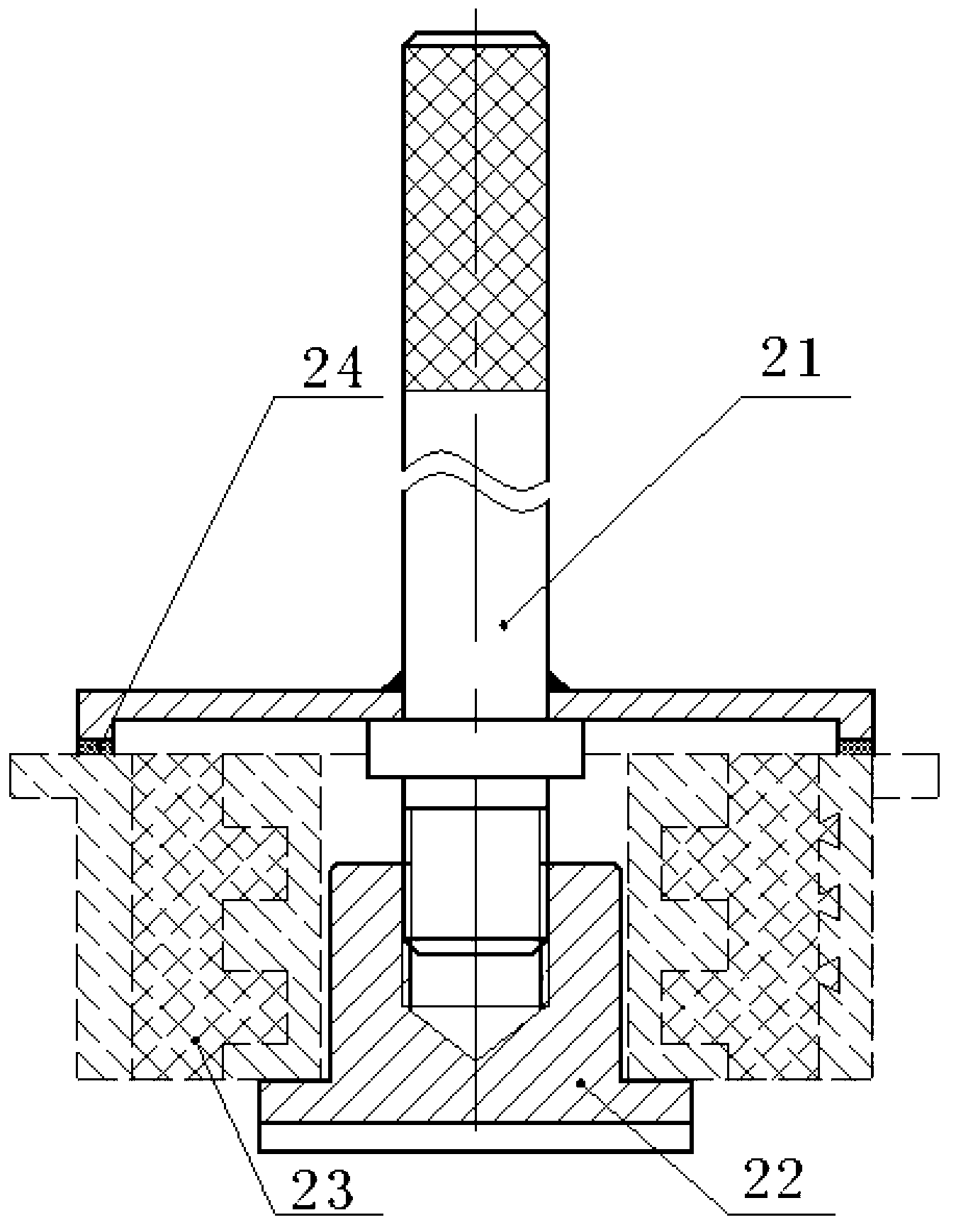

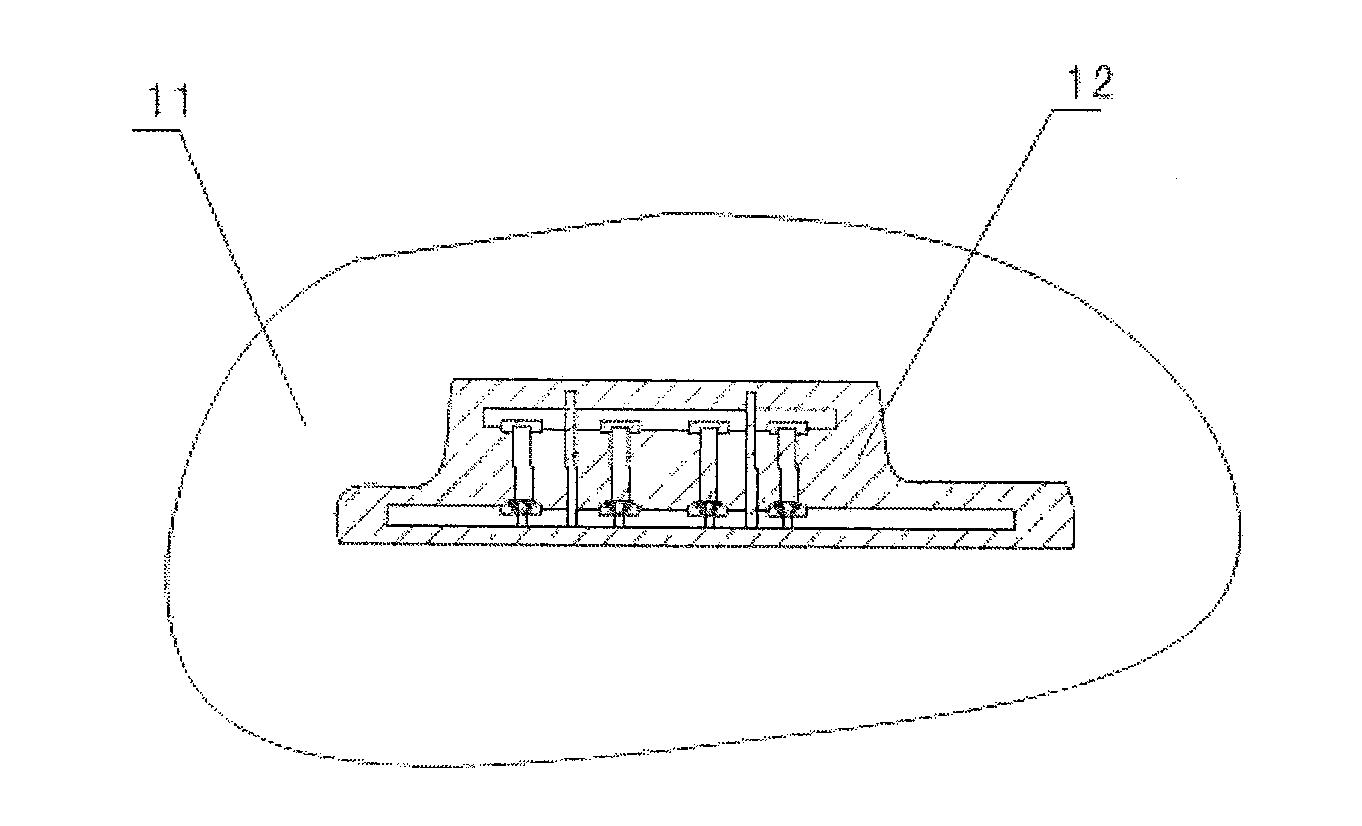

Welding device for lithium ion battery processing

InactiveCN111889937AImprove solder qualityImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering

The invention relates to the technical field of lithium ion battery welding, in particular to a welding device for lithium ion battery processing. The welding device for the lithium ion battery processing comprises a machining table, a moving device, a positioning and fixing device, a welding device and a turnover device, wherein the machining table is arranged on the ground, a rectangular slidinghole is formed in the machining table, a lithium ion battery seat is arranged at the top of the machining table and located on the rectangular sliding hole, the moving device is arranged at the bottom of the machining table, the positioning and fixing device is arranged on the lithium ion battery seat, the welding device is arranged beside the positioning and fixing device and installed at the top of the machining table, the welding end of the welding device is aligned with the positioning and fixing device in a vertical and downward mode, and the turnover device is arranged beside the positioning and fixing device. According to the welding device for the lithium ion battery processing, by means of mutual operation among the moving device, the positioning and fixing device, the welding device and the turnover device, the tin soldering quality of a lithium ion battery is improved, manual assistance is not needed, manpower is saved, and therefore, the whole welding efficiency is improved.

Owner:马程

Module support for electrical/electronic components

InactiveUS7016200B2Increase expensesSmall sectionSemiconductor/solid-state device detailsSolid-state devicesHeat flowElectrical conductor

In a module frame for electronic components, having a conductor structure having a metallic conductor, at least one contact segment of a metallic conductor, the at least one contact segment of the metallic conductor uncovered by the insulation sheathing and conductively connected to a segment of the metallic conductor, the thermal conduction cross section of the at least one connecting web being designed to be so small that when the contact segment is intensely heated, the connecting web has a throttling effect on the heat flow to the segment of the conductor.

Owner:ROBERT BOSCH GMBH

Automatic tin soldering device

ActiveCN107252944AImprove solder qualityImprove efficiencySoldering ironMetal working apparatusGear wheelEngineering

The invention discloses an automatic tin soldering device and relates to the technical filed of automation equipment. The automatic tin soldering device comprises an operation table, a driving device, an adjusting device and a tin soldering device, wherein the driving device, the adjusting device and the tin soldering device are located on the operation table. The operation table is provided with a strip-shaped groove and two sliding rails parallel to the strip-shaped groove. A through groove communicating with the lower end of the operation table is formed in the bottom end of the strip-shaped groove. A tin soldering plate is slidably installed in the sliding rails. A bulge parallel to the sliding rails is arranged on the lower end face of the tin soldering plate. A rack with the downward tooth direction is welded to the bulge. The driving device comprises a first rotating motor and a gear installed at the driving end of the rotating motor. The gear is engaged with the rack through the through groove. The tin soldering device comprises an air pump and a tin soldering pen located at the lifting end of the air pump. Complex tin soldering operation can be adjusted step by step, the tin soldering quality and the tin soldering efficiency are improved, and the production cost is reduced.

