Patents

Literature

133results about How to "Reduce artificial ginseng" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

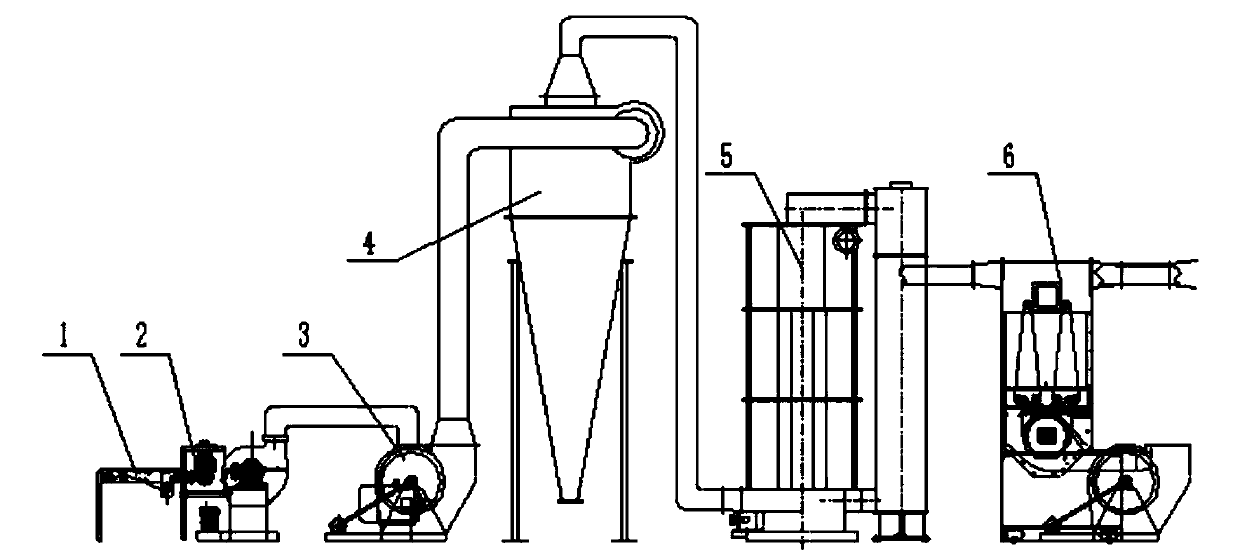

Bulk production line for reconstituted tobacco thin sheets by dry papermaking method

ActiveCN103431514AIncrease profitHigh degree of integration and automationTobacco preparationFiberProduction line

The invention discloses a bulk production line for reconstituted tobacco thin sheets by a dry papermaking method. The whole production line mainly comprises a raw material treatment part, a tobacco forming part and a thin sheet forming part, wherein material transportation is mainly executed through a carrying roller and a mesh belt, and is assisted through air flow of a fan; a conveying component of the whole production line is provided with a cleaning device, a tensioning device and a deviation correction device. According to the production line, wood pulp or tobaccos are smashed into fibers, then reconstituted tobaccos are produced through dry forming; finished products, namely the tobacco thin sheets, are produced through reconstituted tobacco treatment; the production requirements on the reconstituted tobacco thin sheet low sewage emission, low energy consumption and high quality are met.

Owner:SHANXI LIGONG MECHANICAL & ELECTRICAL TECH

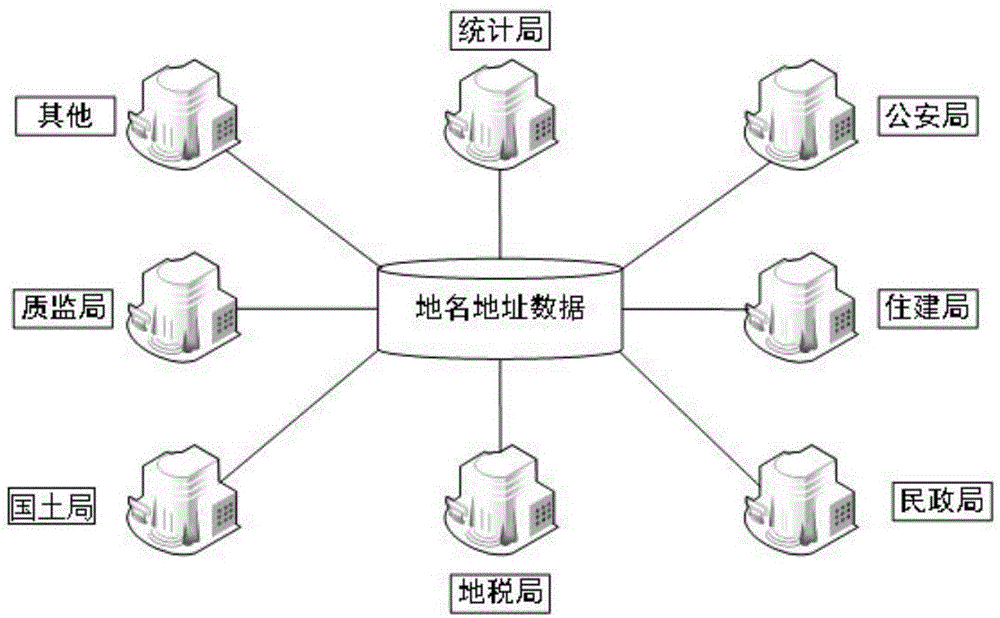

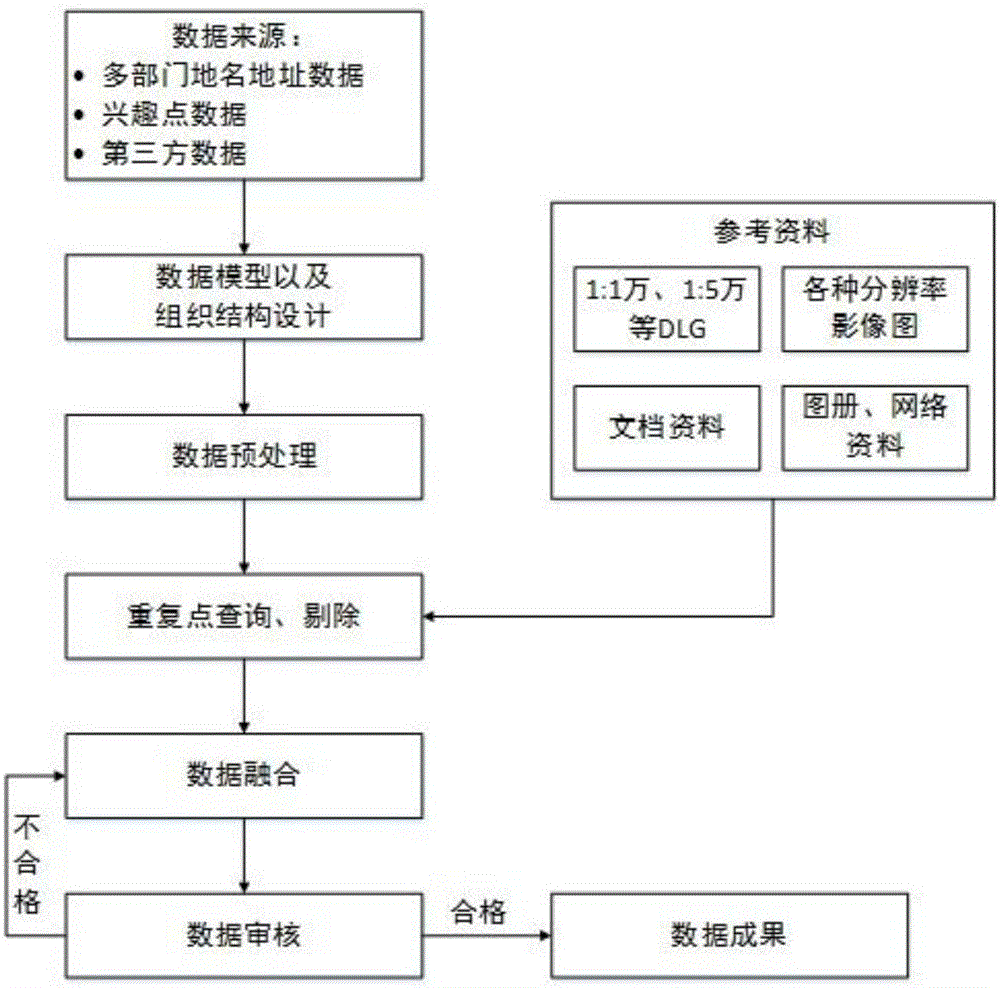

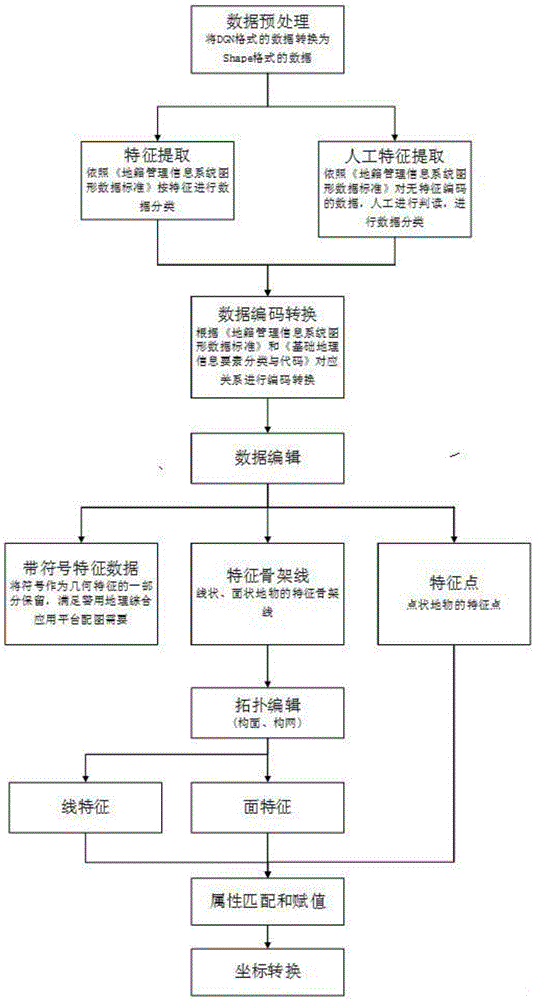

Multisource data-based place name and address data integration method and system

InactiveCN107526786ASolve a wide variety of problems in a variety of formatsSave integration timeData processing applicationsGeographical information databasesData queryData pre-processing

The invention relates to a multisource data-based place name and address data integration system. The system comprises the following steps of: (1) data collection, data model selection and organization structure design: referencing and integrating place names, addresses, interest point data structures, attribute fields and spaces from different sources into a set of data, selecting a data model and designing an organization structure; (2) data preprocessing: standardizing formats of the multisource place name and address data into a uniform processable format; (3) repeated data query and removal: carrying out repeated point query on the multisource place name and address data; (4) data fusion: matching and integrating the multisource data; and (5) data audition: carrying out batched audition on the fused data by utilizing GIS software by adoption of an automatic audition and manual audition combined manner, if the data is audited to be qualified, storing the data to a database and constructing a data result, and if the data is audited to be unqualified, returning to the data fusion step to carry out data fusion again until the data is audited to be qualified.

Owner:SPEED SPACE TIME INFORMATION TECH CO LTD

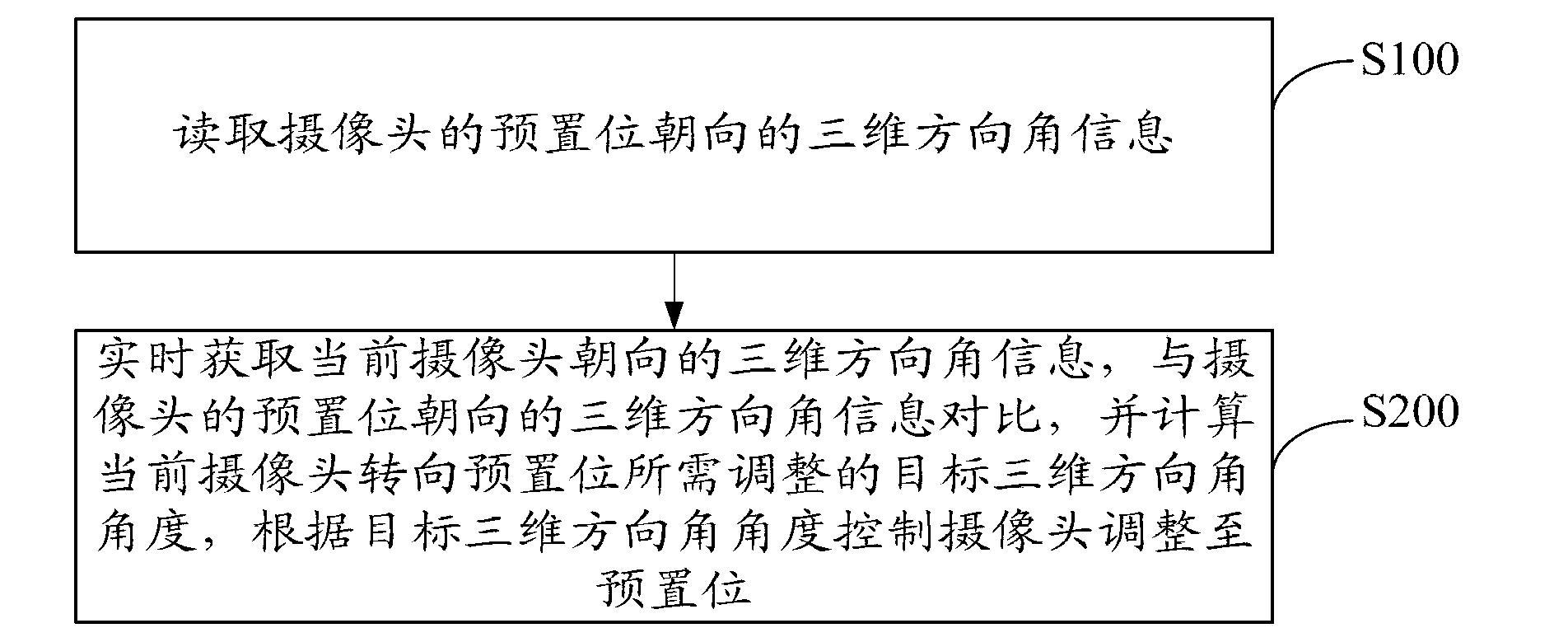

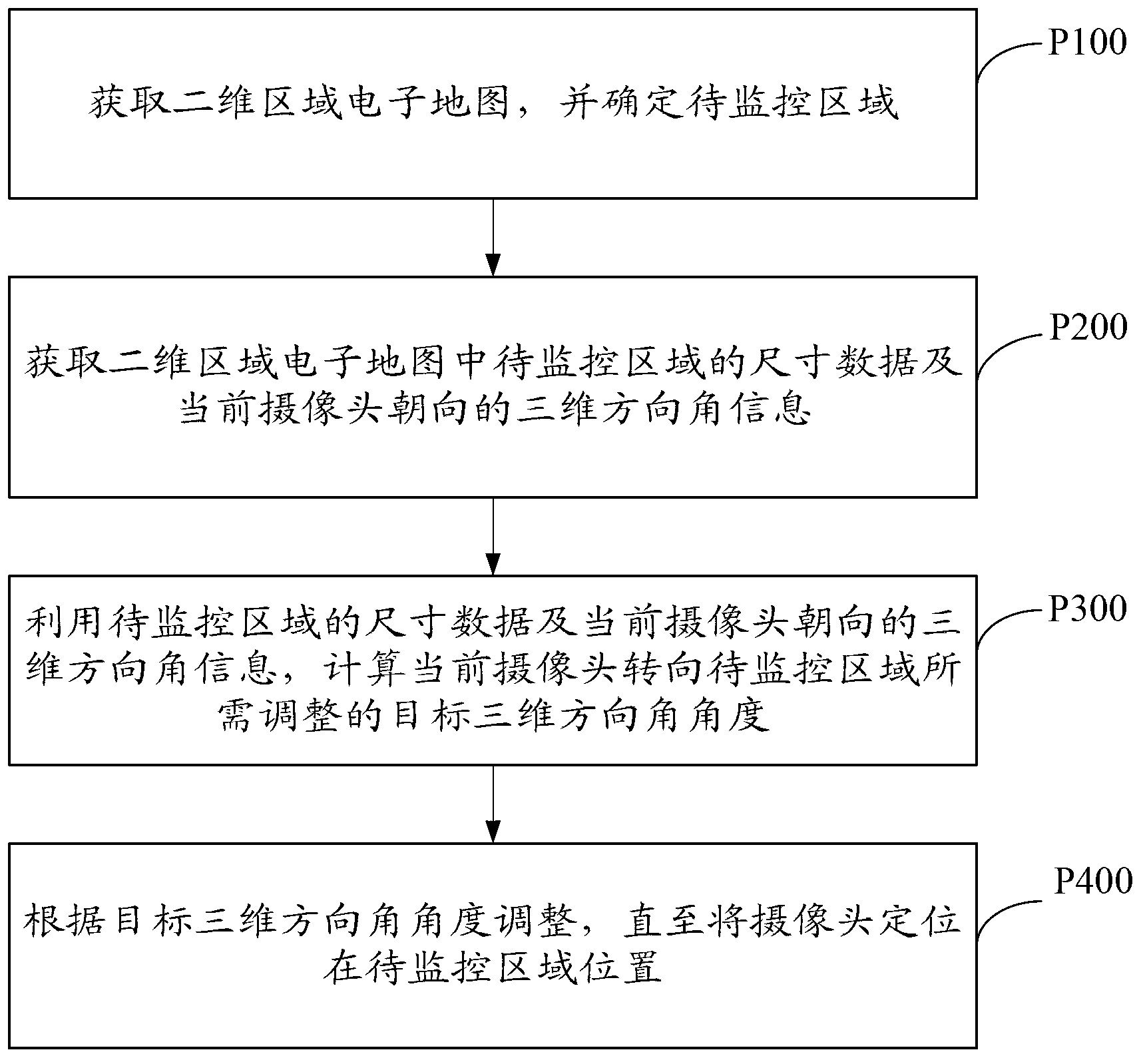

Camera coordinated processing method, camera coordinated processing device and camera

InactiveCN103237198ARealize automatic calculationReduce complexityTelevision system detailsColor television detailsComputer scienceCamera orientation

The invention discloses a camera coordinated processing method, a camera coordinated processing device and a camera. The camera coordinated processing method includes: reading three-dimensional directional angle information of preset position orientation of the camera; and acquiring three-dimensional directional angle information of current camera orientation, comparing the three-dimensional directional angle information of the current camera orientation with the three-dimensional directional angle information of the preset position orientation of the camera, calculating degree of a target three-dimensional directional angle, needing to adjust, of current camera steering preset position, and controlling the camera to be adjusted to the preset position according to the degree of the target three-dimensional directional angle. By the camera coordinated processing method, the camera coordinated processing device and the camera, degree of the target directional angle is calculated automatically, automatic correction is performed according to calculated results, and complexity and manual participation degree of system operation are lowered effectively.

Owner:华雁智能科技(集团)股份有限公司

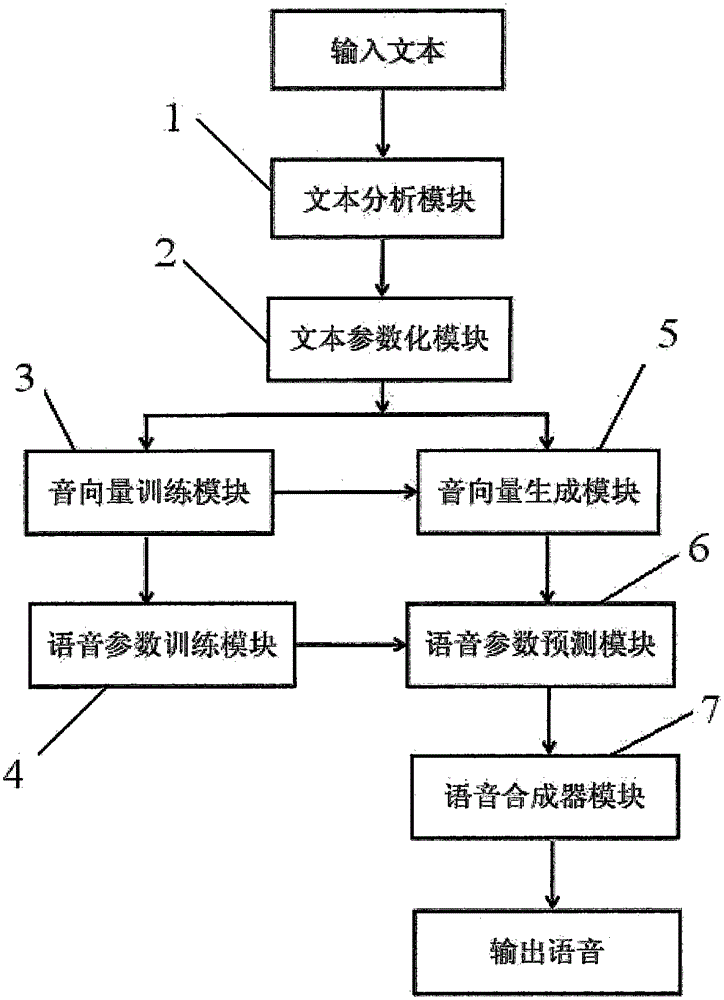

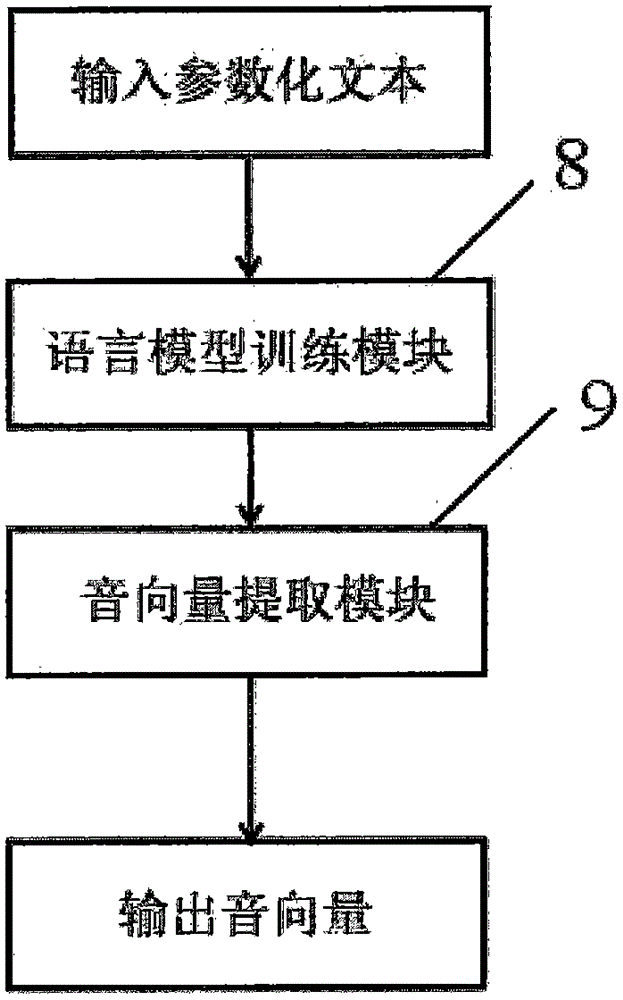

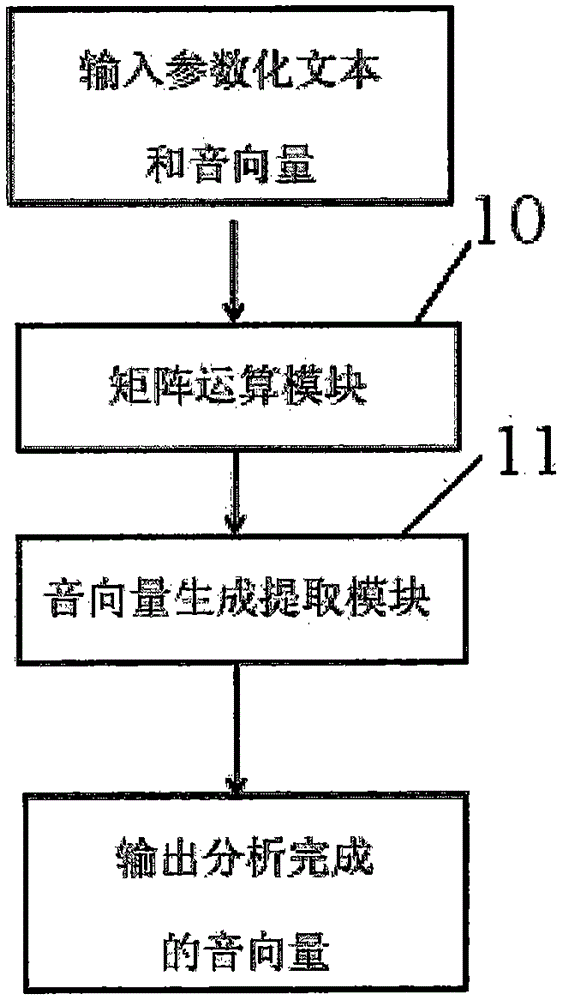

Voice synthesis method based on voice vector textual characteristics

ActiveCN105654939AImprove accuracyPreserve coherenceSpeech synthesisLinguistic modelSynthesis methods

The invention discloses a voice synthesis method based on voice vector textual characteristics. The voice synthesis method comprises the following steps: receiving an input text by a text analyzing module; carrying out regular processing on the textual characteristics and transmitting obtained text data to a text parameterization module; obtaining a parameterized text by adopting a single-bit heat code encoding method; receiving the parameterized text by a voice vector training module, and training a linguistic model based on voice vectors; then transmitting to a linguistic parameter training model to train a mapping model from the text to voice parameters; receiving the output text of the text parameterization module and the voice vector training module through a voice vector generation module, so as to generate the voice vectors of the text data; and transmitting the voice vectors of the text data and the mapping model from the text to the voice parameters to a linguistic parameter predication module to obtain the voice parameters corresponding to the voice vectors; and finally, synthesizing voices by a voice synthesis module. According to the voice synthesis method based on the voice vector textual characteristics, the accuracy of modeling of a voice synthesis system is improved; and the complexity and the manual participation degree of system realization are greatly reduced.

