Patents

Literature

33 results about "Hydrostatic stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In continuum mechanics, a hydrostatic stress is an isotropic stress that is given by the weight of water above a certain point. It is often used interchangeably with "pressure" and is also known as confining stress, particularly in the field of geomechanics.

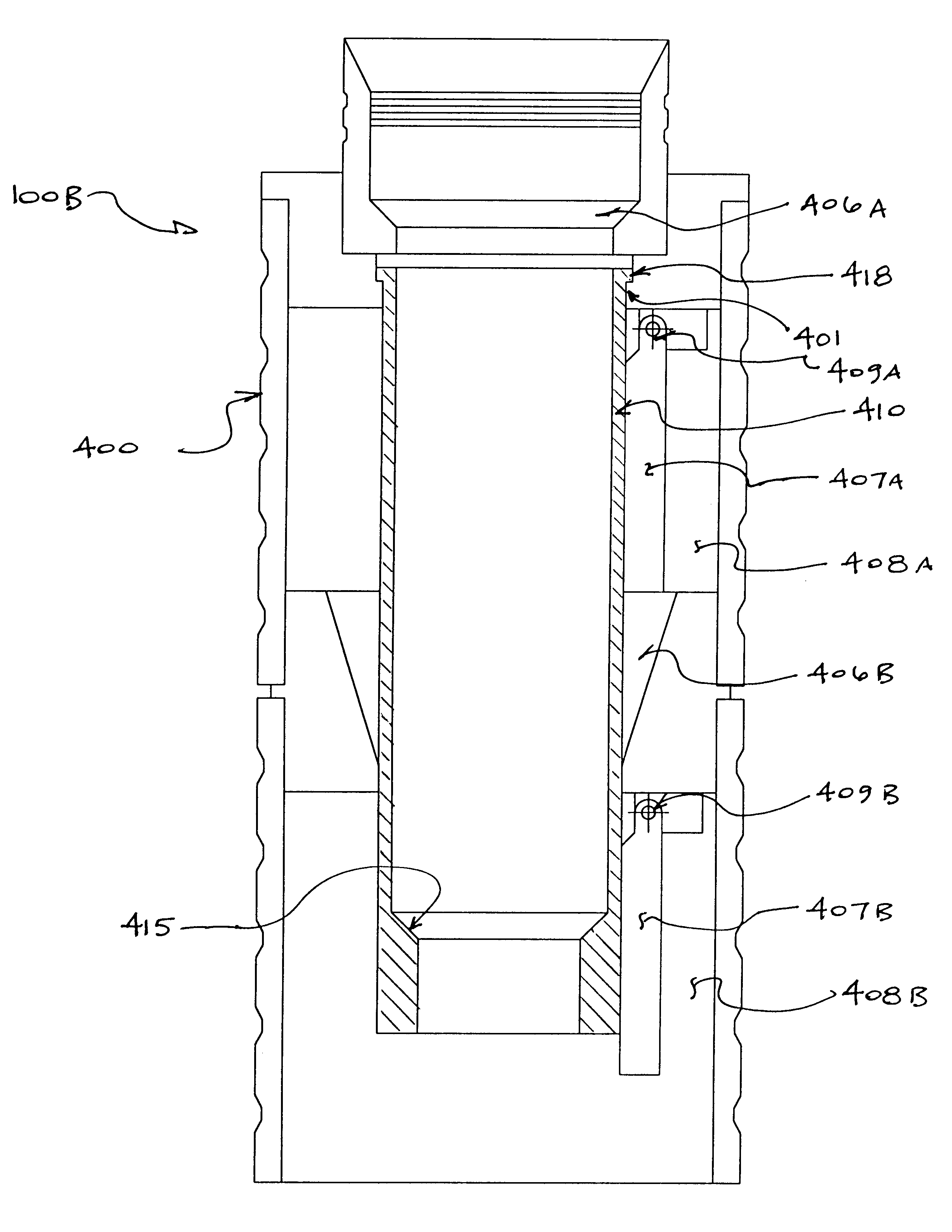

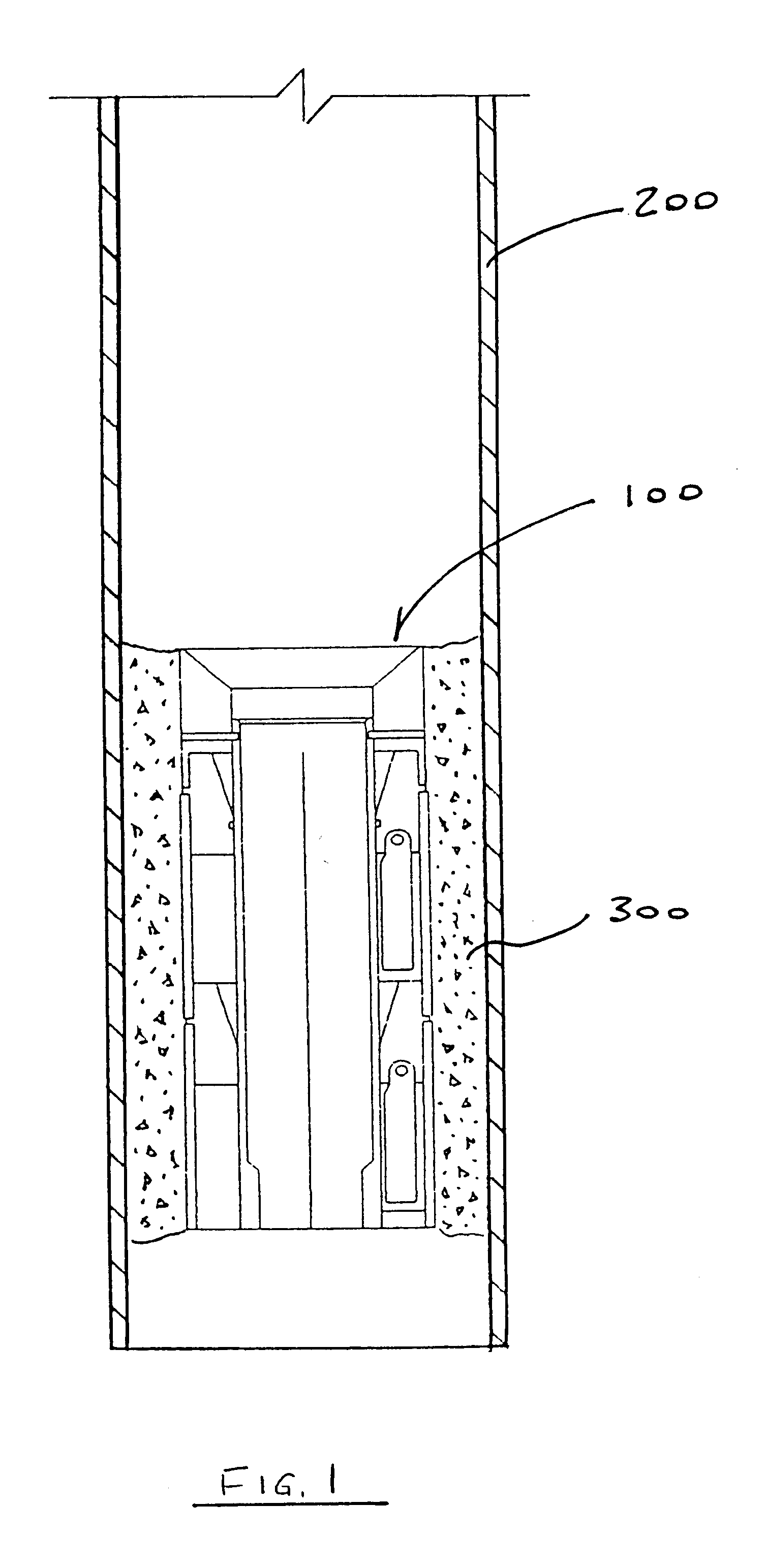

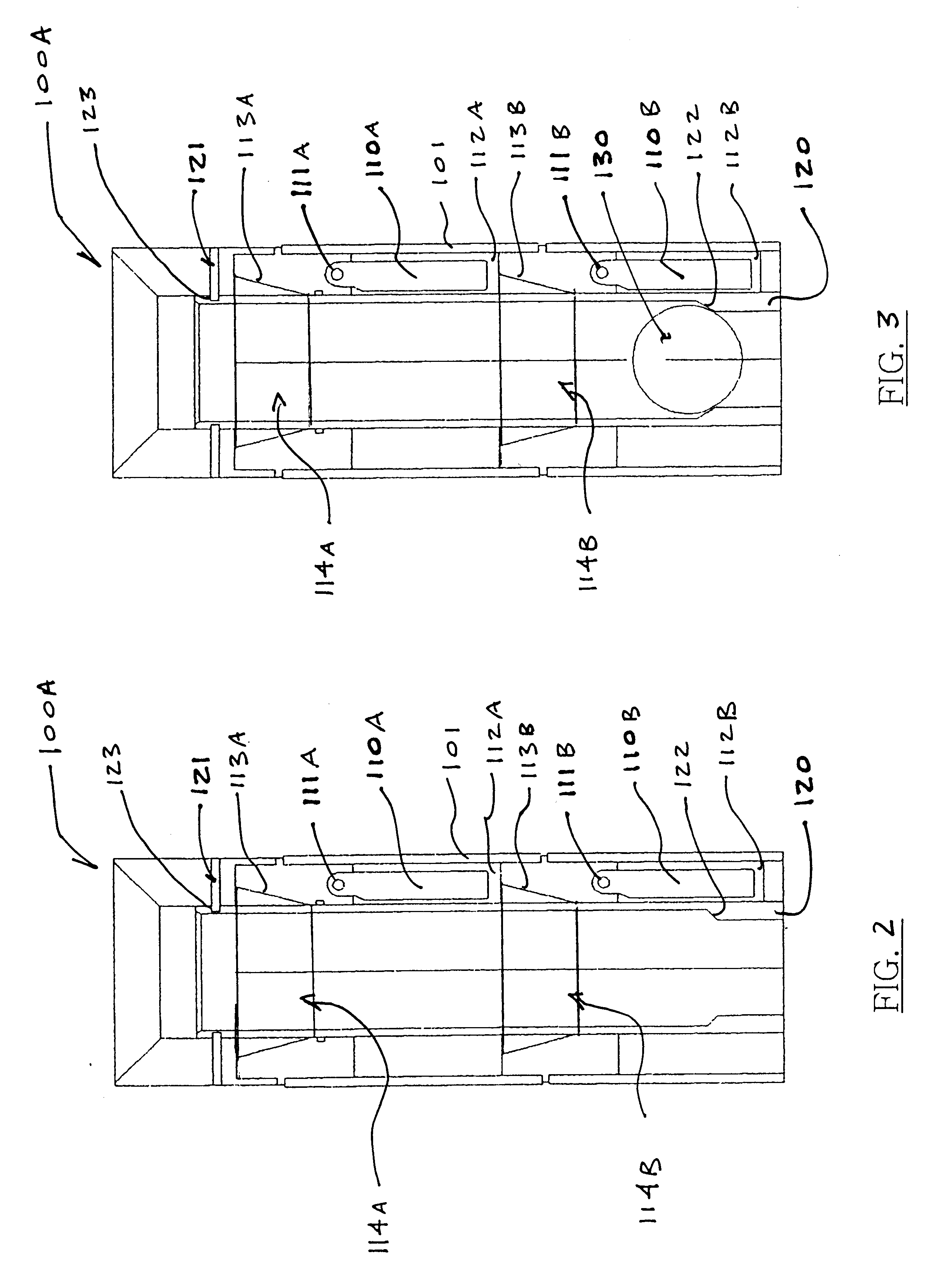

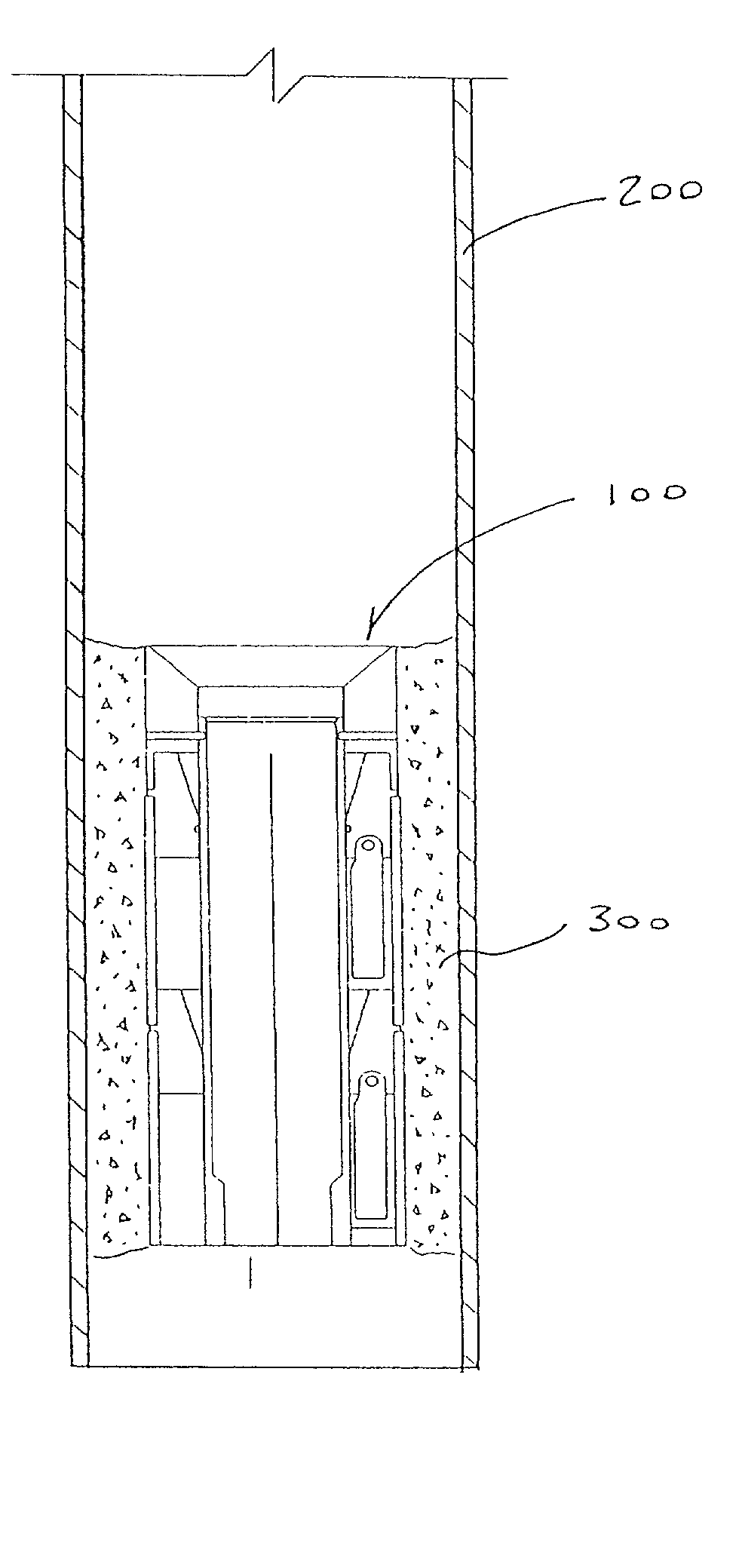

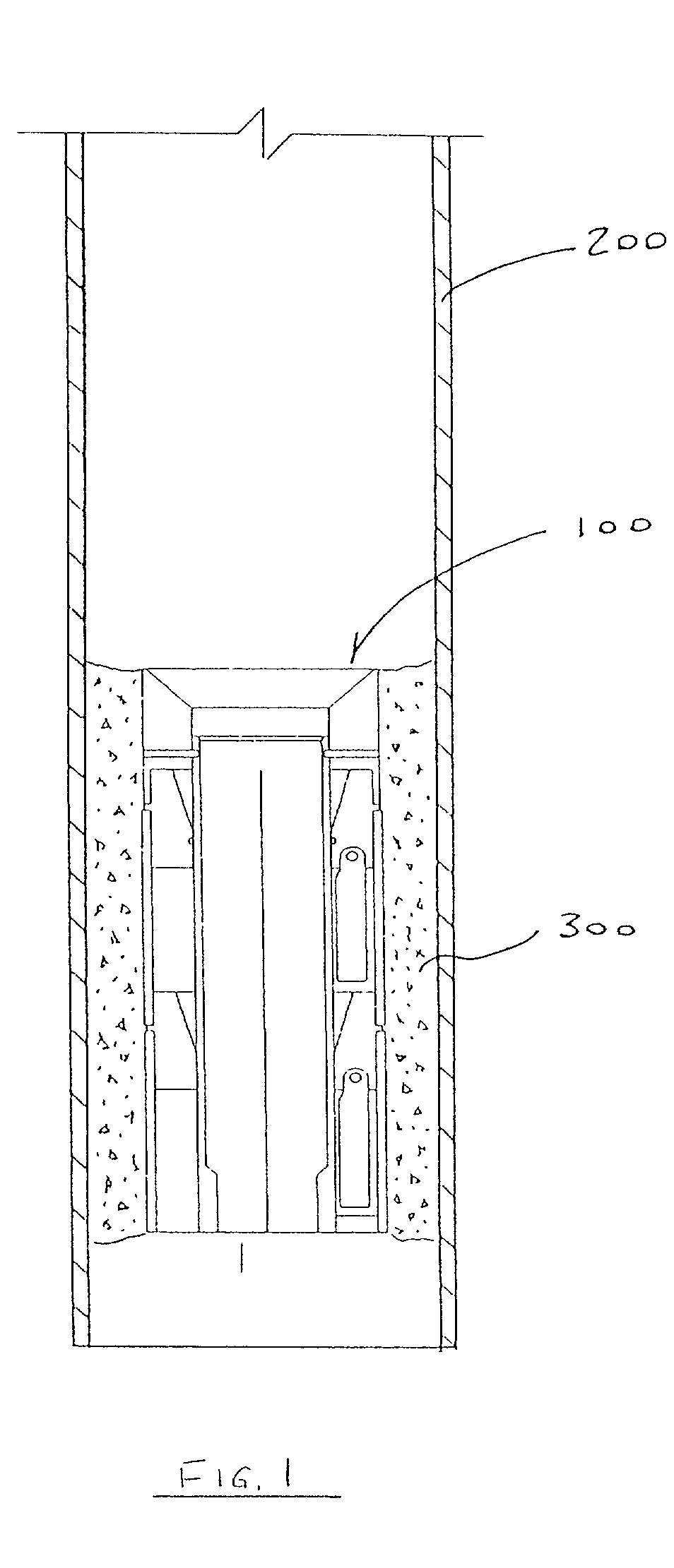

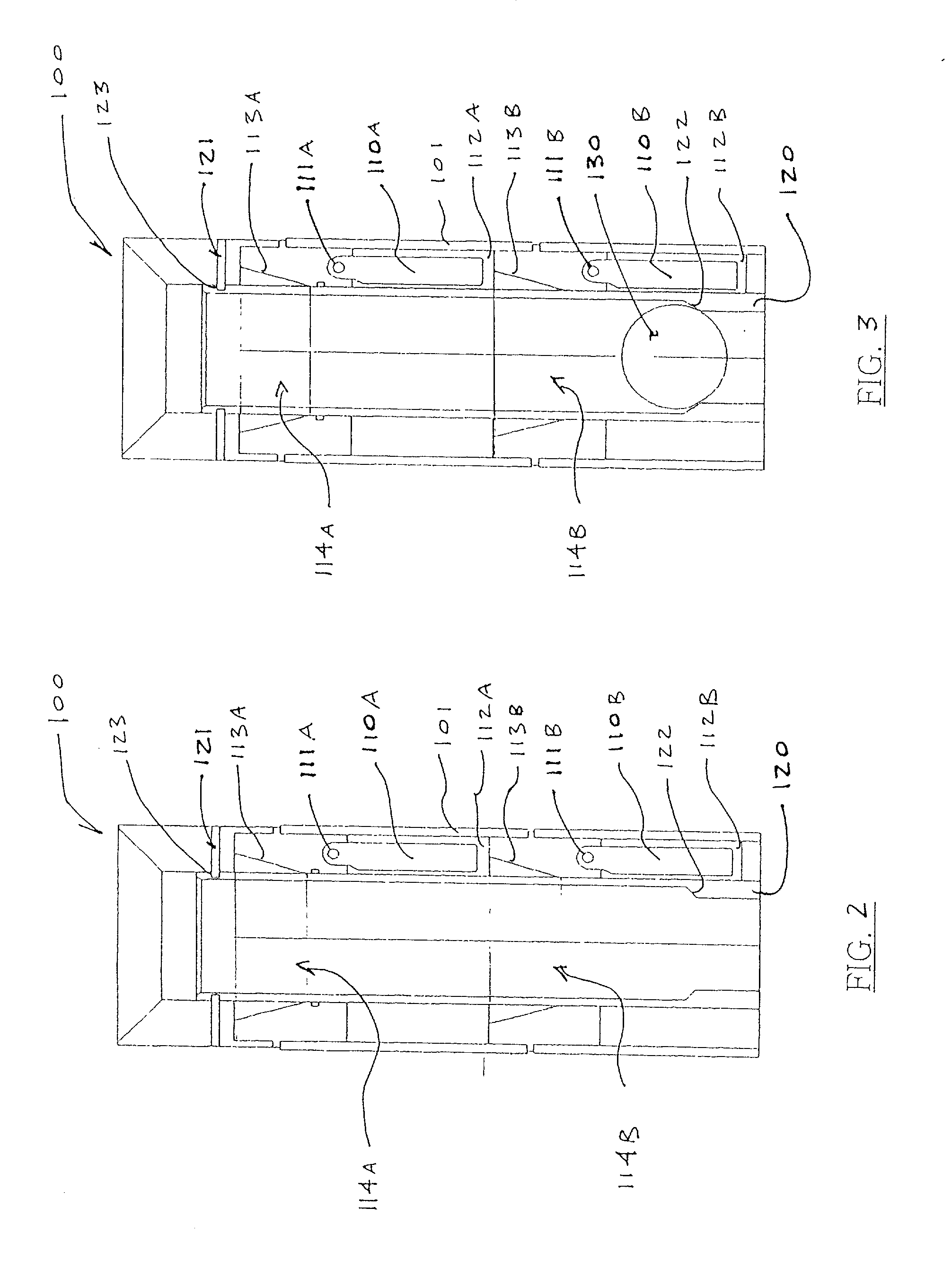

Float collar

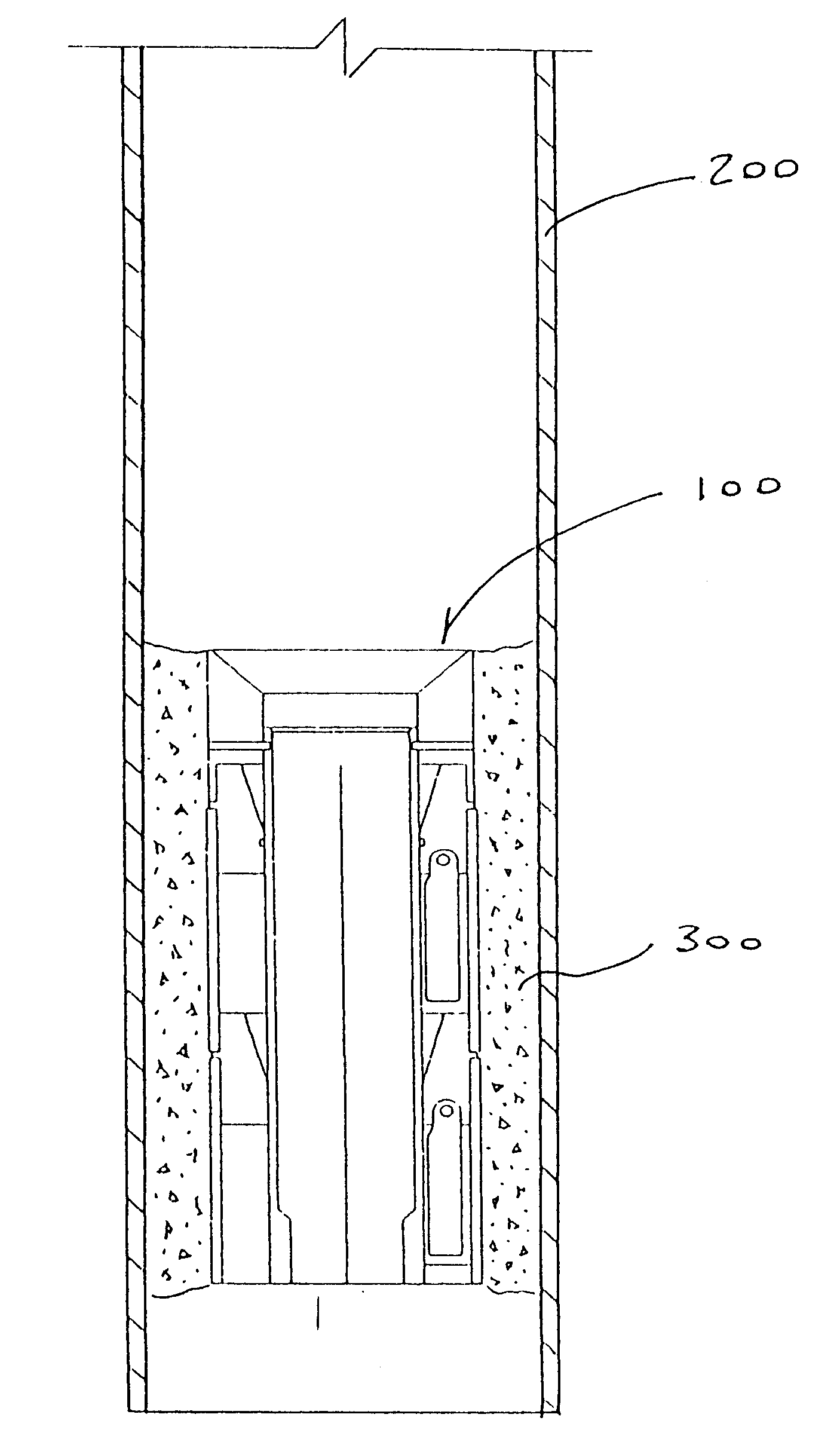

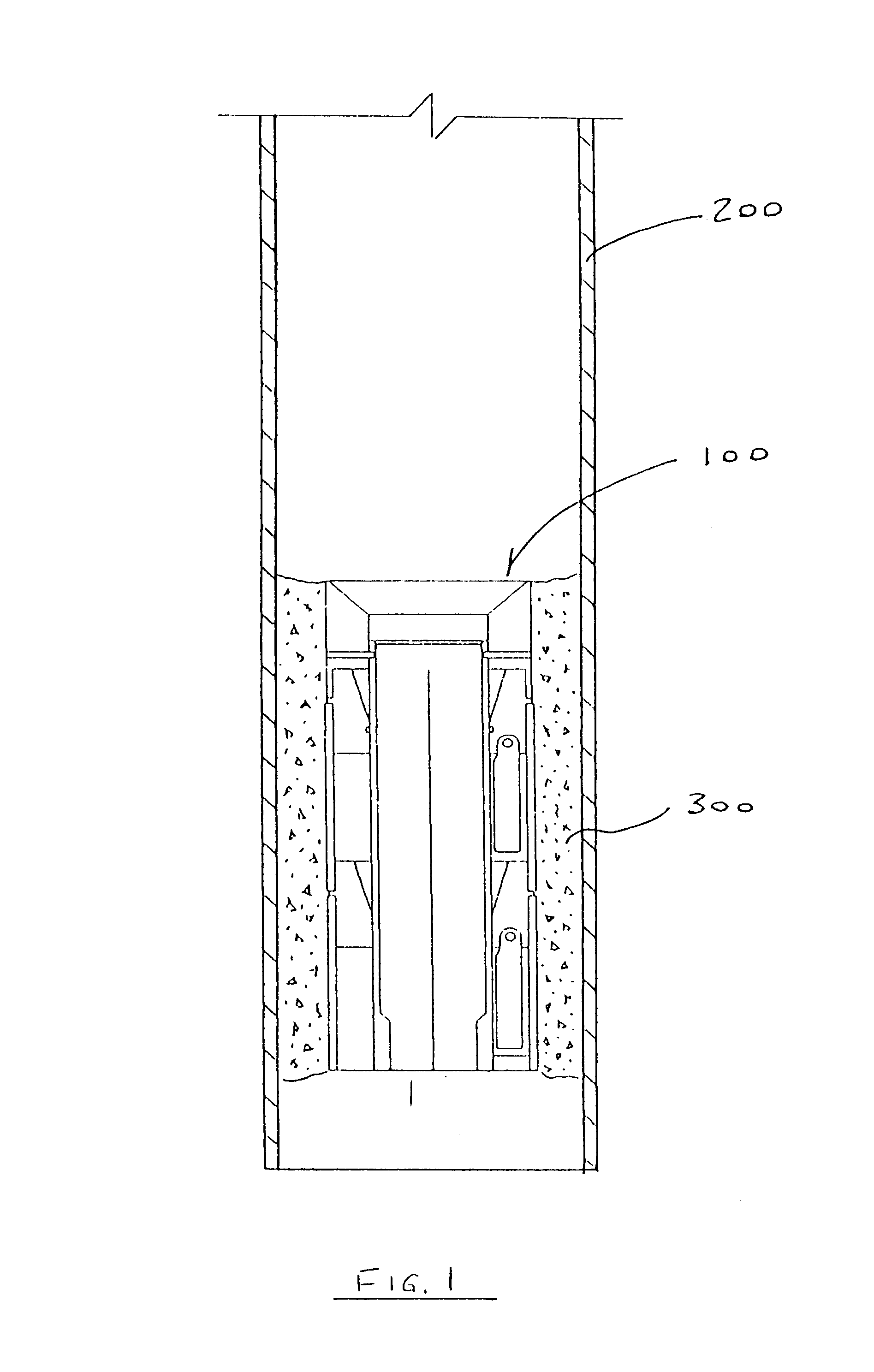

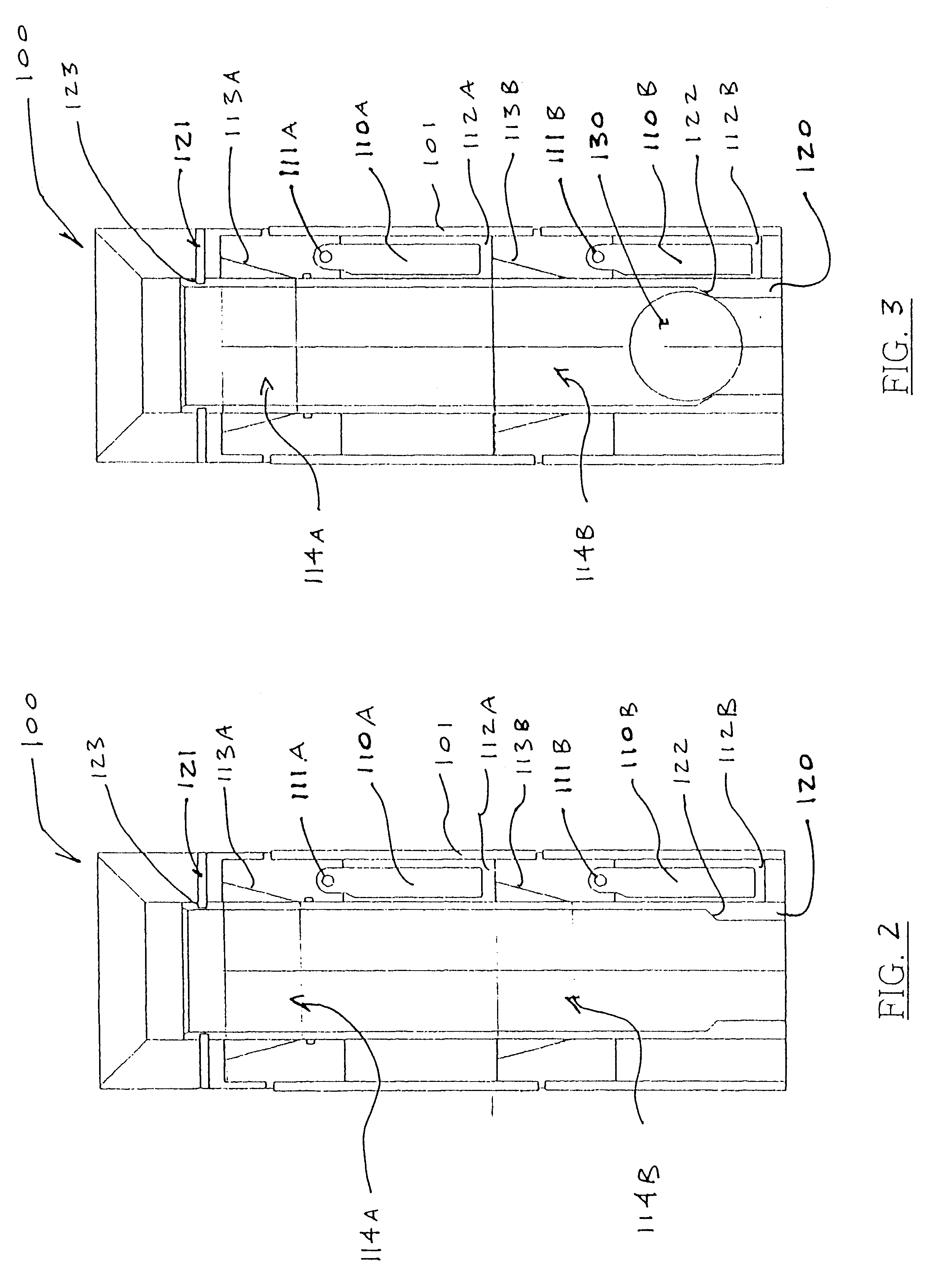

The present invention relates to a float collar apparatus for regulating the passage of fluid through a drilling / production liner or sub-sea casing. Apparatus of the present invention is fabricated using plastic flapper valves and valve-actuating sleeve components in contrast to prior art float collar components which are fabricated almost entirely of hard metals. Particularly, the plastic may be nylon, phenolic, or a phenolic-nylon laminate. The use of plastic components in the float collar apparatus of the present invention provides a substantial reduction in time and resources expended during drilling out of the float collar once cementing operations are completed. Additionally, the float collar apparatus of the present invention is fabricated from a pre-determined combination of plastic components and metal components thereby ensuring that the improved float collar can still endure substantial hydrostatic stresses encountered during casing liner running in and cementing operations.

