Patents

Literature

68results about How to "Realize Quantitative Prediction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

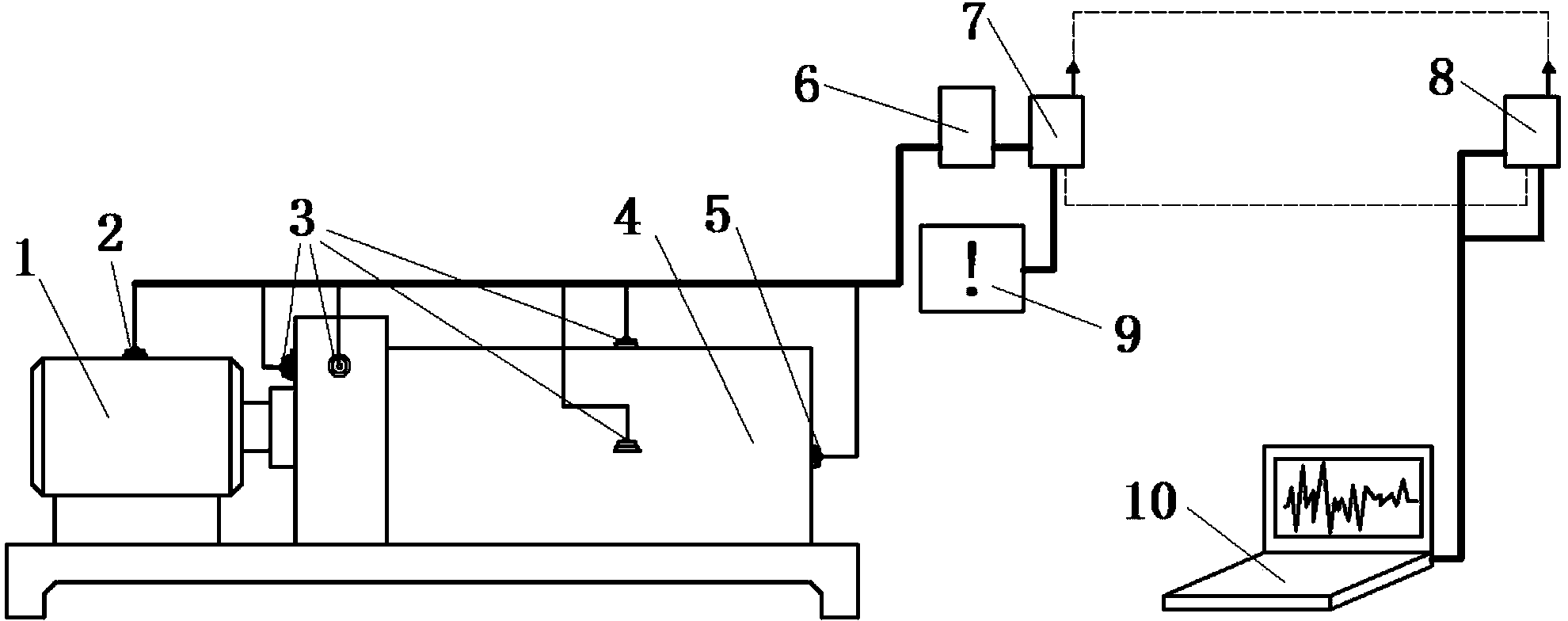

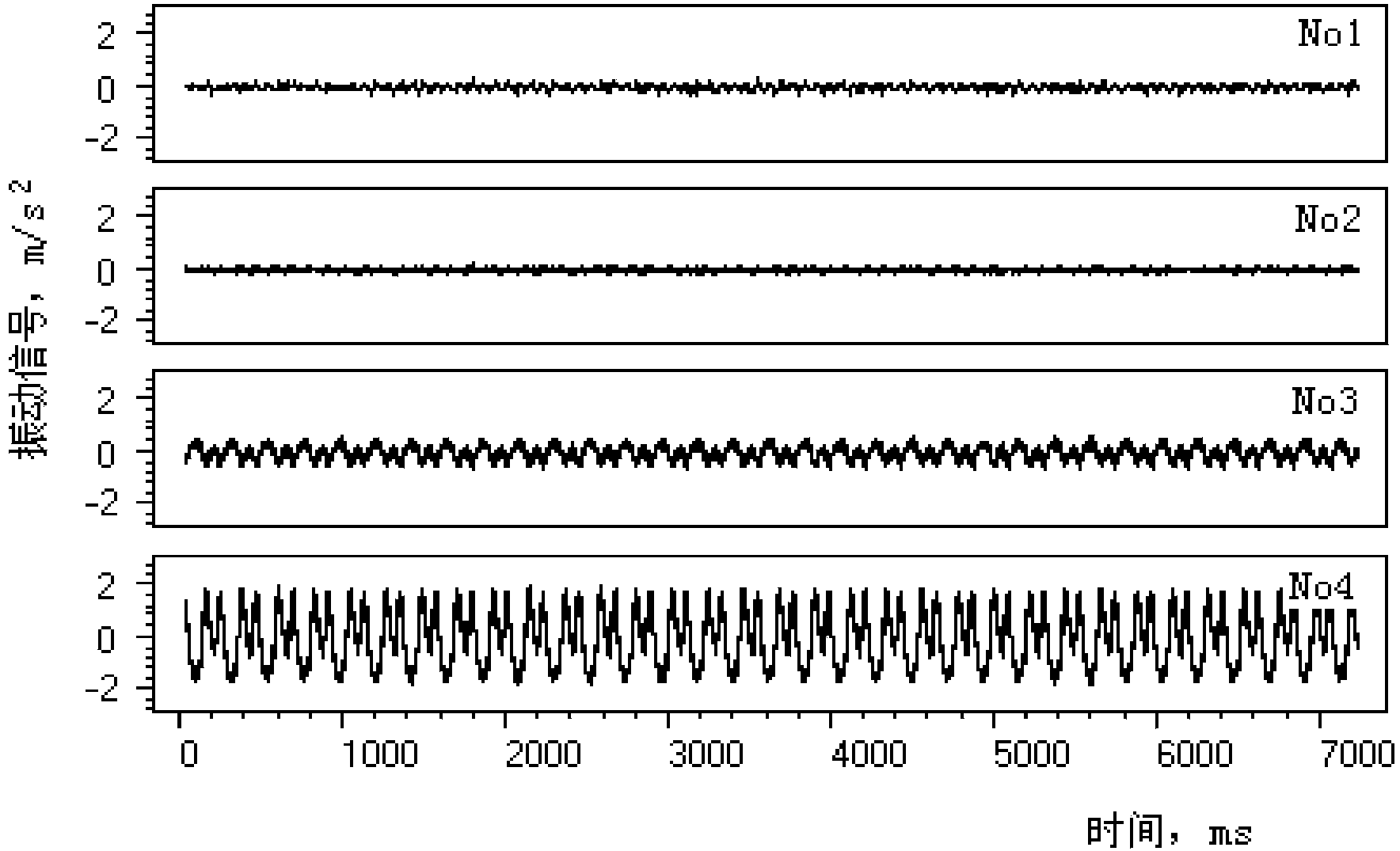

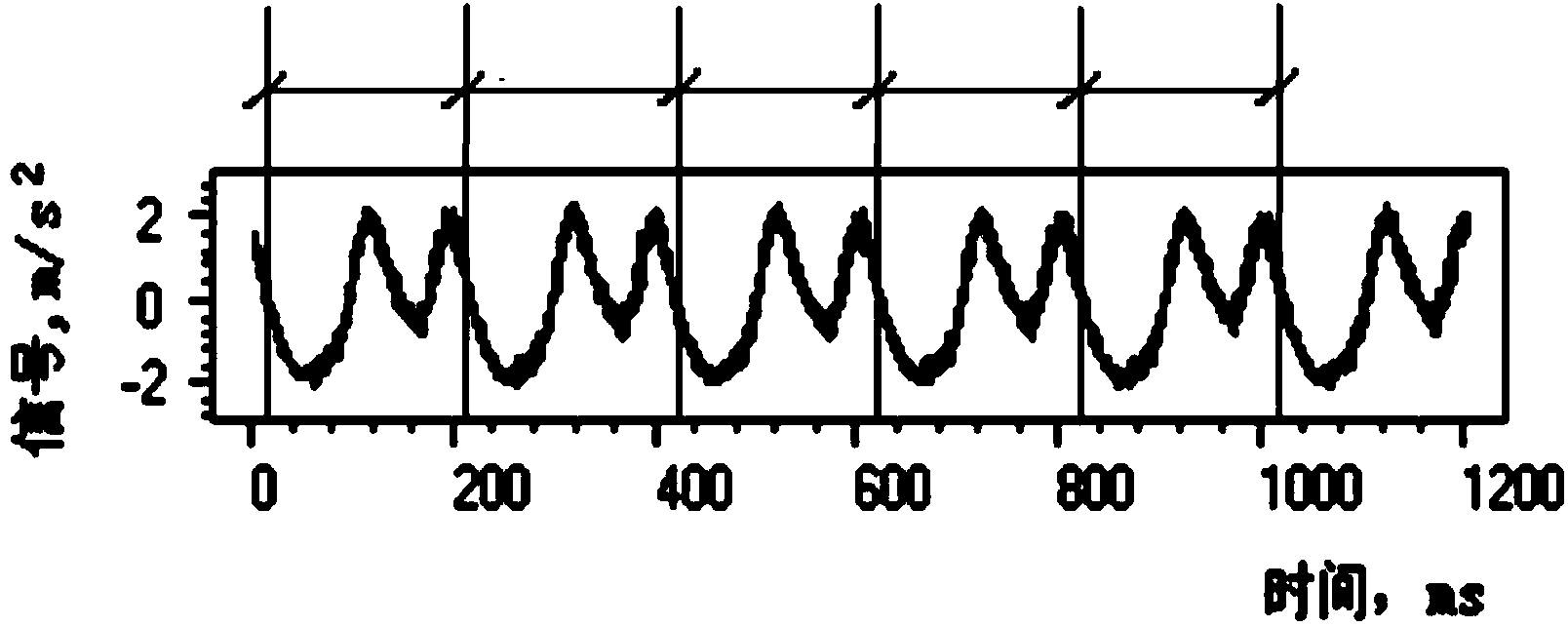

Working condition monitoring and fault diagnosis method for mechanical equipment

ActiveCN103969069ARealize acquisitionAchieving processing powerStructural/machines measurementRelational modelMechanical equipment

The invention relates to a working condition monitoring and fault diagnosis method for mechanical equipment. The method includes the steps that (1), vibration signals are collected; (2), primitive segmentation is performed on the signals; (3), the signals are separated and classified; (4), parameter statistics is performed on the separated signals; (5), two-parameter distribution displaying is performed, wherein all kinds of separated signals are displayed on a two-parameter plane in a scatter plot mode; (6), a motion state matrix is established; (7), by the utilization of the motion state matrix established in the step6, actual measurement vibration signal statistics and equipment state qualitative recognition are performed; (8), a quantitative relation model among the working state, working parameters and separation signal time domain statistics results is established; (9), in the real-time monitoring process, the separation signal time domain parameter statistics results are substituted into the quantitative relation model established in the step8, so that quantitative predication and fault quantitative diagnosis performed on the working parameters are achieved. Through a simple signal monitoring device low in cost, data are collected, and the working conditions of the mechanical equipment are monitored and recognized in real time. By the adoption of the simple algorithm, qualitative diagnosis performed on faults and quantitative predication performed on the working condition parameters are achieved, so that conditions are created for state monitoring and scientific fault quantitative diagnosis of the mechanical equipment.

Owner:常州晶容创机械科技有限公司

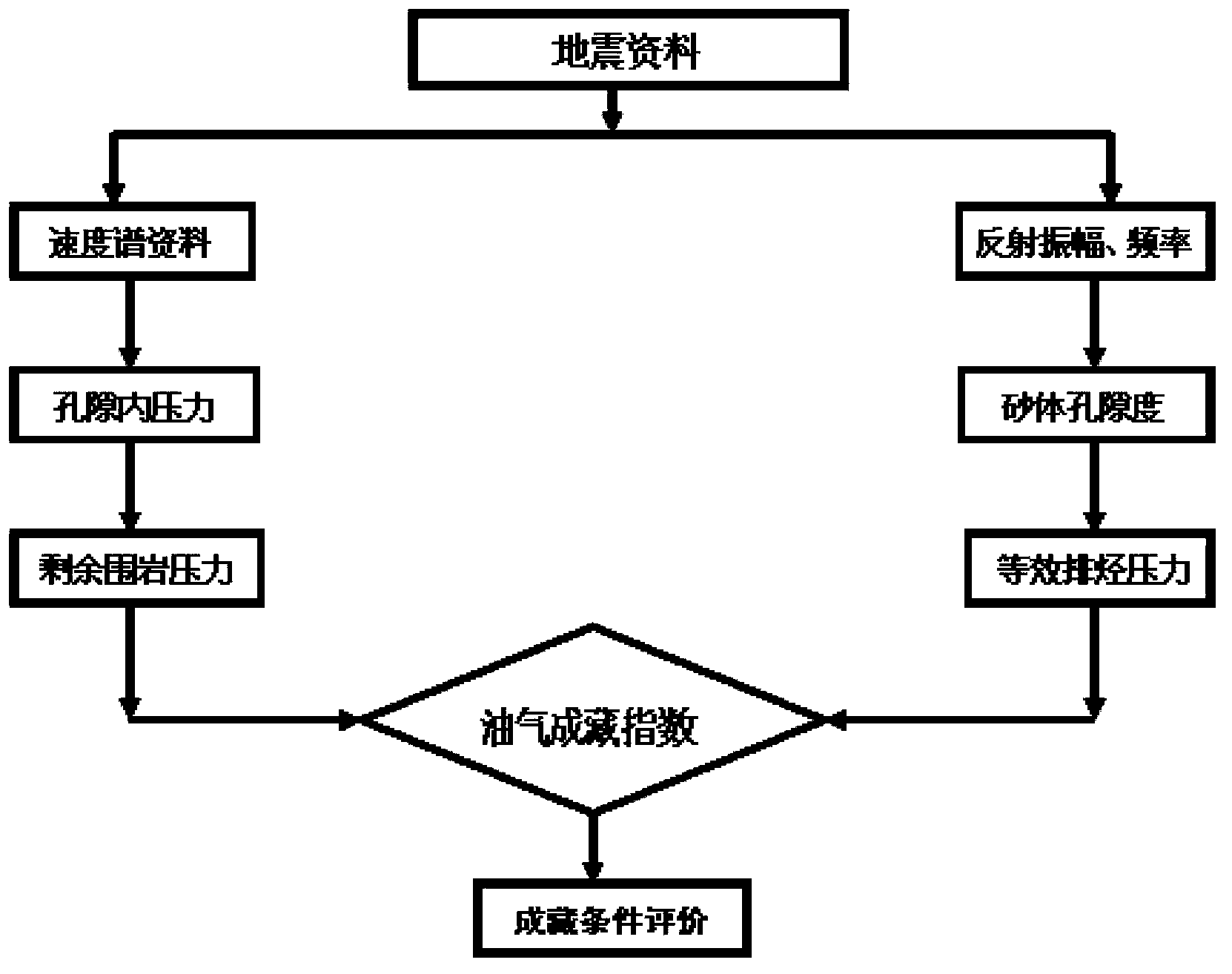

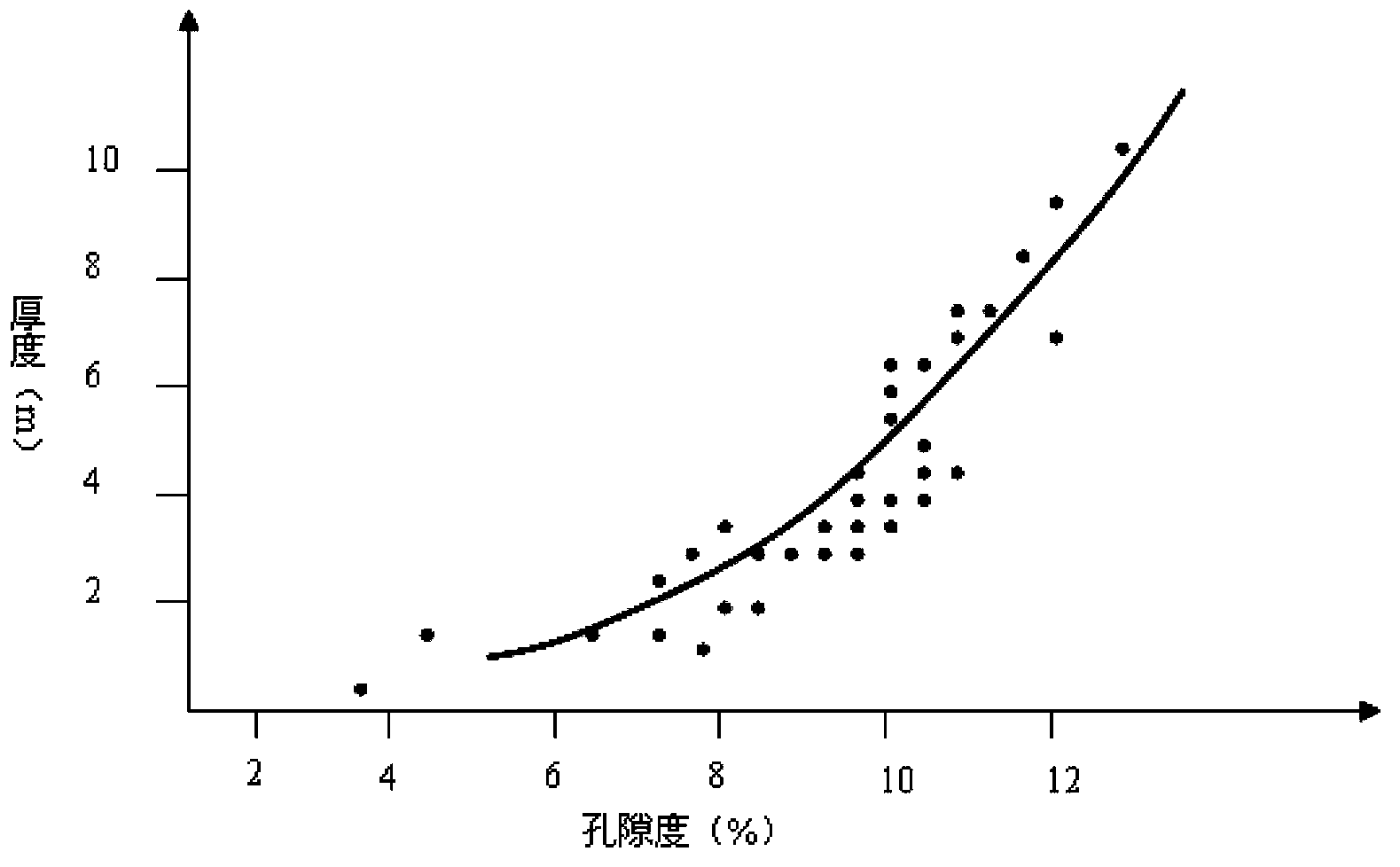

Method of quantitative evaluation on oil and gas accumulation conditions based on seismic data

ActiveCN103777245ARealize Quantitative PredictionImprove exploration efficiencySeismic signal processingPorosityWell drilling

The invention is a method of quantitative evaluation on oil and gas accumulation conditions based on seismic data. According to the evaluation method, a mathematical model between seismic parameters such as seismic interval velocity and sandstone lens body reflection amplitude and hydrocarbon source rock residual pressure and equivalent hydrocarbon expulsion pressure is determined, the seismic interval velocity is acquired through seismic data correcting, and the hydrocarbon source rock residual pressure of a sandstone lens body is acquired according to the seismic interval velocity. Further, the sand body porosity is acquired according to the true thickness of the sandstone lens body, the equivalent hydrocarbon expulsion pressure is acquired according to the sand body porosity, and the oil and gas accumulation index of the sandstone lens body is acquired according to the hydrocarbon source rock residual pressure and the equivalent hydrocarbon expulsion pressure, thus completing quantitative evaluation on oil and gas accumulation conditions of the sandstone lens body. Quantitative evaluation on accumulation conditions of the sandstone lens body is realized with the use of the seismic parameters under the condition of lack of drilling and logging data, and the efficiency of exploration is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

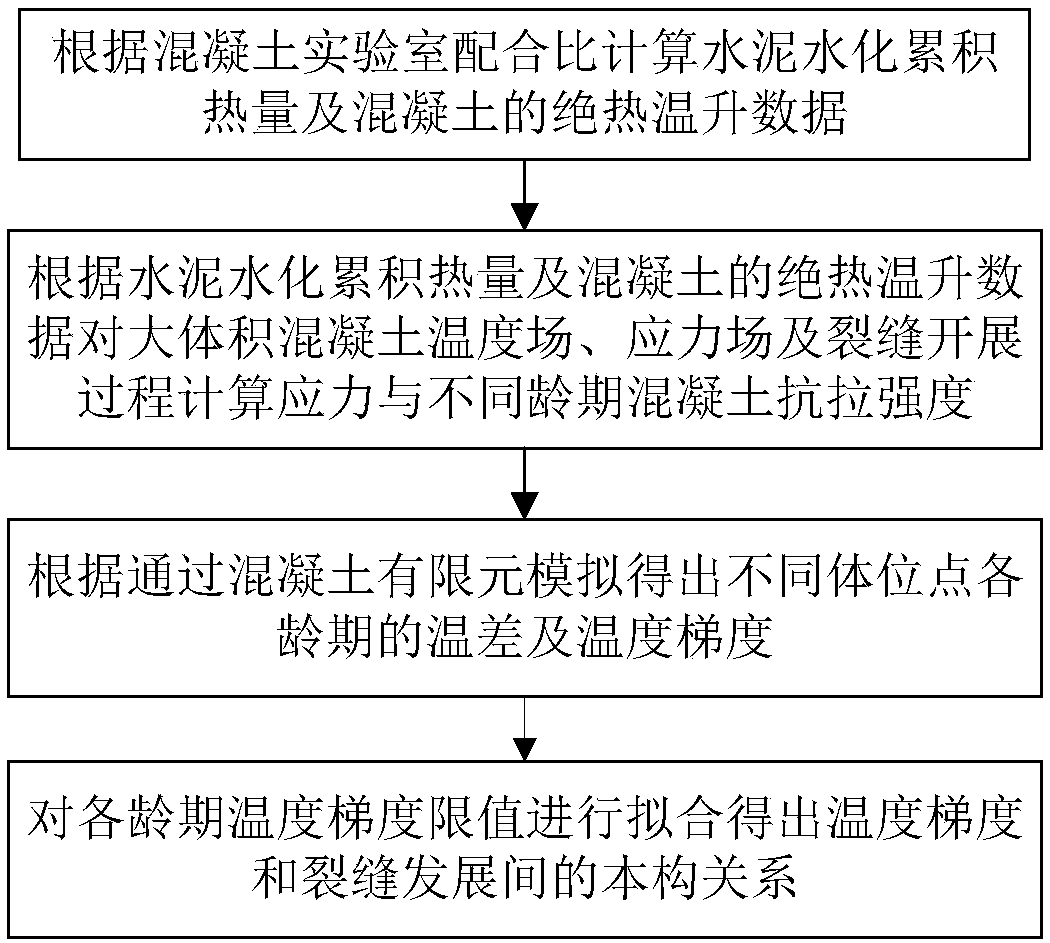

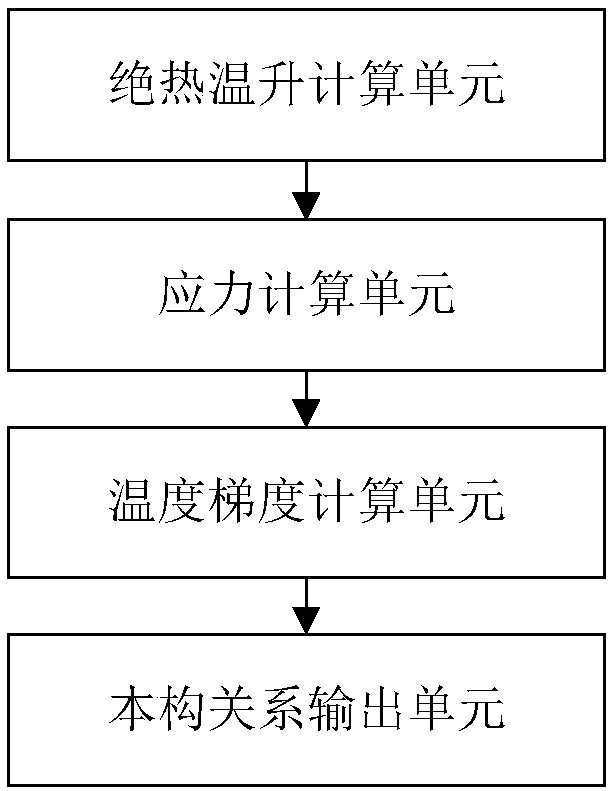

Mass concrete temperature gradient limit value analysis method and device

ActiveCN108981966APrevent Harmful CracksRealize Quantitative PredictionThermometer detailsThermometer applicationsLow inputAnalysis method

The invention discloses a mass concrete temperature gradient limit value analysis method and device. The maximum acceptable temperature gradient limit values can be calculated according to the crack-free conditions at different locations and depths of mass concrete at different ages, a concrete curing scheme can be formulated more reasonably according to the temperature gradient limit values, thecuring quality is improved in a condition with low input, the effect of controlling the development of temperature cracks is achieved, the temperature gradient limit values of mass concrete of different depths at different ages are applied to temperature monitoring of mass concrete construction, and accordingly, a more reasonable mass concrete curing scheme is made, and quantitative prediction andprevention of harmful cracks can be realized.

Owner:雷元新

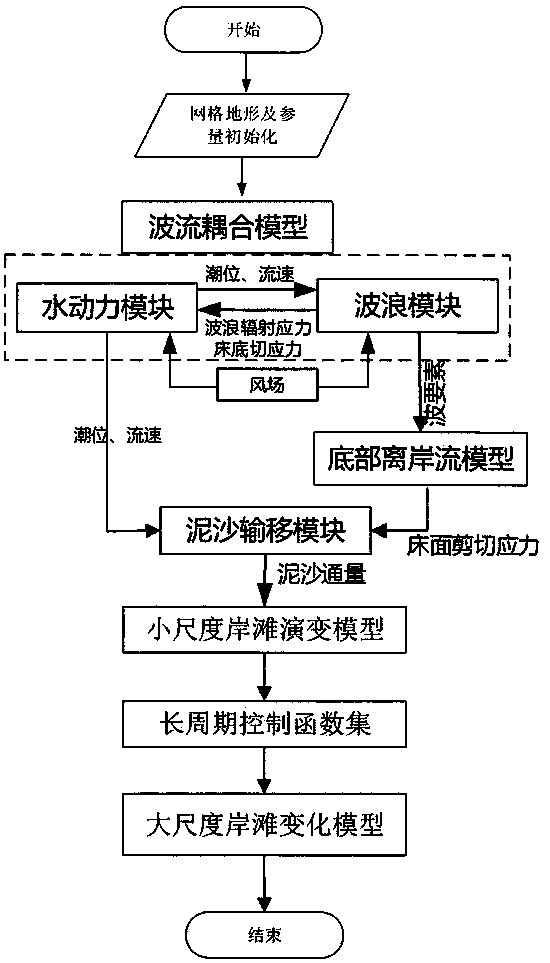

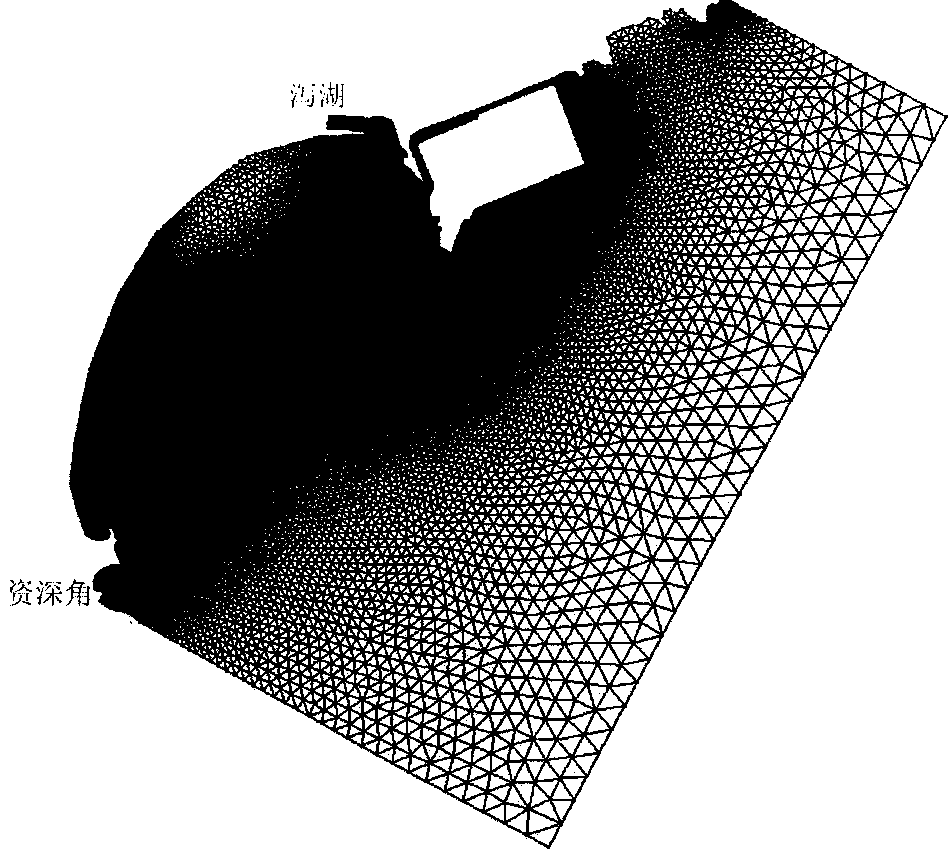

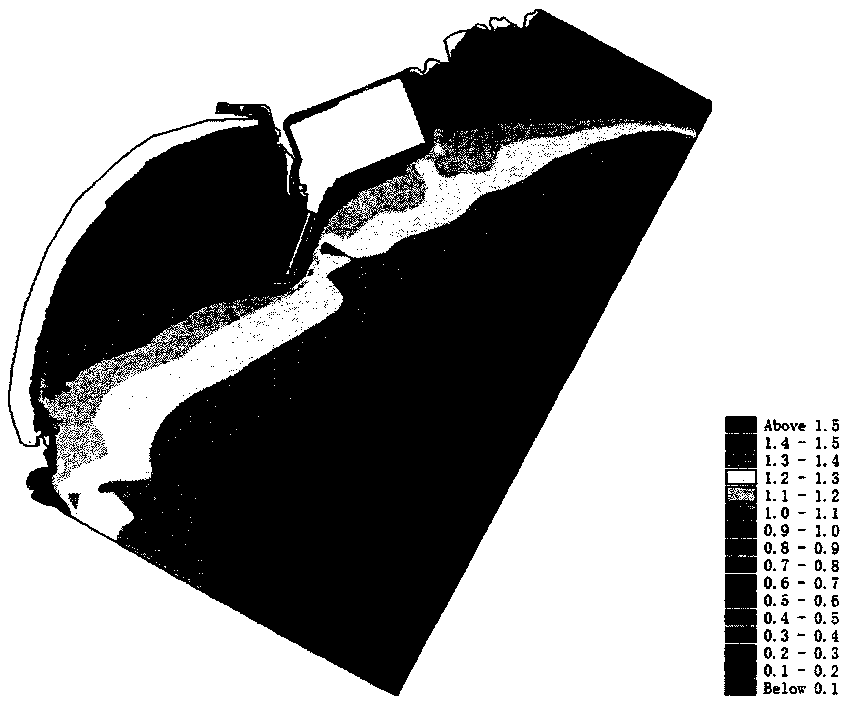

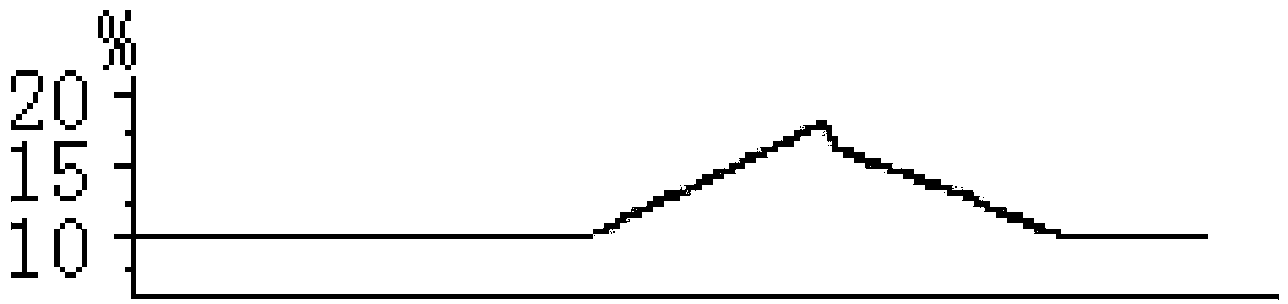

Coupling simulation method for a small-scale beach section and a large-scale shoreline change

PendingCN109582996ARealize Quantitative PredictionHigh practical application valueDesign optimisation/simulationSpecial data processing applicationsMarine engineeringOceanography

The invention discloses a coupling numerical simulation method for small-scale beach section and large-scale shoreline changes. The coupling numerical simulation method comprises the following steps that S1, establishing a wave flow coupling model for accurately and quantitatively describing plane offshore power; S2, establishing a bottom offshore flow model for accurately and quantitatively describing the offshore bottom offshore flow; S3, establishing a small-scale beach profile evolution model; S4, establishing a large-scale shoreline change model by using the long-period control function set; And S5, solving the large-scale shoreline change model by adopting a Godunov type finite volume method on a non-structural grid, and obtaining a large-scale shoreline change value. According to the method, the expansion from the sediment transport volume on the small-scale beach to the transport volume on the large-scale shoreline landform is realized, the simulation of the large-scale shoreline change is completed, and the practical application value of the simulation of the beach evolution can be obviously improved.