Owner:中科极限元(杭州)智能科技股份有限公司

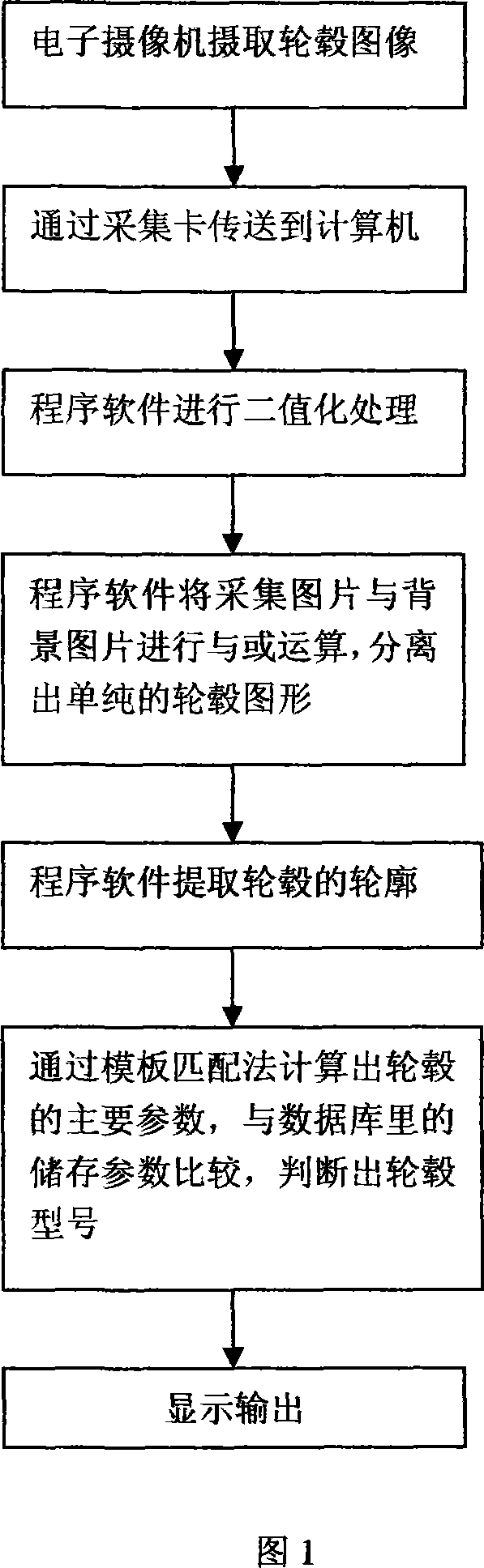

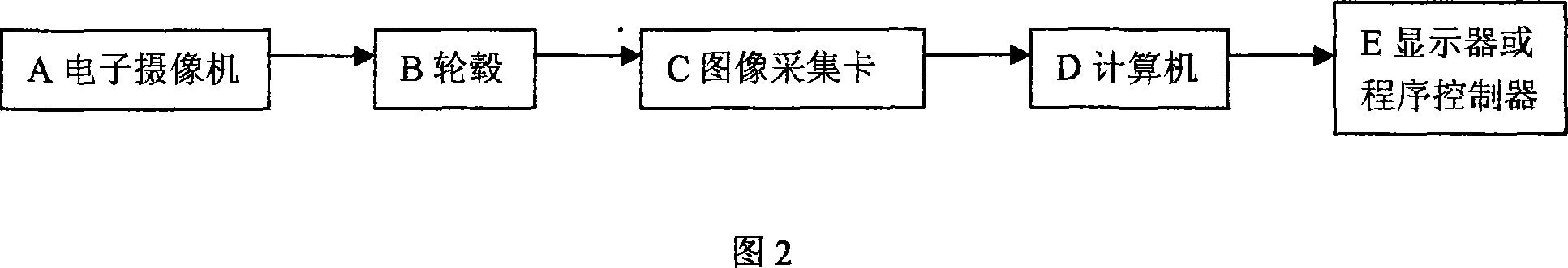

Automatic identification method for hub type

InactiveCN101079107AReduce artificial ginsengShorten the overall cycleCharacter and pattern recognitionProduction lineAutomatic control

The invention provides a hub type automatic identification method, which comprises the following steps: absorbing the hub image with electronic camera on the production line, proceeding automatic identification for the hub type by the image processed by the computer software; transferring to the automatic control software; calling the detecting control parameter of the corresponding hub from the saving data stock; making the nondestructive inspection device proceed the automatic detection without manual intervention. The invention provides the calling of the control program, which reduces the manual participation and the detecting cycle.

Owner:DANDONG HUARI SCIENCE ELECTRIC CO LTD

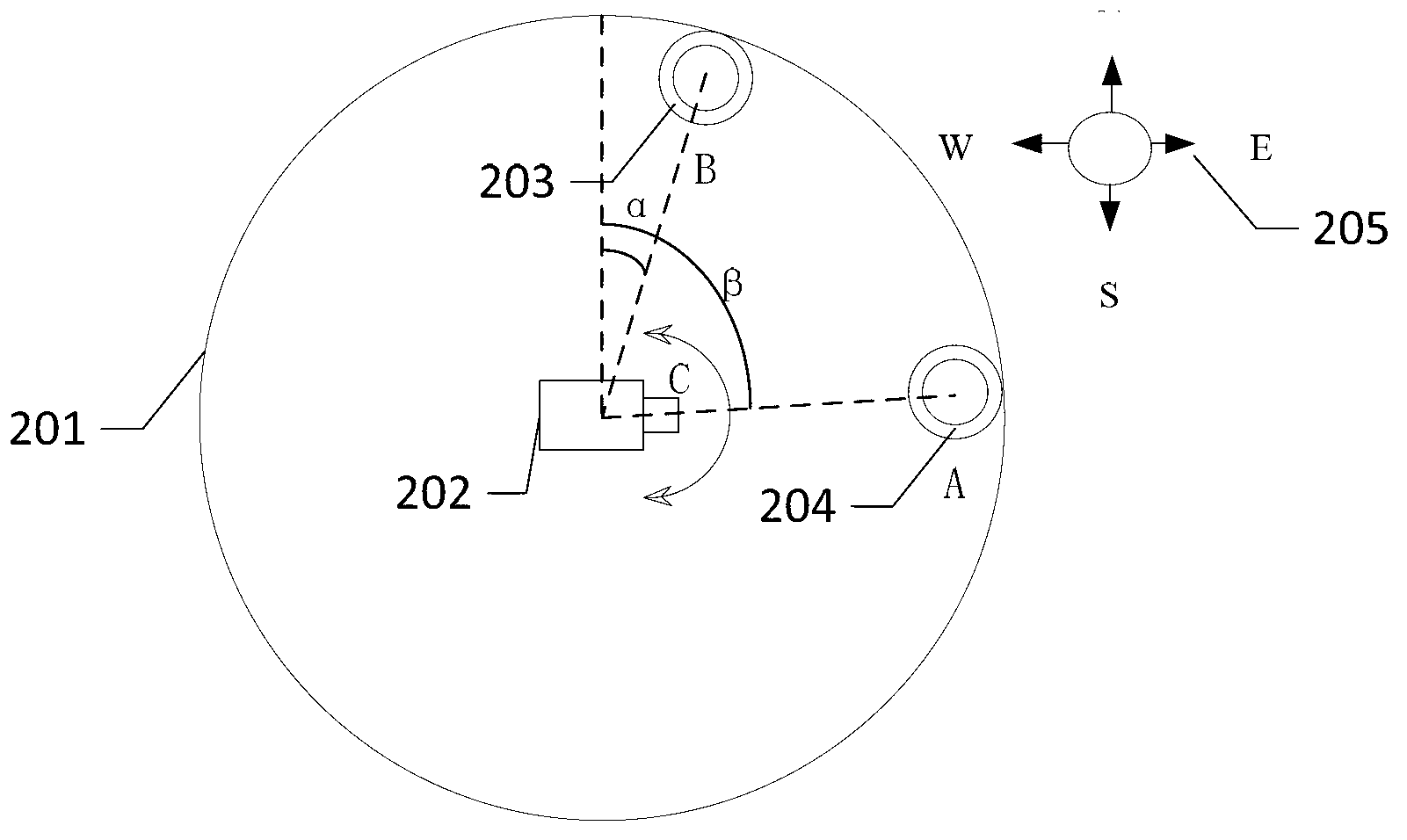

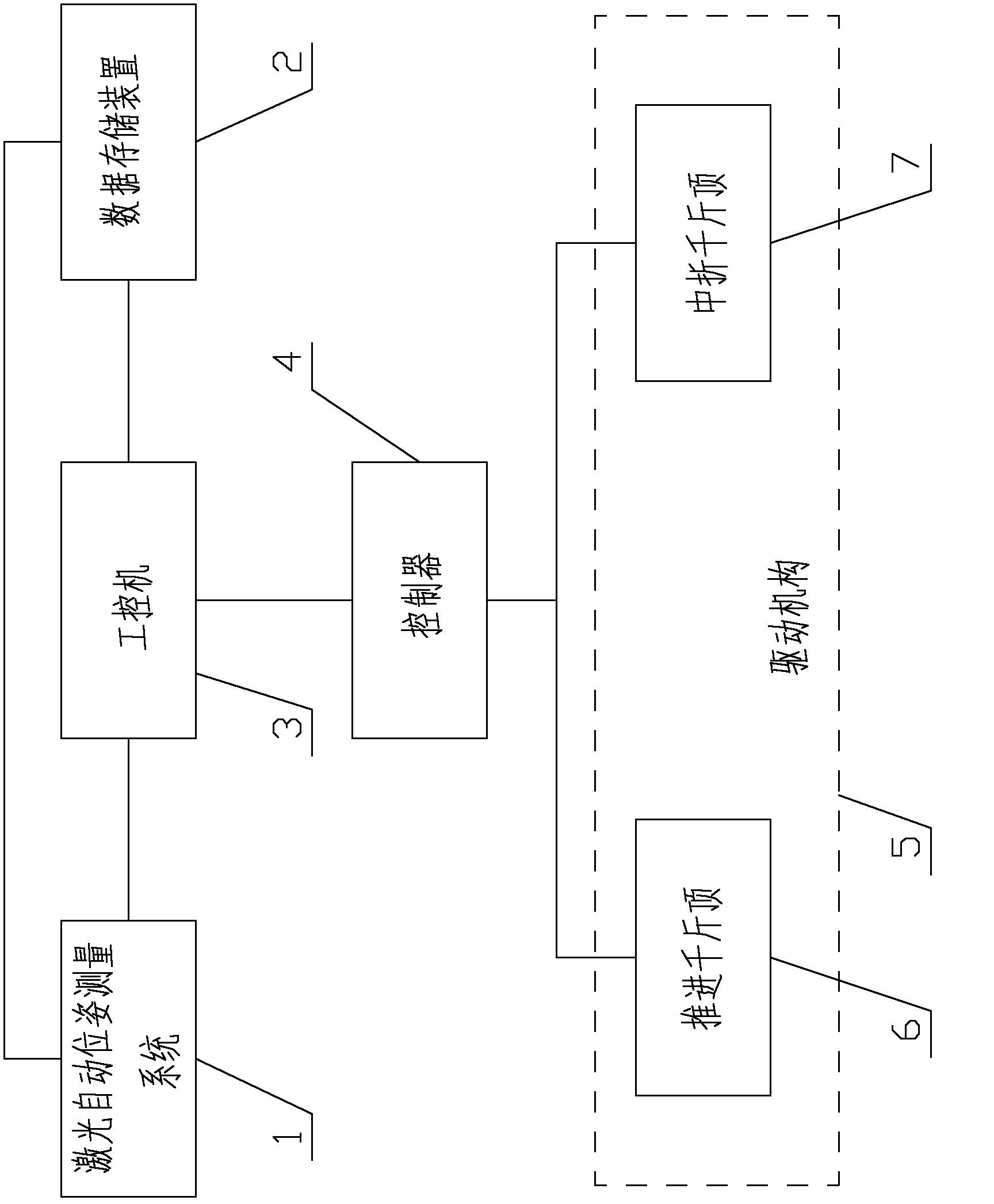

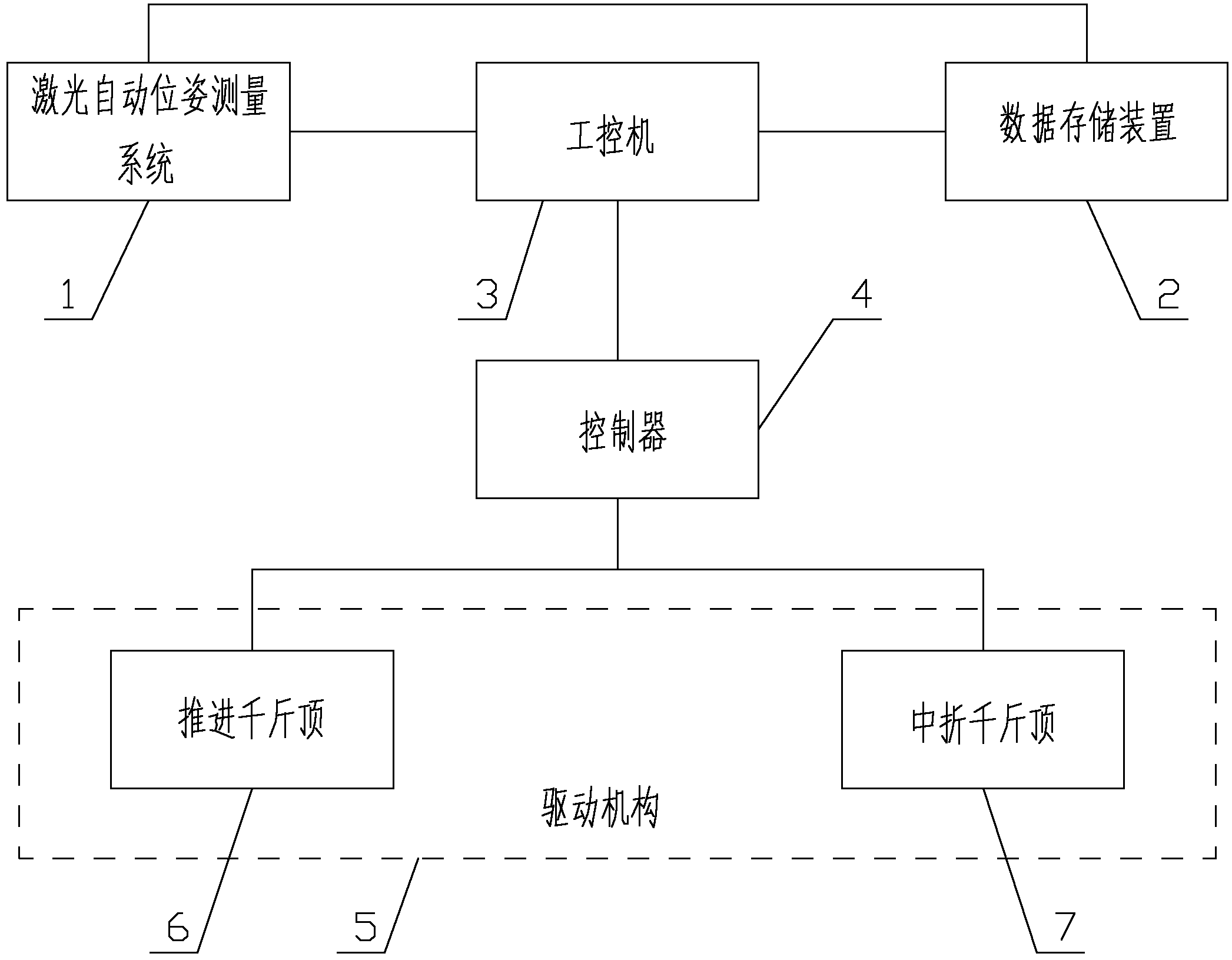

Automatic deviation rectifying system for shield machine and operating method of automatic deviation rectifying system

The invention discloses an automatic deviation rectifying system for a shield machine and an operating method of the automatic deviation rectifying system. The automatic deviation rectifying system comprises an automatic laser position and posture measuring system, a data storage device, an industrial personal computer, a controller and a driving mechanism, wherein the automatic laser position and posture measuring system is used for monitoring the position and the posture of the shield machine in real time, the data storage device is used for storing correct and real-time position and posture data of the shield machine, the industrial personal computer is used for comparing the correct and real-time position and posture data of the shield machine and transmitting deviation rectifying control signals, the controller is used for controlling the driving mechanism to start, and the driving mechanism is used for rectifying deviation of the shield machine. The automatic deviation rectifying system for the shield machine and the operating method of the automatic deviation rectifying system can be used for automatically rectifying the running track of the shield machine, and has the advantages of high precision, high efficiency and the like. Besides, manual intervention in deviation rectifying is decreased, and constructional safety is improved.

Owner:DUNJIAN HEAVY IND MFG

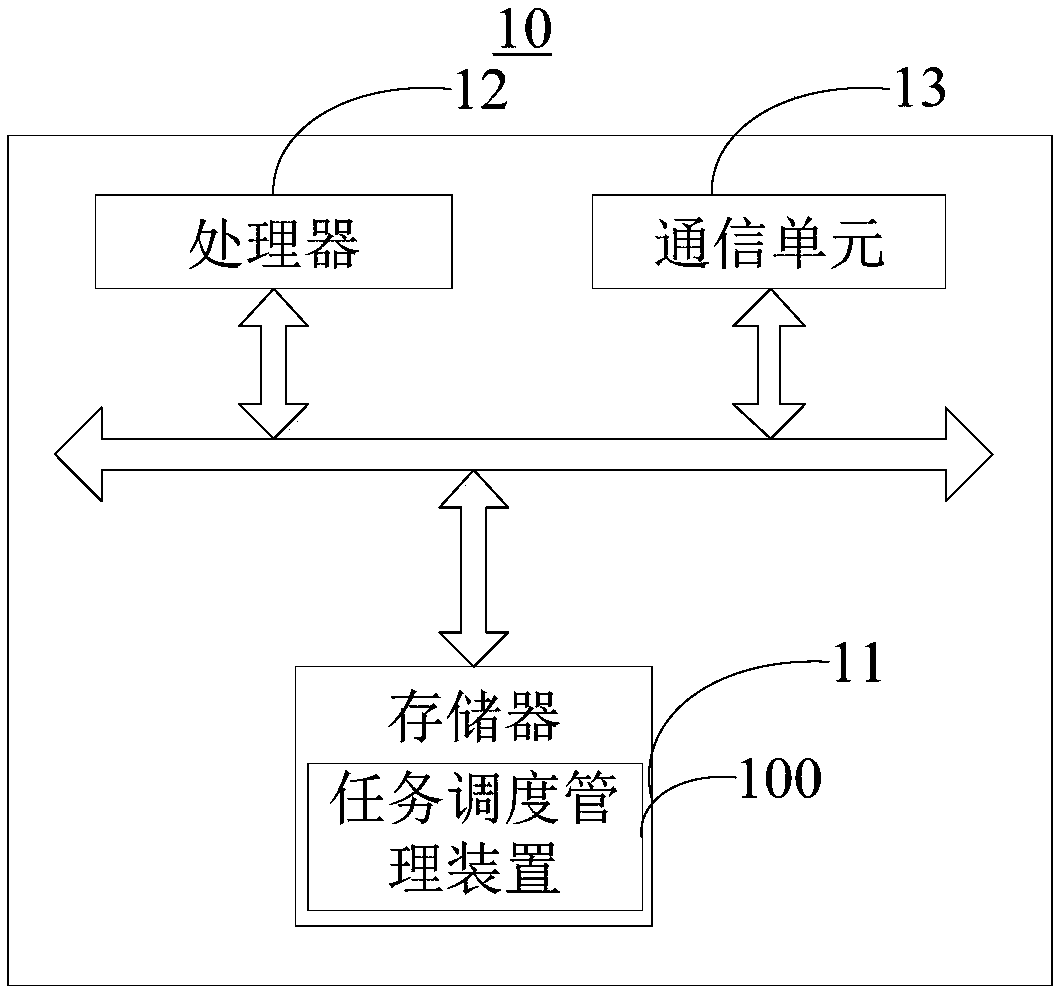

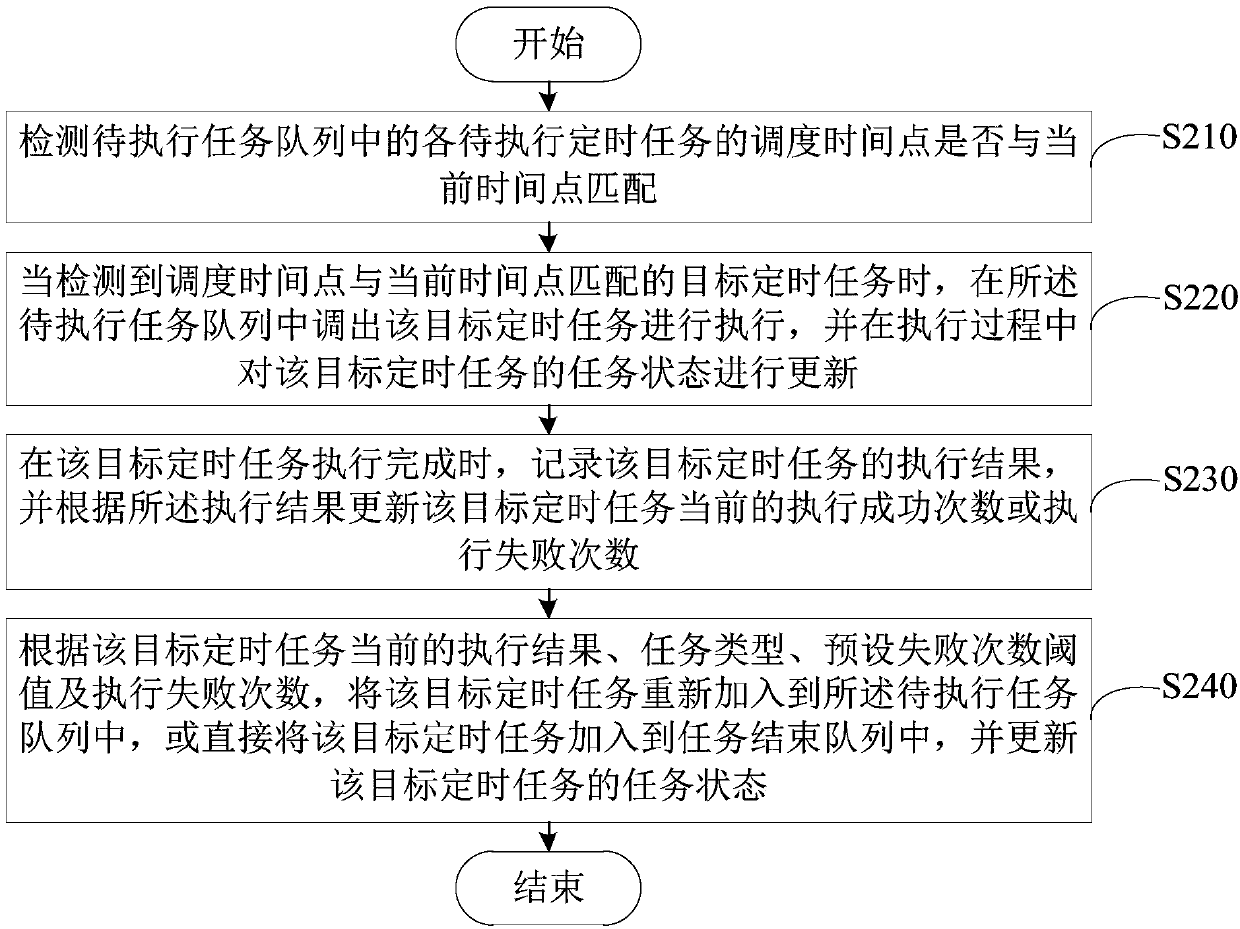

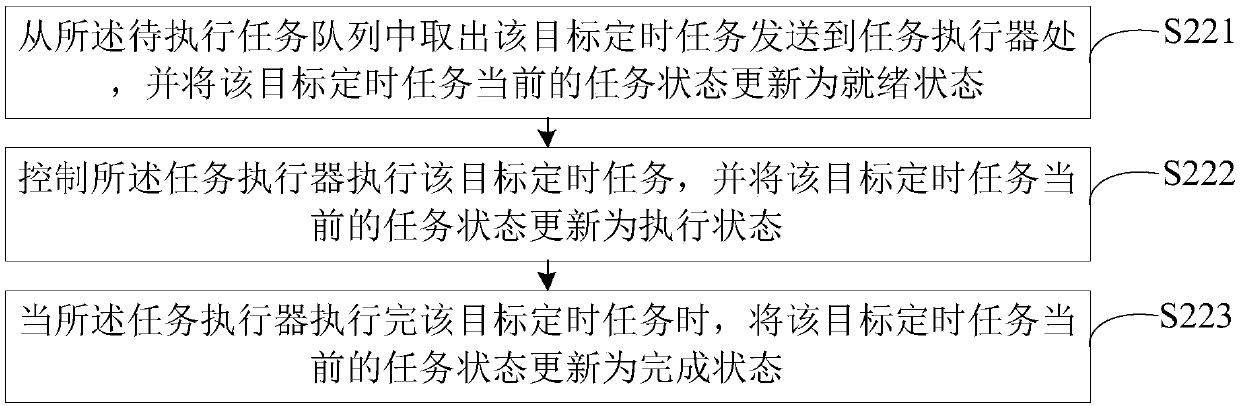

Task scheduling management method and device, and operation and maintenance management server

InactiveCN109634733AImprove construction efficiencyImprove operation and maintenance efficiencyProgram initiation/switchingMaintenance managementOperating system

The invention provides a task scheduling management method and device, and an operation and maintenance management server. The method comprises the steps of detecting whether a scheduling time point of each to-be-executed timing task in a to-be-executed task queue is matched with a current time point or not; When a target timing task of which the scheduling time point is matched with the current time point is detected, calling out the target timing task to execute the target timing task, and updating the task state of the target timing task in the execution process; When the target timing taskis completed, recording an execution result of the target timing task, and updating the current execution success frequency or execution failure frequency of the target timing task; And adding the target timing task into the to-be-executed task queue again, or directly adding the target timing task into the task ending queue, and updating the task state of the target timing task. According to themethod, the labor cost and the manual participation degree can be reduced, the construction efficiency and the operation and maintenance efficiency of the operation and maintenance platform are improved, and automatic management of the operation and maintenance platform is ensured.

Owner:CHENGDU SEFON SOFTWARE CO LTD

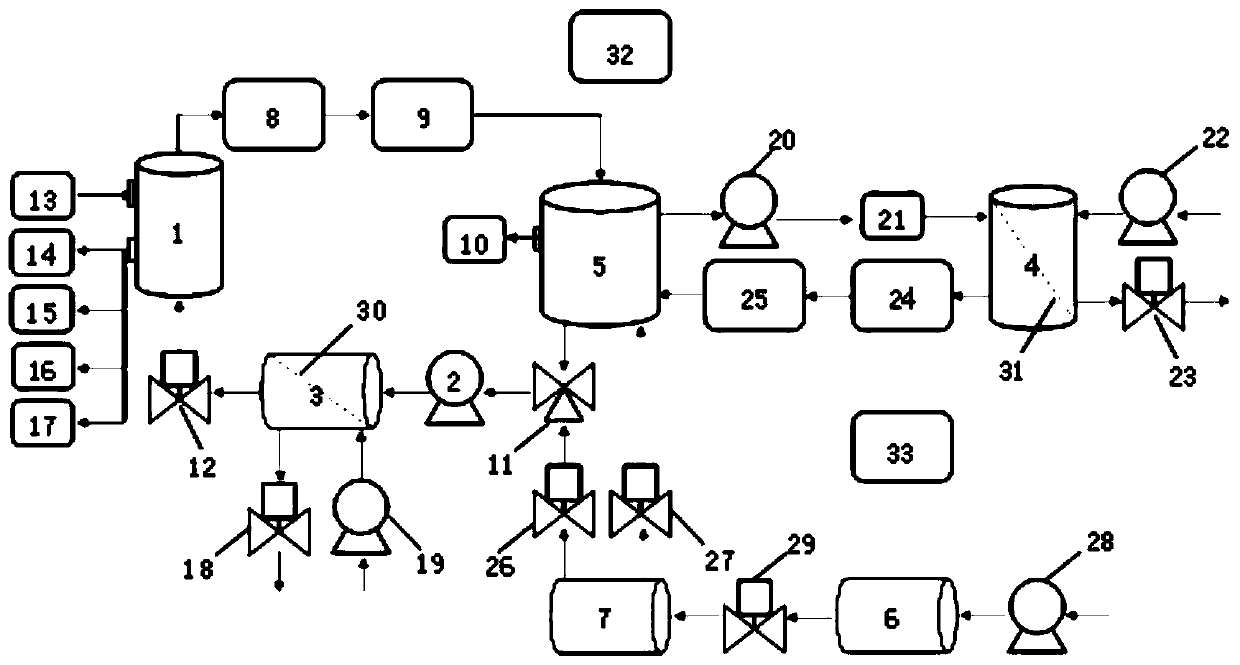

Three-dimensional simulation culture system for stem cells

InactiveCN110129199AQuality improvementA large amountBioreactor/fermenter combinationsBiological substance pretreatmentsDialysis membranesPeristaltic pump

The invention discloses a three-dimensional simulation culture system for stem cells, and belongs to the technical field of biology. The invention solves the problems of complex operation, low efficiency, small yield and poor quality in an existing in-vitro culture of stem cells. The three-dimensional simulation culture system for the stem cells comprises a stem cell nest, a heart region first peristaltic pump, a lung region, a kidney region, a spleen region, a stomach region, a liver region, a first fluid pressure gauge, a first pressure regulating valve, a liquid level meter, a three-way valve, a first control valve, a temperature regulator, a thermometer, an oxygen / carbon dioxide measuring instrument, a PH measuring instrument, a nutritional ingredient measuring instrument, a second control valve, a second peristaltic pump, a third peristaltic pump, a urea / uric acid / inorganic salt measuring instrument, a fourth peristaltic pump, a third control valve, a second fluid pressure gauge,a second pressure regulating valve, a fourth control valve, a fifth control valve, a fifth peristaltic pump, a sixth control valve, a gas permeable membrane, a dialysis membrane, a central control platform, a cloud data center and an electromagnetic field. According to the three-dimensional simulation culture system for the stem cells, the stem cells with higher quality and quantity can be cultured, the stability is good, and the treatment effect of the stem cells is improved.