Owner:ALLAMON JERRY P +2

Float collar

InactiveUS20030047314A1Shorten the timeSave resourcesDrilling rodsFluid removalOcean bottomState of art

The present invention relates to a float collar apparatus for regulating the passage of fluid through a casing liner or sub-sea casing. Apparatus of the present invention is fabricated using plastic flapper valves and sleeve components in contrast to prior art float collar components which are fabricated almost entirely of hard metals. The use of plastic components in the float collar apparatus of the present invention provides a substantial reduction in time and resources expended during drilling out of the float collar once cementing operations are completed. Additionally, the float collar apparatus of the present invention is fabricated from a pre-determined combination of plastic components and metal components thereby ensuring that the improved float collar can still endure substantial hydrostatic stresses encountered during casing liner running in and cementing operations.

Owner:ALLAMON JERRY P +2

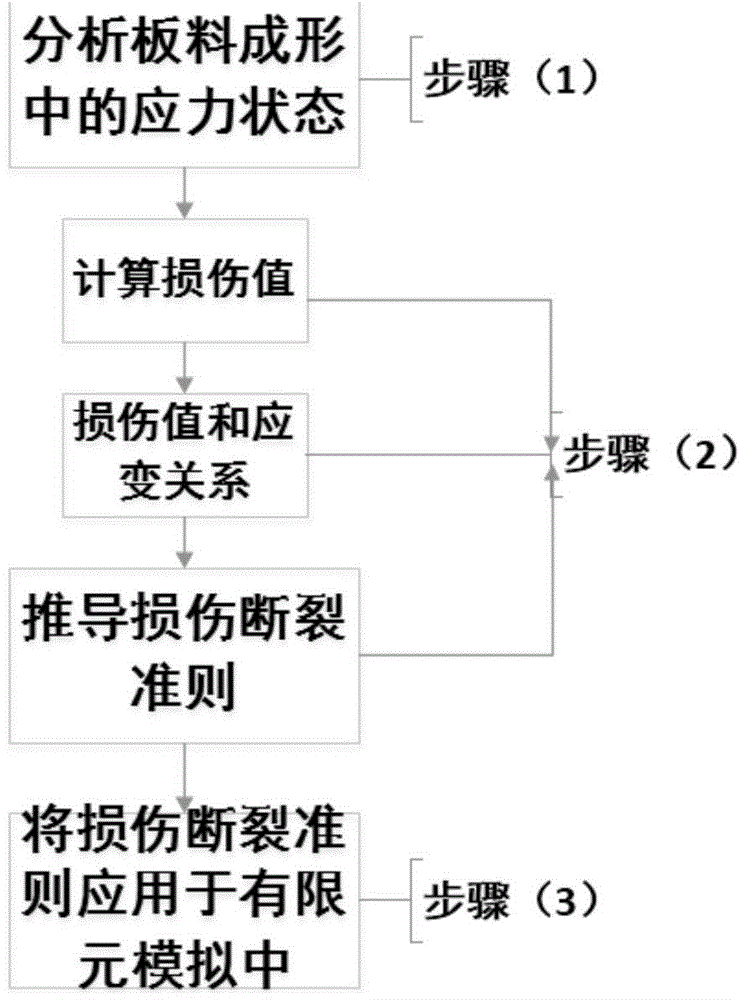

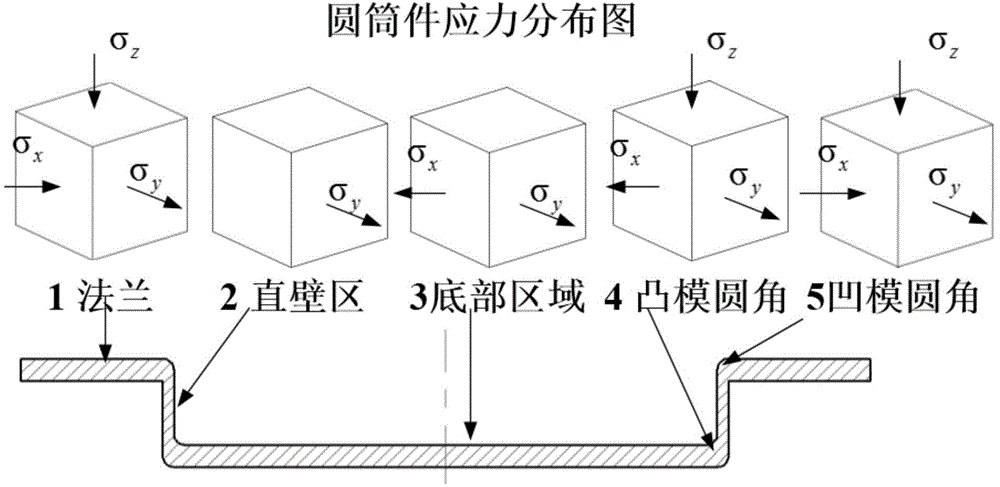

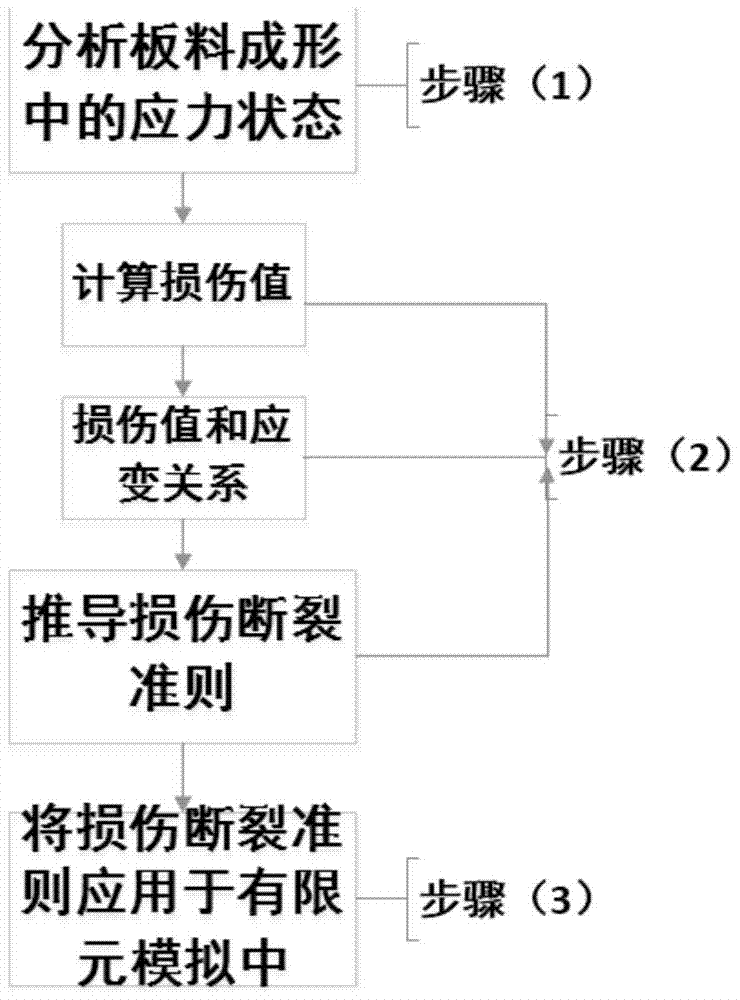

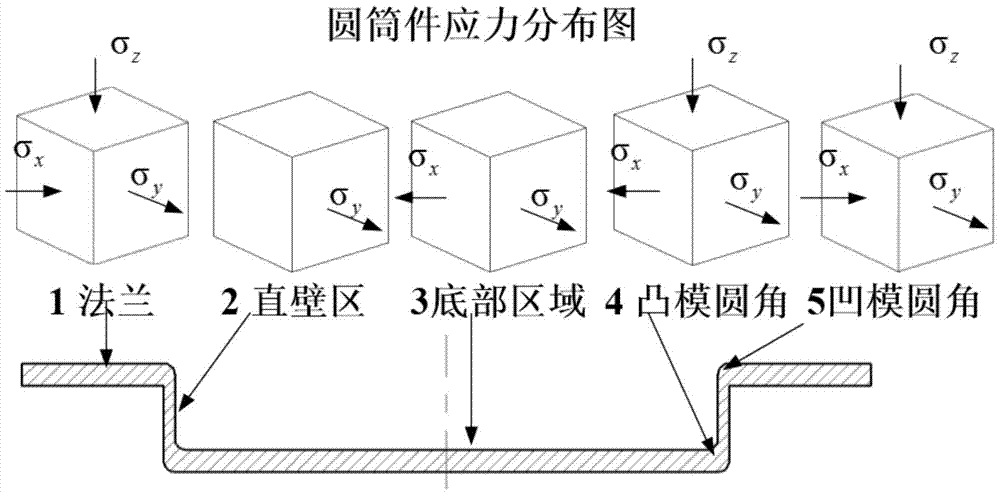

Method for predicting sheet forming fractures based on damage fracture standard numerical value

ActiveCN104636539AReduce mistakesAccurate timeSpecial data processing applicationsContinuum damage mechanicsEngineering

The invention discloses a method for predicting sheet forming fractures based on a damage fracture standard numerical value. The method includes the steps of obtaining the stress state distribution of a metal sheet cylindrical piece in the stamping process according to the thermodynamics irreversible law, obtaining a stress balance differential equation of the metal sheet cylindrical piece in the stamping process according to the stress state distribution, calculating the change rate, occurring when the metal sheet cylindrical piece is damaged, of the area of a small unit of the metal sheet cylindrical piece in the stamping process according to the continuum damage mechanics theory, obtaining the damage to the metal sheet cylindrical piece according to the change rate, calculating the relation between the damage and the strain of the metal sheet cylindrical piece, and finally deriving the relation between the damage value and the true stress, true strain and hydraulic stress of the metal sheet cylindrical piece under the unidimensional scale in the whole stamping process. By means of the method, the technical problem that when fractures during sheet forming are predicted through an existing numerical value method, errors are large can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Float collar

The present invention relates to a float collar apparatus for regulating the passage of fluid through a casing liner or sub-sea casing. Apparatus of the present invention is fabricated using plastic flapper valves and sleeve components in contrast to prior art float collar components which are fabricated almost entirely of hard metals. The use of plastic components in the float collar apparatus of the present invention provides a substantial reduction in time and resources expended during drilling out of the float collar once cementing operations are completed. Additionally, the float collar apparatus of the present invention is fabricated from a pre-determined combination of plastic components and metal components thereby ensuring that the improved float collar can still endure substantial hydrostatic stresses encountered during casing liner running in and cementing operations.