Owner:PEARL RIVER HYDRAULIC RES INST OF PEARL RIVER WATER RESOURCES COMMISSION

Earthquake stratum fracture crack density retrieval method and system

ActiveCN103513277AHigh-precision seismic inversion resultsRealize Quantitative PredictionSeismic signal processingFull waveformSeismic wave

The invention provides an earthquake stratum fracture crack density retrieval method and system. Collected earthquake wave information is fully used through full-waveform retrieval, the propagation behavior of earthquake waves underground is automatically considered, and high-accuracy earthquake retrieval results can be given. Through the elastic full-waveform retrieval theory in HTI media, the full-waveform fracture crack density retrieval method is provided, and quantitative forecast of earthquake underground stratum fracture crack density is achieved.

Owner:PETROCHINA CO LTD

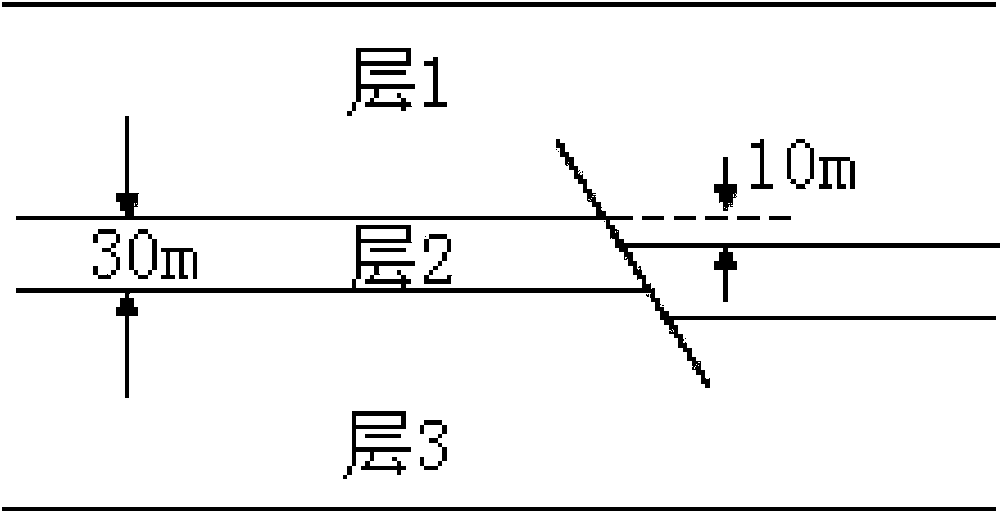

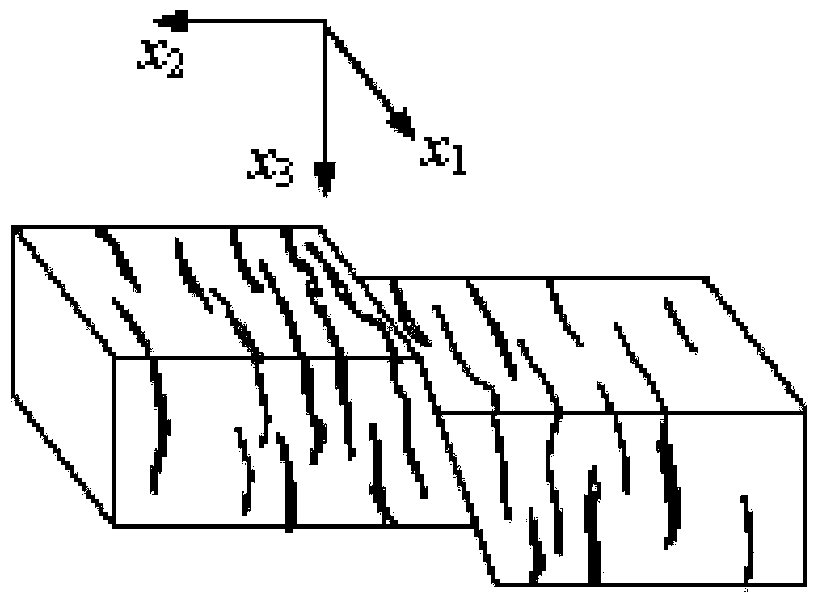

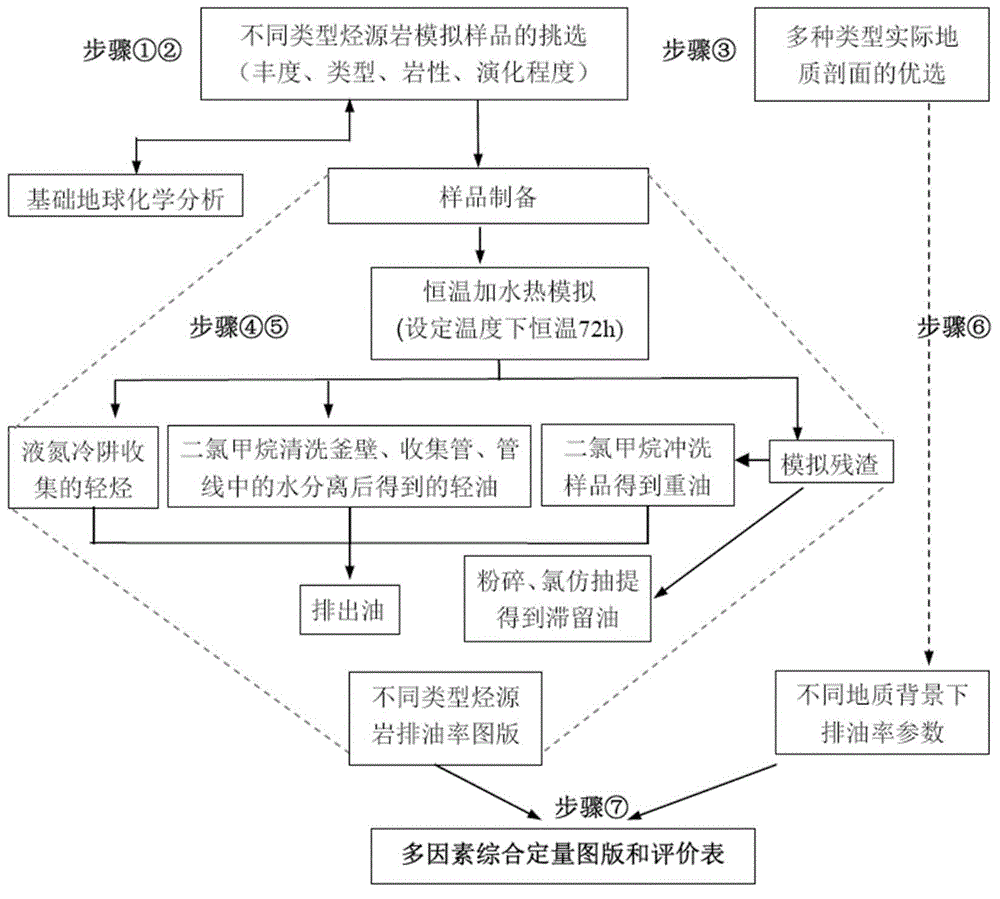

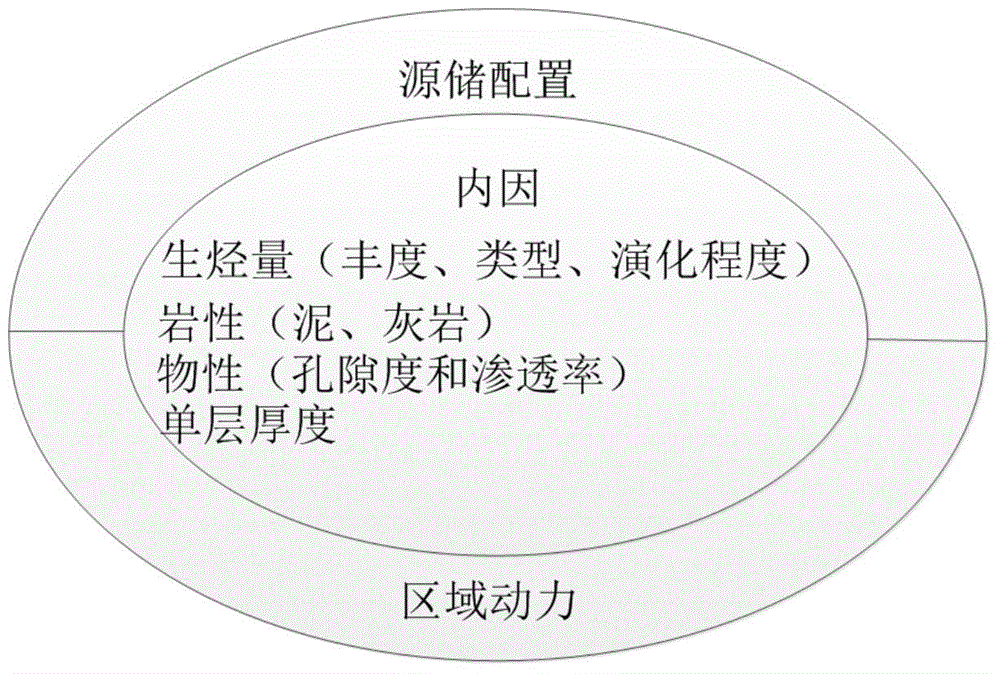

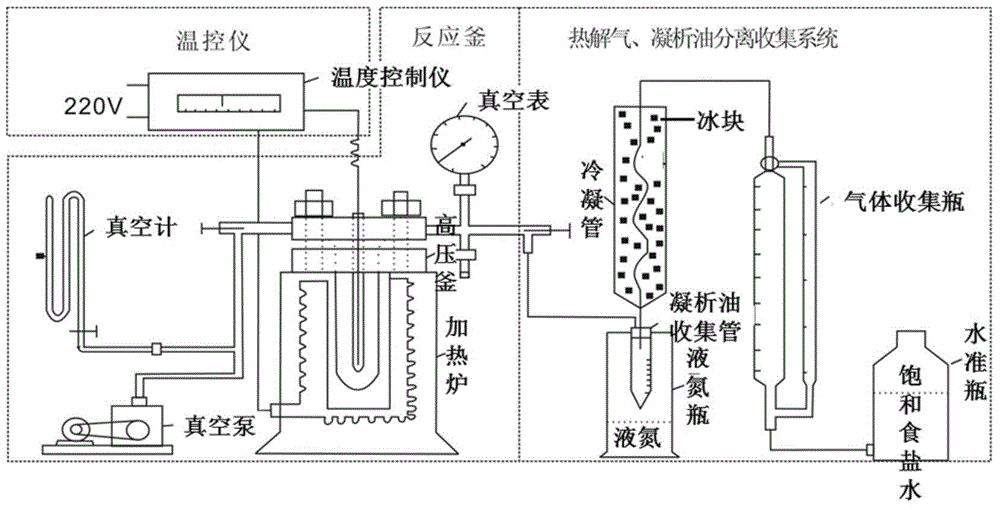

Petroleum spatial distribution quantitative evaluation chart generation method under reservoir configuration constraint

ActiveCN104932033ARealize organic integrationAchieve completenessGeological measurementsLithologyRock eval

The invention provides a petroleum spatial distribution quantitative evaluation chart generation method under reservoir configuration constraint. The method comprises the steps: collecting different types of hydrocarbon source rock samples sequentially according to thermal evolution degree, abundance of organic matter, lithology and organic matter type; carrying out the thermal simulation experiment of the collected samples, quantifying discharged oil and retention oil at each temperature point, employing the organic carbon analysis of residue, Rock-Eval detection, and vitrinite reflectance analysis; drawing an oil discharge rate chart of different types of hydrocarbon source rocks; selecting geological sections of different basins as actual geological samples; densely collecting the hydrocarbon source rocks and storage layer rock core samples and carrying out organic carbon analysis, Rock-Eval detection, vitrinite reflectance analysis and chloroform bitumen quantitative analysis on actual geological sections; drawing an oil discharge rate parameter curve of an actual geological sample; and obtaining the petroleum spatial distribution quantitative evaluation chart generation method under reservoir configuration constraint according to the oil discharge rate charts of different types of hydrocarbon source rocks and the oil discharge rate parameter curve of the actual geological sample.

Owner:PETROCHINA CO LTD

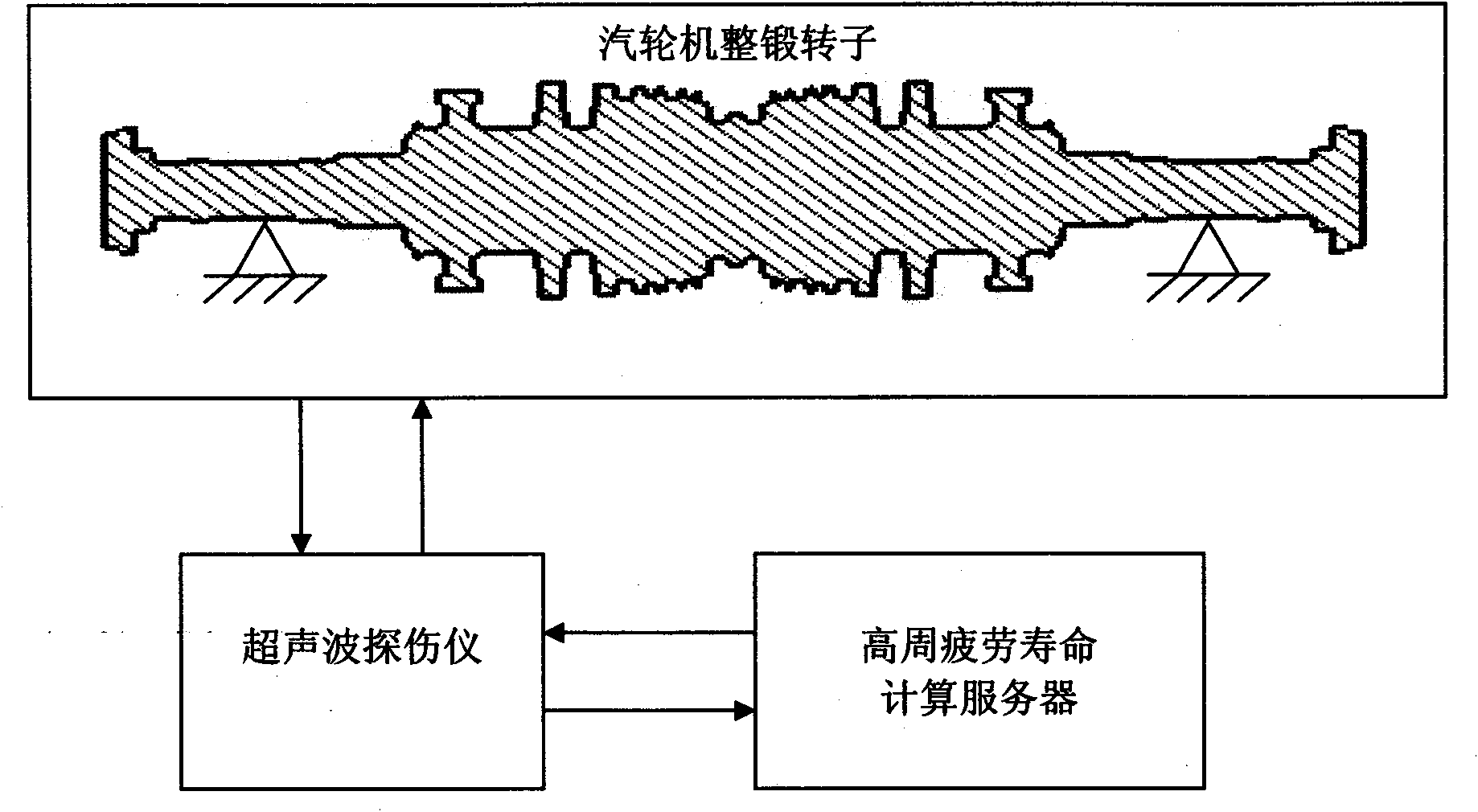

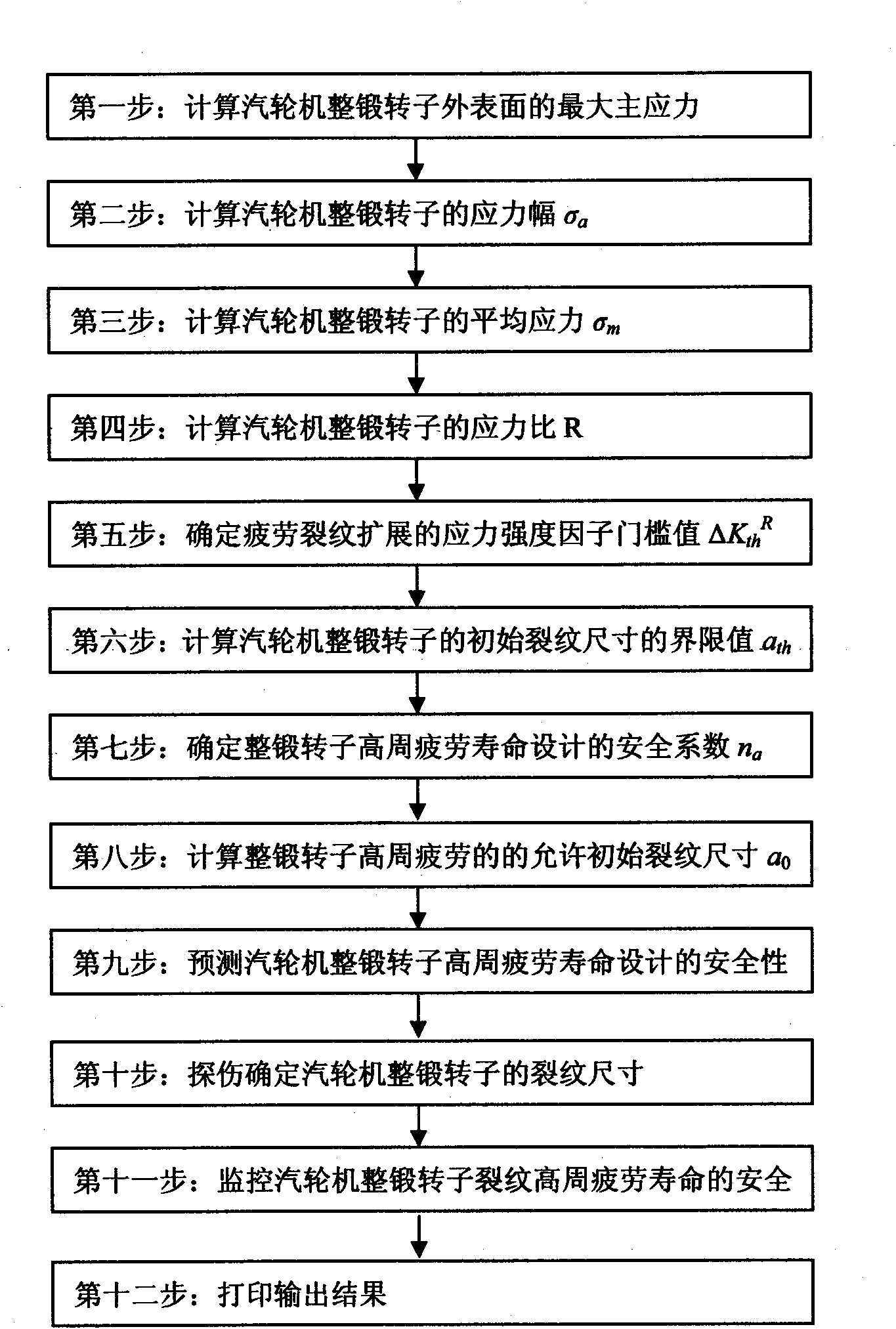

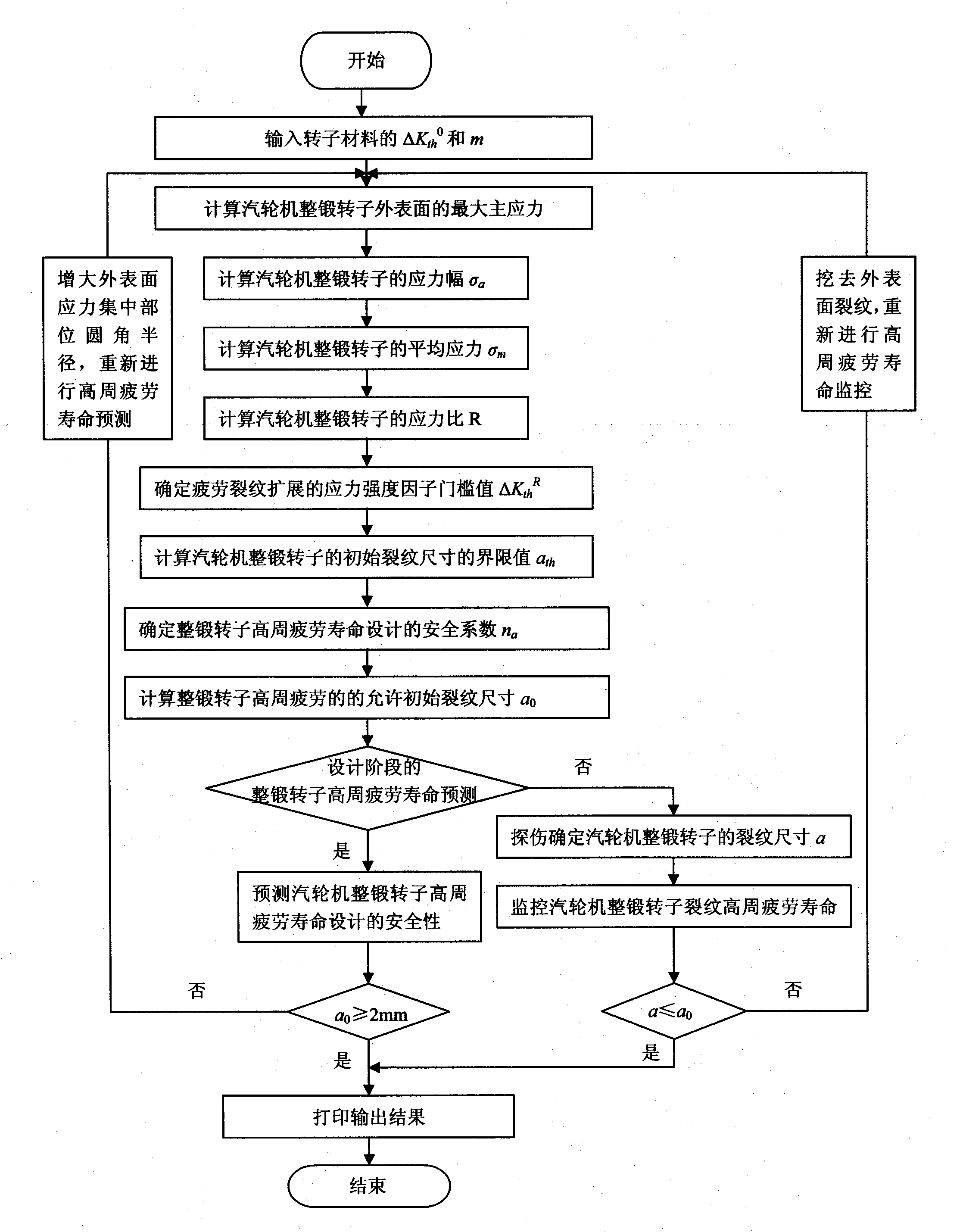

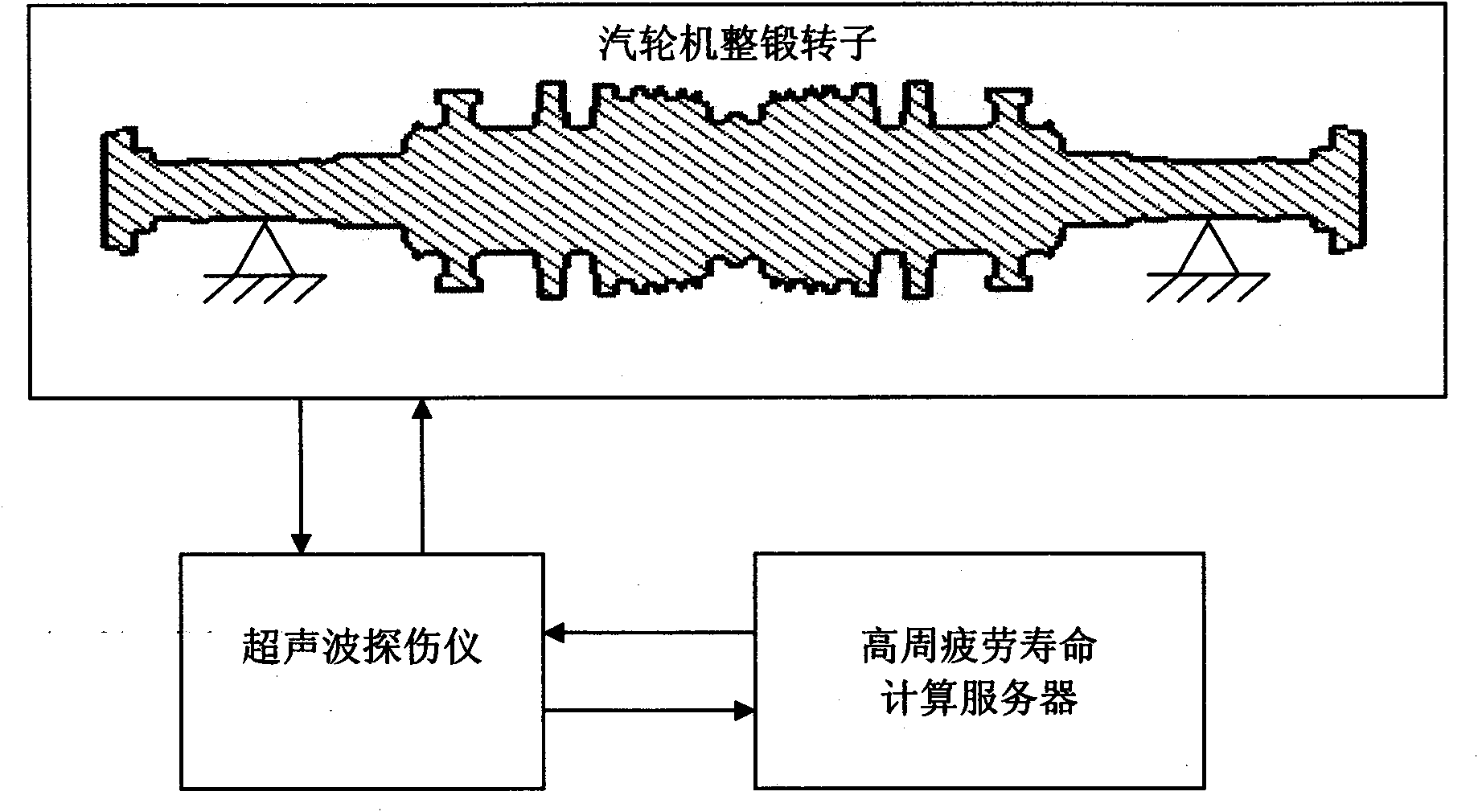

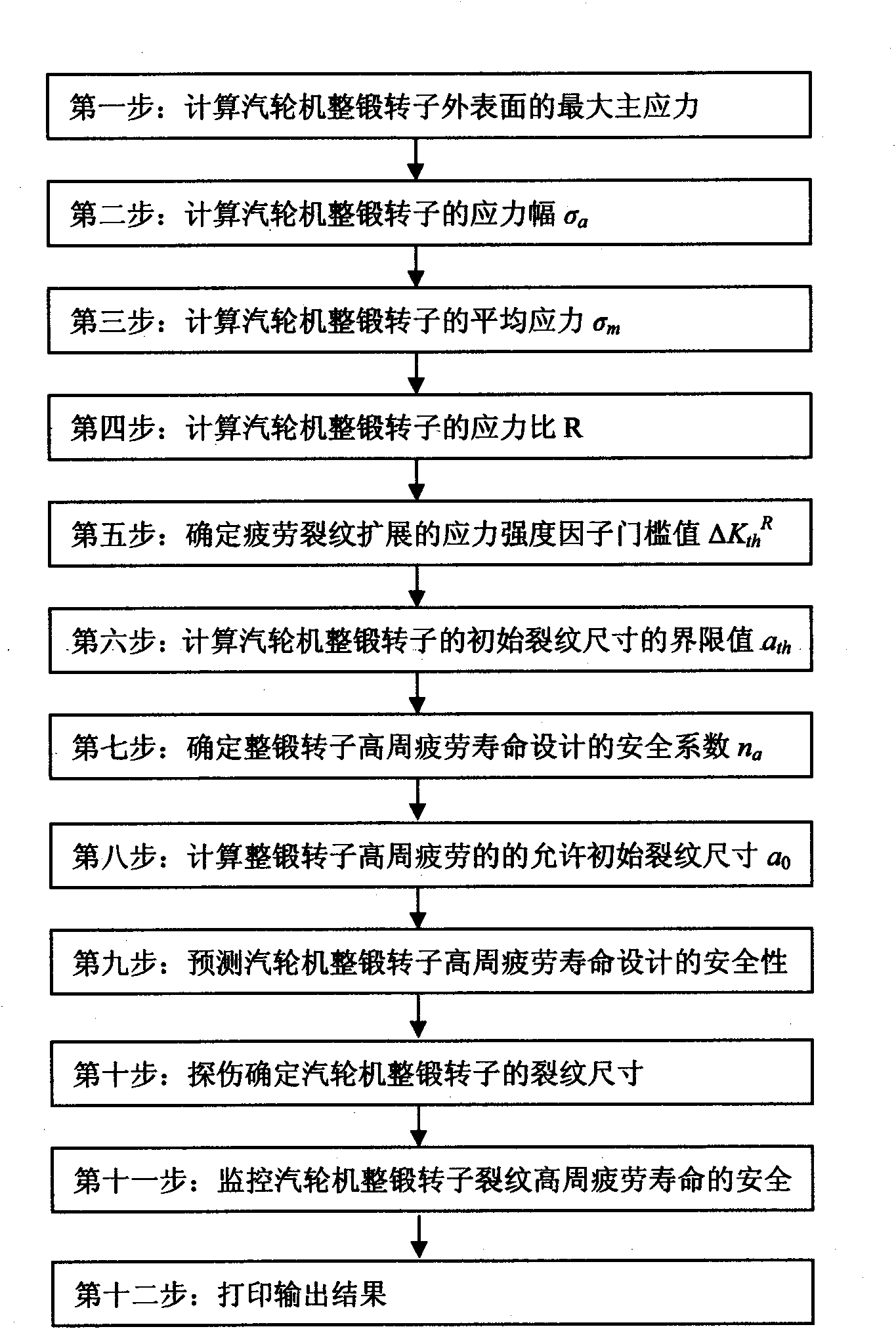

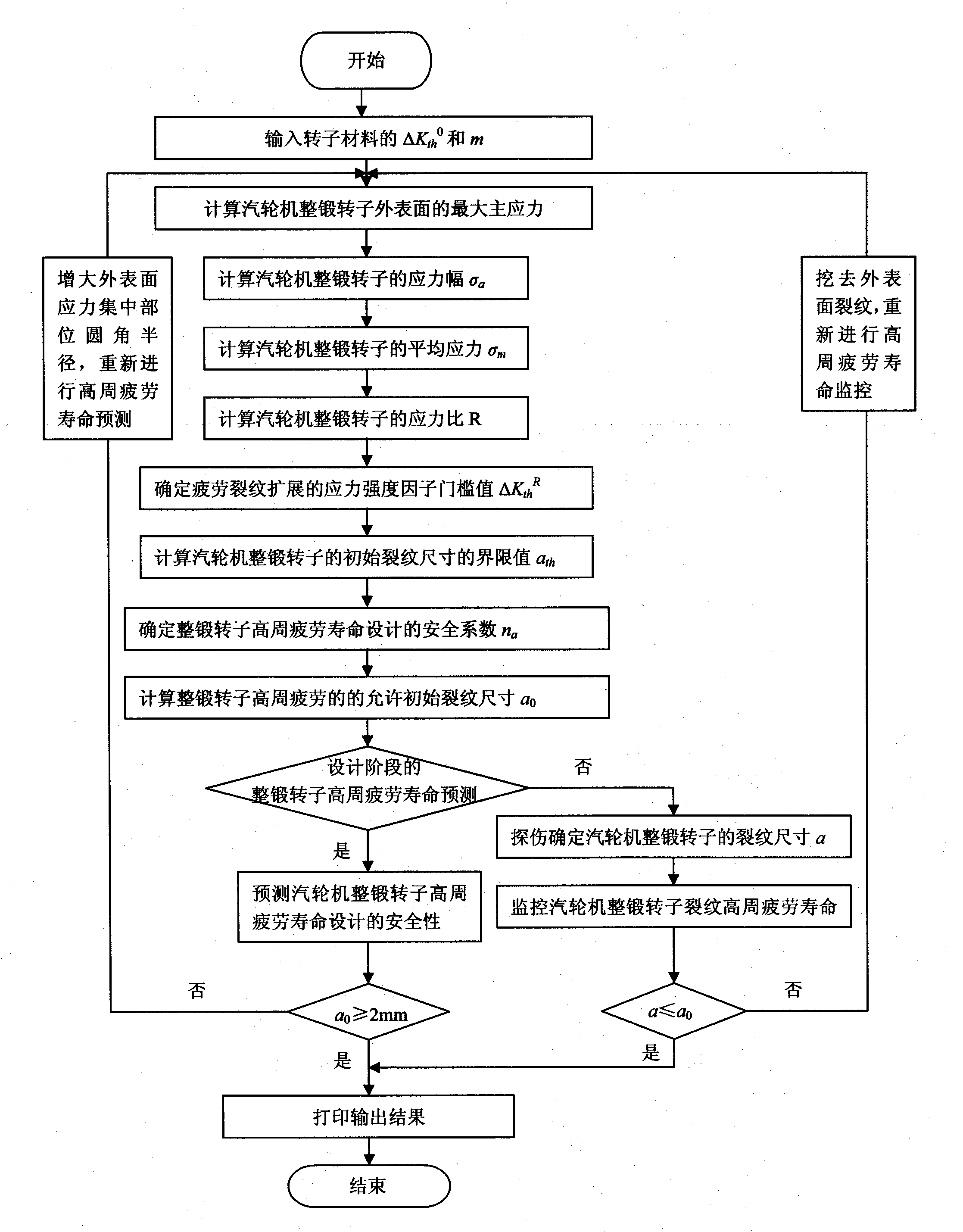

Method and device for monitoring high-cycle fatigue life of steam turbine integral rotor

ActiveCN102589867AQuantitative monitoring of cycle fatigue lifeImprove securityMachine part testingAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringLife length

The present invention provides a method and device for monitoring high-cycle fatigue life of a steam turbine integral rotor. The device for monitoring the high-cycle fatigue life of the steam turbine integral rotor is characterized by comprising an ultrasonic flaw detector and a compute server, wherein the ultrasonic flow detector is connected with the compute server. The invention has the following advantages: the quantitative prediction and the quantitative monitor of the high-cycle fatigue life of the steam turbine integral rotor are realized; if the safety of the high-cycle fatigue life of the steam turbine integral rotor does not meet the requirements, the steam turbine integral rotor is redesigned during the designing step or a crack on the surface of the steam turbine integral rotor is removed during the manufacturing step, so as to satisfy the safety requirement of the high-cycle fatigue life of the steam turbine integral rotor, furthermore the high-cycle fatigue life of the steam turbine integral rotor is quantitatively predicted and monitored.