Owner:哈尔滨工大国际干细胞工程研究院有限公司

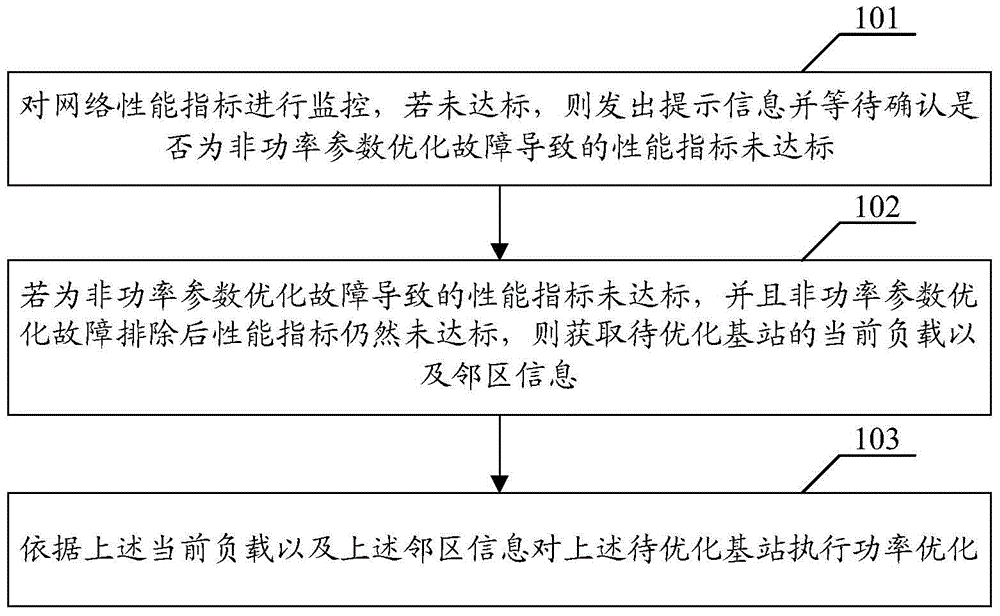

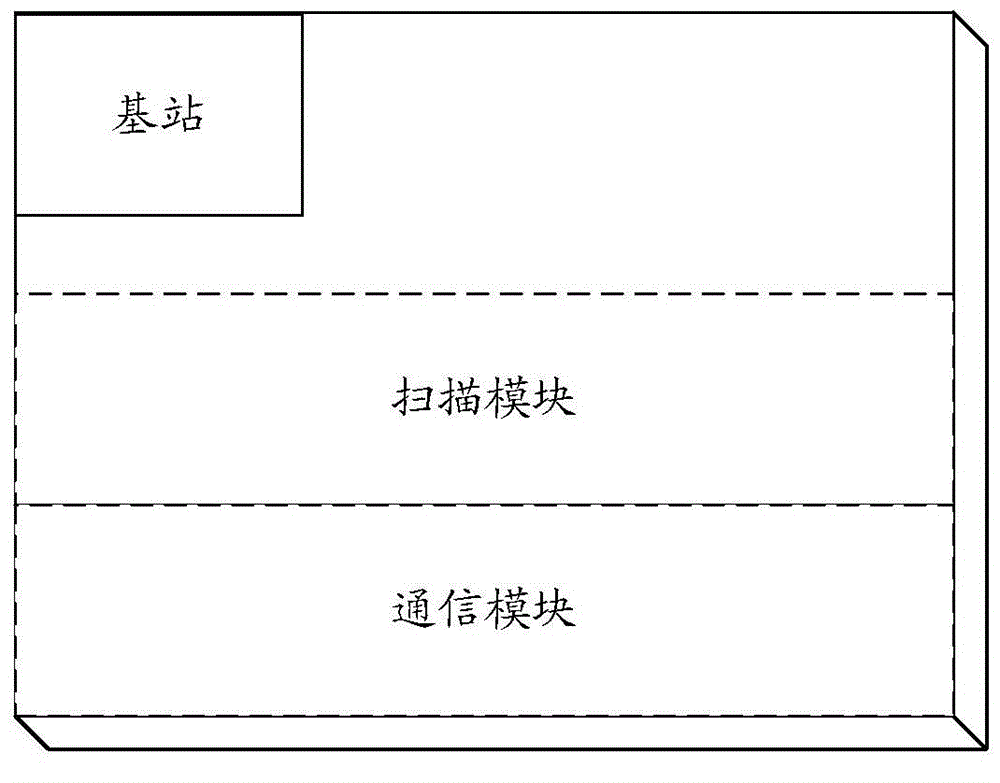

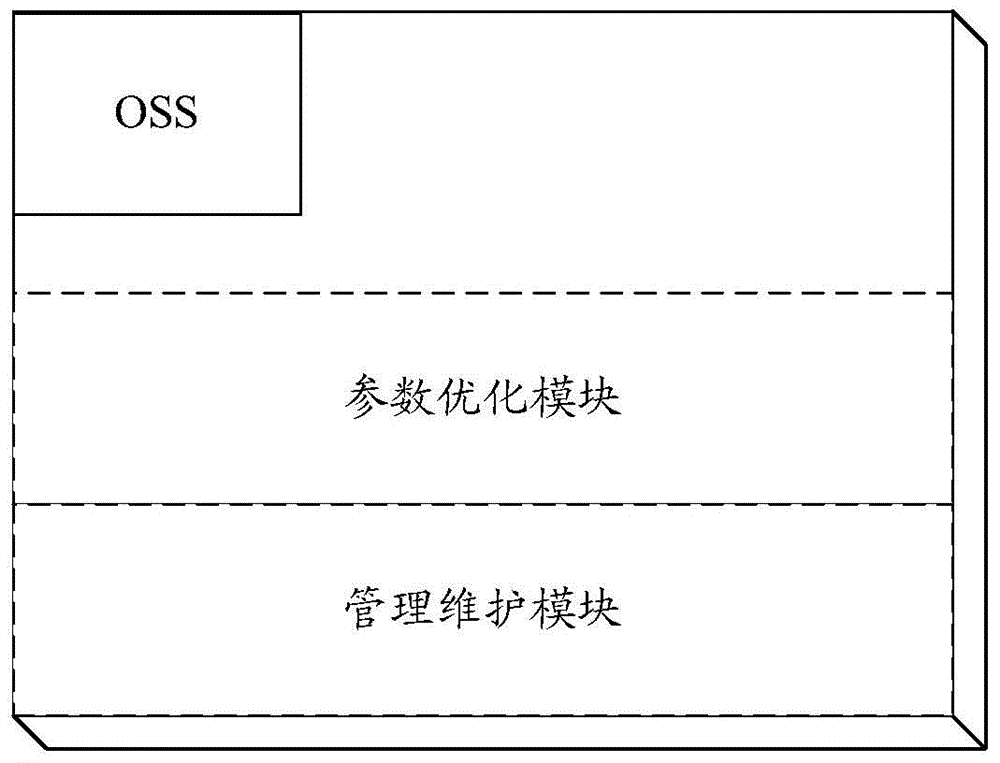

Method, device and system for base station power automatic optimization

InactiveCN103607728AReduce artificial ginsengReduce the impactEnergy efficient ICTPower managementPower parameterPerformance index

The invention discloses a method, a device and a system for base station power automatic optimization. The implementation of the method comprises the steps that a network performance index is monitored, if the index does not reach the standard, prompt information is sent out, and whether a non-power parameter optimization fault leads to that the performance index does not reach the standard is waited to be confirmed; if the non-power parameter optimization fault leads to that the performance index does not reach the standard, and the performance index still does not reach the standard after the non-power parameter optimization fault is corrected, a present load and adjacent region information of a base station to be optimized are obtained; and the base station to be optimized is subjected to power optimization in terms of the present load and the adjacent region information. By employing the above method, the automatic power optimization can be achieved, influence brought by manual intervention can be reduced, and the efficiency and the accuracy of the power optimization are improved.

Owner:SHANGHAI HUAWEI TECH CO LTD

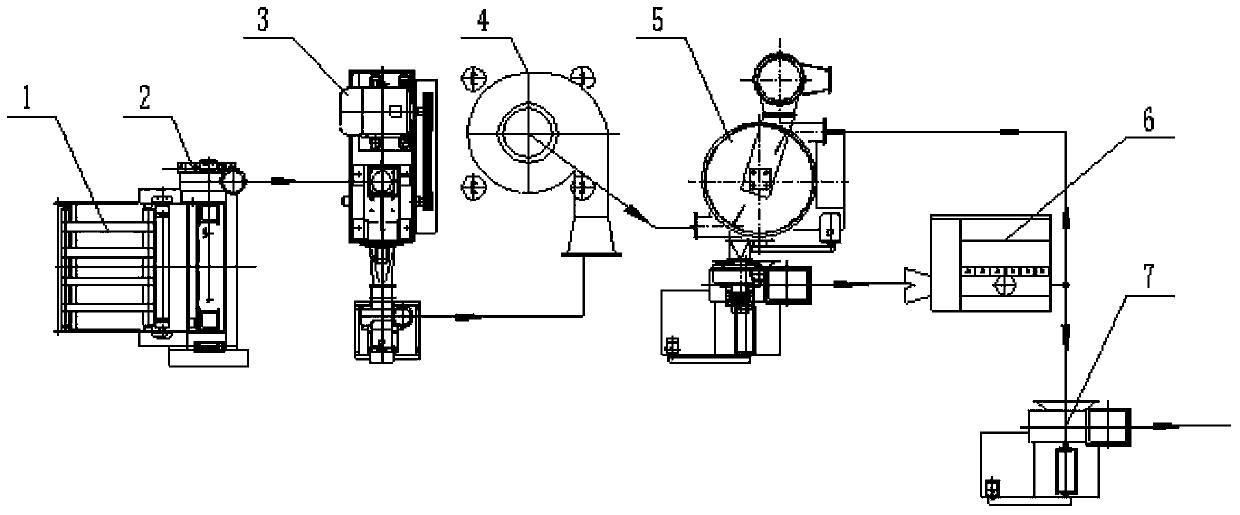

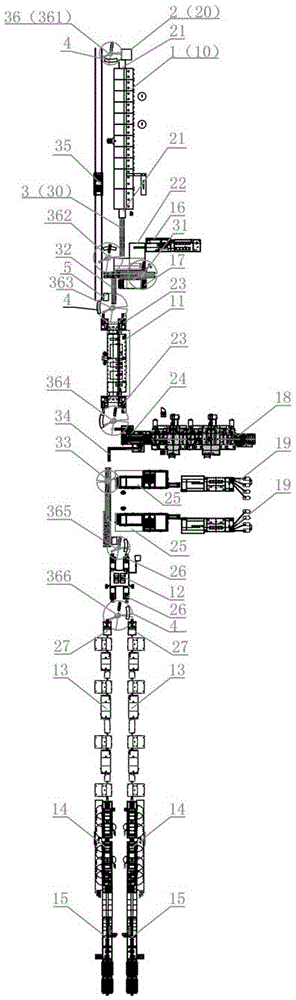

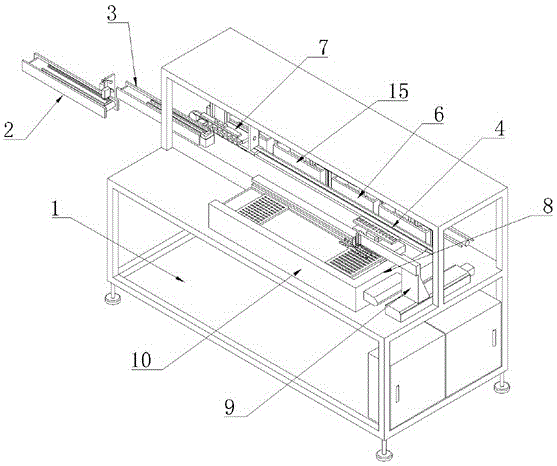

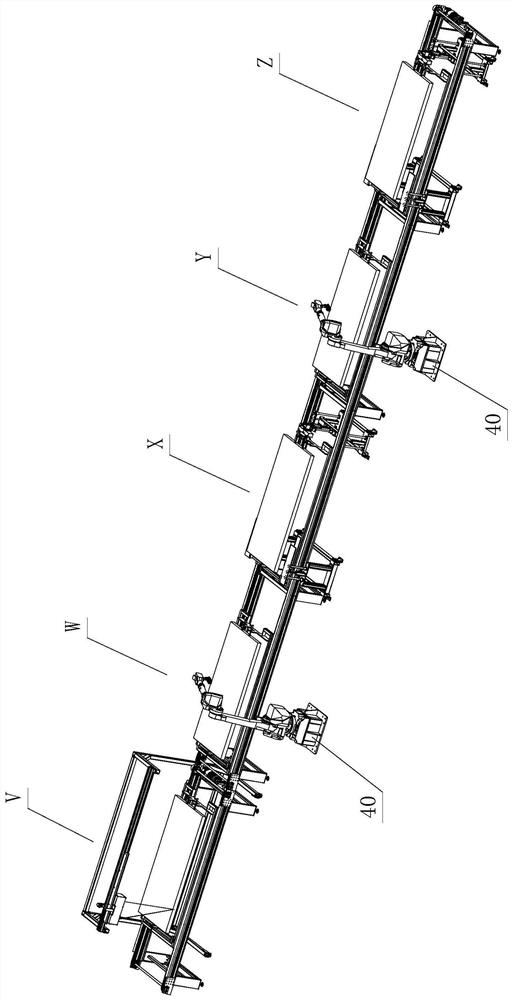

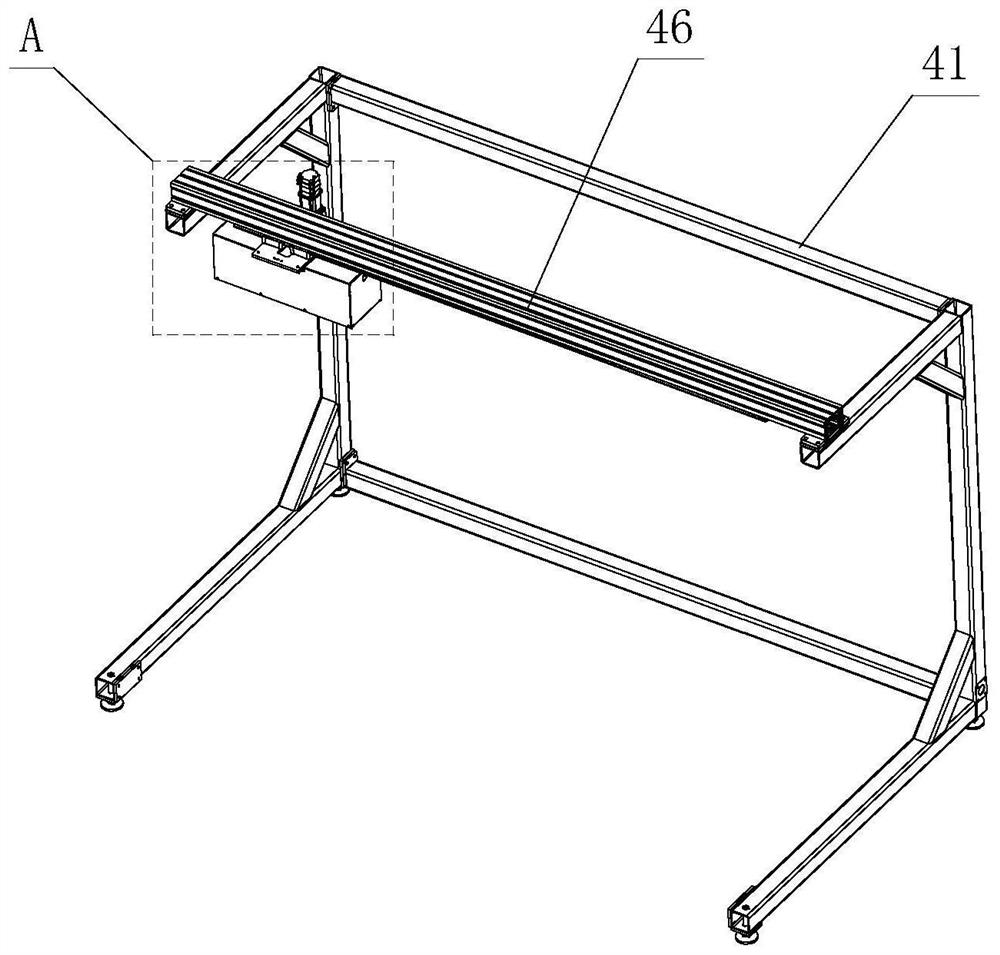

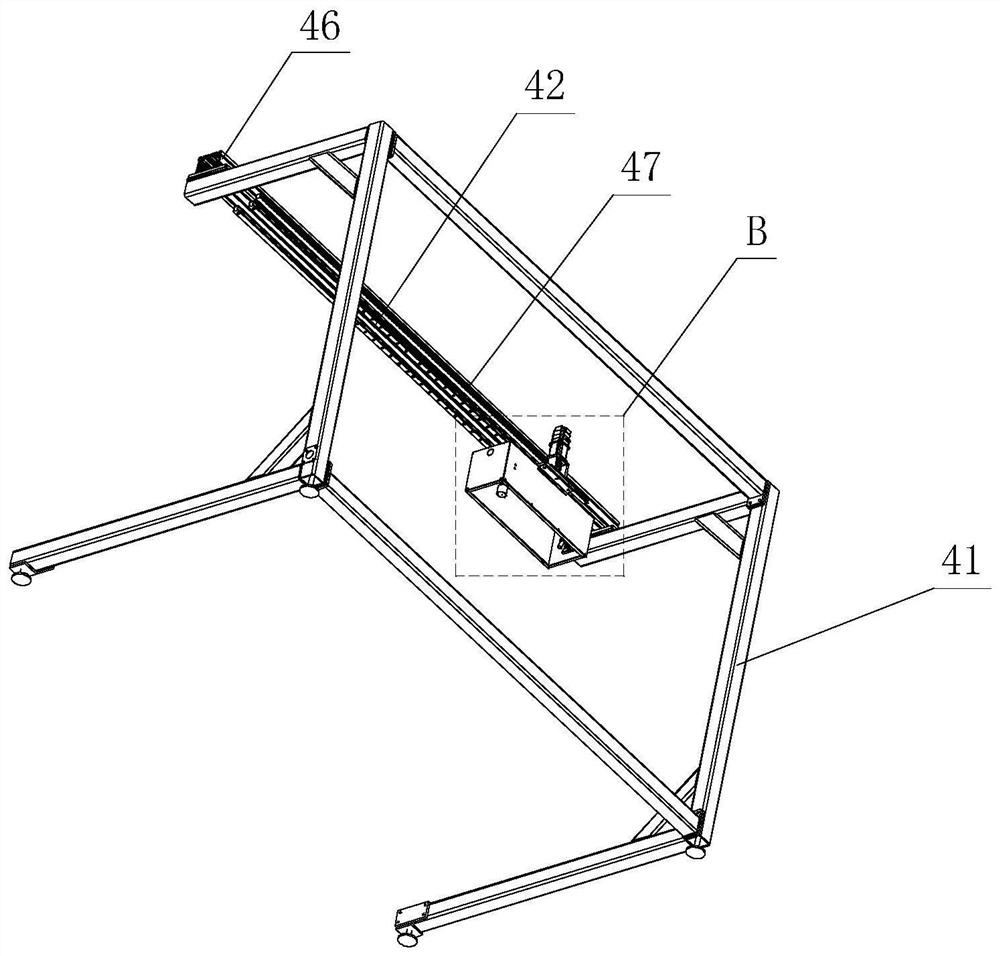

PERC solar cell production line

InactiveCN106449870AImprove operational efficiencyReduce space consumptionFinal product manufacturePhotovoltaic energy generationProduction lineAutomatic transmission

The invention discloses a PERC solar cell production line. The PERC solar cell production line comprises process equipment, automatic feeding and discharging equipment, automatic transmission equipment and a basket, wherein the automatic feeding and discharging equipment is used for circulating a material in a process, the automatic transmission equipment is used for circulating the material between processes, the process equipment comprises a texturing machine, a cleaning and etching machine, a laser ablation machine, a screen printing machine, a sintering furnace, a test sorting machine, a diffusion furnace, a square resistance detection machine, a back passivation plate PECVD (Plasma Enhanced Chemical Vapor Deposition) and a tubular PECVD, wherein the texturing machine, the cleaning and etching machine, the laser ablation machine, the screen printing machine, the sintering furnace and the test sorting machine are sequentially arranged along a longitudinal direction, the diffusion furnace, the square resistance detection machine, the back passivation plate PECVD and the tubular PECVD are arranged along a transverse direction, the diffusion furnace is arranged at a downstream of the texturing machine, the square resistance detection machine is arranged at an upstream of the cleaning and etching machine, the back passivation plate PECVD is arranged at a downstream of the cleaning and etching machine, and the tubular PECVD is arranged at an upstream of the laser ablation machine. The PERC solar cell production line has the advantages of reasonable layout, high automation, high production efficiency and the like, the product quality is ensured, and the production cost is reduced.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

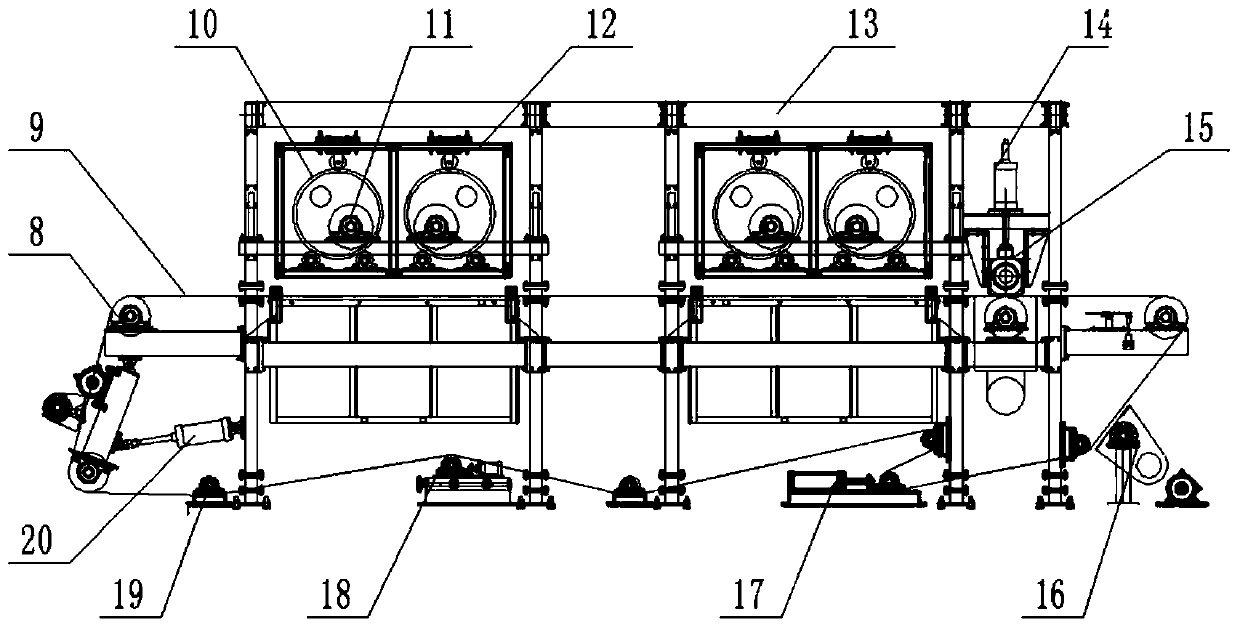

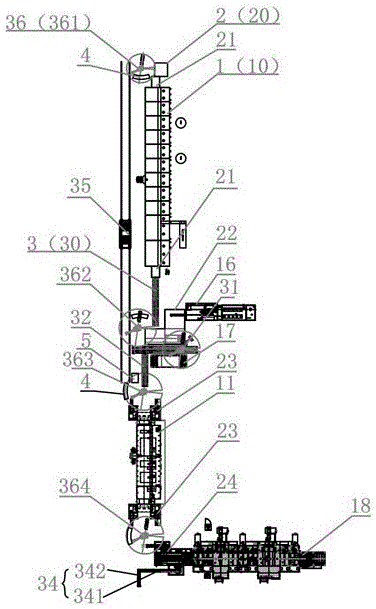

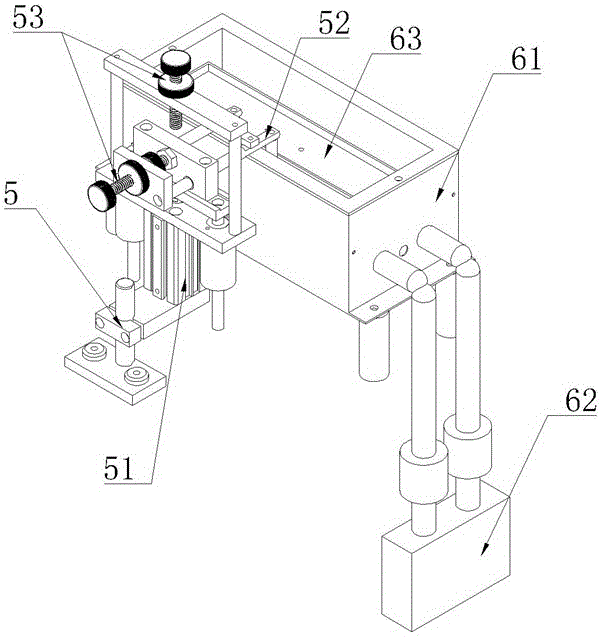

Linear automatic tin soldering device

ActiveCN105127537AImprove securitySave human effortMetal working apparatusSoldering auxillary devicesTransformerHeating furnace

The invention discloses and provides a linear automatic tin soldering device capable of simultaneously completing various motor skills, saving labor and time, relieving labor intensity, improving labor efficiency, guaranteeing the safety of staff and improving the tin soldering quality and yield of products. The linear automatic tin soldering device comprises a rack and a conveying mechanism fixedly arranged on the rack. A feeding mechanism and a linear positioning mechanism are further arranged on the conveying mechanism. A first tin soldering station, a second tin soldering station and a discharging mechanism are further sequentially arranged on the rack. The first tin soldering station and the second tin soldering station each comprise a scaling powder mechanism and a tin furnace which are fixedly arranged on one side of the linear positioning mechanism, the tin furnaces are further provided with high-temperature glue protection devices, a tin soldering mechanism is further arranged on the linear positioning mechanism, the linear positioning mechanism drives the tin soldering mechanism to sequentially pass through the first tin soldering station and the second tin soldering station, and then double-tin-soldering procedures are completed. The linear automatic tin soldering device is suitable for the field of transformer production.