Owner:ALLAMON JERRY P +2

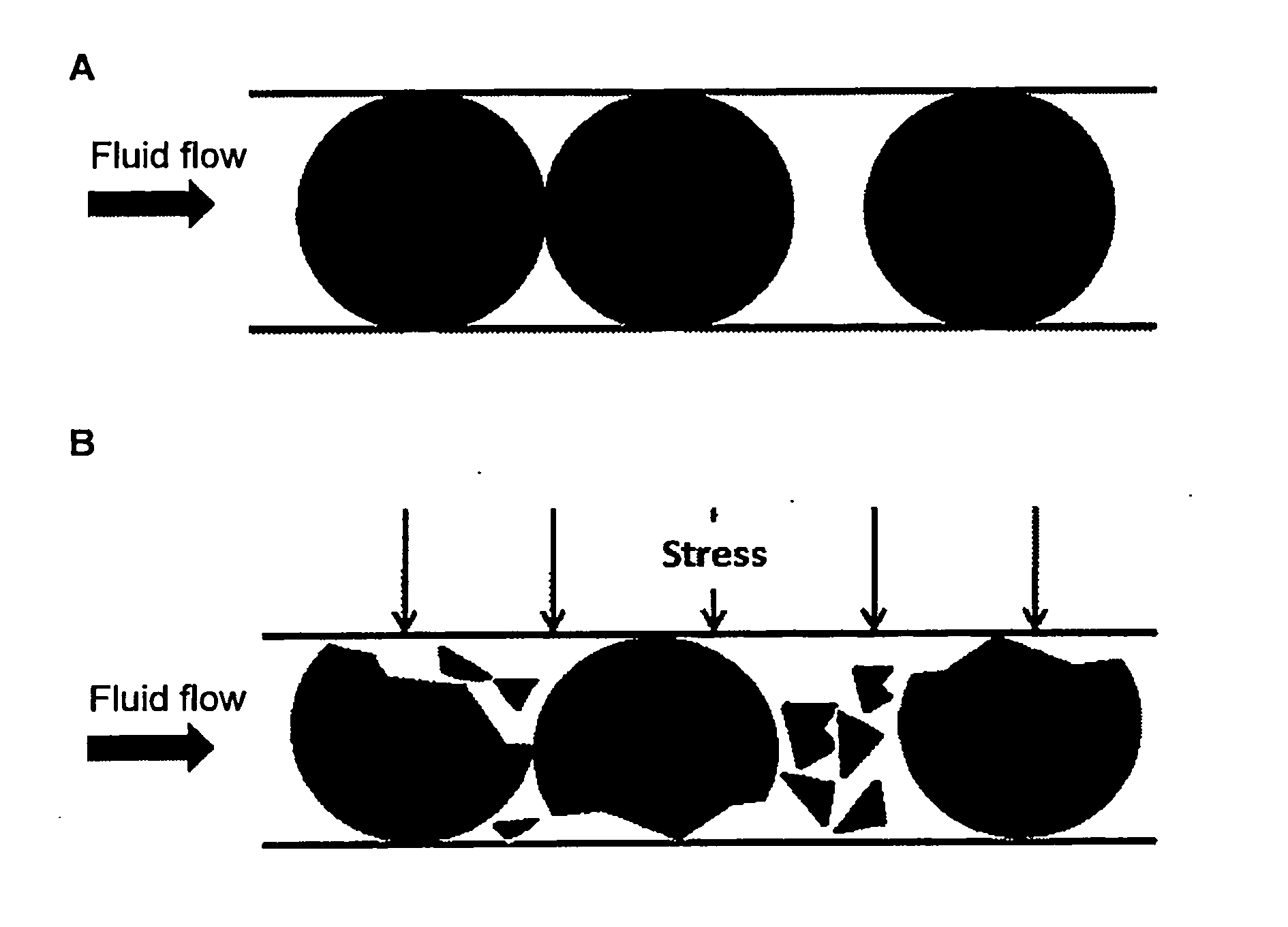

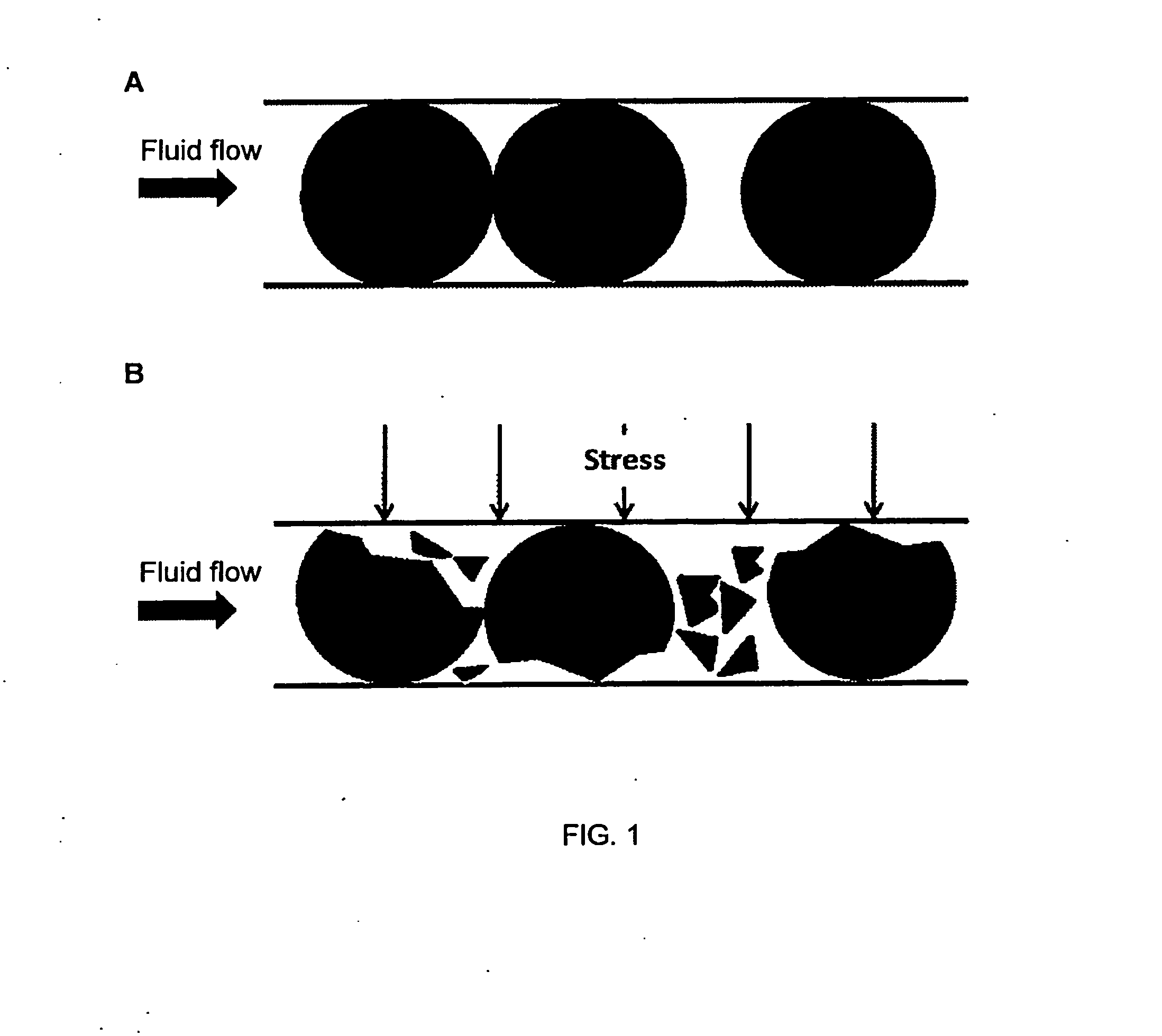

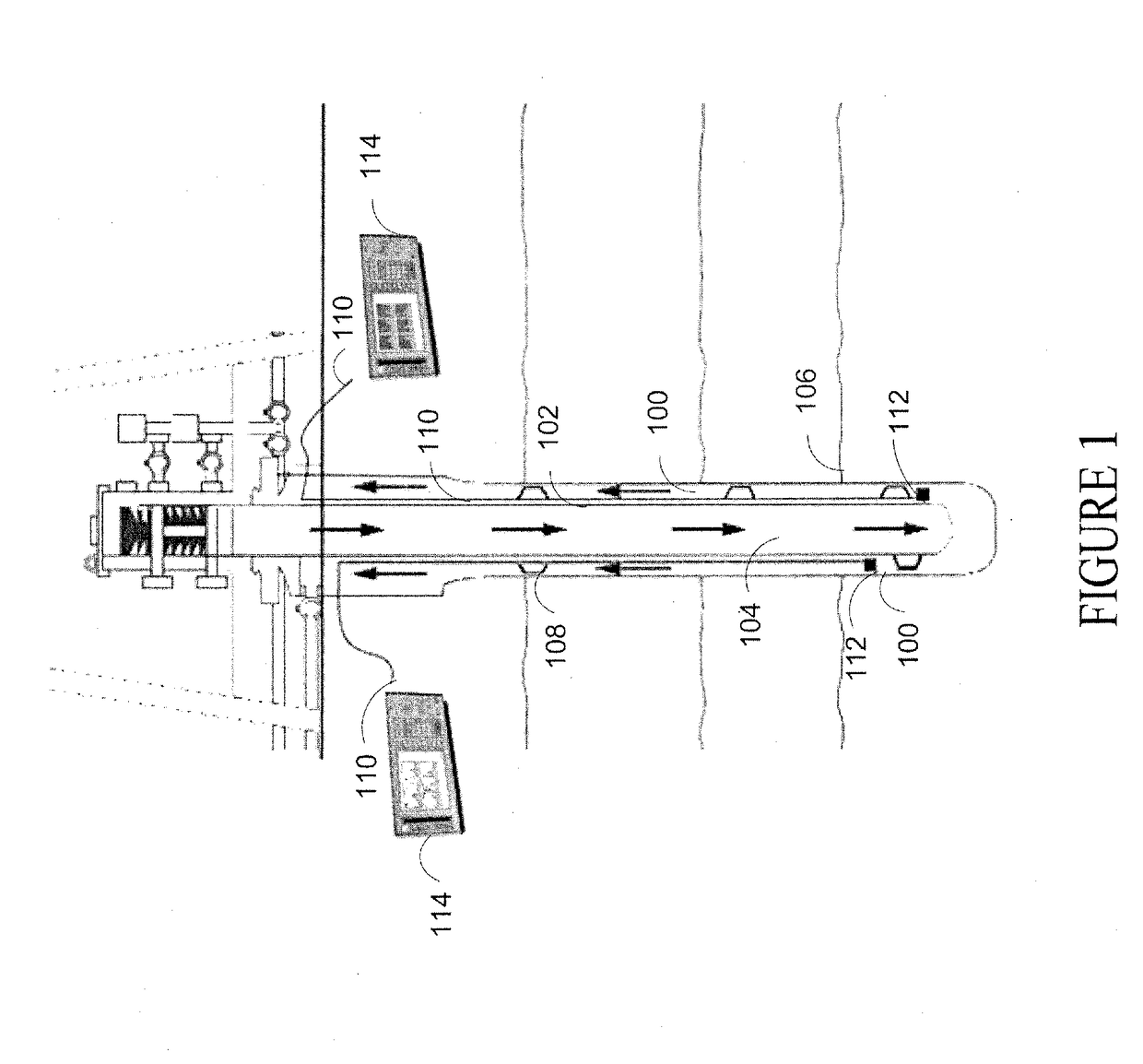

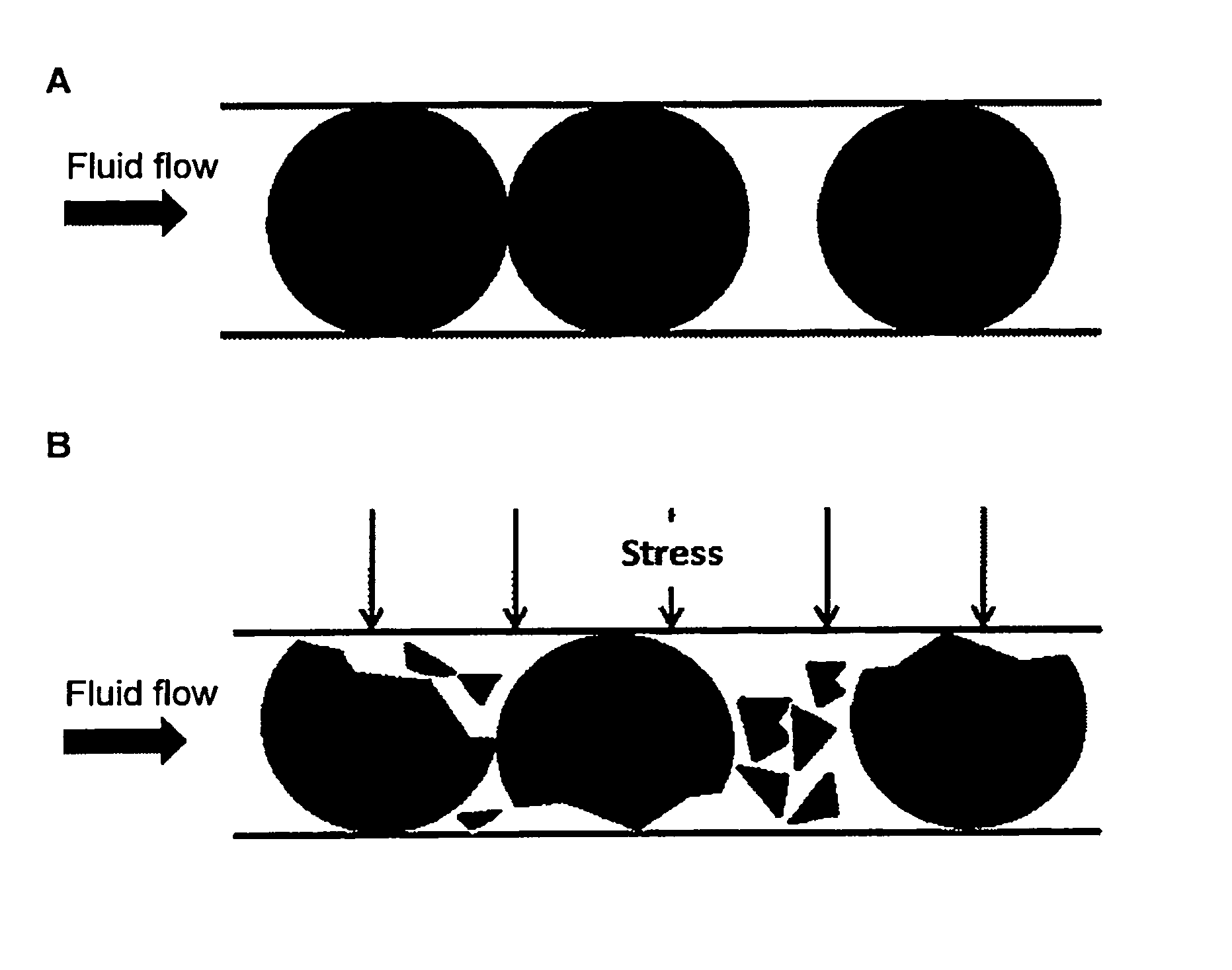

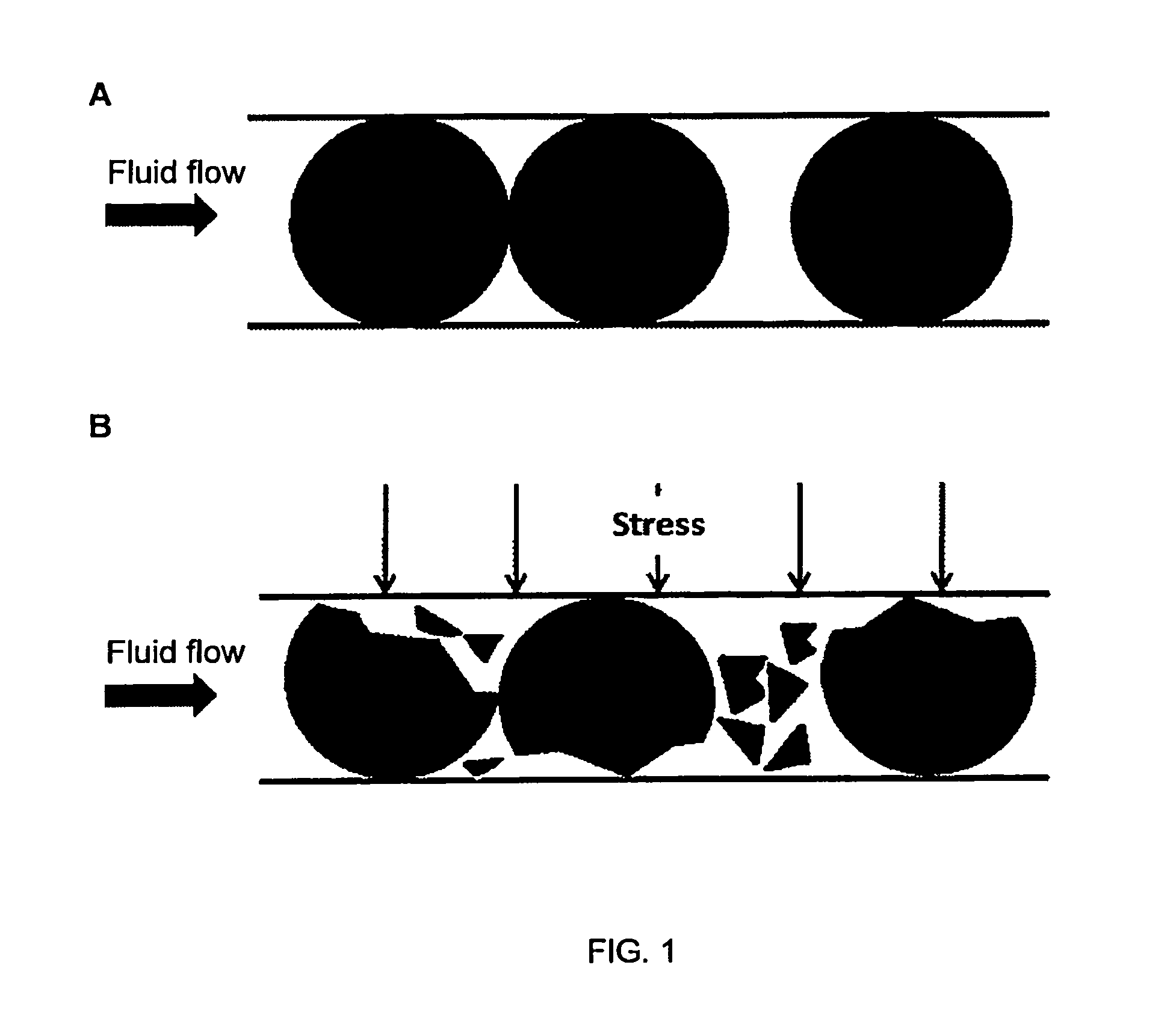

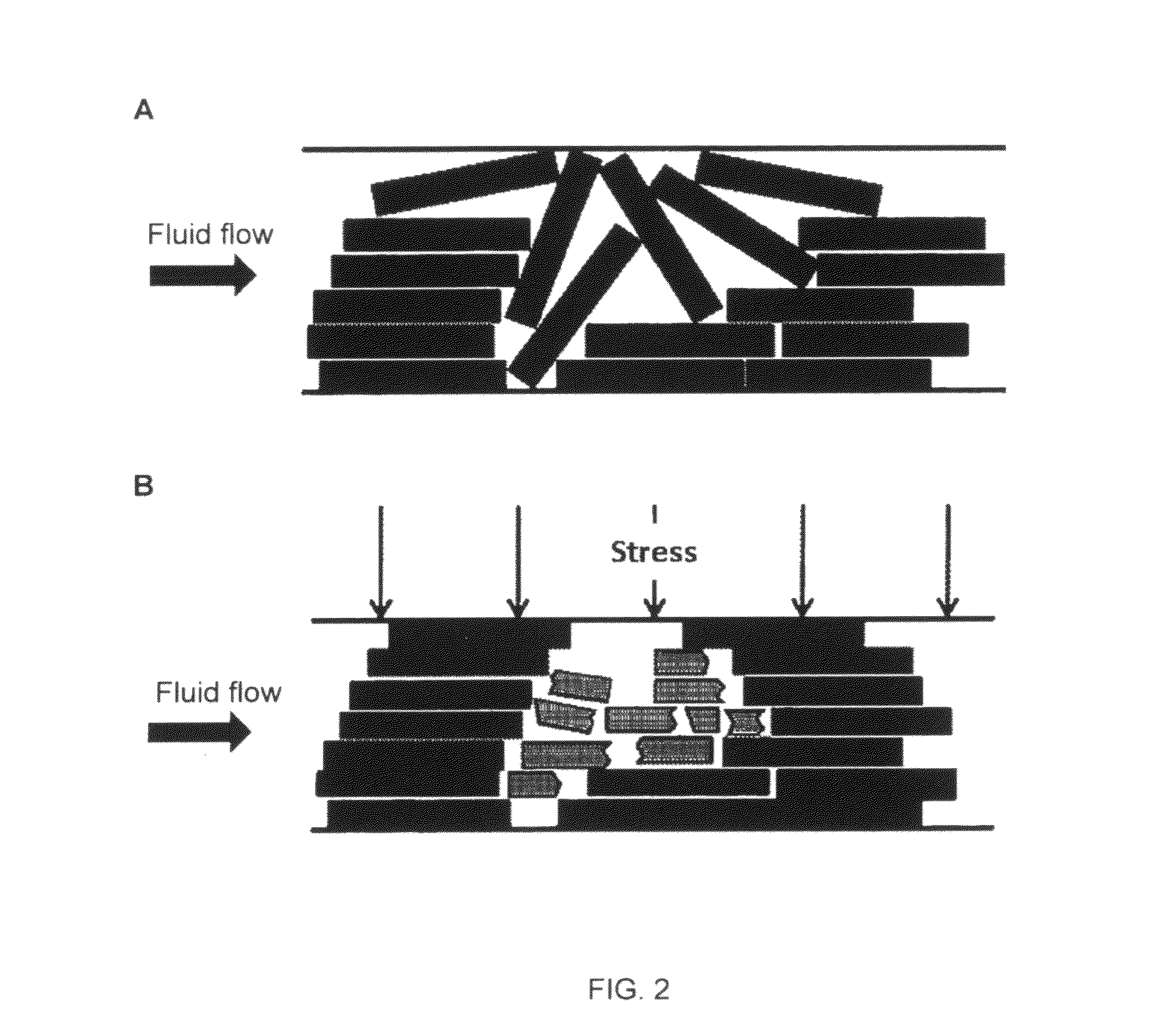

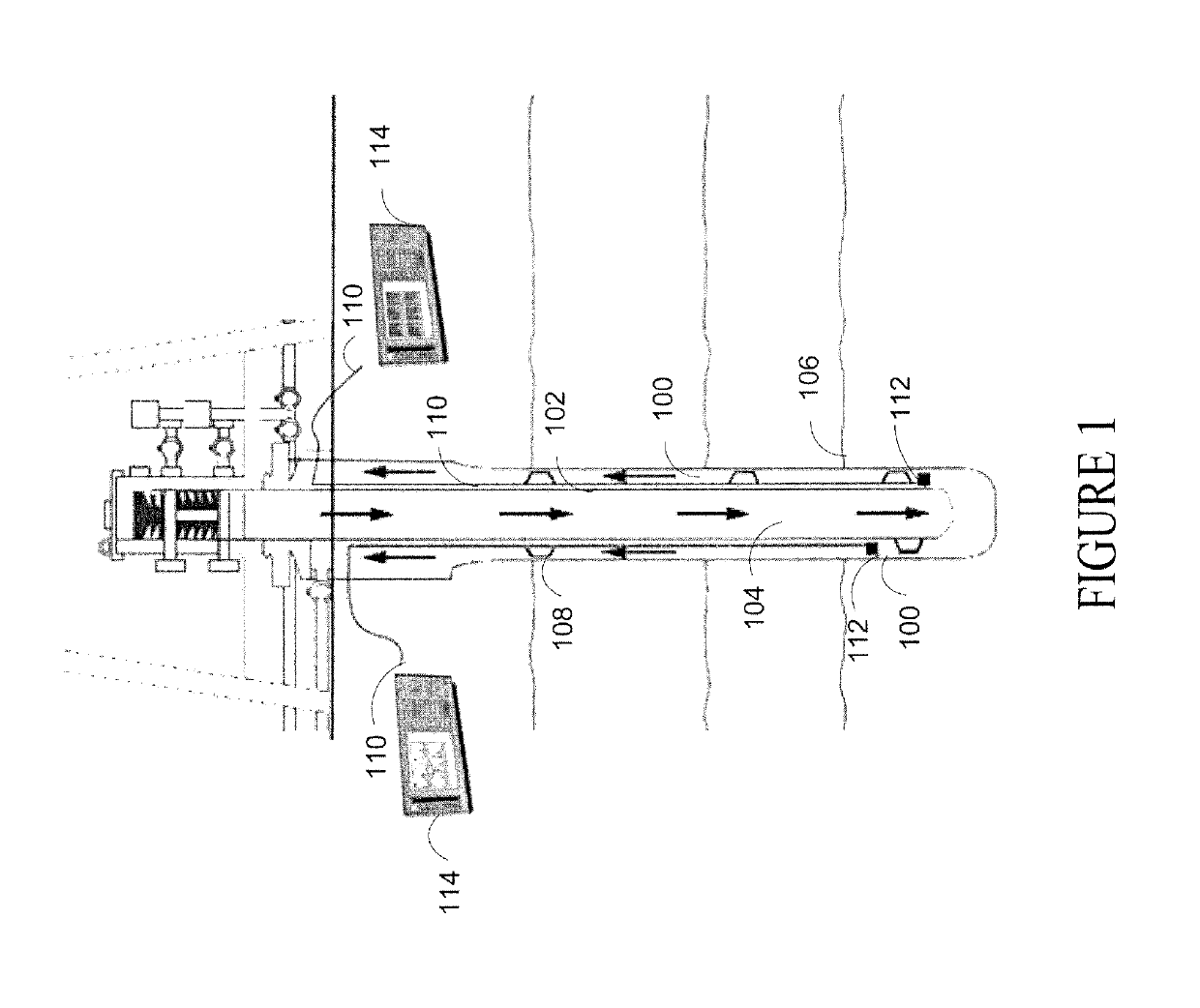

Hydraulic fracturing system

ActiveUS20130014946A1Increase injection rateFluid removalDrilling compositionFlow stressHydrostatic pressure

A method is given for fracturing a formation, in particular far-field in a tight formation, in which at least a portion of the proppant is crushable in situ at some point during pumping, during fracture closure, or at higher Fluid flow stresses experienced later during fracture closure. The closure stress or hydrostatic stress is estimated, then a proppant is selected that is at least partially crushable at that closure stress, and then the fracturing treatment is performed with at least a portion of the total proppant being the selected crushable proppant.

Owner:SCHLUMBERGER TECH CORP

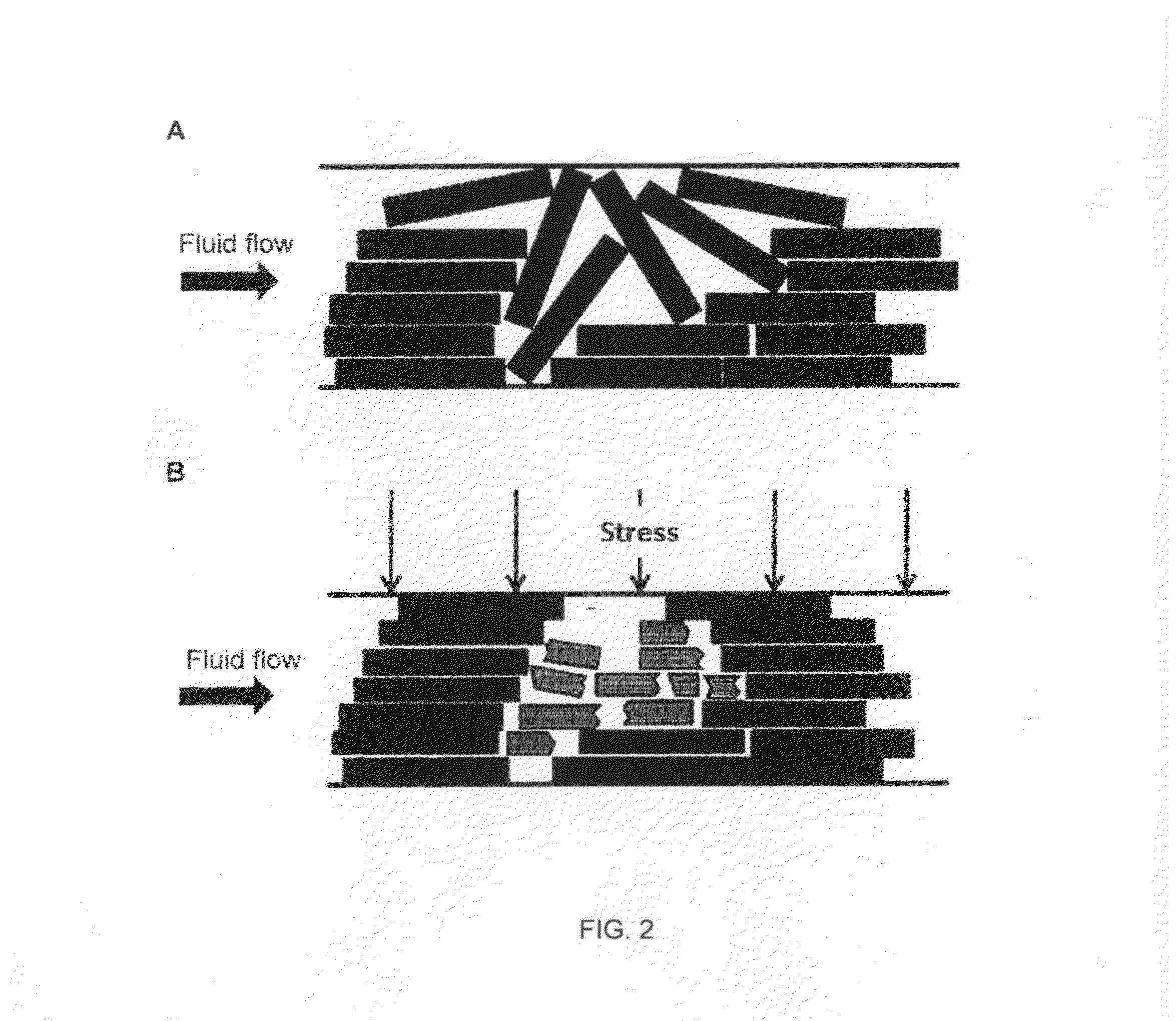

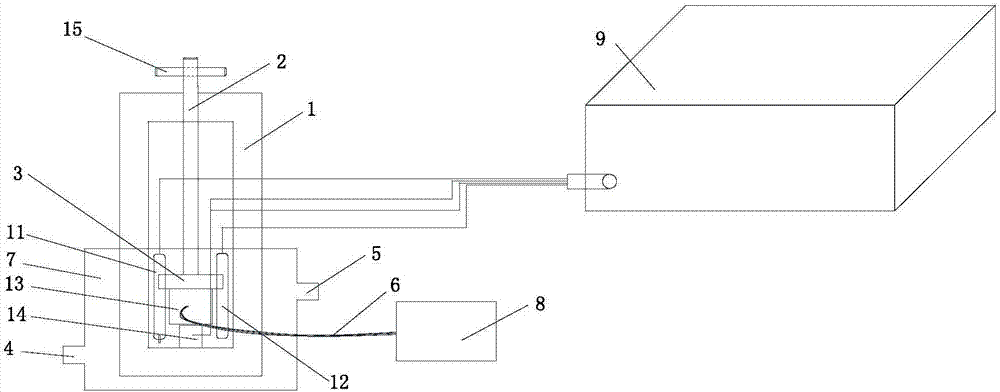

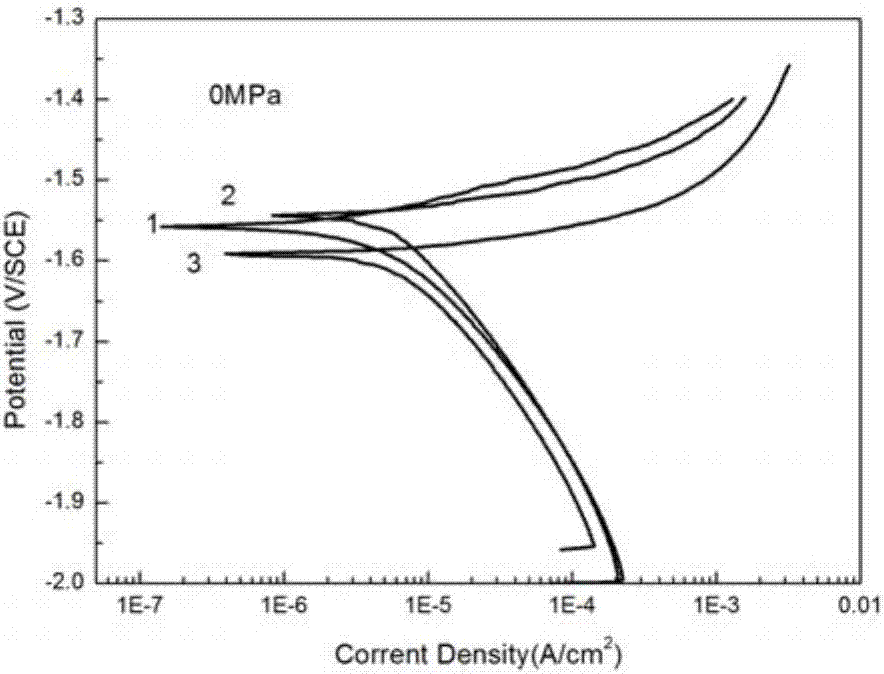

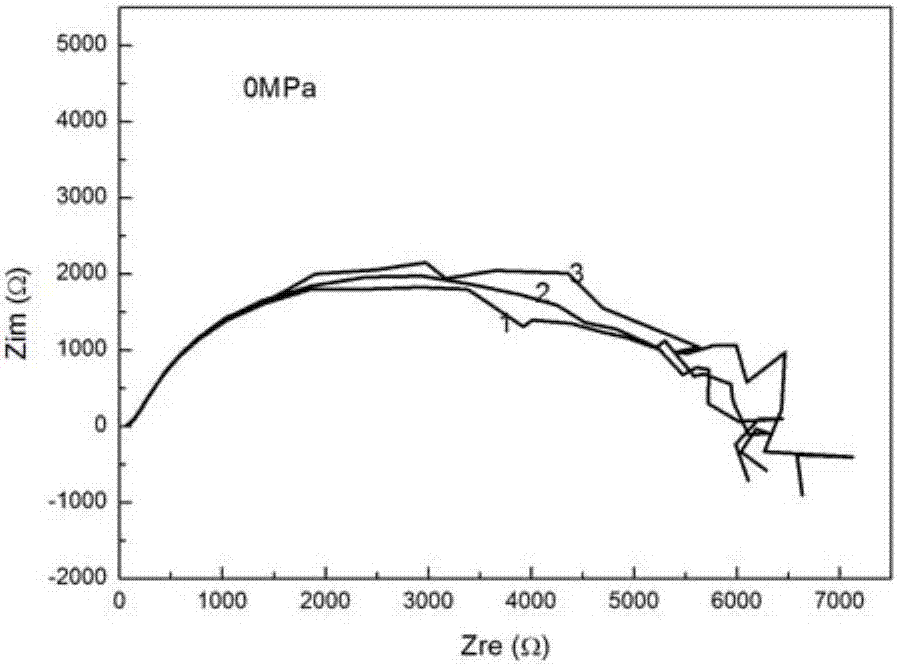

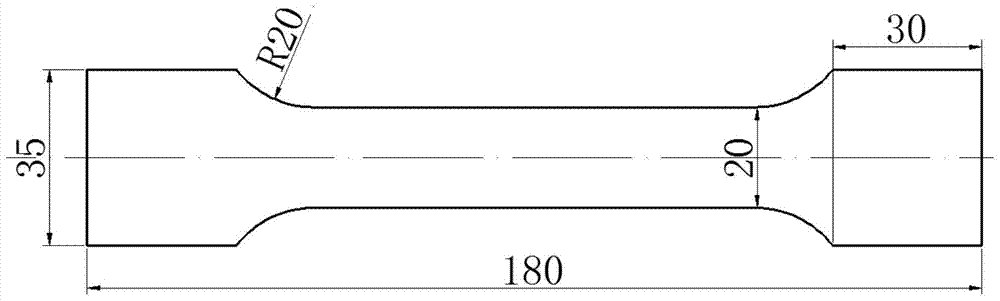

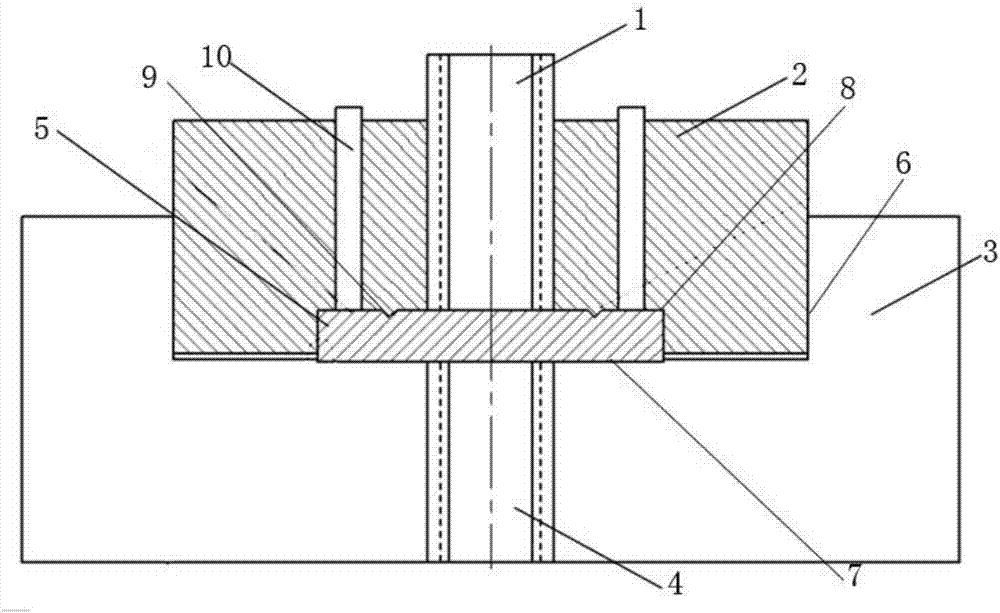

Simulation experiment device for hydrostatic stress corrosion electrochemical action of magnesium alloy and experiment method of simulation experiment device

ActiveCN106872349ASimple structureEasy to adjustWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesPeristaltic pumpTest fixture

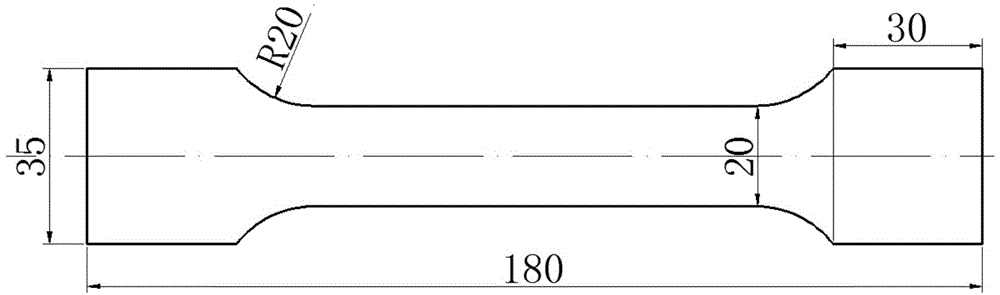

The invention discloses a simulation experiment device for hydrostatic stress corrosion electrochemical action of a magnesium alloy and an experiment method of the simulation experiment device. The simulation experiment device comprises an electrolyte tank, a test device, a computer terminal and an electrochemical workstation, wherein the test device is placed in the electrolyte tank; electrolyte in the electrolyte tank is forced by a high-precision peristaltic pump to cyclically crawl. The simulation experiment device is simple in overall structure, and static pressure can be continuously adjusted. The experiment method is to adjust a screw rod of the test device to apply different sizes of hydrostatic stress on a magnesium alloy test sample, and then adjust the flow rate of the electrolyte through the peristaltic pump to really simulate a living body microenvironment in vitro, so as to carry out a series of electrochemical test operations on open circuit potential, a polarization curve, an alternating current impedance spectrum and electrochemical noise; test results are real and stable, and the reappearance and the reproducibility are high. The simulation experiment device and the simulation method can fully meet the requirement of the magnesium alloy for relevant research use on bearing of the hydrostatic stress in a human bone microenvironment.

Owner:SHANDONG UNIV OF SCI & TECH

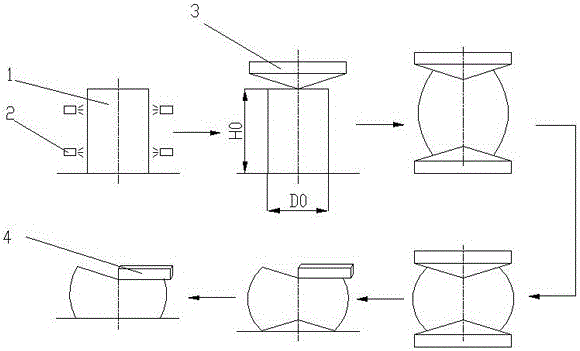

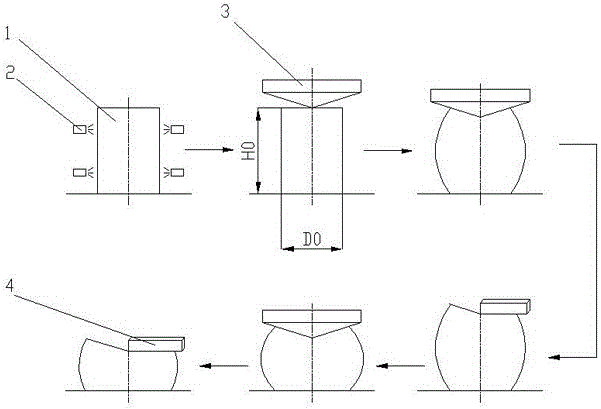

Technology for forging forge pieces through conical plate upsetting method with additional forced cooling

Large steel ingots have their inherent defects, such as segregation, inclusions, loose, coarse columnar crystals, etc. In order to reduce these casting defects, the present invention proposes a conical plate upsetting method with additional forced cooling, which is used to close the gap of forgings. The main technical route is: casting steel ingot → chamfering → blanking → forced cooling + conical plate upsetting Coarse → rolling → smooth. This manufacturing process can increase the internal hydrostatic stress, effectively forge internal defects, and prevent internal cracks.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST +1