Owner:SHANGHAI POWER EQUIP RES INST

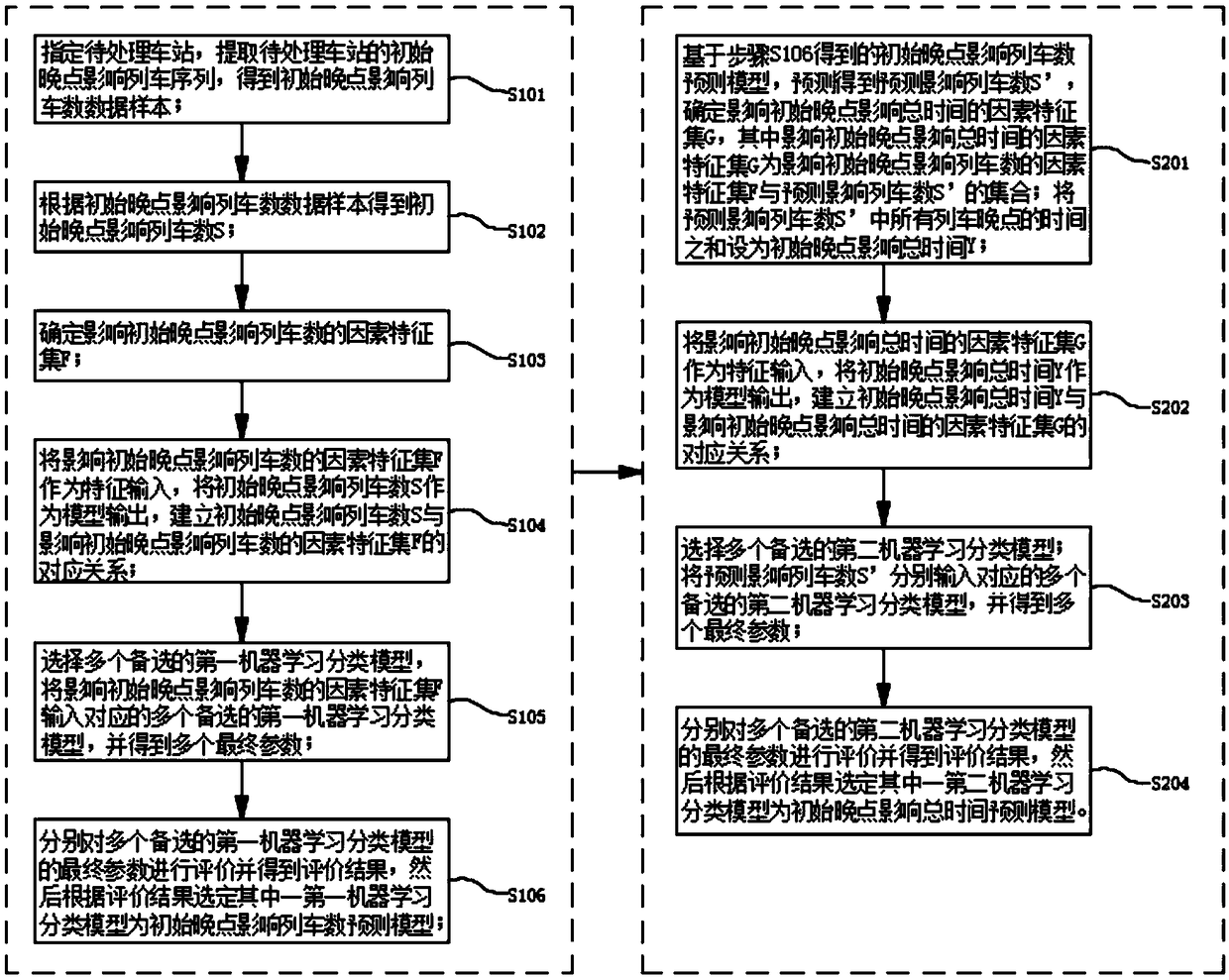

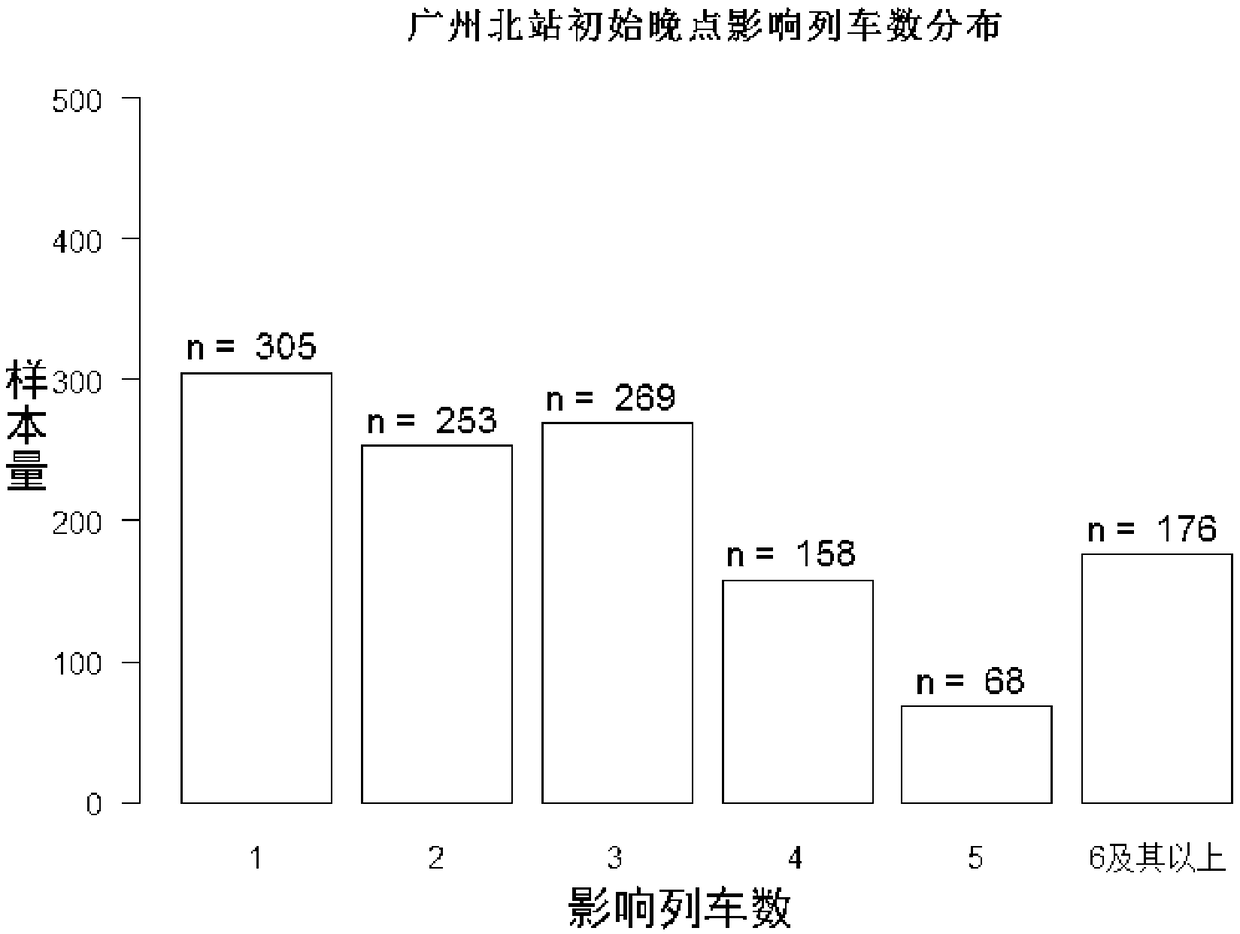

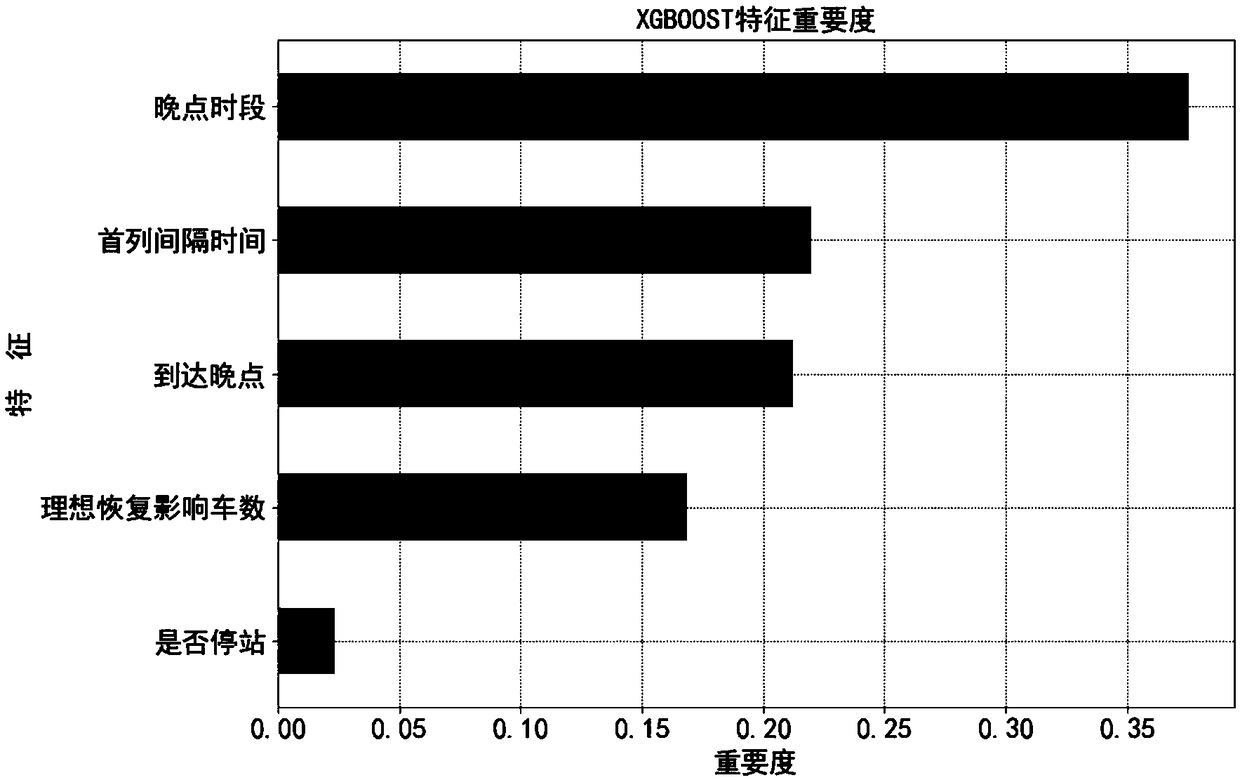

A method for establishing a high-speed train initial delay influence prediction model

ActiveCN109359788ARealize Quantitative PredictionAvoid the modeling processForecastingCharacter and pattern recognitionAlgorithmHigh speed train

The invention relates to the technical field of transportation, and aims at providing a method for establishing a high-speed train initial delay influence prediction model. The invention comprises a method for establishing an initial delay influence train number prediction model and a method for establishing an initial delay influence total time prediction model. The method for establishing an initial delay influence train number prediction model comprises the following steps of: comparing different alternatives of the first machine learning classification model, selecting the final first machine learning classification model, and selecting the final first machine learning classification model as the initial delay affecting train number prediction model. The method for establishing an initial delay influence total time prediction model comprises the following steps of: comparing different alternatives of the second machine learning classification model, selecting the final second machine learning classification model, and selecting the final second machine learning classification model as the initial delay influence total time prediction model. As that model process of the invention is convenient, the number of trains affected by the initial delay and the total time are predicted.

Owner:SOUTHWEST JIAOTONG UNIV

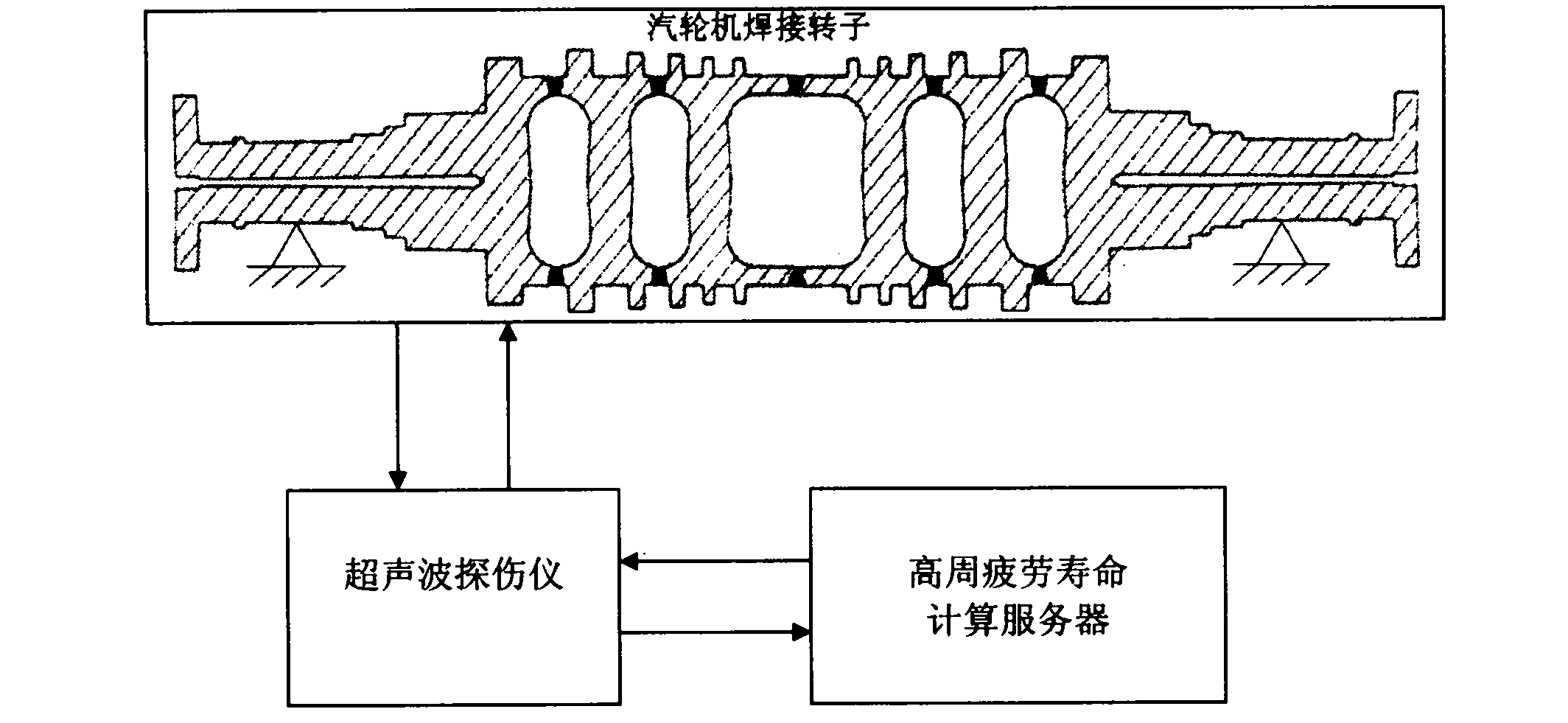

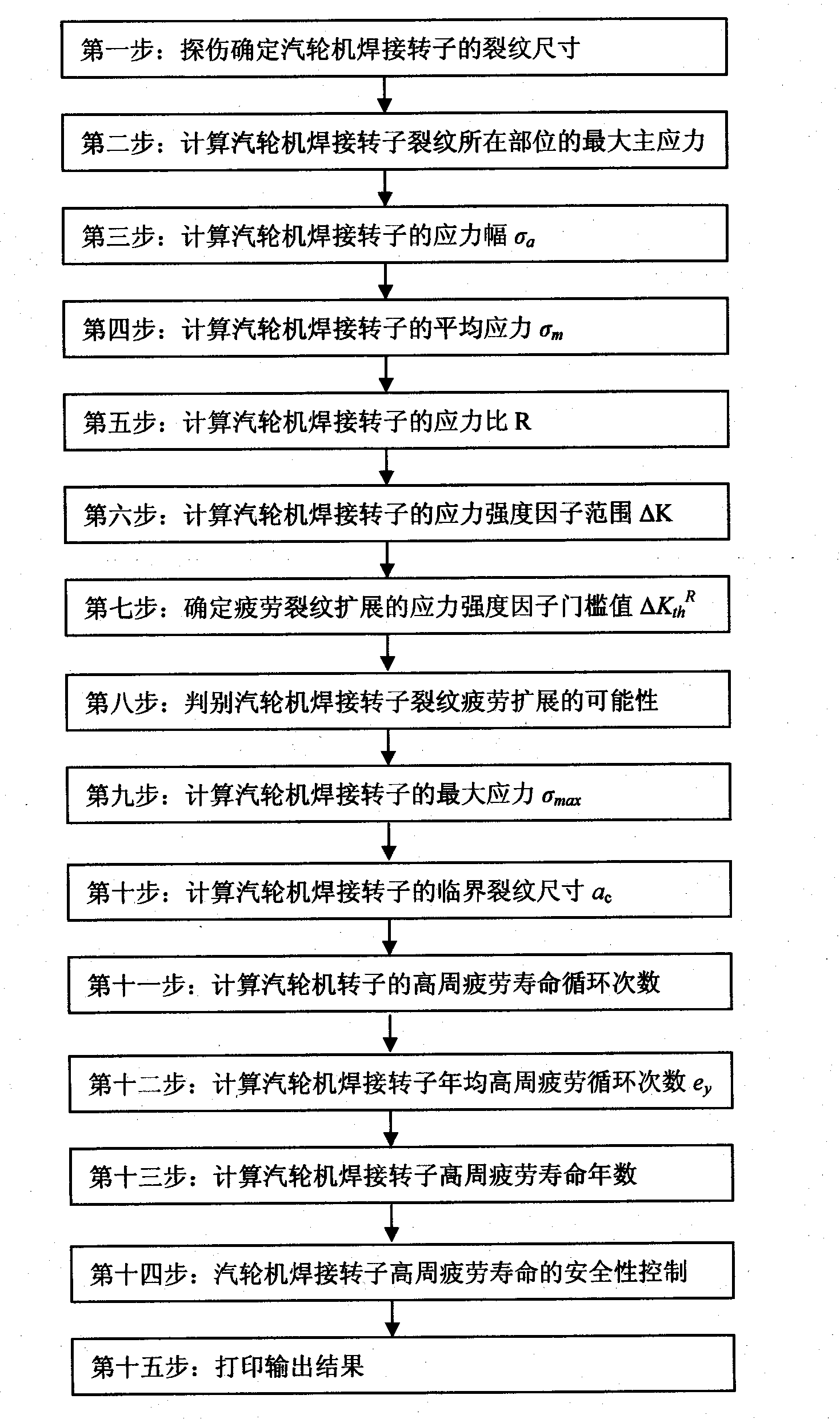

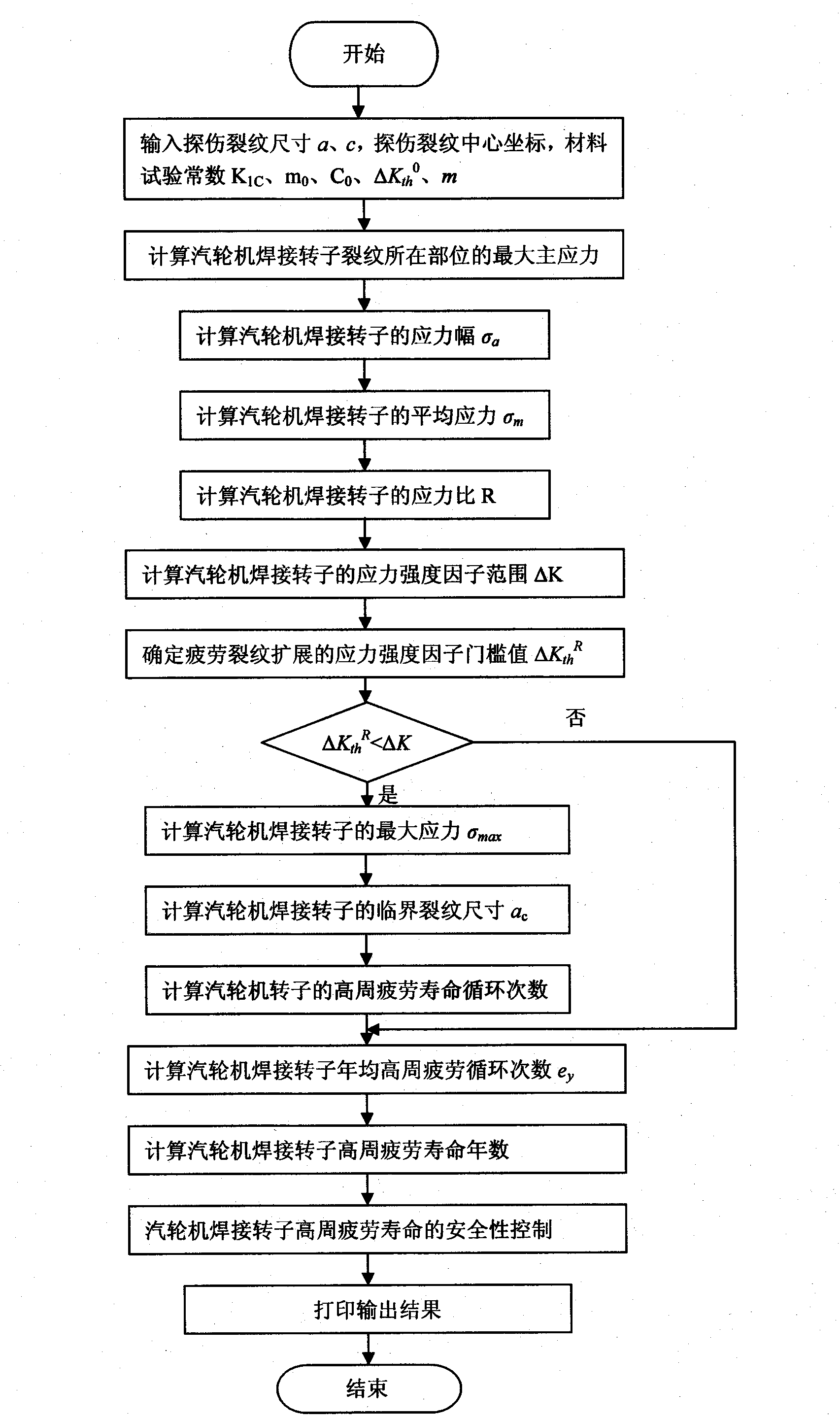

Method and device for predicting and monitoring high-cycle fatigue life of turbine welded rotor

ActiveCN102588012AQuantitative prediction of cycle fatigue lifeHigh cycle fatigue lifeMachines/enginesSafety/regulatory devicesLife timeSteam turbine rotor

The invention relates to a method and device for predicting and monitoring the high-cycle fatigue life of a turbine welded rotor. The device for monitoring the high-cycle fatigue life of a turbine welded rotor is characterized by consisting of an ultrasonic fault detector and a calculation server, wherein the ultrasonic fault detector is connected with the turbine rotor and the calculation server. Through the invention, quantitative prediction and quantitative monitoring of the high-cycle fatigue life of a turbine welded rotor are realized; if the high-cycle fatigue life of the turbine welded rotor is relatively short, the safety requirement on the high-cycle fatigue life of the turbine welded rotor is met by re-welding; and the technical effect on quantitatively monitoring the high-cycle fatigue life of the turbine welded rotor is realized.

Owner:SHANGHAI POWER EQUIP RES INST

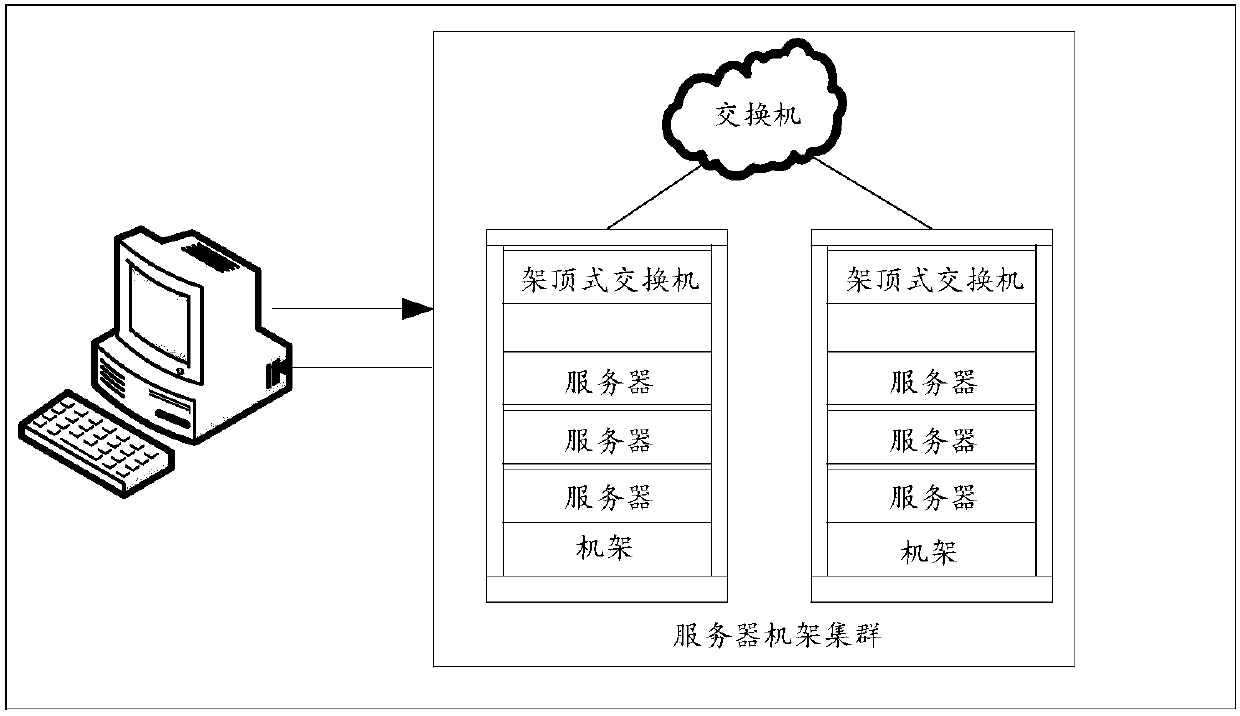

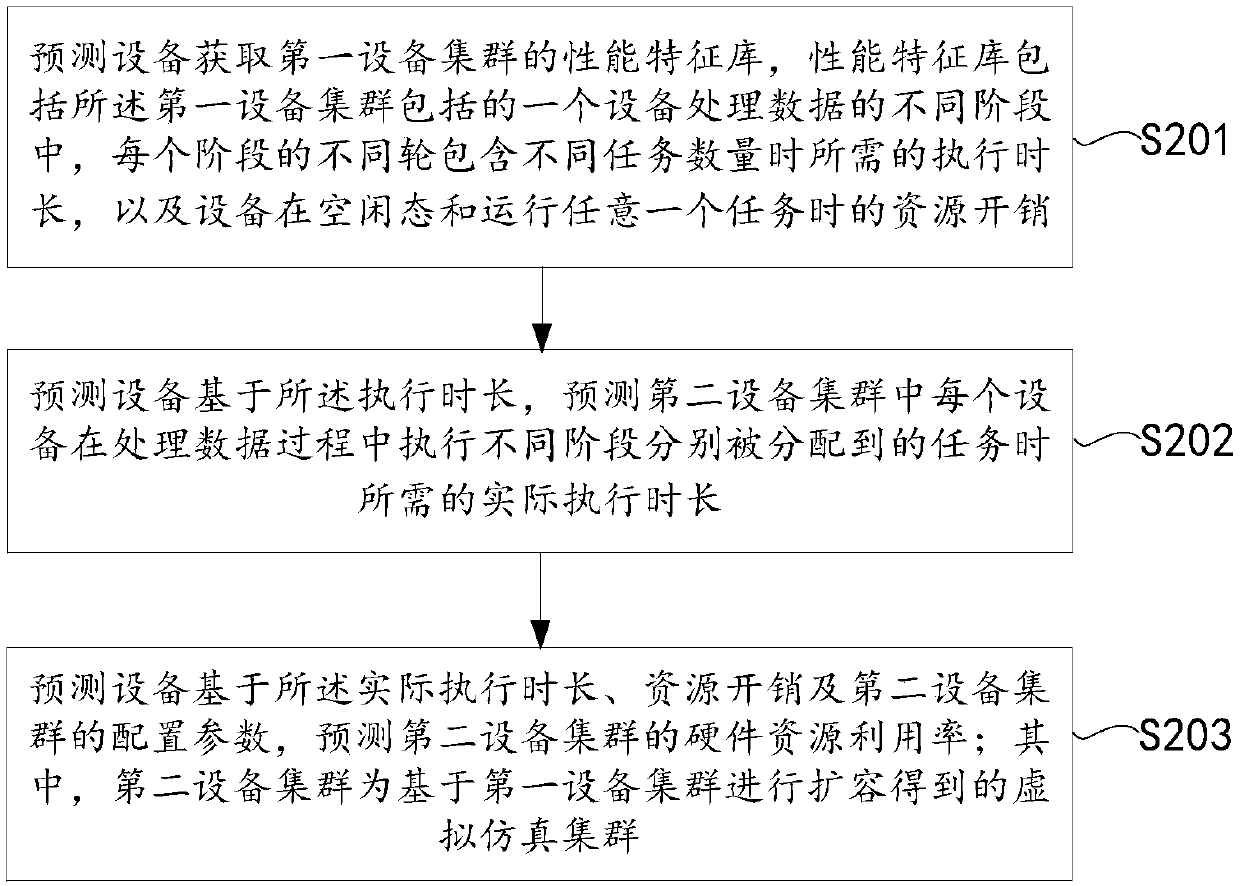

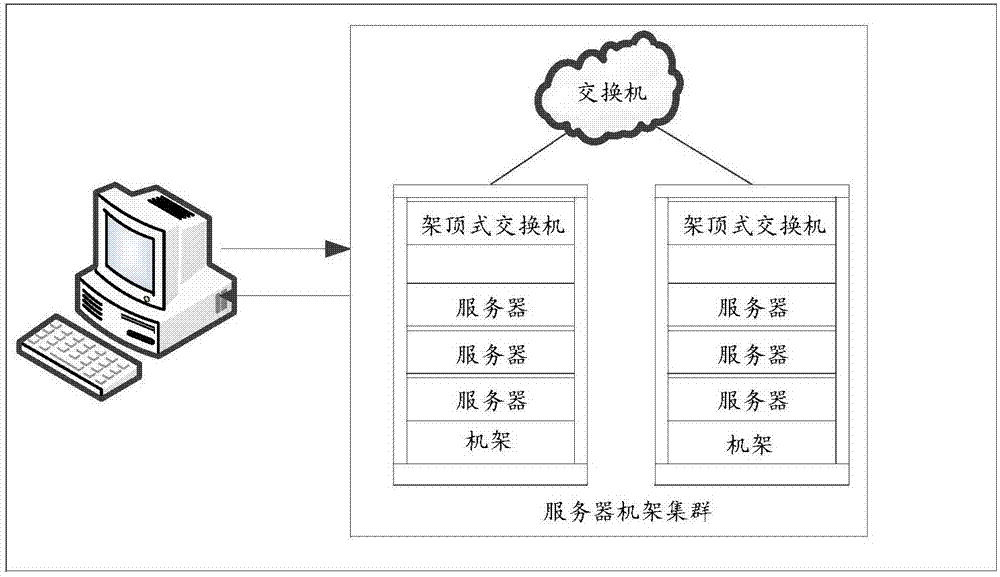

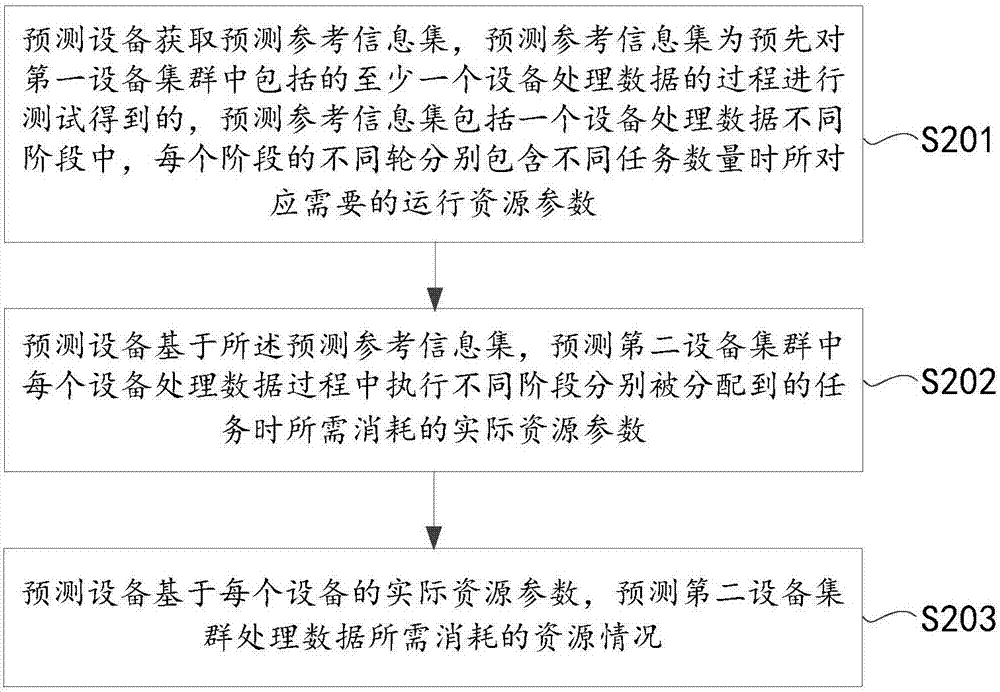

Method and device for predicting hardware resource use ratio of equipment cluster