Owner:珠海科德电子有限公司

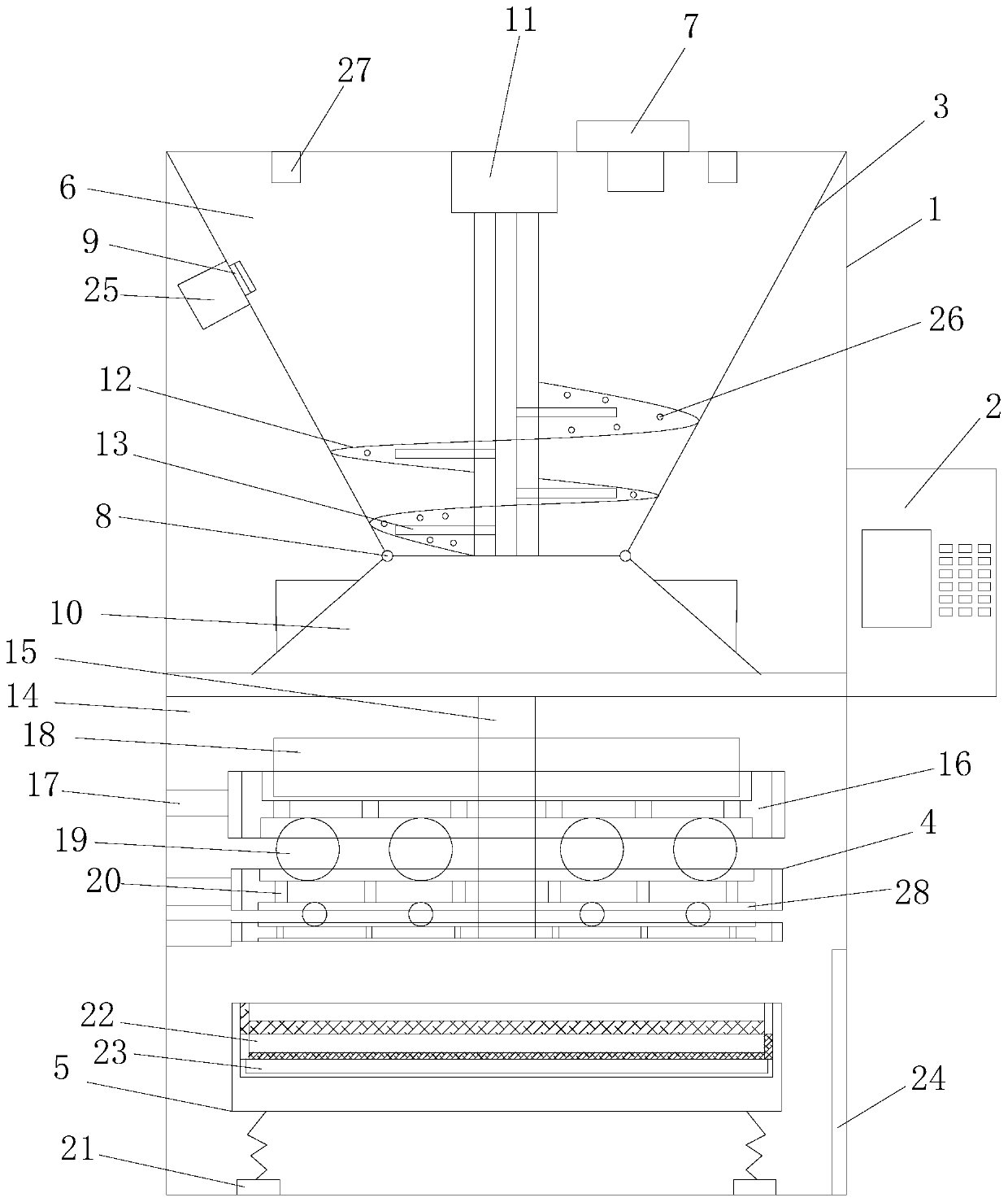

Soil sample grinding and screening device

PendingCN111036372AReduce pollutionImprove sieving stabilityPreparing sample for investigationGrain treatmentsGear grindingElectric machine

The invention discloses a soil sample grinding and screening device which comprises a rack, a control center, a drying and crushing mechanism, a layered grinding mechanism and a precise screening anddischarging mechanism. The drying and crushing mechanism comprises a sealed containing trough, a sealed feeding opening, an electric discharging opening, a one-way exhaust opening, a guide pipe, a stirring motor, a stirring crushing paddle and an inner heating network pipe. The layered grinding mechanism comprises a grinding box, a grinding disc locating column, a layered gear grinding disc, a drive motor, a raw material scraping plate and a grinding ball. The precise screening and discharging mechanism comprises a vibration screen frame, a layered precise screen, a screen bottom and a discharging door. By means of the soil sample grinding and screening device, soil sample grinding and screening can be automatically carried out in the same closed device, the screening period is shortened,the screening efficiency is improved, pollution of dust to the environment is reduced, operation of manual participation is reduced, screening stability of soil samples is improved, and accuracy of soil sample detection results can be improved easily.

Owner:浙江华珍科技有限公司

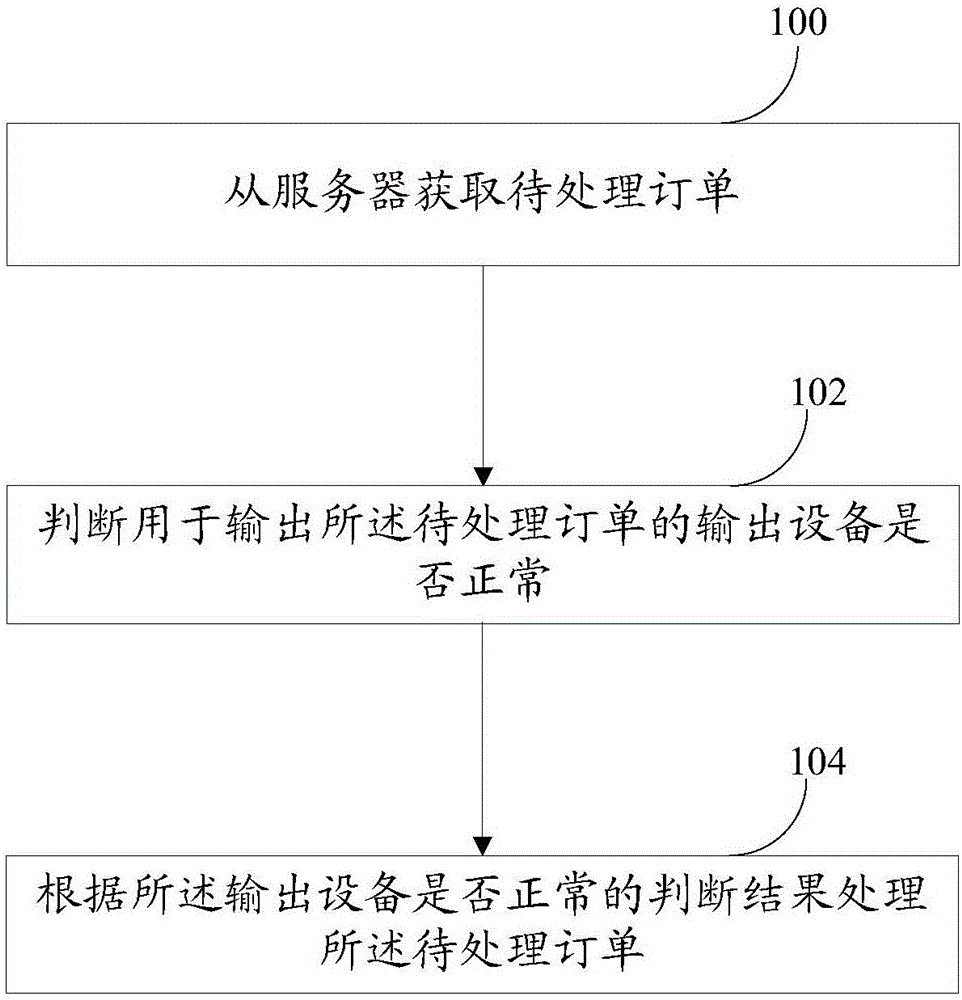

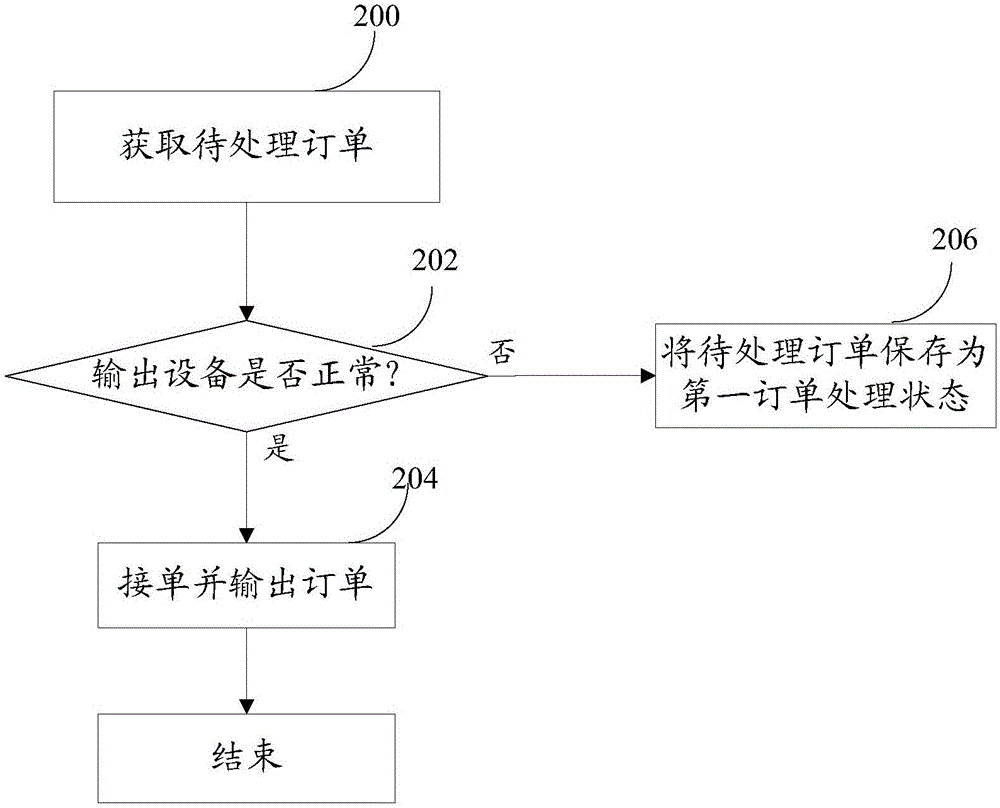

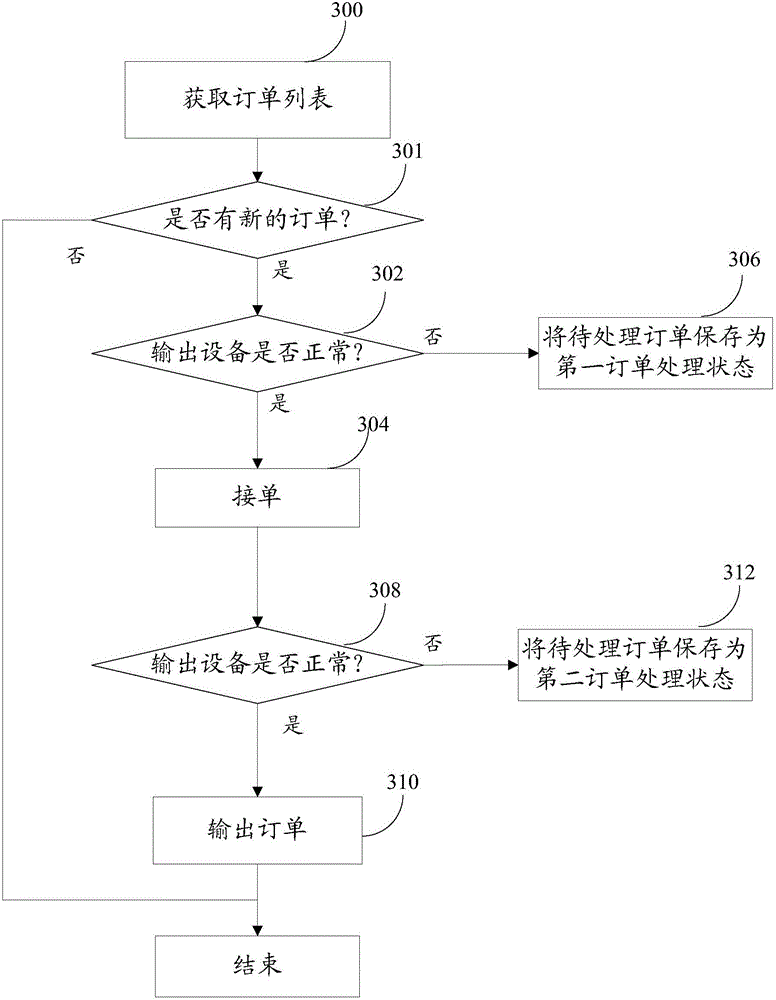

Order processing method, device and system

InactiveCN106327304AReduce labor costsReduce artificial ginsengBuying/selling/leasing transactionsOrder formOutput device

The invention discloses an order processing method, device and system. The method comprises the steps of: acquiring an order to be processed from a server; judging whether output equipment for outputting the order to be processed is abnormal; and processing the order to be processed according to the judgment result about whether the output equipment is normal. By adopting the method, the device and the system, the order processing efficiency can be improved, and the requirement of merchants for convenience is met while the order receiving cost of merchants is reduced.

Owner:BEIJING XIAODU INFORMATION TECH CO LTD

Intelligent door leaf spraying line with robot

PendingCN113145342AGood modelingIncrease productivitySpraying apparatusEngineeringMechanical engineering

The invention discloses an intelligent door leaf spraying line with a robot. The intelligent door leaf spraying line comprises a door leaf clamp used for clamping and supporting a door leaf and a chain conveying device used for conveying the door leaf clamp, and a door leaf scanning area, a door leaf front face spraying area, a door leaf front face supplementary coating area, a door leaf back face spraying area and a door leaf back face supplementary coating area are sequentially arranged in the conveying direction of the chain conveying device. A three-dimensional scanning device is arranged on the door leaf scanning area, and the three-dimensional size and / or shape of a door leaf are scanned through the three-dimensional scanning device; spraying robots are arranged on the outer side of the door leaf front face spraying area and the outer side of the door leaf back face spraying area respectively, and the front face and the back face of the door leaf are sprayed through the spraying robots respectively; and the door leaf front face supplementary coating area and the door leaf back face supplementary coating area conduct manual detection and manual supplementary coating on the front face spraying condition and the back face spraying condition of the door leaf respectively. The intelligent door leaf spraying line has the characteristics of simple and reasonable structure, clear production and processing process planning, high automation degree, high production efficiency, low cost, safe and reliable spraying process and the like, and is strong in practicability.

Owner:广东博硕涂装技术有限公司

Method and system for predicting problem

InactiveCN108628882AGuaranteed recallGuaranteed accuracySpecial data processing applicationsFeature vectorData mining

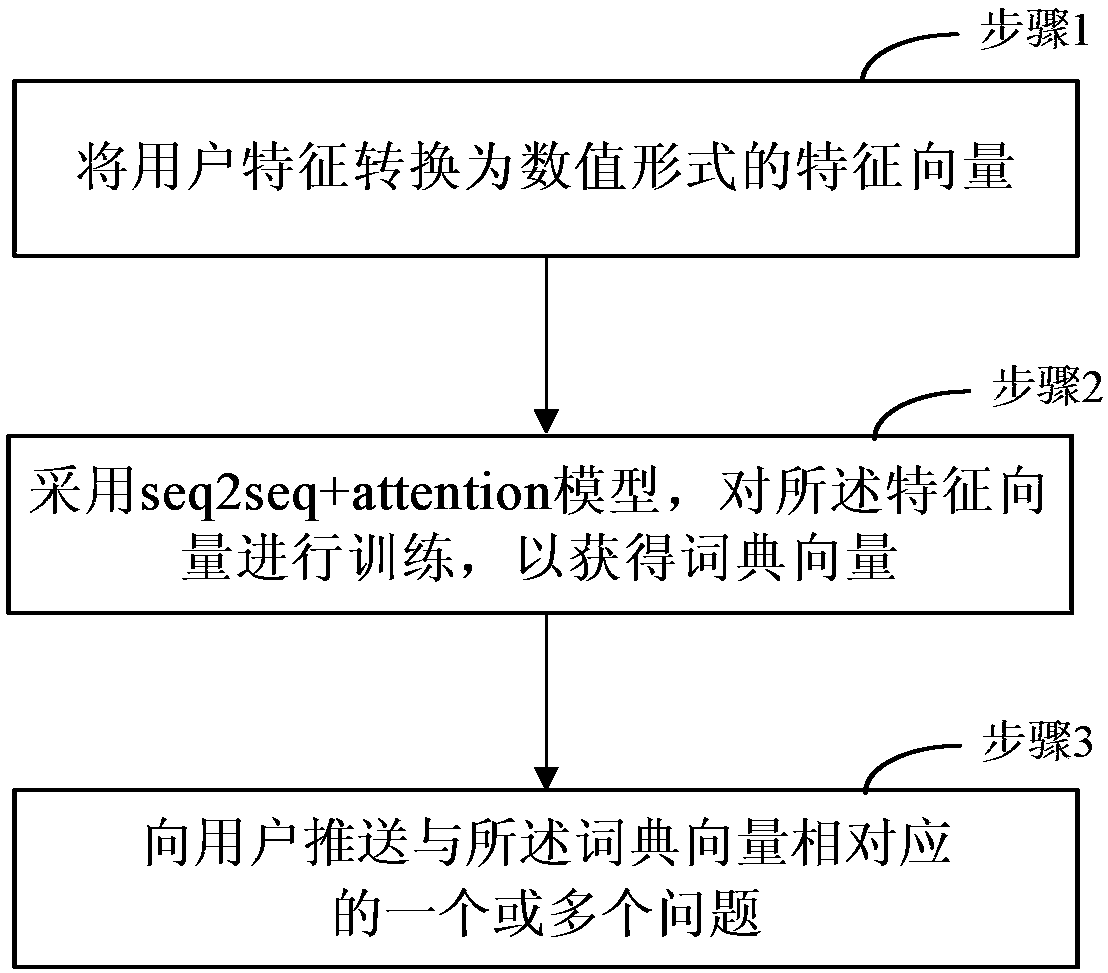

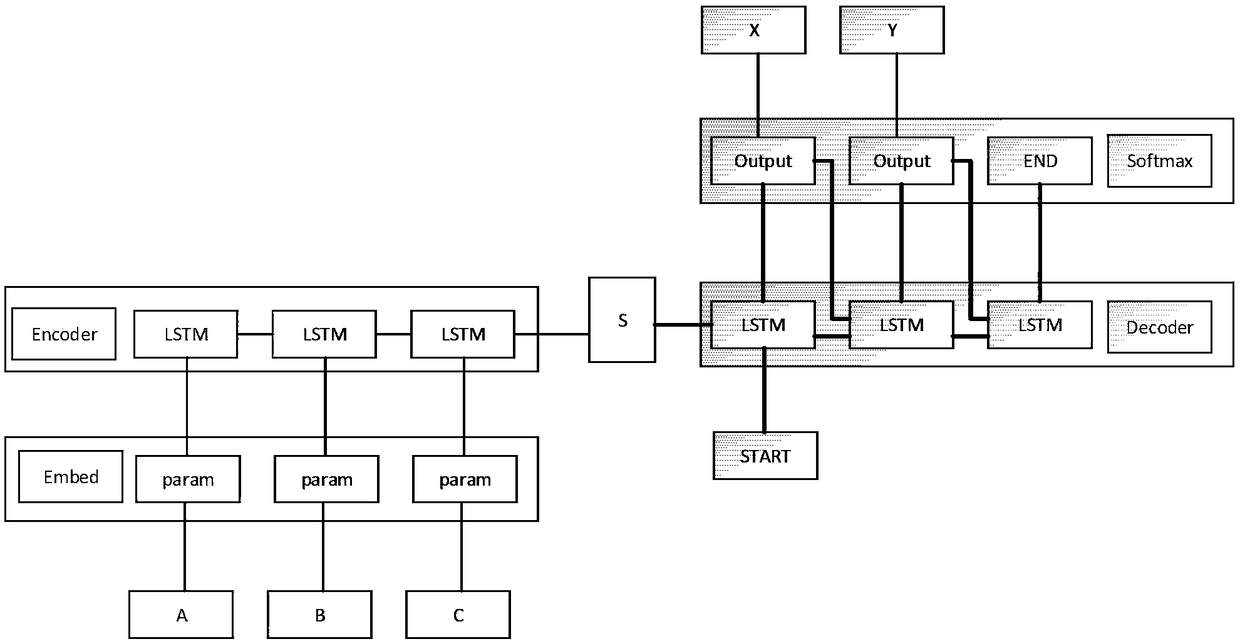

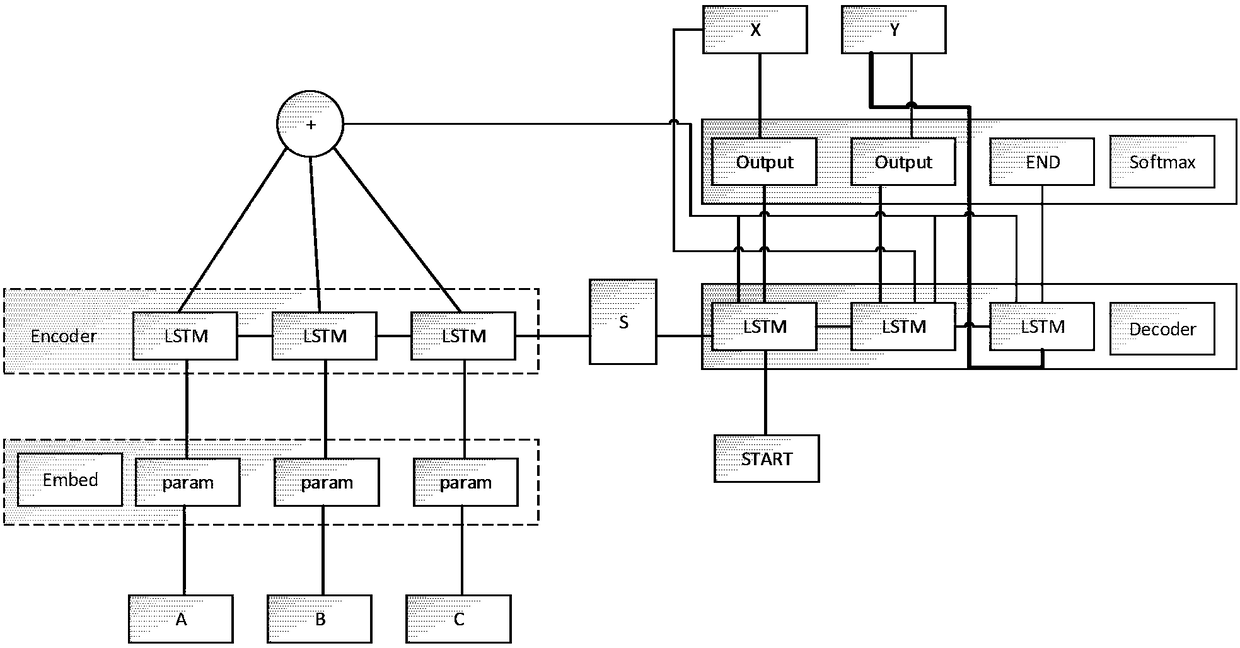

The present invention provides a method and a system for predicting a problem. The method for predicting the problem comprises: step one, converting a user feature into a feature vector in a numericalform; step two, using a training model to train the feature vector to obtain a dictionary vector; and step three, pushing one or more questions corresponding to the dictionary vector to the user.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Bank-corporate direct linkage method and system on cross-border e-commerce platform

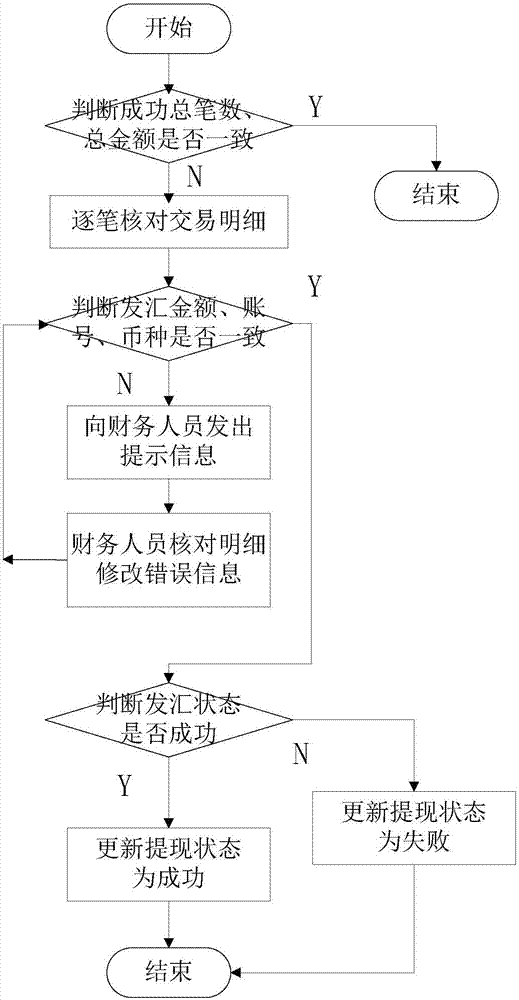

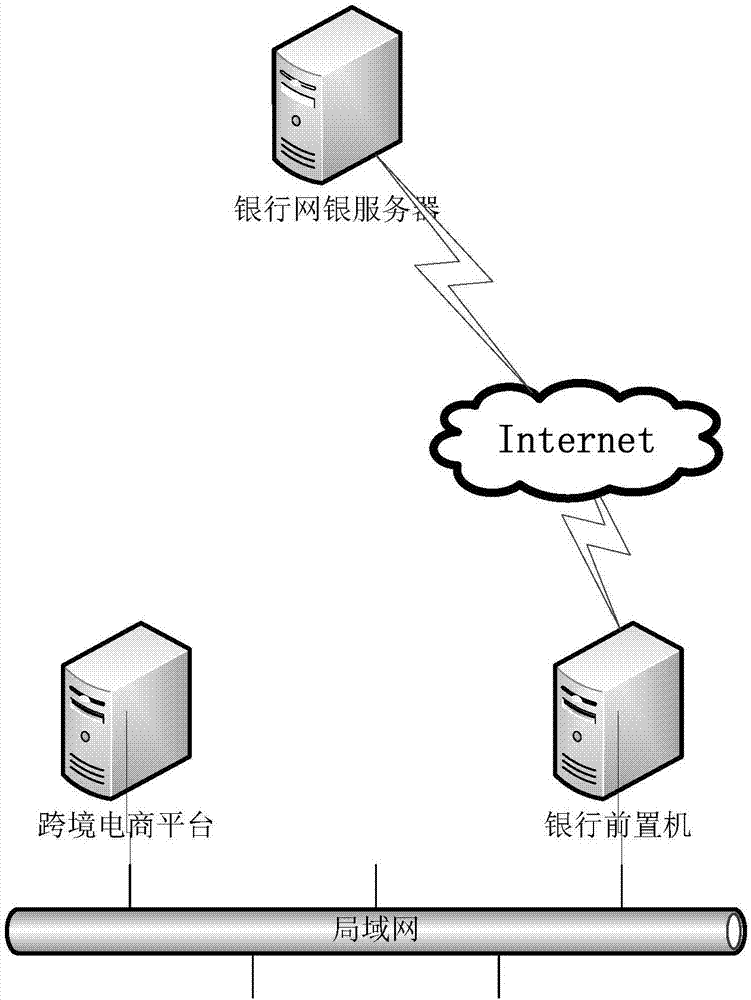

InactiveCN106897869AReduce artificial ginsengReduce process linksFinanceBuying/selling/leasing transactionsOperational costsBank account

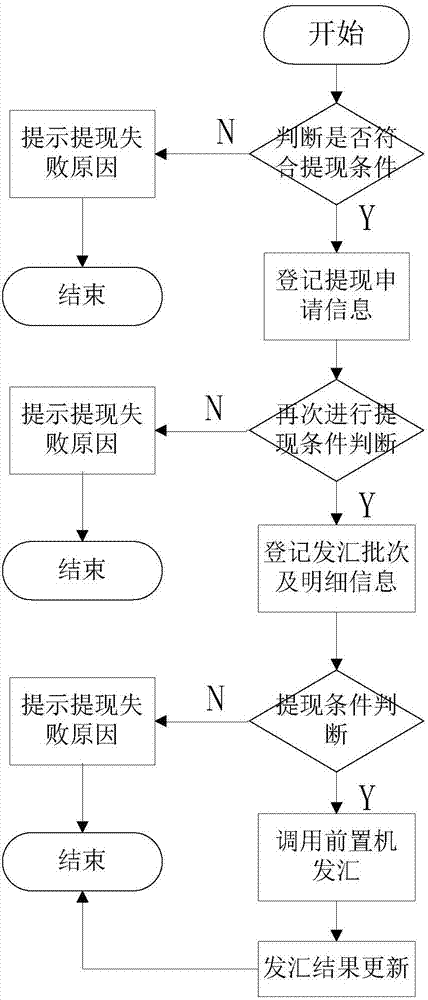

The present invention relates to a bank-corporate direct linkage method and system on a cross-border e-commerce platform. The method comprises that: the e-commerce platform receives the application for withdrawal and checks the application for withdrawal, and if the application for withdrawal meets the conditions of withdrawal, a bank-corporate direct linkage front-end processor is invoked by the e-commerce platform to remit to the application account; according to the total amount of remittances and the bank account balance, the financial operator carries out corresponding allocation of funds, clicks for checking after the corresponding allocation of funds is completed, and still carries out determination on the conditions of withdrawal; and for the records that pass the determination condition, the bank-corporate direct linkage front-end processor is invoked for issuing. According to the bank-corporate direct linkage method and system on the cross-border e-commerce platform disclosed by the present invention, in the process from generating the withdrawal data to registering the issuing batch, systematic processing is realized, steps of manual participation are reduced, and without uploading an issuing file to the e-bank, the financial operating costs are reduced and the operational risk is reduced.