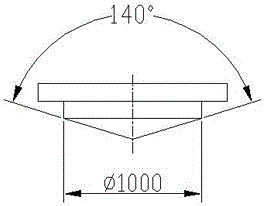

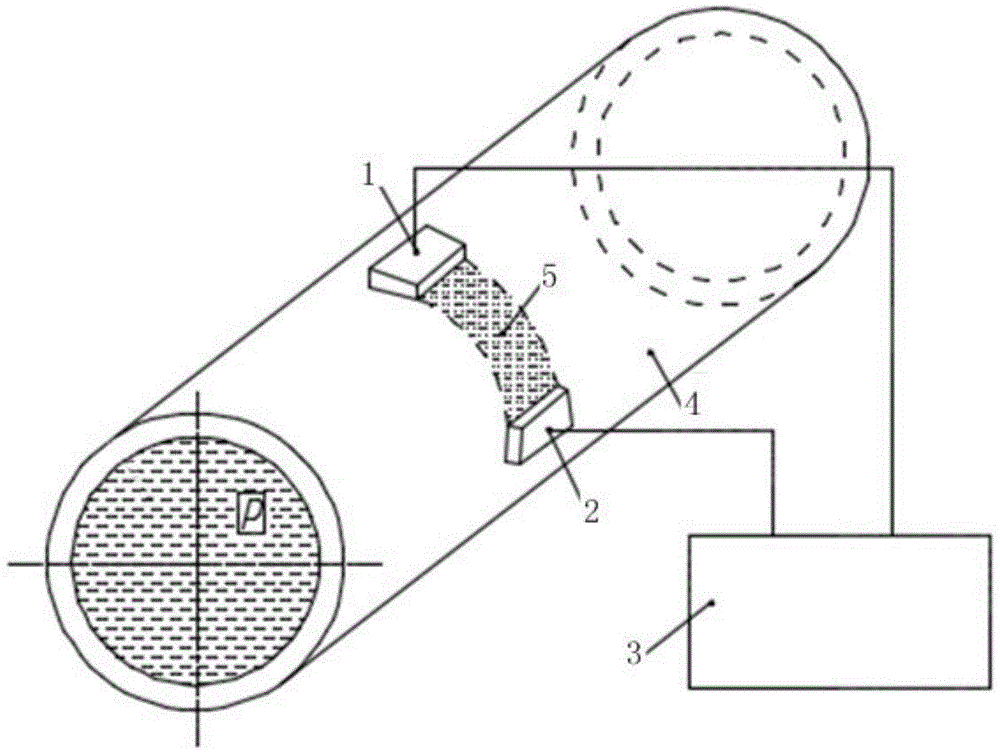

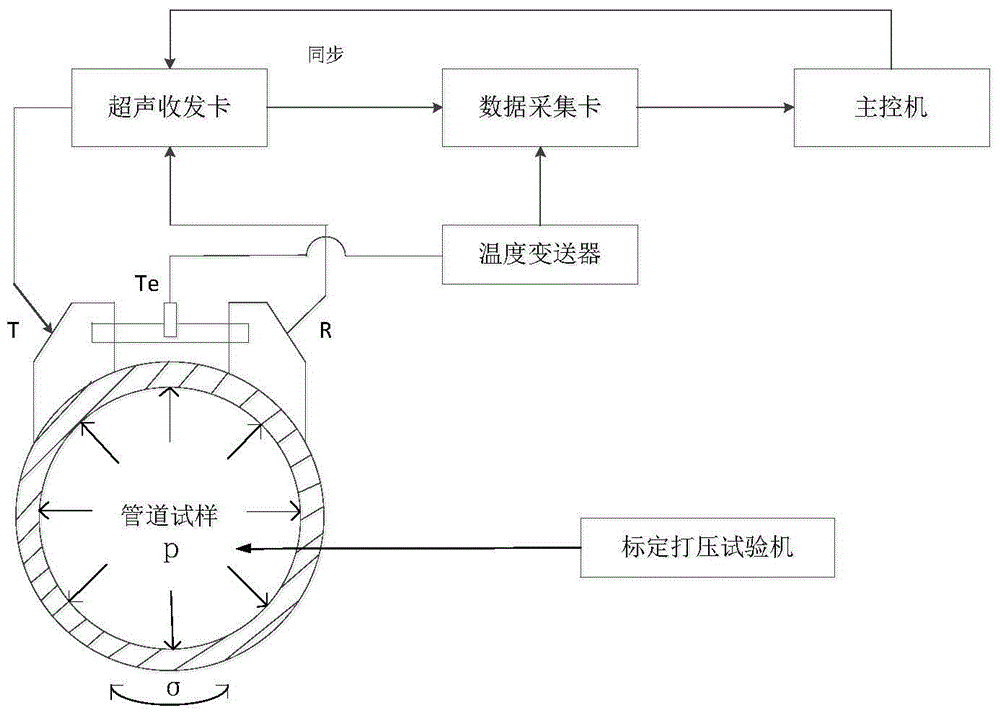

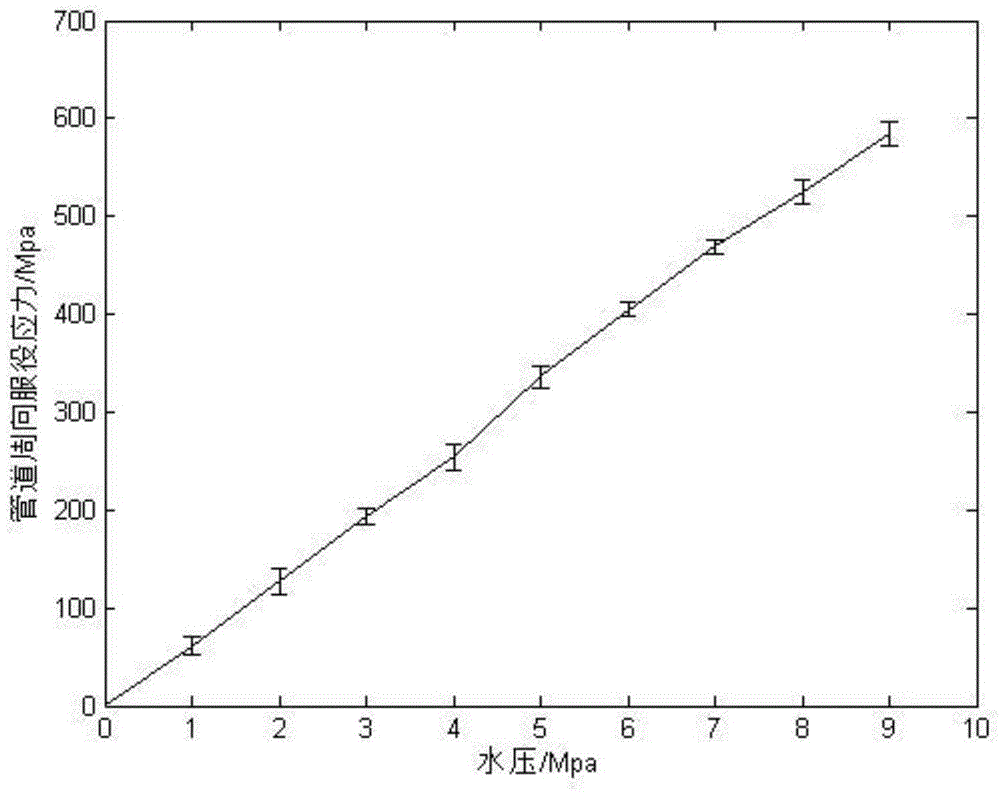

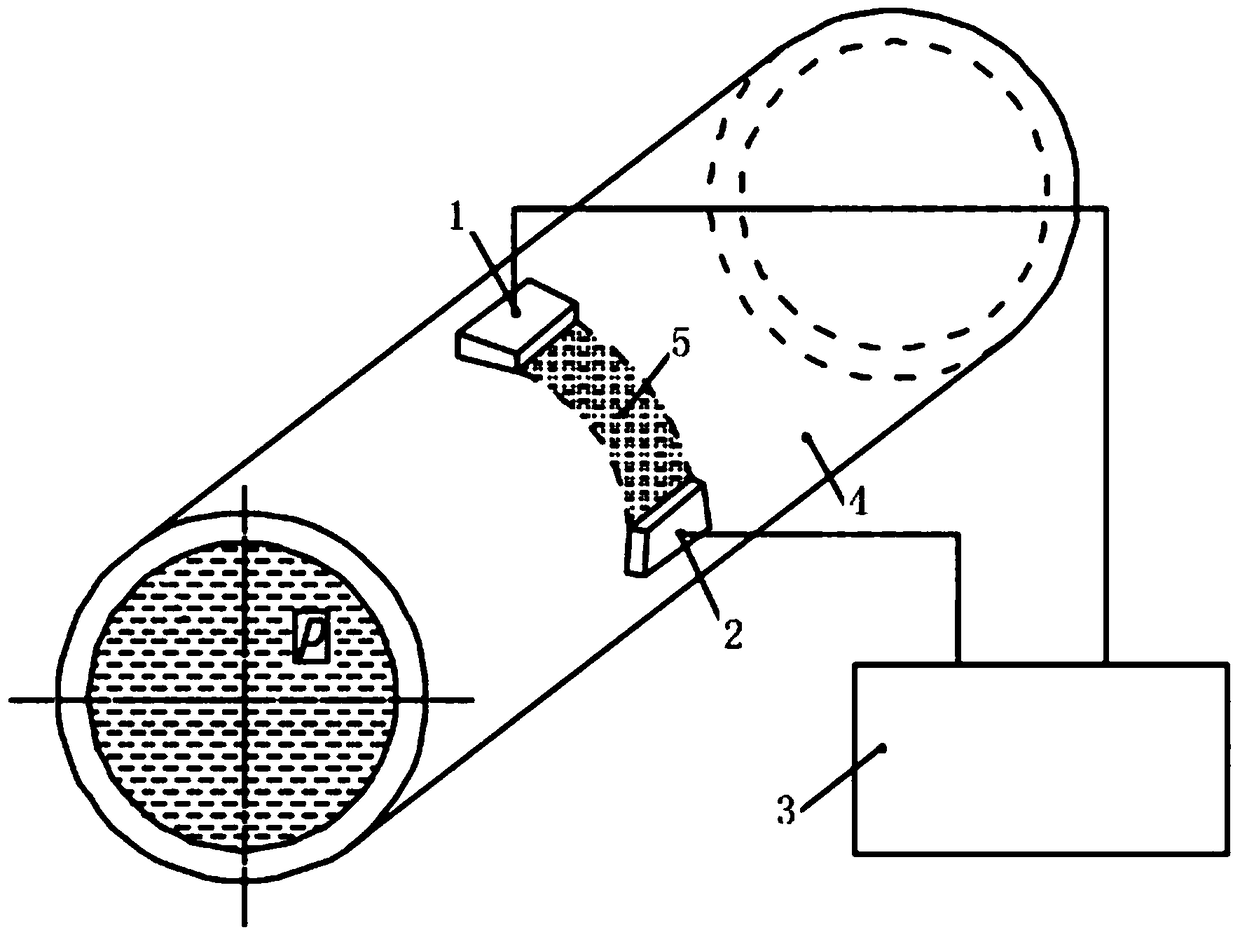

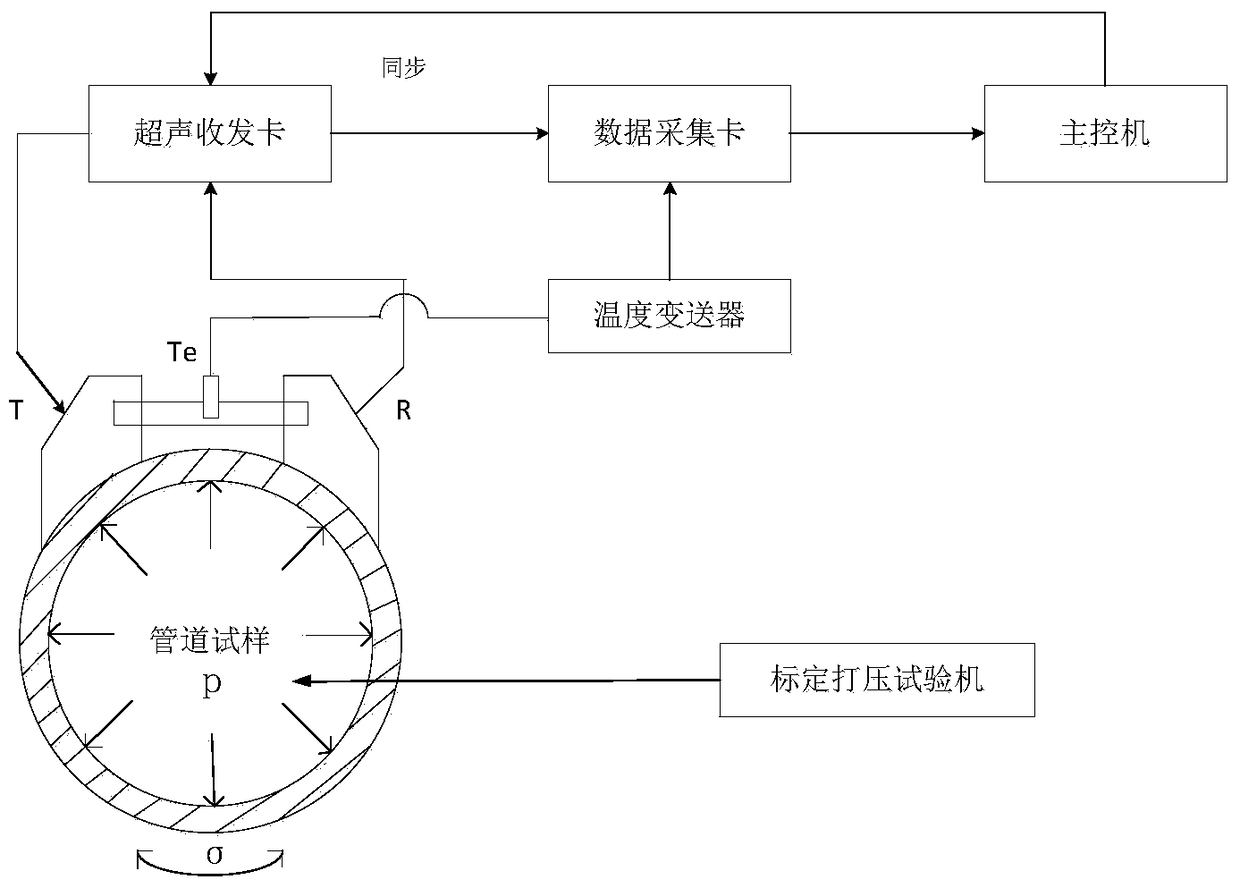

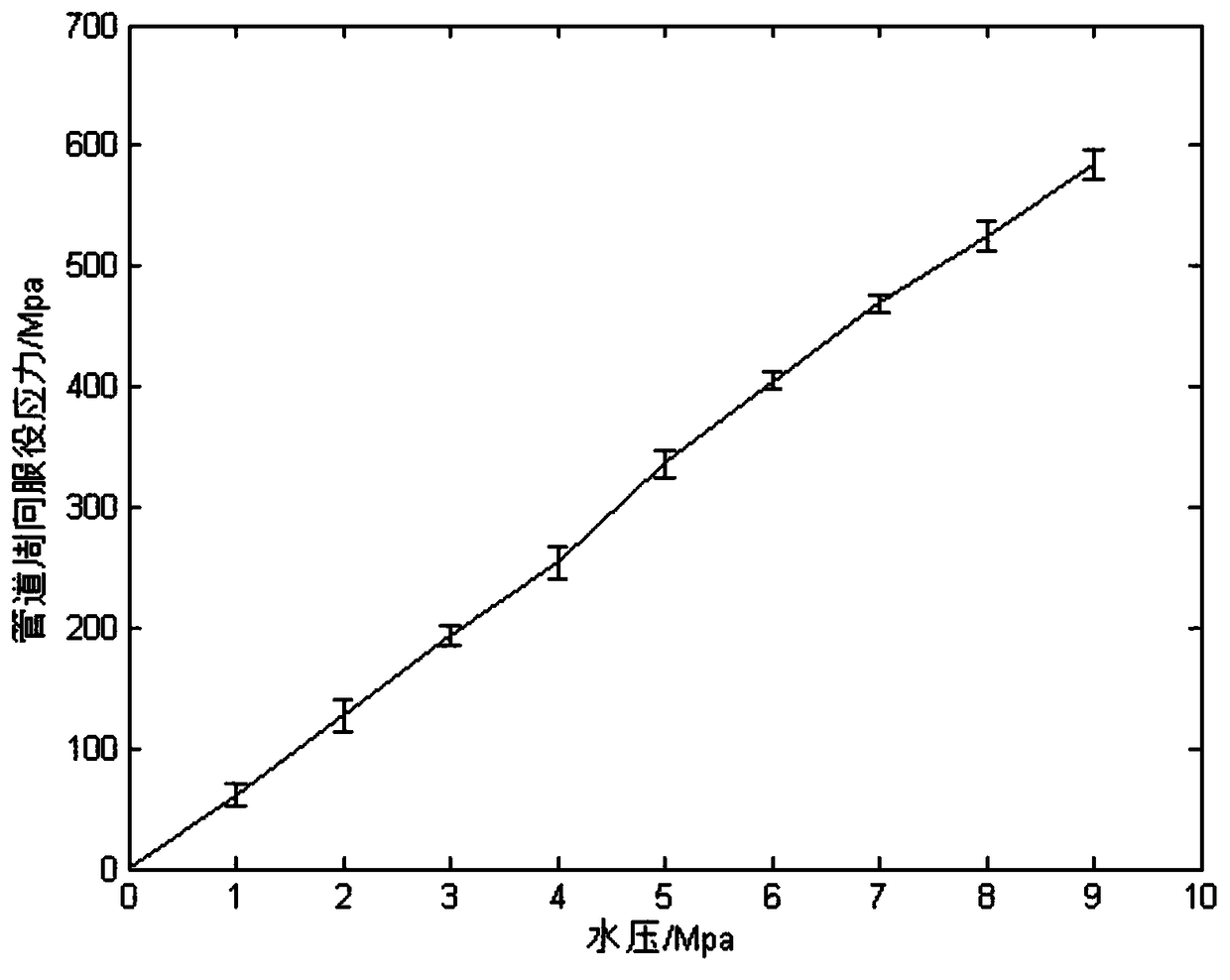

Measurement method for fluid pressure in non-intrusive pipeline

ActiveCN105738028AImprove reliabilityHigh measurement accuracyFluid pressure measurement by acoustic meansSurface stressRelational model

The invention discloses a measurement method for fluid pressure in a non-intrusive pipeline, and solves the problem of monitoring of fluid pressure in the internal part of the pipeline without damaging the structure of the pipeline. According to the method, a stress coefficient K and time of corresponding ultrasonic critical refraction longitudinal wave propagation are acquired based on a selected stretching test block and a zero stress test block; a data acquisition card acquires transit time data of an ultrasonic transmit-receive card to be transmitted to a master control computer, and the master control computer obtains time of ultrasonic critical refraction longitudinal wave propagation of a measured pipeline through calculation; service stress of the measurement position of the external surface of the pipeline is also obtained; a hydrostatic stress measurement experiment is performed by utilizing a pipeline test member so that the fluid pressure measurement coefficient in the non-intrusive pipeline and a quantitative relation model between stress of the external surface of the pipeline and fluid pressure in the pipeline are obtained; and finally the measured value of fluid pressure in the pipeline is obtained. The method is simple in the structure of the experiment device and high in measurement accuracy and reliability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