ActiveCN107562532AHigh precisionRefine the test granularityResource allocationData switching networksUtilization factorData processing

The invention discloses a method and a device for predicting the hardware resource use ratio of an equipment cluster, and is used for improving accuracy for predicting the hardware resource use ratioof the equipment cluster. The method comprises the following steps that: prediction equipment obtains the performance feature library of a first equipment cluster, wherein the performance feature library comprises execution duration and resource expenditures generated when equipment is under an idle state and any one task is operated, the execution duration is required when different rounds of each stage contain different task amounts in different stages of one piece of equipment processing data contained in the first equipment cluster; the prediction equipment predicts practical execution duration required when each piece of equipment in a second equipment cluster executes tasks independently distributed in different stages in a data processing process according to the execution duration;and the prediction equipment predicts the hardware resource use ratio of the second equipment cluster on the basis of the practical execution duration, the resource expenditures and the configurationparameter of the second equipment cluster, wherein the second equipment cluster is a virtual simulation cluster obtained on the basis of the expansion of the first equipment cluster.

Owner:HUAWEI TECH CO LTD

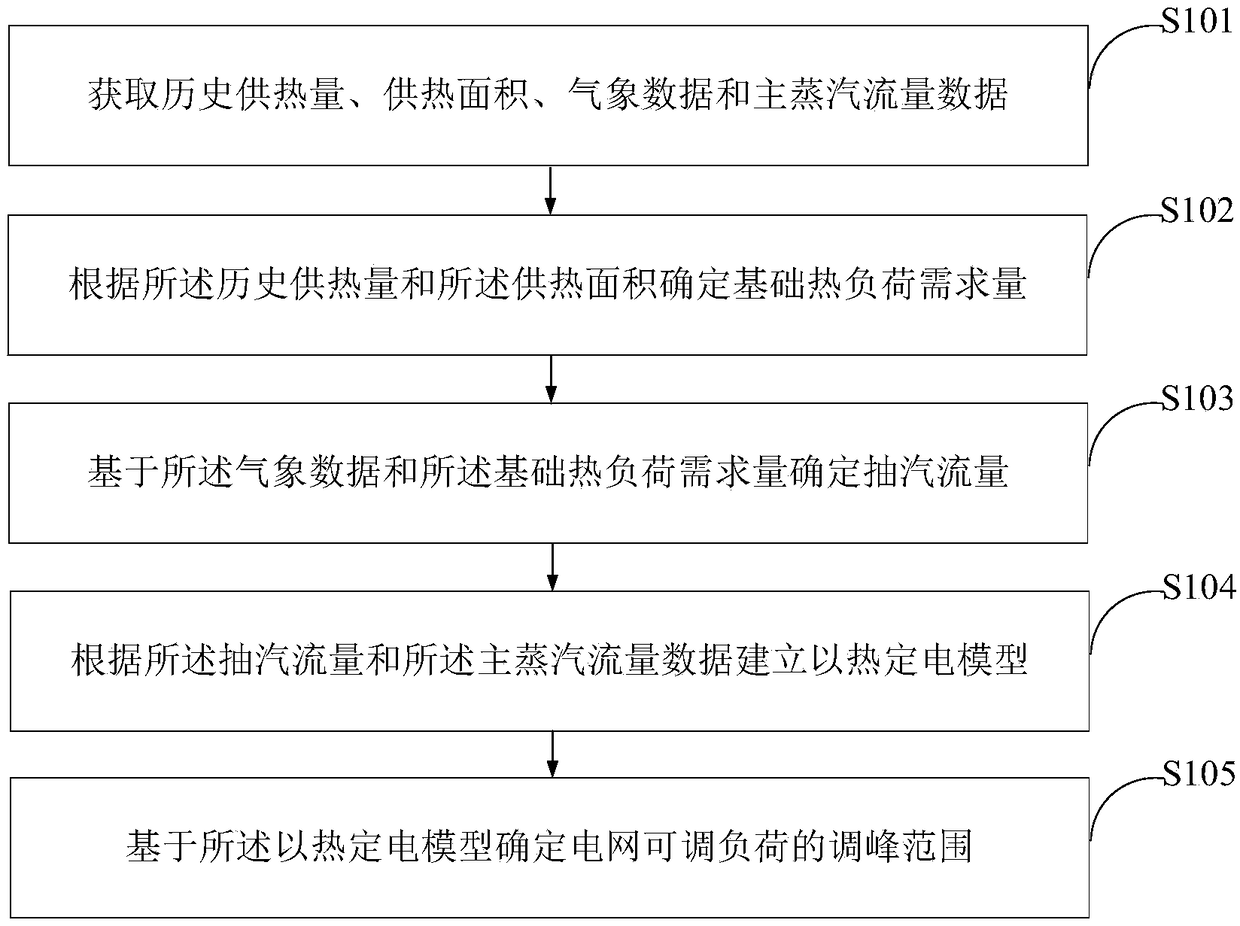

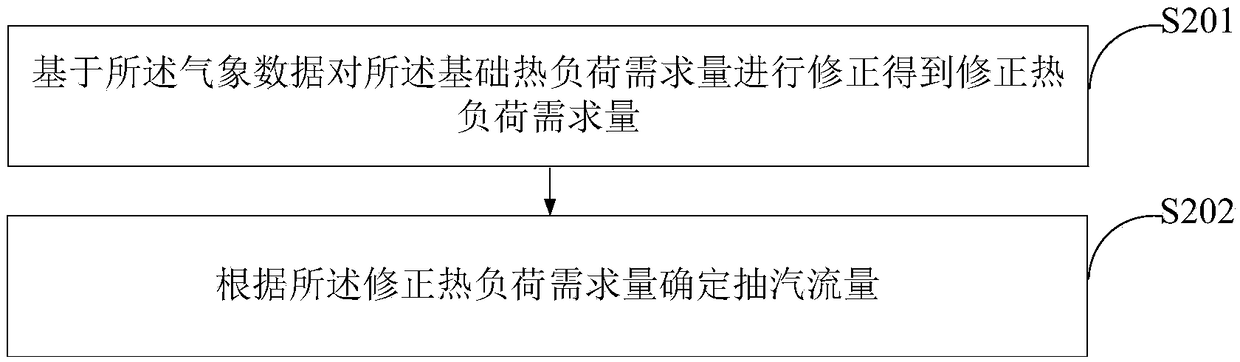

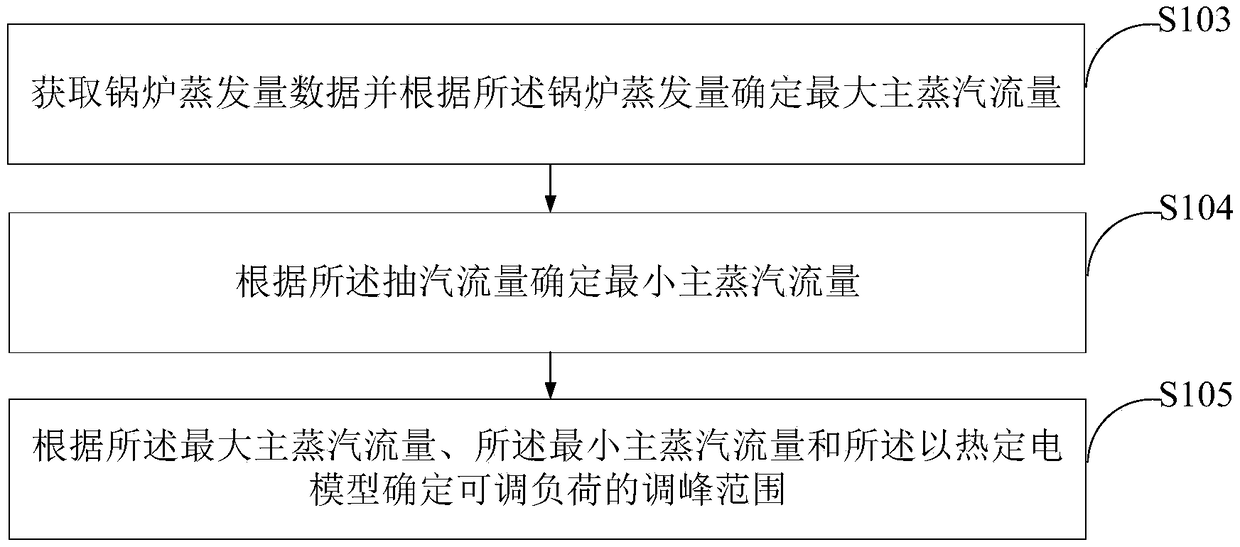

Method and device for predicting peak load regulation capability of power network

InactiveCN109193808ARealize Quantitative PredictionLoad forecast in ac networkSingle network parallel feeding arrangementsPower gridEngineering

The invention provides a method and a device for predicting the peak load regulation capacity of a power network. The method comprises the following steps: acquiring historical heat supply quantity, heat supply area, meteorological data and main steam flow data; Determining a basic heat load demand amount according to the historical heat supply amount and the heat supply area; Determining an extraction steam flow rate based on the meteorological data and the basic heat load demand; Establishing a thermostatic electric model according to the extraction steam flow rate and the main steam flow rate data; Determining a peak regulation range of an adjustable load of a power network based on the thermostatic model. The invention provides a method and a device for predicting the peak load regulation capacity of a power network, which can realize the quantitative prediction of the peak load regulation capacity of the power network.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +2

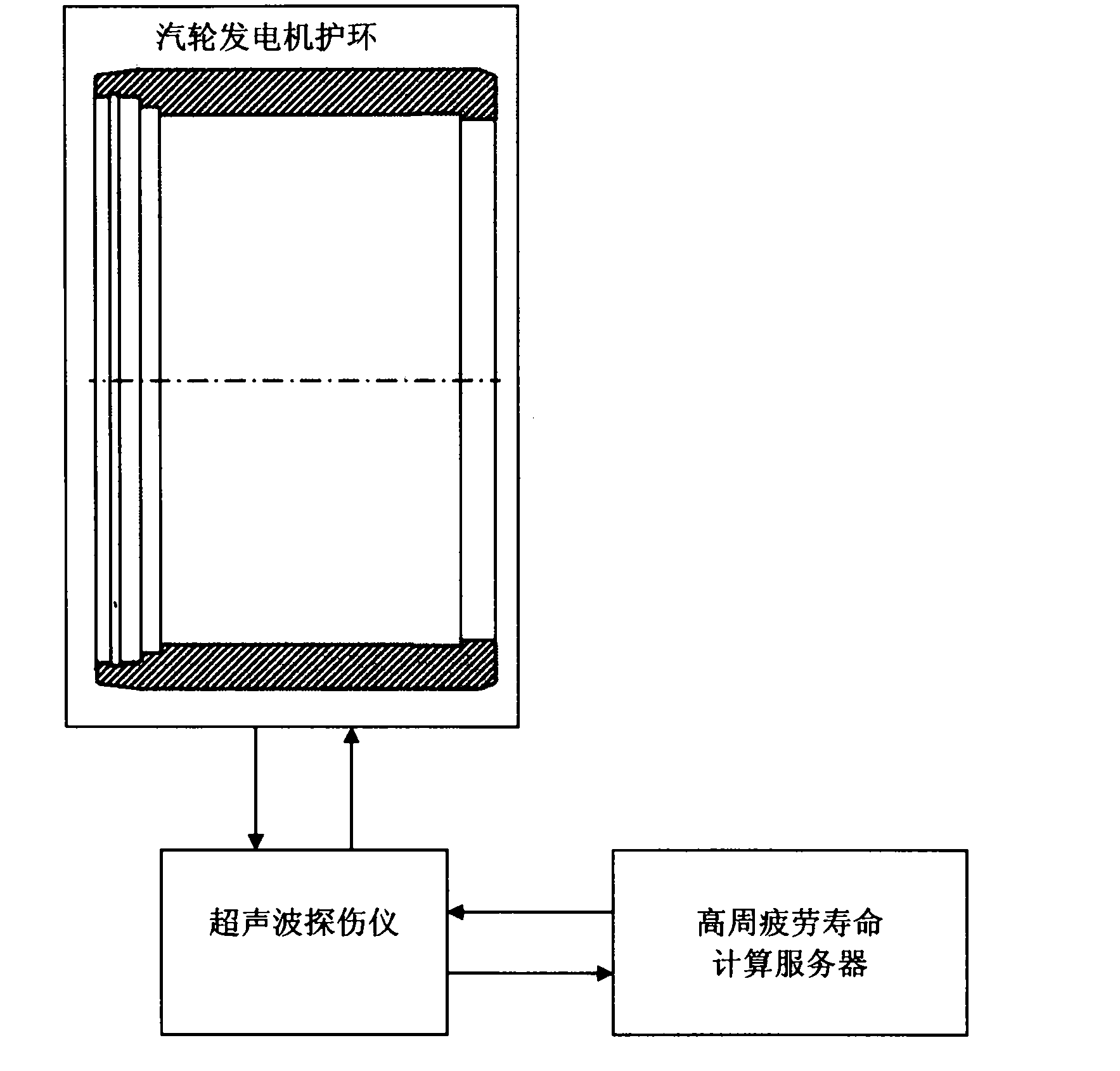

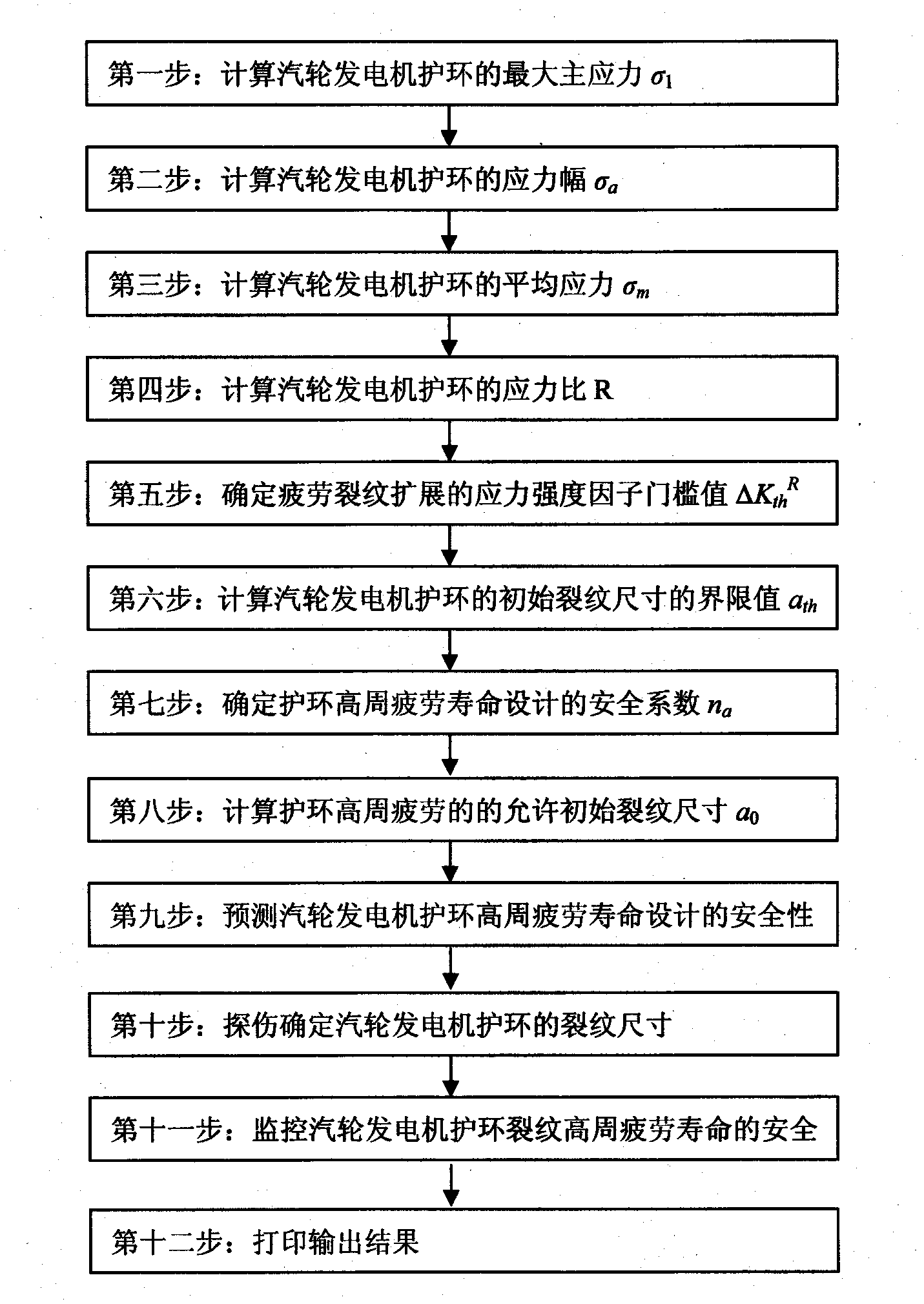

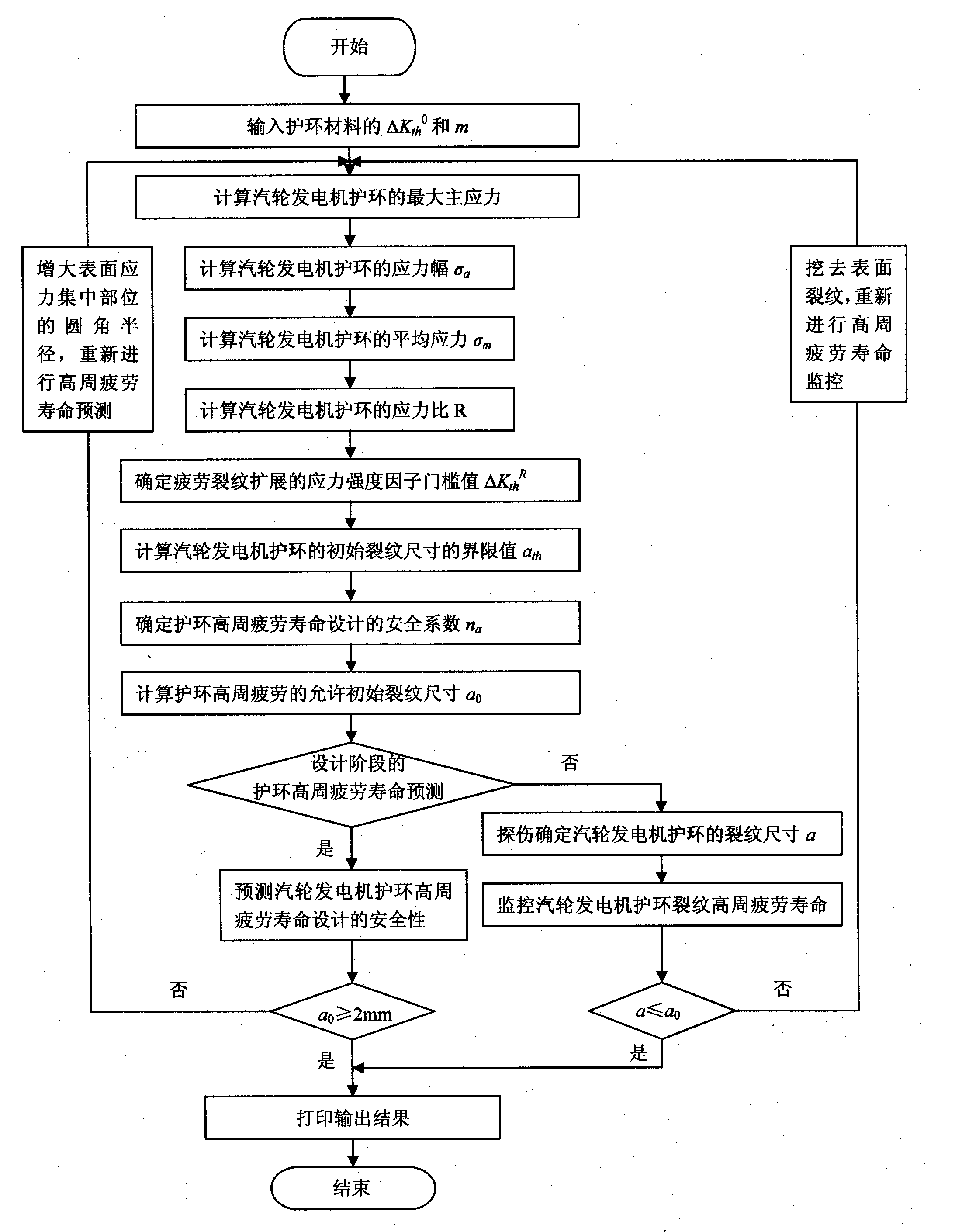

Method for predicting high cycle fatigue life of steam turbine generator retaining ring and device for monitoring high cycle fatigue life of steam turbine generator retaining ring

ActiveCN102541053AHigh cycle fatigue lifeQuantitative monitoring of cycle fatigue lifeAnalysing solids using sonic/ultrasonic/infrasonic wavesElectric testing/monitoringRetaining ringElectric generator

The invention provides a method for predicting high cycle fatigue life of a steam turbine generator retaining ring and a device for monitoring the high cycle fatigue life of the steam turbine generator retaining ring. The device for monitoring the high cycle fatigue life of the steam turbine generator retaining ring is characterized by consisting of an ultrasonic flaw detector and a computation server, wherein the ultrasonic flaw detector is connected with the steam turbine generator retaining ring and the computation server. The invention has the advantages that: quantitative prediction and quantitative monitoring on the high cycle fatigue life of the steam turbine generator retaining ring are realized; and if the safety of the high cycle fatigue life of the steam turbine generator retaining ring does not meet the requirement, the steam turbine generator retaining ring is required to meet the requirement for the safety of the high cycle fatigue life by redesigning in a design stage or removing surface crackles in a manufacturing stage, thus achieving a technical effect that the high cycle fatigue life of the steam turbine generator retaining ring is quantitatively predicted and monitored.

Owner:SHANGHAI POWER EQUIP RES INST

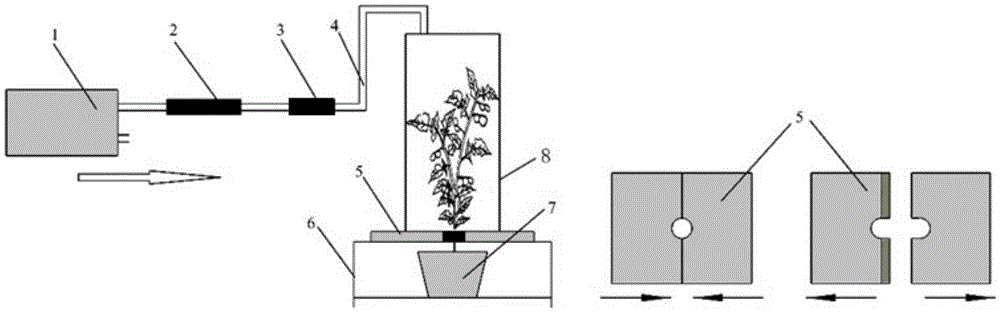

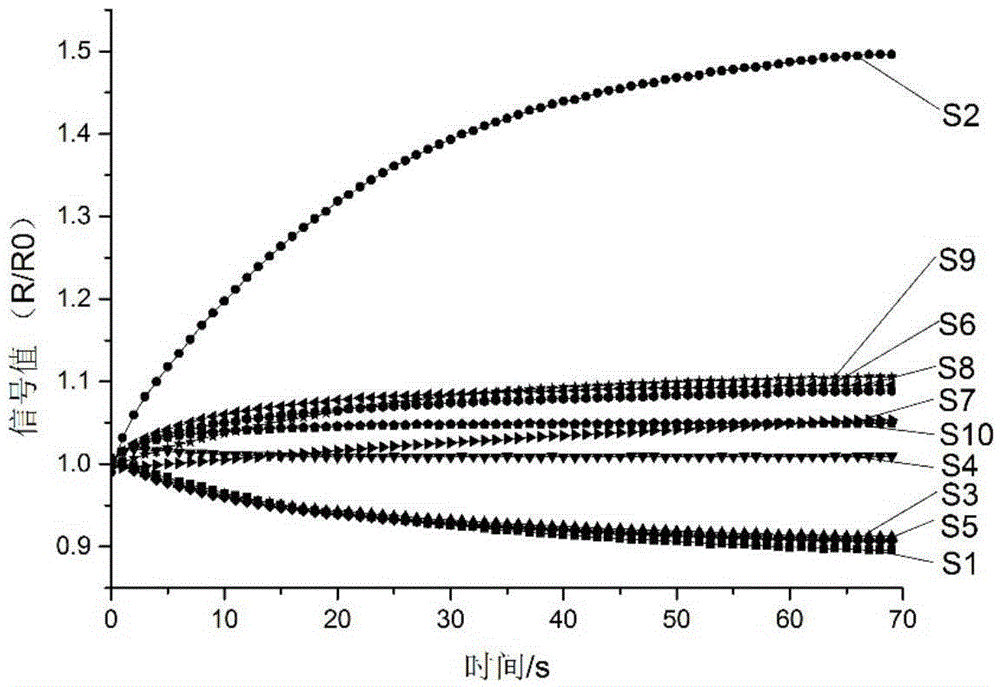

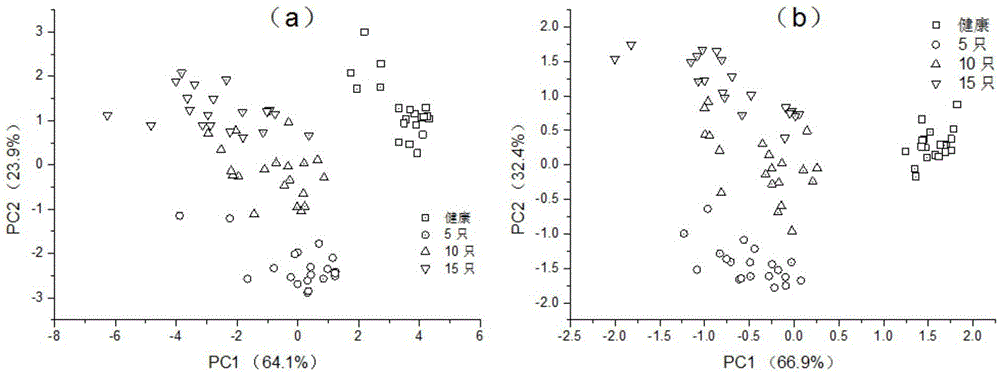

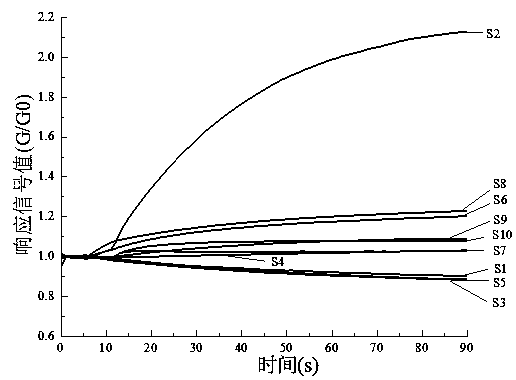

Method for fast predicting injurious insect invading degree of tea trees based on electronic nose

ActiveCN105572305ARealize Quantitative PredictionTesting plants/treesSensor arrayPrincipal component analysis

The invention discloses a method for fast predicting the injurious insect invading degree of tea trees based on an electronic nose. Tea tree leaves are thoroughly washed, dust is removed, and a healthy and undamaged tea tree is selected as a detected object. The tea trees are grouped, injurious insects with different numbers are transplanted to different tea tree sample groups, the tea trees subjected to different kinds of treatment are placed into an electronic nose sample headspace device to stand still for a period of time, then the electronic nose is used for detection, the healthy and undamaged tea tree is adopted as a control group, a sensor array is optimized through a principal component analysis method according to acquired data, and the number of the sensors is reduced. A partial least squares method regression model is adopted for building a quantitative prediction model between the response value of the optimized sensor array and the injurious insect invading degree. The method for fast predicting the injurious insect invading degree of the tea trees is provided, the tea samples are not damaged, operation is easy, a good prediction effect is achieved, and high utilization and popularization value is achieved.