Owner:WUHU BOKANG ELECTRICAL

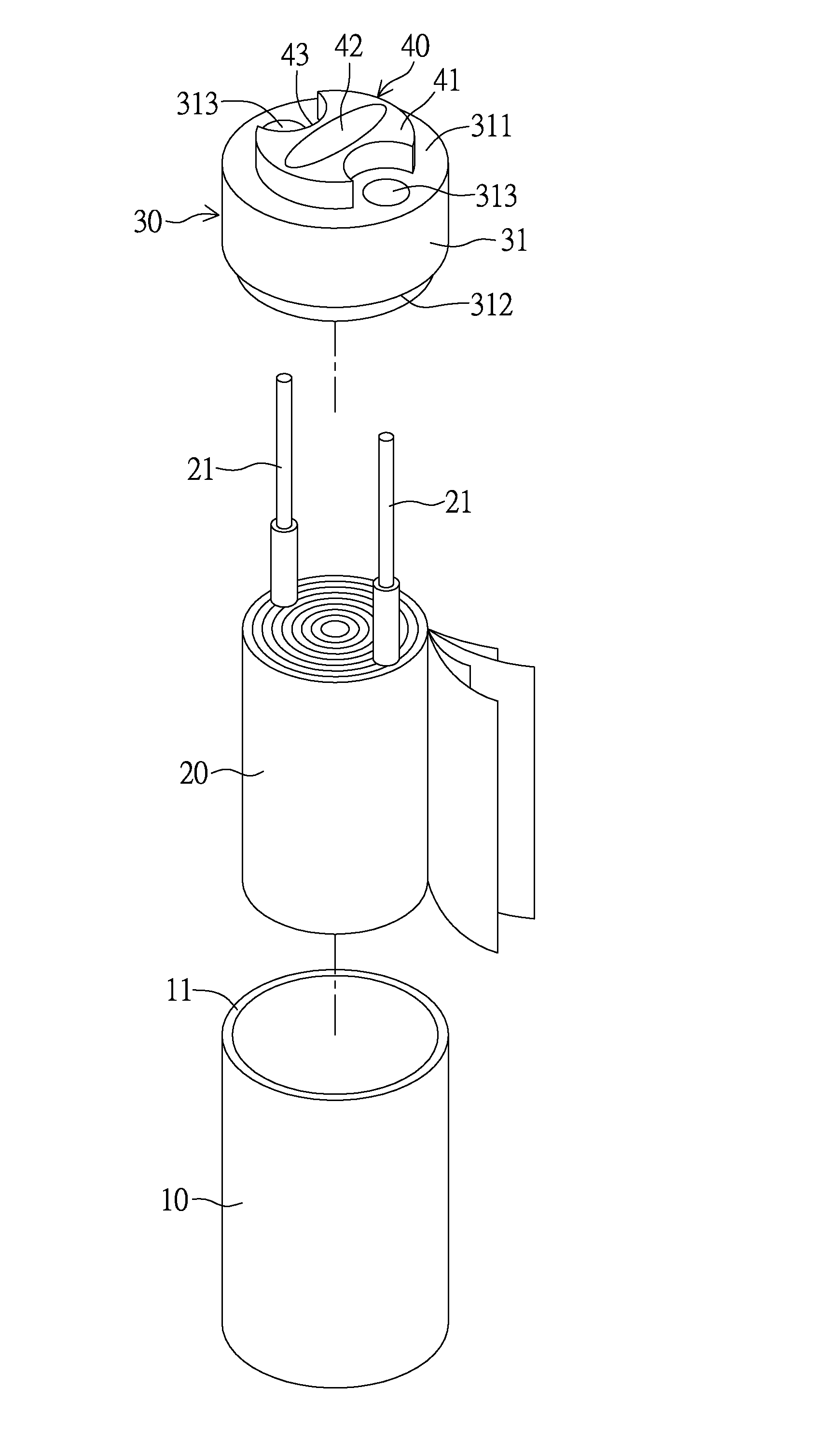

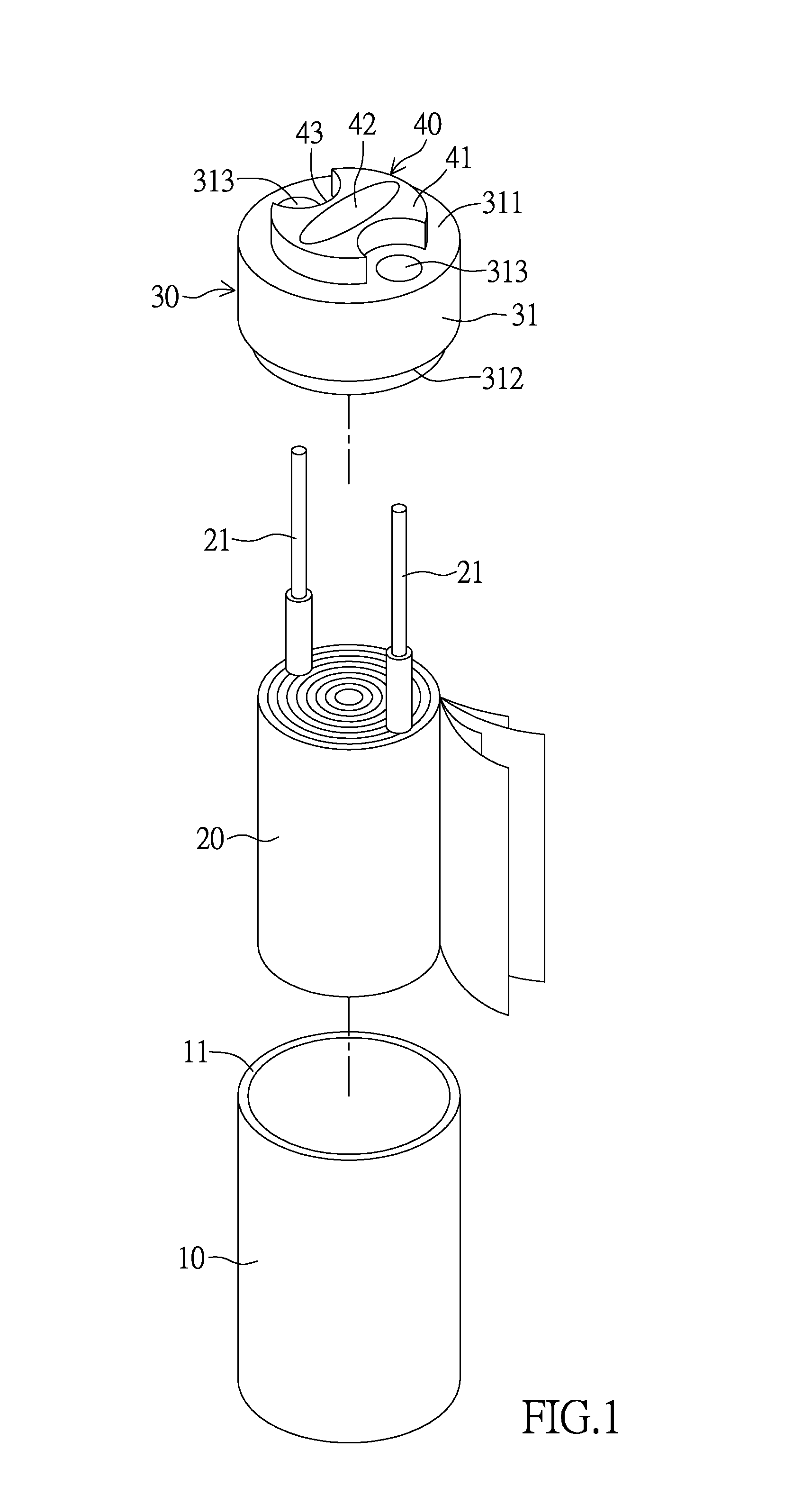

Sealing element and wound-type solid state electrolytic capacitor thereof

ActiveUS20160118196A1Improve qualityEnhance stabilityEngine sealsSolid electrolytic capacitorsSolid-stateMechanical engineering

A sealing element of the instant disclosure includes a cover body, an exterior convex portion, and an interior convex portion. The cover body has a first surface, a second surface arranged opposite to the first surface, and a pair of terminal holes formed on the cover body and extending through the first and second surfaces. The exterior convex portion has at least one first abutting surface arranged on the first surface of the cover body and an expansion space formed concavely in the exterior convex portion. The interior convex portion has at least one second abutting surface arranged on the second surface of the cover body. Specifically, the sealing element is configured to prevent the capacitor element from swaying, so that the electrical property of the wound-type solid state electrolytic capacitor with the sealing element can be improved.

Owner:APAQ TECH

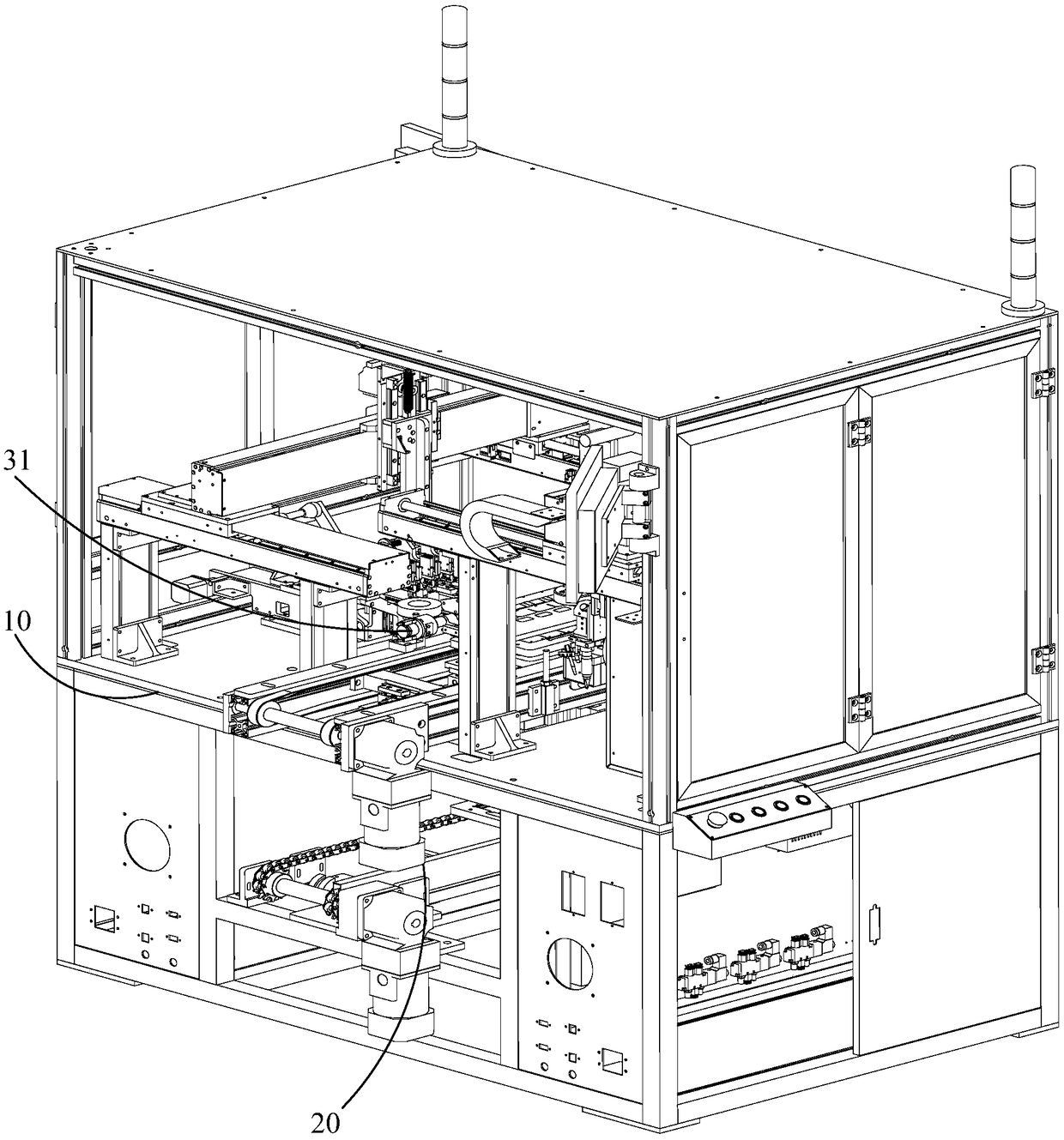

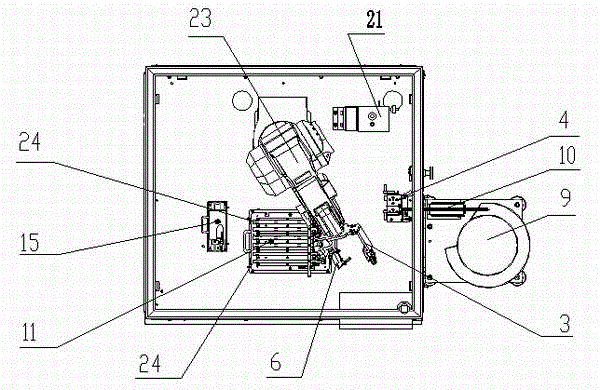

Automatic tin soldering machine assembly

ActiveCN108067699AReduce time consumptionReduce circulation proceduresWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering

The invention provides an automatic tin soldering machine assembly. The automatic tin soldering machine assembly comprises a machine box. The machine box is provided with a plurality of welding cleaning modules which are used for carrying out soldering tin soldering on a workpiece, a conveying module for conveying and transferring the workpiece, a discharging module for discharging the workpiece and a material taking module for transferring the workpiece to the discharging module from the conveying module. The material taking module is arranged between the welding cleaning module and the discharging module. The automatic tin soldering machine assembly is high in automation degree, safety and precision are improved, the whole structure is compact, the space is saved, the tin soldering quality is high, and high-efficiency and high-quality soldering tin soldering work is further achieved while the production cost is reduced.

