Tin furnace structure for manufacture of power modules

A power module and tin furnace technology, which is applied in the direction of manufacturing tools, auxiliary devices, metal processing, etc., can solve the problems of poor heat insulation effect, human body injury, environmental hazards, etc., achieve good heat preservation effect, avoid pollution, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

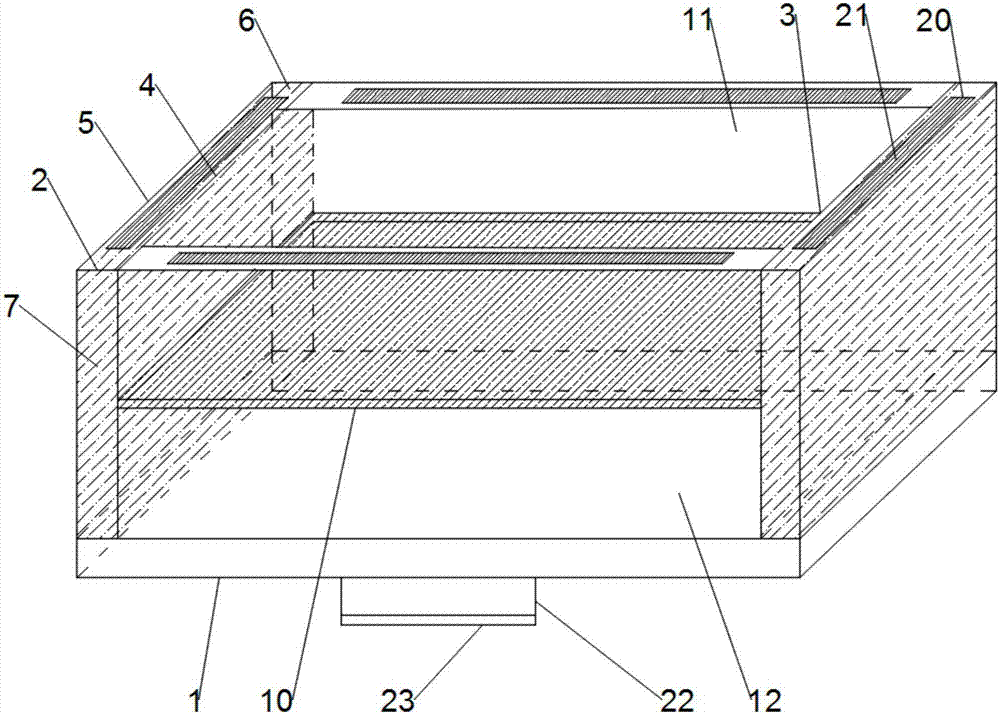

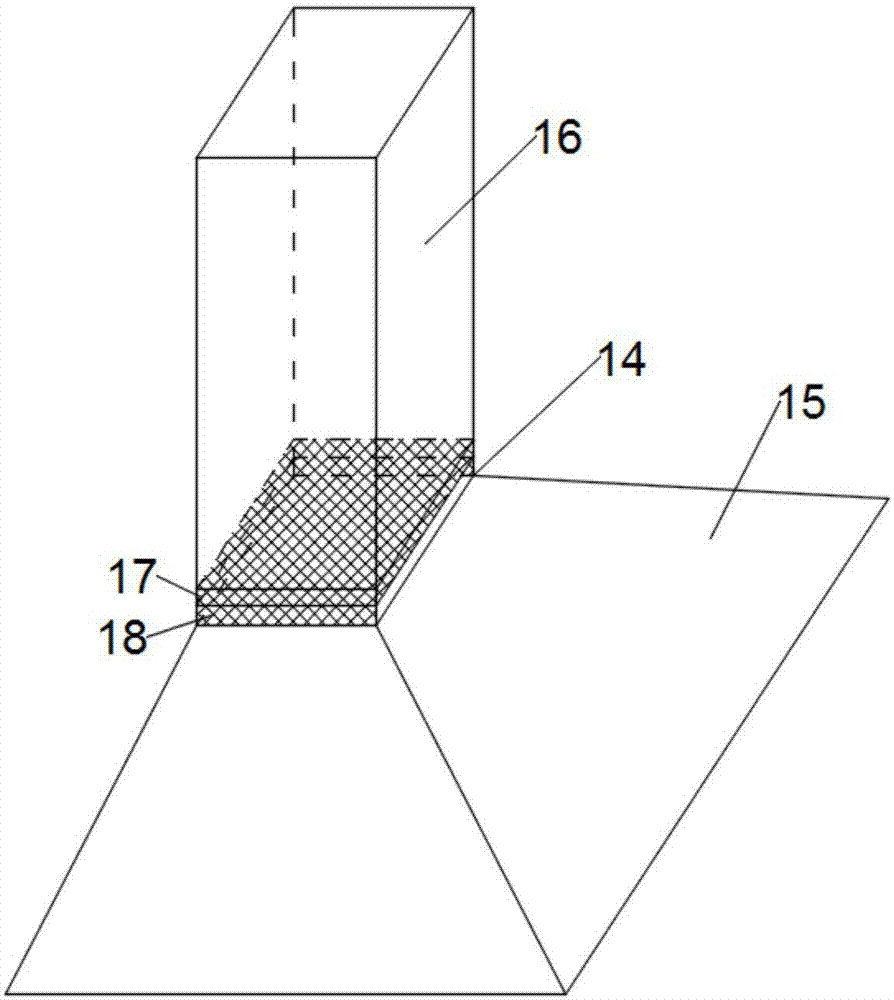

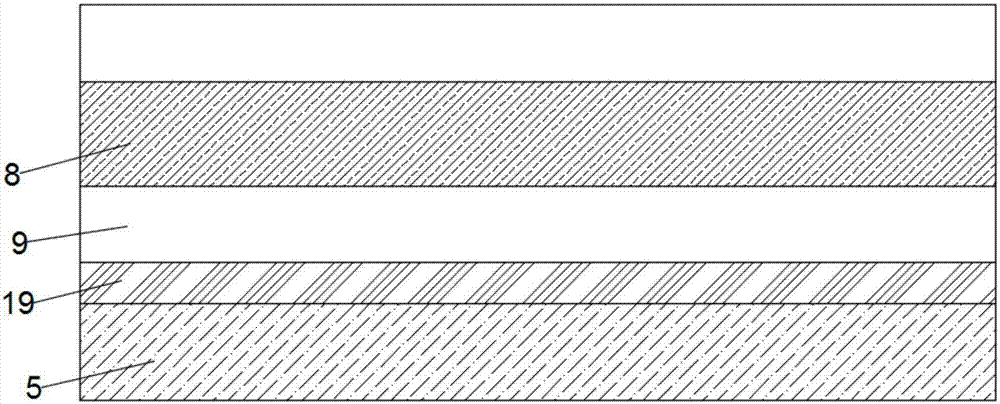

[0024] like Figure 1 to Figure 4 As shown, the present invention provides a tin furnace structure for the manufacture of power modules, including a cuboid furnace body 1, the furnace body 1 includes a shell 2 and an inner cavity 3, and the shell 2 includes an inner layer body 4 and an outer layer body 5, a hollow interlayer 6 is arranged between the inner layer body 4 and the outer layer body 5, and a heat insulation layer 7 is arranged inside the hollow interlayer 6, and the heat insulation layer 7 includes a heat-resistant foamed polymer Ethylene layer 8 and polyurethane fiber non-woven fabric 9, the polyurethane fiber non-woven fabric 9 is arranged on both sides of the heat-resistant foamed polyethylene layer 8, the inner cavity 3 is provided with a horizontal partition 10, the The partition 10 divides the inner cavity 3 into a solder chamber 11 and a tin slag recovery chamber 12. The solder chamber 11 is used for welding the power module to be soldered, and the tin slag r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com