Owner:数贸科技(北京)有限公司

Battery piece front side and back side detecting device and method

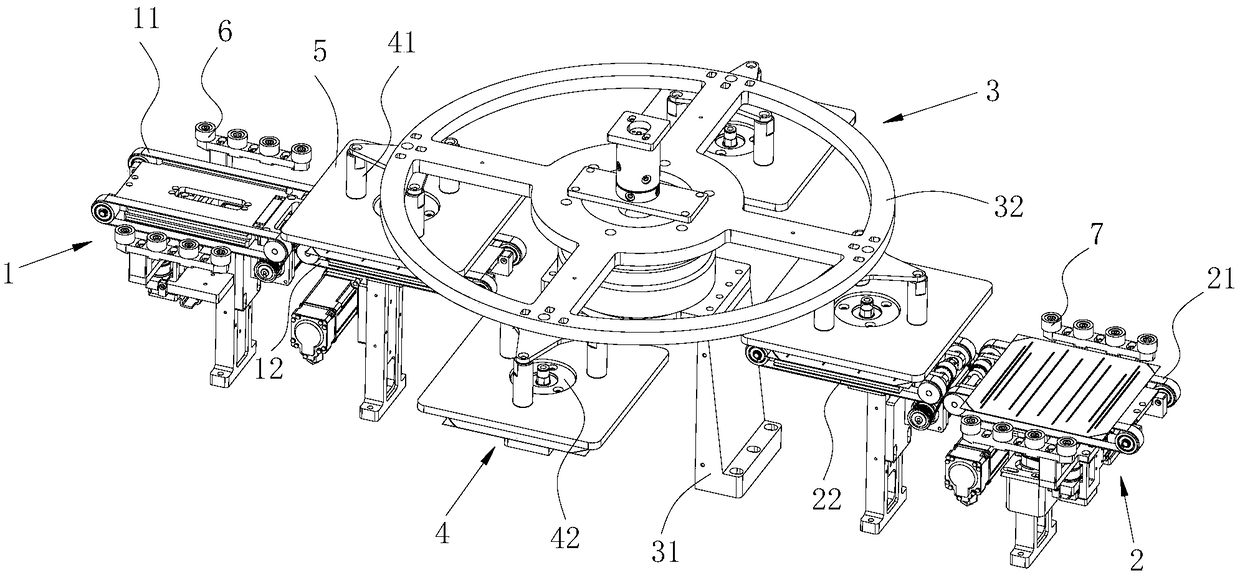

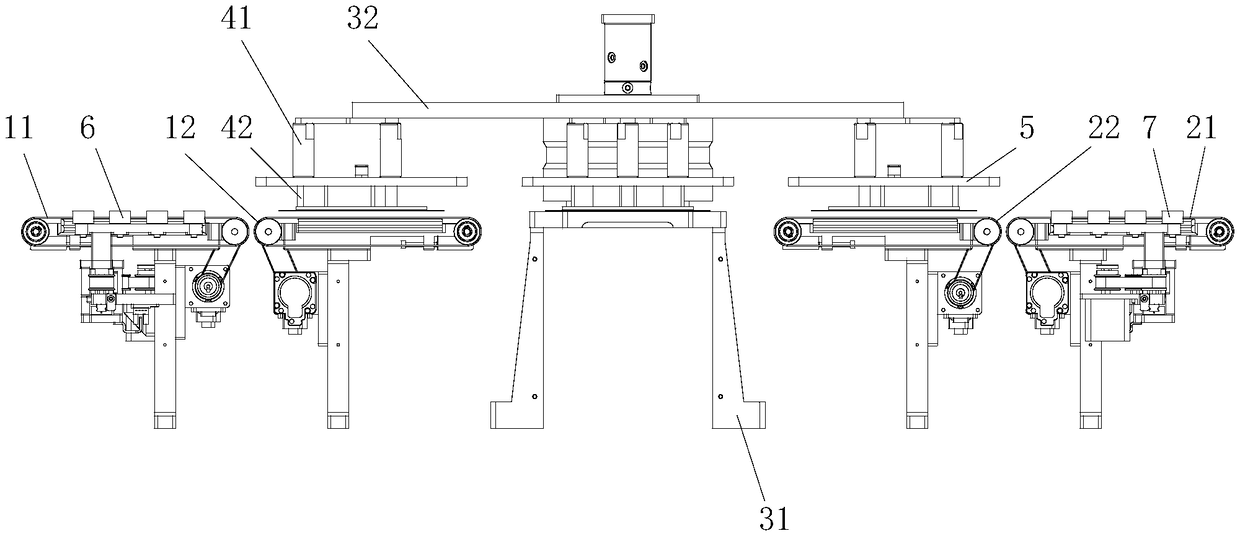

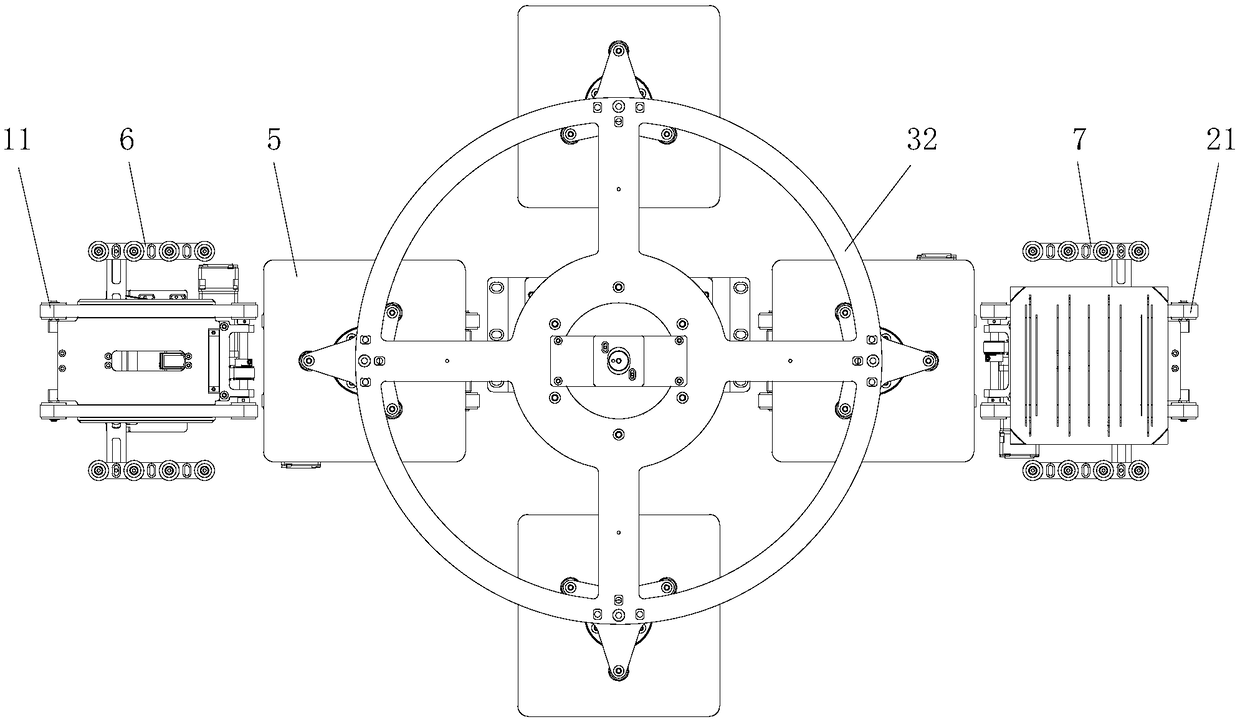

PendingCN108706336ASimple structureReduce artificial ginsengConveyorsConveyor partsEngineeringElectrical and Electronics engineering

The invention discloses a battery piece front side and back side detecting device and method. The detection device comprises conveying mechanisms, a front side detector and a back side detector, and further comprises a rotating table mechanism; the rotating table mechanism comprises a base and a rotating table rotationally arranged on the base; the rotating table mechanism is sequentially providedwith a feeding station, a detecting station and a discharging station in the circumferential direction of the rotating table mechanism; the rotating table is provided with a plurality of vacuum adsorbing mechanisms used for adsorbing battery pieces; the vacuum adsorbing mechanisms are arranged at intervals in the circumferential direction of rotation of the rotating table; the conveying mechanisms comprise a feeding conveying mechanism and a discharging conveying mechanism; the feeding conveying mechanism extends to the feeding station position of the rotating table mechanism; and the discharging conveying mechanism extends to the discharging station position of the rotating table mechanism. Due to the battery piece front side and back side detecting device, the detecting efficiency can be improved, and meanwhile frequent piece falling or breaking can also be reduced.

Owner:SUZHOU MAXWELL TECH CO LTD

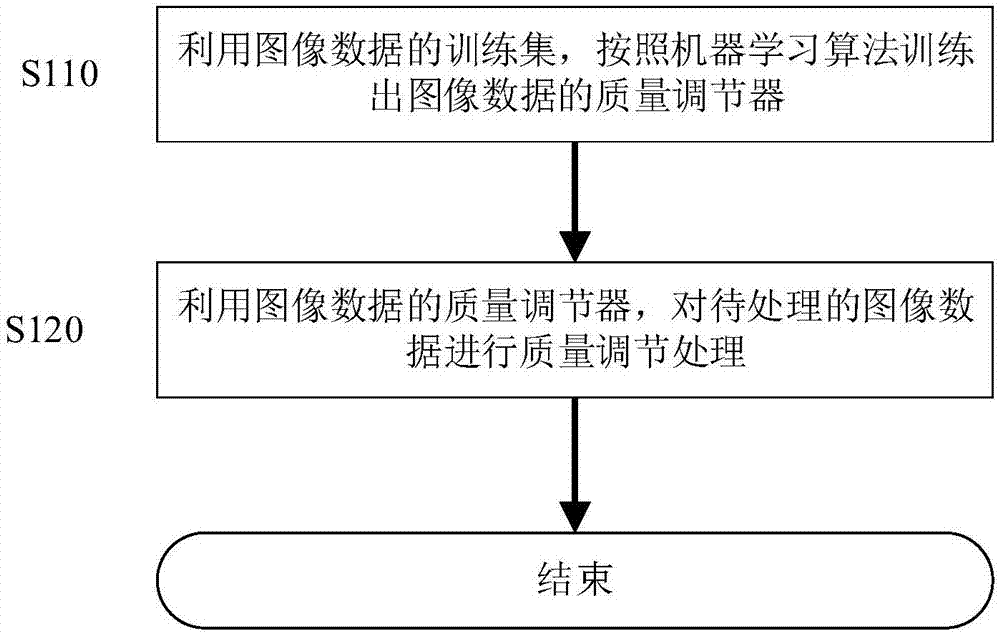

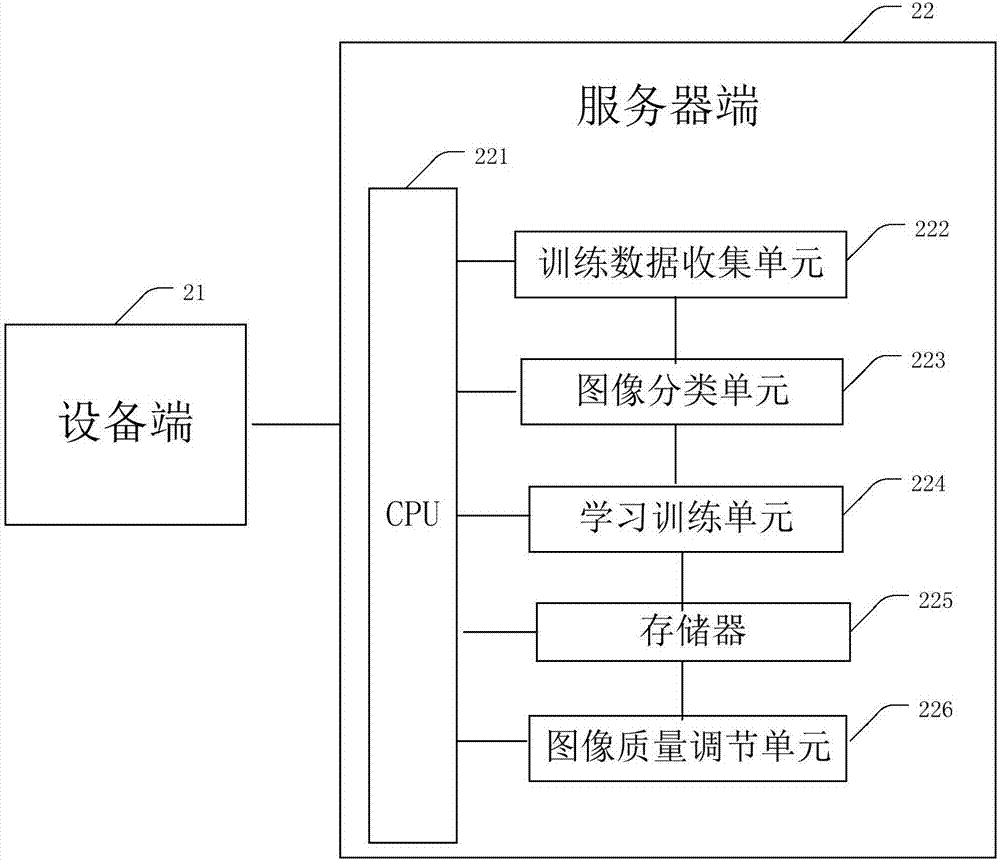

Image quality adjustment method and image processing intelligent platform

InactiveCN107341516AReduce artificial ginsengReduce jointsTelevision system detailsCharacter and pattern recognitionCommunication interfacePattern recognition

The invention provides an image quality adjustment method and an image processing intelligent platform. The image quality adjustment method comprises the steps of training a quality adjustor of image data based on image data by utilizing a machine learning algorithm; and carrying out quality adjustment processing for the to-be-processed image data by utilizing the quality adjustor of the image data. The image processing intelligent platform comprises a device end and a server end; the device end and the server end communicate with each other according to a given communication interface; the server end is provided with a CPU, a memory, a training data collection unit, an image classification unit, a learning training unit and an image quality adjustment unit. According to the image quality adjustment method and the image processing intelligent platform, image data in different shooting scenes can be subjected to quality adjustment automatically through the intelligent platform, the artificial participation links are reduced, and the image quality adjustment efficiency is improved.

Owner:GUANGDONG VIMICRO

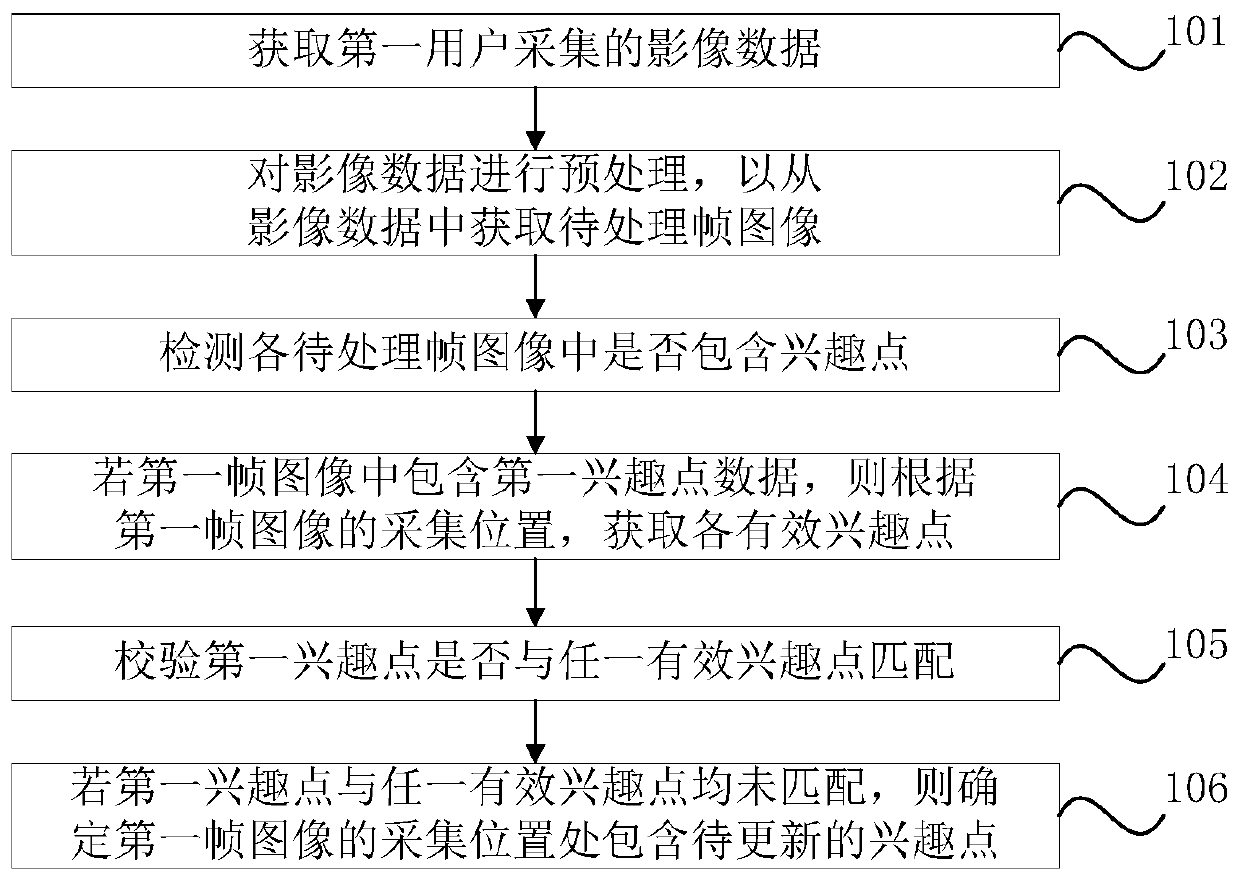

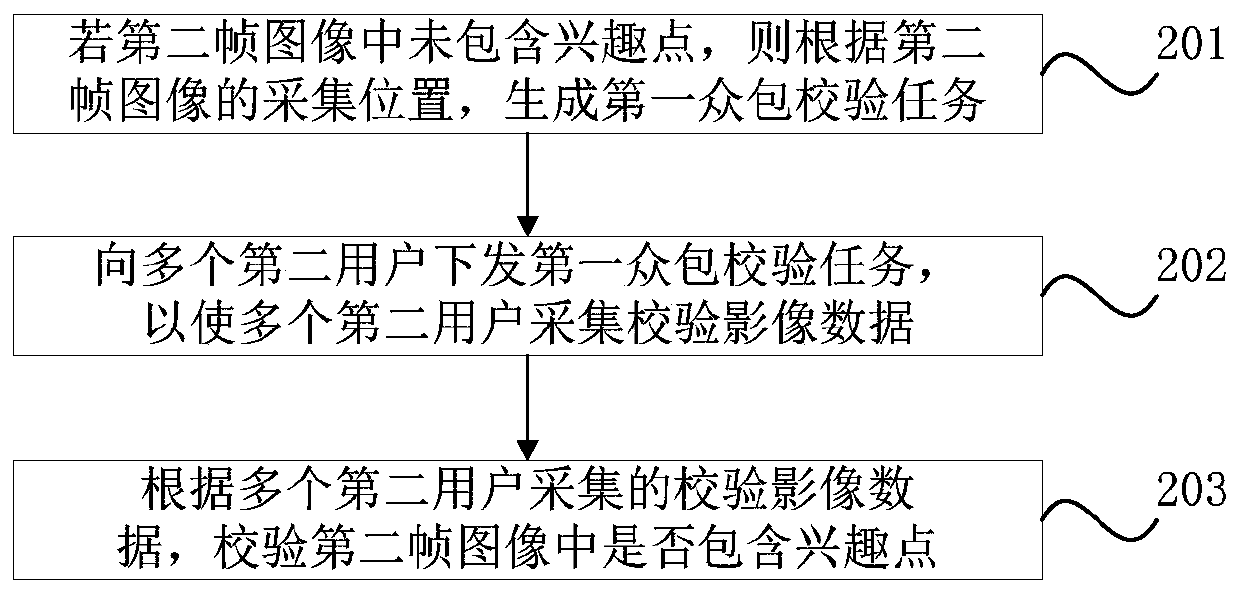

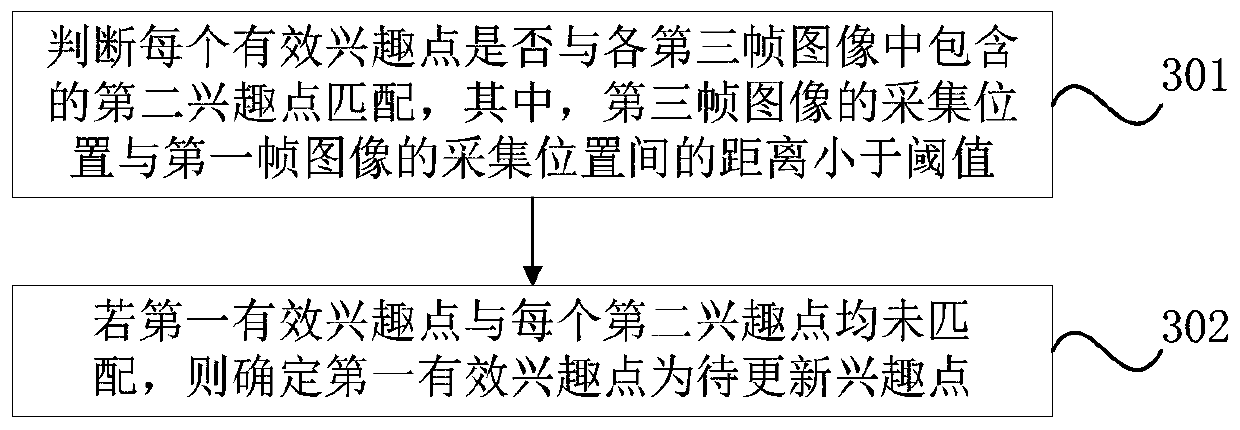

A map interest point processing method and device

InactiveCN109710705AImprove processing efficiencyAcquisition period is shortCharacter and pattern recognitionGeographical information databasesComputer visionImaging data

The invention provides a map interest point processing method and device, and the method comprises the steps: obtaining image data collected by a first user; preprocessing the image data to obtain a to-be-processed frame image from the image data; detecting whether each to-be-processed frame image contains an interest point or not; If the first frame of image contains the first interest point data, obtaining each effective interest point according to the collection position of the first frame of image; Verifying whether the first interest point is matched with any effective interest point or not; and if the first interest point is not matched with any effective interest point, determining that the collection position of the first frame image contains a to-be-updated interest point. According to the method, the processing efficiency can be improved, the acquisition period of the interest point data is shortened, and the acquisition cost is saved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

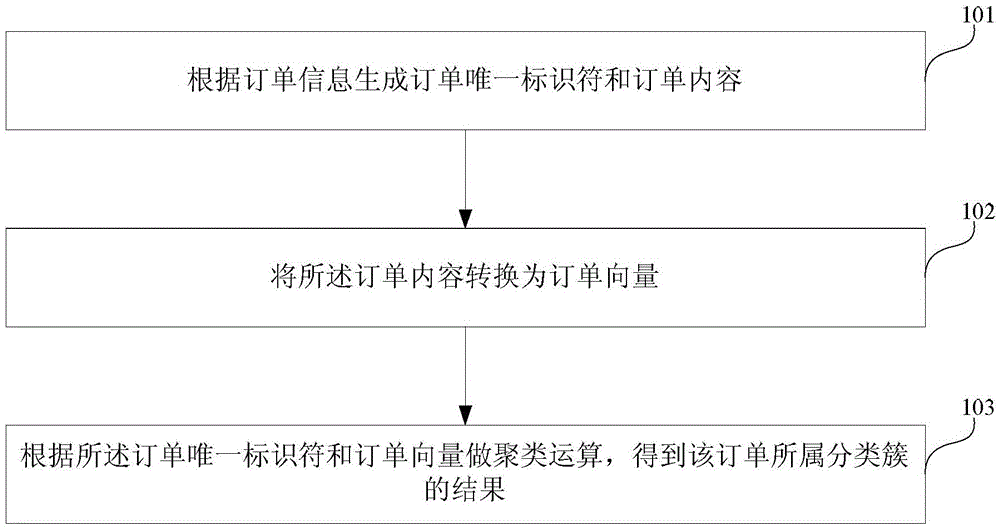

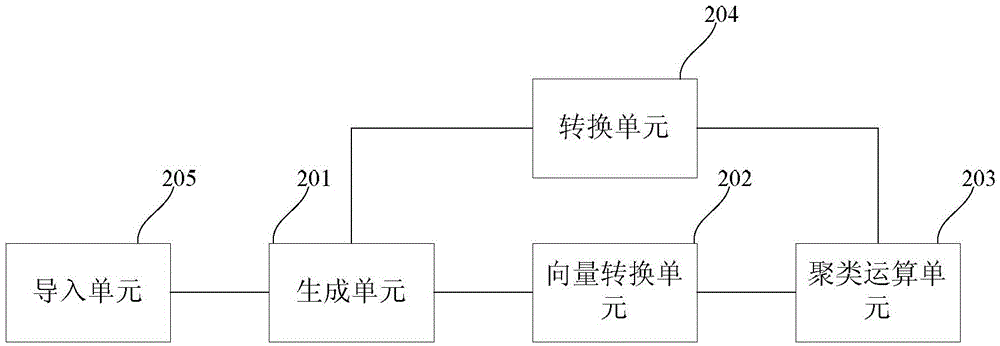

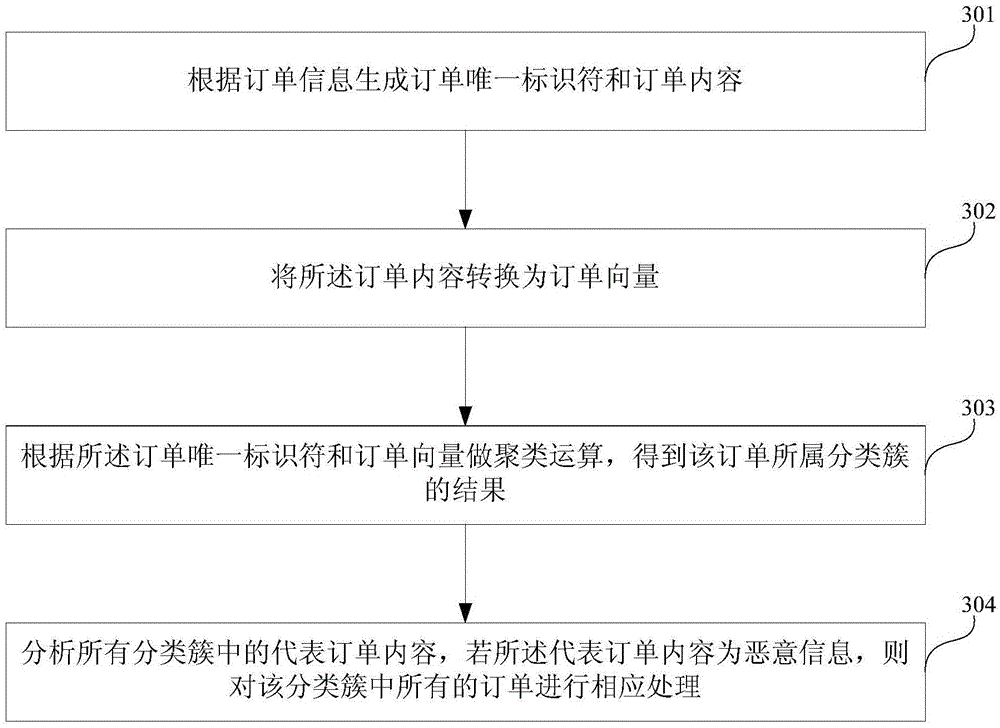

Order clustering method and apparatus thereof, and anti-malicious information method and apparatus thereof

InactiveCN106709777AReduce artificial ginsengDegree of reductionBuying/selling/leasing transactionsTransmissionOrder formContent analytics

The invention relates to the network communication technology field and especially relates to an order clustering method and an apparatus thereof, and an anti-malicious information method and an apparatus thereof. The clustering method comprises the following steps of according to order information, generating an only order identifier and an order content; converting the order content into an order vector; and according to the only order identifier and the order vector, carrying out clustering operation so as to acquire a result of a classified cluster which an order belongs to. After the above clustering, according to the order content in the classified cluster, whether the classified cluster is the classified cluster of malicious information can be detected. And if the classified cluster is the classified cluster of malicious information, all the orders in the whole classified cluster are processed correspondingly. Through the methods and the apparatuses of the invention, the orders of an electronic transaction can be automatically classified; according to real-time contents of the orders, a new classification can be analyzed and acquired; and all the orders in the whole classified cluster can be uniformly processed for one time and anti-malicious information efficiency is increased.