Owner:石超

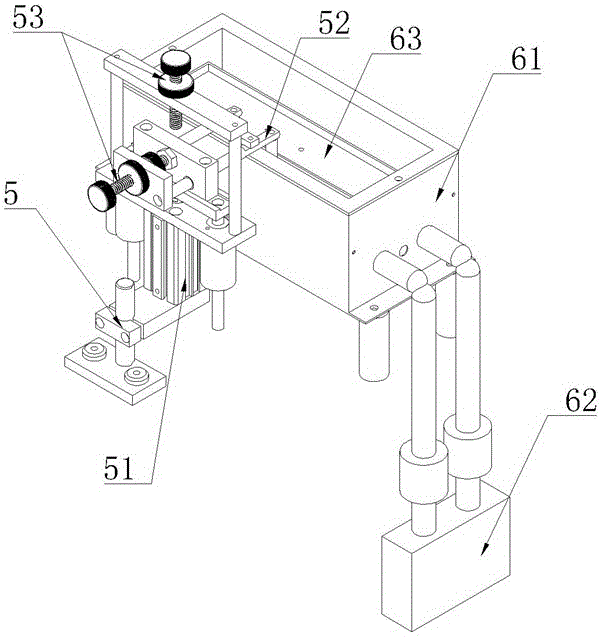

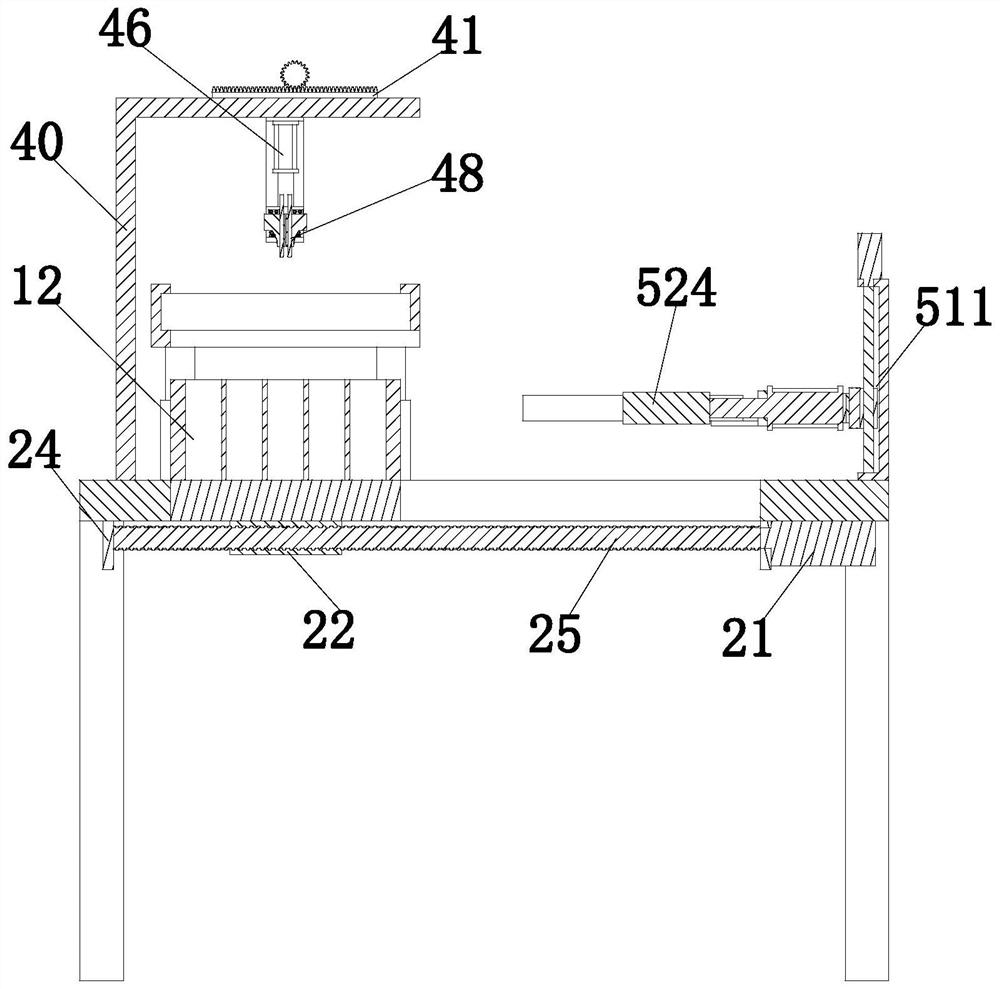

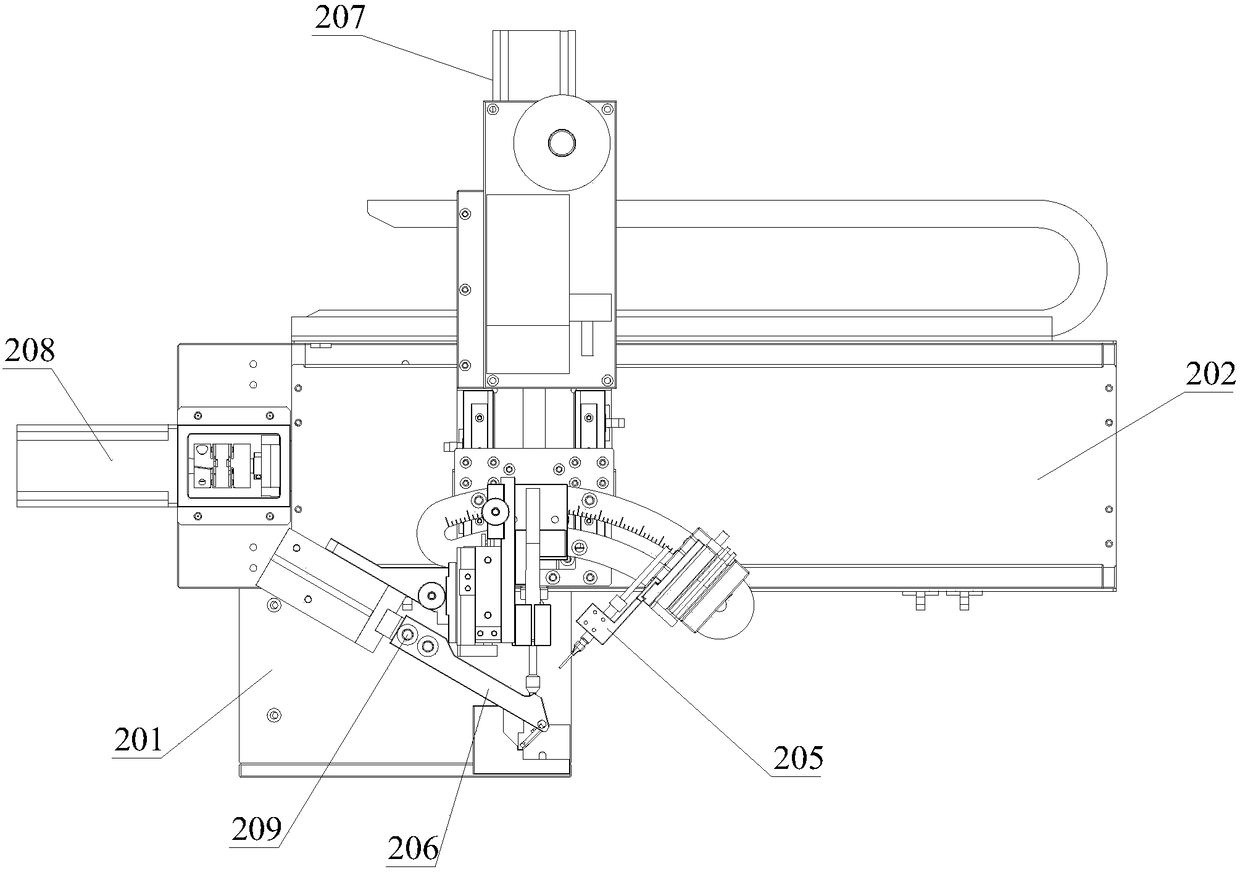

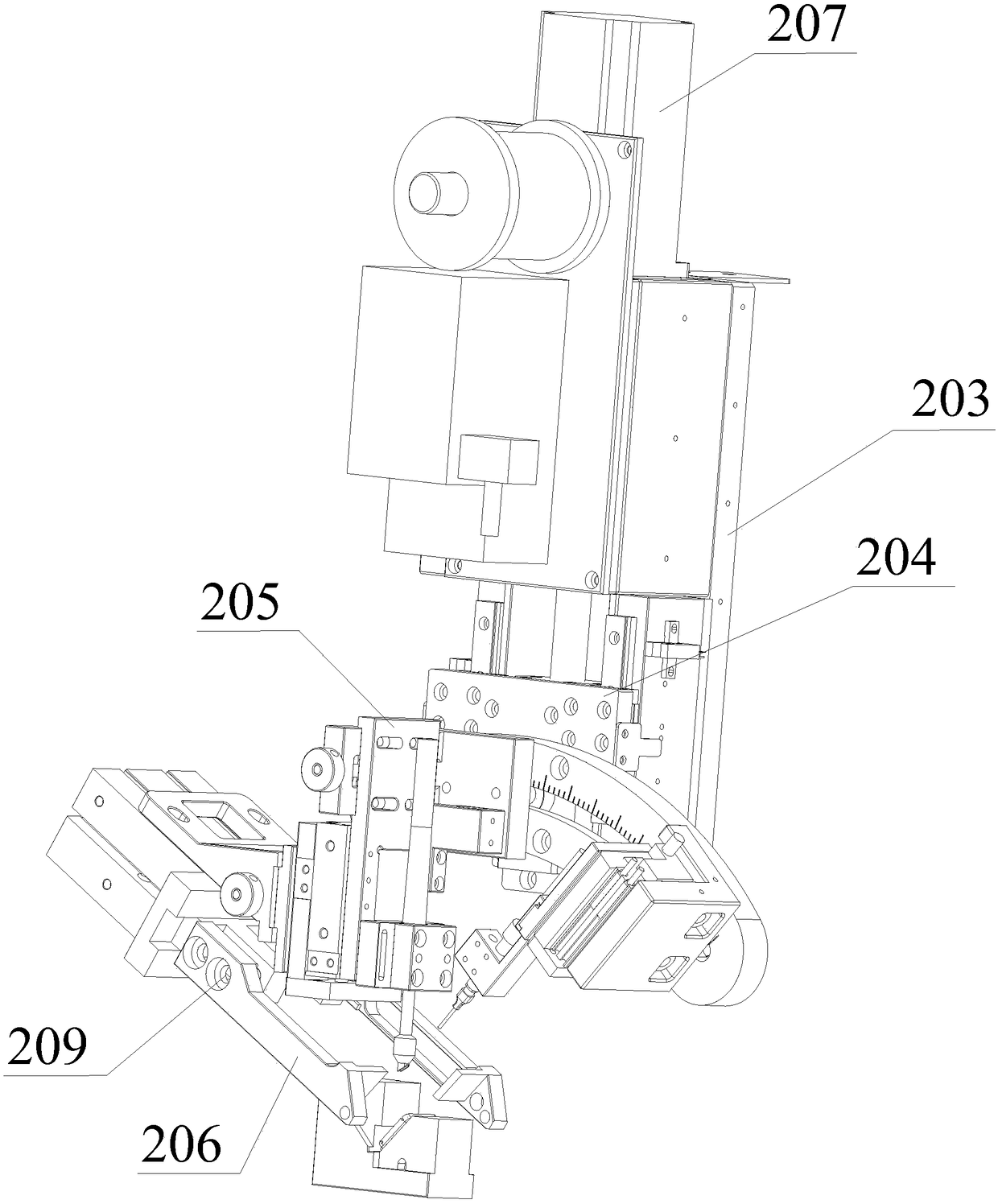

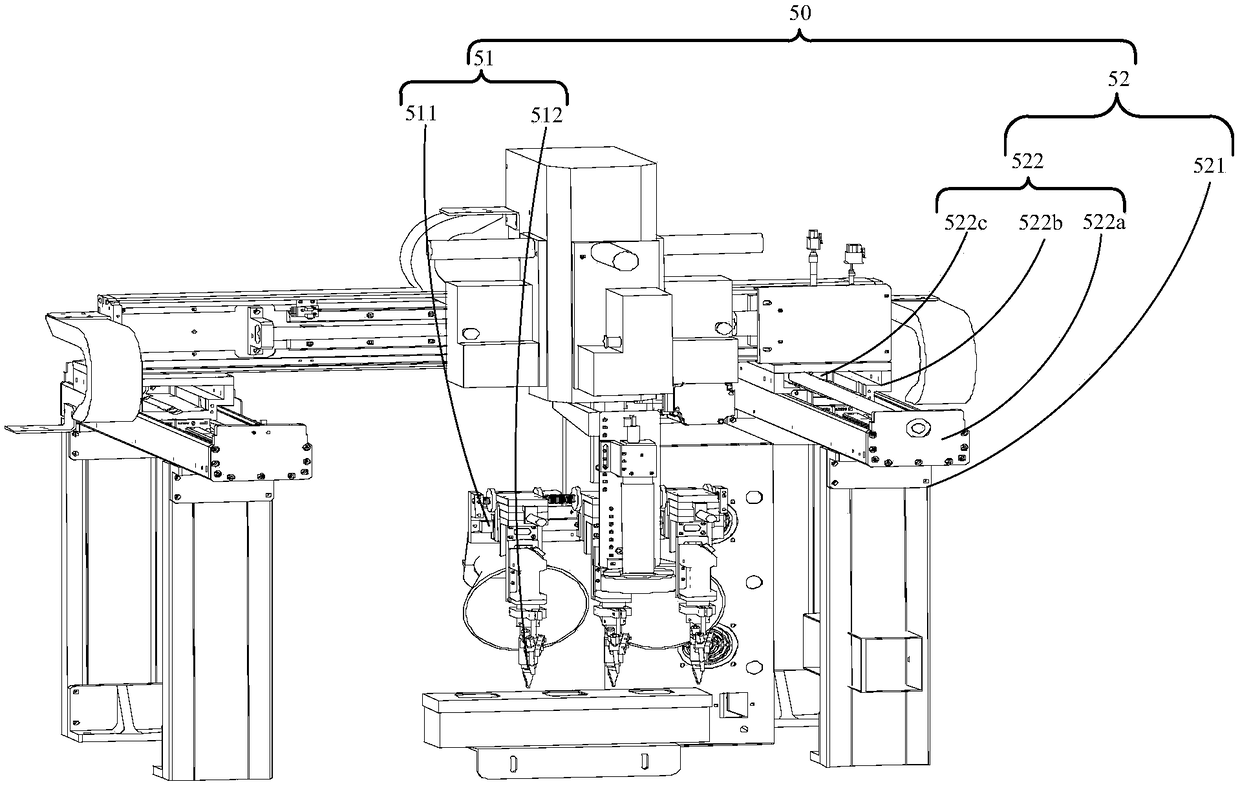

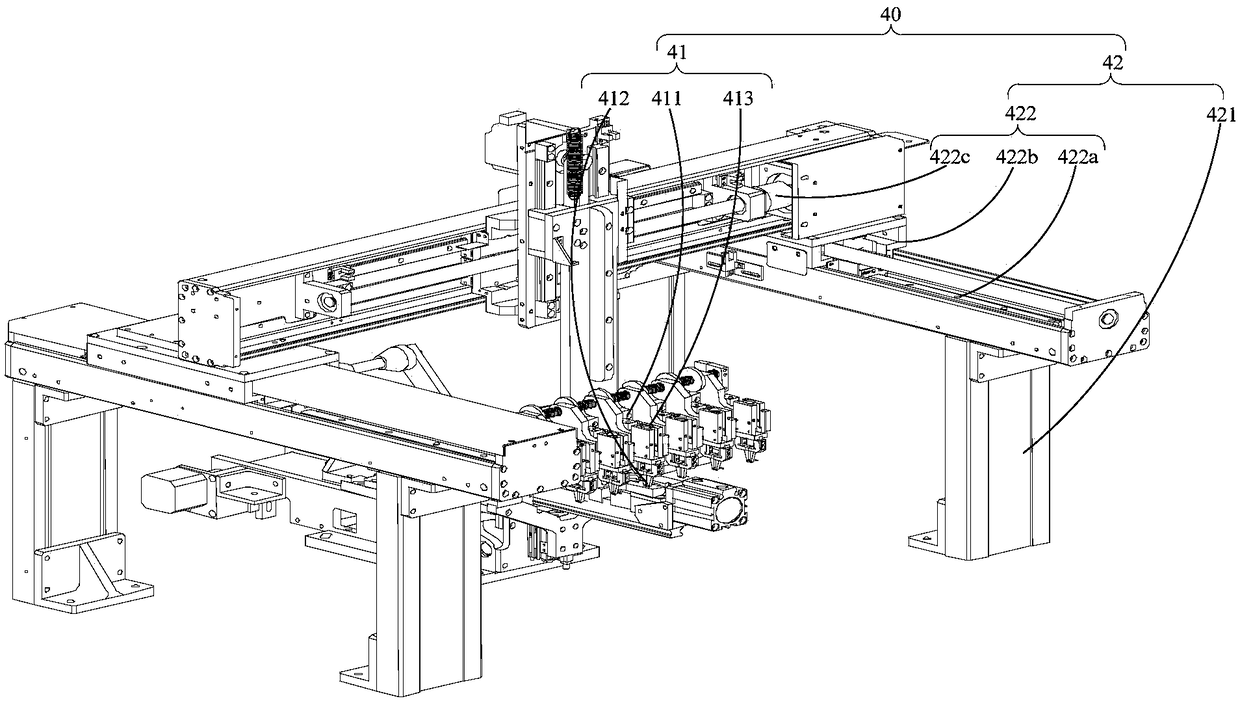

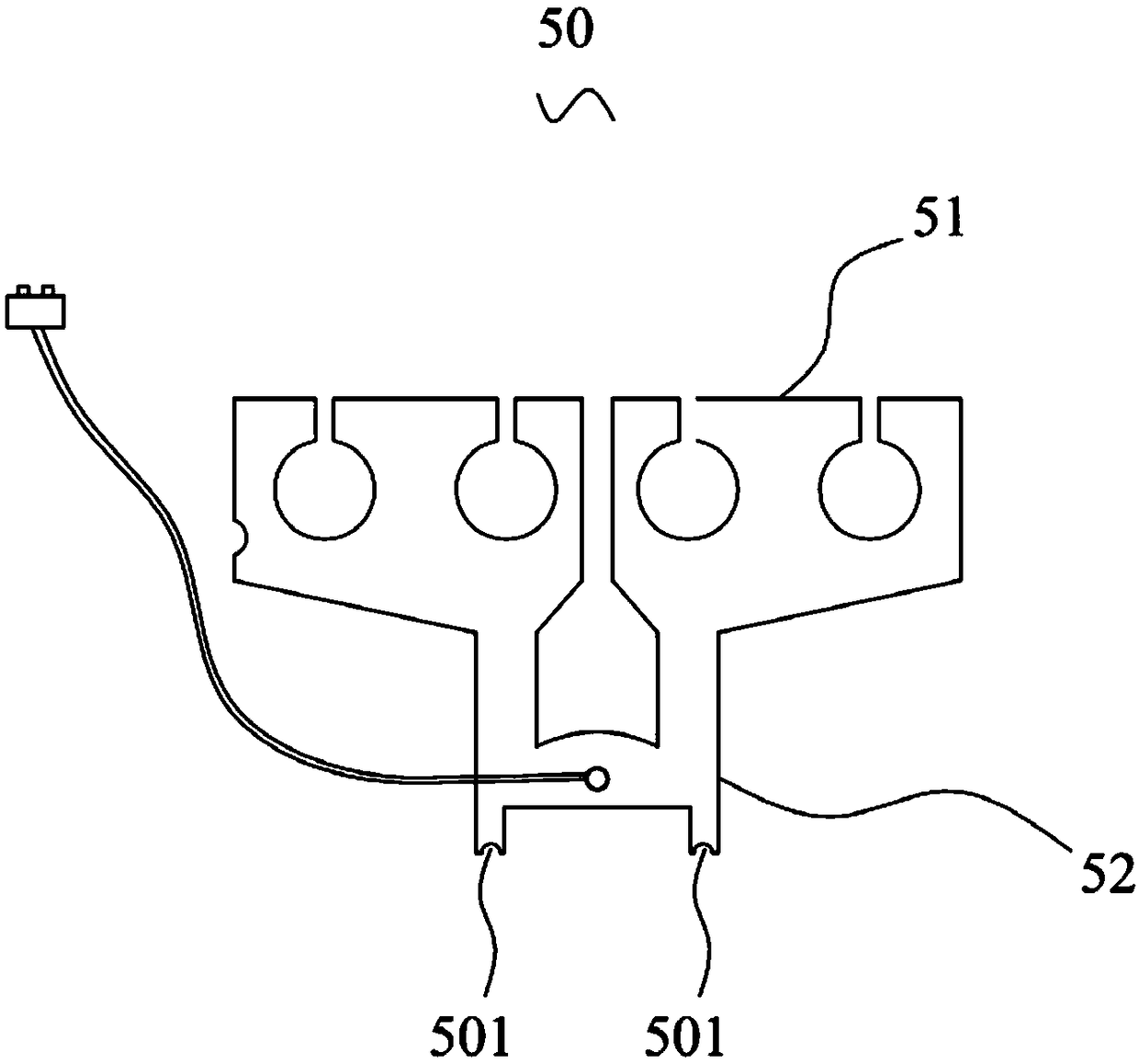

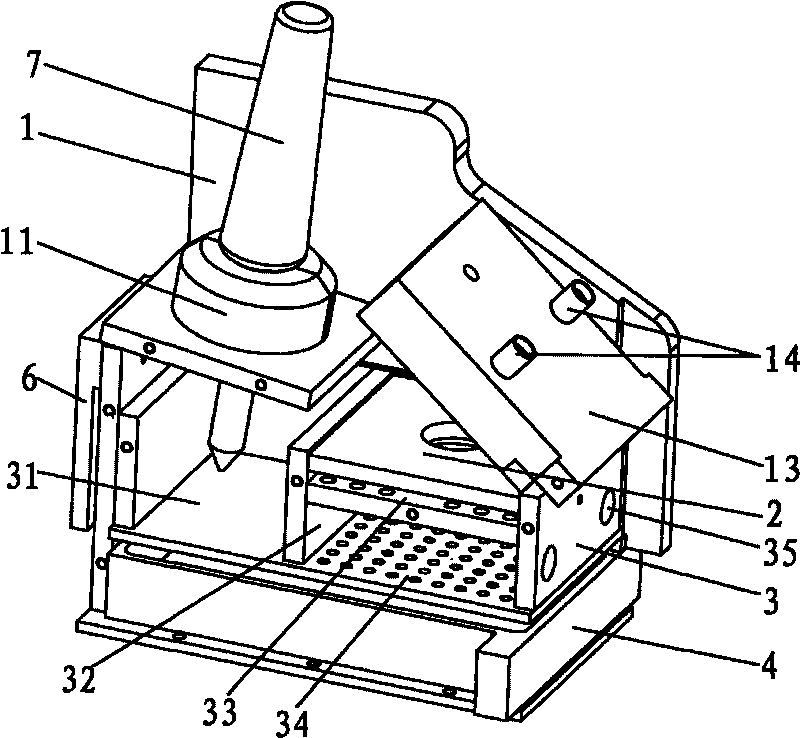

Special-shaped part automatic plug-in soldering robot and control method thereof

PendingCN109108423AImprove accuracyImprove solder qualityWelding/cutting auxillary devicesAuxillary welding devicesSolderingMaterial supply

The invention discloses a special-shaped part automatic plug-in soldering robot and a control method thereof. The special-shaped part automatic plug-in soldering robot comprises a rack, a transmissiondevice, a material supply device, a plug-in device and a soldering device; a worktable is arranged on the rack, the transmission device is arranged on the worktable, and is used for conveying a to-be-machined circuit board to the machining position, the material supply device is arranged on the worktable, and used for conveying a special-shaped part to be machined to the loading position, the plug-in device comprises a clamping assembly and a plug-in moving assembly driving the clamping assembly to move, the clamping assembly is arranged on the plug-in moving assembly, and the plug-in movingassembly is arranged on the worktable; the soldering device comprises a soldering assembly and a soldering moving assembly for driving the soldering assembly to move, the soldering assembly is arranged on the soldering moving assembly, and the soldering moving assembly is arranged on the worktable. Manual cost is reduced, and production efficiency is improved.

