Monitoring method for creep deformation design of high-temperature part of thermal power generating unit

A technology for thermal power generating units and high-temperature components, which is applied in computing, electrical digital data processing, special data processing applications, etc., and can solve problems such as creep damage of high-temperature components of thermal power generating units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

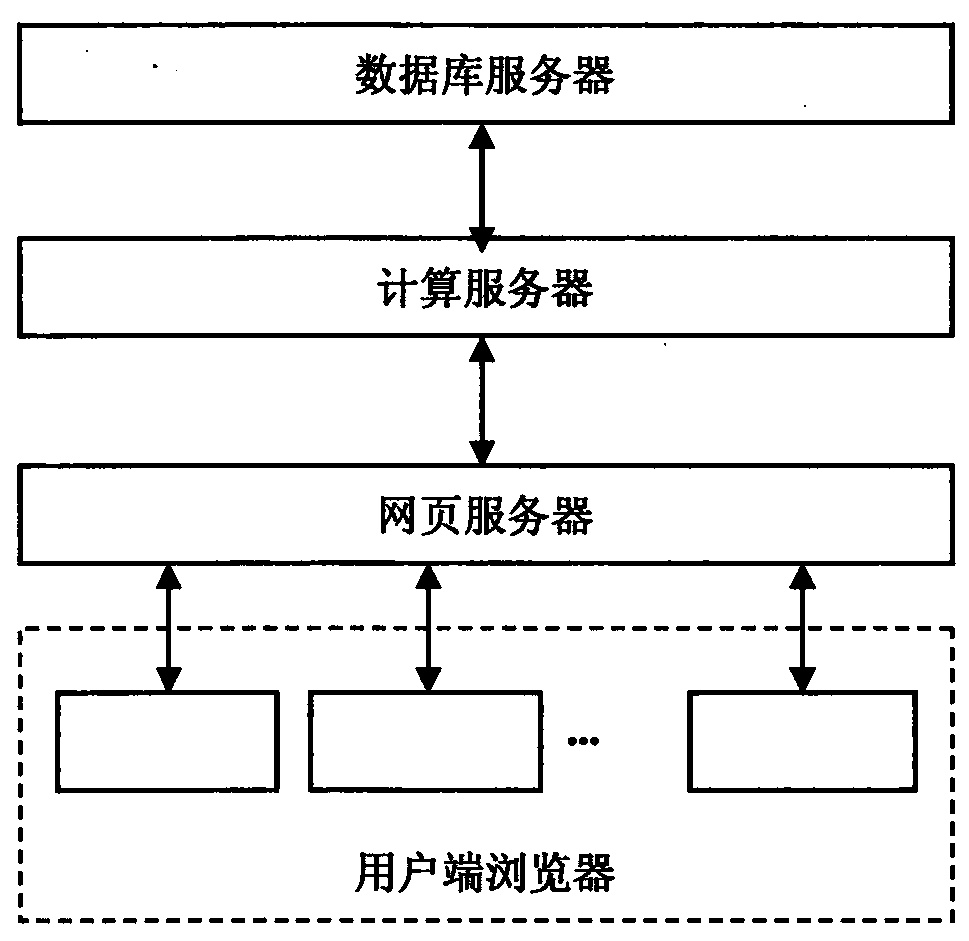

[0048] Such as figure 1 As shown, it is a block diagram of the design monitoring system for the creep deformation of the high-temperature parts of the power generating set adopted in the present invention, and the creep deformation design monitoring system of the high-temperature parts of the thermal power generating set is composed of a creep deformation online computing server and a database server , web server and client browser, the computing server is connected to the database server and the web server, the web server is connected to the client browser, and the database server stores the physical performance data of the high-temperature components of the power generation unit, including the material creep test constant n Wait.