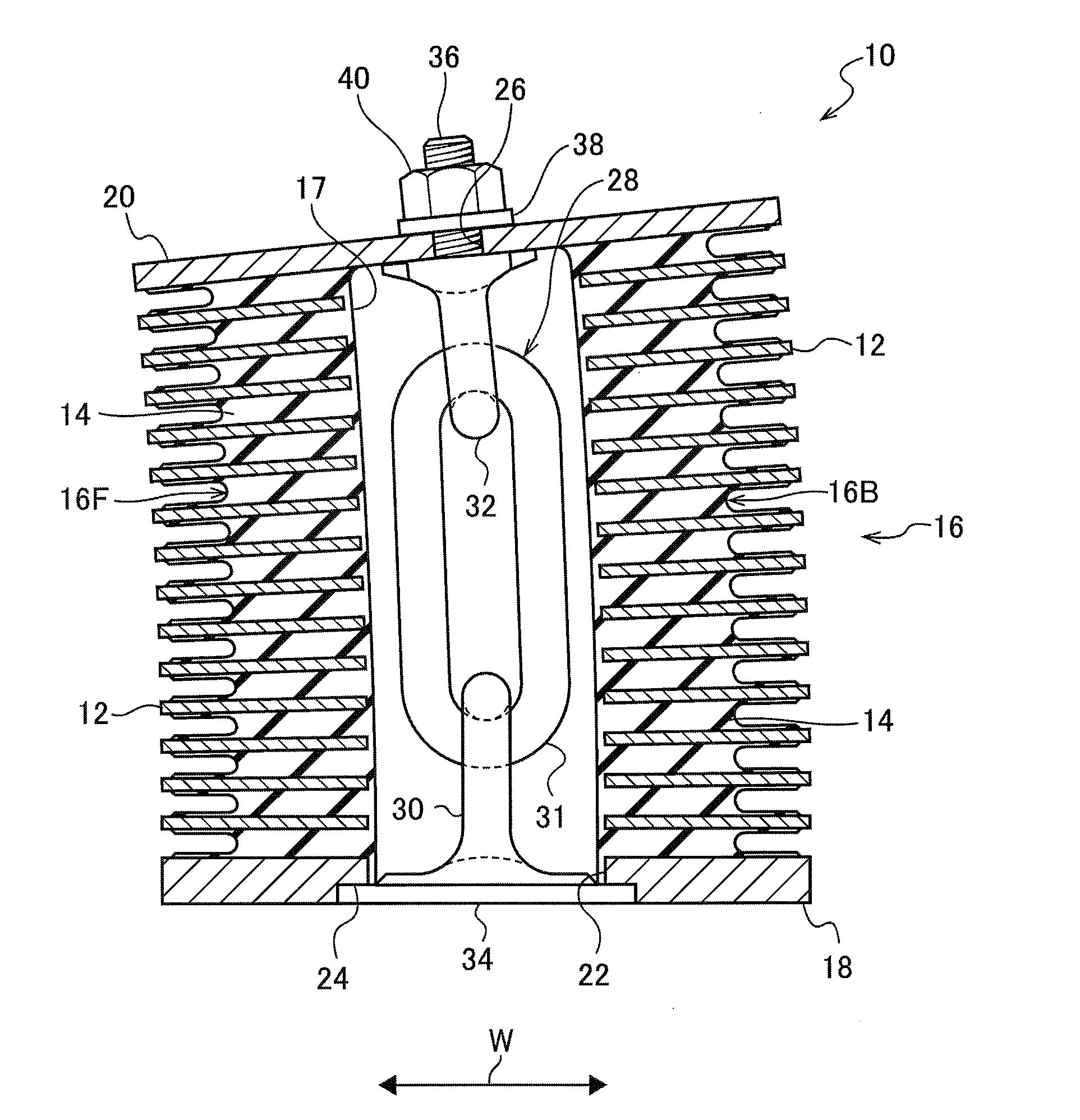

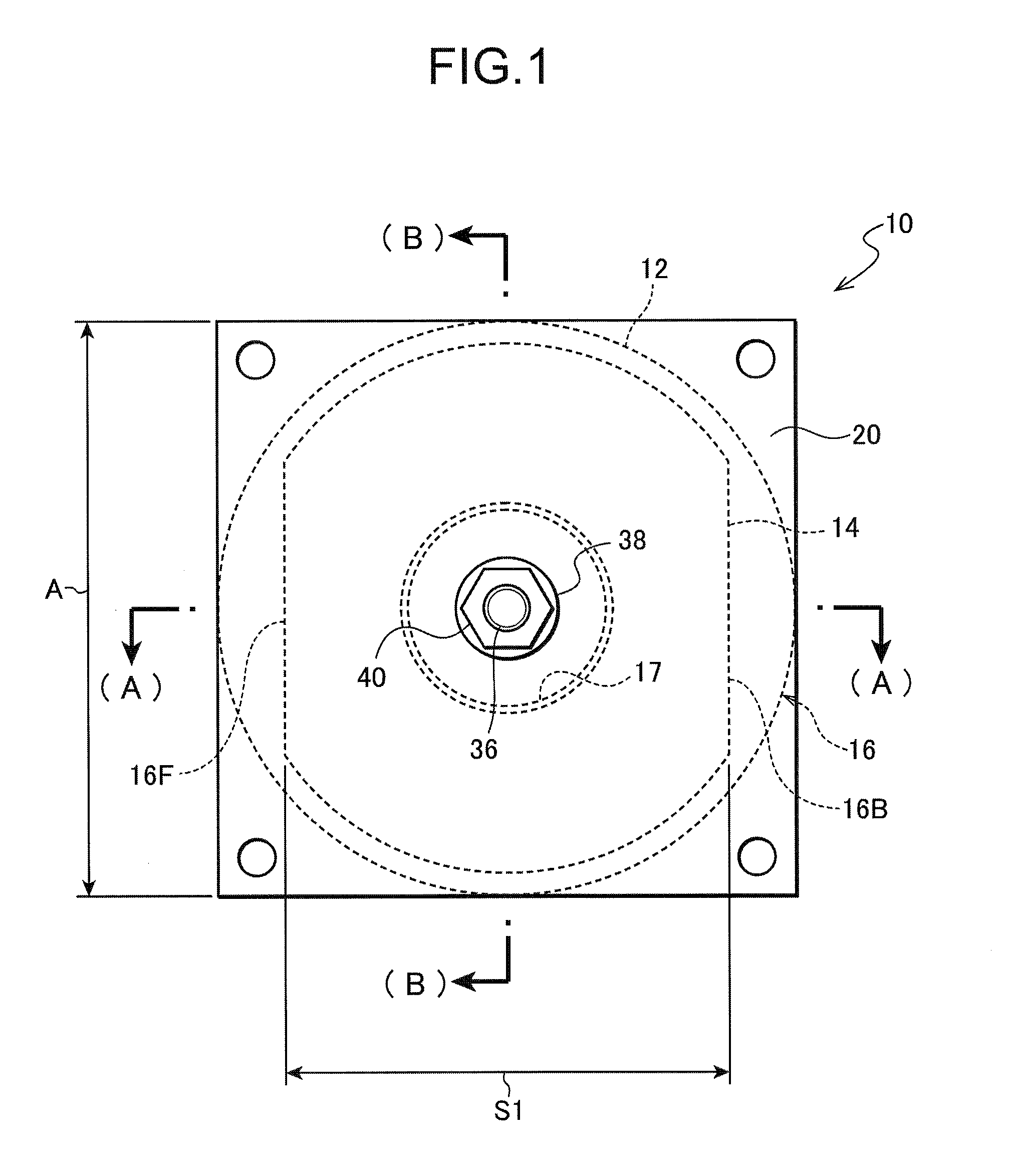

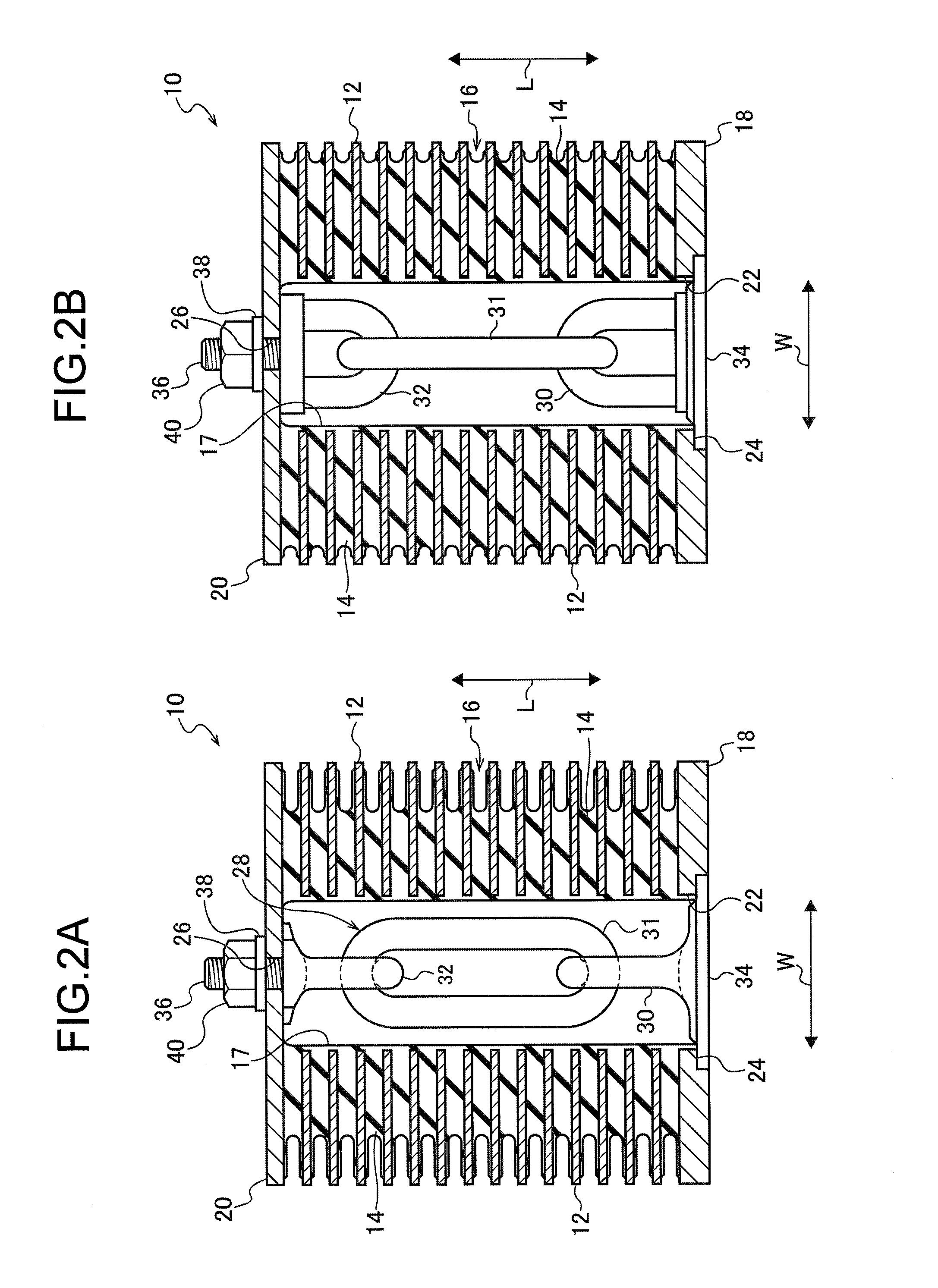

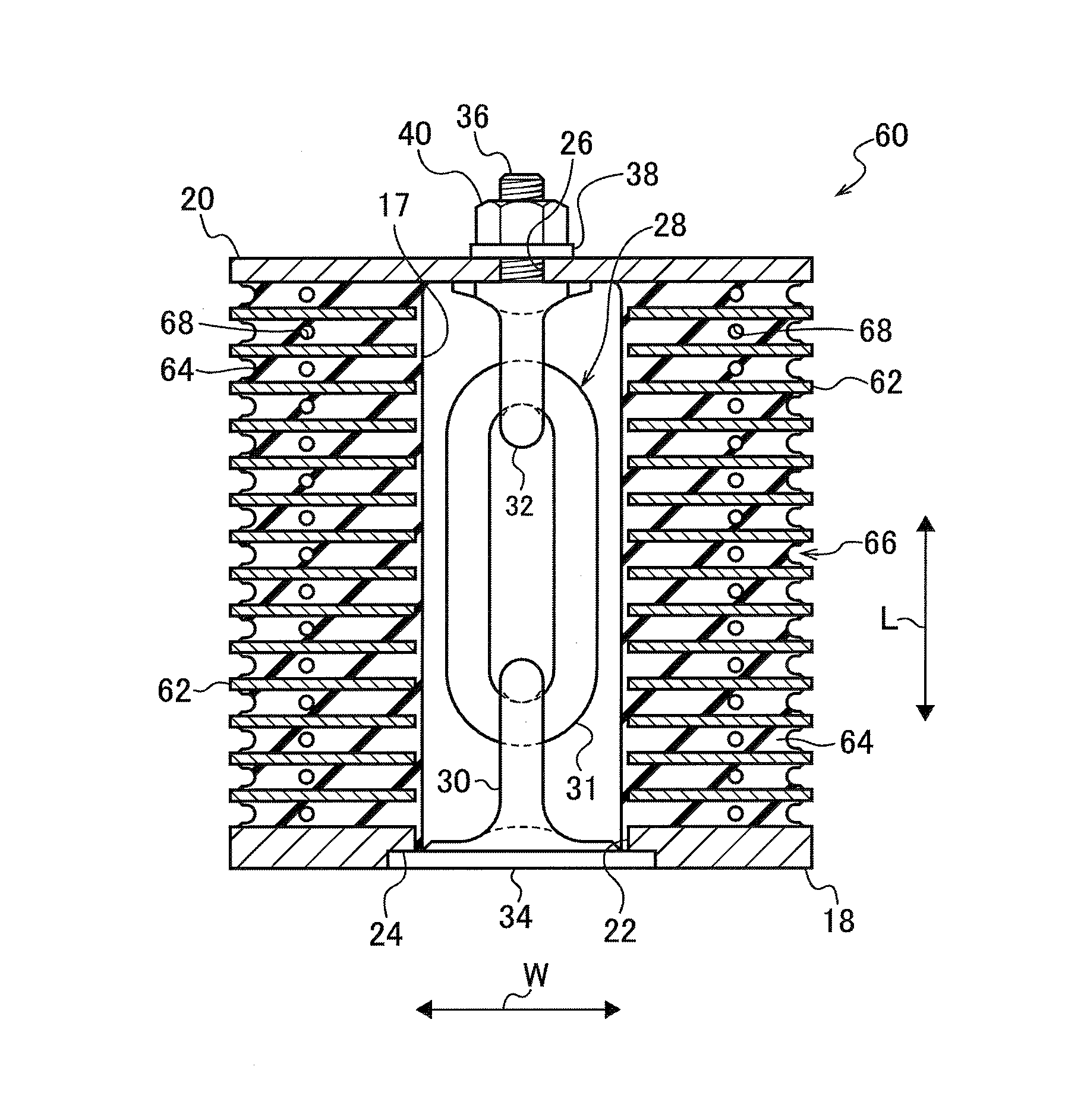

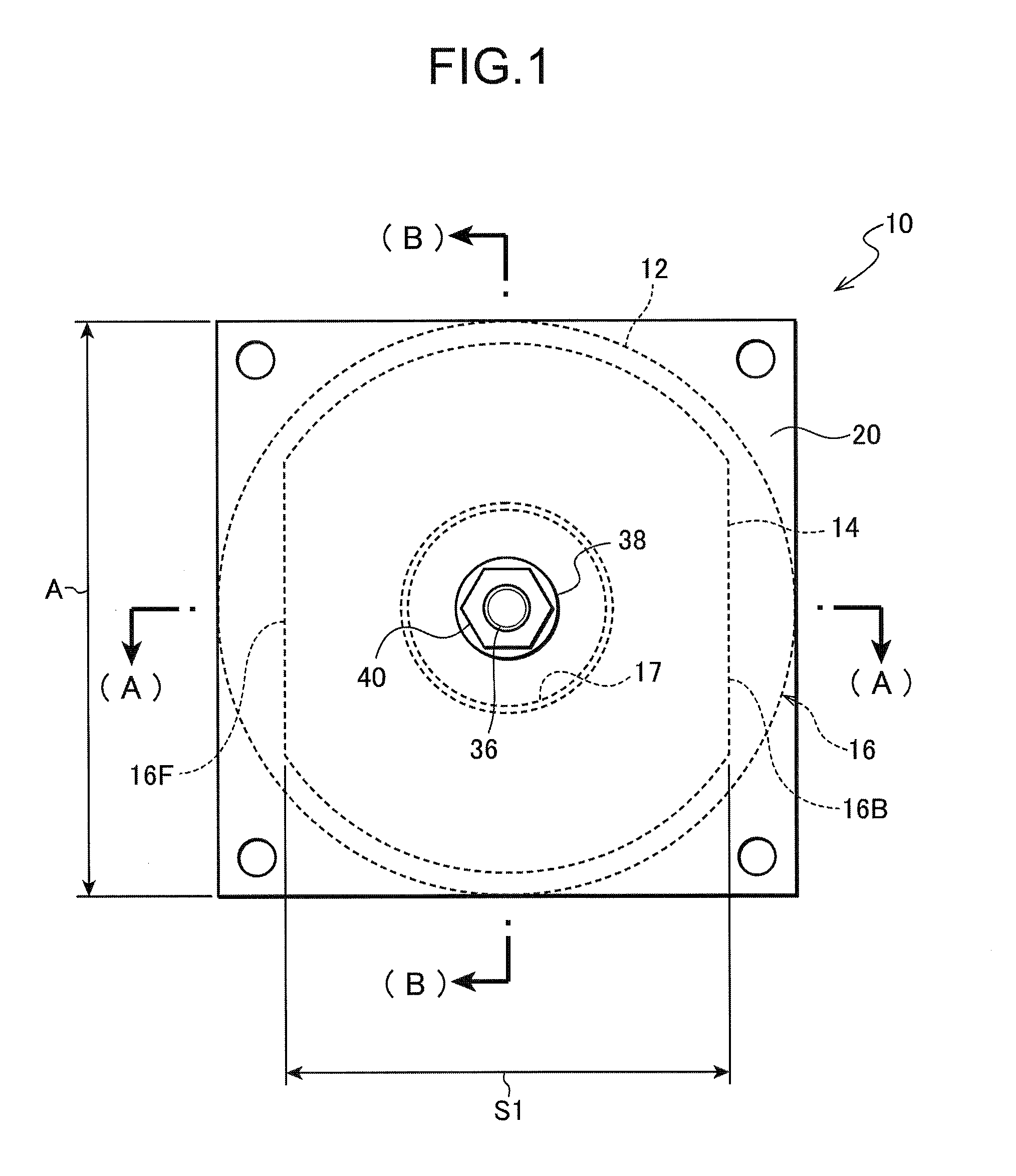

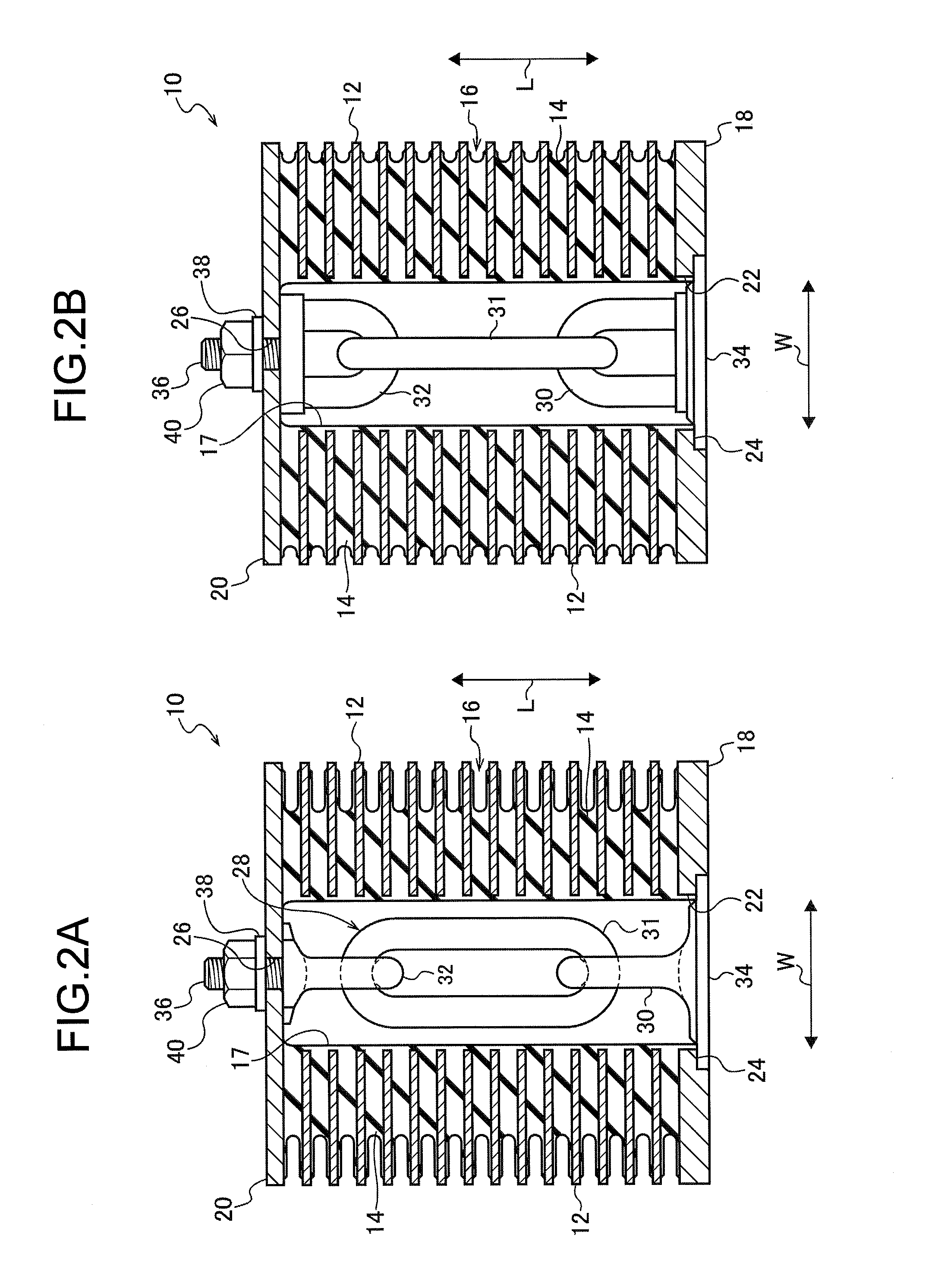

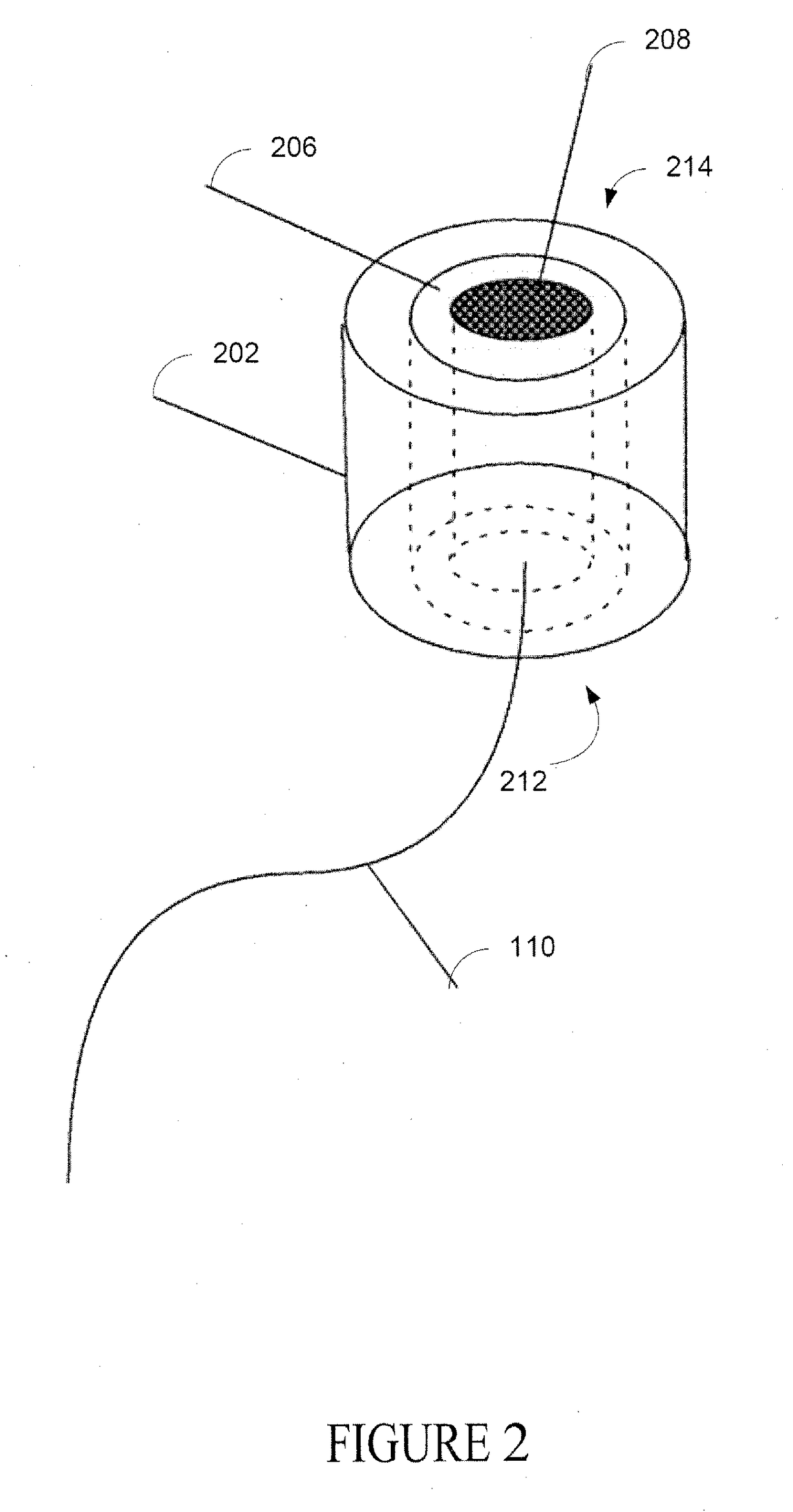

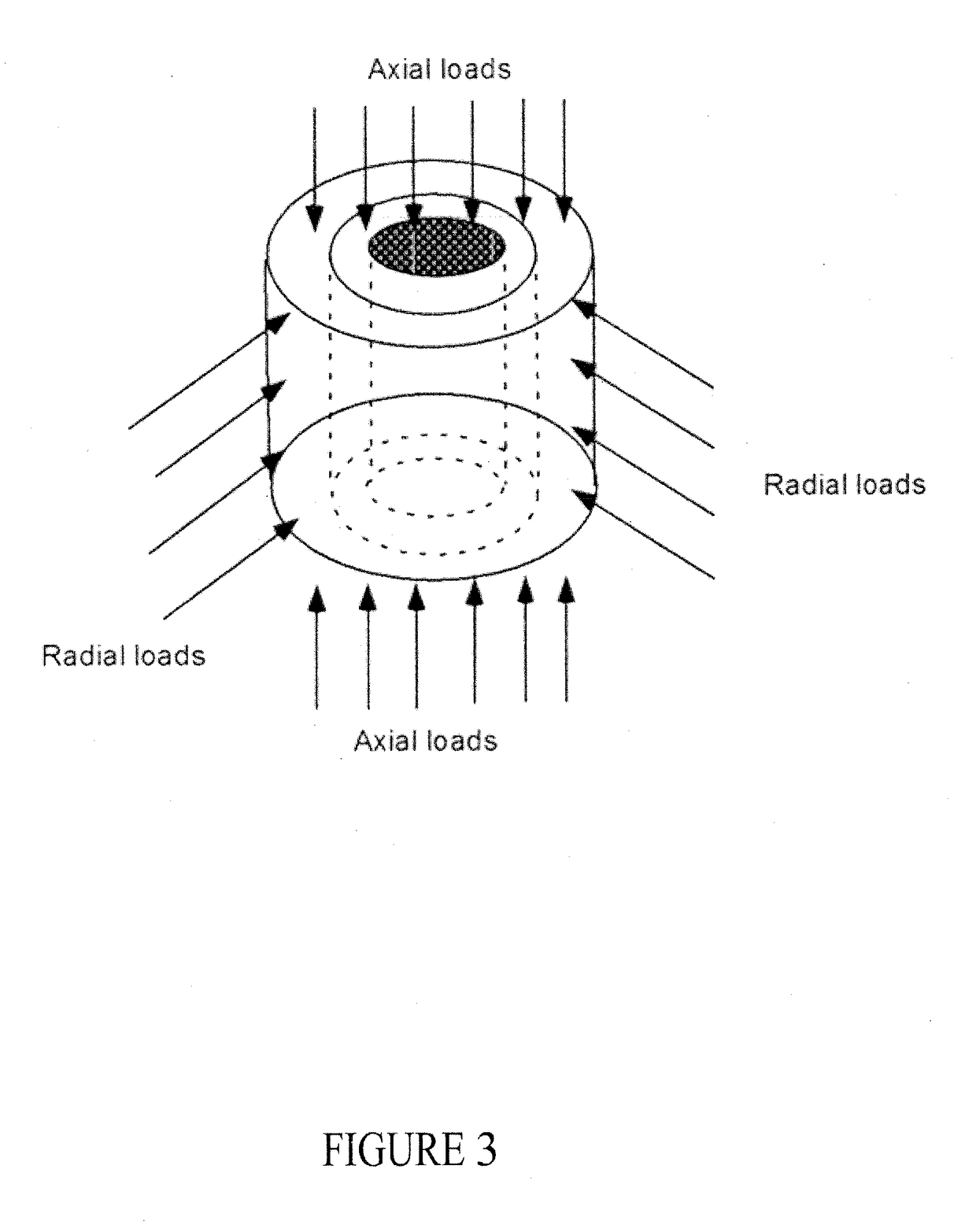

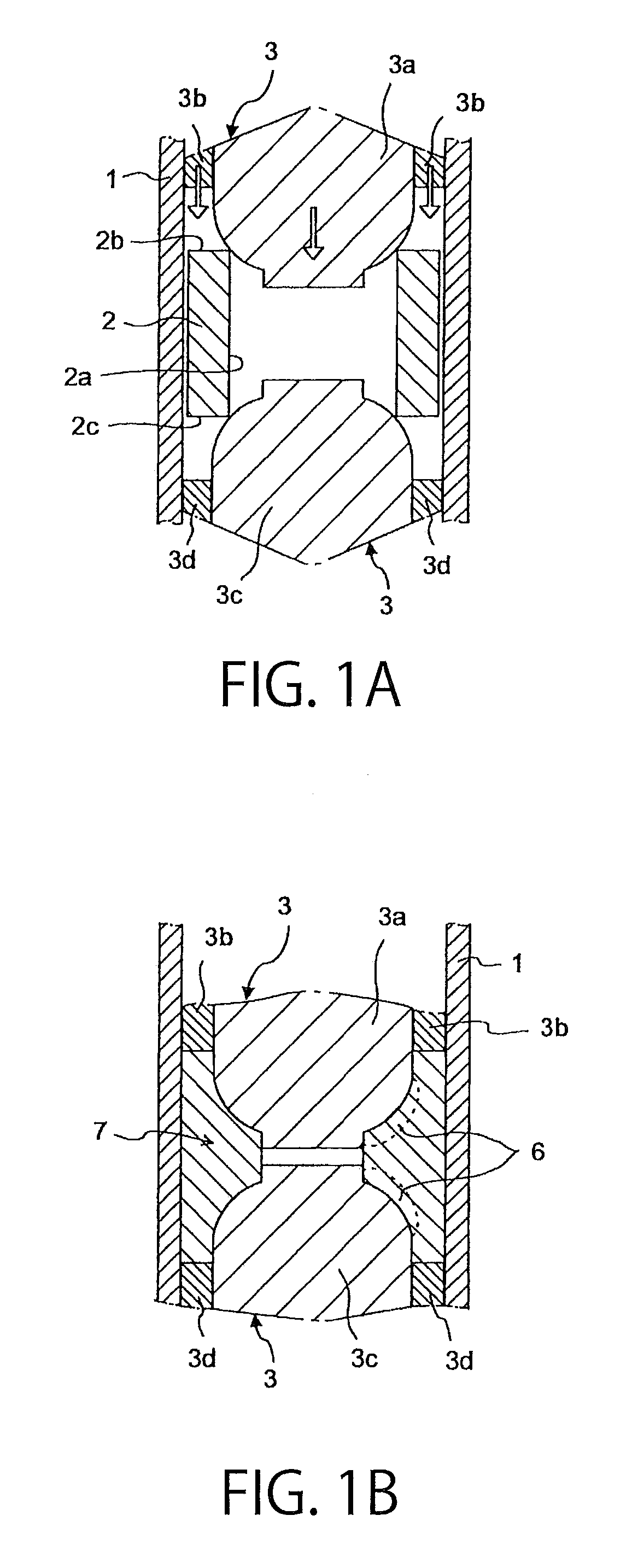

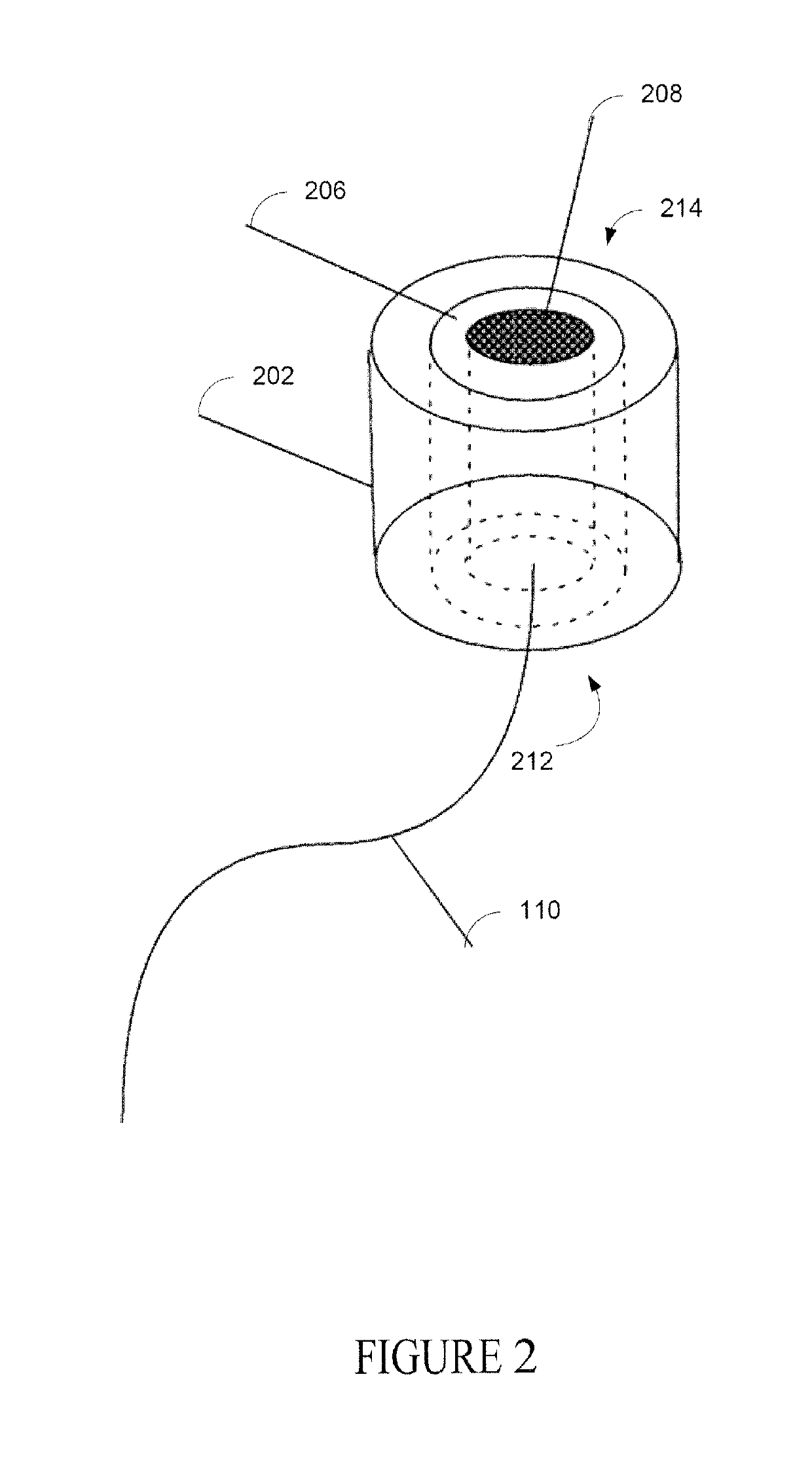

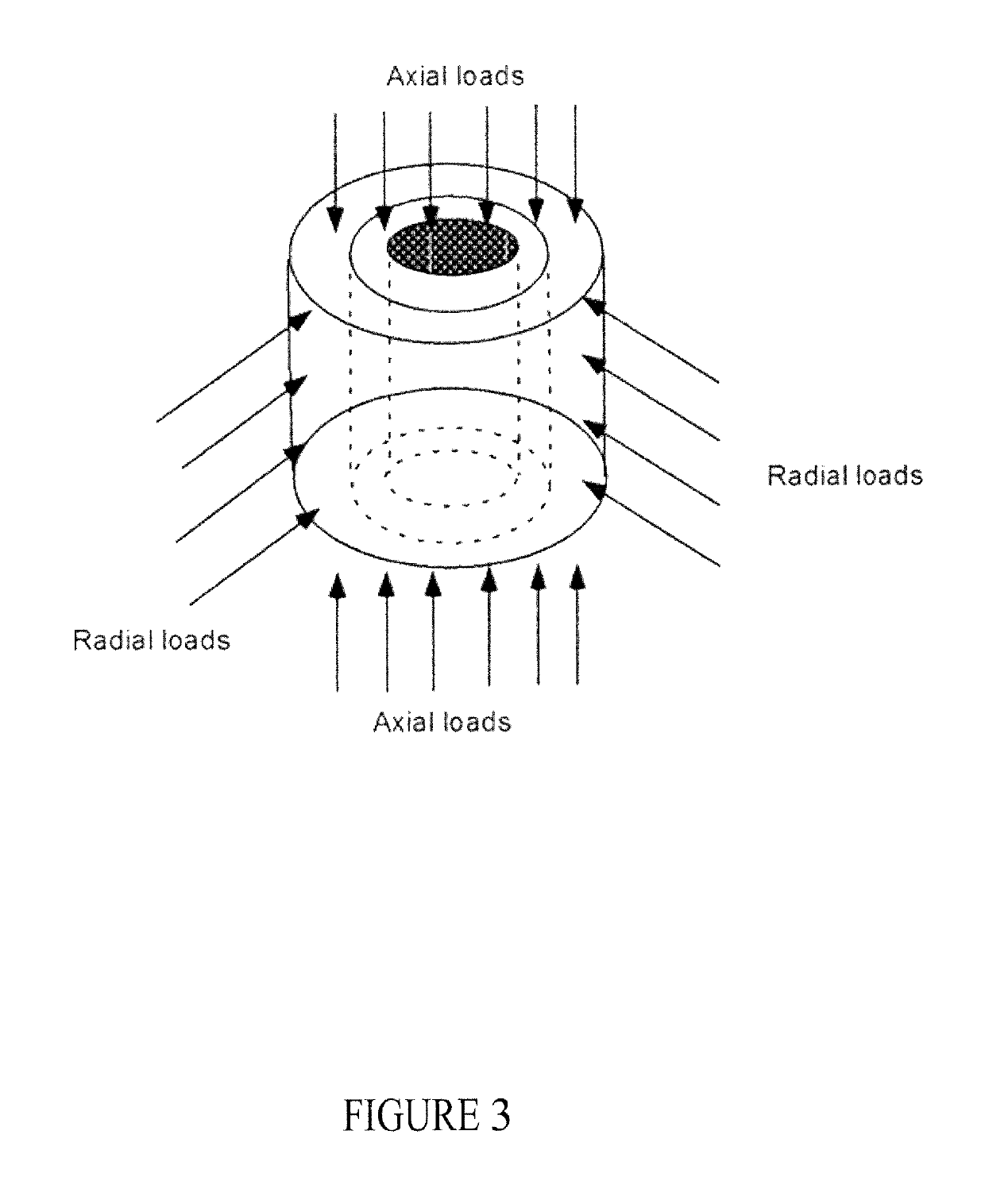

Vibration isolation structure

ActiveUS20120326366A1Damage to a composite laminated member can be effectively suppressedPortable framesNon-rotating vibration suppressionComposite laminatesEngineering

A vibration isolation structure is provided with a stress reduction section that can reduce the hydrostatic stress from tensional load along a stacking direction of portions of a composite laminated member corresponding to a first end side and a second end side in a shear direction orthogonal to the stacking direction to lower than the hydrostatic stress from tensional load along the stacking direction of other portions of the composite laminated member.

Owner:PROSPIRA CORP

Vibration isolation structure

ActiveUS8864115B2Damage to a composite laminated member can be effectively suppressedPortable framesSprings/dampers design characteristicsComposite laminatesEngineering

A vibration isolation structure is provided with a stress reduction section that can reduce the hydrostatic stress from tensional load along a stacking direction of portions of a composite laminated member corresponding to a first end side and a second end side in a shear direction orthogonal to the stacking direction to lower than the hydrostatic stress from tensional load along the stacking direction of other portions of the composite laminated member.

Owner:PROSPIRA CORP

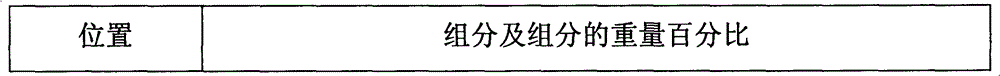

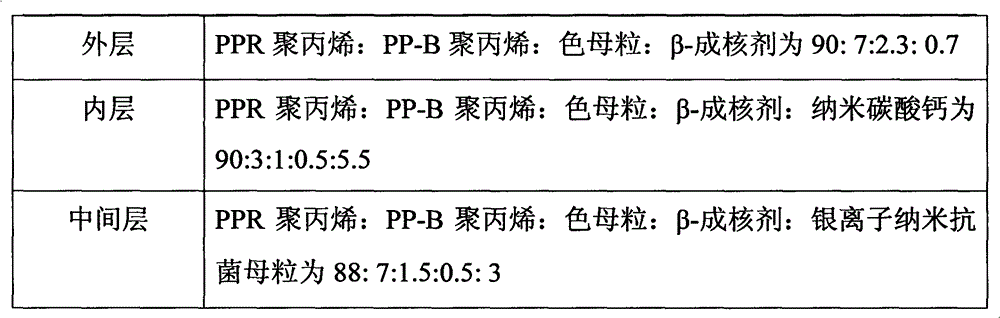

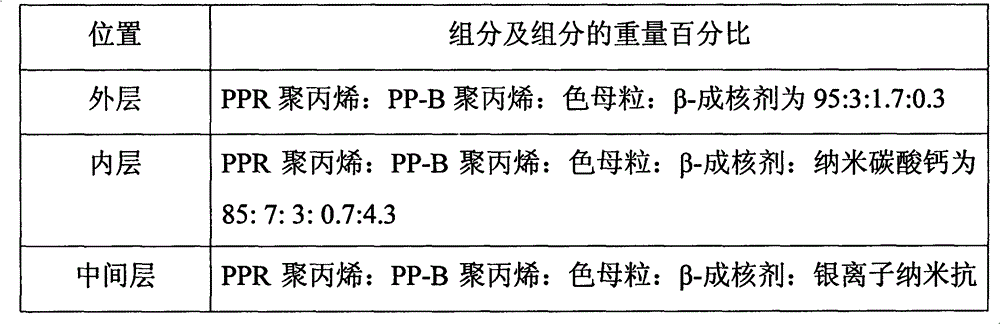

Pipe as well as preparation method and purpose of pipe

InactiveCN102720896AUnique high-strength crystal structureUnique Strength Crystal StructureSynthetic resin layered productsRigid pipesMasterbatchCrystal structure

The invention provides a pipe as well as a preparation method and a purpose of the pipe. The pipe consists of an outer layer, a middle layer and an inner layer and has the recipe that the outer layer comprises PPR (polypropylene randon coplymer) polypropylene, PP-B (polypropylene block copolymer pipe) polypropylene and beta-nucleating agents, the middle layer comprises PPR polypropylene, PP-B polypropylene, beta-nucleating agents and nanometer calcium carbonate, an inner layer comprises PPR polypropylene, PP-B polypropylene, silver ion nanometer antibacterial masterbatch and beta-nucleating agents. The preparation comprises the step that stirring is carried out, stirred materials are added into a mold with a three-layer structure and are extruded under the condition that the mold temperature is 195 to 205 DEG C, and the screw rod temperature is 175 to 210 DEG C, the post treatment is carried out, and the pipe is obtained. The pipe has the advantages that the unique high-intensity crystal structure is realized, the pressure bearing capability and the high temperature resistance capability of a pipeline system are optimized, the creep resistance capability of the pipeline is greatly improved, and the fifty-year long-period hydrostatic stress at 70 DEG C reaches 5.0MPa.

