Plasticized fine blanking forming process based on crack initiation control

A forming process and plasticizing technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of energy waste, increased mold wear, etc., to improve the forming quality, increase the service life of the mold, and suppress the initiation of cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

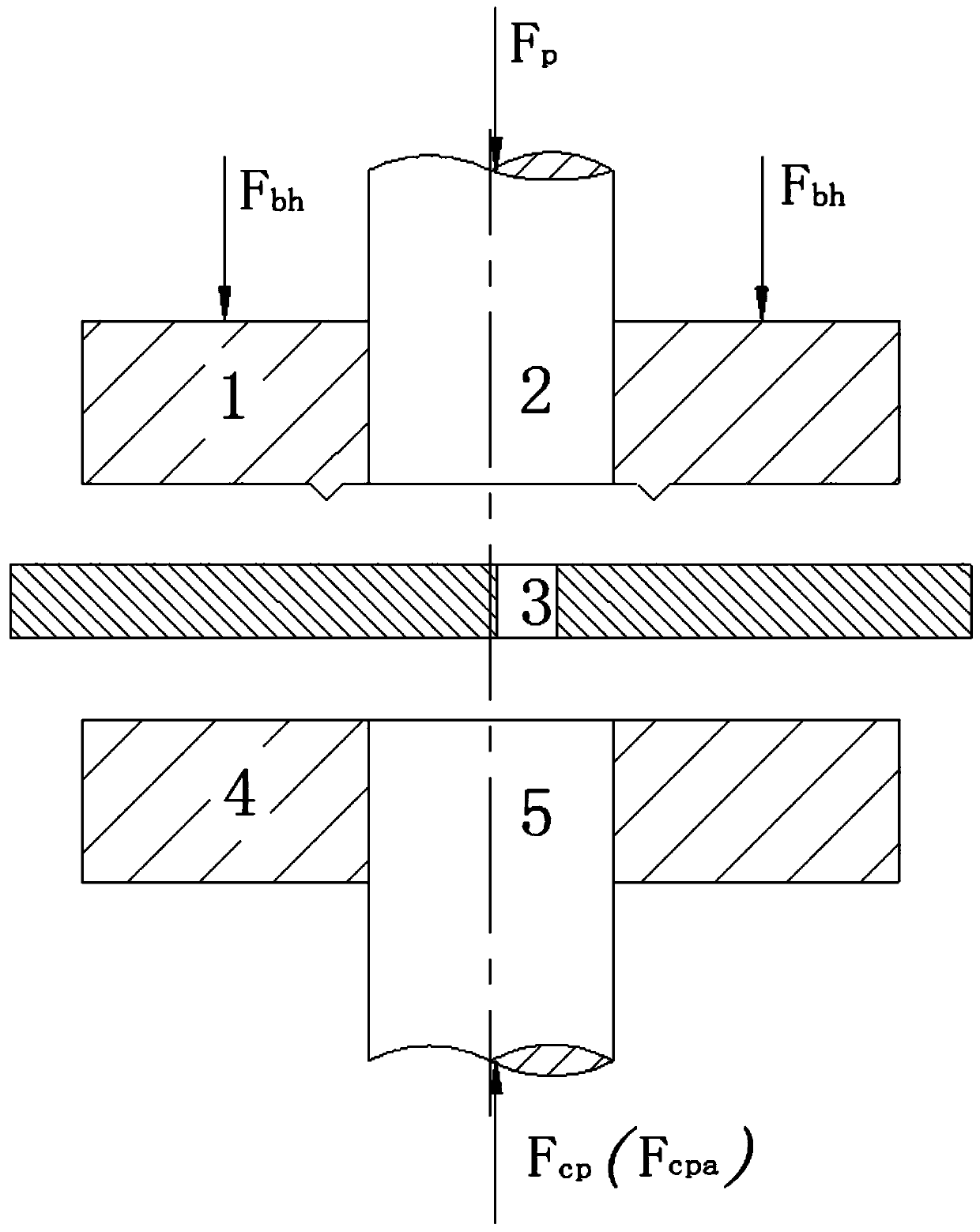

[0031] refer to Figure 1 to Figure 9 As shown, the plasticized fine blanking forming process method based on crack initiation control in an embodiment provided by the present invention realizes the fine blanking equipment used in the plasticized fine blanking forming process method, including the relative arrangement of the punch 2 and the concave die 4 , the fine blanking sheet 3 is placed between the punch 2 and the die 4, the punch 2 is provided with a blank holder 1, and the die 4 is connected to the top of the reverse top plate 5;

[0032] The described plasticized fine-blanking process based on crack initiation control comprises the following steps:

[0033] 1) According to the fracture criterion of the fine blanking material, the critical hydrostatic stress at the crack initiation of the sheet metal 3 is reversely calculated;

[0034] 2) Dur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com