Model selection method of water turbine control ring facade wear plate

A technology of anti-wear plates and ring facades, which is applied in the direction of hydropower, mechanical equipment, machines/engines, etc., can solve the problems that cannot guarantee the safety and economical efficiency of anti-wear plates on facades, and achieve safety and economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0022] A type selection method of an anti-friction plate on the façade of a hydraulic turbine control ring, comprising the following steps:

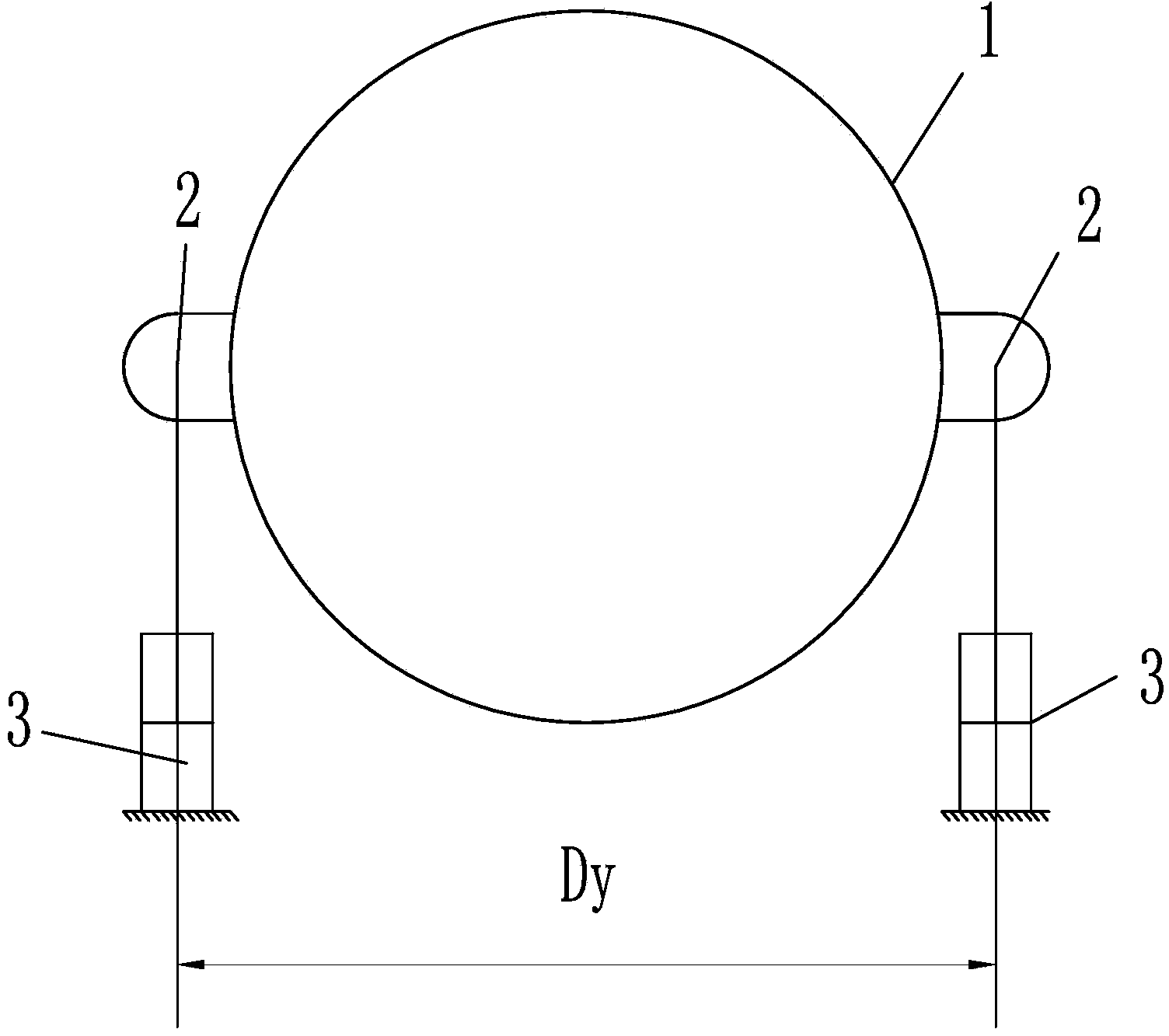

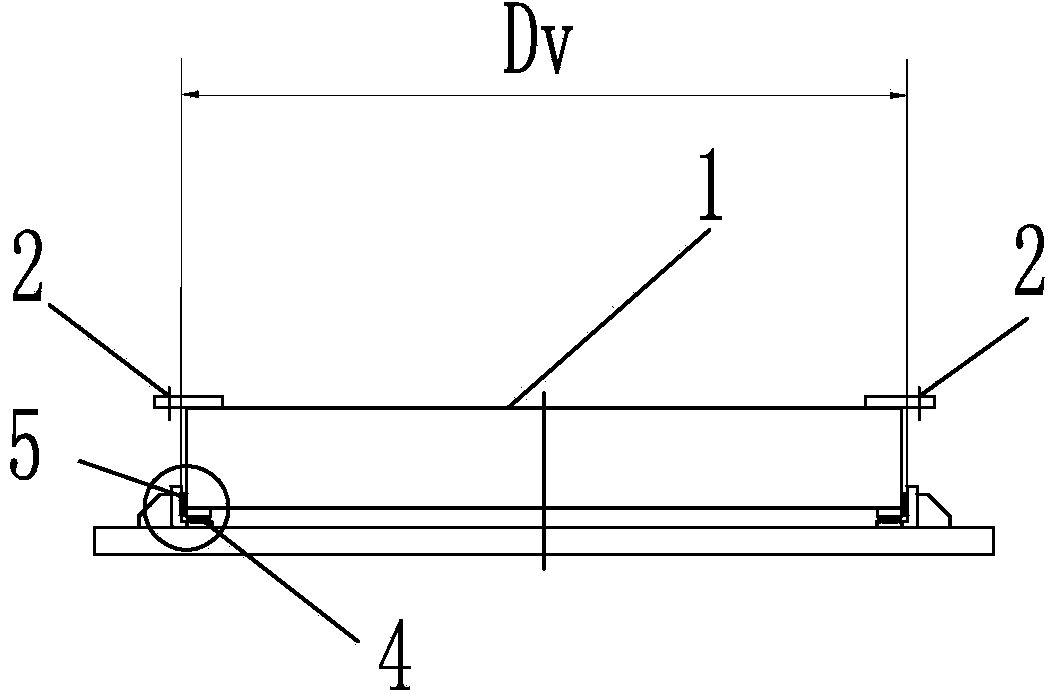

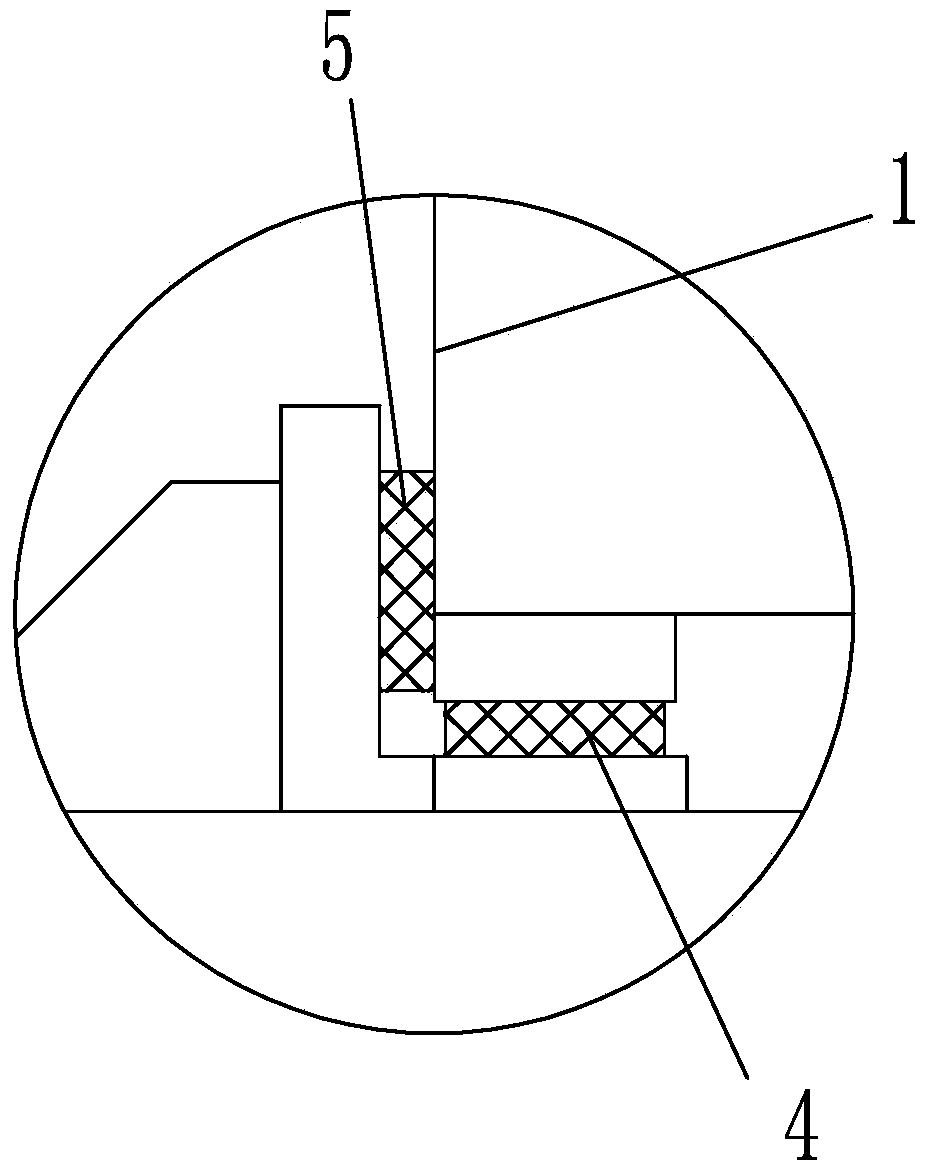

[0023] (A), calculate the static pressure stress P of the anti-wear plate on the facade of the control ring V=0 ;

[0024] Static compressive stress P of anti-wear plate on control ring facade V=0 =Fmax / (N'A)=(π / 4*d 2 )*Pmax / (N'*B*L), where: N is the total number of anti-wear plates on the facade; N' is the number of force calculations on the anti-wear plates on the facade, when N≤14, take N' as 2. When N>14, take N' as 4; Fmax is the maximum total force of the guide vane servomotor, Pmax is the maximum oil pressure of the guide vane servomotor, d is the diameter of the piston rod of the guide vane servomotor, and B is a single The width of the facade wear plate, L is the length of a single facade wear plate (such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com