Owner:锐驰机器人(深圳)有限公司

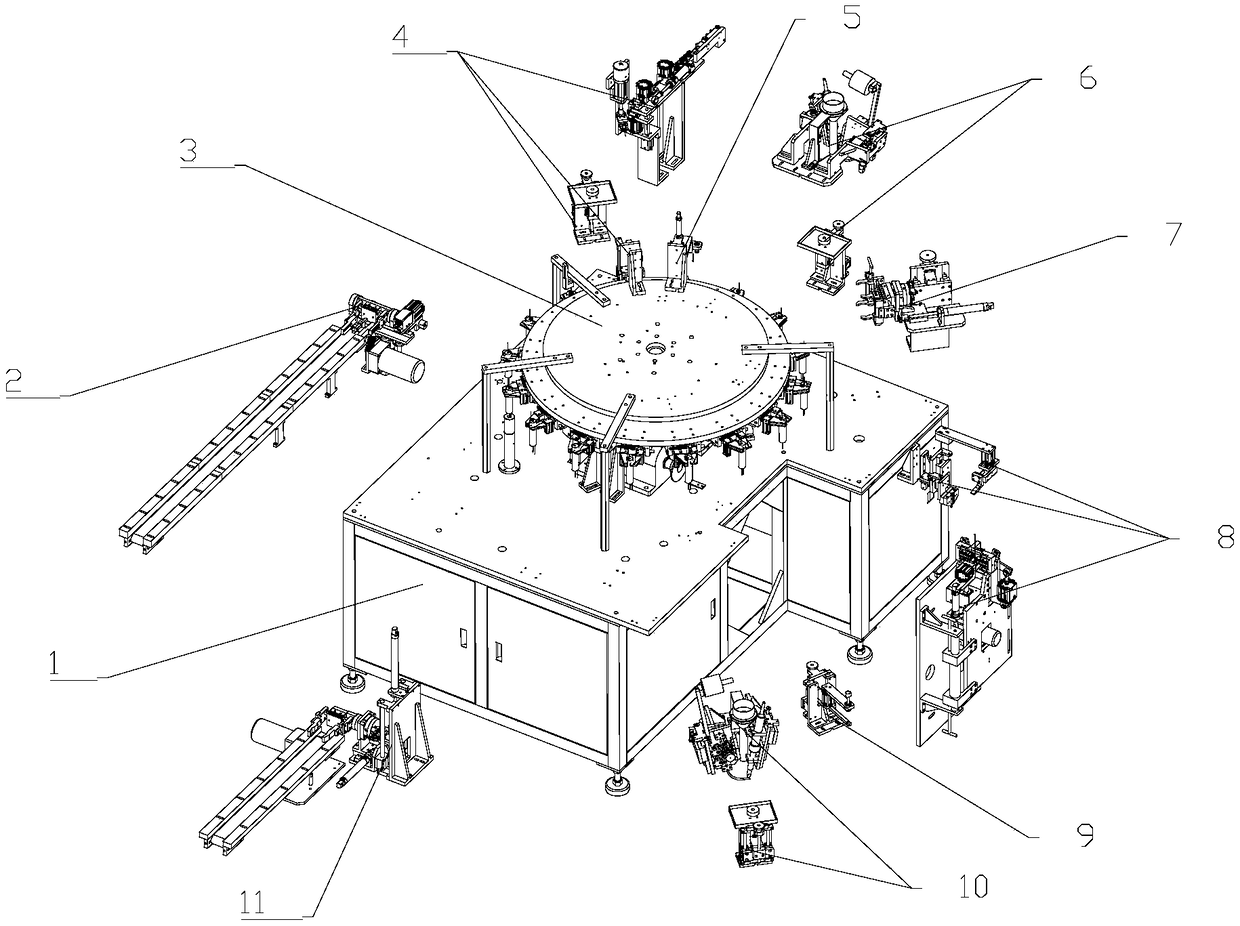

Circular capacitor production machine

InactiveCN109500611AImprove pass rateEasy to transportLine/current collector detailsOther manufacturing equipments/toolsCapacitanceCapacitor

The invention discloses a circular capacitor production machine. The circular capacitor production machine comprises a machine frame, and a capacitor feeding device, a swivel plate conveying device, atinned wire point-welding device, a tinned wire detecting device, a tinned wire welding device, a capacitor overturning device, a rubber wire point-welding device, a rubber wire detecting device, a rubber wire welding device, and a finished product discharging device. The capacitor feeding device, the tinned wire point-welding device, the tinned wire detecting device, the tinned wire welding device, the capacitor overturning device, the rubber wire point-welding device, the rubber wire detecting device, the rubber wire welding device, and the finished product discharging device are sequentially arranged. The circular capacitor production machine has the advantages that the automation degree is high, working efficiency is high, the qualified rate of finished products is high, and welding is firm and stable.

Owner:张玉仙

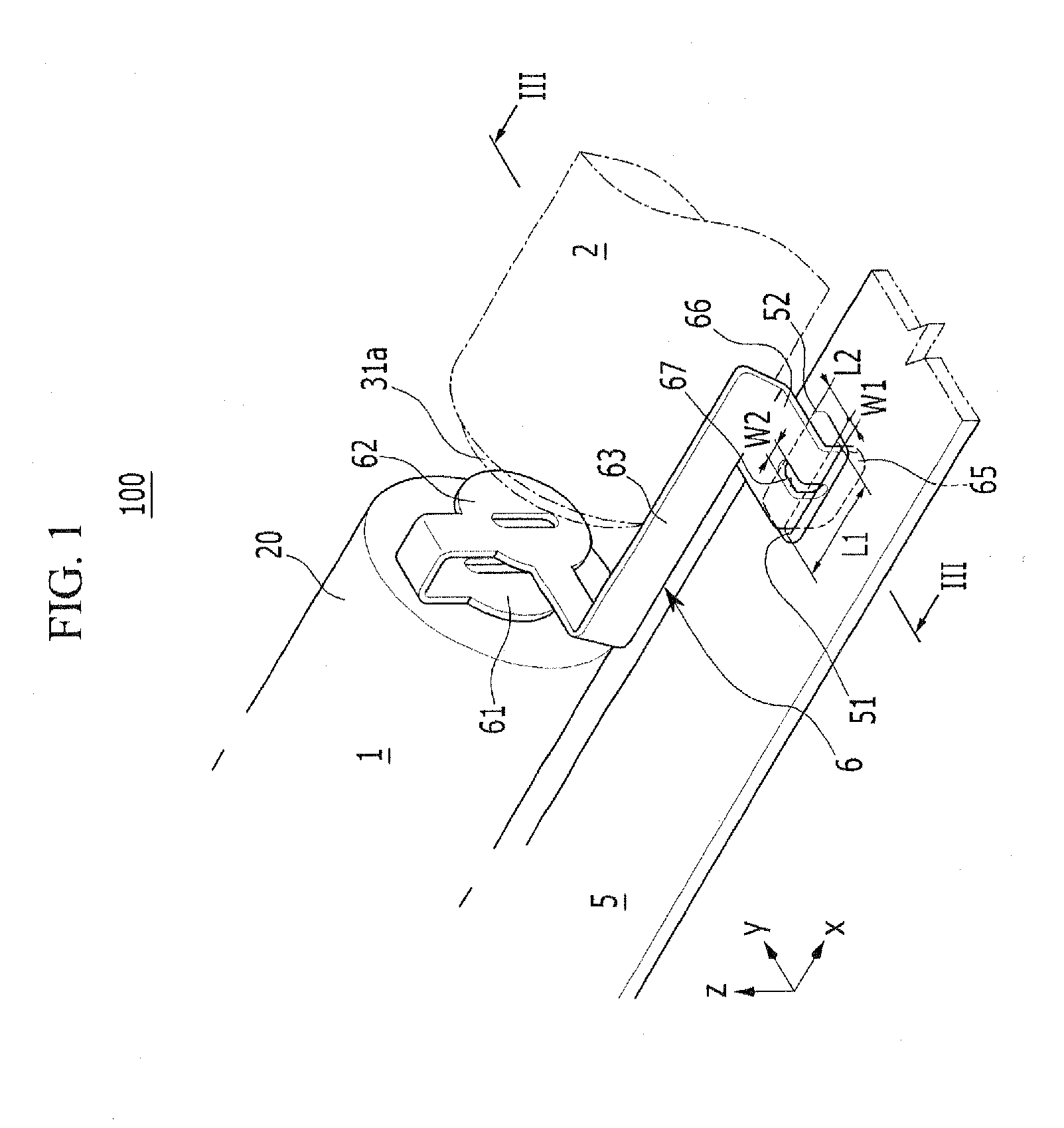

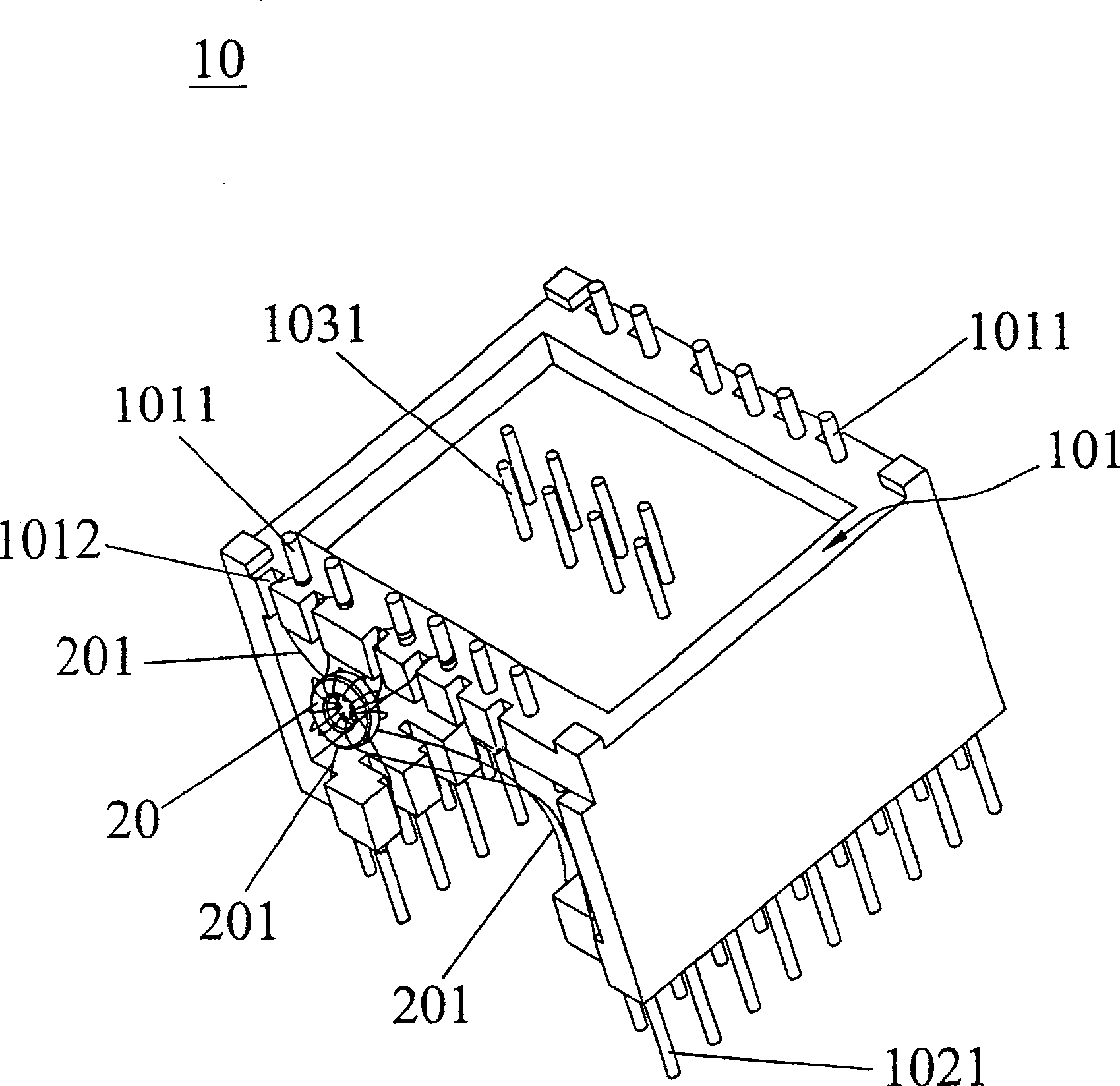

Holding mechanism for electrical connectors and pcbs

InactiveUS20110107592A1Reduce welding difficultyImprove solder qualityCoupling device connectionsLine/current collector detailsEngineeringElectrical connector

Owner:CHENG UEI PRECISION IND CO LTD

Battery pack

InactiveCN102222785AReduce manpower requirementsEasy to importCell component detailsNon destructiveElectricity

The present invention provides a battery pack which comprises: a cover; a first battery assembly box set inside the space defined by the cover; a second battery assembly box; a first conductor, a second conductor, a third conductor, a conductive layout and a circuit substrate. The conductor and the conductive layout are electrically connected between the battery unit of the battery assembly box and the circuit substrate. The first battery assembly box and the second battery assembly box are disassembled from the housing space in a non-destructive way. As a result, the battery pack can be assembled and / or disassembled in a modular way. Consequently, the manpower needed for executing welding process can be reduced, the quality issues caused by artificial soldering operation can be decreased, and the production process can be simplified and carried out by introducing automatic assembly line.