Owner:ZHEJIANG UNIV

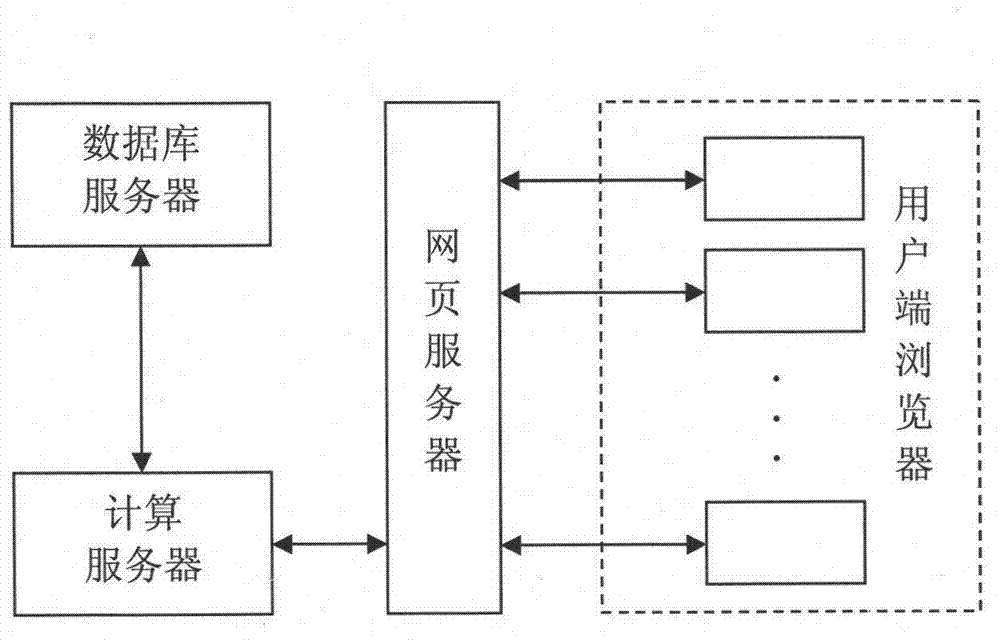

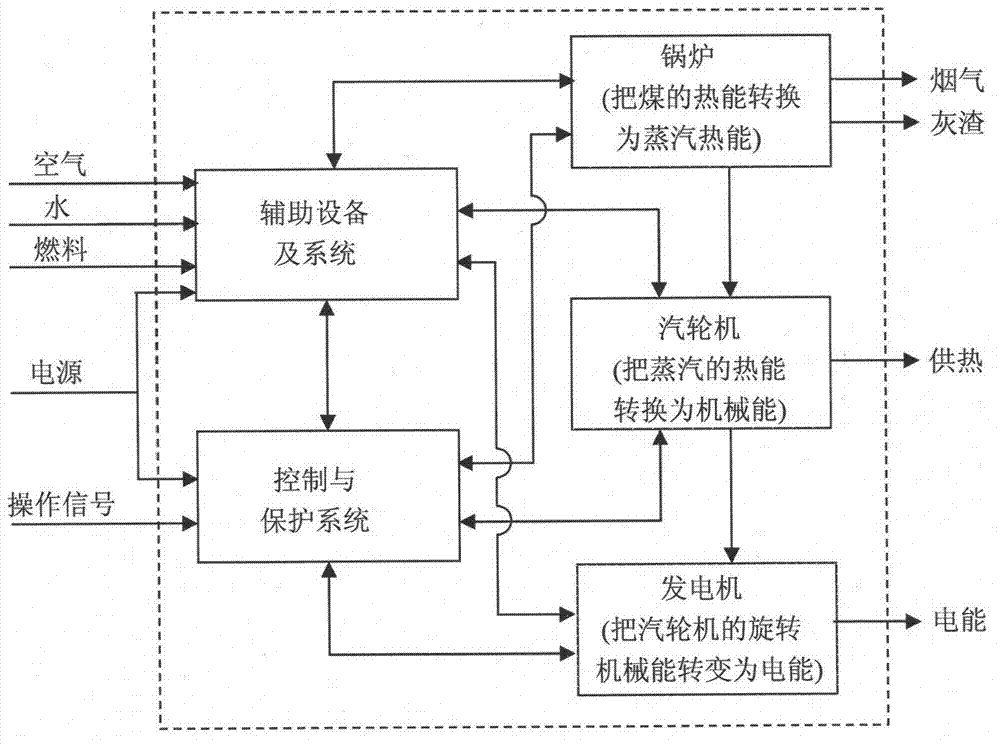

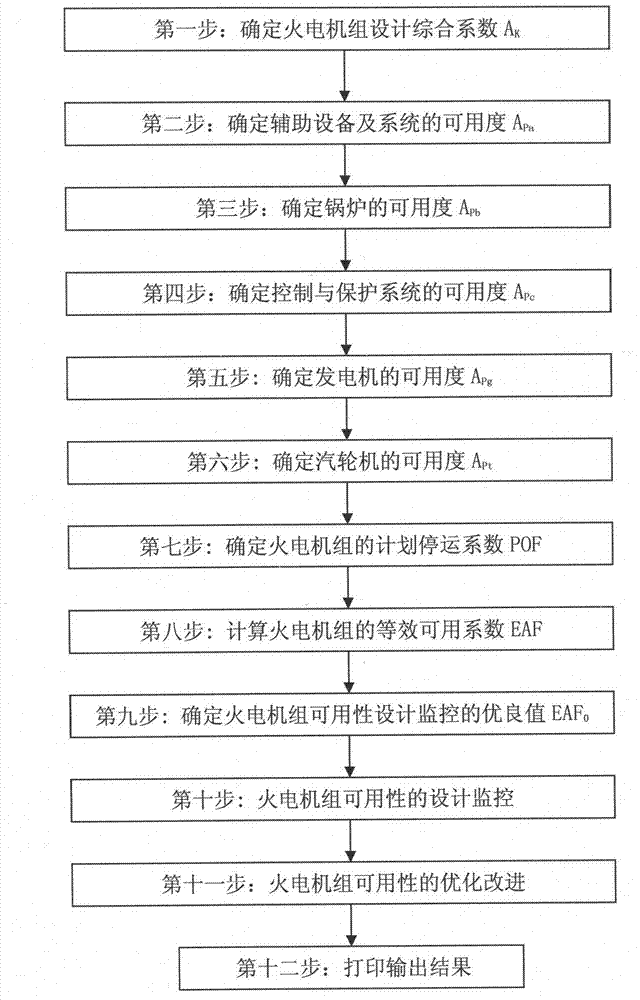

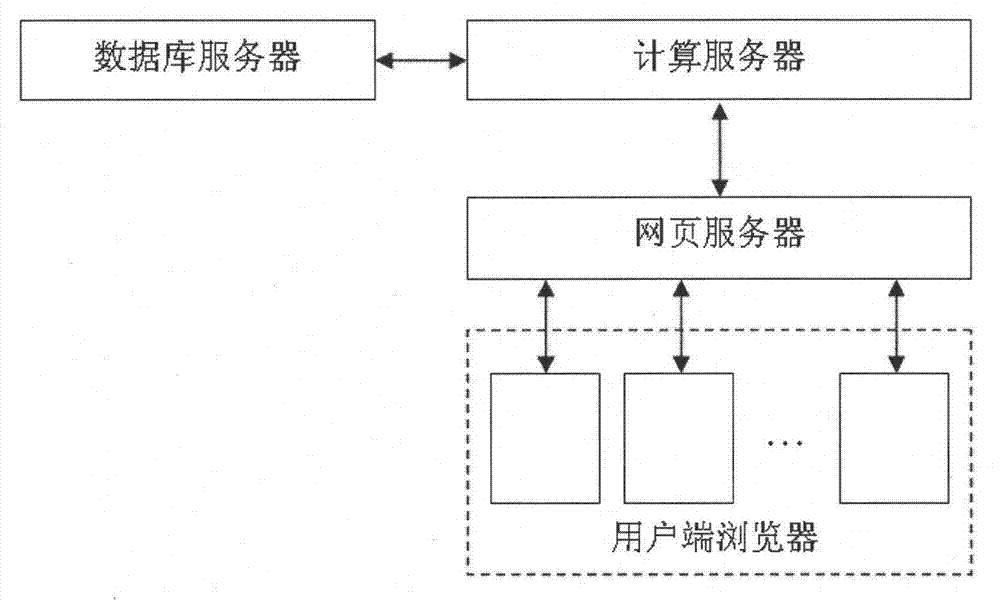

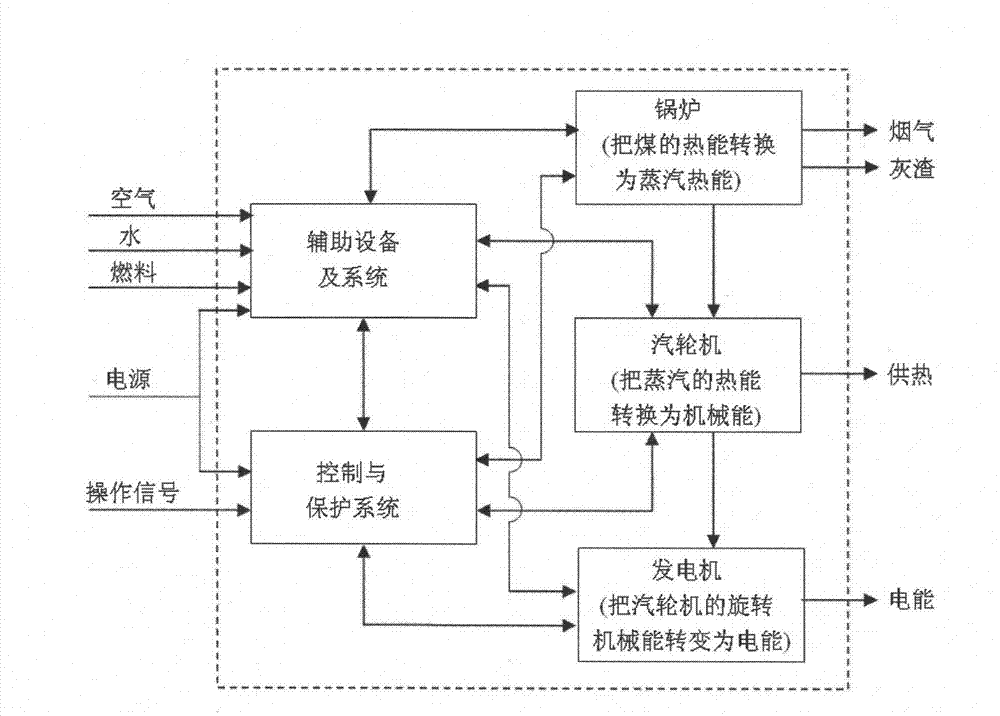

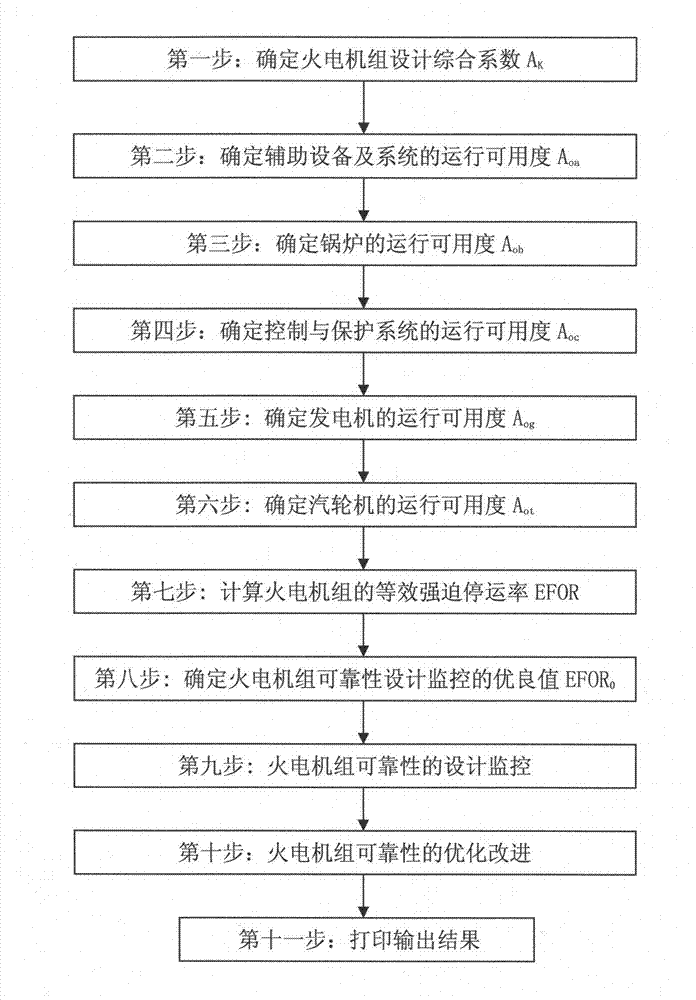

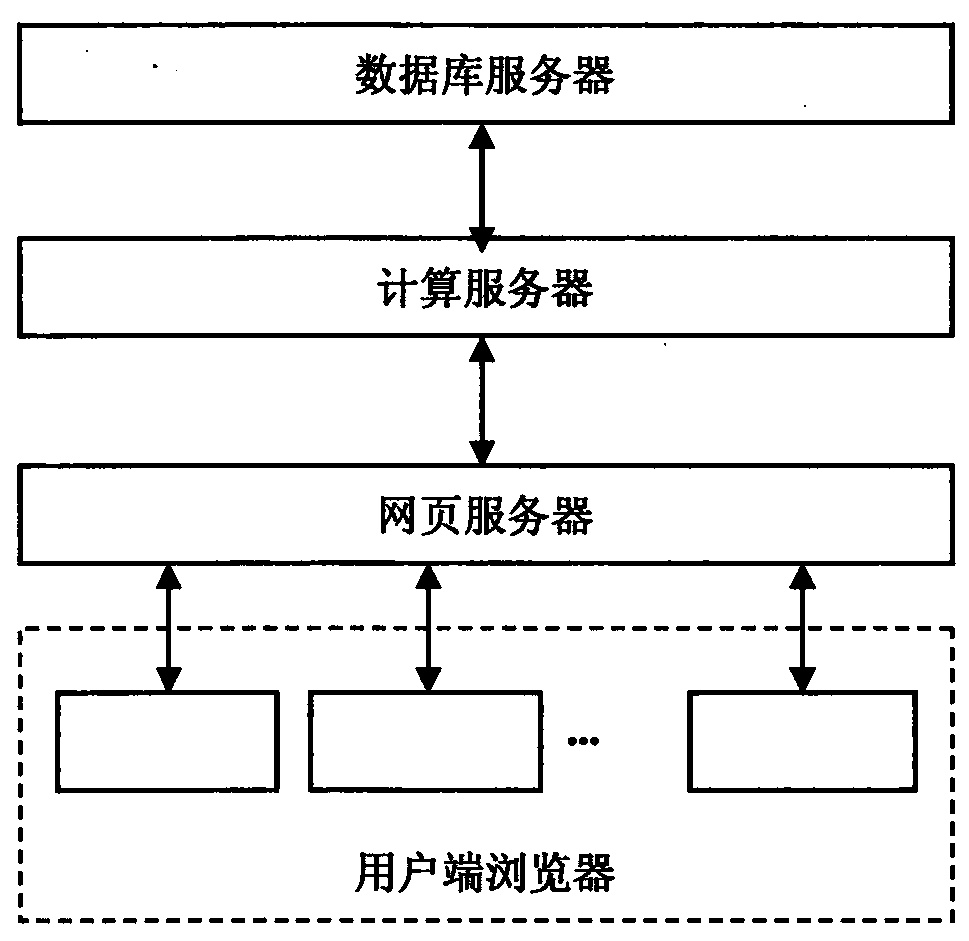

Design monitoring device and method for thermal power generating unit usability

ActiveCN103093032AImprove usabilityRealize Quantitative PredictionSpecial data processing applicationsInformation technology support systemWeb serverMaterial Design

The invention relates to a design monitoring device for thermal power generating unit usability. The design monitoring device for the thermal power generating unit usability is characterized by comprising a thermal power generating unit usability computing server, a data base server, a web page server and a user side browser, wherein the computing server is connected with the data base server and the web page server, and the web page server is connected with the user side browser. The other technical scheme of the invention provides a thermal power generating unit usability design monitoring method adopted for the design monitoring device for the thermal power generating unit usability. The design monitoring device and the design monitoring method for the thermal power generating unit usability have the advantages that the design monitoring device and the design monitoring method for the thermal power generating unit usability are provided, and the quantitative forecast and the design monitoring for the thermal power generating unit usability are achieved. If the equivalent available factor (EAF) of a thermal power generating unit falls short of a good value, the optimization and the improvement of the thermal power generating unit usability are achieved through the improvement of material design of high-temperature steam pipelines of the thermal power generating unit, the adoption of redundancy design for major auxiliary devices and systems and the adoption of matured products or products of the same type.

Owner:SHANGHAI POWER EQUIP RES INST +1

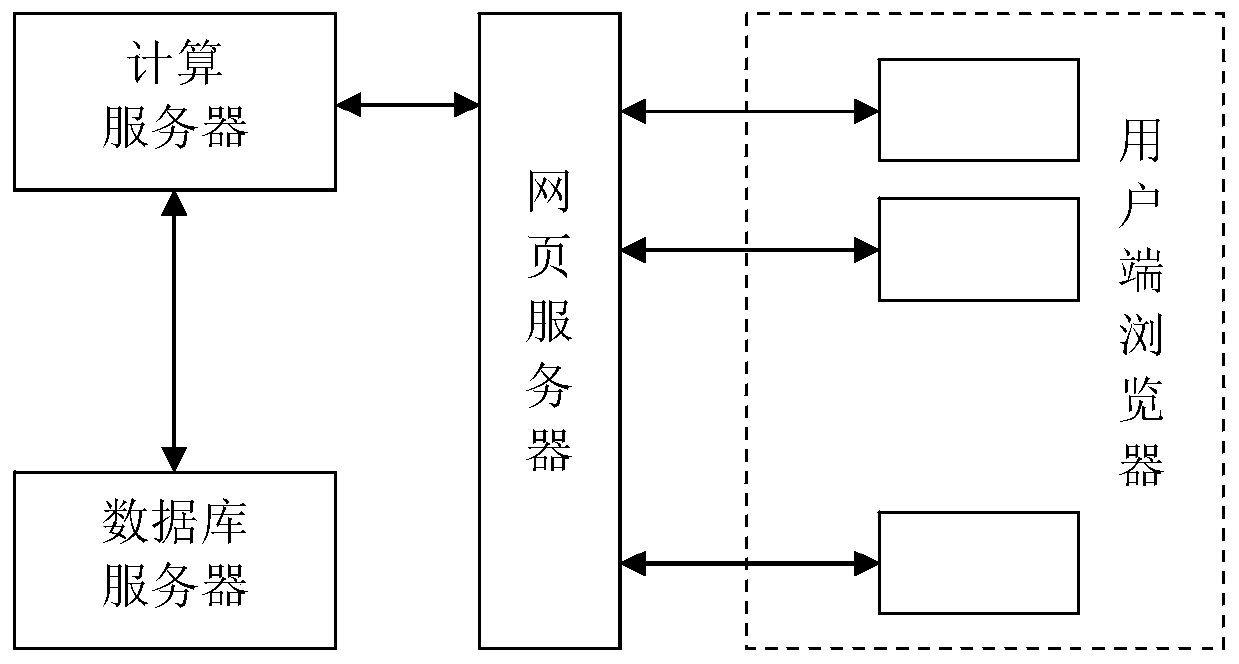

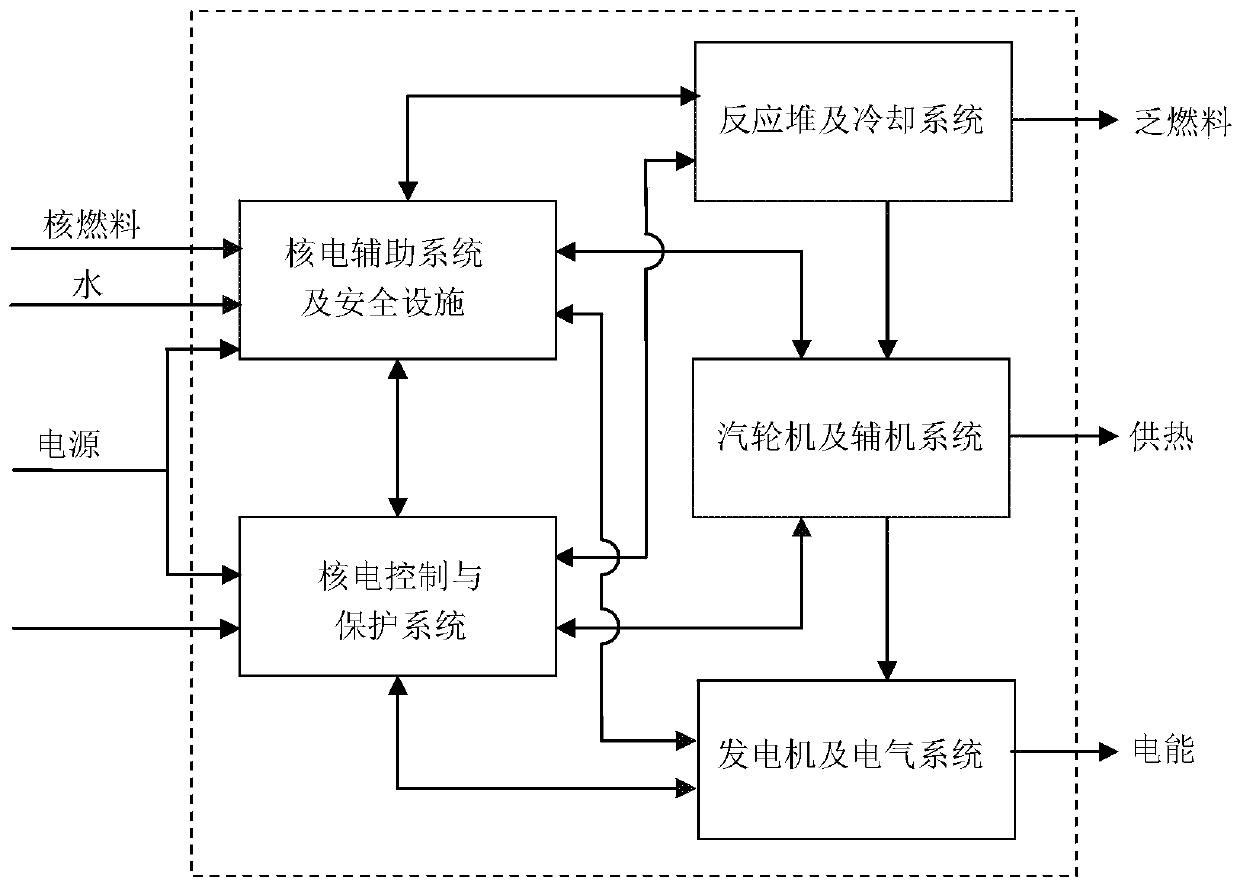

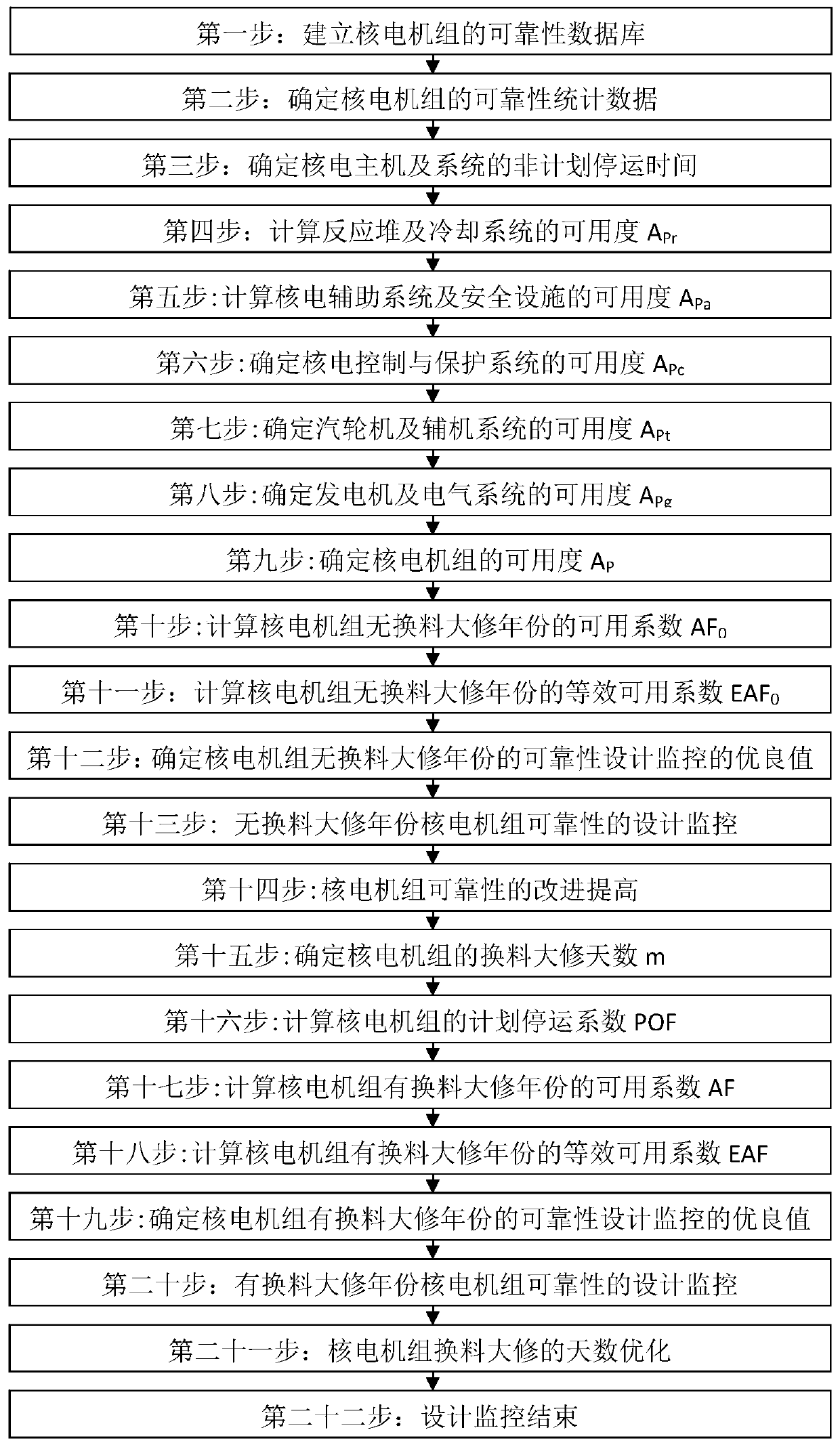

High-reliability design monitoring system and method for nuclear power unit

ActiveCN110930077AImprove reliabilityOptimizing refueling and overhaul daysResourcesComplex mathematical operationsNuclear powerDatabase server

The invention provides a high-reliability design monitoring system and method for a nuclear power unit. The high-reliability design monitoring system comprises a nuclear power unit reliability computing server, wherein the computing server is used for operating reliability design monitoring and improvement software of the nuclear power unit, the computing server is in communication connection witha database server used for storing basic data of the operation reliability of the nuclear power unit and a webpage server; and the webpage server is in communication connection with a user side browser. The high-reliability design monitoring system improves the reliability of the nuclear power unit by improving and designing materials, structures and subsystems of the first three parts with relatively long non-planned outage hours of the nuclear power unit host and the subsystems, adopting mature products, optimizing refueling overhaul days of the nuclear power unit and the like, achieves thetechnical effect of improving the reliability of the nuclear power unit through reliability design monitoring, and achieves quantitative prediction and design monitoring of the reliability of the nuclear power unit in the design stage.

Owner:SHANGHAI POWER EQUIP RES INST

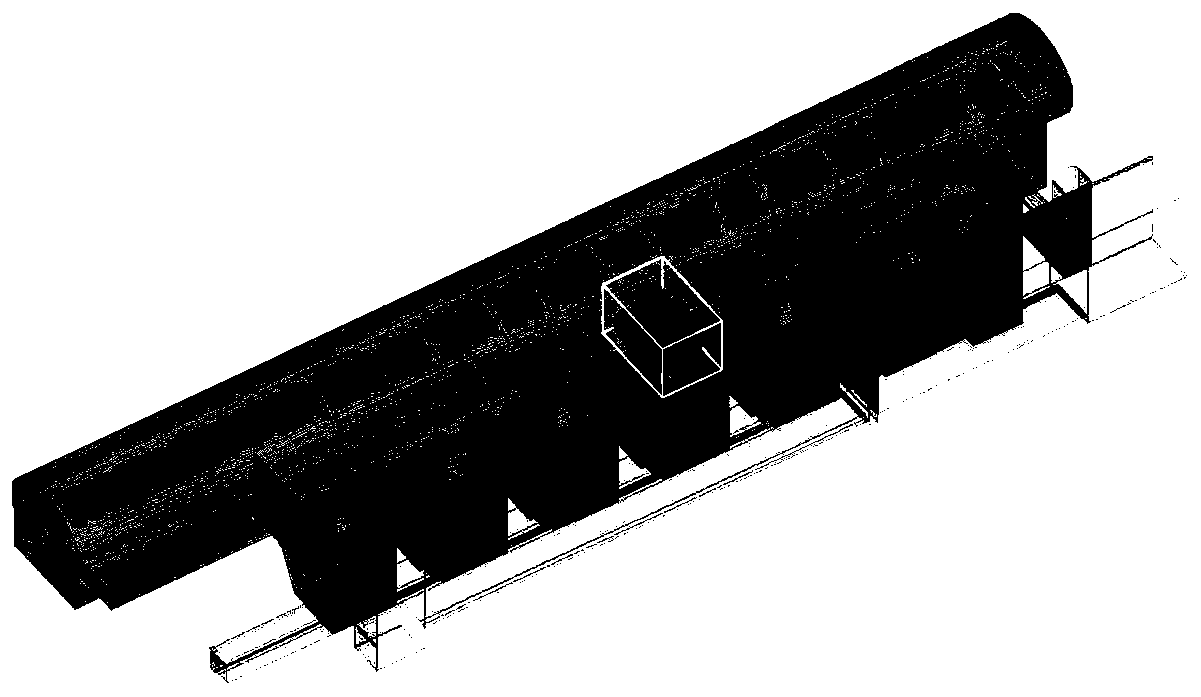

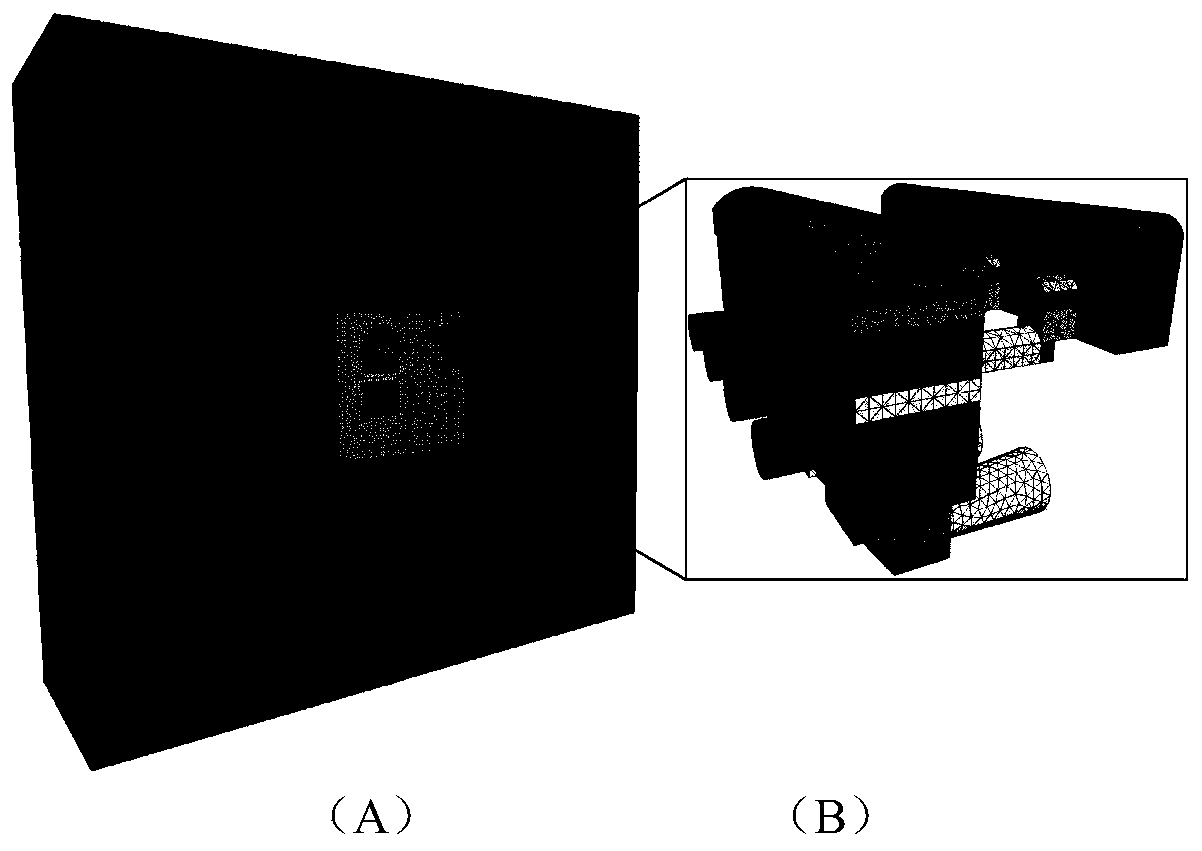

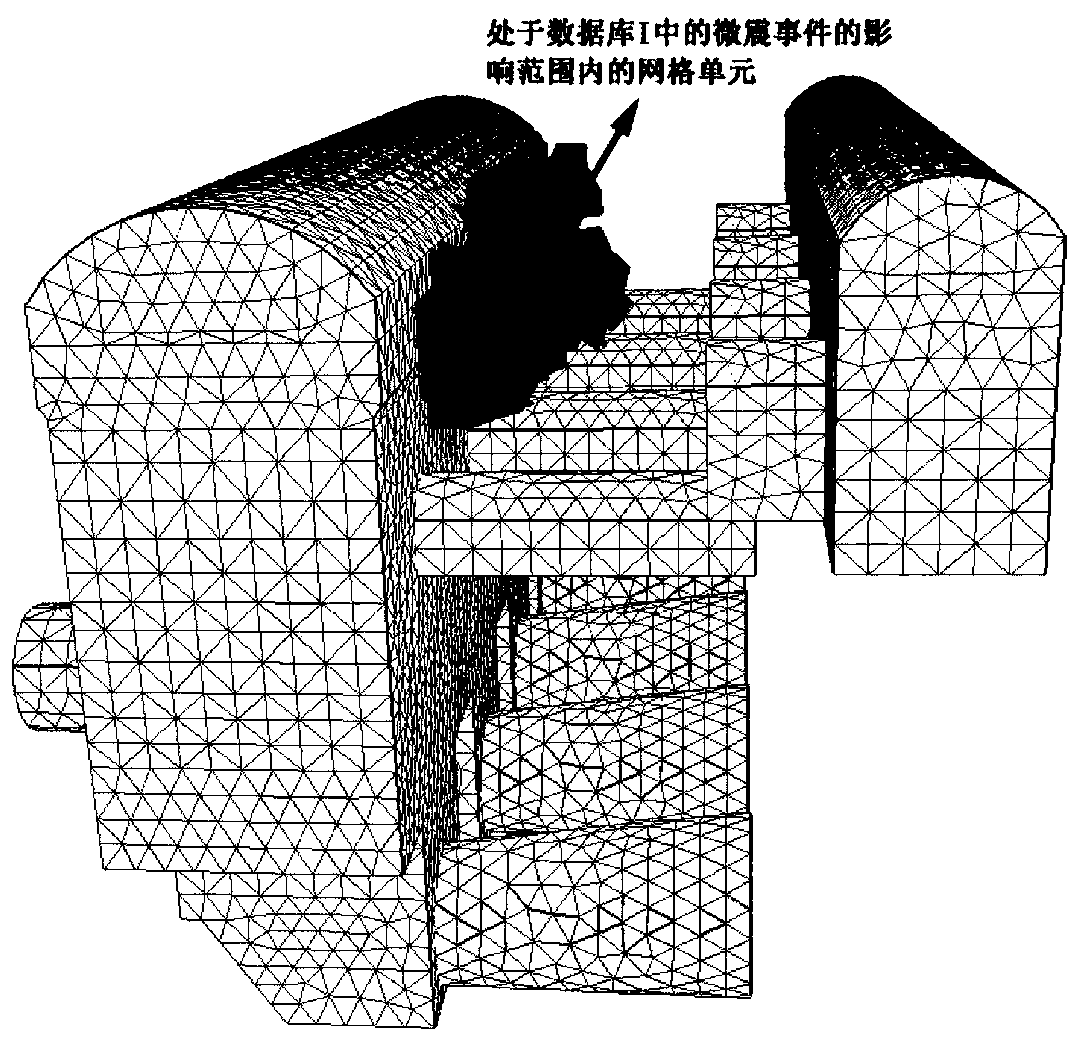

High side wall displacement quantitative prediction method for a steeply-inclined stratified rock cavern group

ActiveCN111538071AApplicable to real-time dynamic analysis of stabilityReduce the minimum configuration requirementsGeometric CADEarthquake measurementAnalogue computationUnderground cavern

The invention provides a high side wall displacement quantitative prediction method for a steeply-inclined stratified rock cavern group. The method comprises the following steps: installing an ESG micro-seismic monitoring system, capturing a micro-seismic event occurring in a side wall area, and establishing micro-seismic databases I and II; establishing a numerical calculation model, and performing simulation calculation on an excavation process by adopting FLAC3D software according to a field excavation scheme of the underground cavern; determining the influence range of each micro-seismic event in the micro-seismic database I and calculating the seismic efficiency; calculating a mechanical strength parameter after the grid unit is degraded; after the ESG micro-seismic monitoring systemcaptures a micro-seismic event each time, substituting the mechanical strength parameters after grid unit degrading into a calculation model and carrying out analog calculation; obtaining the displacement values of all the grid units after the micro-seismic event occurs, and calculating a predicted displacement value of the layered surrounding rock of each part of the underground cavern side wallarea by combining the centroid coordinates of each grid unit, so as to realize the real-time quantitative prediction of the displacement of the high side wall.

