Pre-tensioned track board assembly-unit production tooling device and method

A technology for producing tooling and production methods, applied in the field of rail transit, can solve the problems of difficulty in guaranteeing the accuracy and flatness of the track slab, low production efficiency, large demand for human resources, etc., so as to reduce the demand for human resources and production costs. , The effect of improving production efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

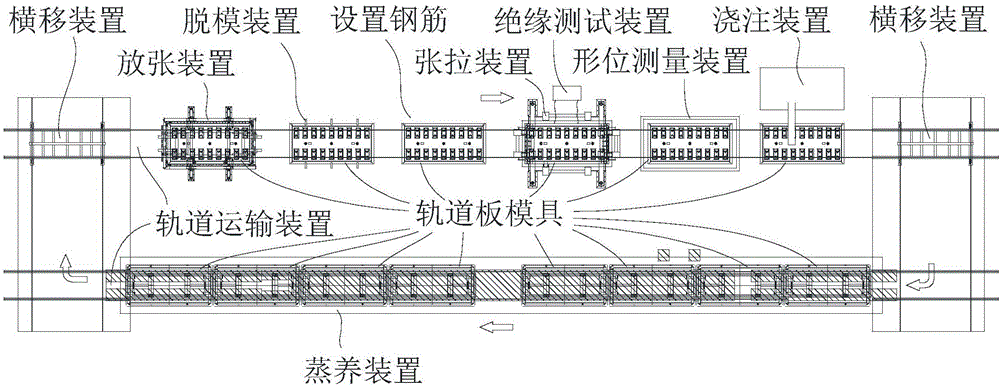

[0093] Such as Figure 1-10Shown, the pre-tensioned track slab assembly line method production tooling equipment of the present invention comprises:

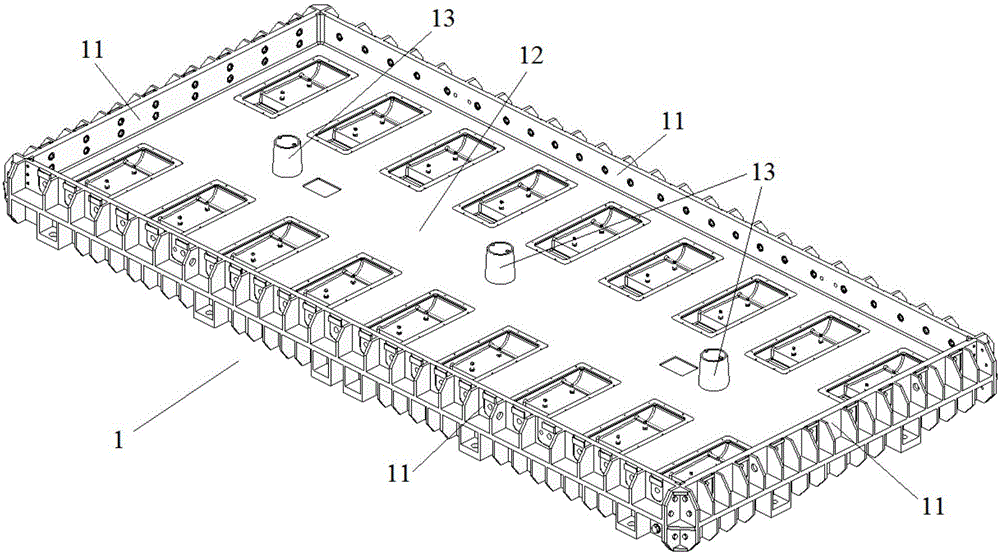

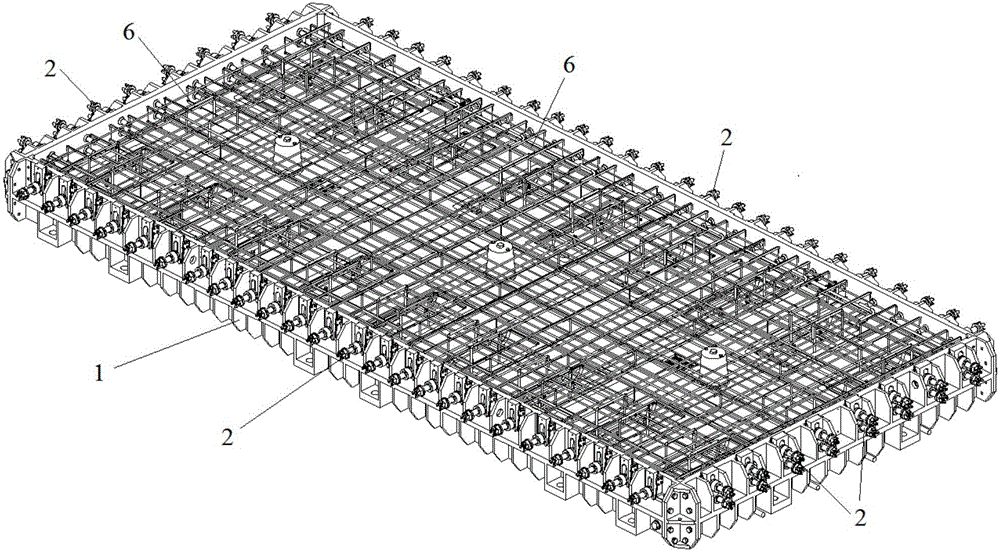

[0094] The track slab mold 1 includes a bottom mold 12 and side molds 11 connected around the bottom mold 12, used to set a ballastless track slab structure including a reinforcement cage and a prestressed steel bar 6, and cast the mold in it. track plate;

[0095] The tension rod 2 is arranged at the four side molds 11 of the track slab mold 1, and is used for screwing the prestressed steel bars 6 inside the track slab mold 1, and extends to the outside through the side molds. , adapting to the stretching and releasing of the prestressed steel bars 6;

[0096] The tensioning device 3 is adapted to the tension rod 2 and is used for prestressing the prestressed steel bar 6;

[0097] pouring device, for pouring concrete into the track slab mold 1;

[0098] A vibrating device for vibrating the concrete in the poured track slab ...

Embodiment 2

[0113] Such as Figure 1-11 As shown, the production method of the pre-tensioned track slab assembly line method of the present invention uses the pre-tensioned track slab assembly line method to produce tooling equipment as described in Example 1, and the method comprises the following steps:

[0114] A. Clean up the track slab mold 1 on the track transport device 1, and place embedded parts, reinforcement cages and some prestressed steel bars 6 therein;

[0115] B, all described prestressed reinforcing bars 6 are threaded with corresponding tension rods 2;

[0116] C. The track slab mold 1 is adapted to the tensioning device 3 located on the rail transport device 1, and the tensioning device 3 stretches the prestressed steel bars 6 in place, and anchors the tensioning rod 2;

[0117] D, the insulation testing device that is positioned on described rail transportation device 1 carries out insulation test to described reinforcement cage and all described prestressed steel bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com