Linear automatic tin soldering device

A linear, automatic welding technology, used in auxiliary devices, welding equipment, manufacturing tools, etc., can solve the problems that the processing process cannot meet the requirements of mass production, prone to quality problems, and reduced efficiency, so as to reduce manual participation in the process and save money. Manpower, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

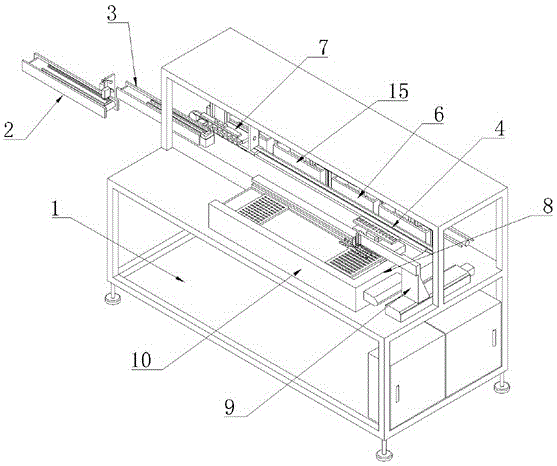

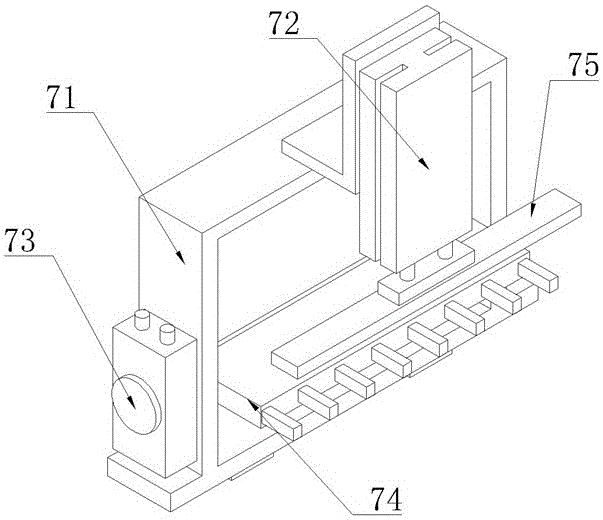

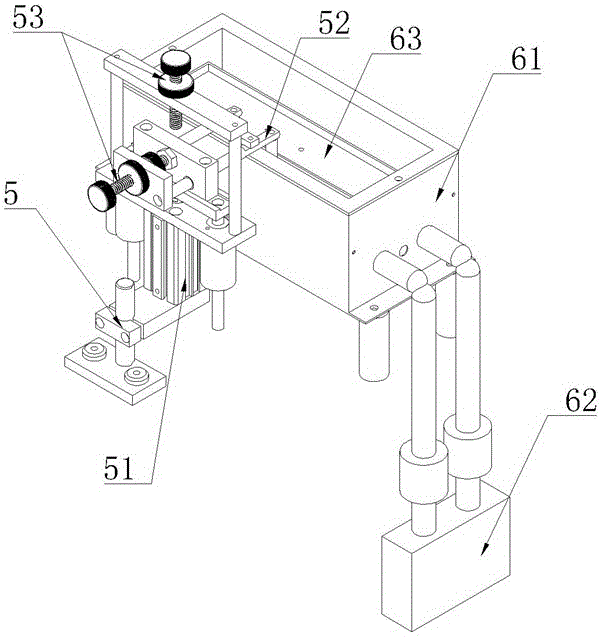

[0023] Such as figure 1 As shown, the present invention includes a frame 1 and a transmission mechanism 2 fixedly arranged on the frame 1, and a feeding mechanism 3 and a linear positioning mechanism 4 are also arranged on the transmission mechanism 2, and on the frame 1 There are also a first soldering station, a second soldering station and a discharge mechanism 8 in sequence, and both the first soldering station and the second soldering station include an auxiliary device fixed on one side of the linear positioning mechanism 4. The flux mechanism 6 and the tin furnace 15 are also provided with high-temperature glue protection on the tin furnace 15, and the solder mechanism 7 is also arranged on the linear positioning mechanism 4, and drives the solder mechanism 7 to pass through the first The soldering station and the second soldering station complete the double soldering process. In the present invention, a solder scraper and a transverse sliding rail matched with the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com