Automatic deviation rectifying system for shield machine and operating method of automatic deviation rectifying system

An automatic deviation correction and shield machine technology, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of reduced construction efficiency, harsh working environment, and slow correction speed, so as to ensure construction quality, high deviation correction efficiency, and corresponding fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

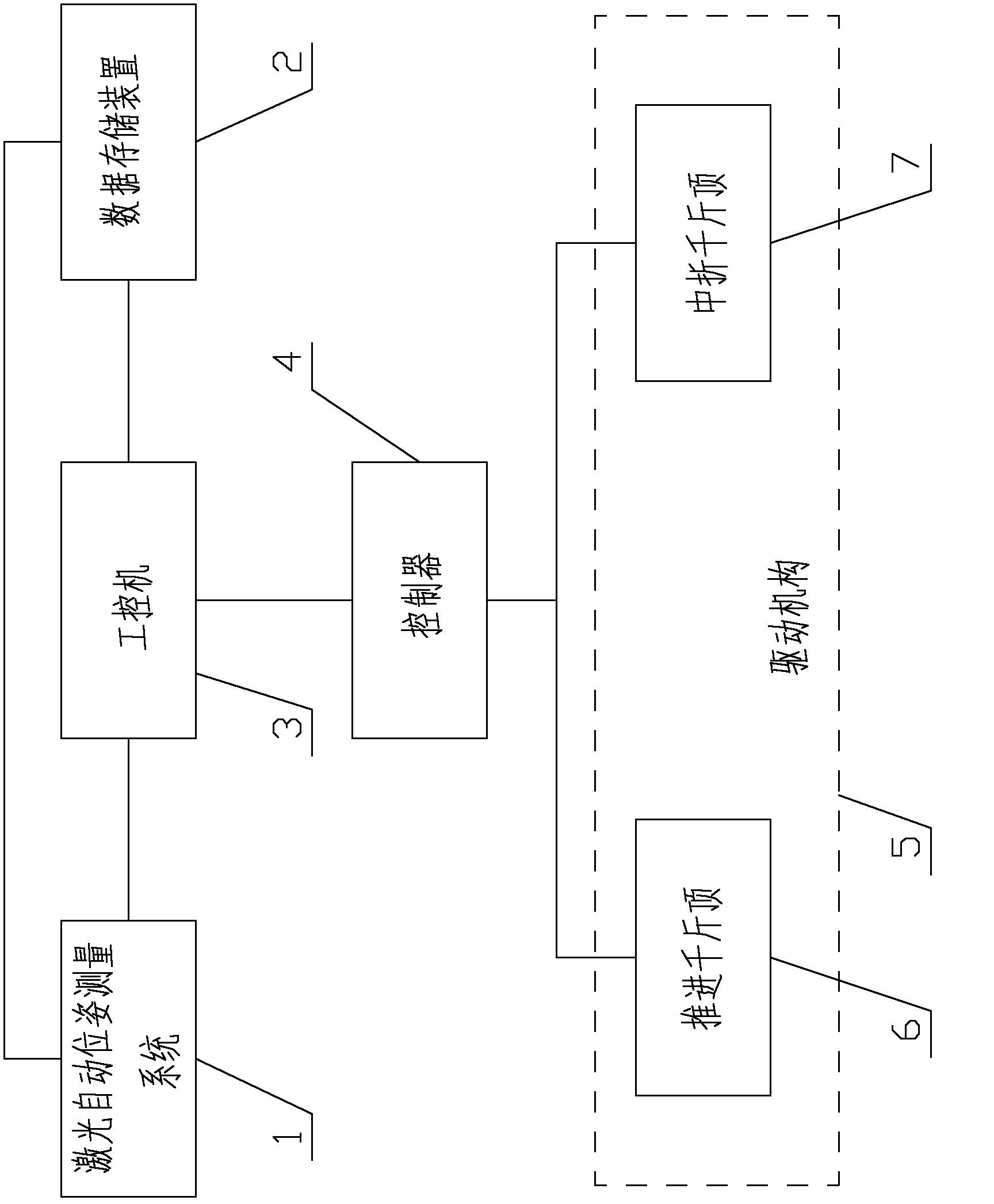

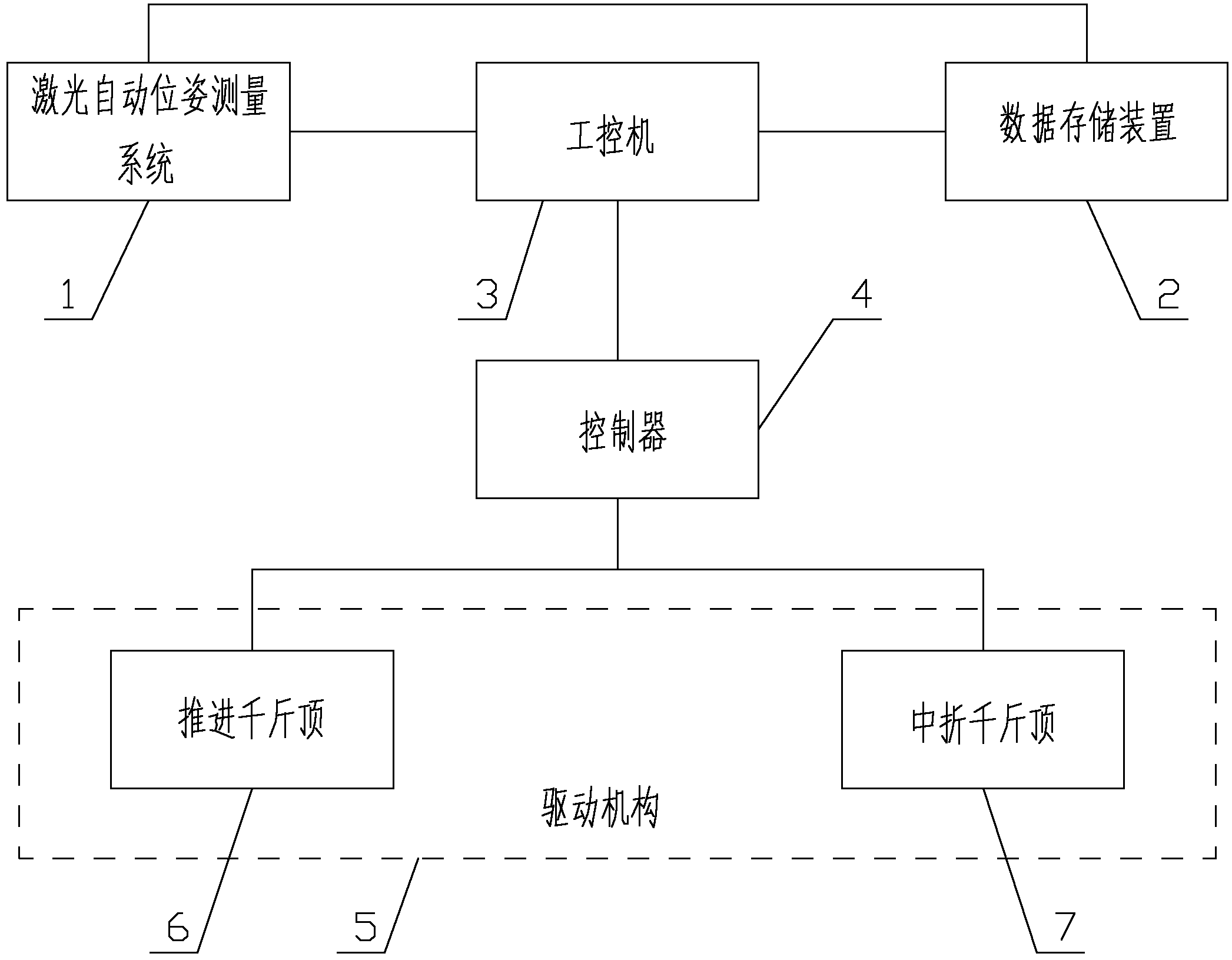

[0026] Such as figure 1 As shown, the automatic deviation correction system for the shield machine includes: a laser automatic pose measurement system 1 , a data storage device 2 , an industrial computer 3 , a controller 4 and a driving mechanism 5 .

[0027] Its connection method is:

[0028] One output end of the laser automatic pose measurement system 1 is connected to the industrial computer 3, and the other output end is connected to the data storage device 2; the output end of the data storage device 2 is connected to the industrial computer 3; the output end of the industrial computer 3 is connected to the controller 4; The output terminal of the controller 4 is connected with the driving mechanism 5 .

[0029] Among them, the data storage device 2 is used to store the received data on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com