Owner:杭州恒标管业有限公司

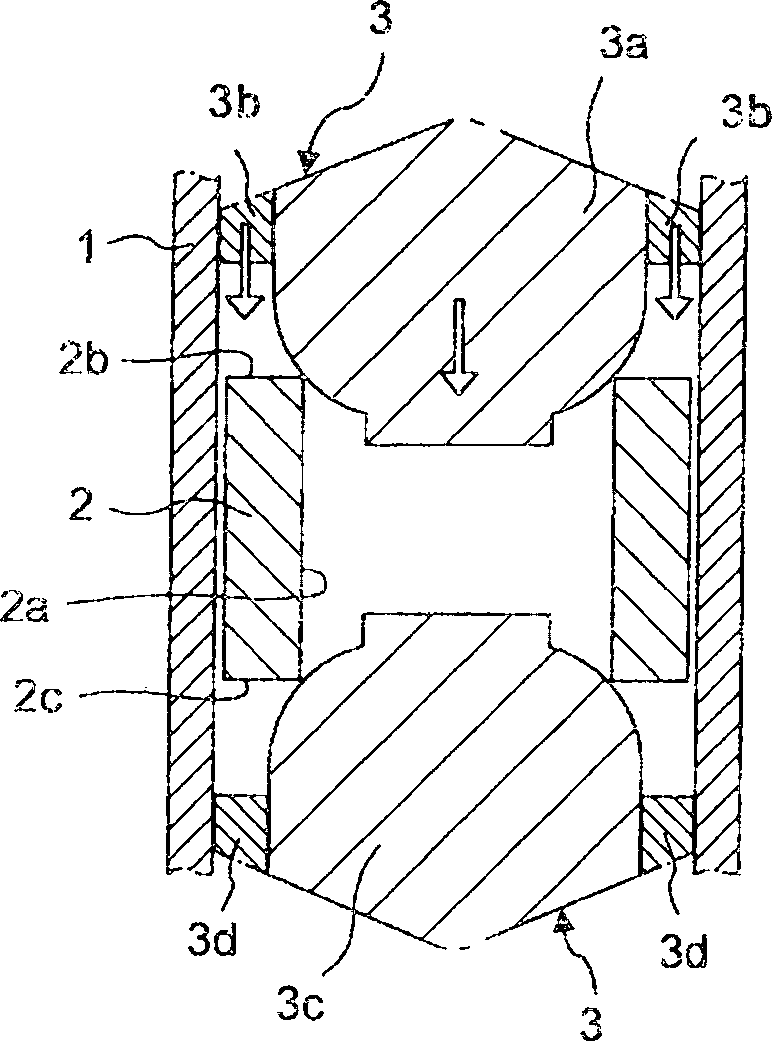

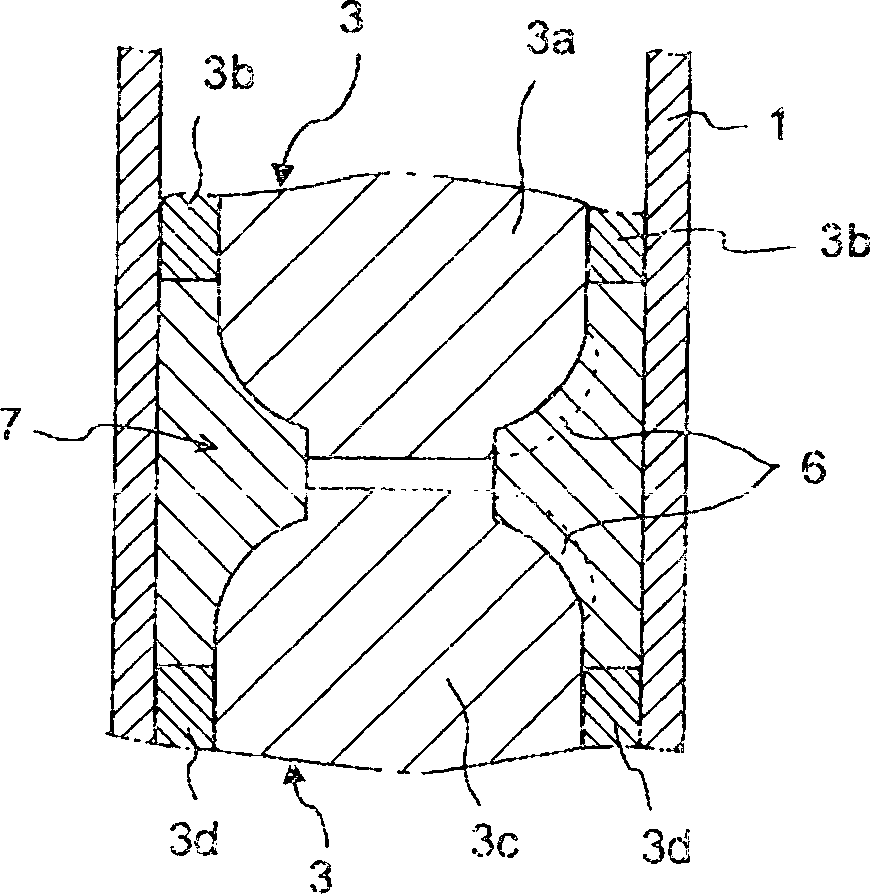

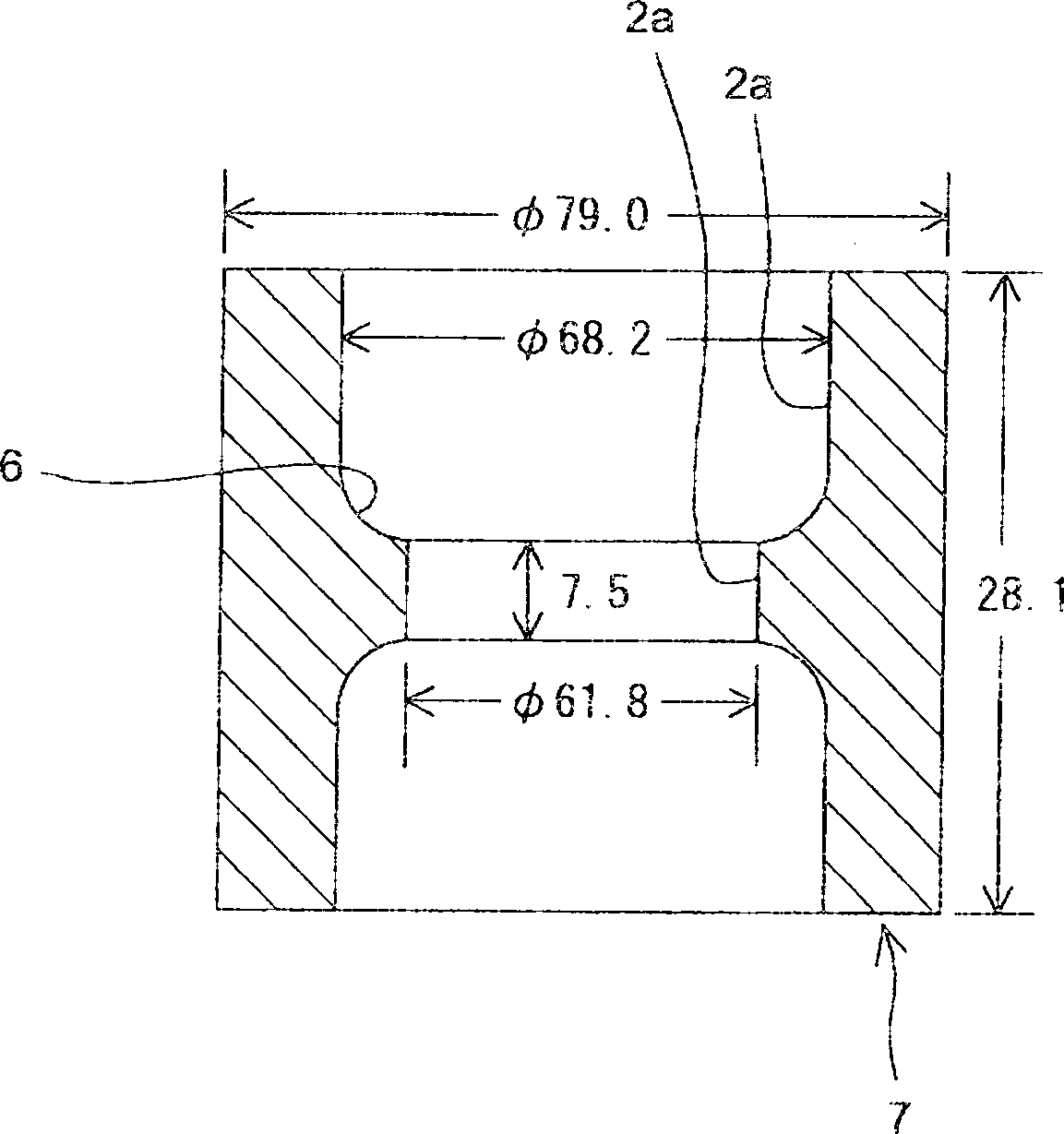

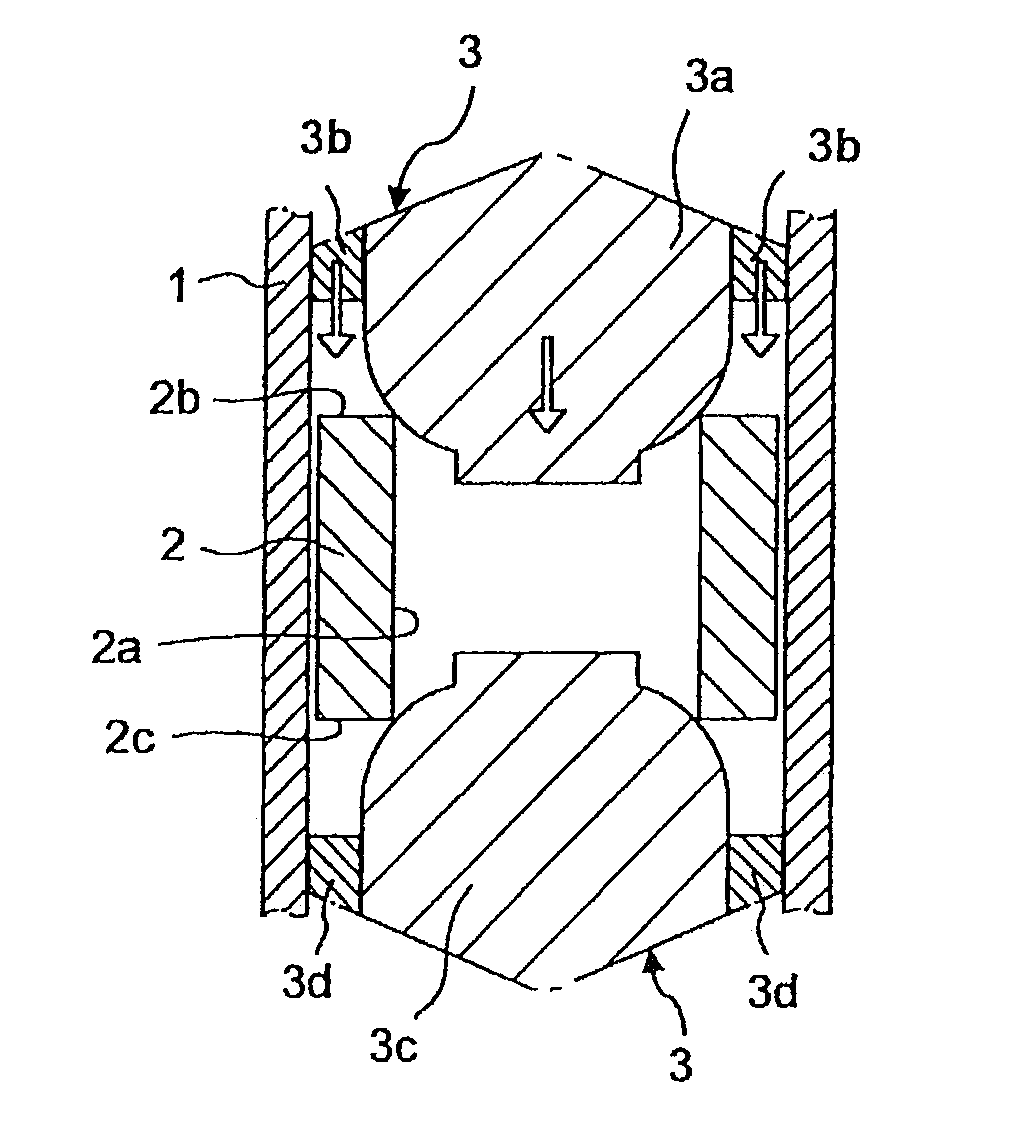

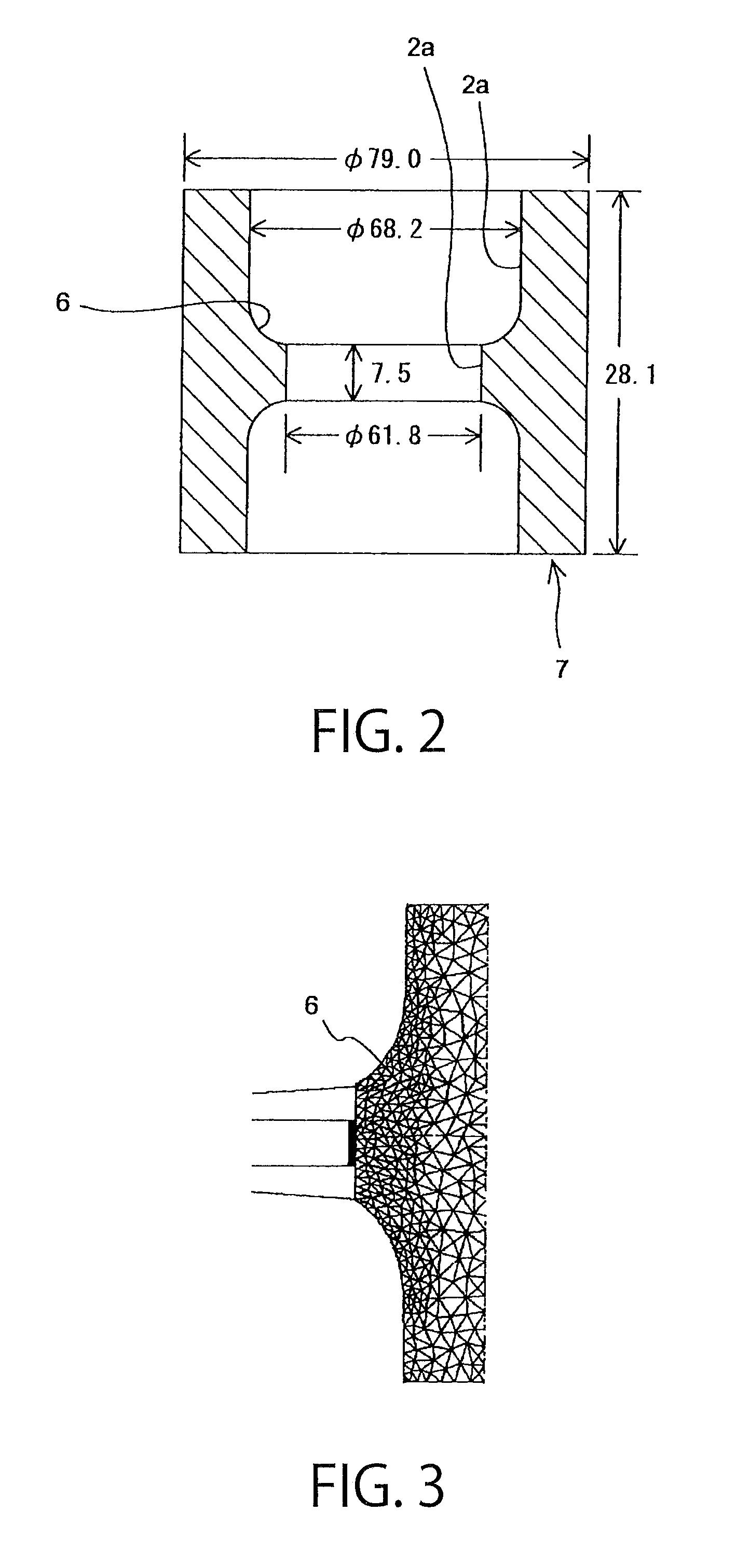

Method for manufacturing mechanical part excellent in rolling fatigue life

ActiveCN102574196AClose or reduce voidsAvoid strippingRolling contact bearingsShaftsNon-metallic inclusionsHydrostatic stress

Provided is a method for manufacturing a mechanical part (7) which has a rolling portion (6) on which a rolling element rolls and which is excellent in rolling fatigue life. An annular blank (2) to form the rolling portion (6) is subjected to cold forging by applying hydrostatic stress onto an inner diameter surface (2a) of the annular blank (2), whereby the rolling portion (6) on which the rolling element rolls is formed on the inner diameter surface (2a) of the annular blank (2) and the inner diameter of the portion of the annular blank (2) other than the rolling portion (6) is increased. Thus, an interface state between non-metallic inclusions contained in the steel material of which the annular blank (2) is made and the steel material, which is the matrix phase, is improved, and the annular mechanical part (7) having on the inner diameter portion the rolling portion (6) which is excellent in rolling fatigue life is manufactured.

Owner:SANYO SPECIAL STEEL COMPANY

Stress sensor for cement or fluid applications

A system and method measuring subterranean stress. The system and method includes a non-destructive sheath enveloping a tubular structure positioned in direct contact with a lateral subterranean rock formation for sensing expansive changes in the subterranean rock formation. A fiber optic is directly embedded in the non-destructive sheath positioned adjacent to the exterior surface of the tubular structure. The fiber optic transmits light and thereafter receives light in proportion to the expansive changes in the subterranean rock formation. A spectrometer connected to the fiber optic remote from the non-destructive sheath. The spectrometer measures hydrostatic stress in the subterranean rock formation without estimating acoustoelastic effects or occluding the tubular structure.

Owner:UT BATTELLE LLC

Method for Manufacturing Mechanical Part Excellent in Rolling Fatigue Life

InactiveUS20120210765A1Good conditionImprove fatigue lifeRolling contact bearingsShaftsMechanical componentsHydrostatic stress

Disclosed is a method for producing a mechanical part superior in rolling fatigue life. The mechanical part includes a rolling portion for a rolling element to roll along an inner diameter surface of an annular workpiece material subjected to cold forging. The method includes performing cold forging by applying a hydrostatic stress to the inner diameter surface of the annular workpiece material on which the rolling portion is to be formed, thereby forming the rolling portion on the inner diameter surface of the annular workpiece material for the rolling element to roll therealong and increasing an inner diameter of the annular workpiece material other than the rolling portion, so as to provide an annular mechanical part including the rolling portion superior in rolling fatigue life.

Owner:SANYO SPECIAL STEEL COMPANY

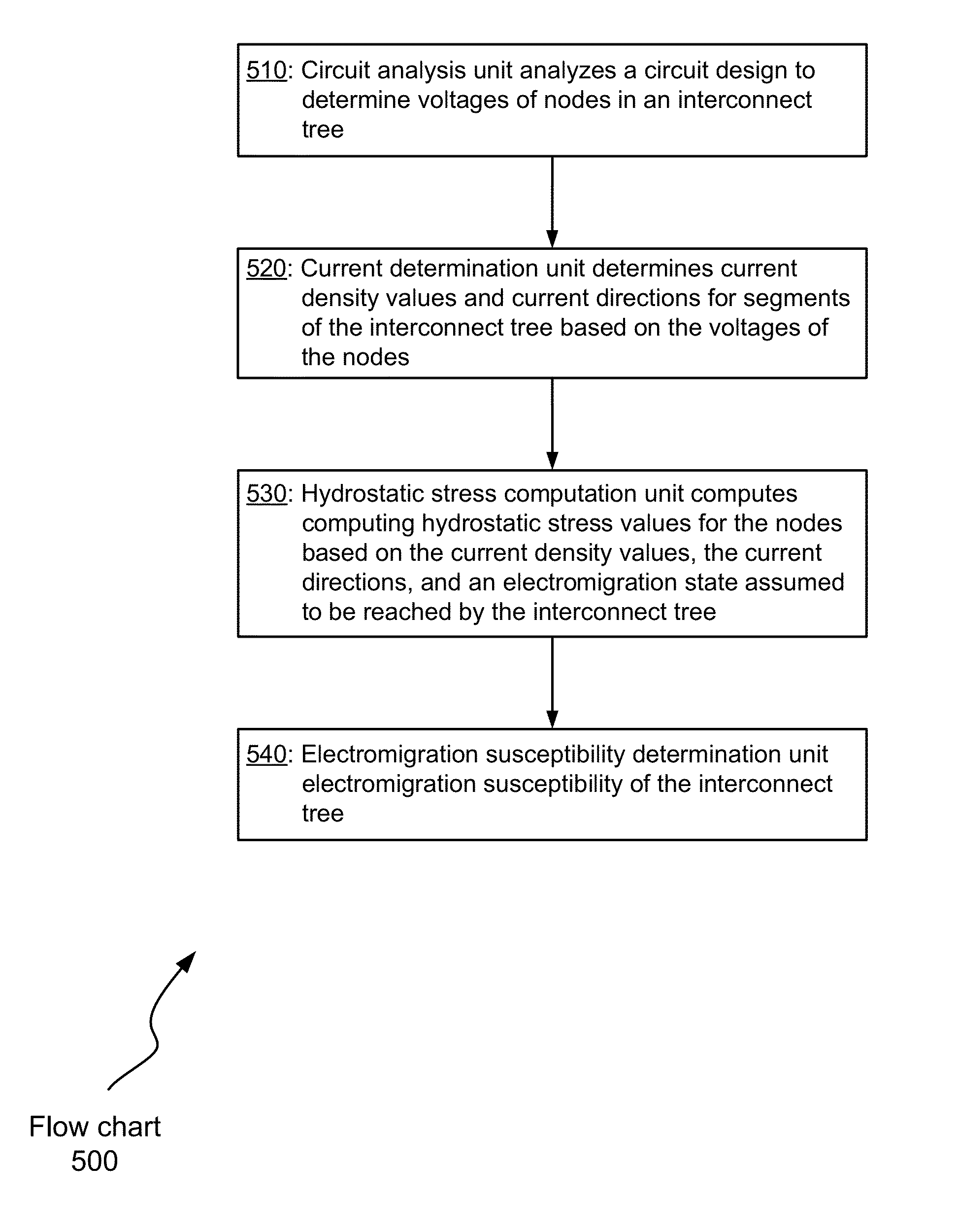

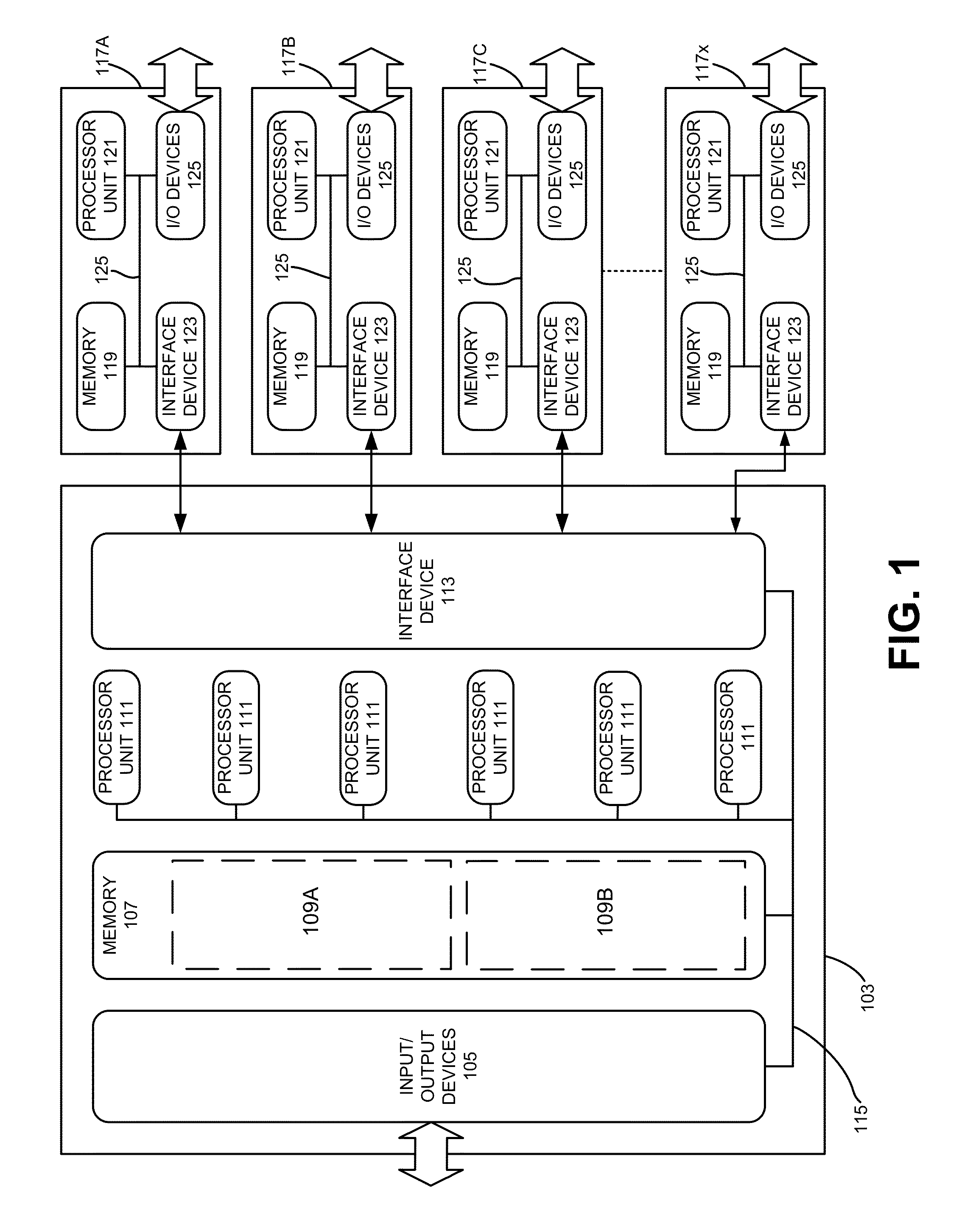

Determination of electromigration susceptibility based on hydrostatic stress analysis

Aspects of the invention relate to techniques for determining the electromigration features corresponding to layout design data. According to various examples of the invention, a circuit design is analyzed to determine voltages of nodes in an interconnect tree. From the voltages of the nodes, current density values and current directions for the segments of the interconnect tree are determined. Based on the current density values and the current directions, hydrostatic stress values for the nodes are computed under a steady-state condition and conservation of the conductive material within the interconnect tree. The electromigration susceptibility of the interconnect tree is then determined based on the computed hydrostatic stress values.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

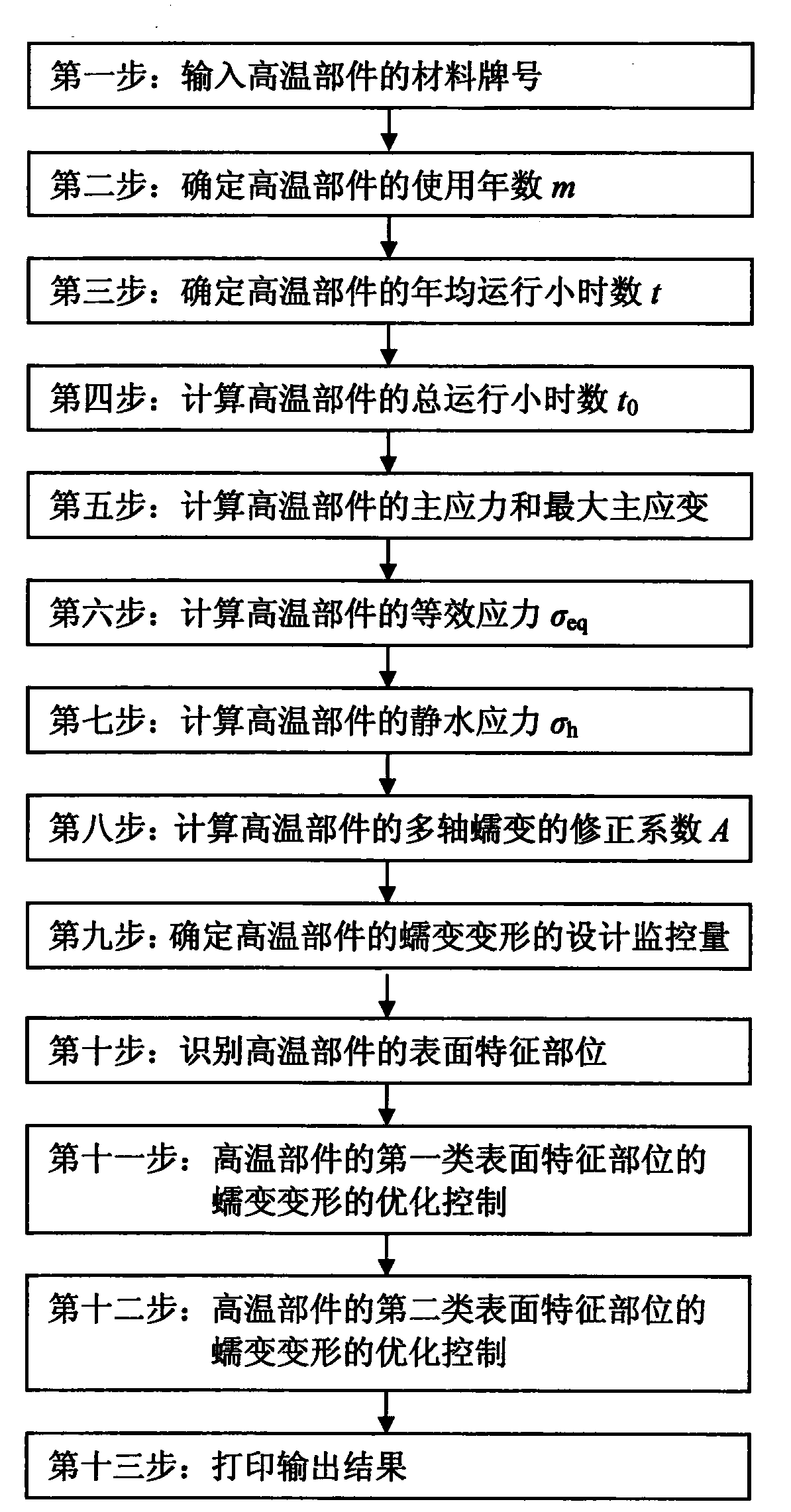

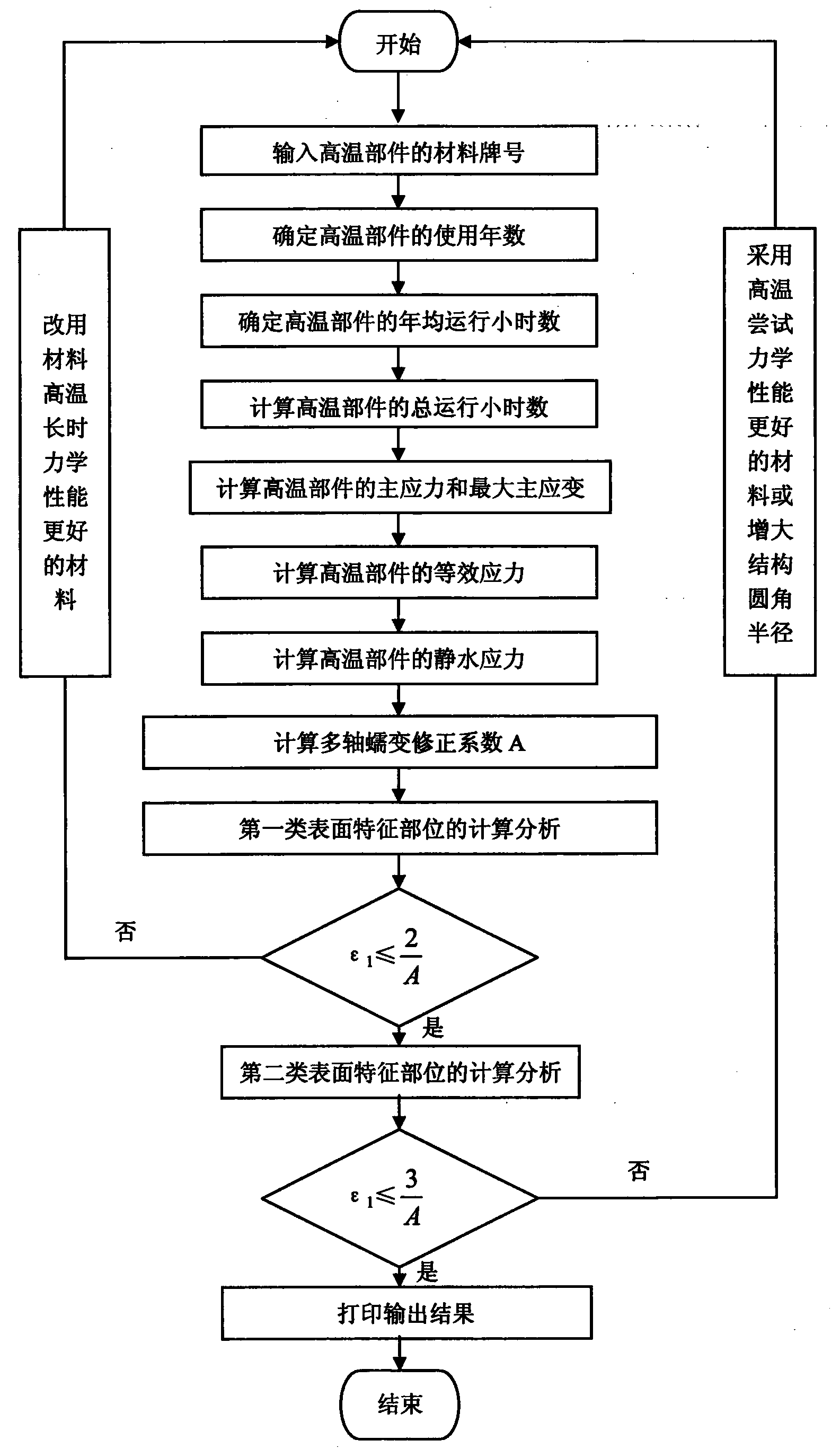

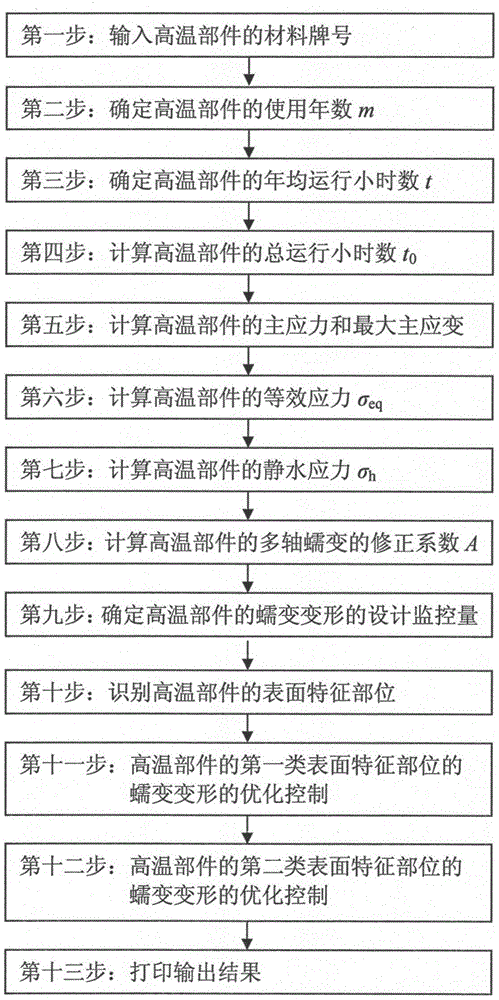

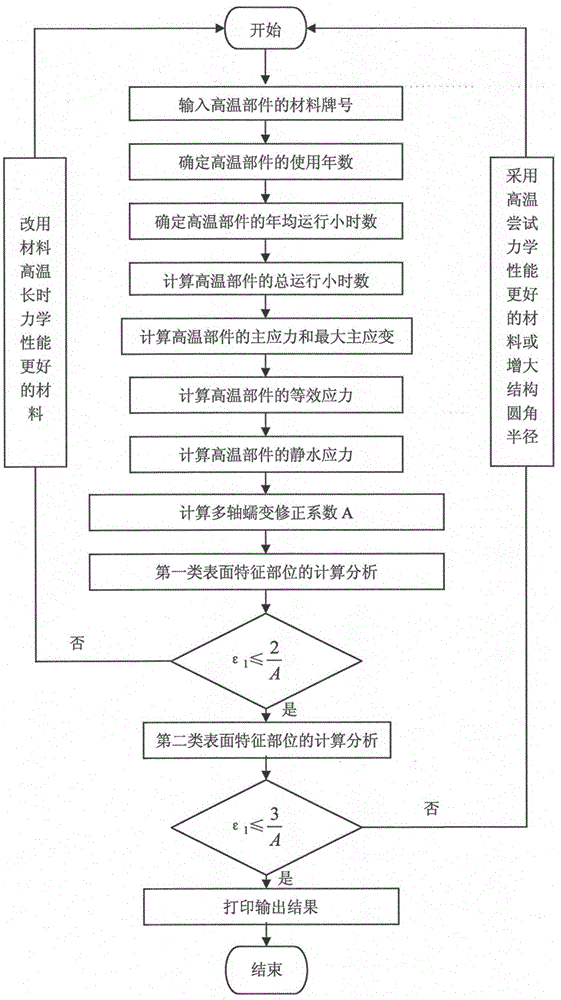

Monitoring method for creep deformation design of high-temperature part of thermal power generating unit

ActiveCN104239682ARealize Quantitative PredictionImprove mechanical propertiesSpecial data processing applicationsPrincipal stressEngineering

The invention provides a monitoring method for creep deformation design of a high-temperature part of a thermal power generating unit. The monitoring method specifically comprises the following steps: inputting a material mark of the high-temperature part; determining service years m of the high-temperature part; determining annual average running hours t of the high-temperature part; calculating total running hours t0 of the high-temperature part; calculating principal stress and maximum principal strain of the high-temperature part; calculating equivalent stress sigma<eq> of the high-temperature part; calculating hydrostatic stress sigma<h> of the high-temperature part; calculating a correction factor A of multi-axial creep of the high-temperature part; determining design monitoring amounts of creep deformation of the high-temperature part; recognizing surface characteristic parts of the high-temperature part; conducting optimization control of creep deformation of a first class of surface characteristic parts; conducting optimization control of creep deformation of a second class of surface characteristic parts; printing output results. The monitoring method for the creep deformation design of the high-temperature part of the thermal power generating unit realizes quantitative prediction and design monitoring of the creep deformation of the high-temperature part of the thermal power generating unit.

