Intelligent door leaf spraying line with robot

A robot and spraying line technology, applied in the field of door leaf intelligent spraying line, can solve the problems of complex structure of the loading and unloading mechanism, reducing the spraying quality of the finished product, and the spraying quality cannot be guaranteed, so as to achieve the safety of the spraying process, improve production efficiency and finished product quality, reduce The effect of human participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

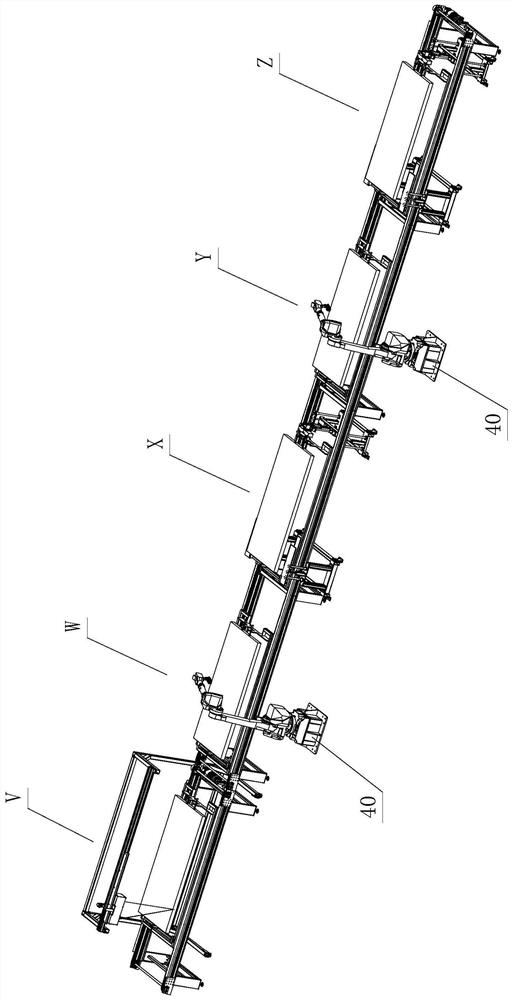

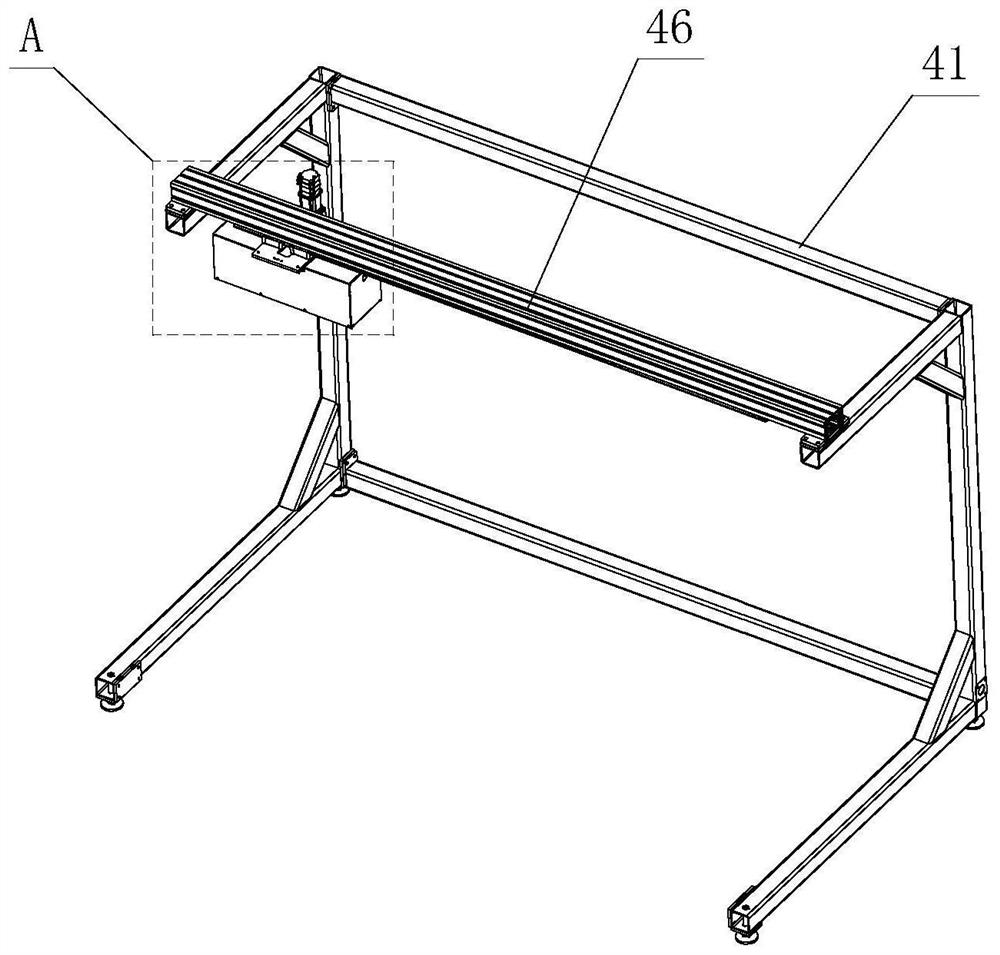

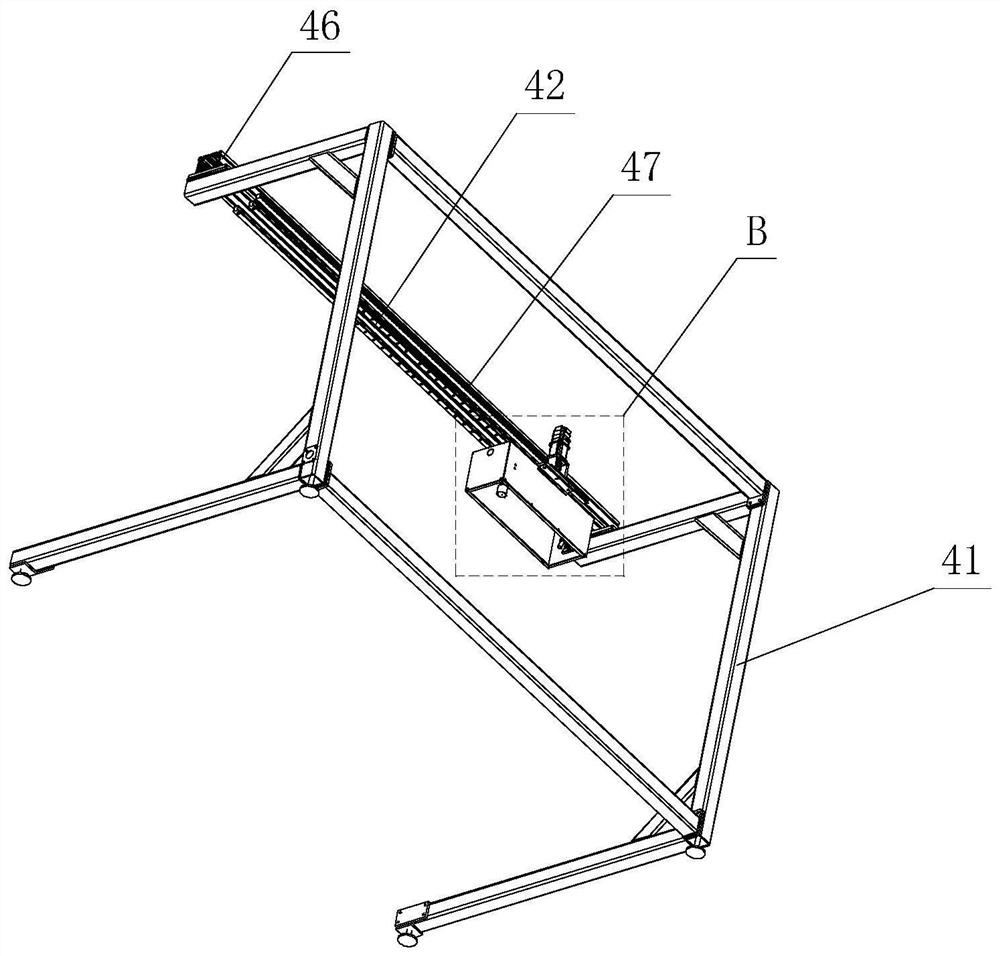

[0055] see Figure 1-Figure 19 , the door leaf intelligent spraying line with robot, including the door leaf clamp for clamping and supporting the door leaf 2, the chain conveying device for conveying the door leaf fixture, along the conveying direction of the chain conveying device, there are door leaf scanning area V, door leaf front Spraying area W, repainting area X on the front of the door leaf, spraying area Y on the back of the door leaf, and repainting area Z on the back of the door leaf.

[0056] A three-dimensional scanning device is provided on the door leaf scanning area V, and the three-dimensional size and / or shape of the door leaf 2 is scanned by the three-dimensional scanning device.

[0057] A spraying robot 40 is respectively arranged outside the spraying area W on the front side of the door leaf and the spraying area Y on the back si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com