Soldering machine of automatic insertion robot for car lamp LED (Light Emitting Diode) substrate, and working method thereof

A LED substrate and automatic plug-in technology, which is applied to vehicle parts, tin feeding devices, manufacturing tools, etc., can solve problems such as unstable welding quality, low production efficiency, and high scrap rate, and achieve high solder quality, high production efficiency, and high output. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

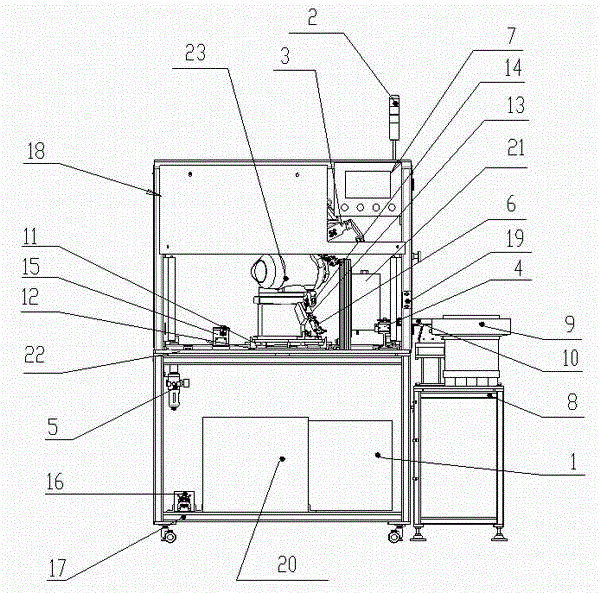

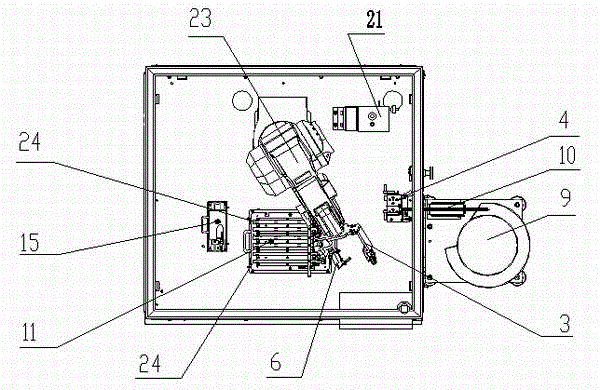

[0012] figure 1 , 2 It shows a structural diagram of a robot soldering machine for automatic insertion of LED substrates for car lamps. In the figure, the auto lamp LED substrate automatic plug-in robot soldering machine includes a frame structure composed of a frame 17, a frame top plate 22 and a work area protection 18, and a six-axis robot 23. The six-axis robot 23 is installed on the frame top plate 22. The frame 17 is provided with a robot controller 20 and an electrical control box 1 . The front end of the six-axis robot 23 is provided with a gripper mechanism 3 and a soldering iron tip soldering unit 6, which are equivalent to the left and right hands of a human being, with one hand grabbing the plug-in and the other holding the soldering iron tip for soldering. The right side of frame 17 is provided with vibrating plate mechanism, and vibrating plate mechanism is arranged on vibrating plate 9 on the vibrating plate support 8, and vibrating plate 9 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com