Owner:SHANGHAI POWER EQUIP RES INST

A Numerical Prediction Method of Sheet Metal Forming Fracture Based on Damage Fracture Criterion

ActiveCN104636539BReduce mistakesAccurate timeSpecial data processing applicationsContinuum damage mechanicsMetal sheet

Owner:HUAZHONG UNIV OF SCI & TECH

Hydraulic fracturing system

ActiveUS9458710B2Increase injection rateFluid removalDrilling compositionHydraulic fracturingHydrostatic stress

A method is given for fracturing a formation, in particular far-field in a tight formation, in which at least a portion of the proppant is crushable in situ at some point during pumping, during fracture closure, or at higher stresses experienced later during fracture closure. The closure stress or hydrostatic stress is estimated, then a proppant is selected that is at least partially crushable at that closure stress, and then the fracturing treatment is performed with at least a portion of the total proppant being the selected crushable proppant.

Owner:SCHLUMBERGER TECH CORP

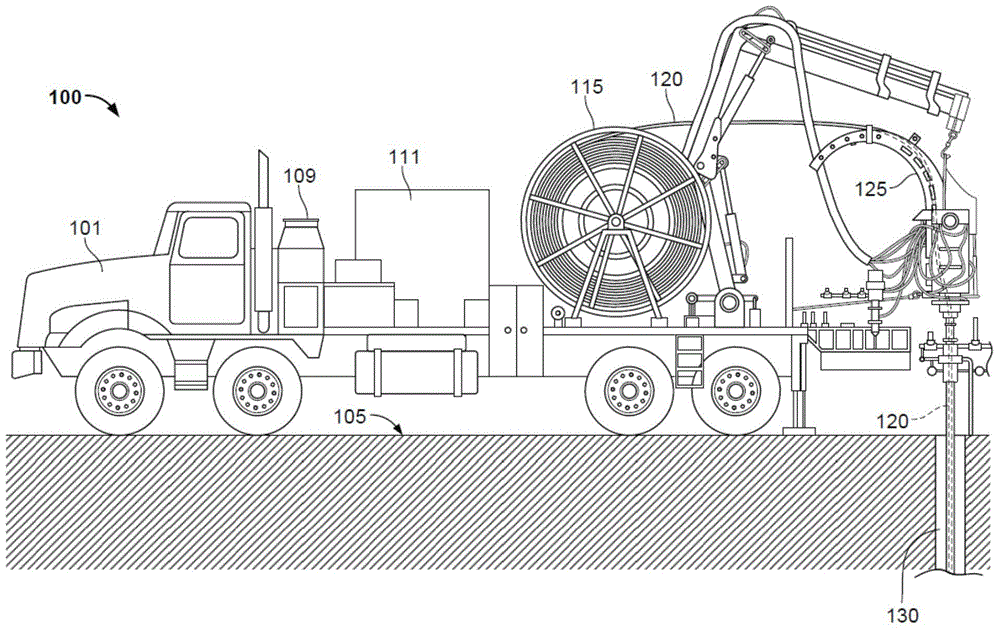

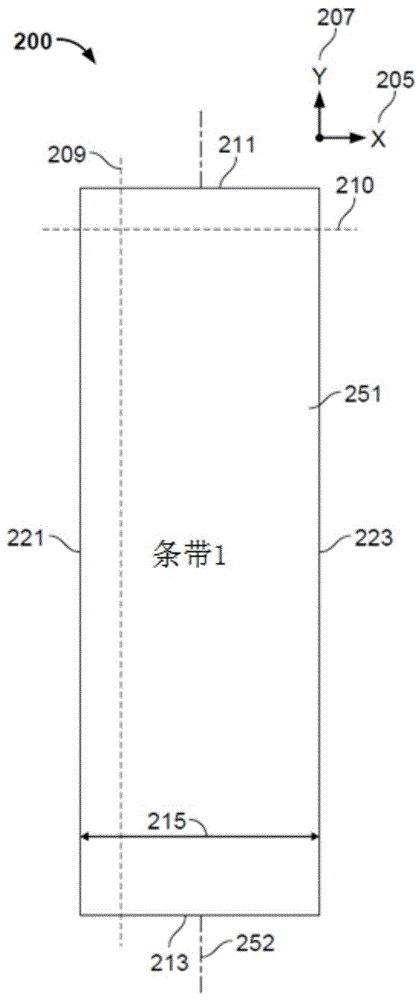

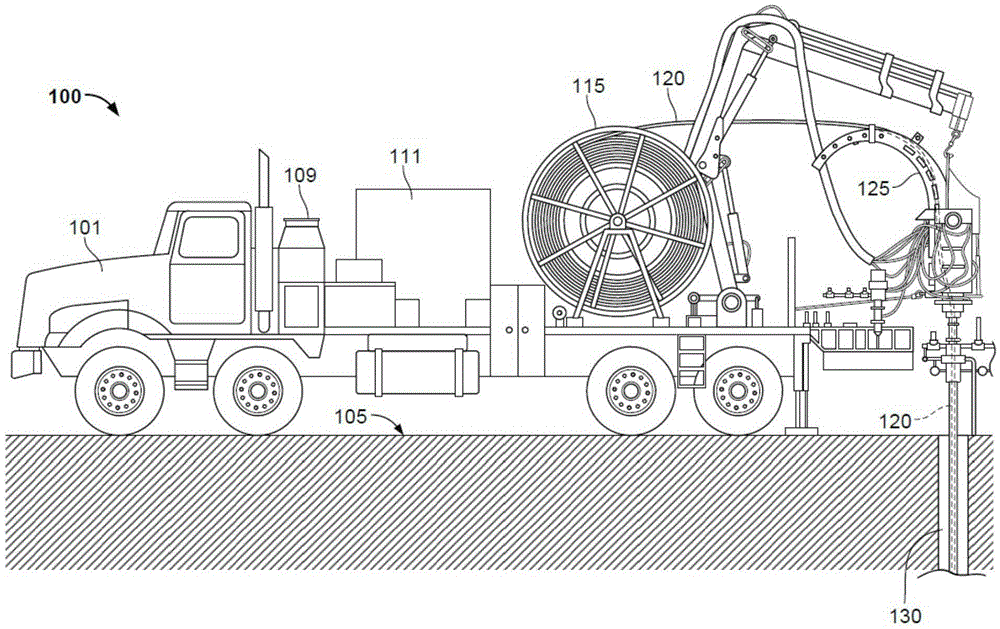

Fatigue Resistant Coiled Tubing

The disclosed manufacture method for a length of tubing can produce a length of fatigue resistant tubing that has relatively high fatigue resistance and relatively low strip-to-strip welding length. The Fatigue resistance is calculated from experimental settings with controlled parameters and / or simulations reproducing similar material properties and loading conditions. A high fatigue resistance means certain product characteristics (e.g., low plasticization, low hydrostatic stress levels and free of imperfections welds) can be retained with an adequate bias weld design at low values after a specific test number of cyclic loading. The relatively low strip-to-strip welding length is an advantage for reducing probabilities of having cracks initiated and / or propagated at weld locations, where imperfections and localized differences of mechanical properties commonly cause failure. Low strip-to-strip welding length can also reduce the costs for welding.

Owner:TENARIS COILED TUBES LLC

Determination of electromigration susceptibility based on hydrostatic stress analysis

Aspects of the invention relate to techniques for determining the electromigration features corresponding to layout design data. According to various examples of the invention, a circuit design is analyzed to determine voltages of nodes in an interconnect tree. From the voltages of the nodes, current density values and current directions for the segments of the interconnect tree are determined. Based on the current density values and the current directions, hydrostatic stress values for the nodes are computed under a steady-state condition and conservation of the conductive material within the interconnect tree. The electromigration susceptibility of the interconnect tree is then determined based on the computed hydrostatic stress values.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

Stress sensor for cement or fluid applications

A system and method measuring subterranean stress. The system and method includes a non-destructive sheath enveloping a tubular structure positioned in direct contact with a lateral subterranean rock formation for sensing expansive changes in the subterranean rock formation. A fiber optic is directly embedded in the non-destructive sheath positioned adjacent to the exterior surface of the tubular structure. The fiber optic transmits light and thereafter receives light in proportion to the expansive changes in the subterranean rock formation. A spectrometer connected to the fiber optic remote from the non-destructive sheath. The spectrometer measures hydrostatic stress in the subterranean rock formation without estimating acoustoelastic effects or occluding the tubular structure.

Owner:UT BATTELLE LLC

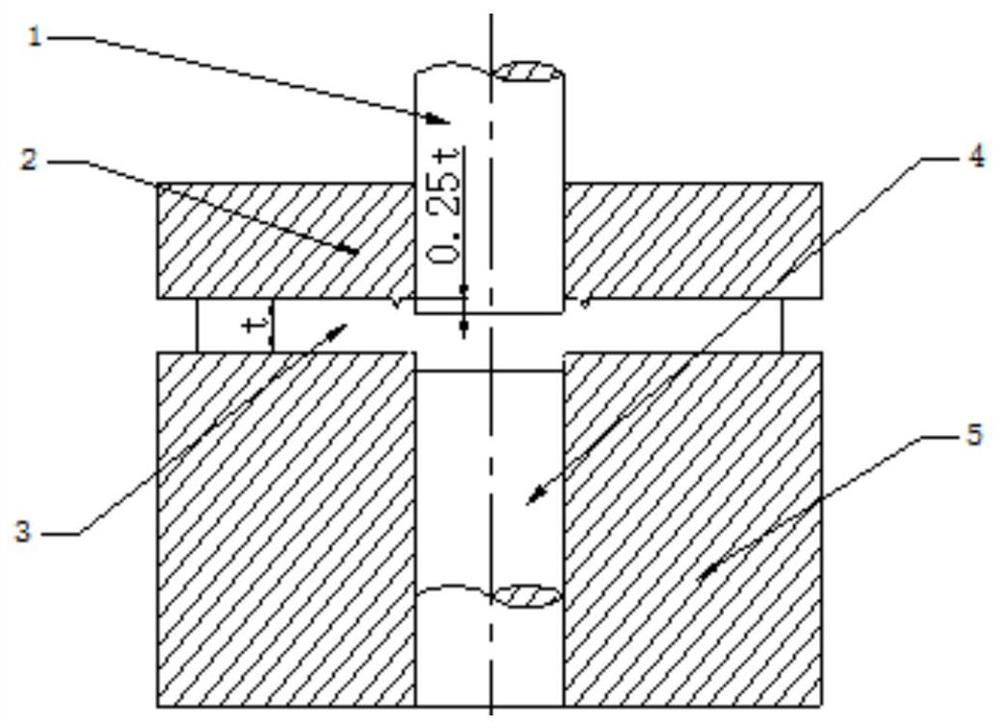

Rotary fine-stamping mold and method for helical cylindrical gear

InactiveCN106862474AImprove distributionControl tensile stressForging/hammering/pressing machinesWheelsGear wheelEngineering

The invention provides a rotary fine-stamping mold and method for a helical cylindrical gear. According to the rotary fine-stamping method, a blank is subjected to upsetting by utilizing a press plate; when the blank flows radially, the radial flow of the blank is stopped by the groove wall of a compression groove in the press plate; and meanwhile, the radial force is applied to the blank by utilizing the reacting force, so that the three-dimensional compressive stress during the formation of a common rotary fine-stamping helical cylindrical gear is enhanced, and then the hydrostatic stress distribution state in a fine-stamping process is improved. By adoption of the rotary fine-stamping mold and method provided by the invention, the too early appearance of the tensile stress in a shear plasticity and deformation region in the fine-stamping process is effectively controlled, thereby inhibiting the formation in advance and the propagation of cracks, reducing and even eliminating the torn belt of a fine-stamping part, and improving the quality of the fine-stamping part.

Owner:WUHAN UNIV OF TECH

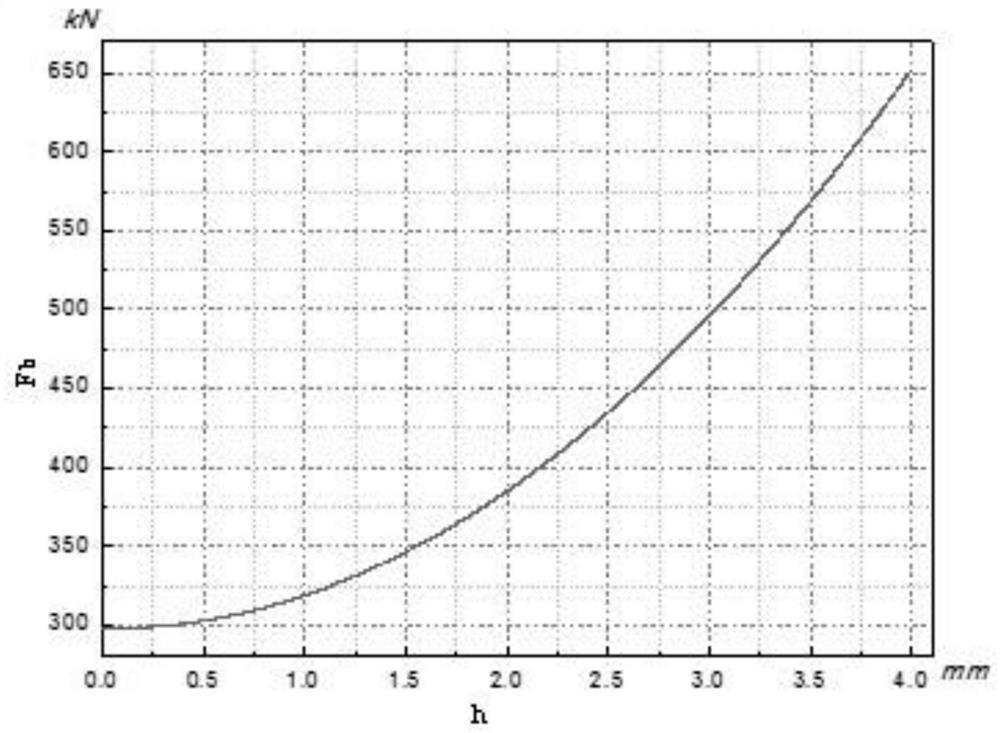

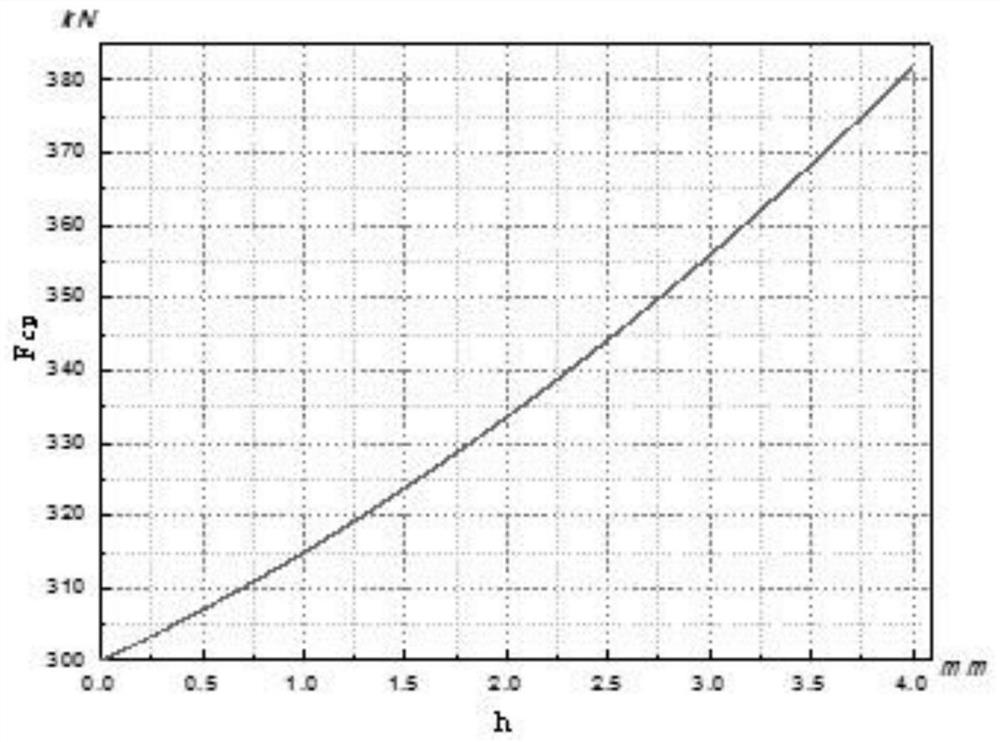

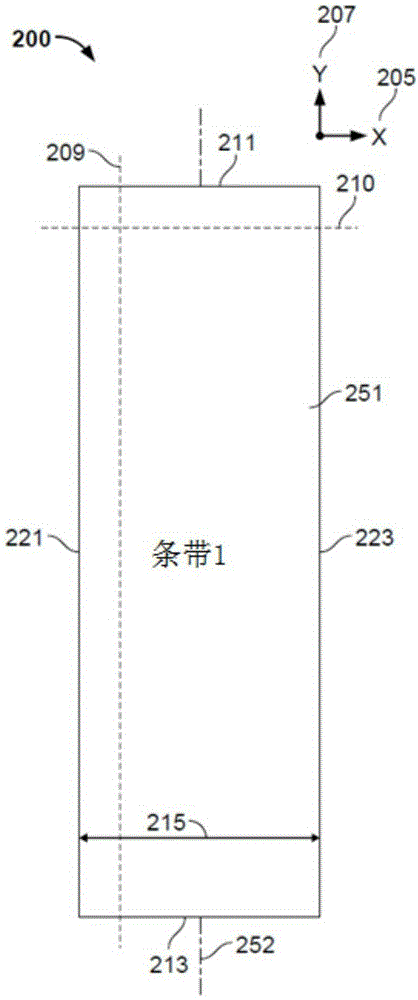

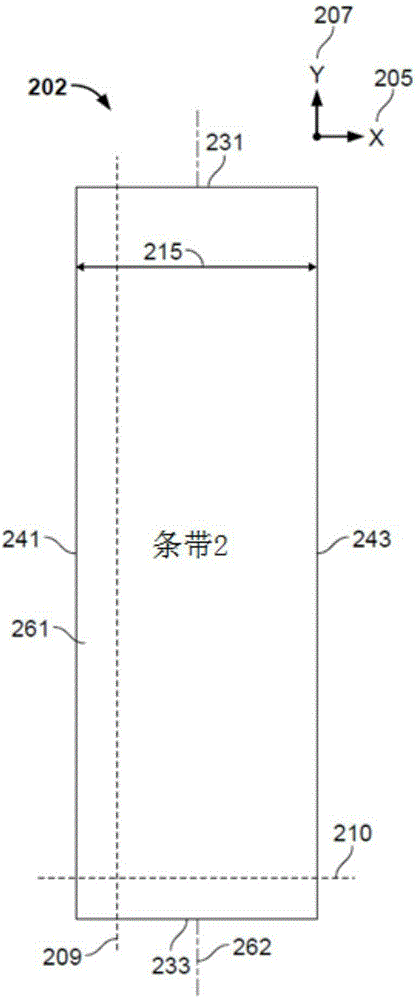

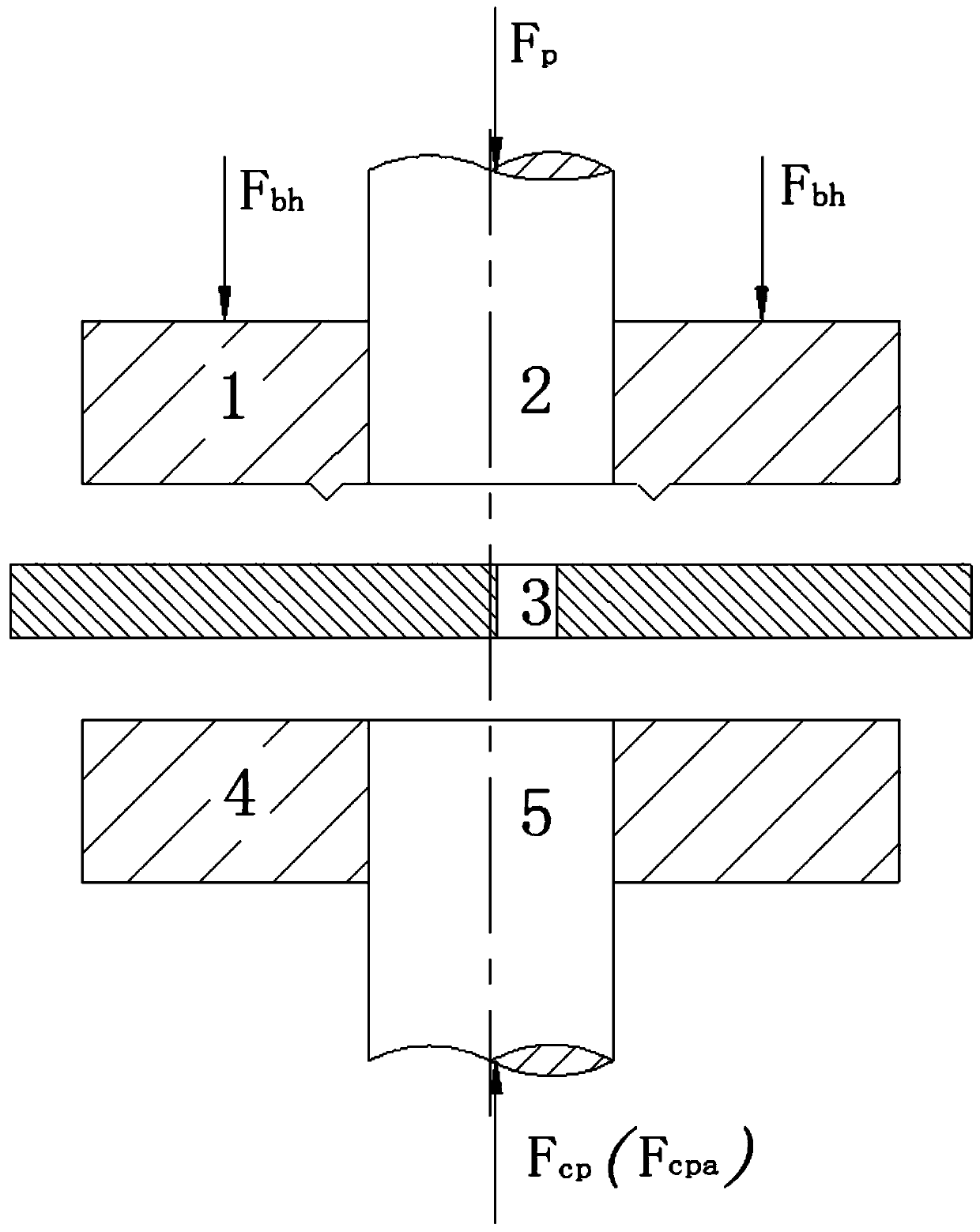

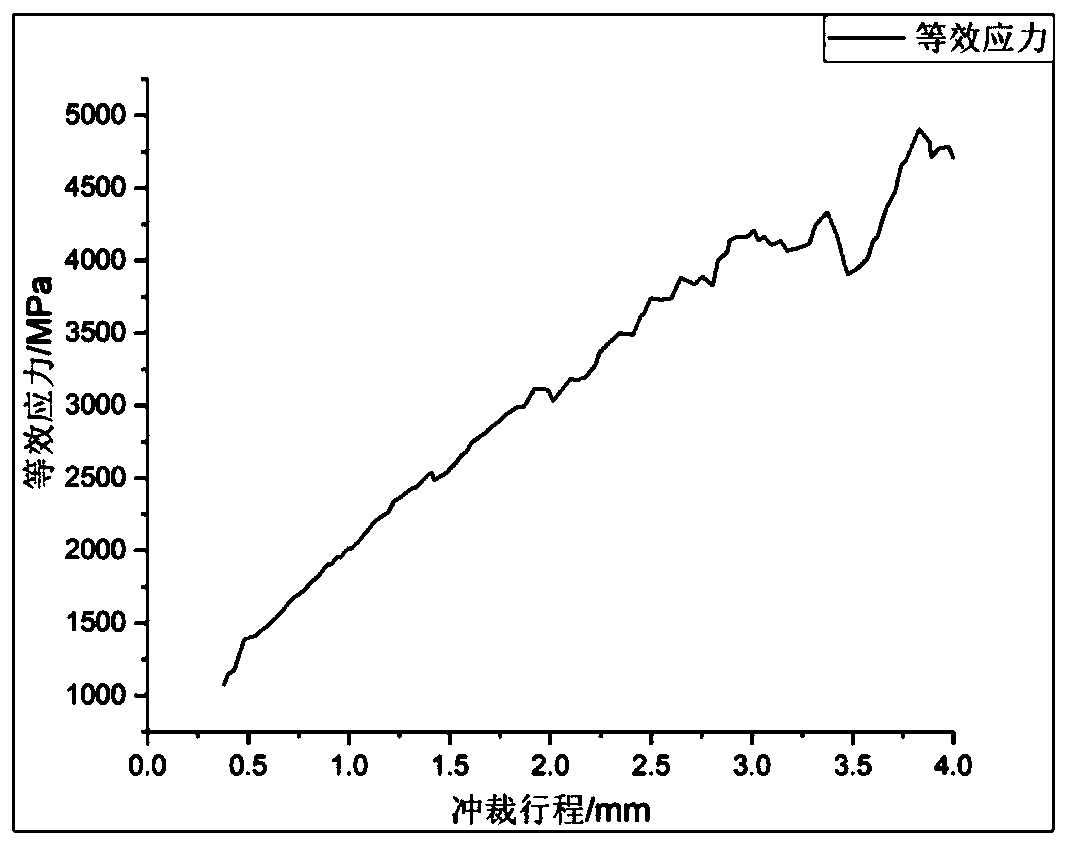

A kind of titanium alloy fine blanking forming method

ActiveCN108536948BImprove plasticityIncrease profitDesign optimisation/simulationSpecial data processing applicationsPunchingManufactured material

The present invention proposes a titanium alloy fine-blanking forming method. For TC4 titanium alloys of different thicknesses, fine-blanking is carried out by using finite element and experimental methods to obtain blank holder force, anti-deterministic force and stamping speed. The influence relationship of the hydrostatic pressure stress in the cutting strip, and then use the fracture criterion to judge the cracks under the hydrostatic pressure stress. Through a large number of experiments and simulation data fitting, the blank holder force and anti-bracket force obtained in the patent are obtained. The design relationship curve of force and blanking speed can be used to obtain the optimal combination of blank holder force, reverse jacking force and blanking speed, that is, the blank holder force and reverse jacking force increase continuously with the fine blanking process. , the punching speed is continuously reduced, so that the material in the shear zone is always in a good hydrostatic stress state, and a good shear bright zone is obtained. The invention realizes the fine blanking forming of the titanium alloy material, has high production efficiency, high utilization rate of raw materials, and good surface quality of formed parts.

