Battery pack

A battery module and battery assembly technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of consuming tin resources and human resources, unusable batteries, increasing environmental pollution, etc., to improve solder quality and operation The effect of simplifying the operation and reducing the manpower requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

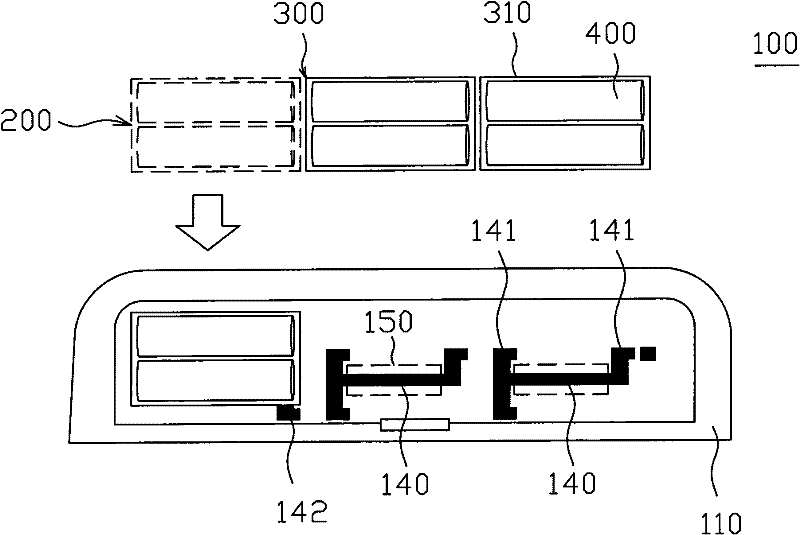

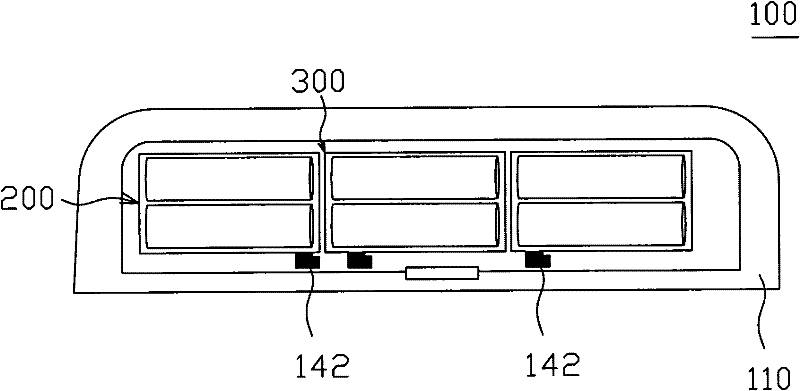

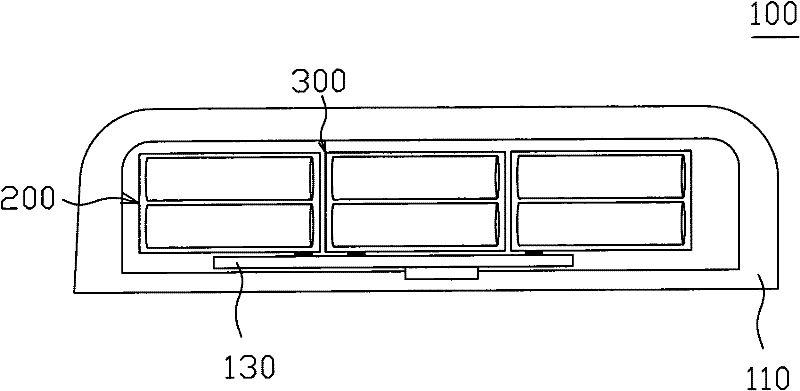

[0058] Figure 1A ~ Figure 1C A schematic diagram showing an assembly process of a battery module according to an embodiment of the present invention. Such as Figure 1A ~ Figure 1C As shown, the battery module 100 according to an embodiment of the present invention adopts a modular design, mainly by arranging a plurality of battery units 400 in a battery assembly box (Resin Box) 310 to form a battery pack 300 as the minimum unit of this modularization , and then respectively put a plurality of battery packs 300 into the lower cover 110 of the battery module 100 in sequence, and these battery packs 300 are connected in series and / or in parallel to form the battery device 200 (that is, the battery device 200 includes multiple series and / or or parallel battery pack 300 ), and then put the circuit substrate 130 into the lower cover 110 of the battery module 100 , and couple the circuit substrate 130 to the battery device 200 to complete the assembly of the battery module 100 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com