Owner:CHANGAN UNIV

Thermal power generating unit reliability design monitoring device and thermal power generating unit reliability design monitoring method

ActiveCN103049613AImprove reliabilityRealize Quantitative PredictionSpecial data processing applicationsMaterial DesignDatabase server

The invention provides a thermal power generating unit reliability design monitoring device. The device is characterized by comprising a thermal power generating unit reliability compute server, a database server, a web server and user side browsers, the compute server is connected with the database server and the web server, and the web server is connected with the user side browsers. In another technical scheme, the invention provides a thermal power generating unit reliability design monitoring method adopting the thermal power generating unit reliability design monitoring device. By the thermal power generating unit reliability design monitoring device and the thermal power generating unit reliability design monitoring method, quantitative forecasting and design monitoring of power generating unit reliability area achieved. If equivalent forced outage rate of a thermal power generating unit cannot reach an excellent value, reliability of the thermal power generating unit is improved and optimized by means of improving material design of a high-temperature steam pipeline of the thermal power generating unit, adopting redundancy design for important auxiliary equipment and a system or adopting mature products, and accordingly technical effect of improving the reliability of the thermal power generating unit is achieved by the aid of reliability design monitoring.

Owner:SHANGHAI POWER EQUIP RES INST

Equipment cluster scaling performance prediction method and device

ActiveCN107493205ARealize Quantitative PredictionHigh precisionData switching networksReal-time computingTask number

The invention provides an equipment cluster scaling performance prediction method and device which are used for improving the equipment cluster scaling performance prediction precision. The method comprises the steps that prediction equipment acquires a prediction reference information set, wherein the prediction reference information set is obtained by testing the process that at least one equipment in a first equipment cluster process data in advance and comprises operating resource parameters correspondingly needed when different rounds of each stage contain different task numbers in the process that one equipment processes the data in different stages; the prediction equipment predicts actual resource parameters needing to be consumed when each equipment in a second equipment cluster executes allocated tasks in different stages in the data processing process on the basis of the prediction reference information set; and the prediction equipment predicts the resource consuming condition when the second equipment cluster processes the data on the basis of the actual resource parameters of each equipment, wherein the second equipment cluster is a virtual simulation cluster obtained by scaling the first equipment cluster.

Owner:HUAWEI TECH CO LTD

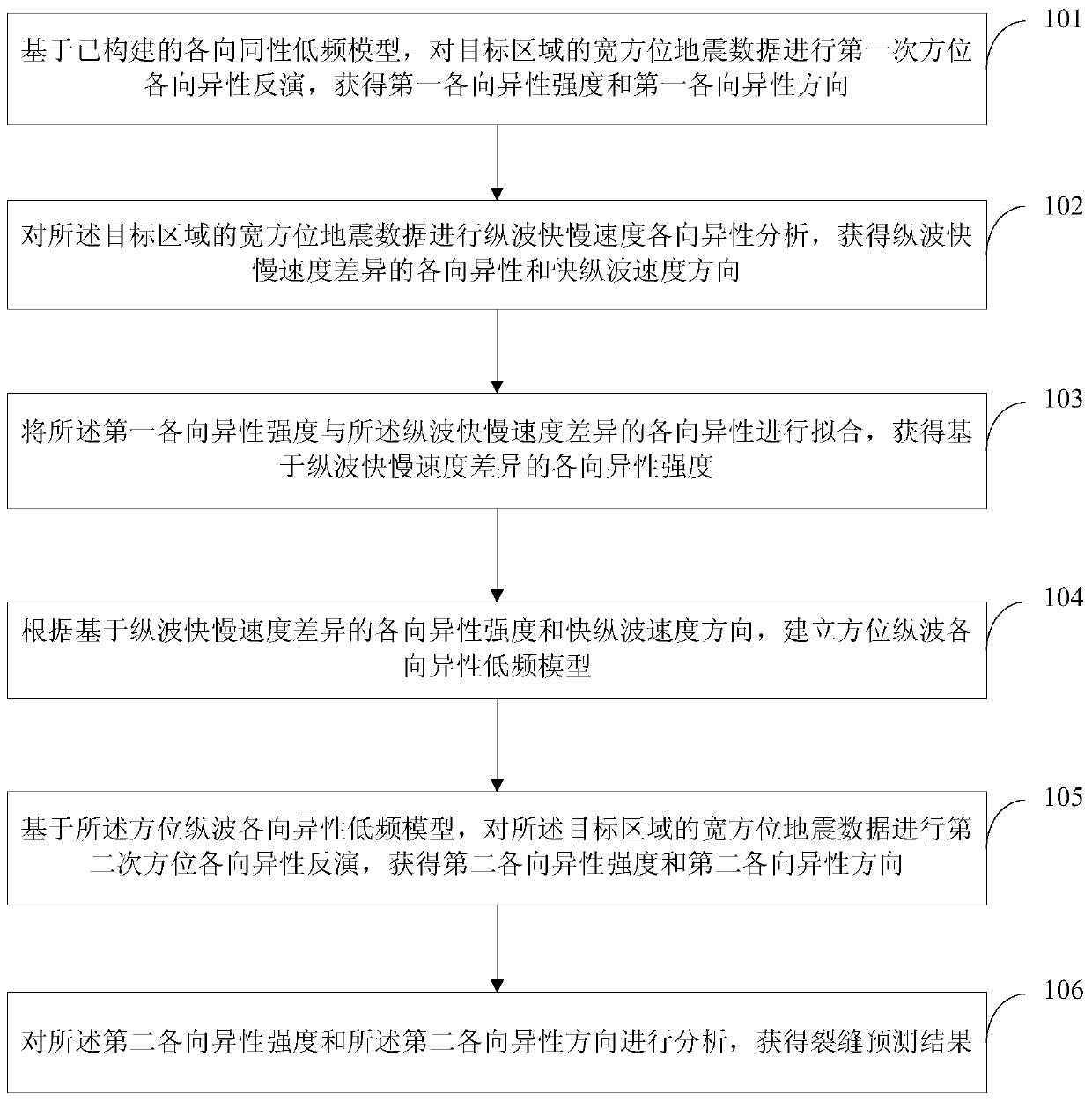

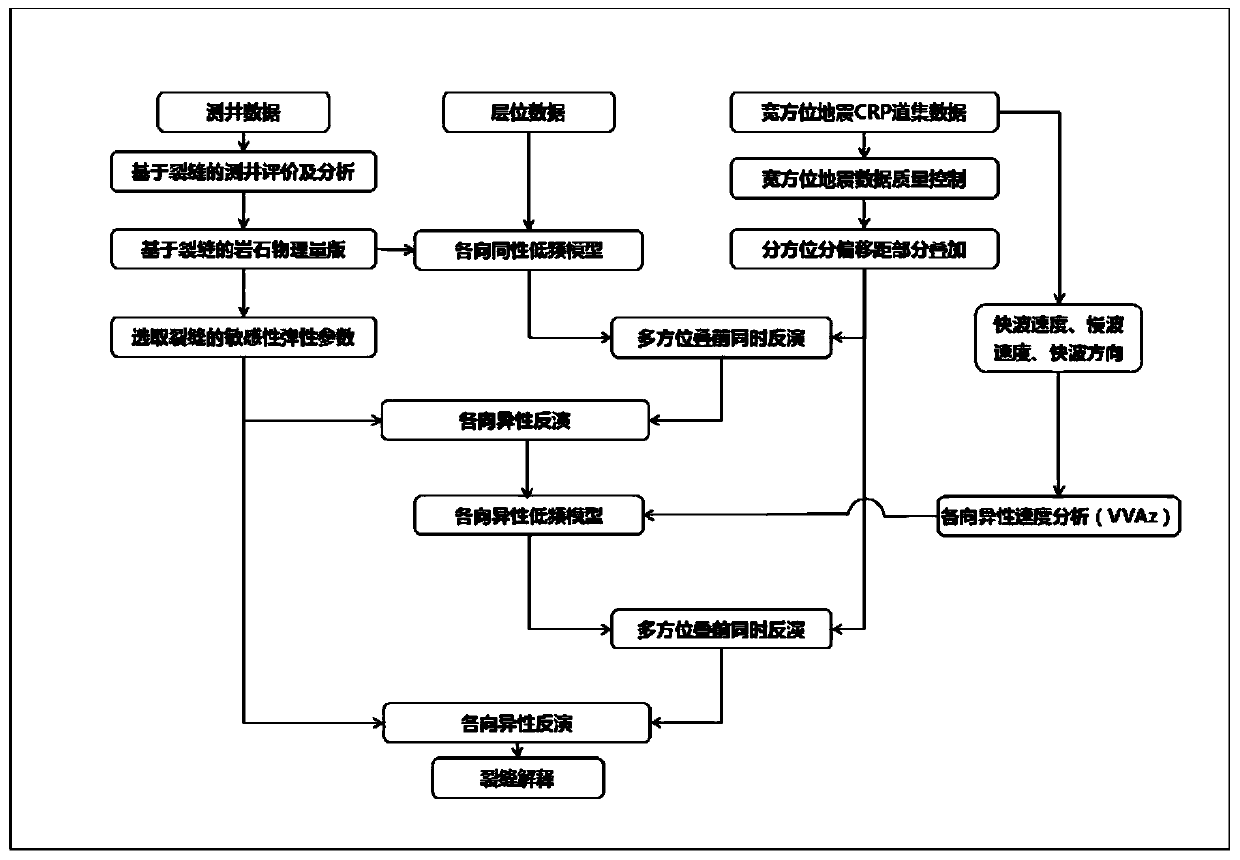

High-angle crack prediction method and device

ActiveCN111399050ARealize Quantitative PredictionGuaranteed prediction accuracyMaterial strength using steady shearing forcesSeismic signal processingEarth quakeGeophysics

The invention provides a high-angle crack prediction method and device. The method comprises the following steps: performing first azimuth anisotropy inversion on wide azimuth seismic data based on aconstructed isotropic low-frequency model to obtain a first anisotropy intensity and a first anisotropy direction, and performing longitudinal wave speed anisotropy analysis to obtain anisotropy of alongitudinal wave speed difference and a fast longitudinal wave speed direction; carrying out anisotropism fitting on the first anisotropism intensity and the longitudinal wave speed difference to obtain the anisotropism intensity based on the longitudinal wave speed difference; and establishing an azimuth longitudinal wave anisotropy low-frequency model according to the anisotropy intensity basedon the longitudinal wave speed difference and the fast longitudinal wave speed direction, performing secondary azimuth anisotropy inversion on wide azimuth seismic data by the azimuth longitudinal wave anisotropy low-frequency model to obtain a second anisotropy intensity and a second anisotropy direction, and analyzing the second anisotropy intensity and the second anisotropy direction to obtaina crack prediction result. According to the scheme, a technical problem that a reasonable low-frequency model cannot be provided in the anisotropism inversion crack prediction process in the existingmethod is solved.

Owner:PETROCHINA CO LTD

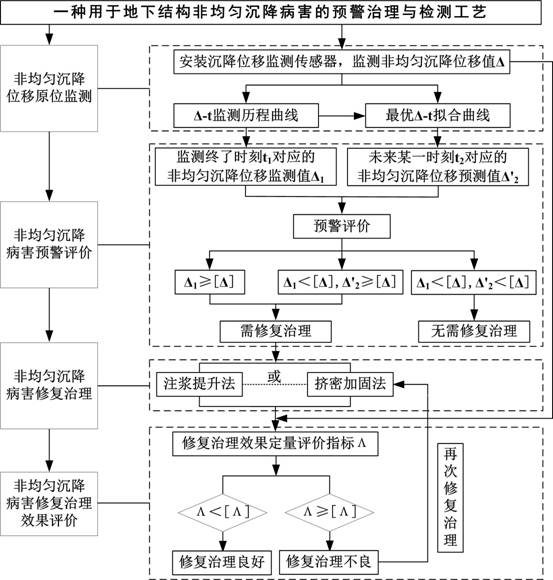

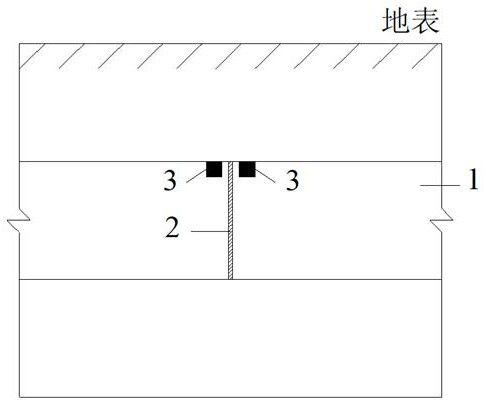

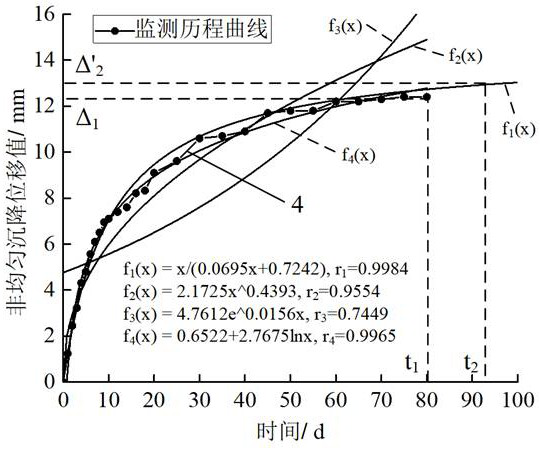

Early warning treatment and detection process for underground structure differential settlement diseases

ActiveCN114150718AImprove informatizationImprove the level of intelligent managementMining devicesFoundation testingDiseaseCurve fitting

The invention discloses an early warning treatment and detection process for underground structure differential settlement diseases, and belongs to the technical field of underground structure disease treatment, the early warning treatment and detection process comprises the following steps: monitoring differential settlement displacement values at two sides of a disease part, and drawing a monitoring process curve; curve fitting is carried out, and an optimal fitting curve and an optimal fitting function expression are determined through comparison and selection; comparing a non-uniform settlement displacement monitoring value corresponding to a monitoring ending moment, a non-uniform settlement displacement predicted value corresponding to a certain moment in the future and a non-uniform settlement displacement allowable value, and performing early warning evaluation on the disease degree of the part; treating the part needing to be repaired and treated by adopting a grouting lifting method or a compaction reinforcement method; and establishing a quantitative evaluation index of the disease repair treatment effect, and quantitatively evaluating the repair treatment effect. Quantitative evaluation of the safe operation and maintenance state of the repaired underground structure can be achieved, and the problem that an effective quantitative early warning and treatment detection technology is lacked for the differential settlement disease of the underground structure at present is solved.

Owner:SHANDONG JIANZHU UNIV

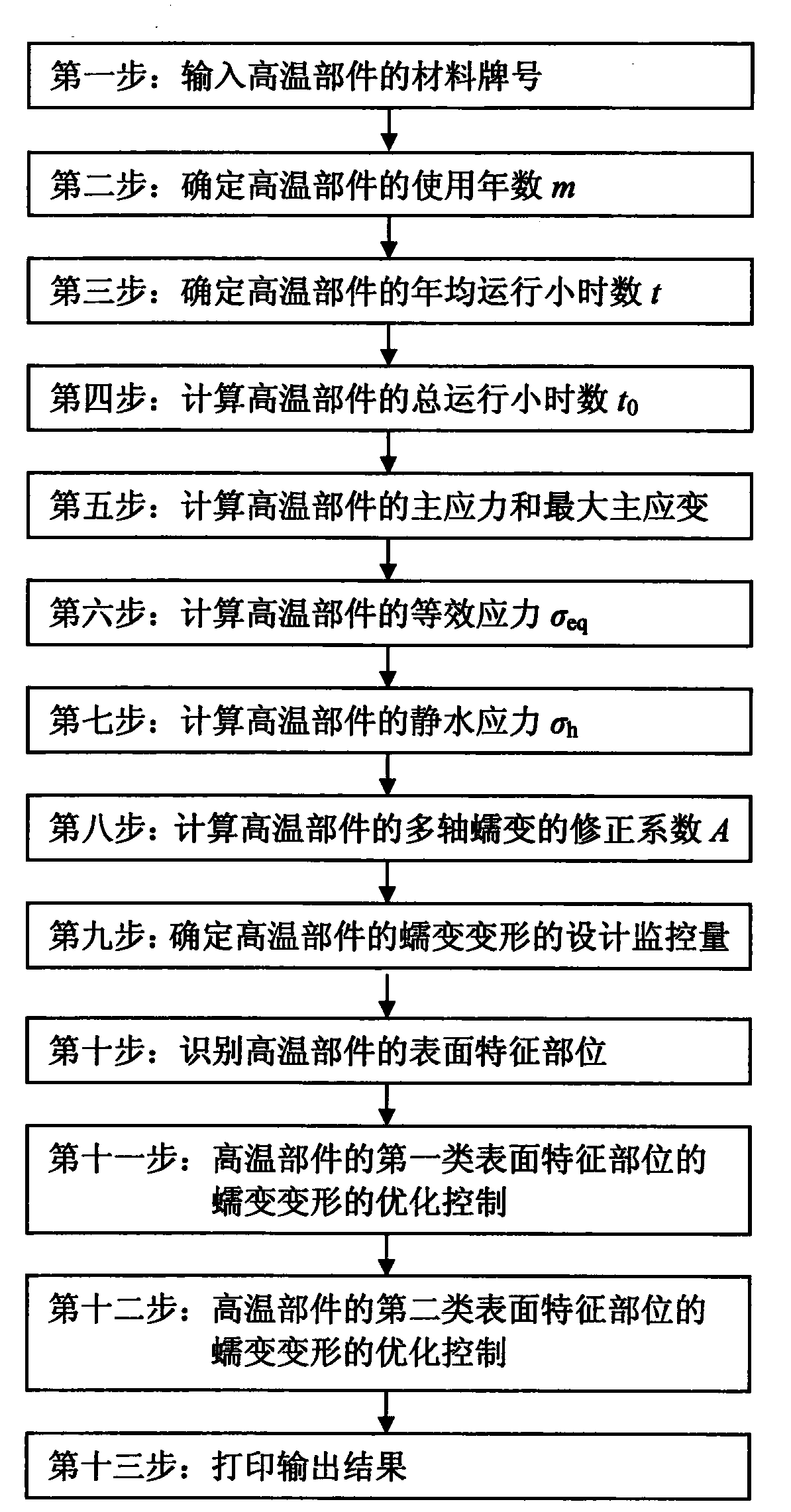

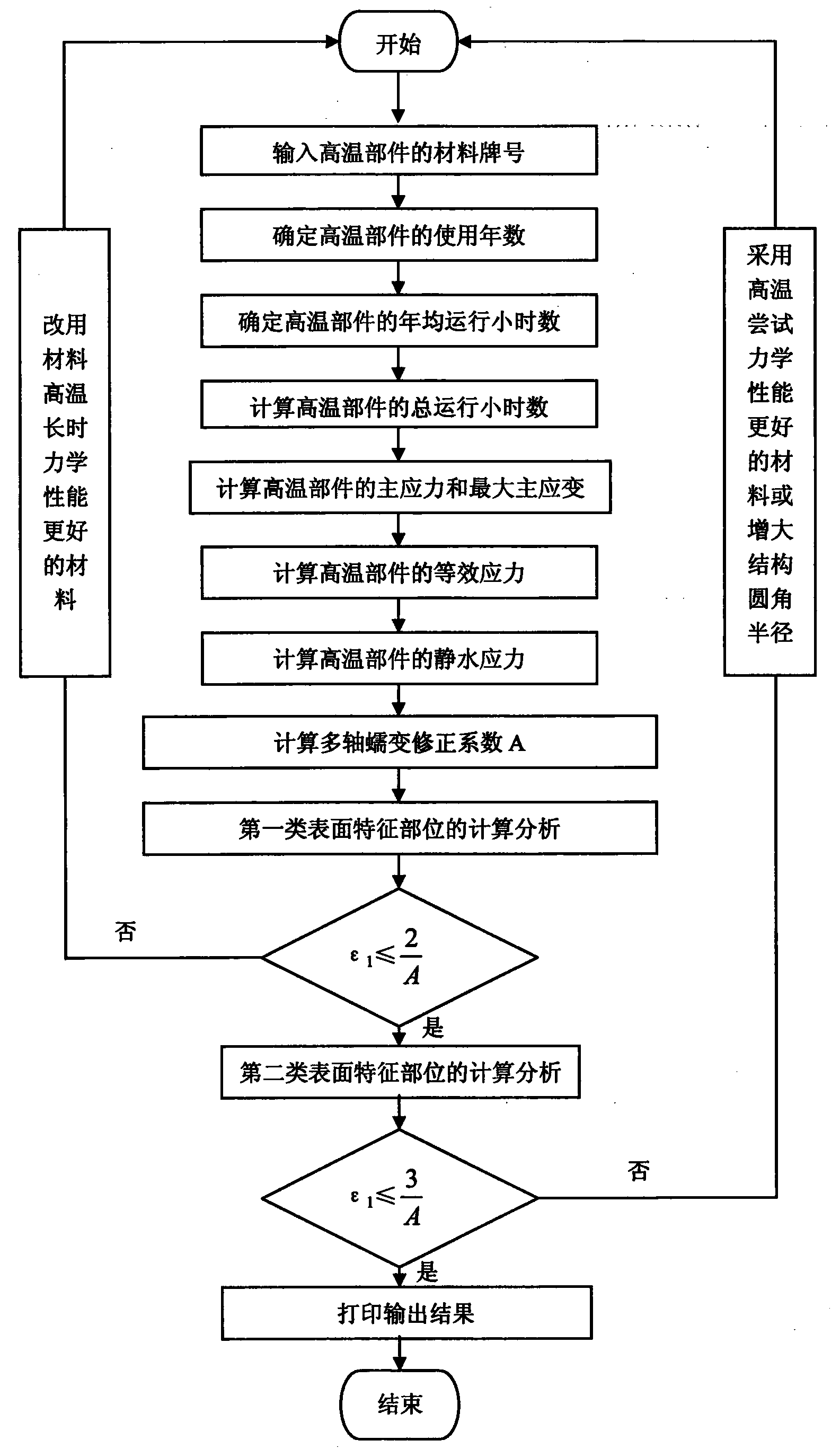

Monitoring method for creep deformation design of high-temperature part of thermal power generating unit

ActiveCN104239682ARealize Quantitative PredictionImprove mechanical propertiesSpecial data processing applicationsPrincipal stressEngineering

The invention provides a monitoring method for creep deformation design of a high-temperature part of a thermal power generating unit. The monitoring method specifically comprises the following steps: inputting a material mark of the high-temperature part; determining service years m of the high-temperature part; determining annual average running hours t of the high-temperature part; calculating total running hours t0 of the high-temperature part; calculating principal stress and maximum principal strain of the high-temperature part; calculating equivalent stress sigma<eq> of the high-temperature part; calculating hydrostatic stress sigma<h> of the high-temperature part; calculating a correction factor A of multi-axial creep of the high-temperature part; determining design monitoring amounts of creep deformation of the high-temperature part; recognizing surface characteristic parts of the high-temperature part; conducting optimization control of creep deformation of a first class of surface characteristic parts; conducting optimization control of creep deformation of a second class of surface characteristic parts; printing output results. The monitoring method for the creep deformation design of the high-temperature part of the thermal power generating unit realizes quantitative prediction and design monitoring of the creep deformation of the high-temperature part of the thermal power generating unit.