Owner:WUHAN UNIV OF TECH

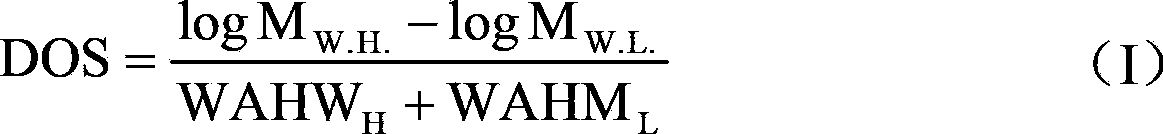

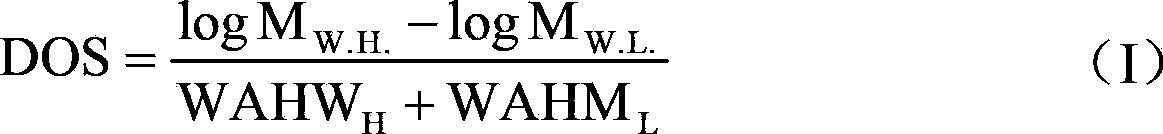

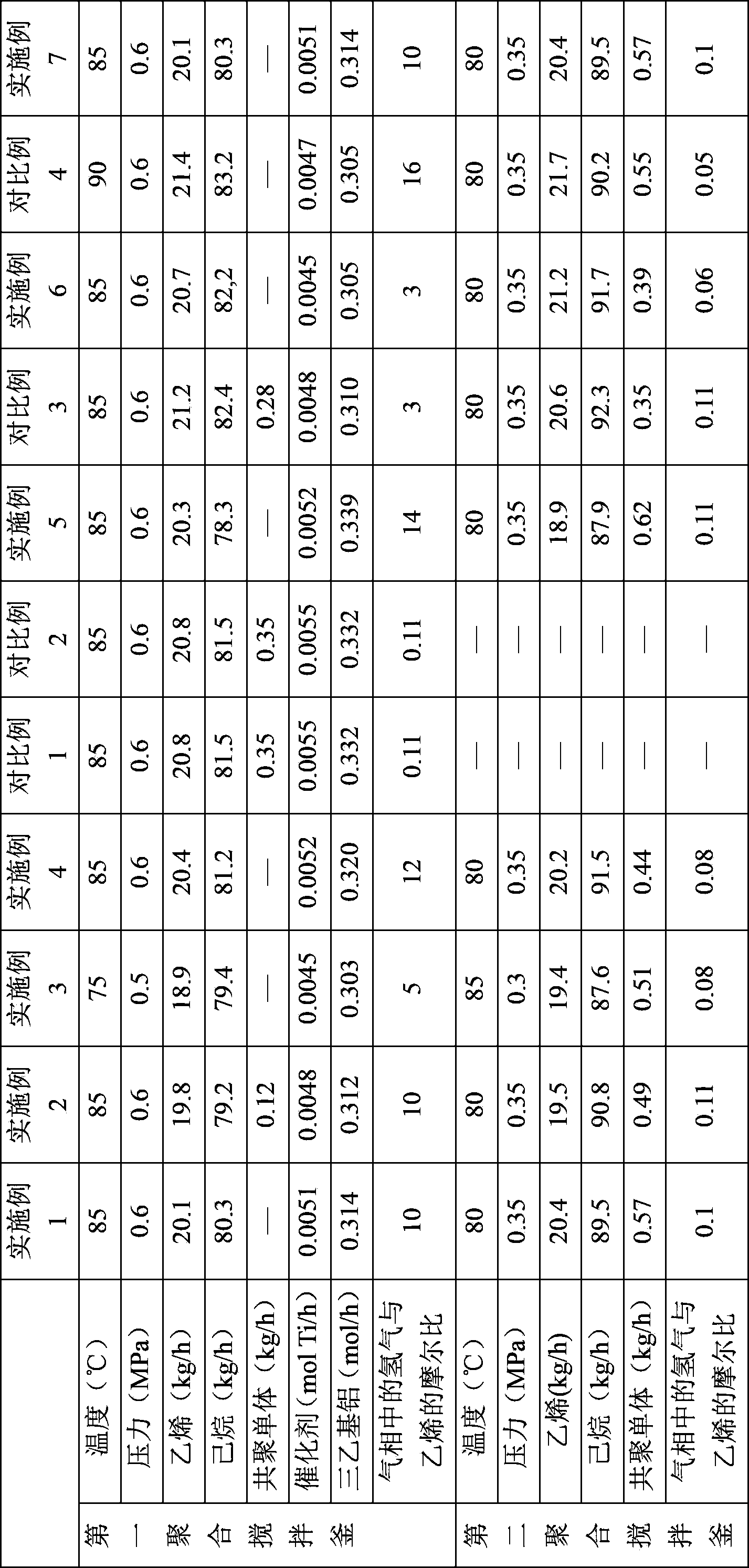

Ethene polymer, composition containing ethene polymer, applications of ethene polymer, and pipeline

ActiveCN103804555AHigh resistance to hydrostatic stress failureIncrease productivityRigid pipesPolymer scienceAlpha-olefin

The invention provides an ethene polymer and applications thereof. Total weight of the ethene polymer is taken as a base, the ethene polymer contains monomeric units formed from ethene, and monomeric units formed form alpha-alkenes containing 4 to 10 carbon atoms. Molecular weight bimodal distribution of the ethene polymer is shown by results of gel permeation chromatography testing; weight average molecular weight of low molecular weight ingredients ranges from 5000 to 50000Da, weight average molecular weight of high molecular weight ingredients ranges from 50000 to 3000000; and separation degree DOS of the low molecular weight ingredients to the high molecular weight ingredients ranges from 0.28 to 0.52. The invention also provides a composition containing the ethene polymer, and applications thereof. The invention provides a pipeline prepared from the composition. The pipeline is prepared via extrusion of the ethene polymer, extrusion can be carried out at a relatively high speed, and the pipeline possesses relatively high hydrostatic stress rupture resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

A non-intrusive method for measuring fluid pressure in pipelines

ActiveCN105738028BImprove reliabilityHigh measurement accuracyFluid pressure measurement by acoustic meansSurface stressLongitudinal wave

The invention discloses a measurement method for fluid pressure in a non-intrusive pipeline, and solves the problem of monitoring of fluid pressure in the internal part of the pipeline without damaging the structure of the pipeline. According to the method, a stress coefficient K and time of corresponding ultrasonic critical refraction longitudinal wave propagation are acquired based on a selected stretching test block and a zero stress test block; a data acquisition card acquires transit time data of an ultrasonic transmit-receive card to be transmitted to a master control computer, and the master control computer obtains time of ultrasonic critical refraction longitudinal wave propagation of a measured pipeline through calculation; service stress of the measurement position of the external surface of the pipeline is also obtained; a hydrostatic stress measurement experiment is performed by utilizing a pipeline test member so that the fluid pressure measurement coefficient in the non-intrusive pipeline and a quantitative relation model between stress of the external surface of the pipeline and fluid pressure in the pipeline are obtained; and finally the measured value of fluid pressure in the pipeline is obtained. The method is simple in the structure of the experiment device and high in measurement accuracy and reliability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

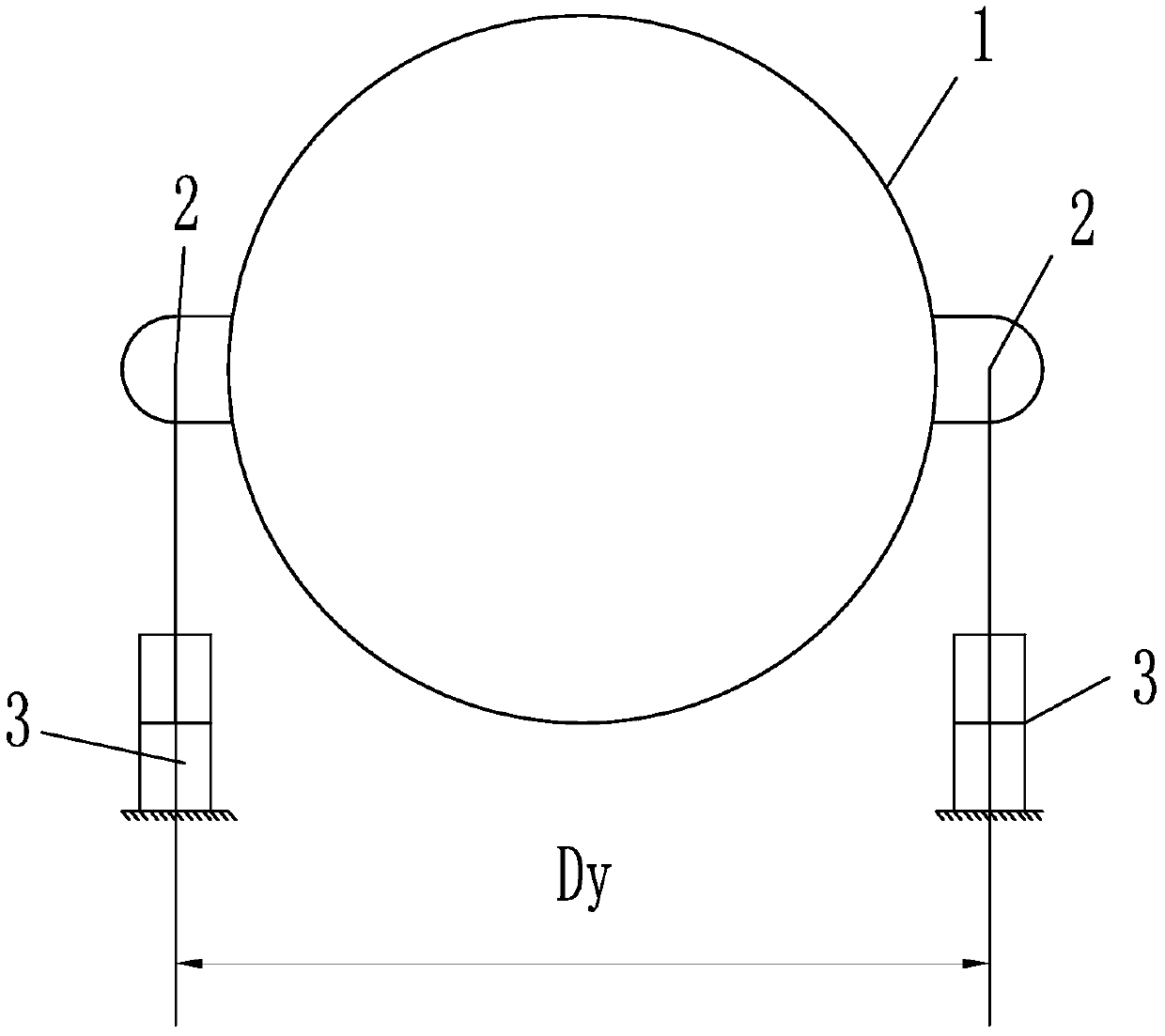

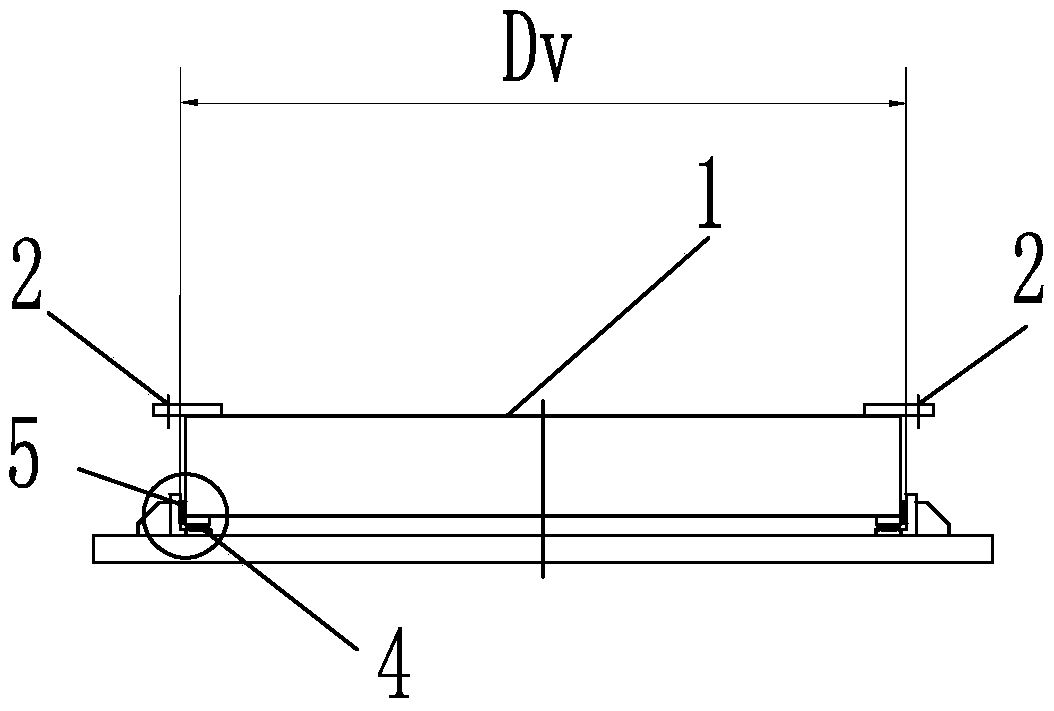

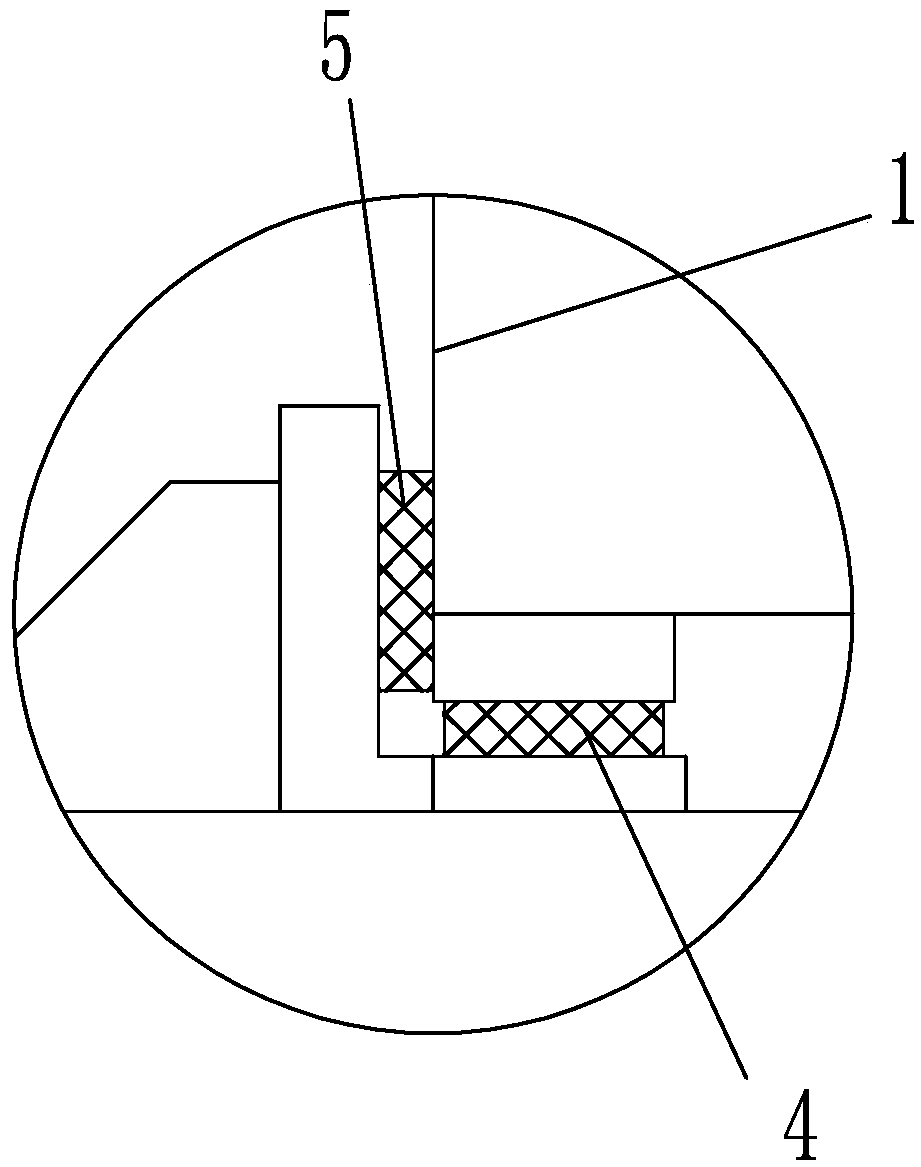

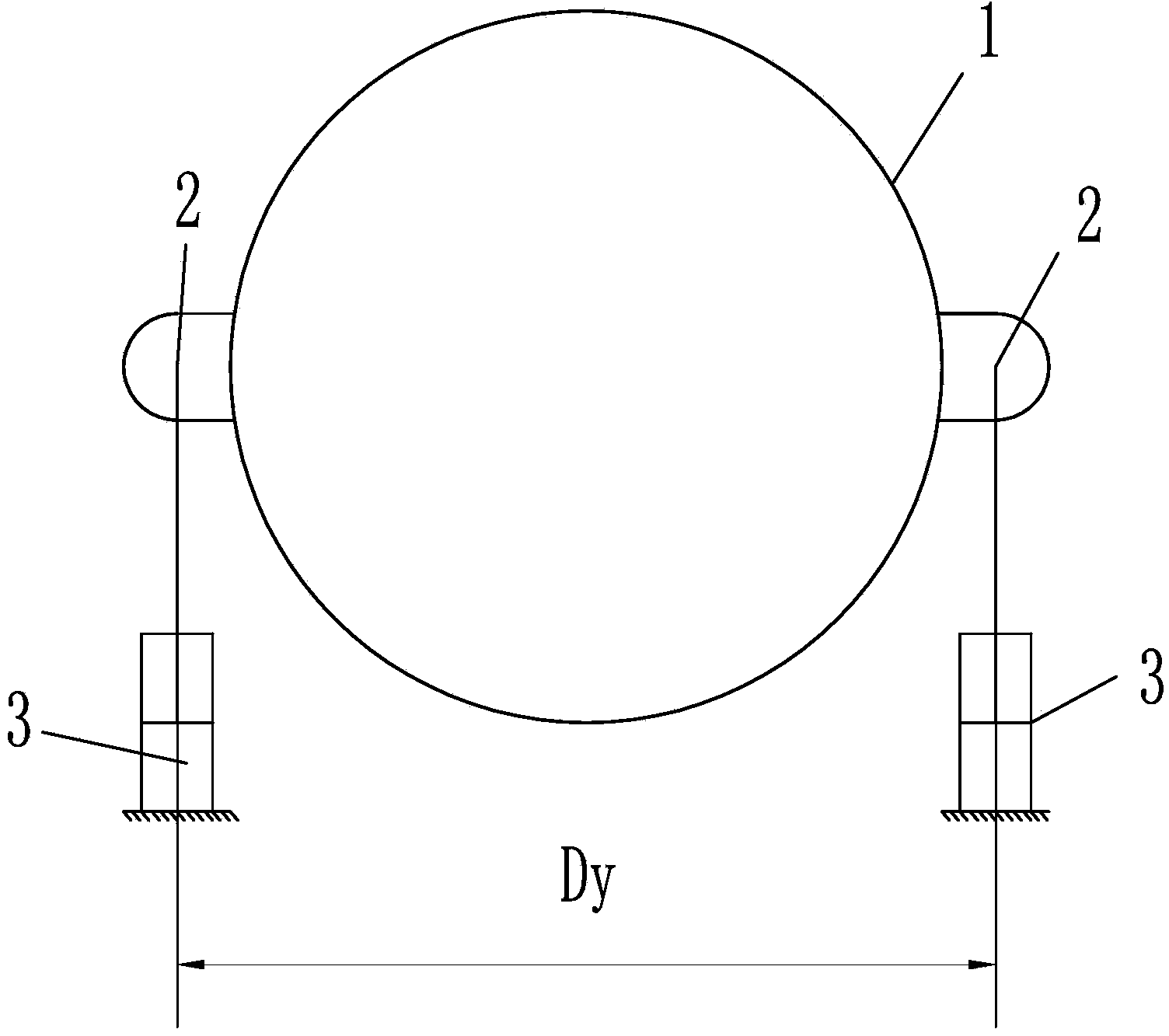

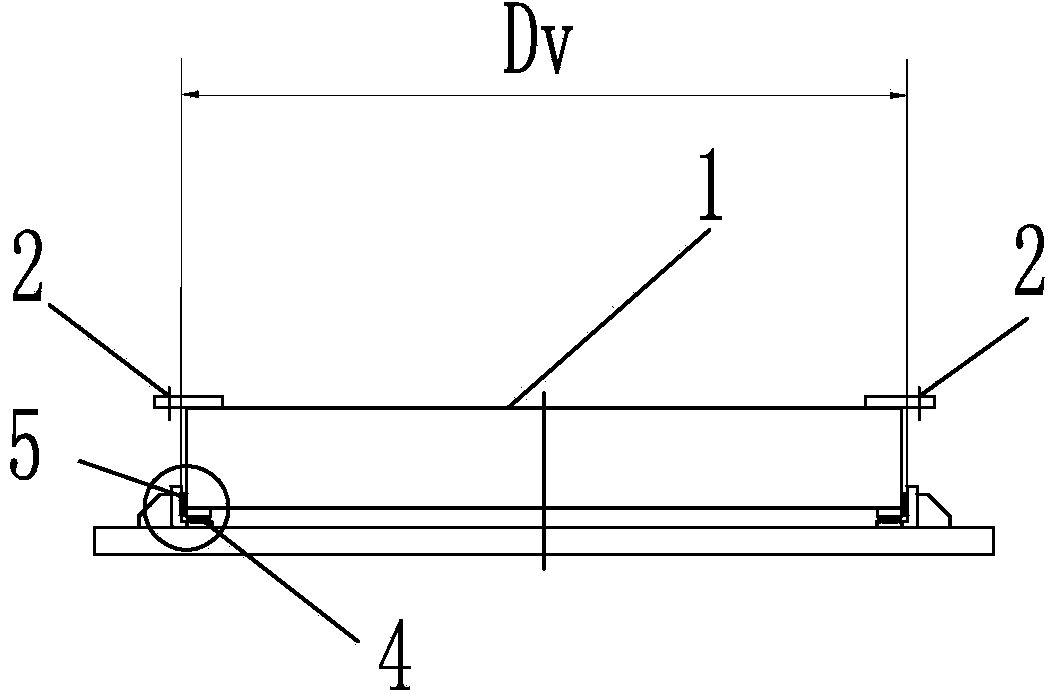

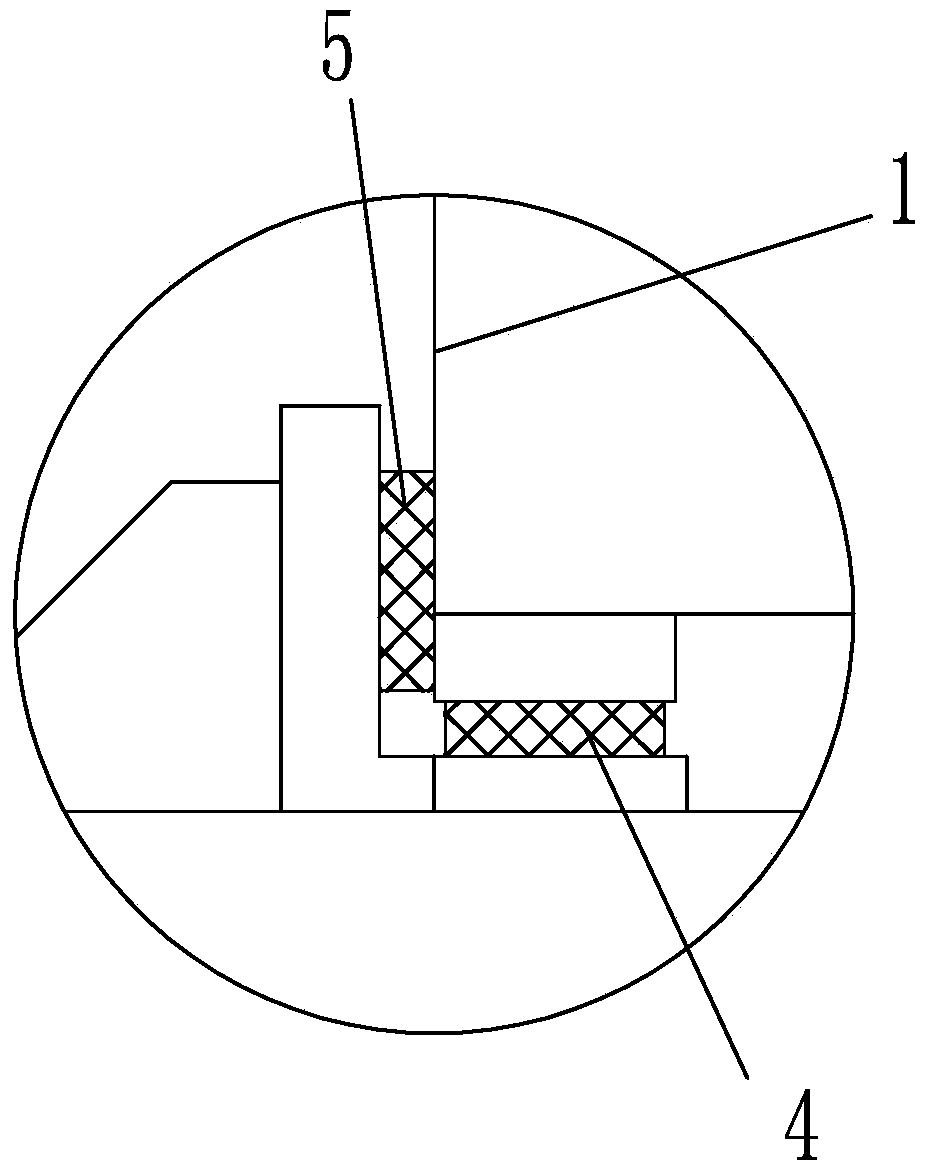

A type selection method of anti-wear plate on the facade of hydraulic turbine control ring

ActiveCN104141578BPerfect selection methodScientific selection methodHydro energy generationReaction enginesWater turbineModel selection

The invention discloses a model selection method of a water turbine control ring facade wear plate. The model selection method comprises the following steps of: calculating the hydrostatic stress PV = 0 = (phi / 4*d2)*Pmax / (N '* B * L) of the facade wear plate, wherein N is the total number of the facade wear plate, N 'is 2 when N is less than or equal to 14, and N' is 4 when N is more than 14, Pmax is the maximum oil pressure of a guide vane servomotor, d is the diameter of a piston rod of the guide vane servomotor, B is the width of a single facade wear plate, and L is the length of the single facade wear plate; calculating the sliding speed V = Dv / Dy * S / Ts of the facade wear plate, wherein Dy is a distance between large earholes of two control rings, Dv is the diameter of an excircle of the facade wear plate, S is a large earring stroke of the control ring, and Ts is guide vane closing time; calculating the sliding stress PV is not equal to 0V = 0.56PV = 0 * V of the facade wear plate; comparing the hydrostatic stress PV = 0 of the facade wear plate with the allowable hydrostatic stress of the selected wear plate material, and the sliding stress Pv is not equal to 0V value of the fade wear plate with the allowable sliding stress value of the selected wear plate material. The model selection method is perfect and scientific, and the safety and economy of the facade wear plate are ensured.

Owner:CHONGQING DATANG INT WULONG HYDROPOWER DEV

Design monitoring method for creep deformation of high temperature components of thermal power generating units

ActiveCN104239682BRealize Quantitative PredictionImprove mechanical propertiesSpecial data processing applicationsPrincipal stressEngineering

The invention provides a monitoring method for creep deformation design of a high-temperature part of a thermal power generating unit. The monitoring method specifically comprises the following steps: inputting a material mark of the high-temperature part; determining service years m of the high-temperature part; determining annual average running hours t of the high-temperature part; calculating total running hours t0 of the high-temperature part; calculating principal stress and maximum principal strain of the high-temperature part; calculating equivalent stress sigma<eq> of the high-temperature part; calculating hydrostatic stress sigma<h> of the high-temperature part; calculating a correction factor A of multi-axial creep of the high-temperature part; determining design monitoring amounts of creep deformation of the high-temperature part; recognizing surface characteristic parts of the high-temperature part; conducting optimization control of creep deformation of a first class of surface characteristic parts; conducting optimization control of creep deformation of a second class of surface characteristic parts; printing output results. The monitoring method for the creep deformation design of the high-temperature part of the thermal power generating unit realizes quantitative prediction and design monitoring of the creep deformation of the high-temperature part of the thermal power generating unit.

Owner:SHANGHAI POWER EQUIP RES INST

Fatigue Resistant Flexible Tubing

The disclosed method of making a length of pipe can produce a fatigue resistant length of pipe having a relatively high fatigue resistance and a relatively small strip-to-strip weld length. Fatigue resistance is calculated from an experimental setup with control parameters and / or a simulation replicating similar material properties and loading conditions. High fatigue resistance means that certain product characteristics, such as low plasticity, low hydrostatic stress levels and defect-free welds, can be maintained after a specific number of tested cyclic loadings with adequate weld offset design at low values. The relatively small strip-to-strip weld length reduces the likelihood of crack initiation and / or propagation at weld locations where defects and local differences in mechanical properties often cause failure. Small strip-to-strip weld lengths can also reduce weld costs.

Owner:TENARIS COILED TUBES LLC

Plasticized fine blanking forming process based on crack initiation control

ActiveCN109821966BExtended service lifeImprove forming qualityMetal working apparatusCrazingClassical mechanics

The invention discloses a plastifying fine blanking formation technology design method based on crack initiation control. The method comprises the following steps that according to the fracture criterion of fine blanked materials, critical hydrostatic stress during crack initiation of plates is obtained; in the fine blanking process, edge pressing force, blanking force and counter ejection force are exerted on an edge pressing ring, a male die and a counter ejection plate, and the counter ejection force is increased along with increase of the blanking stroke; when the blanking stroke initial position 0 travels to the blanking stroke position S1, the edge pressing force is increased gradually, when the blanking stroke position S1 travels to the blanking stroke, in the finishing process, theedge pressing force is reduced gradually, and when the blanking stroke reaches the stroke position S1, the plates reach the critical hydrostatic stress. According to the method, the effect of restraining crack initiation is restrained, fine blanked parts with full euphotic belts are obtained, thus energy consumption in the fine blanking process is reduced, the forming quality of the parts is improved, the service life of the die is prolonged, and the good comprehensive economic benefits are obtained.

Owner:WUHAN UNIV OF TECH

Model selection method of water turbine control ring facade wear plate

ActiveCN104141578APerfect selection methodScientific selection methodHydro energy generationReaction enginesWater turbineModel selection

The invention discloses a model selection method of a water turbine control ring facade wear plate. The model selection method comprises the following steps of: calculating the hydrostatic stress PV = 0 = (phi / 4*d2)*Pmax / (N '* B * L) of the facade wear plate, wherein N is the total number of the facade wear plate, N 'is 2 when N is less than or equal to 14, and N' is 4 when N is more than 14, Pmax is the maximum oil pressure of a guide vane servomotor, d is the diameter of a piston rod of the guide vane servomotor, B is the width of a single facade wear plate, and L is the length of the single facade wear plate; calculating the sliding speed V = Dv / Dy * S / Ts of the facade wear plate, wherein Dy is a distance between large earholes of two control rings, Dv is the diameter of an excircle of the facade wear plate, S is a large earring stroke of the control ring, and Ts is guide vane closing time; calculating the sliding stress PV is not equal to 0V = 0.56PV = 0 * V of the facade wear plate; comparing the hydrostatic stress PV = 0 of the facade wear plate with the allowable hydrostatic stress of the selected wear plate material, and the sliding stress Pv is not equal to 0V value of the fade wear plate with the allowable sliding stress value of the selected wear plate material. The model selection method is perfect and scientific, and the safety and economy of the facade wear plate are ensured.

Owner:CHONGQING DATANG INT WULONG HYDROPOWER DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com