Owner:SIMPLO TECH COMPANY

Audio element welding device

PendingCN109290653ASolve the problem of difficult control of consistencyReduce scrapSoldering ironMetal working apparatusPower flowEngineering

The invention discloses an audio element welding device. The device comprises a pulse power supply, a three-dimensional operation mechanism, a welding head connecting device, a thermocouple and a hot-pressing welding head, wherein the welding head connecting device is fixed on the three-dimensional operation mechanism, and the hot-pressing welding head is fixed at the bottom of the welding head connecting device; the pulse power supply is electrically connected with the welding head connecting device, and the pulse power supply transmits a current to the hot-pressing welding head so as to heatthe hot-pressing welding head; the thermocouple is fixed on the hot-pressing welding head, and is used for measuring the temperature of the hot-pressing welding head, and feeding back a temperature measurement result to the pulse power supply, and the pulse power supply controls magnitude of the current according to the temperature measurement result fed back by the thermocouple so as to controlthe temperature of the hot-pressing welding head; and the three-dimensional operation mechanism is used for driving the welding head connecting device to move so as to adjust the welding position of the hot-pressing welding head, and an inner groove is formed in the hot-pressing welding head. According to the device, the problems that workers are tired, the efficiency is low, requirements on operation proficiency are high, hands are easy to scald, and consistency of the welding spots is difficult to control in the case of manual tin soldering with a soldering iron can be solved.

Owner:JIANGXI LIANCHUANG HONGSHENG ELECTRONICS

Method for Reliably Soldering Microwave Dielectric Ceramics with Metal

InactiveUS20130062398A1Improve environmental reliabilitySave soldering costSoldering apparatusGas flame welding apparatusElectricityPorosity

A method for reliably soldering microwave dielectric ceramics with metal adopting the way of vapor soldering, a strict process of heating up, then soldering under heat preservation and finally cooling is provided. Therefore, thermal stress generated during the soldering of dielectric ceramics and metal material is reduced, reliability of a solder structure is ensured, porosity of the soldering side is effectively lowered, soldering quality is improved, soldering cost is reduced, and the demand of large-scale production can be met.

Owner:CHENGDU TIGER MICROWAVE TECH

Filter and its coil arrangement frame

InactiveCN100538933CReduce defective rateLittle job difficultyMultiple-port networksTransformers/inductances coils/windings/connectionsEngineeringElectronic component

Owner:DELTA ELECTRONICS INC

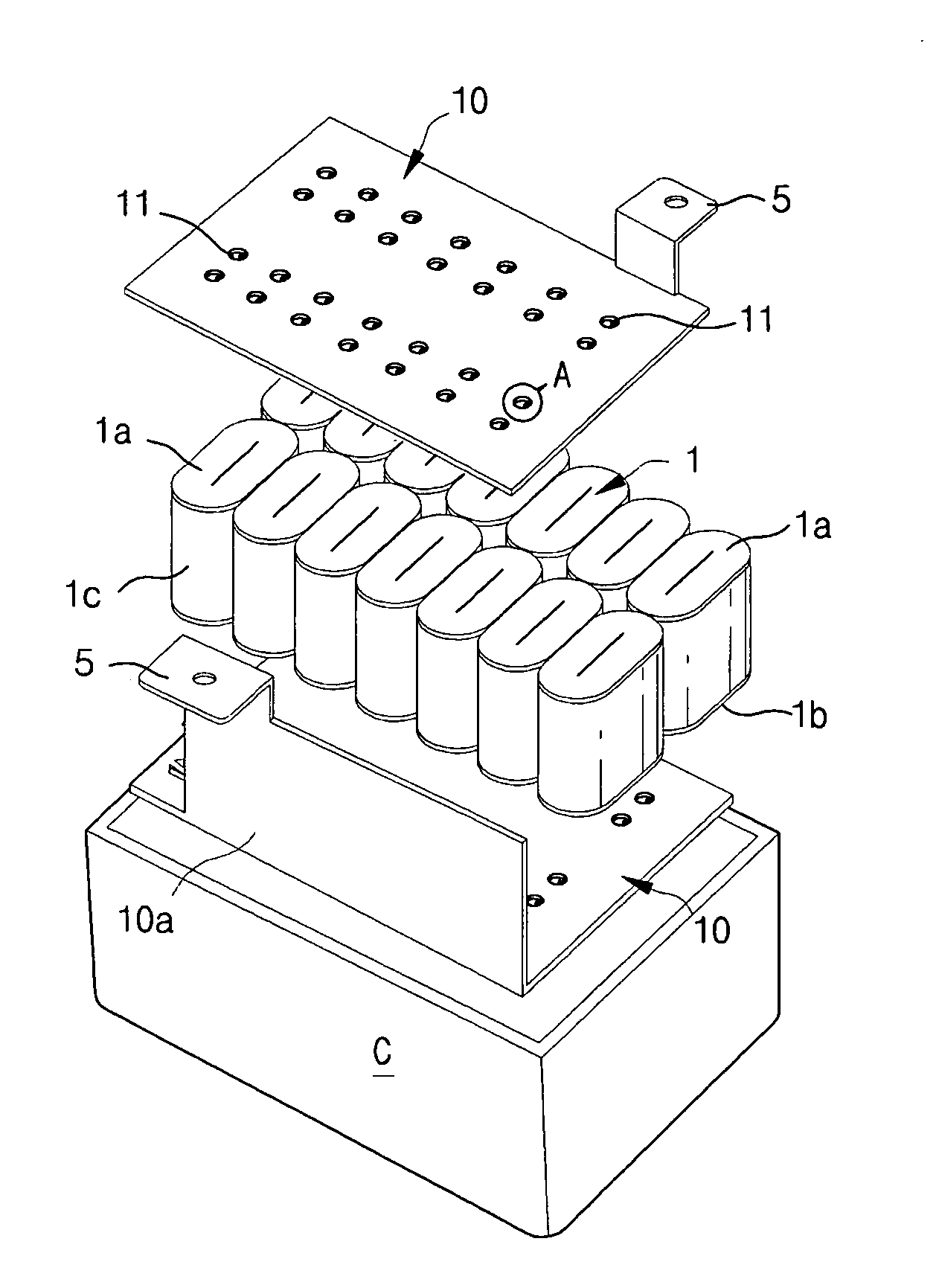

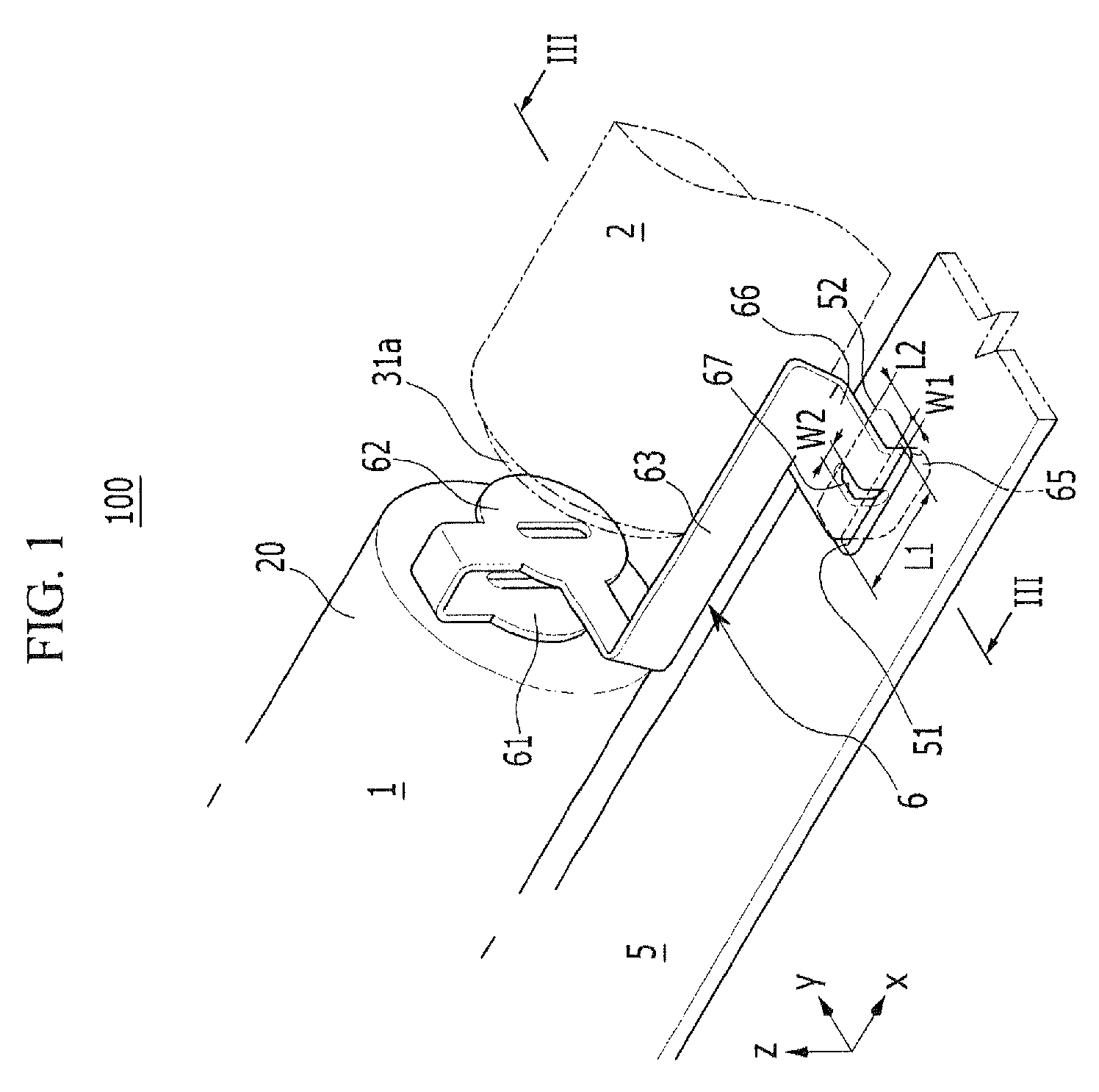

Rechargeable battery pack

InactiveUS9077026B2Strong and more resilient electrical connectionAccurate connectionCells structural combinationCell component detailsElectricityElectrical battery

A rechargeable battery pack that accurately fixes connection locations of a connection tab and a first pad and strengthens the impact resistance of a connection unit. A rechargeable battery pack according to an exemplary embodiment may include a first unit cell and a second unit cell formed by a rechargeable battery; a connection tab electrically connecting the first unit cell and the second unit cell to each other; and a protection circuit module (PCM) where an aperture in the protection circuit module is formed in a first pad connected to the connection tab, wherein the connection tab includes a first portion inserted into the aperture in the protection circuit module, and a second portion bent and connected to the first portion and overlapped with the first pad and including an aperture in the second portion of the connection tab.