Owner:ADVANCED NEW TECH CO LTD

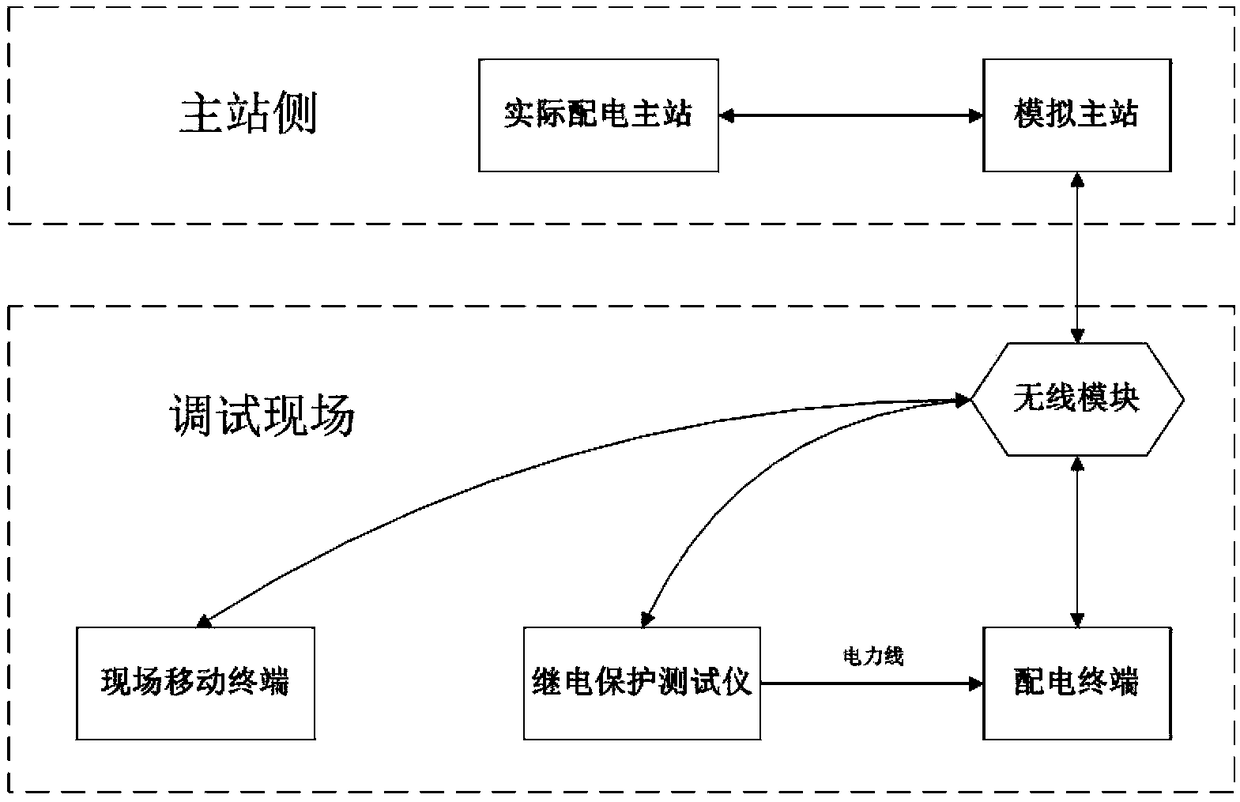

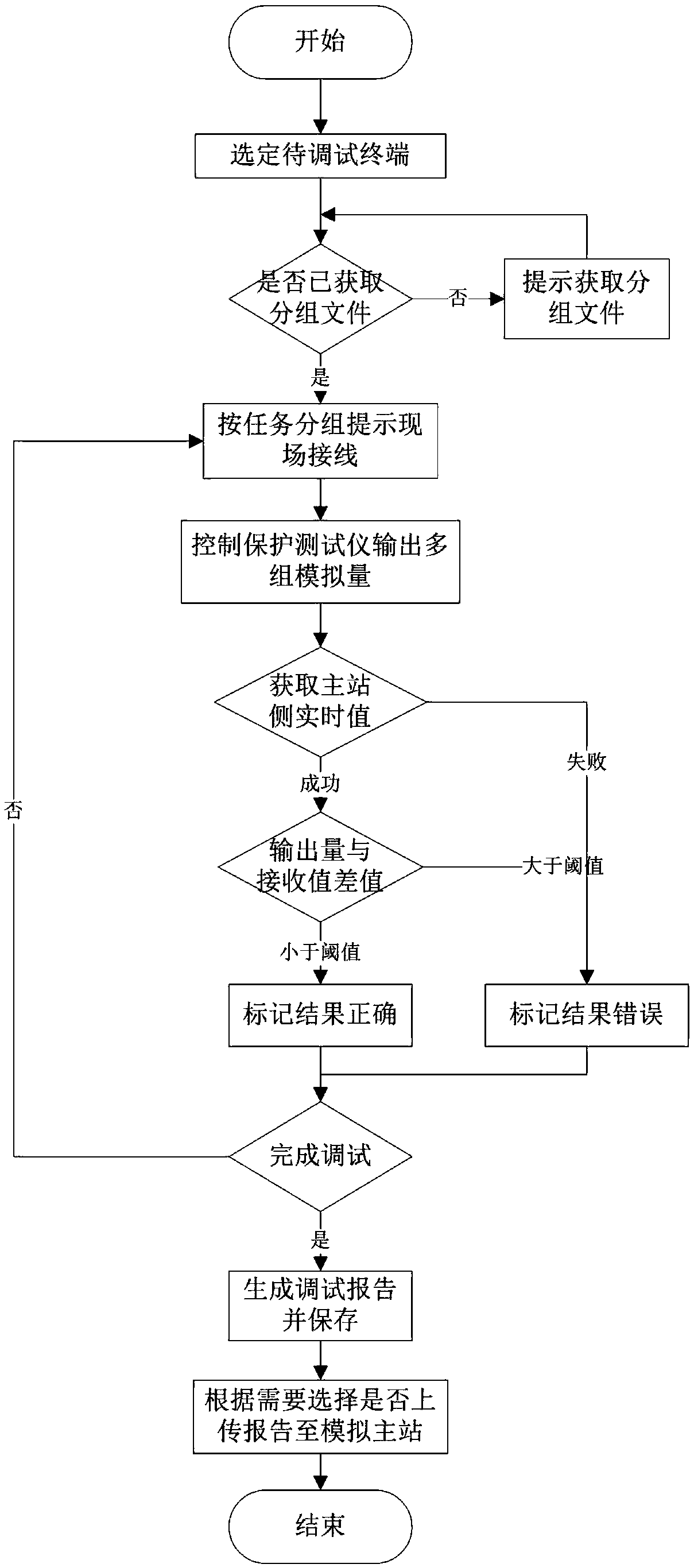

Power distribution terminal side automatic debugging method based on field mobile terminal and analog main station

ActiveCN109444582AImprove work efficiencyFlexible commissioning sequenceElectrical testingData switching networksTest powerPrimary station

The invention relates to a power distribution terminal side automatic debugging method based on a field mobile terminal and an analog main station. The method comprises the steps of 1, building a power distribution terminal side automatic debugging system; 2, acquiring a sequence table transmitted from the power distribution terminal by the analog main station from a three-area pre-database of a power distribution automatic system, and grouping each sequence table by the analog main station; 3, establishing an HTTP connection by the field mobile terminal to the analog main station, and acquiring the power distribution terminal grouping sequence table of an affiliated administrated area according to an authority distribution rule; 4, performing communication between the field mobile terminal and a relay protecting tester; 5, setting the initial value of the automatic debugging parameter of the power distribution terminal by the field mobile terminal; and 6, selecting the to-be-tested power distribution terminal, and starting independent automatic debugging at the power distribution terminal side. The power distribution terminal side automatic debugging method has advantages of no requirement for actual power distribution main station side artificial cooperation, high working efficiency, flexible debugging sequence and high debugging accuracy. A debugging result is automaticallygenerated and a debugging report can be conveniently checked. The system can be carried with personnel for reducing load of the personnel, thereby further improving working efficiency.

Owner:INTEGRATED ELECTRONICS SYST LAB

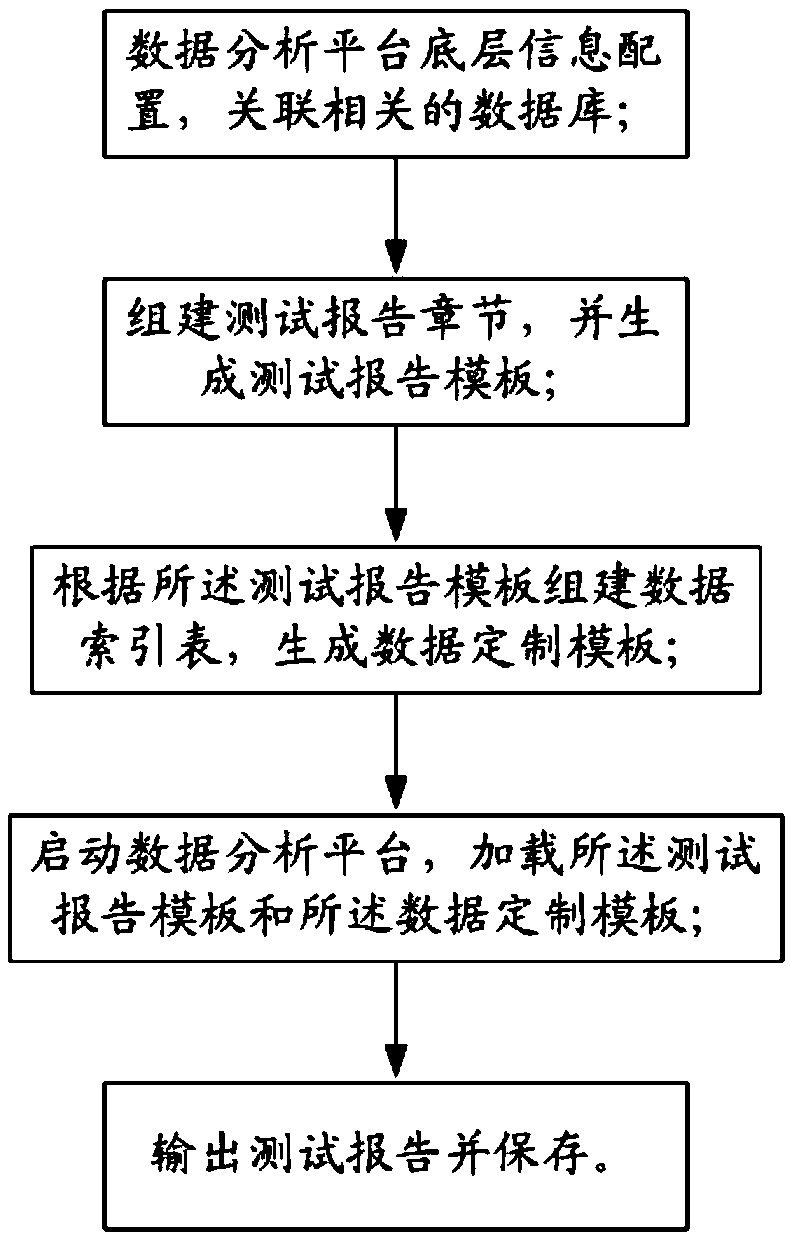

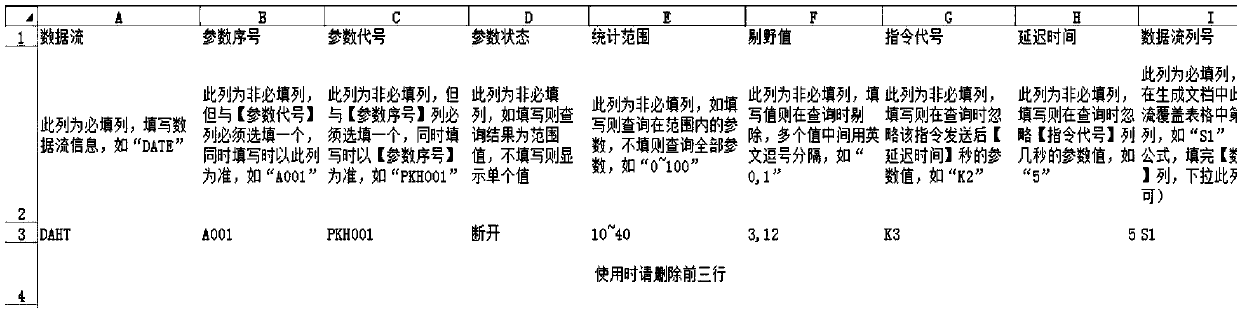

Spacecraft test report automatic generation method based on a data analysis platform

ActiveCN109657224AReduce usageImprove work efficiencyText processingSpecial data processing applicationsSoftware engineeringData profiling

The invention relates to a spacecraft test report automatic generation method based on a data analysis platform, and the method comprises the following steps: a, carrying out the configuration of bottom layer information of the data analysis platform, and associating a related database; B, establishing test report chapters, and generating a test report template; C, establishing a data index tableaccording to the test report template, and generating a data customization template; D, starting a data analysis platform, and loading the test report template and the data customization template; Ande, outputting and storing the test report. According to the spacecraft test report automatic generation method based on the data analysis platform, the working efficiency of testers is greatly improved, and the progress of model development work is effectively promoted.

Owner:BEIJING SPACE TECH RES & TEST CENT

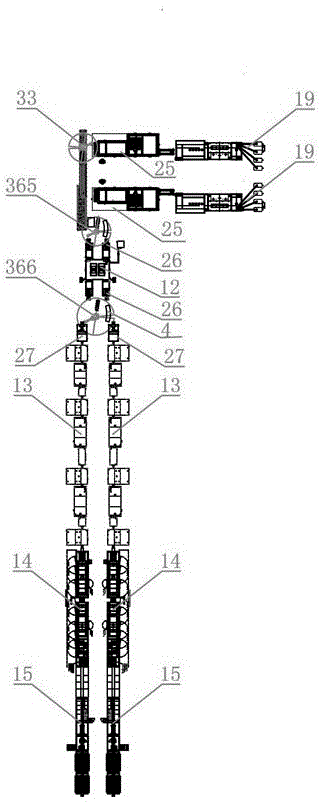

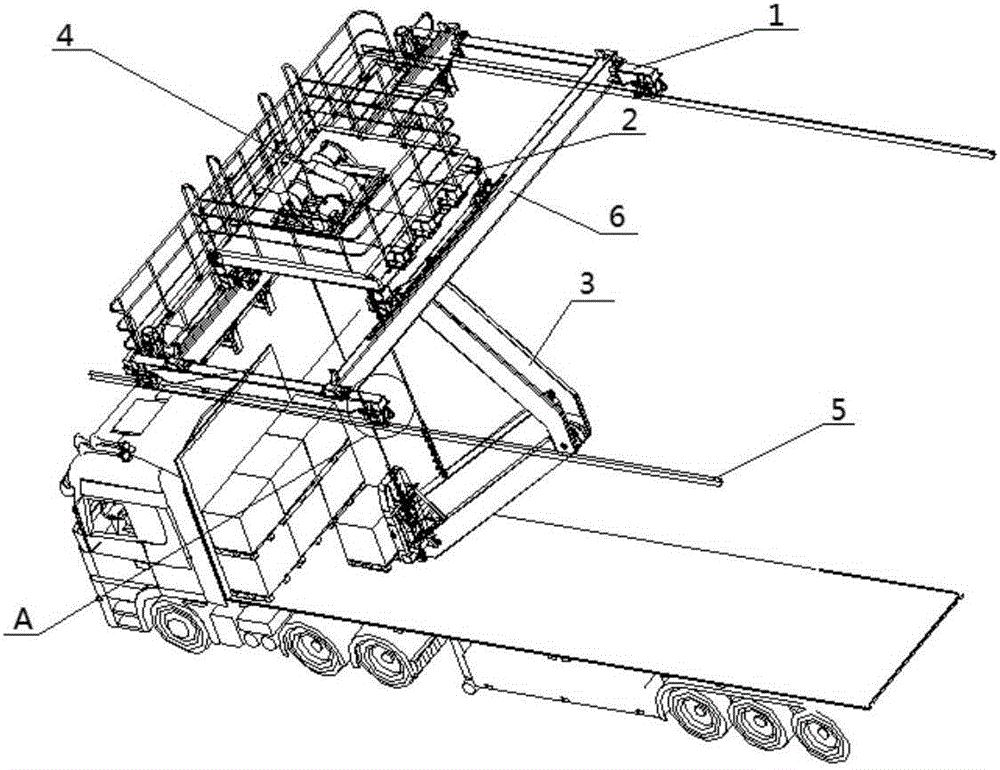

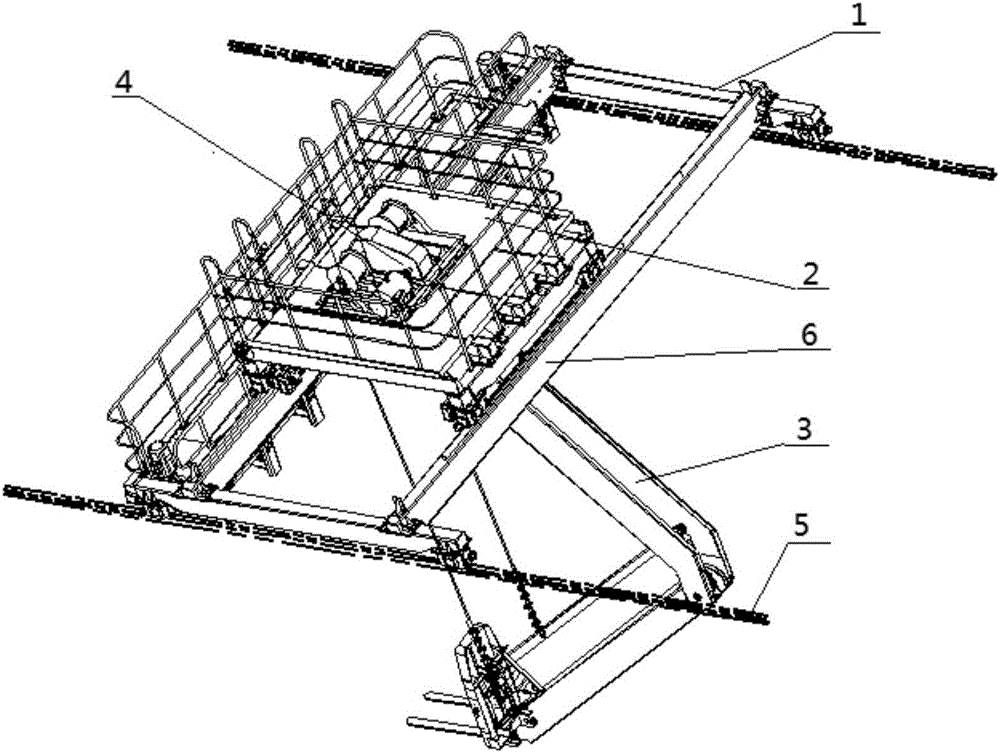

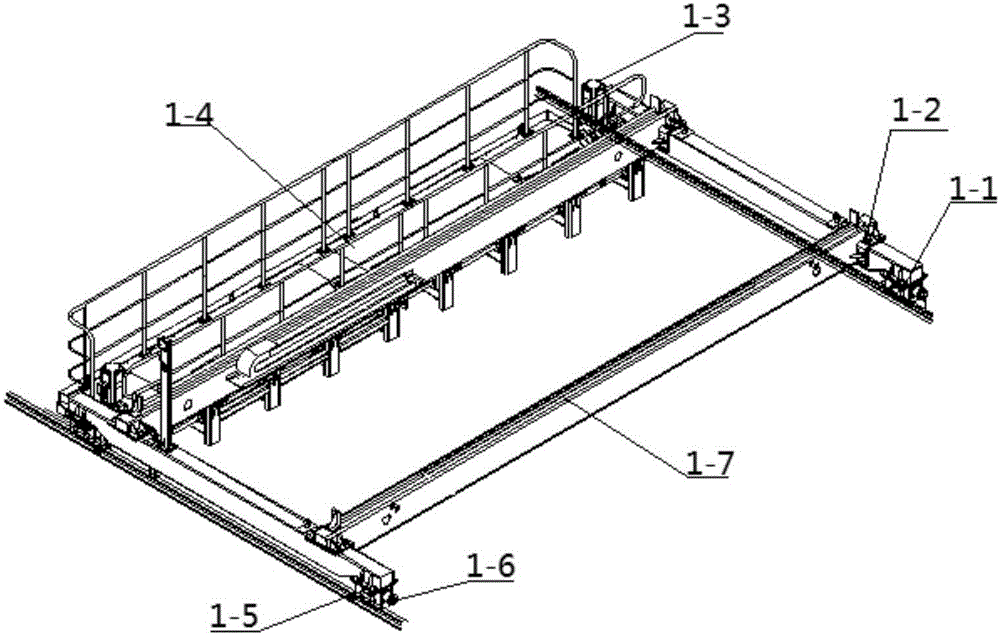

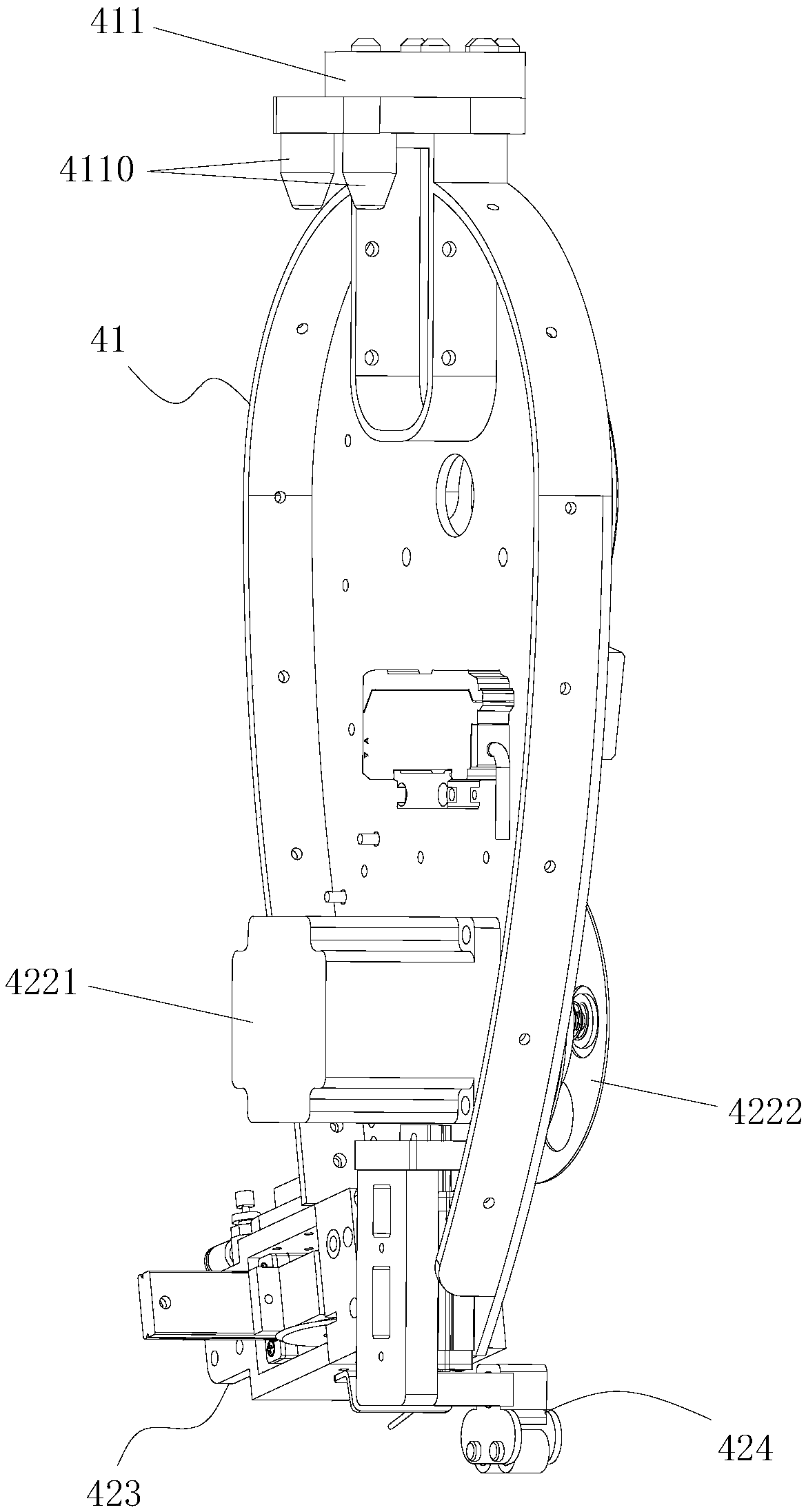

Full automatic loader

The invention relates to a full automatic loader and belongs to the technical field of carrying devices for materials in bags or cases. The full automatic loader comprises a track mobile cart, a lifting device, a cart guide rail, a trolley guide rail, a track mobile trolley and a mechanical arm. The track mobile trolley is mounted on the track mobile cart, the mechanical arm is mounted at the lower end of the track mobile trolley, both the track mobile cart and the track mobile trolley are wheel type walking mechanisms, and two of four walking wheels are driven by two variable frequency motors, so that the track mobile cart and the track mobile trolley move forward and backward; the mechanism arm can be stopped in any a position, so that intelligent car finding and locating can be realized. The mechanical arm is of a sectional parallel four-connecting rod structure and a driving power source is on the track mobile trolley, so that a fork on the mechanical arm moves along a certain track, and the fork is still maintained in a horizontal state; the position of the mechanical arm is more accurate, so that materials are loaded in integral bags or stacks.

