Melt and concrete interaction analysis method based on particle method

An analysis method and concrete technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of not fully considering mechanical phenomena, neglecting chemical decomposition of non-condensable gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

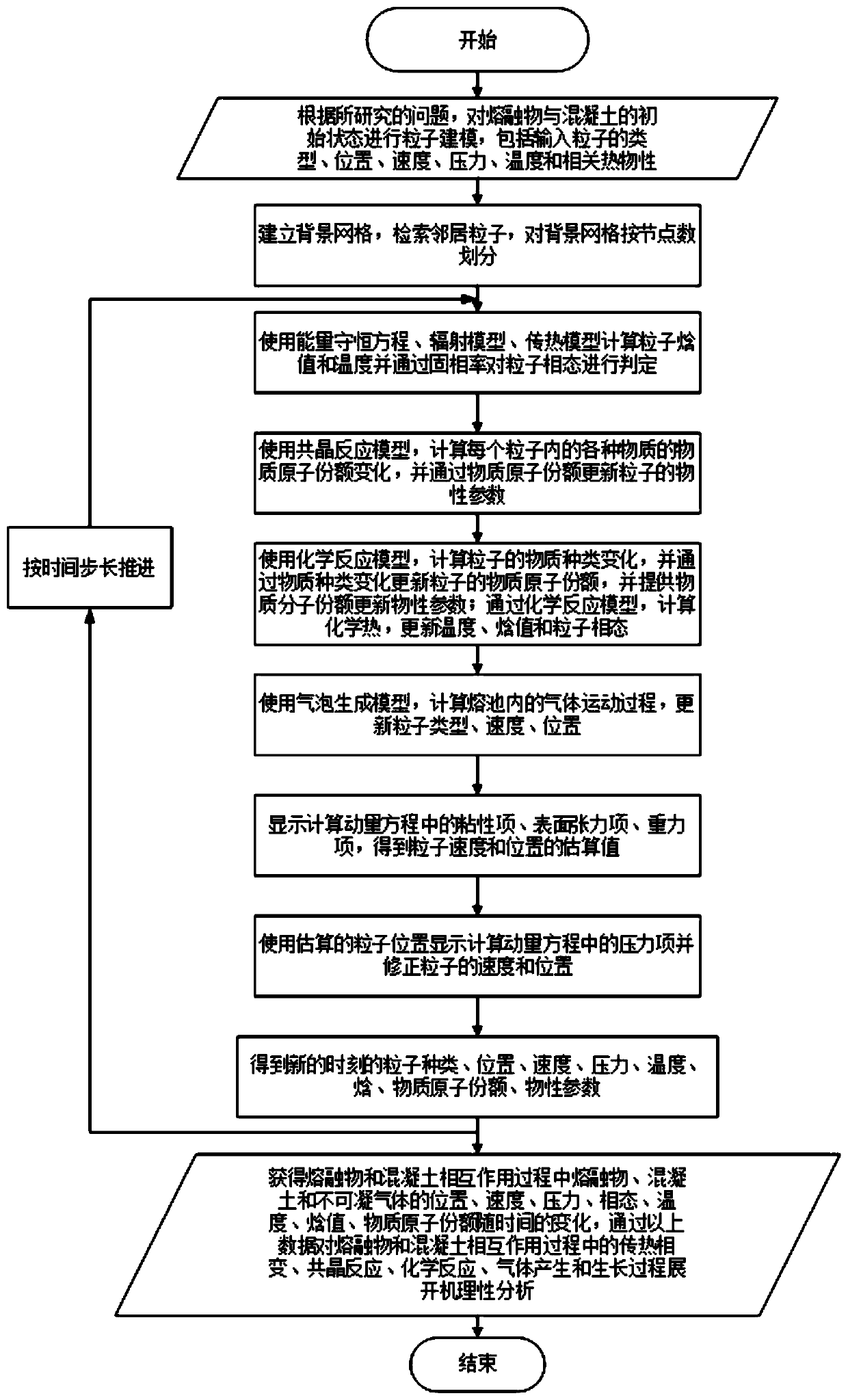

[0260] The present invention is based on the particle method to analyze the interaction between the melt and the concrete, such as figure 1 As shown, the steps are as follows:

[0261] Step 1: Perform particle modeling on the initial state of the molten pool and concrete, use different kinds of particles to represent different substances, and use particles 1, 2, and 3 to simulate the liquid phase, solid-liquid mixed phase, and solid phase of the molten particles. Particles No. 4, 5, and 6 are used to simulate the liquid phase, solid-liquid mixed phase, and solid phase of concrete. Each particle has corresponding mass, density, specific heat, melting point, temperature, and enthalpy information according to the substance it represents; During the interaction between the pool and the concrete, the material composition is complex, and there are many mutually soluble or mutually insoluble material compositions. For the mutually soluble materials, for the particle i, add the substance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com