Owner:SHANGHAI POWER EQUIP RES INST

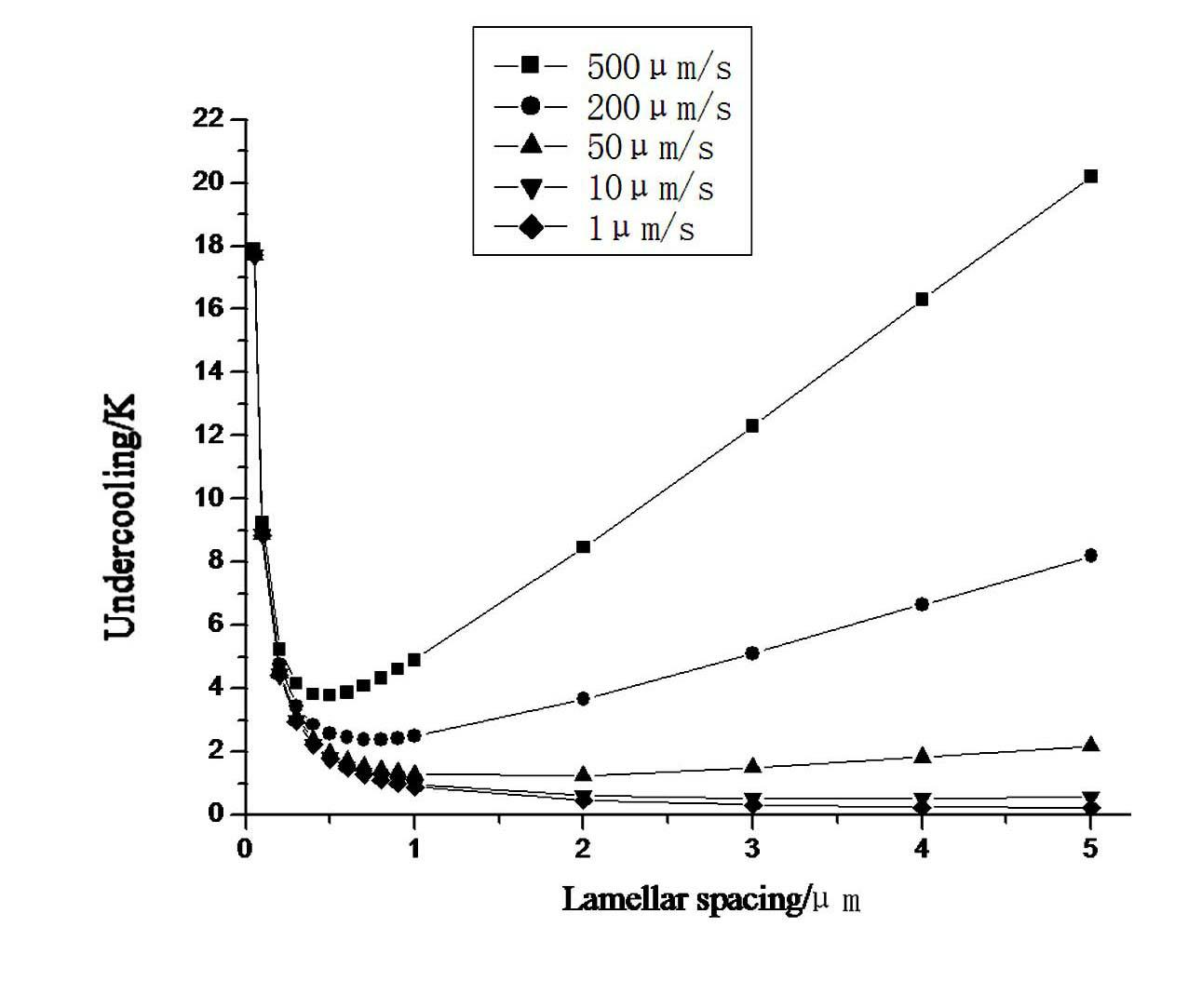

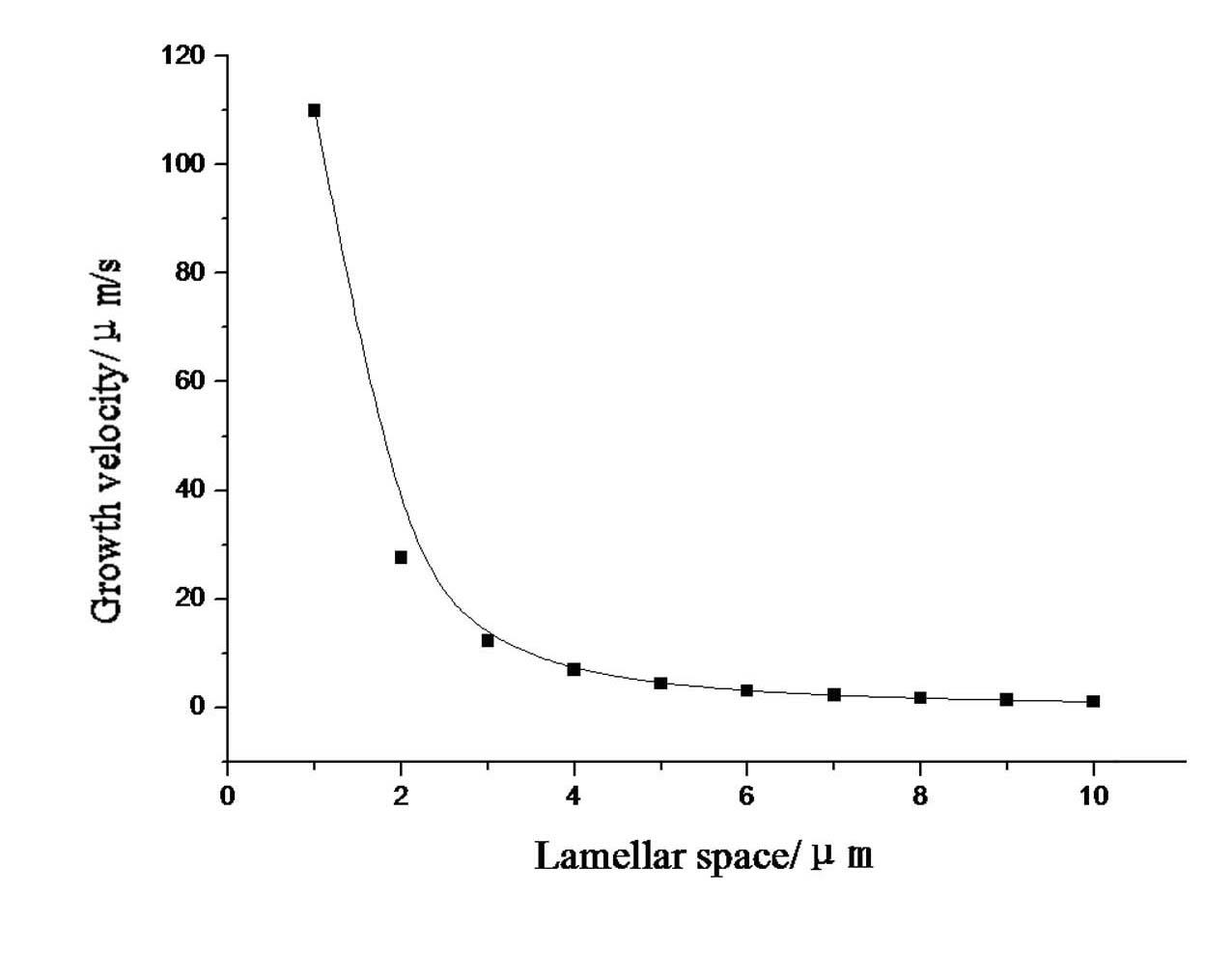

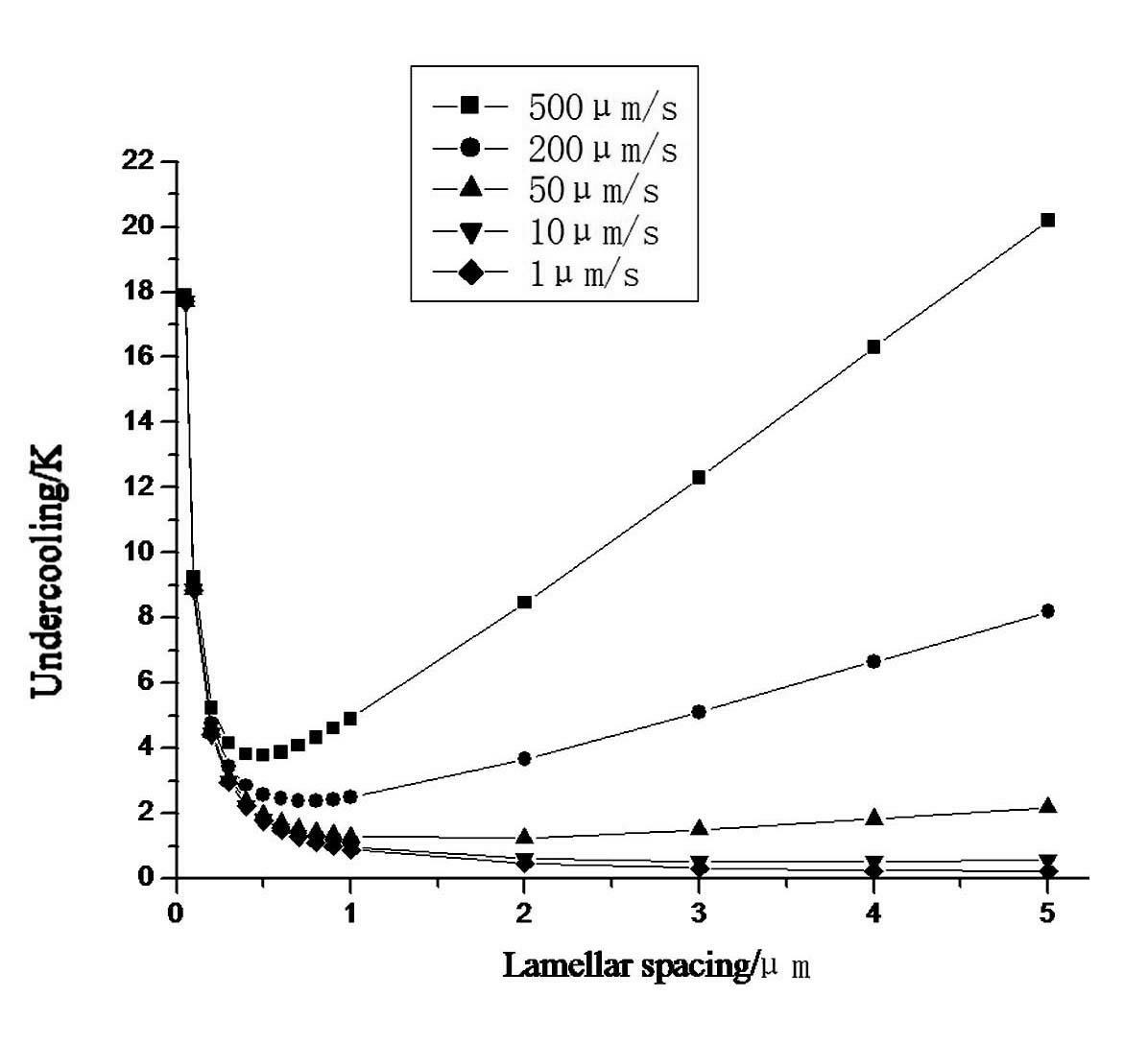

Method for predicting space between aluminium-silicon alloy eutectic structure lamellas

InactiveCN102156184ARealize Quantitative PredictionShort experiment cycleTesting metalsExperimental methodsSilicon alloy

The invention relates to a method for predicting space between aluminium-silicon alloy eutectic structure lamellas; the method is characterized in that an experimental period can be greatly shortened by using a numerical simulation method to predict the space between aluminium-silicon alloy eutectic lamellas; the cost is low, and the prediction result is not limited by the experimental conditions; and the influences of a certain single factor to the space between the aluminium-silicon alloy eutectic structure lamellas can be inspected. The shortages that the cost of the existing experimental method for measuring the space between aluminium-silicon alloy eutectic structure lamellas is relatively high, the experimental period is long and the experiment results are influenced obviously by the experimental conditions are overcome; the computation is fast; the error is small; and the quantitative prediction to the space between eutectic lamellas can be realized.

Owner:SHENYANG POLYTECHNIC UNIV

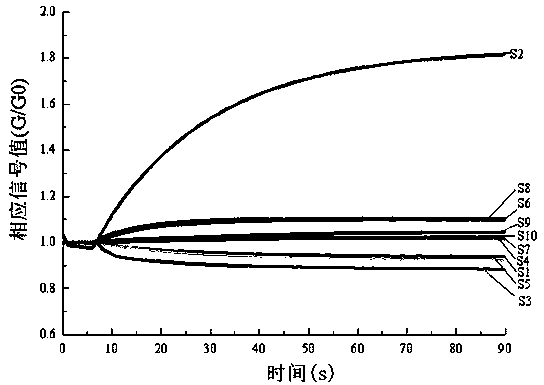

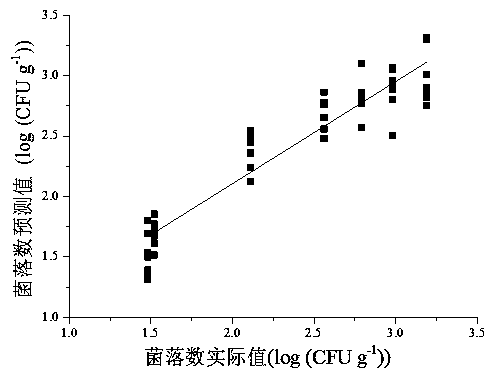

A method for rapidly predicting the quantity of rice infected by aspergillus fungi based on an electronic nose

PendingCN109711603ARealize Quantitative PredictionMicrobiological testing/measurementMicroorganism based processesHorticulturePlate count

The invention discloses a method for rapidly predicting the quantity of rice infected by aspergillus fungi based on an electronic nose. The method comprises the following steps: carrying out ultraviolet sterilization on rice, and inoculating a certain amount of aspergillus fungi into the rice; carrying out headspace gas detection on the samples of the inoculated rice with different storage times by using an electronic nose; meanwhile, detecting the colony number of the rice smaples by adopting a traditional plate count method; and optimizing the electronic nose sensor array according to principal component analysis, and performing feature extraction on the optimized sensor response signal by using a stable value method; and finally, establishing a prediction model based on an electronic nose signal characteristic value and the colony number by adopting a partial least squares regression algorithm, and selecting a regression model with a large correlation coefficient and a small root-mean-square error as a final colony number prediction model so as to obtain a predicted colony number. The method has no damage to the rice sample, is simple to operate, has a good prediction effect, and has relatively high practical application value.

Owner:ZHEJIANG UNIV

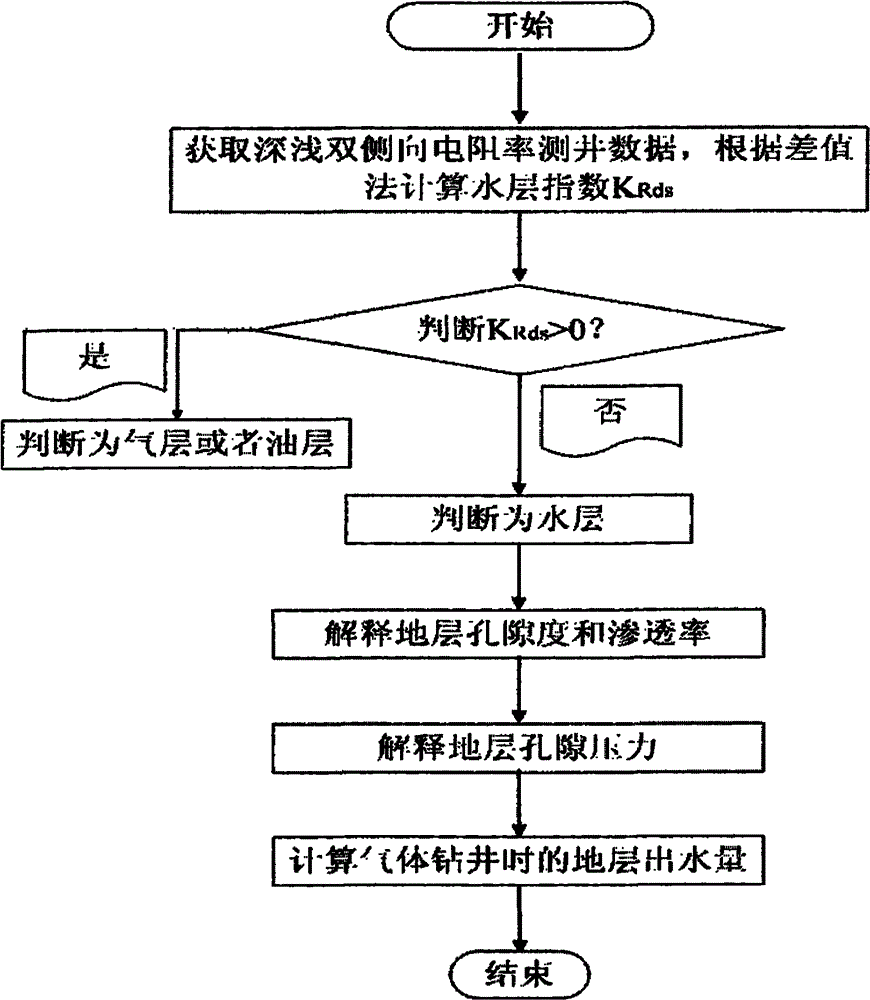

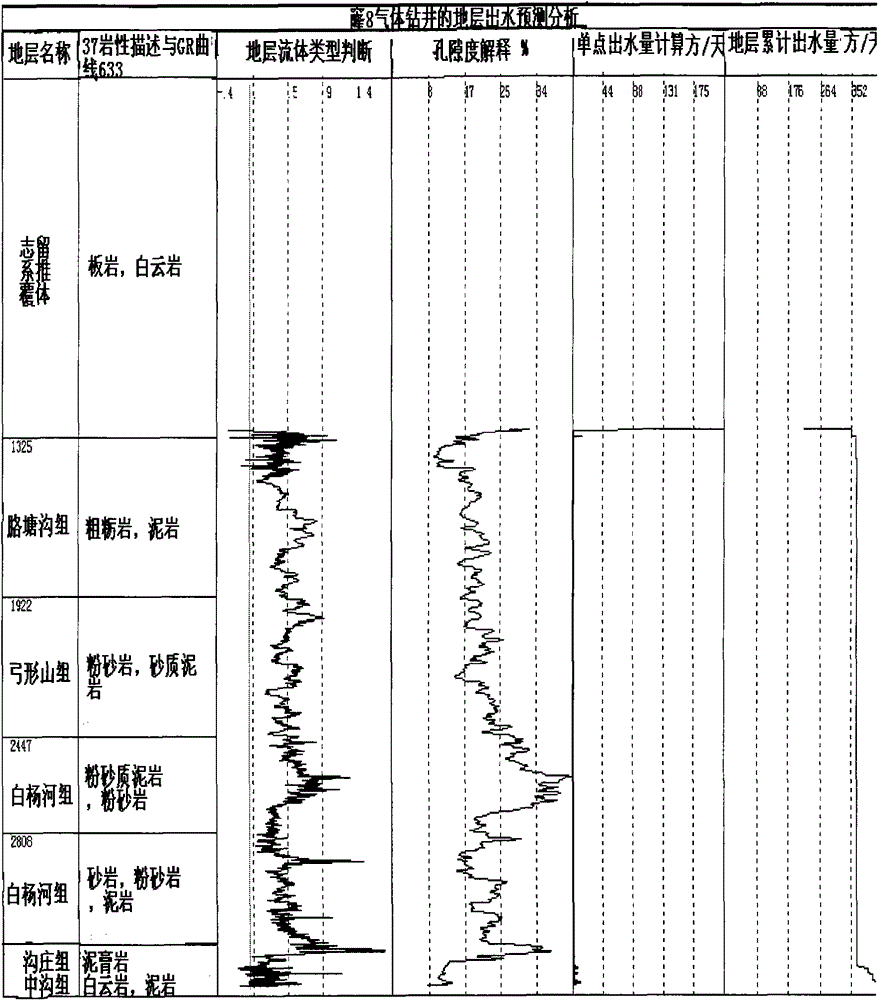

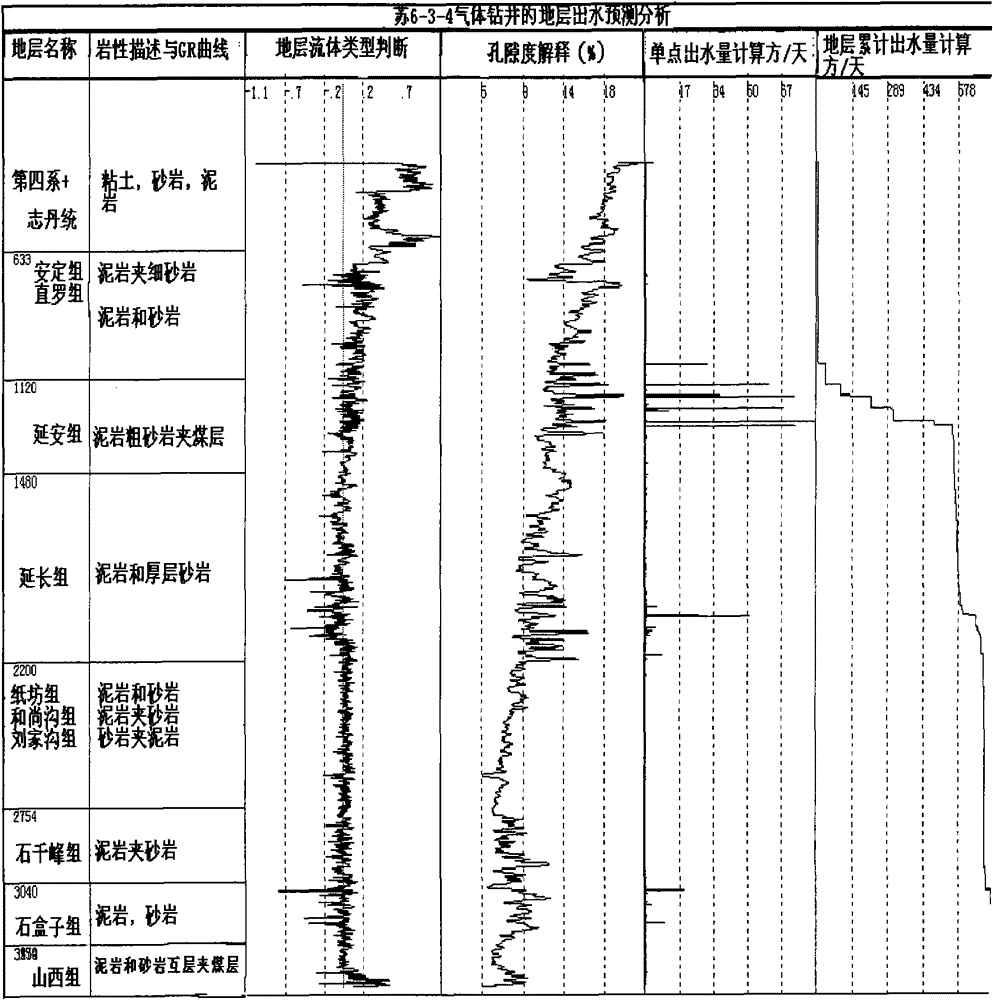

Quantitative predication method applicable to formation water production before drilling of gas drilling

InactiveCN102748014ARealize Quantitative PredictionHigh engineering application valueBorehole/well accessoriesProduced waterFormation water

The invention relates to a method for accurately predicating the size of a formation water production amount before drilling of gas drilling, which is characterized by comprising the following steps of: (a) judging formation fluid; (b) explaining formation porosity; (c) explaining formation permeability; (d) explaining formation pressure; and (e) calculating the water production amount. According to the method disclosed by the invention, the formation pore pressure is explained and a seepage mechanics principle is finally combined to realize the quantitative predication of the produced water by utilizing an output formula; with the adoption of the method, the size of the formation water production amount can be accurately calculated before frilling and evidences can be provided for reasonable region selection and layer selection of the gas drilling; a water production complicated condition is avoided during the gas drilling and the success rate of the gas drilling is improved; the method is successfully applied to the Qingxi region of Yumen, the Sulige region of Changqing, a deep layer of Songliao basin, Sichuan-Chongqing region and the like; and a predicated result is matched with a field actual condition and an engineering application prospect is good.

Owner:邹灵战

Method and device for monitoring high-cycle fatigue life of steam turbine integral rotor

ActiveCN102589867BQuantitative monitoring of cycle fatigue lifeImprove securityMachine part testingAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringLife length

The present invention provides a method and device for monitoring high-cycle fatigue life of a steam turbine integral rotor. The device for monitoring the high-cycle fatigue life of the steam turbine integral rotor is characterized by comprising an ultrasonic flaw detector and a compute server, wherein the ultrasonic flow detector is connected with the compute server. The invention has the following advantages: the quantitative prediction and the quantitative monitor of the high-cycle fatigue life of the steam turbine integral rotor are realized; if the safety of the high-cycle fatigue life of the steam turbine integral rotor does not meet the requirements, the steam turbine integral rotor is redesigned during the designing step or a crack on the surface of the steam turbine integral rotor is removed during the manufacturing step, so as to satisfy the safety requirement of the high-cycle fatigue life of the steam turbine integral rotor, furthermore the high-cycle fatigue life of the steam turbine integral rotor is quantitatively predicted and monitored.

Owner:SHANGHAI POWER EQUIP RES INST

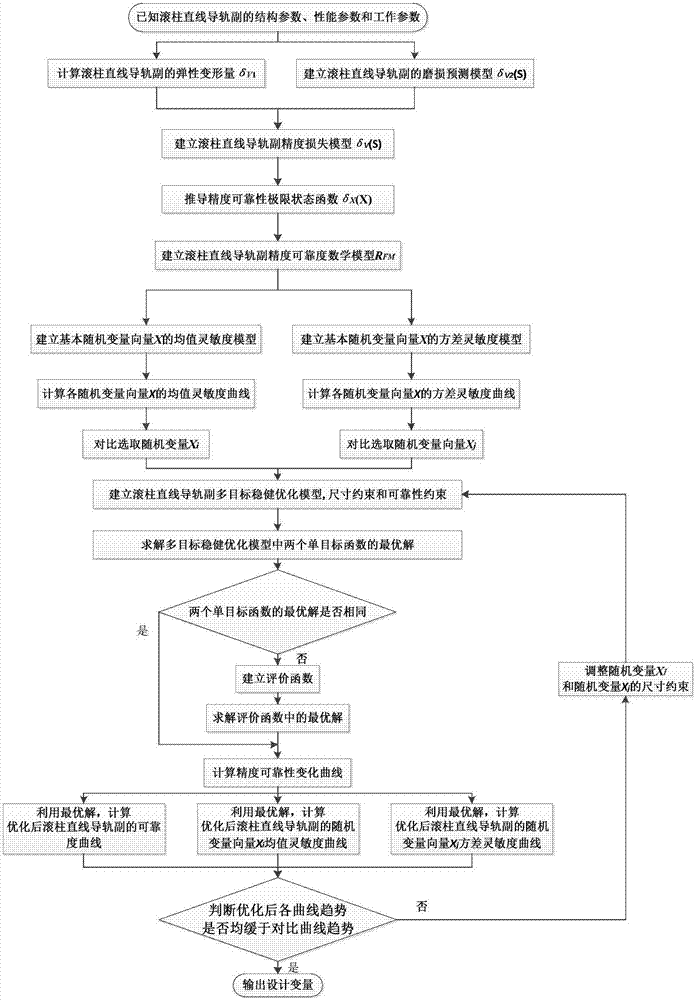

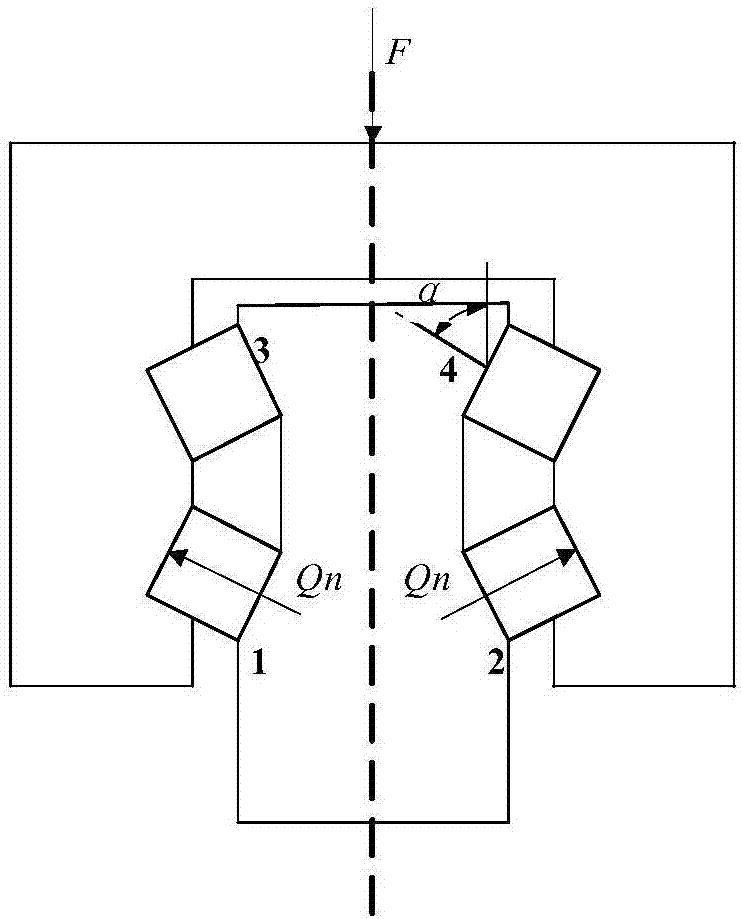

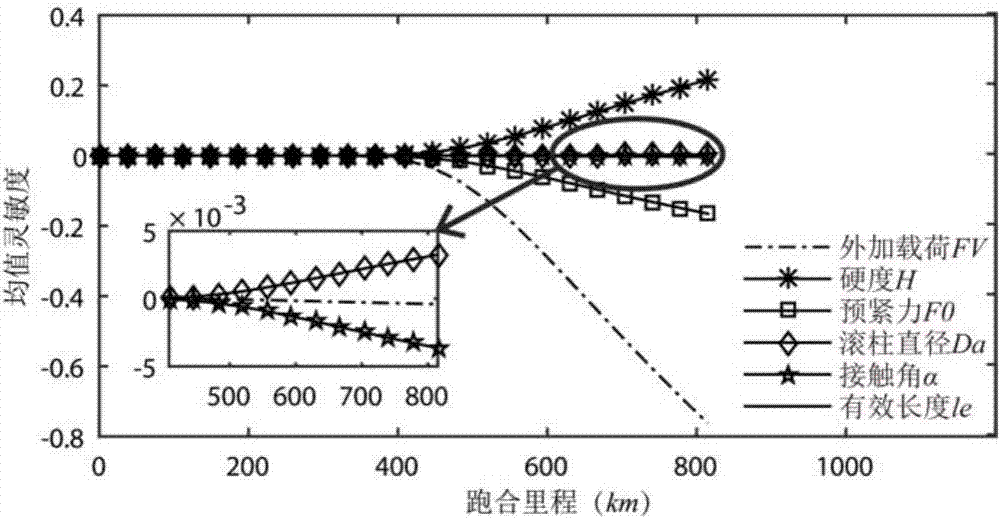

Optimal design method for accuracy reliability of roller linear guide pair

ActiveCN107229800ARealize Quantitative PredictionGuaranteed reliabilityGeometric CADDesign optimisation/simulationDelta-vMathematical model

The invention provides an optimal design method for the accuracy reliability of a roller linear guide pair, aims to achieve the quantitative prediction of the accuracy reliability of the roller linear guide pair, and the accuracy reliability is improved. The method is achieved in the follow steps that a roller linear guide pair accuracy loss model delta V(S); an accuracy reliability limit state function delta X(X) is derived; an accuracy reliability mathematical model RFM, a mean sensitivity model and a variance sensitivity model are built; a random variable xi and a random variable xj are selected randomly; a dimension constraint and a reliability constraint of a multi-objective steady optimization model are created; in order to make the mean sensitivity of the random variable Xi minimum and the variance sensitivity of the random variable xj minimum, a multi-objective steady optimization model F (xi, xj) of the roller linear guide pair is built; a shortest ideal point method is used for optimization searching of the multi-objective steady optimization model of the roller linear guide pair, and the optimal solution of the random variable xi and the optimal solution of the random variable xj are obtained.

Owner:西安启工数据科技有限公司

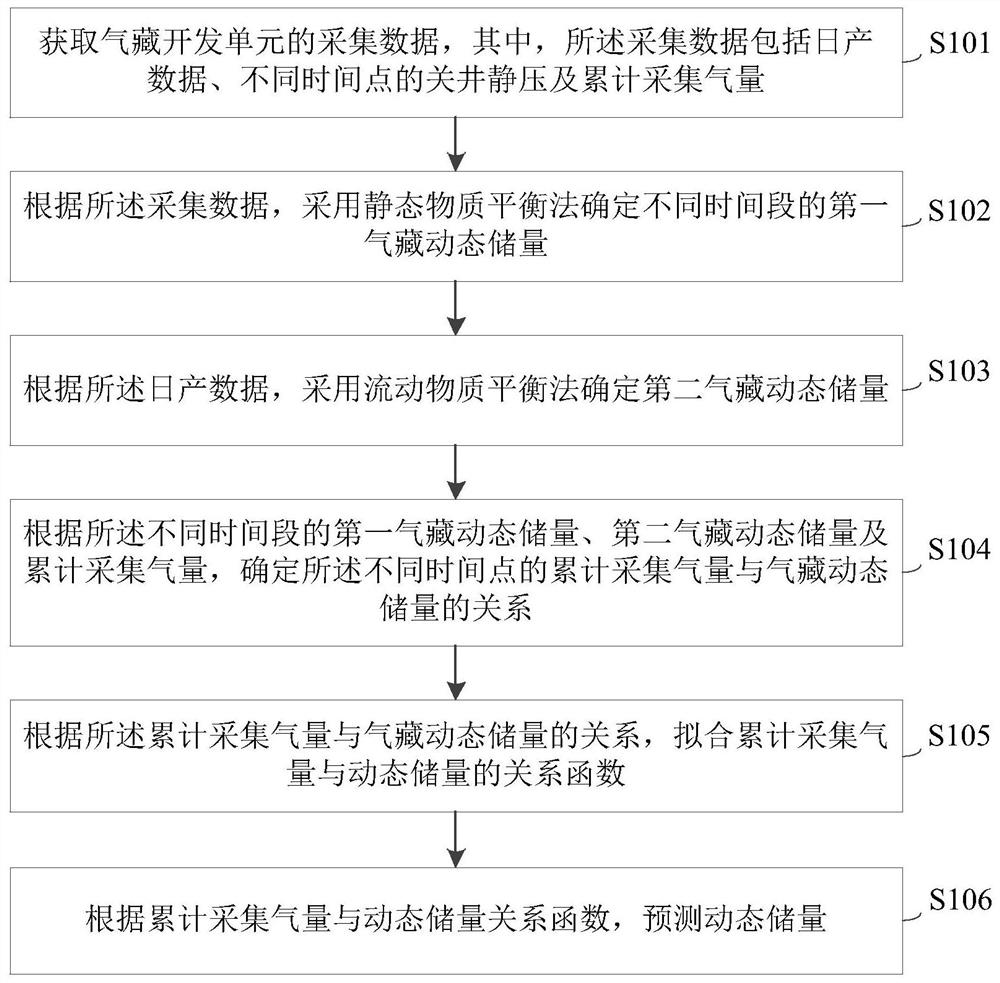

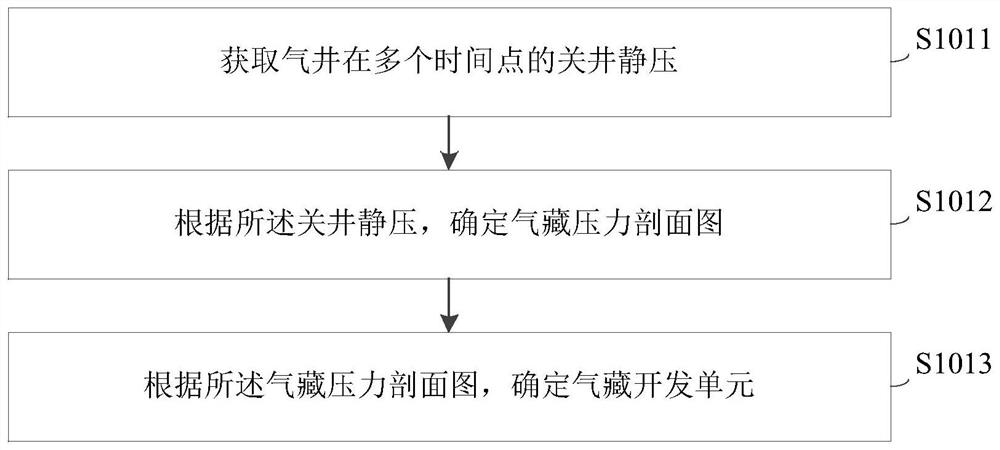

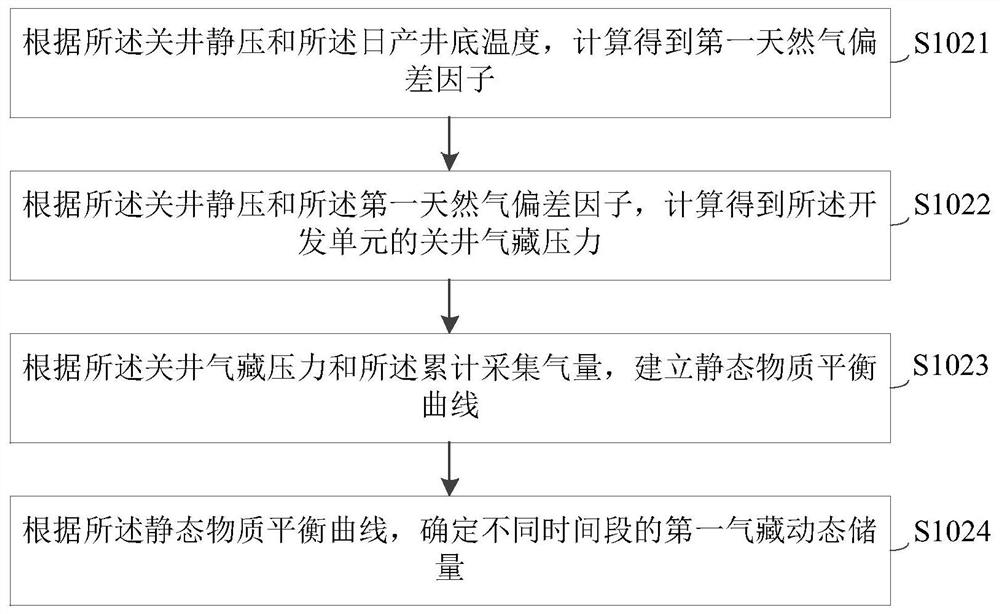

Water invasion gas reservoir dynamic reserve prediction method, device and equipment and storage medium

PendingCN114575833ARealize Quantitative PredictionData processing applicationsClimate change adaptationThermodynamicsSoil science

The invention provides a water invasion gas reservoir dynamic reserve prediction method, device and equipment and a storage medium, and the method comprises the steps: obtaining collection data of a gas reservoir development unit, the collection data comprising daily production data, well shut-in static pressure at different time points and accumulated collection gas amount; according to the collected data, determining first gas reservoir dynamic reserves in different time periods by adopting a static material balance method; according to the daily production data, a flowing substance balance method is adopted to determine the dynamic reserve of a second gas reservoir; according to the first gas reservoir dynamic reserves, the second gas reservoir dynamic reserves and the accumulatively collected gas volumes in the different time periods, determining the relationship between the accumulatively collected gas volumes and the gas reservoir dynamic reserves at the different time points; according to the relation between the accumulatively collected gas quantity and the dynamic reserves of the gas reservoir, fitting a relation function between the accumulatively collected gas quantity and the dynamic reserves; the dynamic reserves are predicted according to the relation function of the accumulated collected gas quantity and the dynamic reserves, and the dynamic reserves of the gas reservoir can be accurately and rapidly predicted.