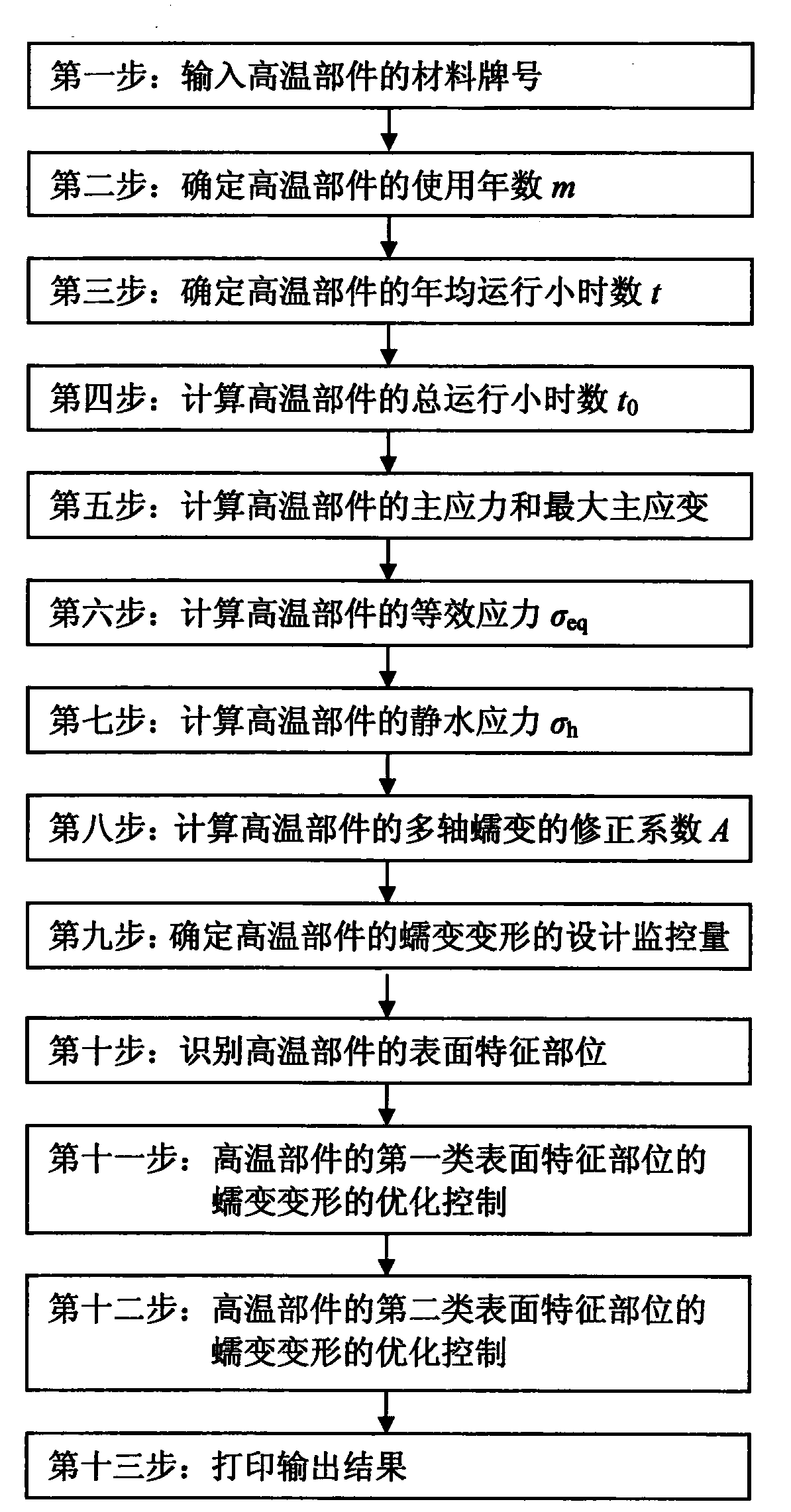

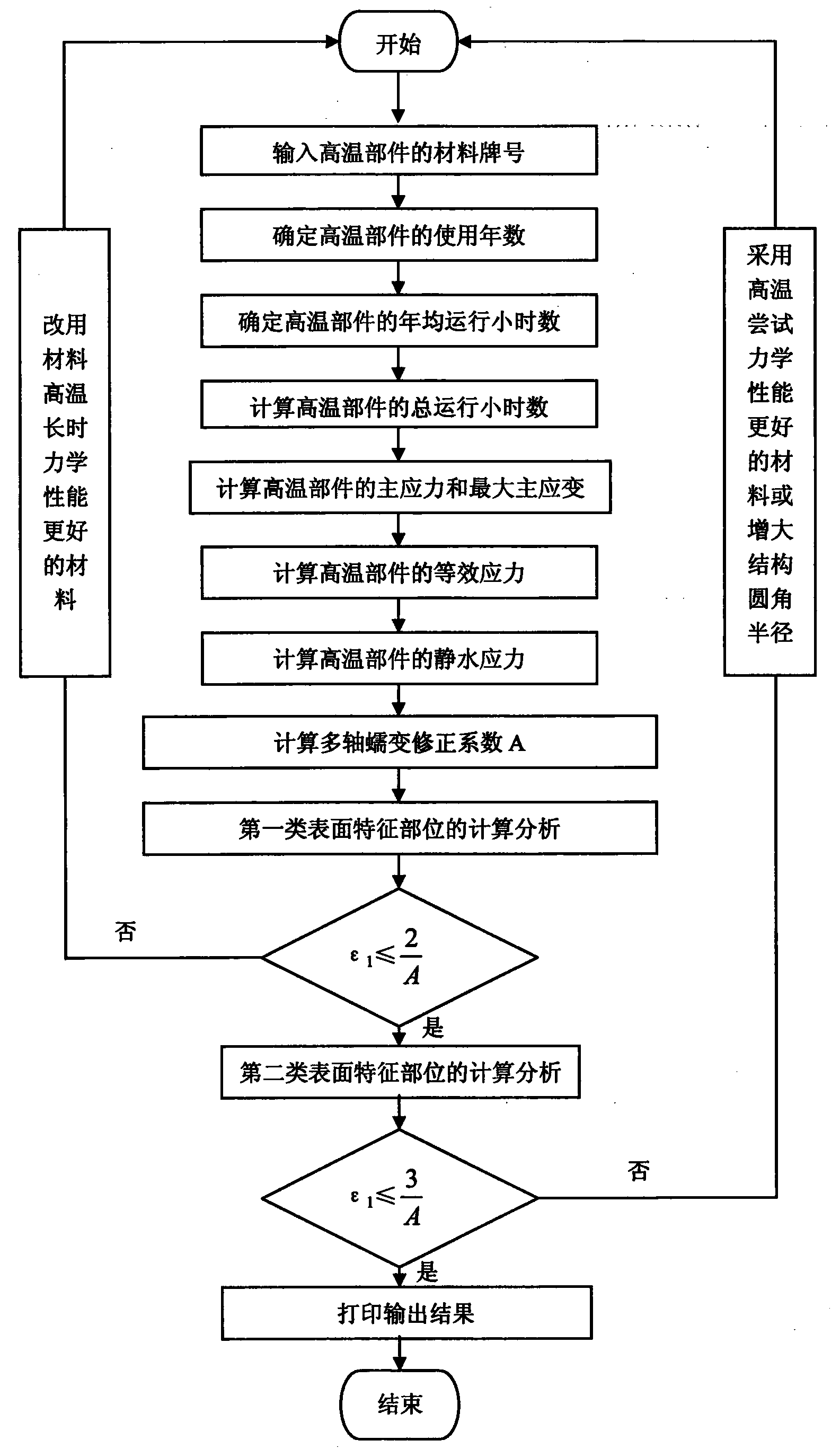

[0049] Such as figure 2 Shown, is the flowchart of the method adopted in the present invention, as image 3 As shown, it is a block diagram of the computer software adopted by the creep deformation calculation server of the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com