Owner:HARBIN BOSHI AUTOMATION

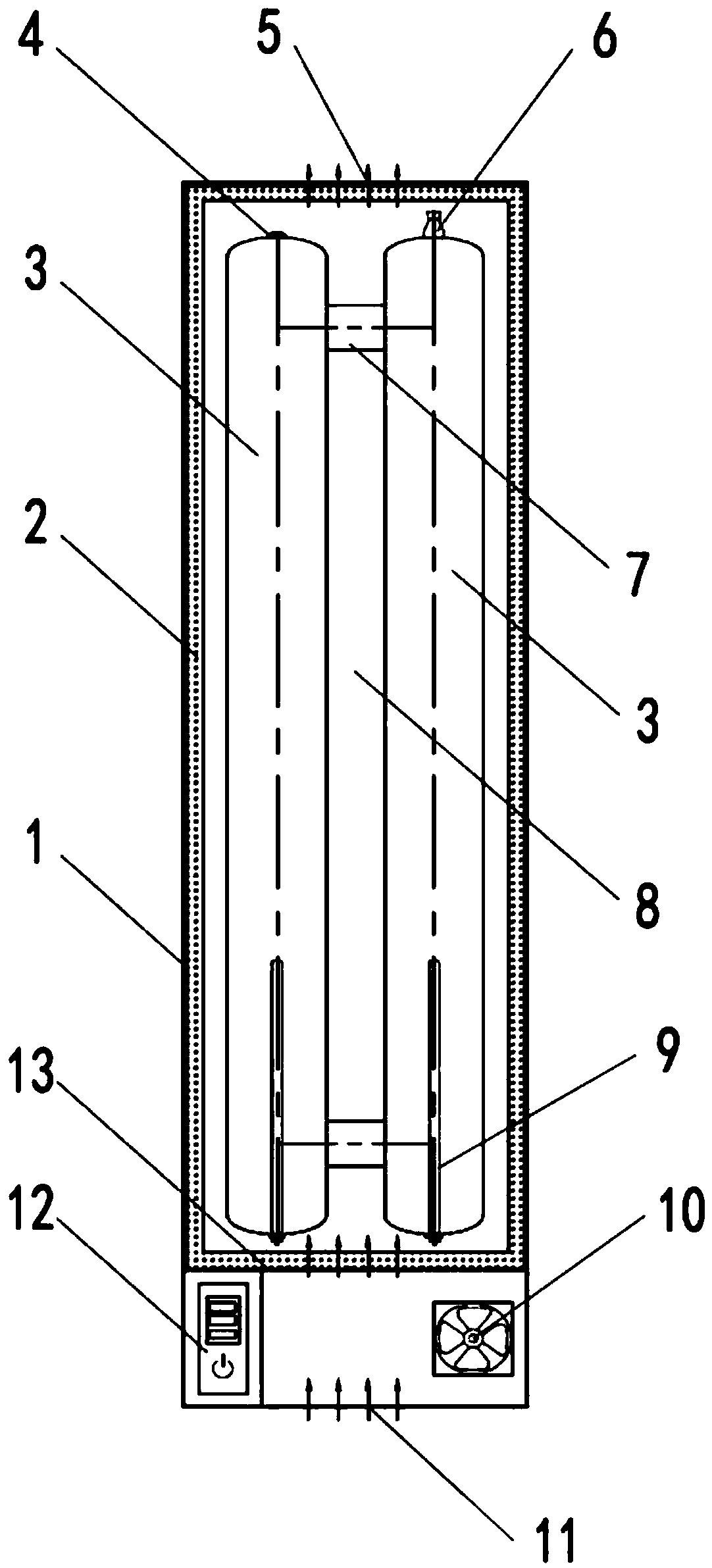

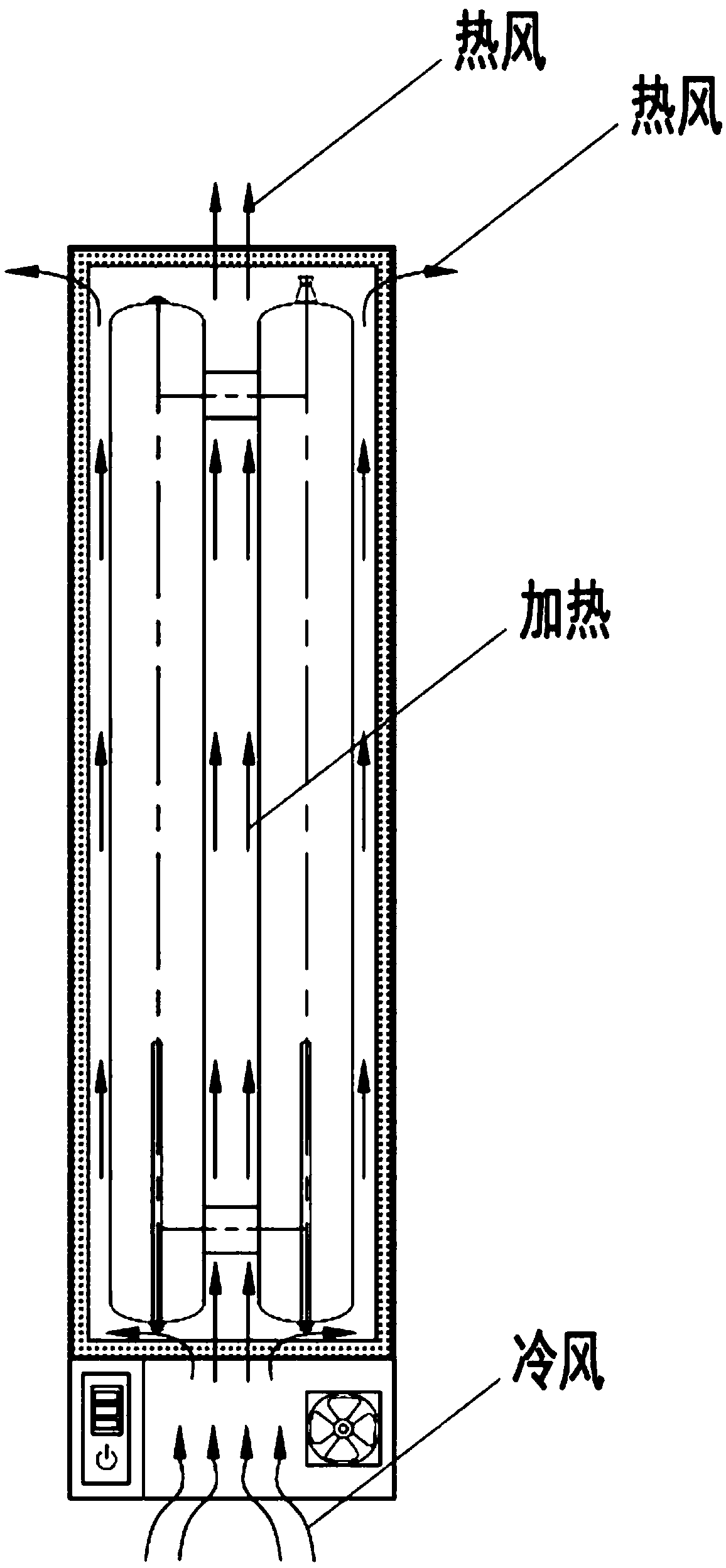

Water heat storage type electric heater

PendingCN109539360AHigh degree of automationReduce artificial ginsengCentral heating with accumulated heatLighting and heating apparatusElectricityCold air

The invention relates to a water heat storage type electric heater. The water heat storage type electric heater comprises a housing; the housing is divided into an upper housing part and a lower housing part; a heat insulating material and a water heat storing body are arranged inside the upper housing part; the heat insulating material clings to the inner wall of the housing; the water heat storing body is filled with a specific amount of a water heat storing medium and is internally provided with an electric heating tube; a circulating fan and an electric control component are arranged inside the lower housing part; the electric heating tube and the circulating fan are both connected with the electric control component; the upper part and / or the side of the upper part of the housing are / is provided with hot air discharging grids; and the bottom and / or the side of the housing are / is provided with cold air charging grids. The air discharging grids are used for sending cold air which passes through an air channel to an external space after the cold air is heated by the water heat storing body. The water heat storage type electric heater provided by the invention has the beneficial effects that off-peak electricity is adopted for supplying heat in order to reduce the heating fee and balance the load of a power grid; and the water heat storage type electric heater is small in size, convenient to install, environmentally friendly, simple and convenient to operate, low in maintenance cost and low in manufacturing cost.

Owner:BEIJING ZETA ENERGY TECH CO LTD

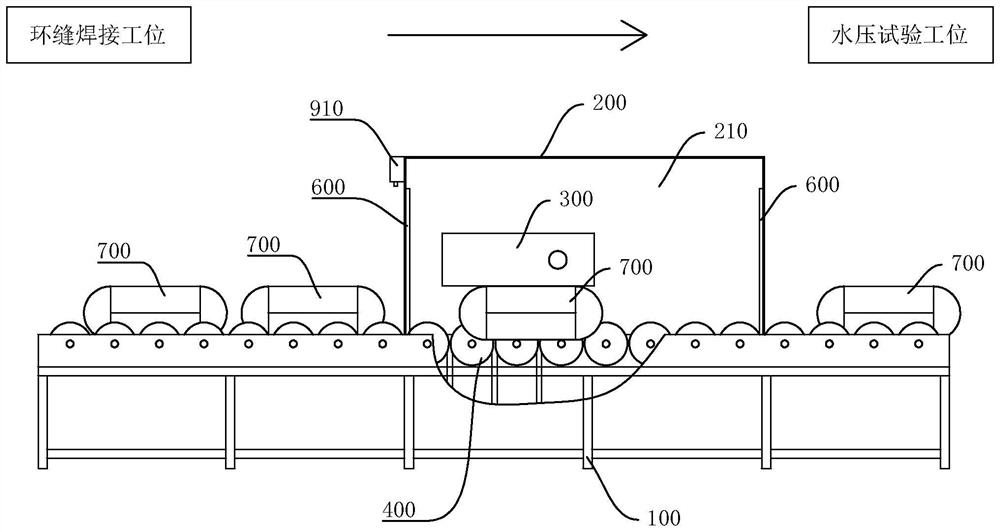

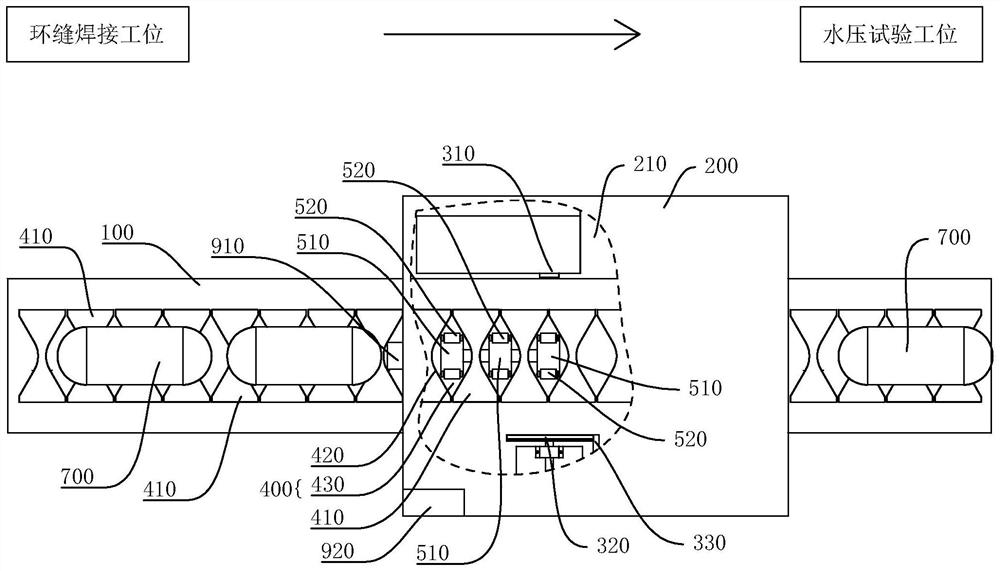

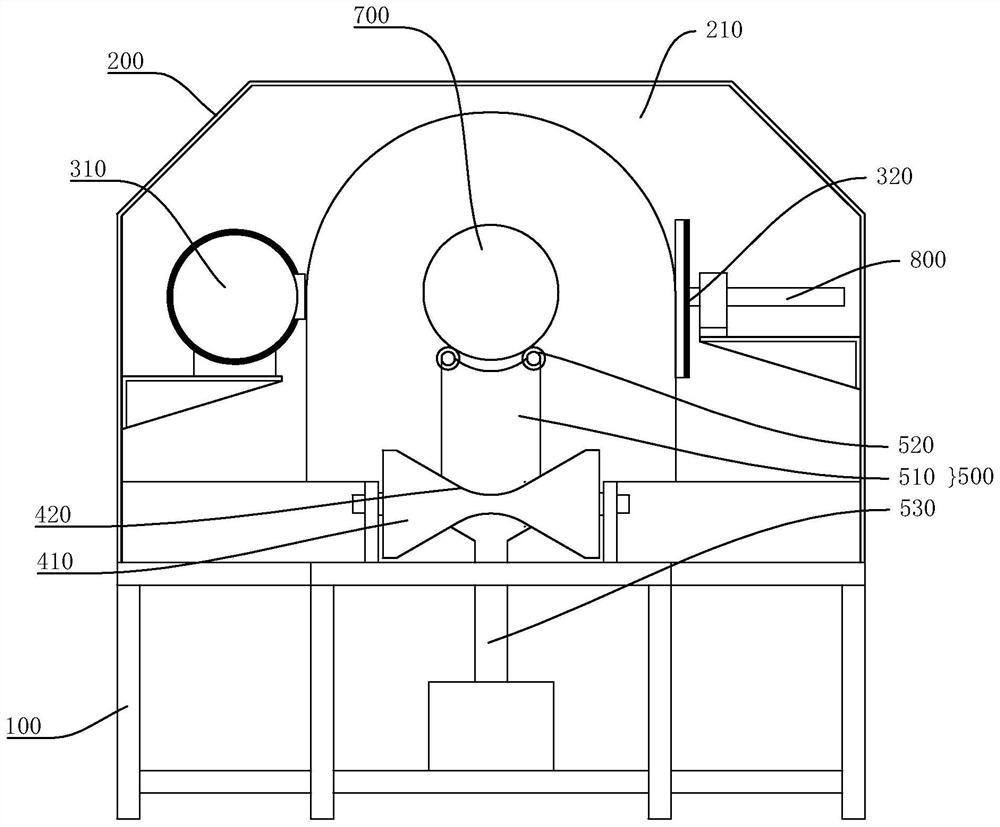

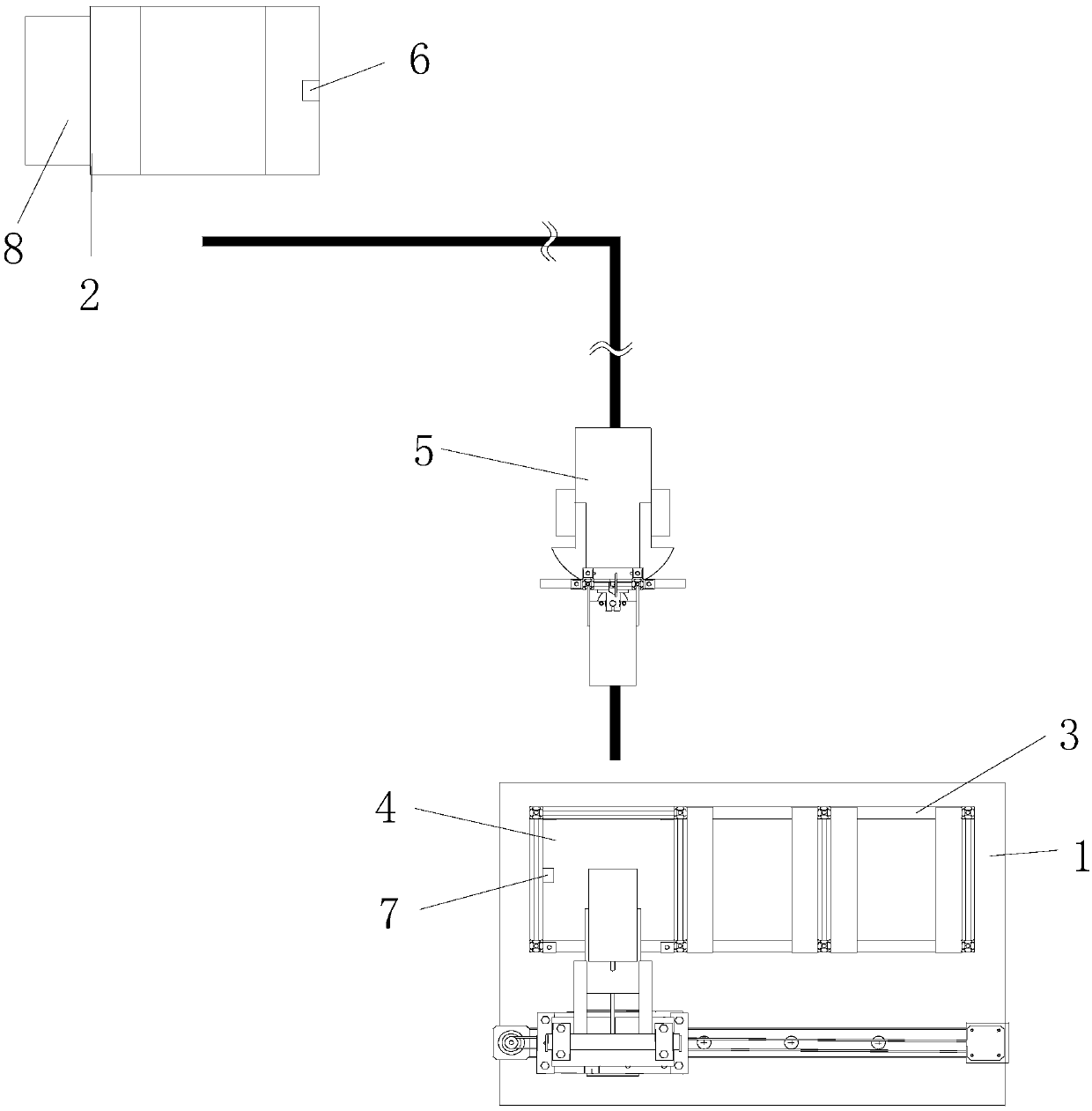

Container flaw detection device and container production technology

PendingCN114062400AReduce labor intensityEnsure safetyMaterial strength using tensile/compressive forcesDomestic vesselsInformation controlStructural engineering

The invention discloses a container flaw detection device and a container production technology. The container flaw detection device comprises a base frame, a shielding shell internally provided with a flaw detection cavity, a flaw detection module, a conveying mechanism, a form positioning detection component, a deflection adjusting mechanism, an identification mechanism and a control module, the shielding shell is provided with an opening communicated with the flaw detection cavity, the flaw detection module is arranged on the base frame and located in the flaw detection cavity, the flaw detection module can detect different containers to be detected, part of the transmission mechanism is arranged in the flaw detection cavity through the opening, the transmission mechanism can transmit a to-be-detected container to get in and out of the flaw detection cavity, the form positioning detection component is used for obtaining welding seam position information of the to-be-detected container, the deflection adjusting mechanism can drive the to-be-detected container to rotate, and the control module is connected with the form positioning detection component, the transmission mechanism and the deflection adjusting mechanism so as to control the transmission mechanism and the deflection adjusting mechanism to operate according to the welding seam position information of the to-be-detected container. The flaw detection efficiency can be improved, and the safety of a user is guaranteed.

Owner:ZHONGSHAN POLYTECHNIC

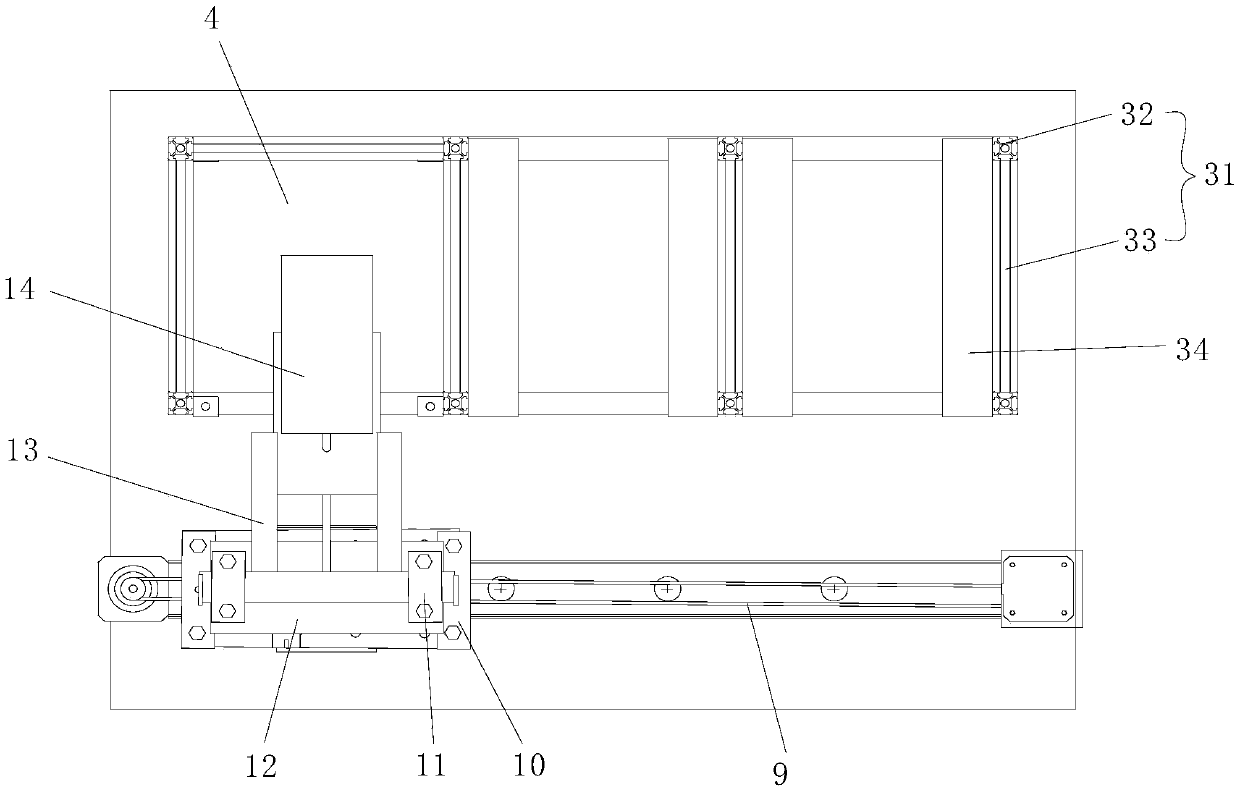

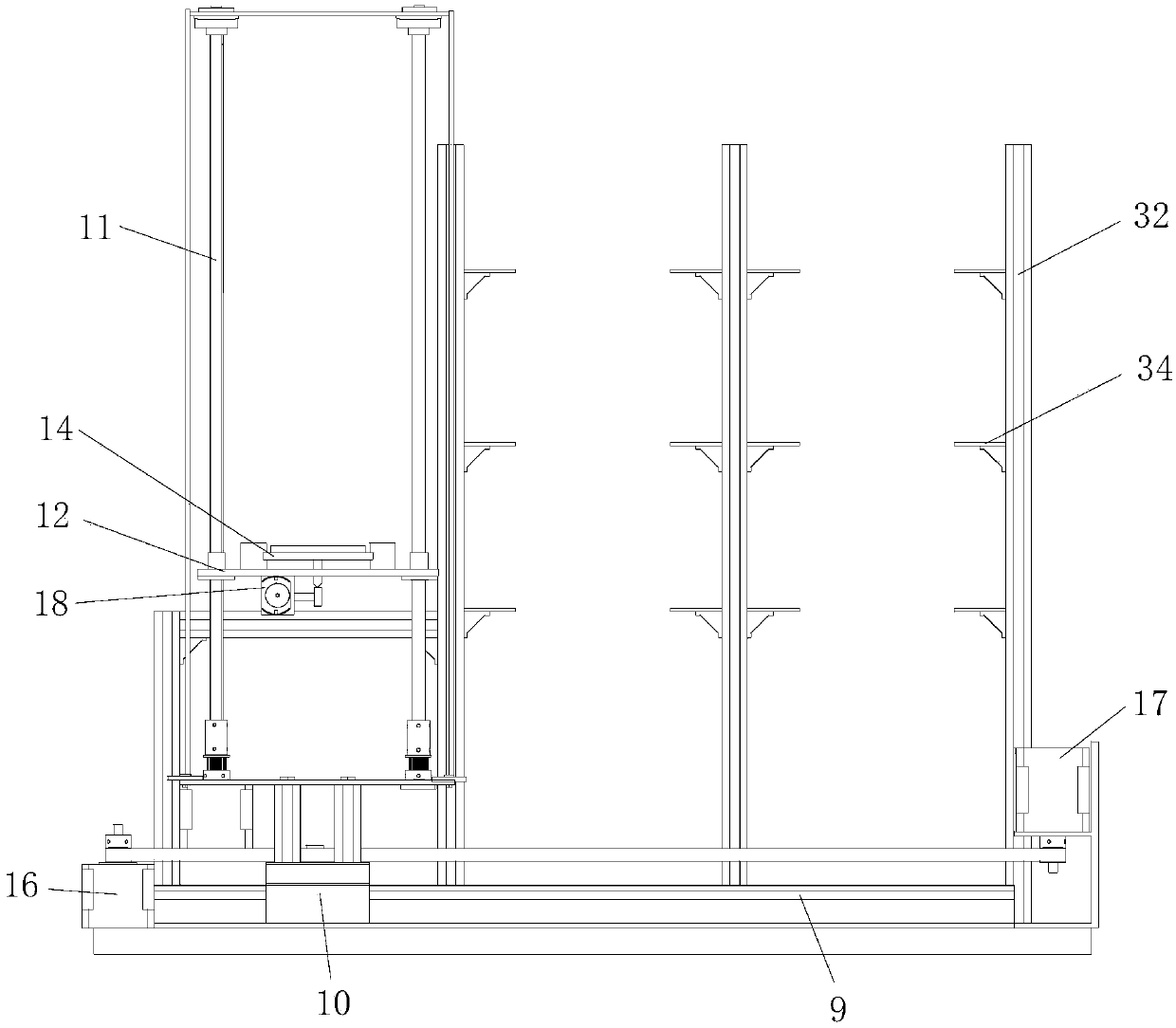

Intelligent logistics transiting system and control method thereof

PendingCN109533765AIncrease transit speedReduce artificial ginsengConveyorsControl devices for conveyorsLogistics managementEngineering

The invention discloses an intelligent logistics transiting system. The intelligent logistics transiting system comprises a three-dimensional warehouse and an express-item delivering opening, whereinthe three-dimensional warehouse is provided with multiple layers of shelves, and a carrying table and a warehouse delivering mechanism for delivering the carrying table to a specified shelf position are arranged nearby the shelves; an unmanned vehicle for delivering express items is also arranged between the three-dimensional warehouse and the express-item delivering opening, a first infrared inductor is arranged at the express-item delivering opening, and a second infrared inductor is arranged at the carrying table; the intelligent logistics transiting system also comprises a control module,and the control module is in circuit connection with the first infrared inductor, the second infrared inductor and the warehouse delivering mechanism, and is in wireless connection with the unmanned vehicle. By means of the intelligent logistics transiting system, the express items can be intelligently signed and collected and are distributed to a next level city as required, the whole logistics transiting speed is increased, and labor is also saved. The invention also discloses a control method of the intelligent logistics transiting system.