Owner:PETROCHINA CO LTD

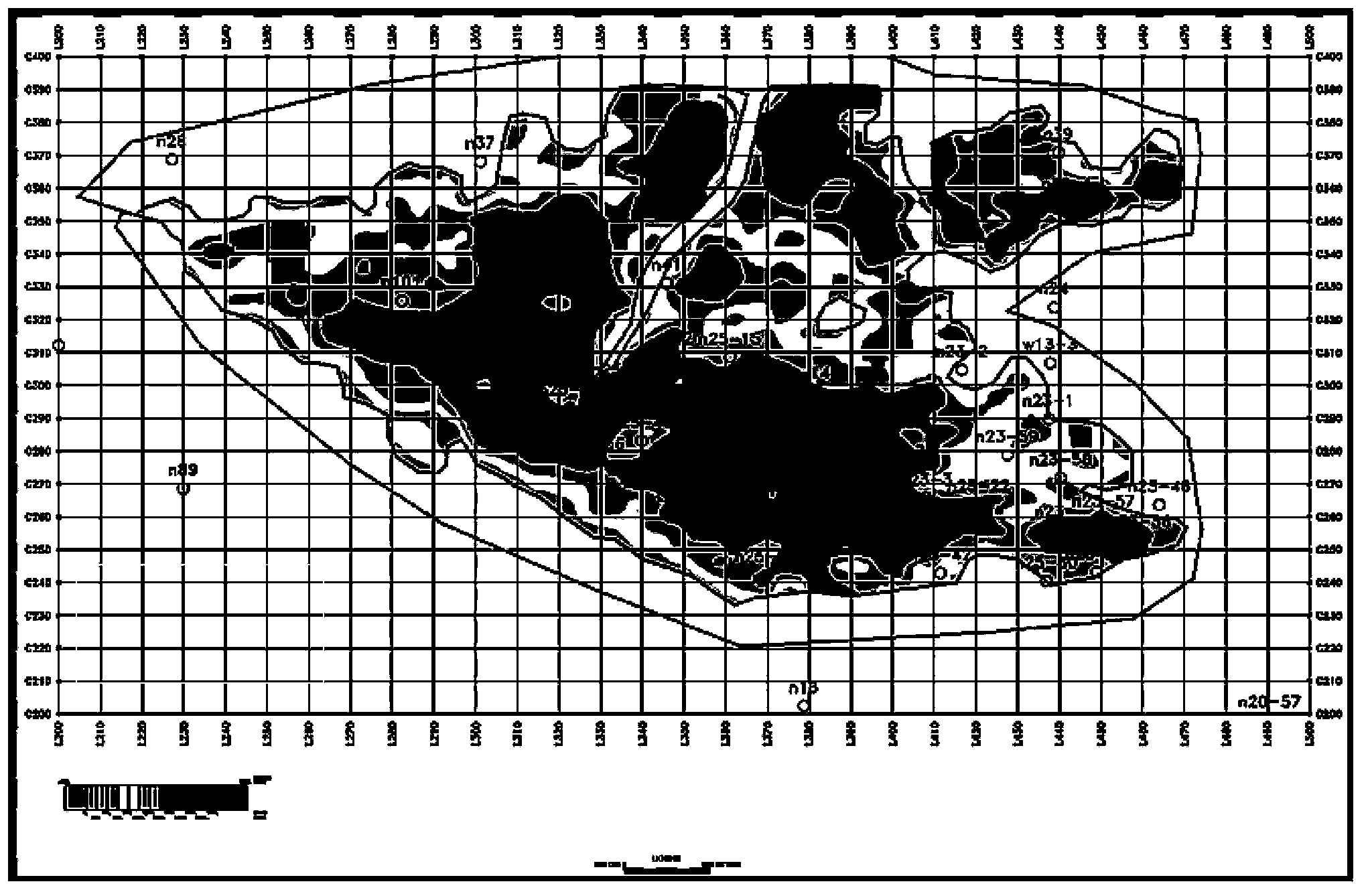

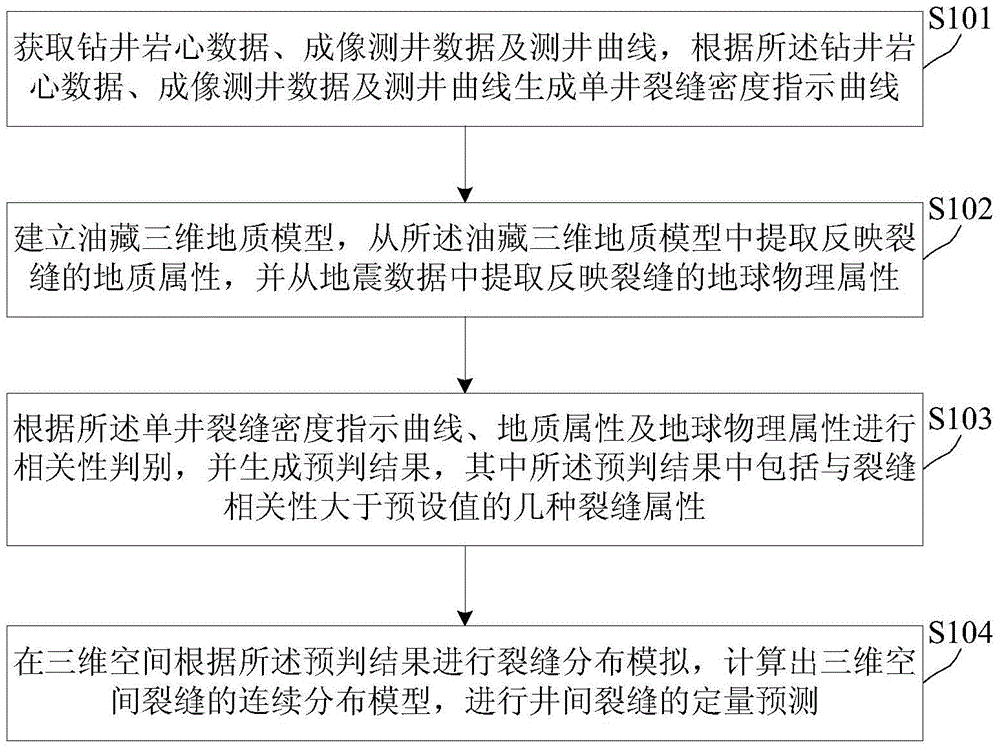

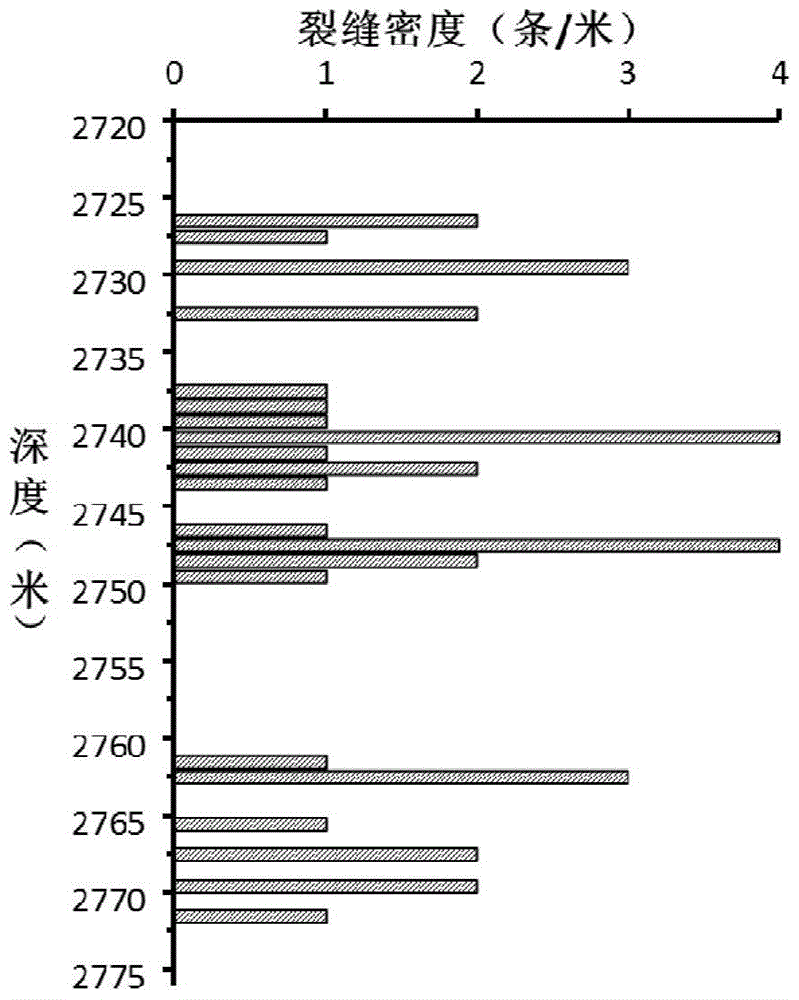

Quantitative prediction method and device for volcanic rock cracks

ActiveCN104914465BRealize Quantitative PredictionAccurately determineSeismic signal processingRock coreWell logging

The invention discloses a method and a device for volcanic rock crack quantitative prediction. The method for volcanic rock crack quantitative prediction comprises steps of obtaining drilling well rock core data, imaging well logging data and logging curves, generating single well crack density indication curves according to the drilling well rock core data, imaging logging data and logging curves, establishing an oil reservoir three dimensional geology model, extracting geology attribute reflecting cracks from the oil reservoir three dimensional geology model and extracting earth physics attribute reflecting cracks from earthquake data, performing correlation discrimination and generating a pre-judging result according to the single well crack density indication curve, the geology attribute and earth physics attribute, wherein the pre-judging result comprises some kinds of crack attributes, the crack correlation of which is greater than a preset vale, performing crack distribution simulation in a three dimensional space according to the pre-judging result, calculating the continuous distribution model of the three dimensional space and performing quantitative prediction on the crack between wells. The method and device for volcanic rock crack quantification prediction disclosed by the invention can realize the quantitative prediction of the crack between wells and can quickly and accurately determine the favorable task during the volcanic rock oil reservoir exploration and development.

Owner:PETROCHINA CO LTD

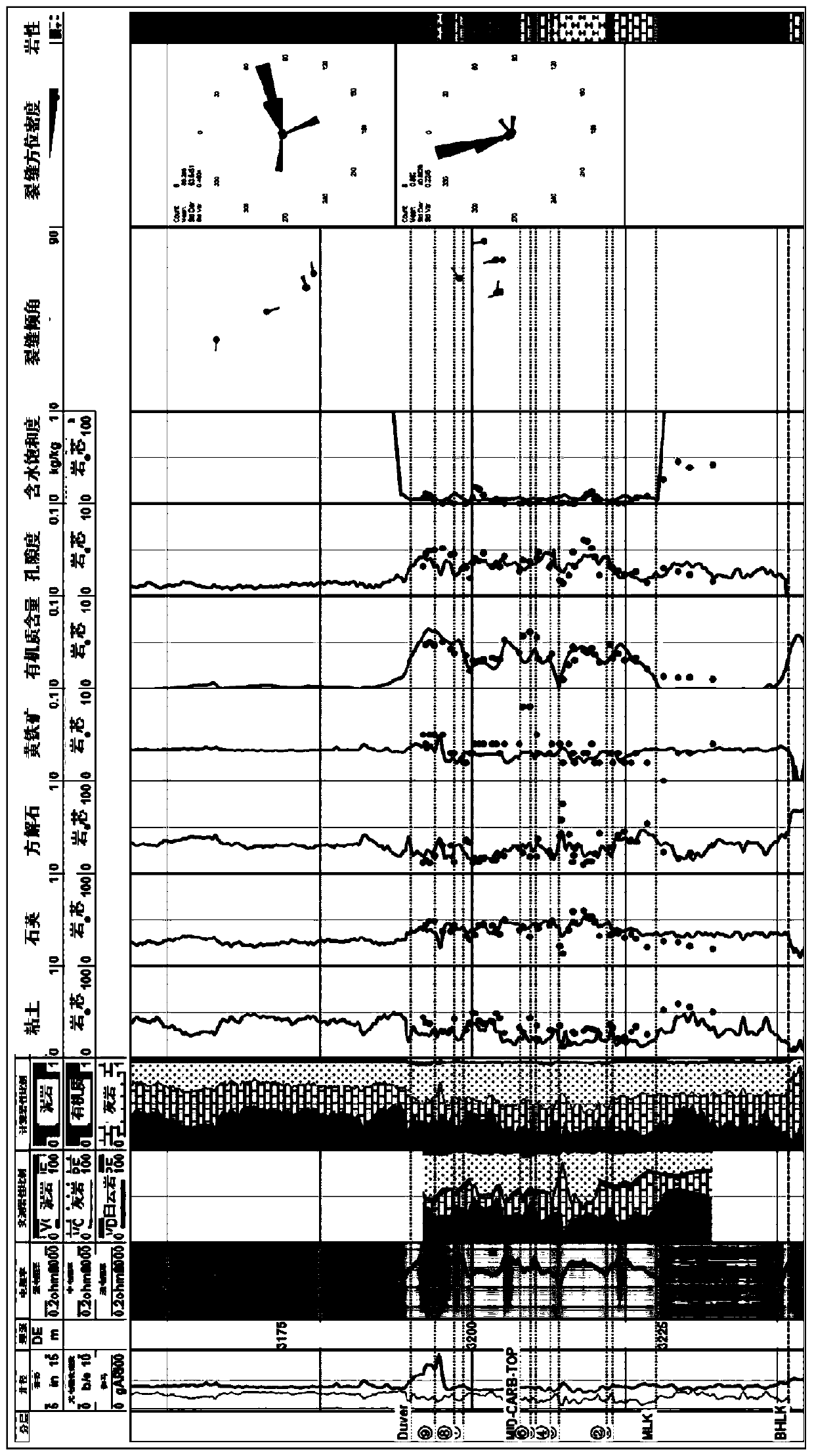

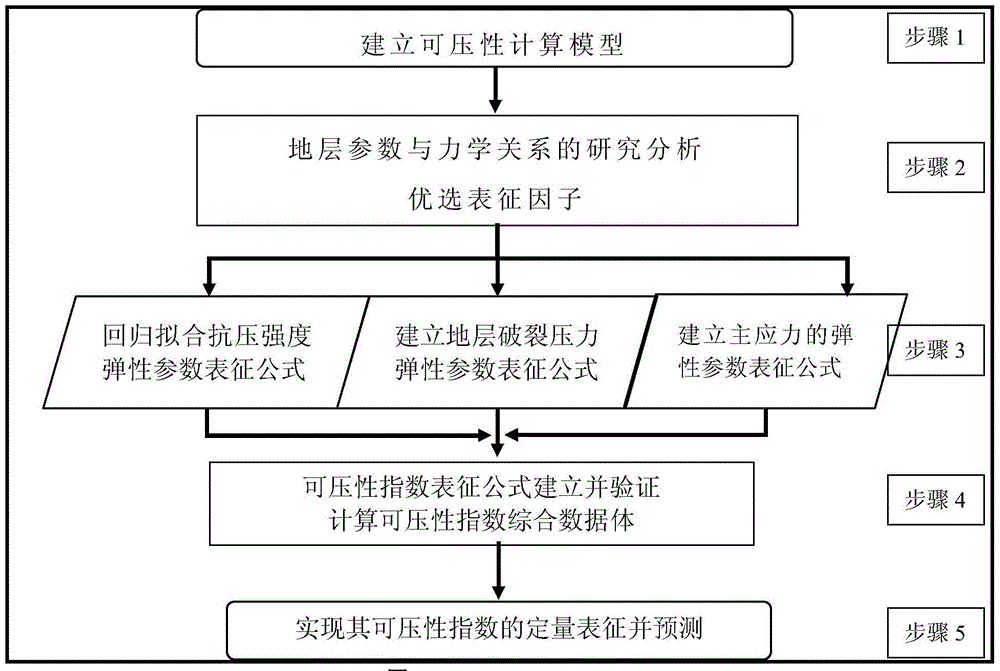

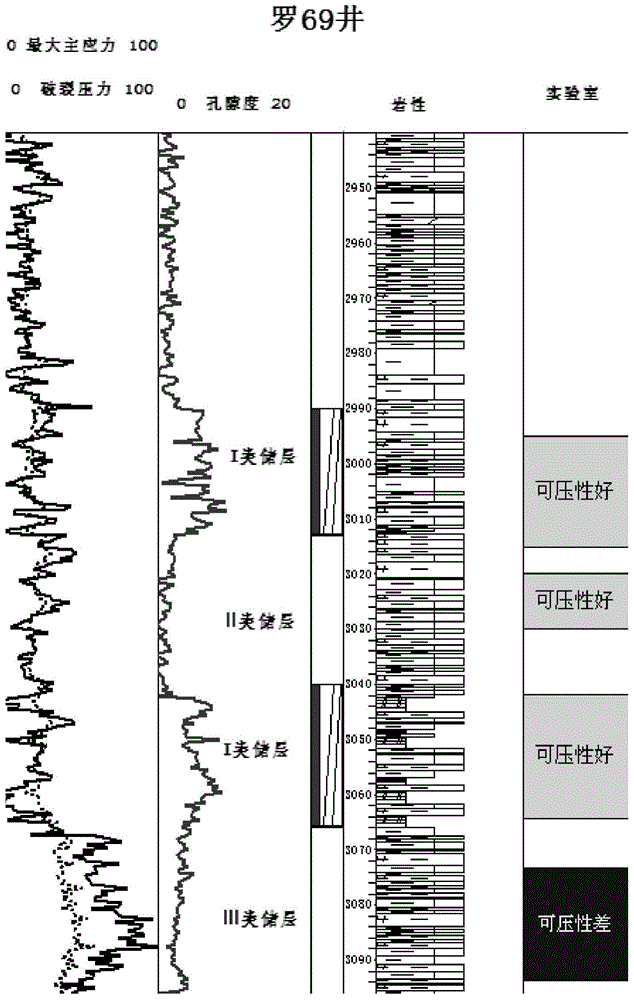

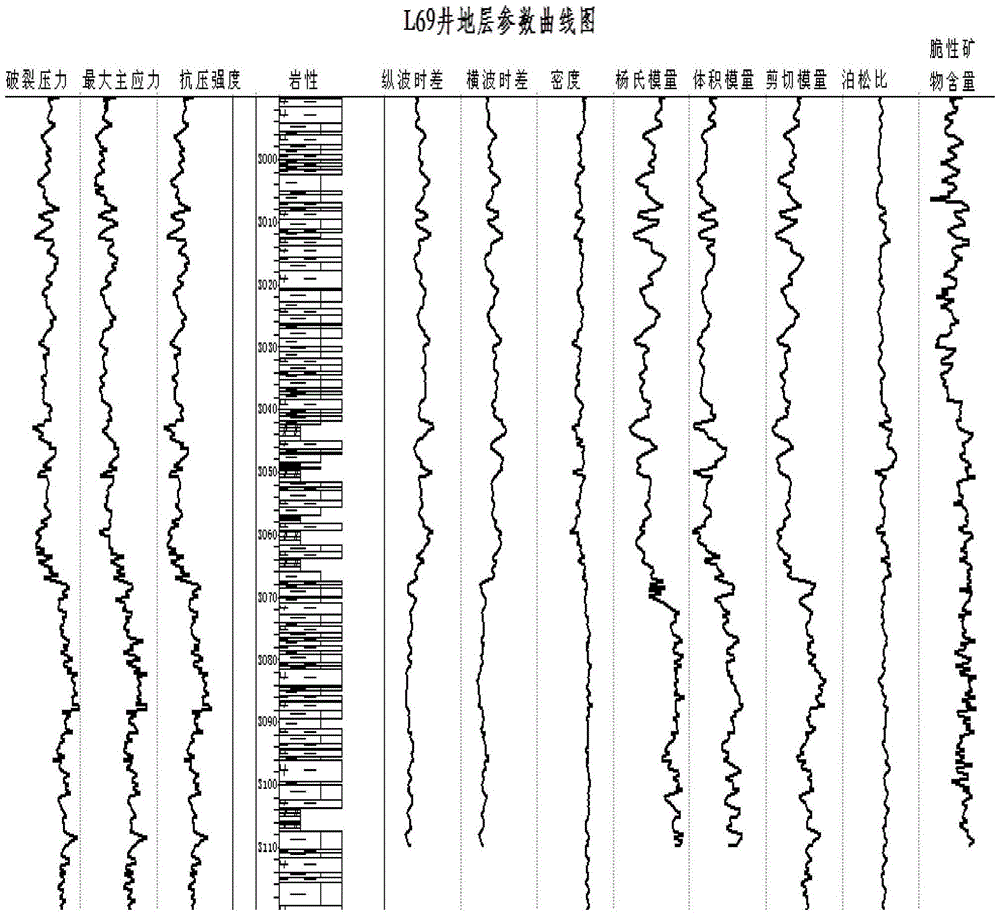

A Quantitative Characterization Method of Shale Compressibility Based on Petrophysics

ActiveCN104749622BImprove description accuracyGood application effect and promotion prospectSeismic signal processingSpecial data processing applicationsEnvironmental geologyFracture pressure

The invention discloses a method for quantitatively characterizing the shale compressibility based on rock physics. The method comprises the following steps: (1) establishing a shale compressibility mathematical model; (2) analyzing the relationship between formation parameters and mechanics, and preferably selecting formation mechanical parameter characterizing factors; (3) regressively fitting a compressive strength elastic parameter characterization formula and establishing a formation fracture pressure elastic parameter characterization formula and a principal stress elastic parameter characterization formula; (4) establishing a compressibility index characterization formula, and verifying and calculating a compressibility index comprehensive data body; and (5) quantitatively characterizing and predicting the formation compressibility. According to the method, effective characterization factors of shale formation compressibility are selected through multi-parameter analysis to establish a shale compressibility index characterization formula, so that quantitatively characterization of shale compressibility is realized, the identification standard of shale compressibility is established, target optimization of formation fracturing reformation layers can be guided, the cost of shale exploration is reduced, and the success rate of shale exploration is effectively improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

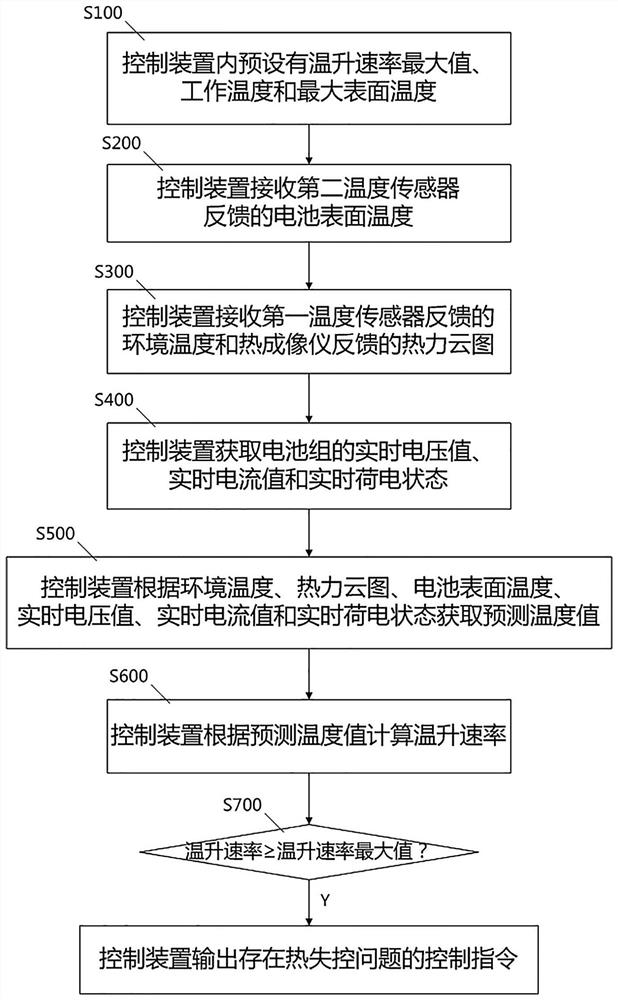

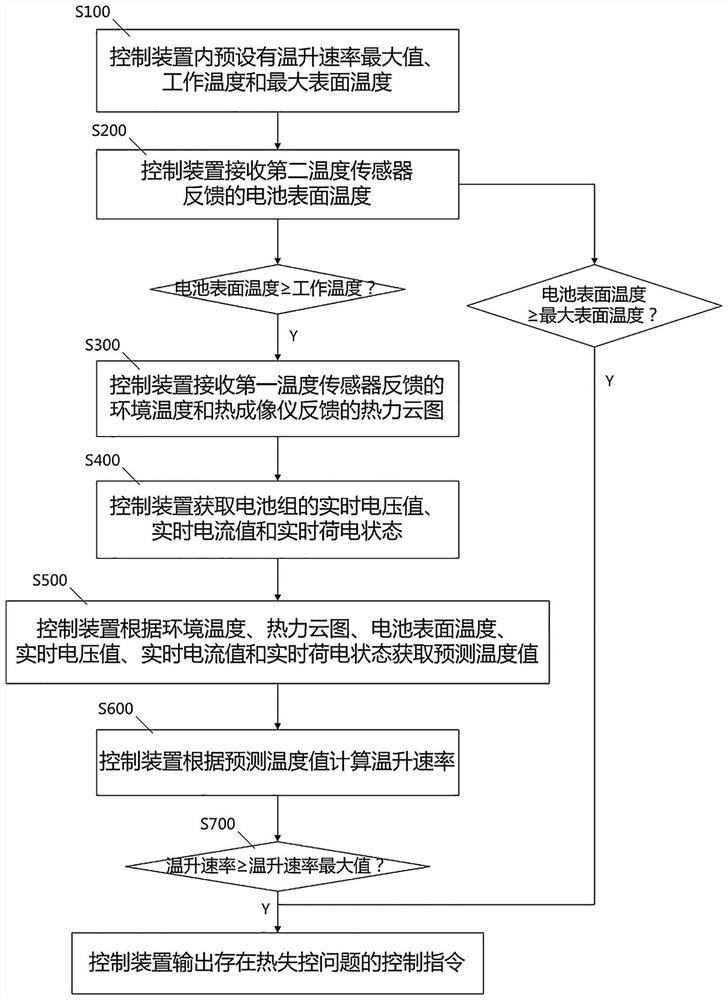

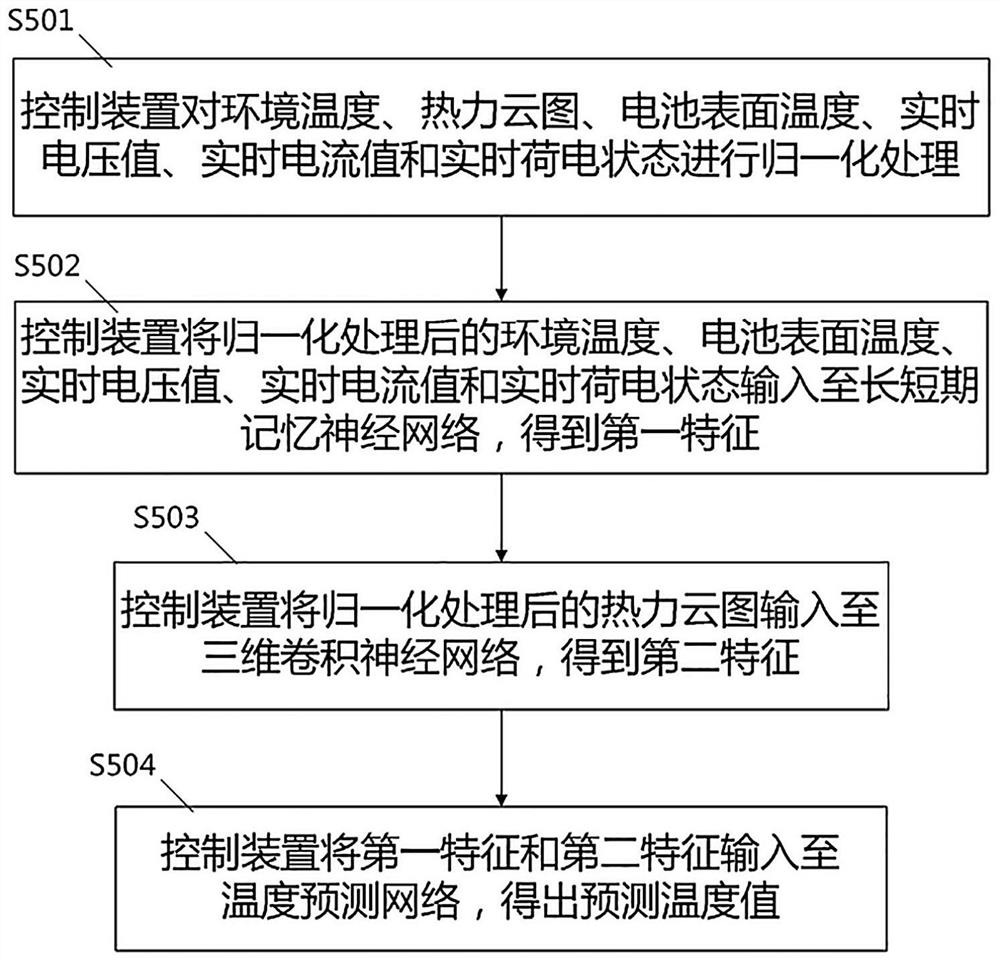

Thermal runaway spreading prediction method, and thermal runaway spreading prediction system

PendingCN113962452AImprove securityHarm reductionSecondary cellsForecastingThermal runawayOperating temperature

The invention discloses a thermal runaway spreading prediction method, and a thermal runaway spreading prediction system. The prediction method comprises the following steps: a maximum temperature rise rate value, working temperature, and maximum surface temperature are preset in a control device; the control device receives battery surface temperature fed back by a second temperature sensor; the control device receives environment temperature fed back by a first temperature sensor and a thermodynamic cloud picture fed back by a thermal imager; the control device obtains a real-time voltage value, a real-time current value, and a real-time charge state of a battery pack; the control device obtains a predicted temperature value according to the environment temperature, the thermodynamic cloud picture, the battery surface temperature, the real-time voltage value, the real-time current value, and the real-time charge state; the control device calculates a temperature rise rate according to the predicted temperature value; when the temperature rise rate is greater than a preset maximum value of the temperature rise rate, the control device outputs a control instruction with a thermal runaway problem. According to the prediction method disclosed by the invention, quantitative prediction of the thermal runaway spreading condition can be realized, the safety of lithium batteries during working is improved, and accidents are avoided.

Owner:FOSHAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com