Owner:SAMSUNG SDI CO LTD

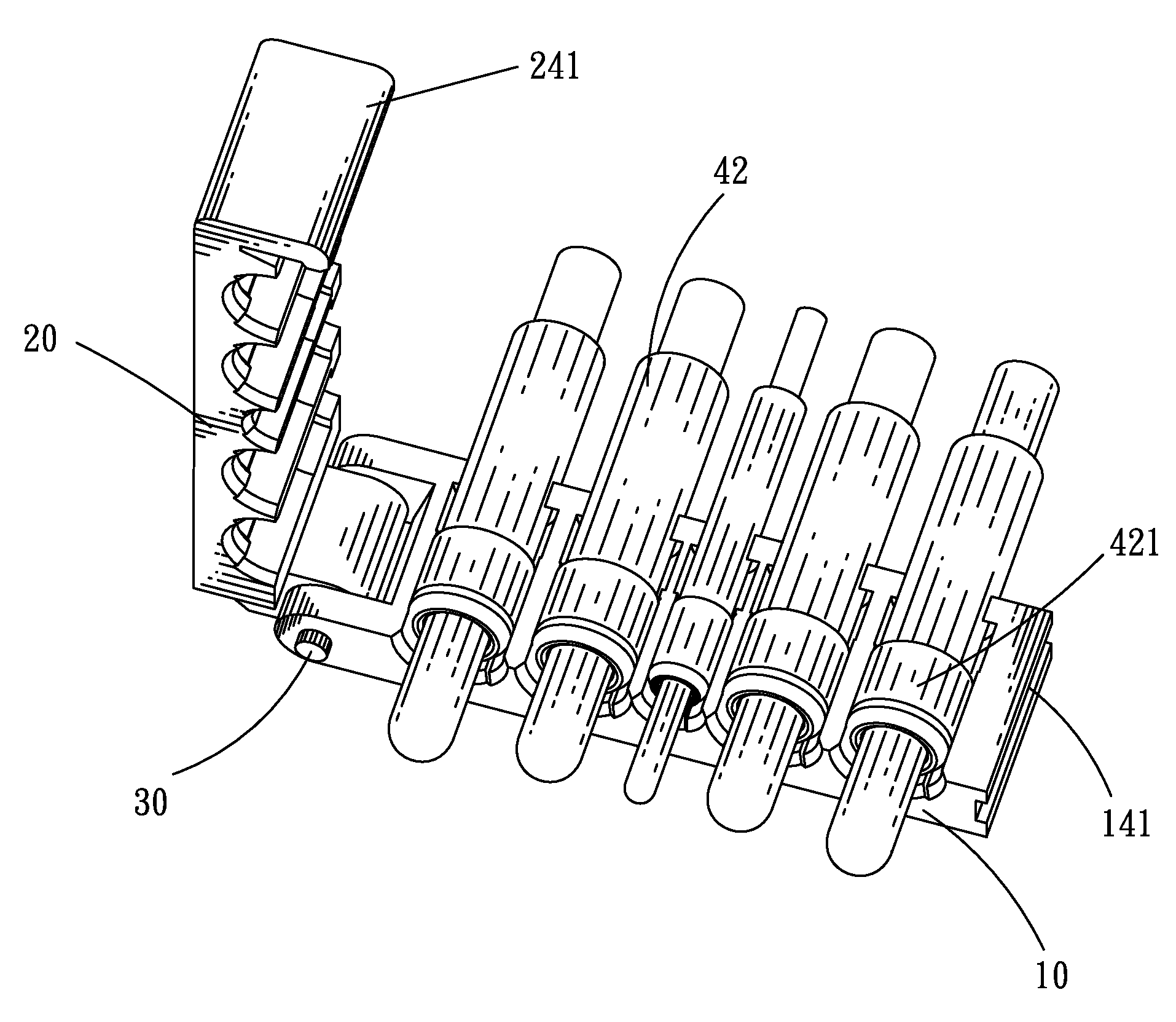

Jig For Probe Connector

InactiveUS20110138612A1Promote progressImprove solder qualityCoupling device detailsWelding/cutting auxillary devicesFront and back endsBiomedical engineering

A jig for clutching a plurality of probe assemblies each of which has a connecting portion and a soldering portion has a base body and a covering body. The base body has a plurality of first receiving grooves each penetrating a front end and a rear end thereof. The covering body is formed with a plurality of second receiving grooves corresponding to the first receiving grooves. The covering body is openably fixed on the base body, the first receiving grooves and the second receiving grooves are matched to form a plurality of passageways. A front end of each of the passageways has a portion protruded inwards to form a resisting rib. The connecting portions of the probe assemblies are received in the passageways and abut against the resisting ribs, with tip ends of the soldering potions exposing outside the passageways from rear ends of the passageways.

Owner:CHENG UEI PRECISION IND CO LTD

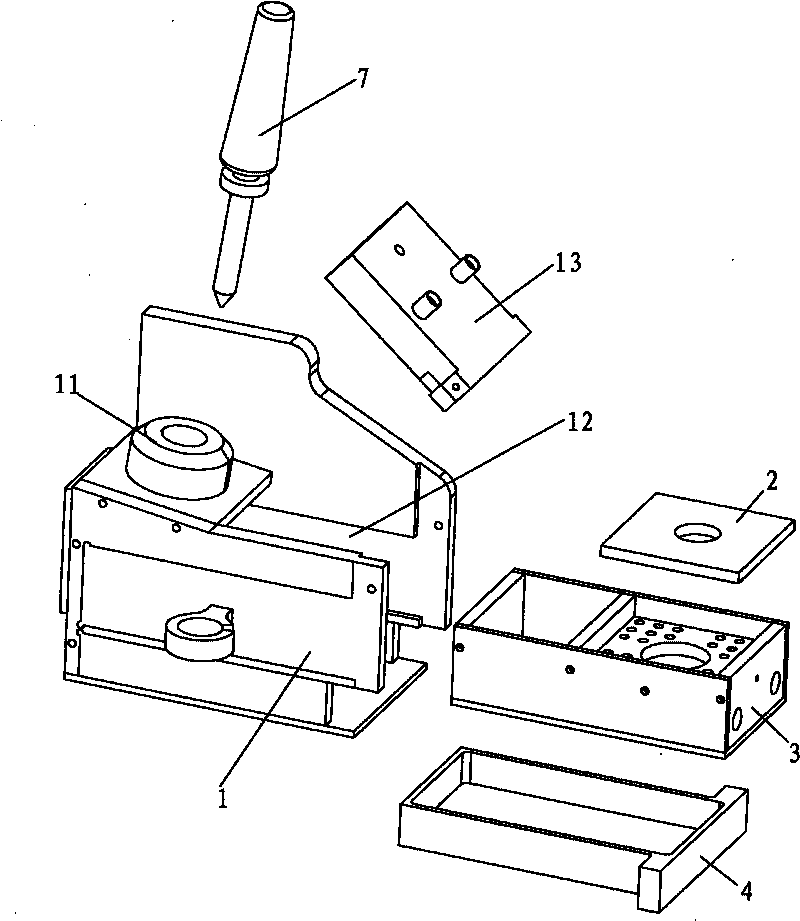

Soldering machine of automatic insertion robot for car lamp LED (Light Emitting Diode) substrate, and working method thereof

InactiveCN103949747ACompact structureSave spaceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLight-emitting diode

The invention relates to a soldering machine of an automatic insertion robot for a car lamp LED (Light Emitting Diode) substrate, and belongs to processing machinery for soldering after the robot carries out automatic insertion. The front end of the six-axis robot of the soldering machine is provided with a gripper mechanism and a welding head soldering unit, and a vibration disc mechanism is arranged at the right side of a rack; a vibration disc is connected onto an insert feeding mechanism on a rack top plate through a straight-line feed channel, and a working bottom plate is fixedly arranged on the upper surface of the rack top plate; soldering tooling is arranged on the upper surface of the working bottom plate, and the welding head soldering unit is arranged on the six-axis robot through a welding head mounting rack; a threading disc is arranged on the welding head soldering unit, and a touch screen is arranged at the upper right corner of the protective front of a working area; a three-color lamp is arranged at the protective top end of the working area, and a miniature limit switch is arranged in the front of the working area. The soldering machine is in an acting range of the six-axis robot, the overall structure is compact, and the space is saved. The six-axis robot has an accurate insertion function, the soldering quality is high, the yield is stable, the production efficiency is high, the degree of mechanization is high, the cost is low, and the labor intensity is reduced.

Owner:TODAY MACHINERY EQUIP DALIAN

Multifunction drawer type soldering iron wiping stand

ActiveCN101722345ASave waterImprove solder qualitySoldering auxillary devicesWater contentWork status

The invention relates to the technical field of soldering iron stands, in particular to a multifunction drawer type soldering iron wiping stand. The stand comprises a frame and an absorbent foam. A soldering iron placing hole is arranged on the upper end face of the frame. A solder splash box and a water containing box, which can be drawn out along the front end of the frame, are glidingly arranged in the frame from top to bottom and are of drawer type structure in the frame. The absorbent foam is arranged in the solder splash box. The soldering iron is inserted from the soldering iron placing hole under the non-working state. The soldering iron tips are arranged in the solder splash box. After the soldering iron is wiped on the absorbent foam under the working state, the solder splash falls into the solder splash box and the redundant left water on the absorbent foam flows into the water containing box. The stand is of composite structure, can recycle the left water, save the water resources, standardize the water content in the absorbent foam, improve the soldering tin quality and be widely applied to tin soldering sites, has multiple functions and is convenient to use, install and clean, easy to maintain and convenient for production line operation.