Owner:WUZHOU UNIV

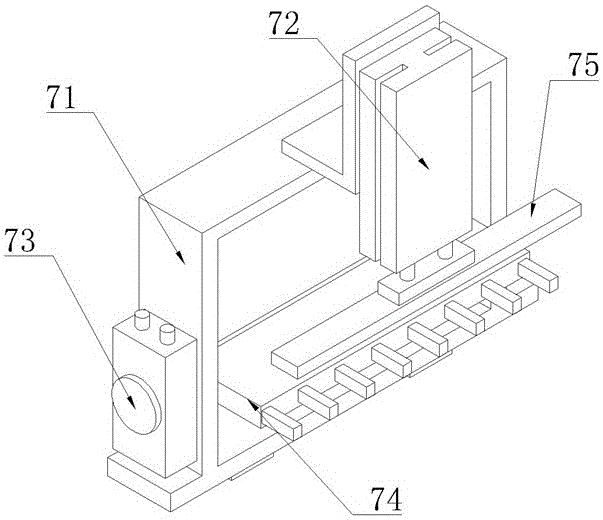

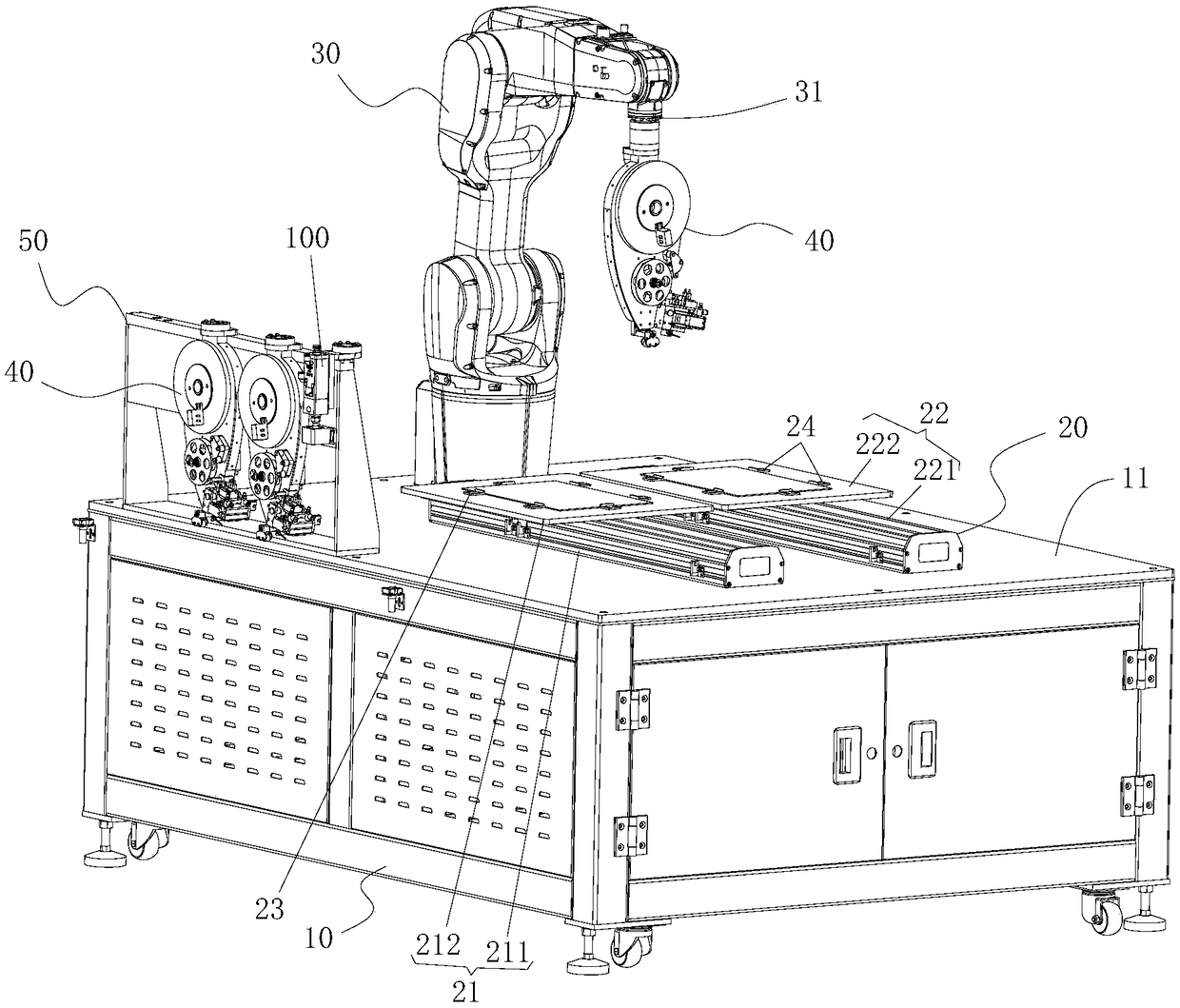

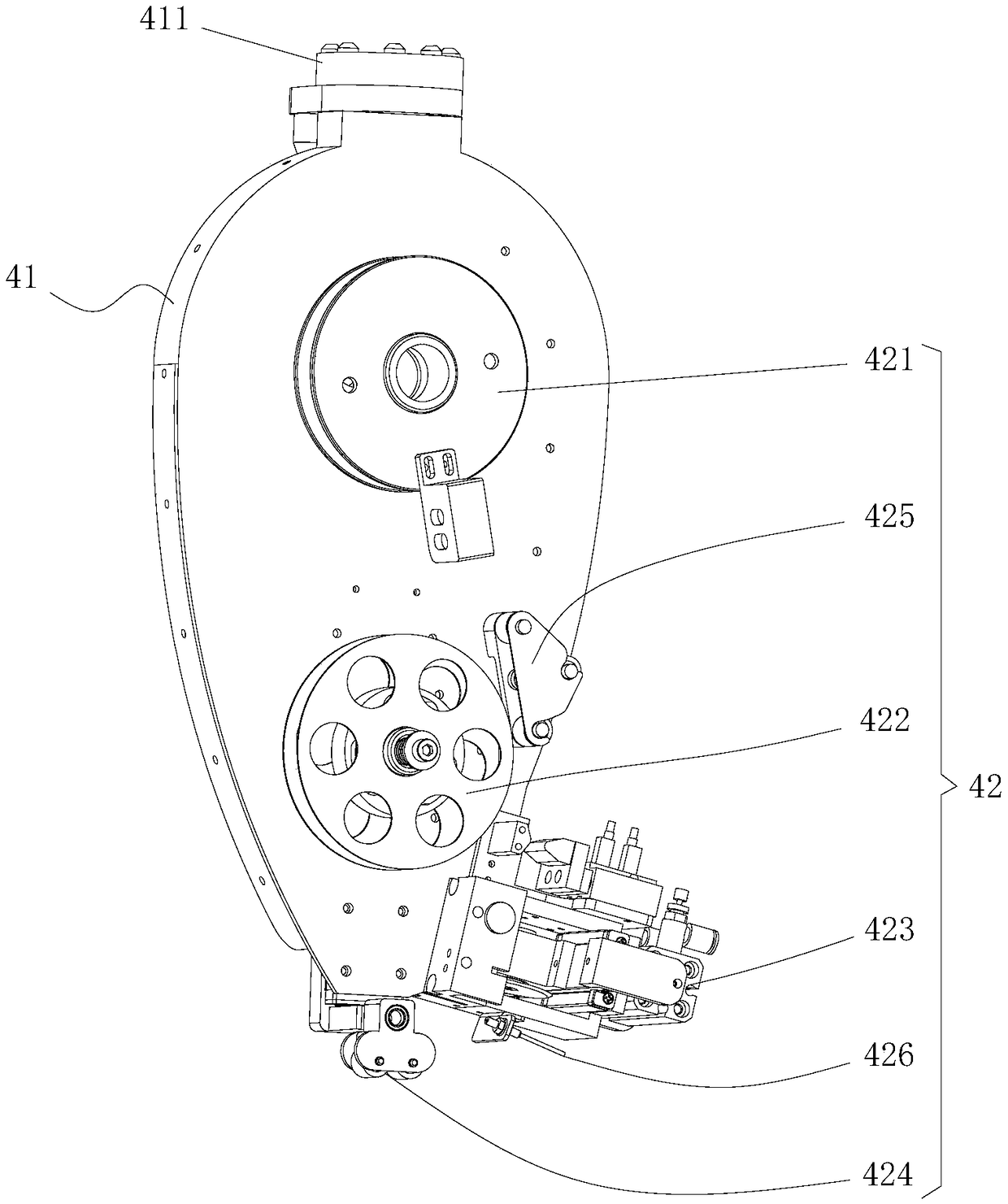

Automatic double-sided adhesive tape pasting equipment

PendingCN108975039AImprove work efficiencyReduce artificial ginsengArticle deliveryEngineeringProduction quality

The invention provides automatic double-sided adhesive tape pasting equipment. The automatic double-sided adhesive tape pasting equipment comprises a controller, a table frame, a workpiece clamp, a mechanical arm and an adhesive tape pasting mechanism. The table frame is provided with a working table face. The workpiece clamp is arranged on the working table face and electrically connected with the controller. A workpiece on which double-sided adhesive tape is to be pasted is clamped on the workpiece clamp. The mechanical arm is arranged on the working table face, electrically connected with the controller, and provided with a grabbing head extending to a position above the workpiece clamp. The adhesive tape pasting mechanism comprises a mounting frame and an adhesive tape pasting component, wherein the adhesive tape pasting component is mounted on the mounting frame. The mounting frame is provided with a connecting part. The grabbing head grabs and is connected with the connecting part, and then the adhesive tape pasting component is electrically connected with the controller. According to the technical scheme, the problems that double-sided adhesive tape is poor in production efficiency and the production quality is poor when the double-sided adhesive tape is pasted on products in the prior art can be solved.

Owner:深圳市世椿机器人有限公司

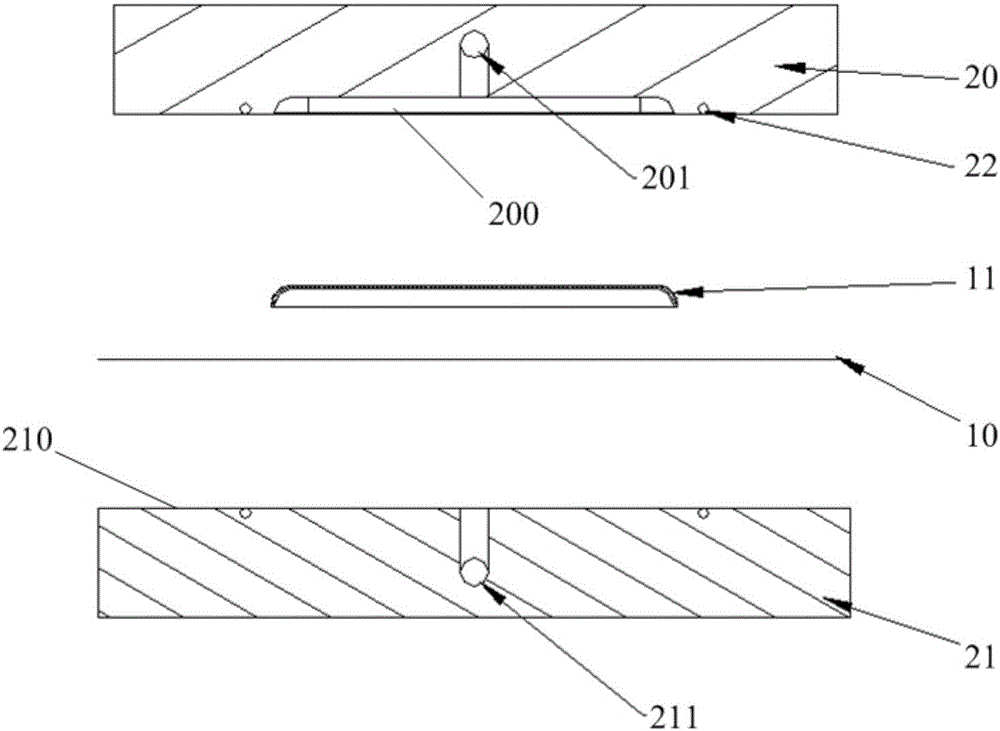

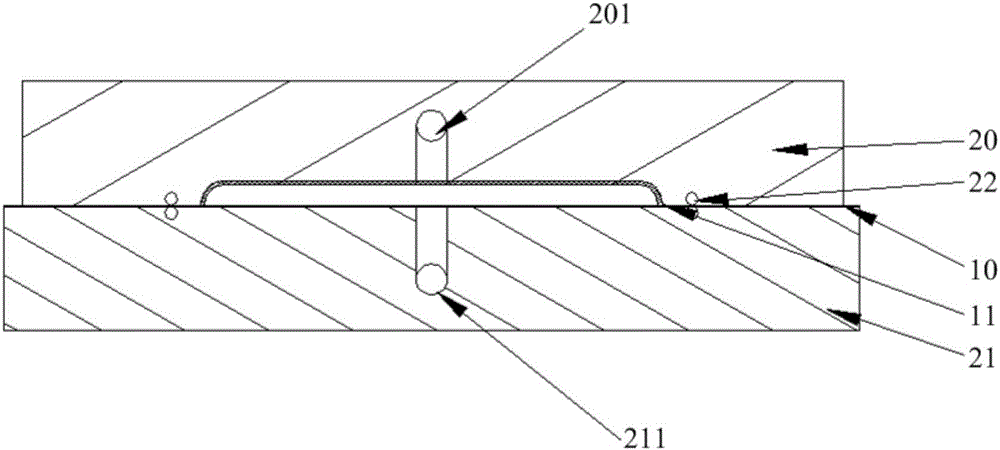

Film-sticking mold and film-sticking process

InactiveCN106626685AReduce artificial ginsengDegree of reductionLaminationLamination apparatusGlass sheetMaterials science

Owner:SHENZHEN TINNO WIRELESS TECH

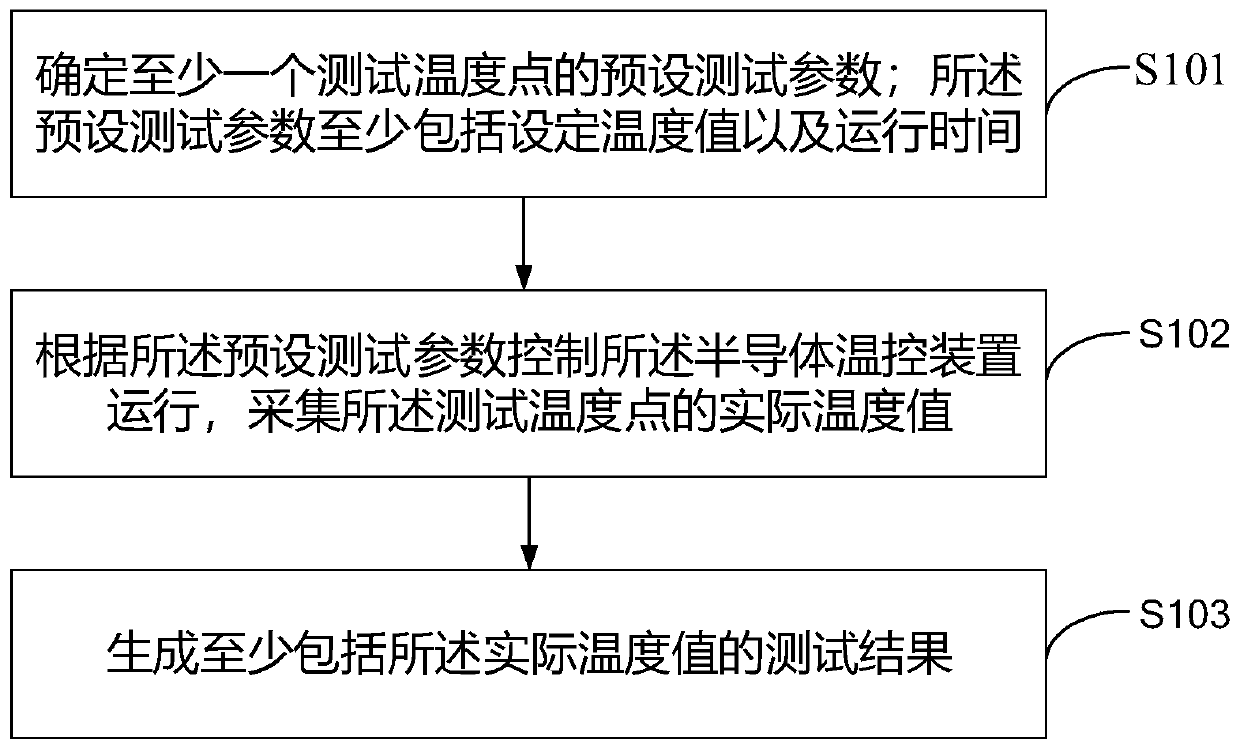

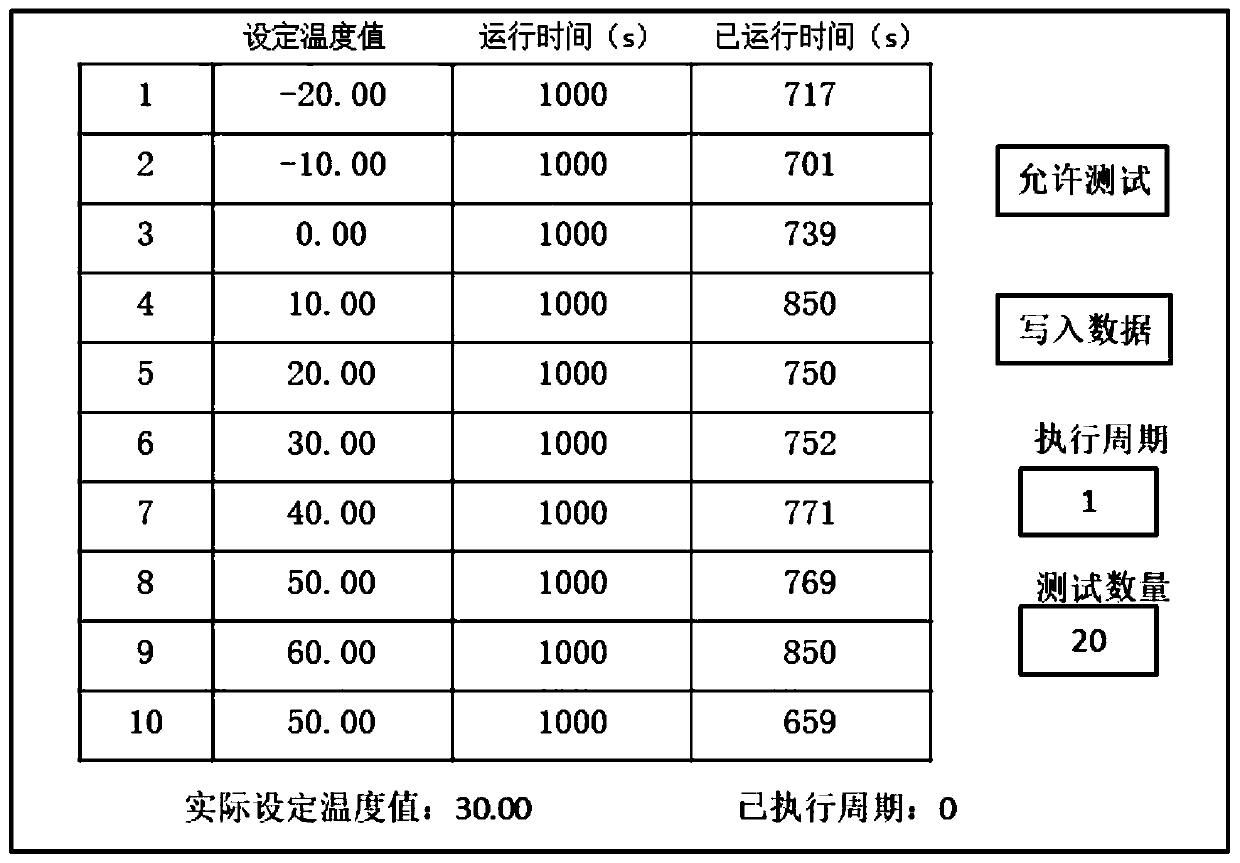

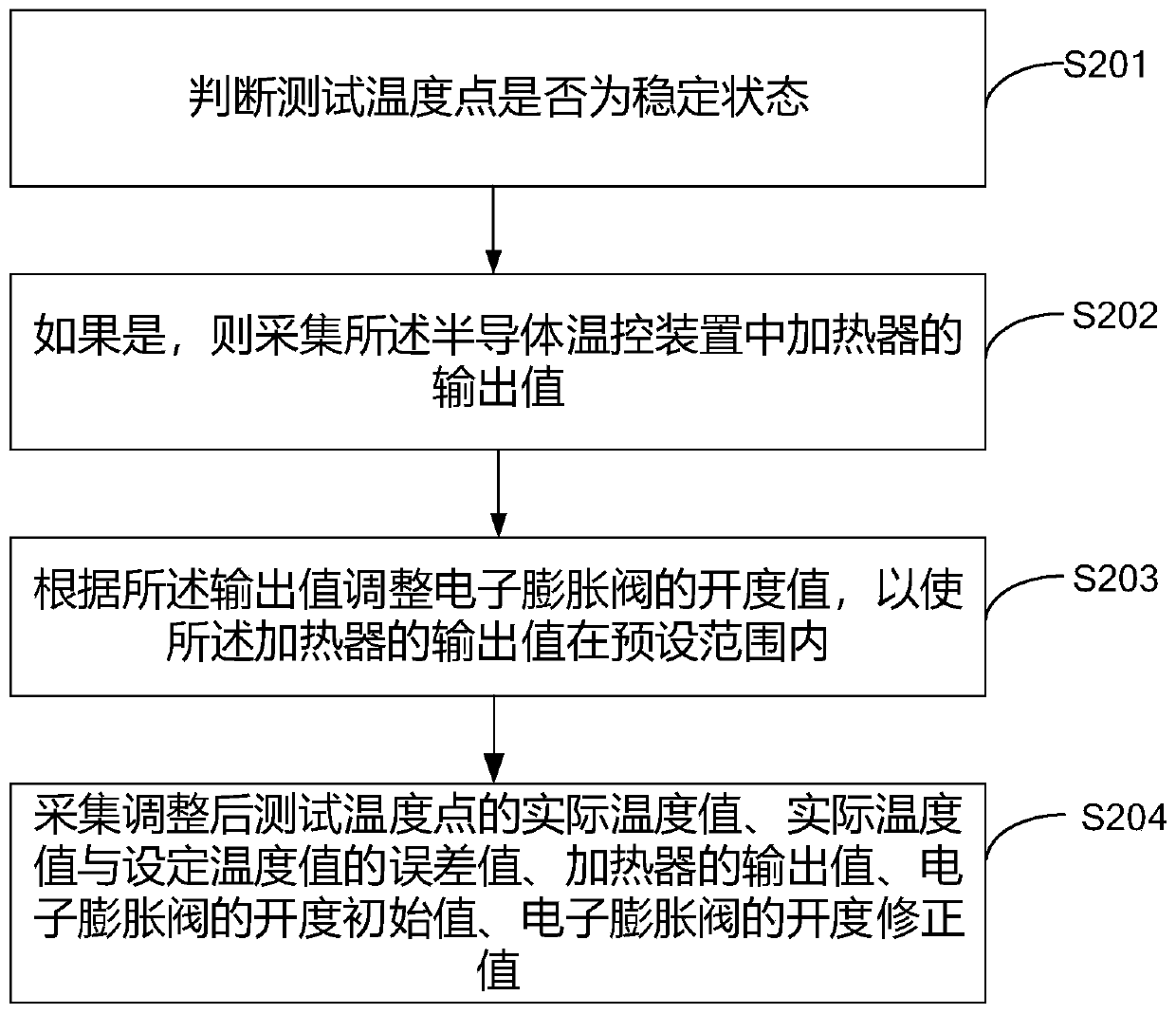

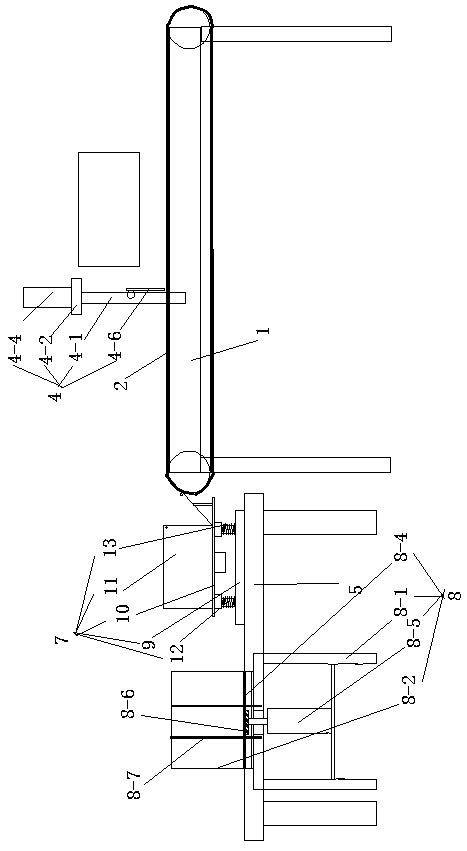

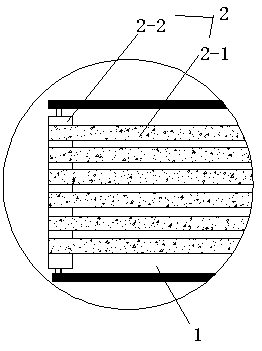

Test method and device of semiconductor temperature control device, electronic equipment and storage medium

ActiveCN111522324AReduce artificial ginsengDegree of reductionProgramme controlSemiconductor/solid-state device manufacturingTemperature controlProcess engineering

The embodiment of the invention provides a test method and device of a semiconductor temperature control device, electronic equipment and a storage medium. The method comprises the steps of determining a preset test parameter of at least one test temperature point; controlling the semiconductor temperature control device to operate according to preset test parameter, and collecting an actual temperature value of the test temperature point; and generating a test result at least comprising the actual temperature value. According to the embodiment of the invention, a mode that a test link needs to be manually operated in the prior art is changed, the manual participation degree is reduced, and the debugging efficiency is improved.

Owner:BEIJING JINGYI AUTOMATION EQUIP CO LTD

Conveying arrangement device after cutting for packaging bags

ActiveCN110722836AGuaranteed continuityAvoid unevennessBag making operationsPaper-makingStructural engineeringMachining

The invention discloses a conveying arrangement device after cutting for packaging bags. The conveying arrangement device after cutting for the packaging bags comprises a receiving platform erected below a cutting machine, wherein cyclic conveying belts which are arranged in the length direction of the receiving platform are distributed on the receiving platform; the upper end surfaces of the cyclic conveying belts cling to the receiving platform; a packaging bag falling limit mechanism is erected at a position close to the cutting machine, above the receiving platform; an arrangement platformis erected at discharge ends of the cyclic conveying belts; a vibration-type receiving arrangement mechanism is erected on the arrangement platform and at the discharge ends of the cyclic conveying belts; a receiving frame collection mechanism is erected at one side of the arrangement platform; the receiving frame collection mechanism comprises a rack; a receiving frame is arranged on the rack; aguide hole is formed in a bottom plate of the receiving frame; a supporting plate capable of lifting up and down in the receiving frame is arranged on the bottom plate; and the lifting of the supporting plate is driven by a cylinder at the bottom end of the supporting plate. The conveying arrangement device after cutting for the packaging bags is reasonable in structural design; and the process of manual involvement is reduced, and collection and arrangement for the packaging bags after cutting are facilitated, so that the requirement of large-batch machining and production is met.

Owner:ANHUI THE PARKSON SOURCE PACKAGING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com