Owner:DELTA ELECTRONICS DONGGUAN +1

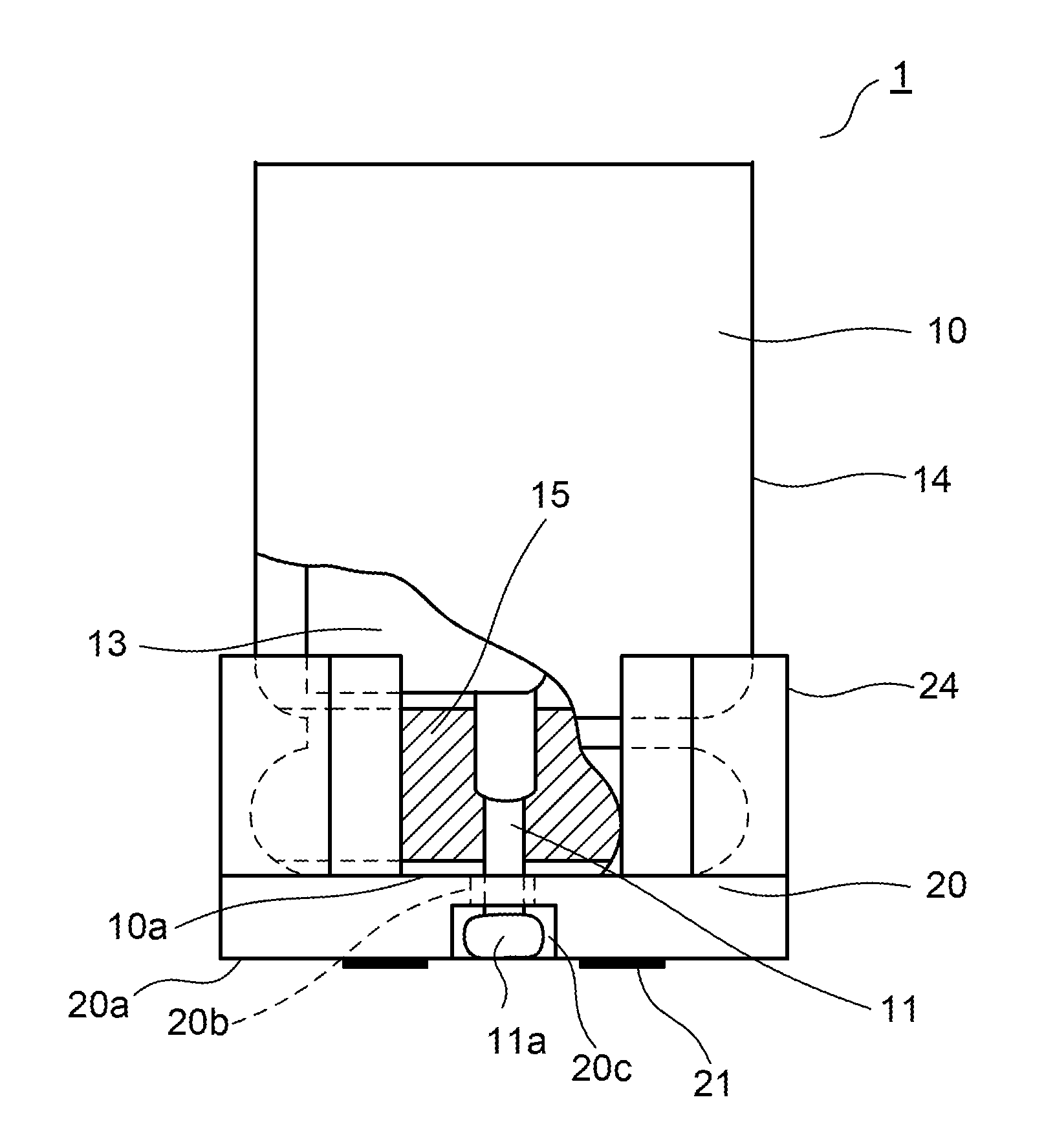

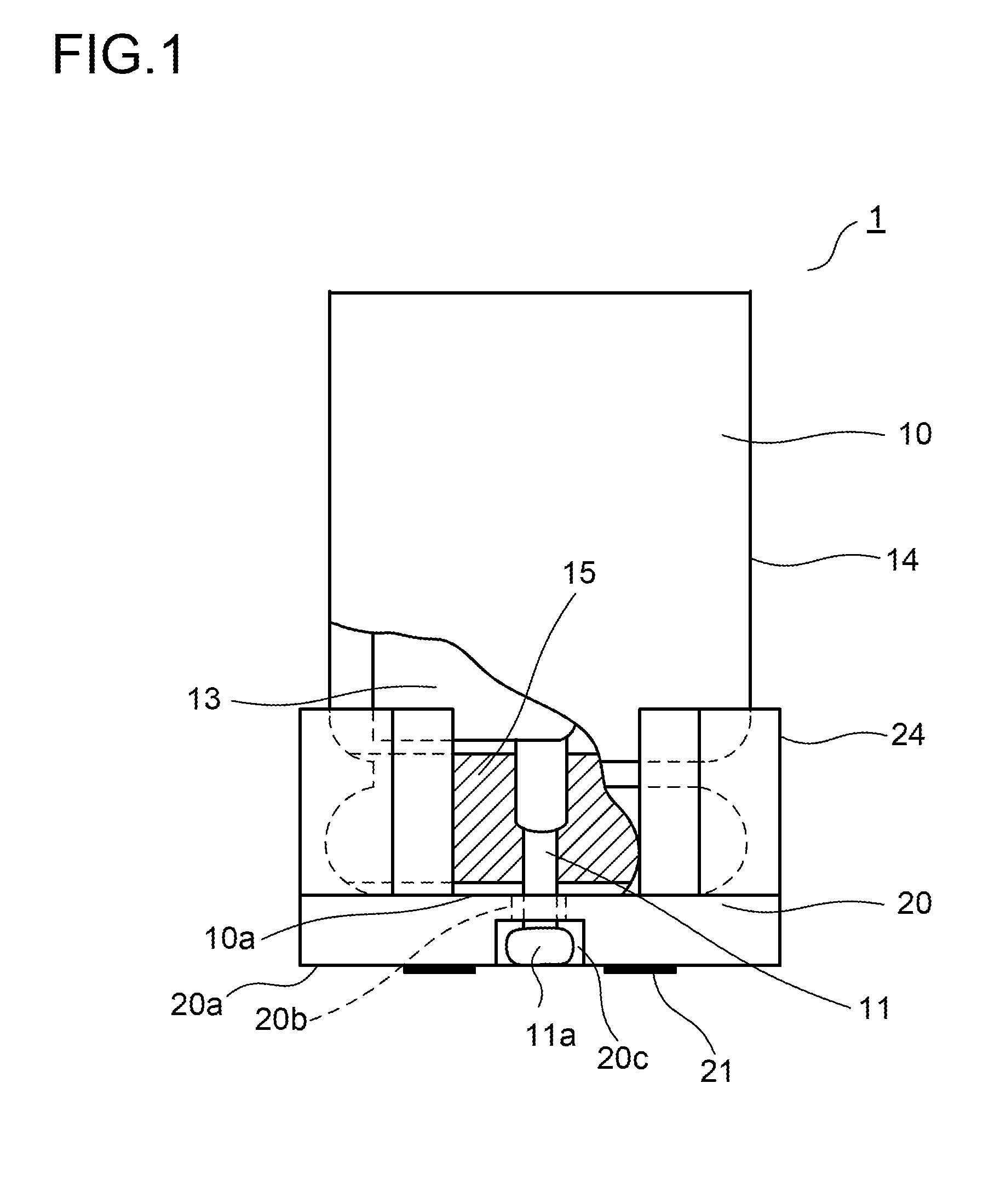

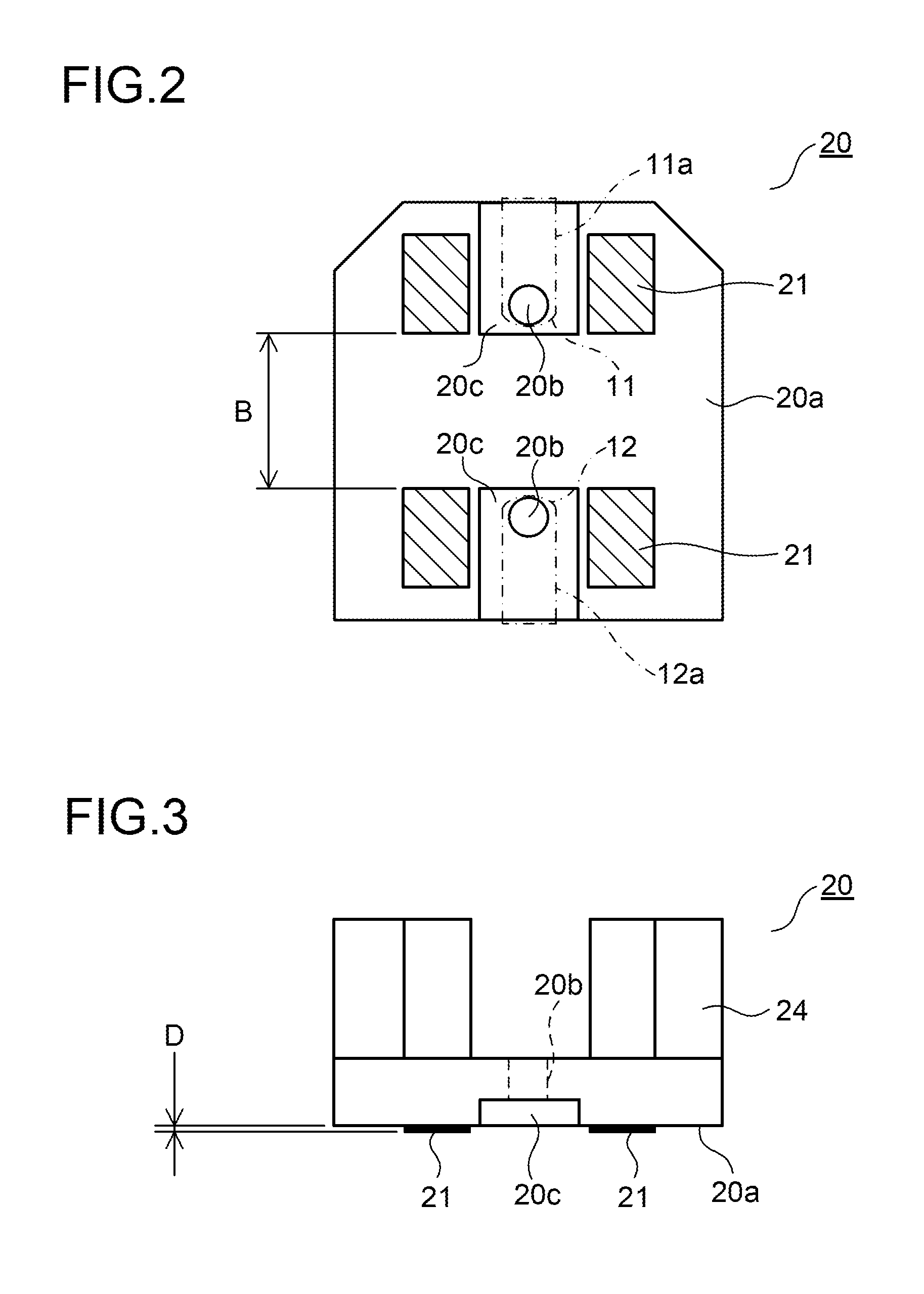

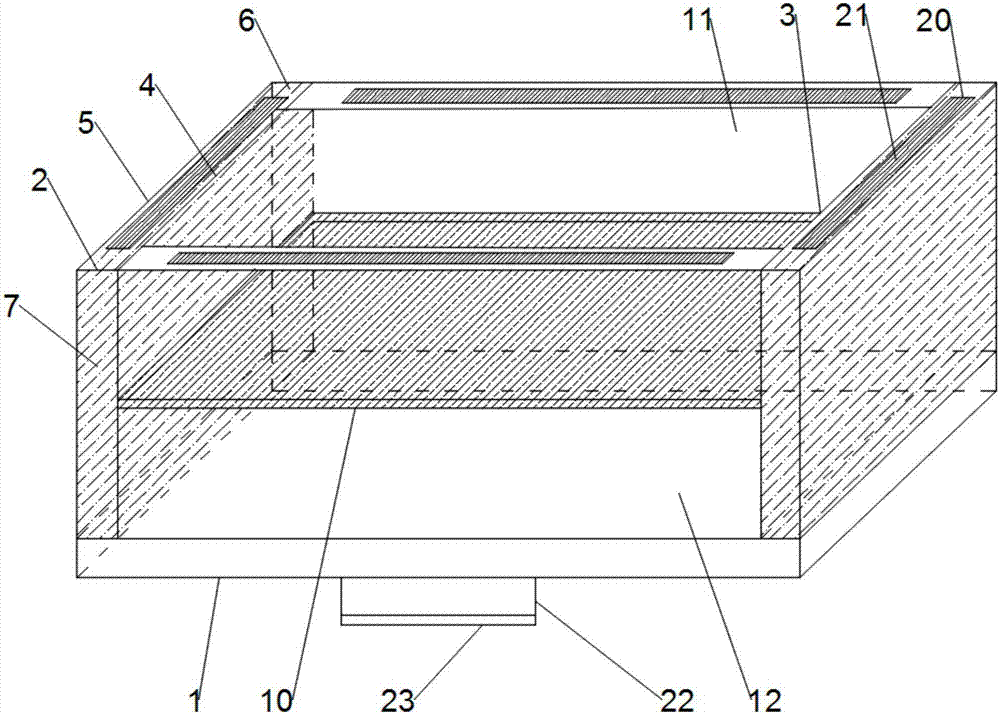

Chip capacitor and method of manufacturing same

InactiveUS20120162860A1Improve chip resistanceLow costPrinted circuit assemblingPrinted circuit aspectsLaser lightCapacitor

A chip capacitor (1) includes: a capacitor body (10) from which an anode lead wire (11) and a cathode lead wire (12) are extended out; and a mount portion (20) which is fitted to the capacitor body (10), in which terminal portions (11a and 12a) of the lead wires (11 and 12) are arranged in a board mounting surface (20a) and which is placed on a circuit board. In the chip capacitor (1) in which the terminal portions (11a and 12a) are soldered to the circuit board, the mount portion (20) is formed of a resin containing an organic metal complex compound, and an assistant terminal portion (21) formed by plating a region to which a metal is exposed by applying laser light onto the board mounting surface (20a) is provided.

Owner:SAN DENSHI INDS

Tin furnace structure for manufacture of power modules

InactiveCN107378169AImprove insulation effectSoldering effect is goodMetal working apparatusSoldering auxillary devicesActivated carbonInsulation layer

The invention discloses a tin furnace structure for manufacture of power modules; the tin furnace structure comprises a furnace body; the furnace body comprises a housing and an inner chamber; the housing comprises an inner layer and an outer layer; a hollow interlayer is arranged between the inner layer and the outer layer; a heat insulation layer is arranged in the hollow interlayer; a partition is arranged in the inner cavity and divides the inner cavity into a soldering tin chamber and a tin residue recovery chamber, the partition is composed of a plurality of support rods, a protective cover is arranged at the top end of the outer layer, the protective cover is composed of four trapezoidal plates identical in shape and size, a suction duct is arranged at the top ends of the four trapezoidal plates, one end of the suction duct is connected with the top ends of the trapezoidal plates, the other end of the suction duct is connected with a suction fan, and the part of the inside of the suction duct close to the top ends of the trapezoidal plates is provided with an activated carbon adsorbing layer and a strainer layer. The tin furnace structure can provide tin soldering for the manufacture of power modules, allows issues provided by the background art to be effectively solved, and is worthy of popularization.

Owner:阜阳扬宇充电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com