A Type Selection Method of Anti-wear Plate on the Bottom Surface of Hydraulic Turbine Control Ring

An anti-wear plate and control ring technology, applied in the directions of hydroelectric power generation, mechanical equipment, machines/engines, etc., can solve the problem that the safety and economy of the bottom anti-wear plate cannot be guaranteed, and achieve the effect of ensuring safety and economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0022] A type selection method of an anti-friction plate on the bottom surface of a water turbine control ring, comprising the following steps:

[0023] (A) Calculate the static pressure P of the anti-wear plate on the bottom surface of the control ring V=0 ;

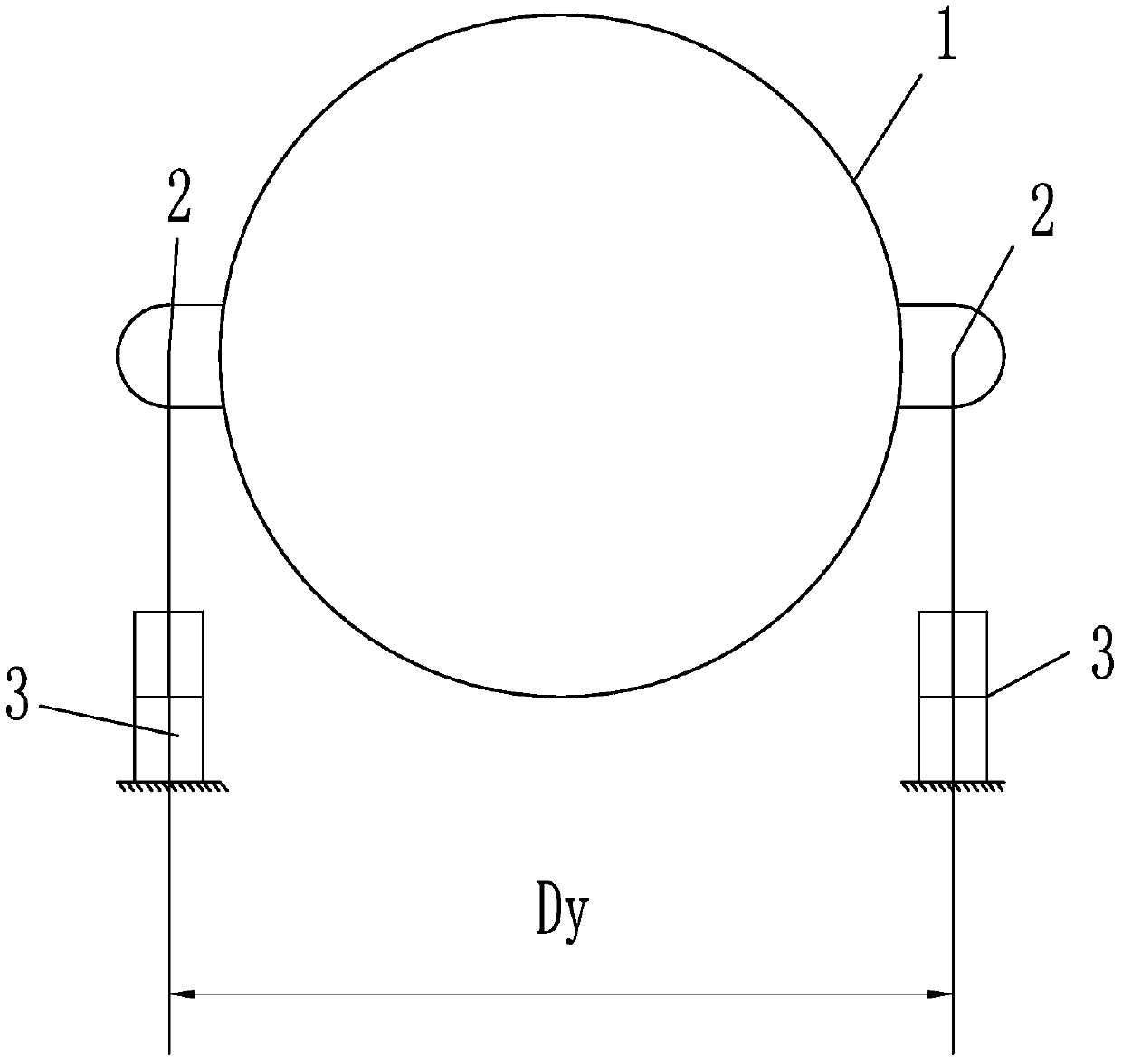

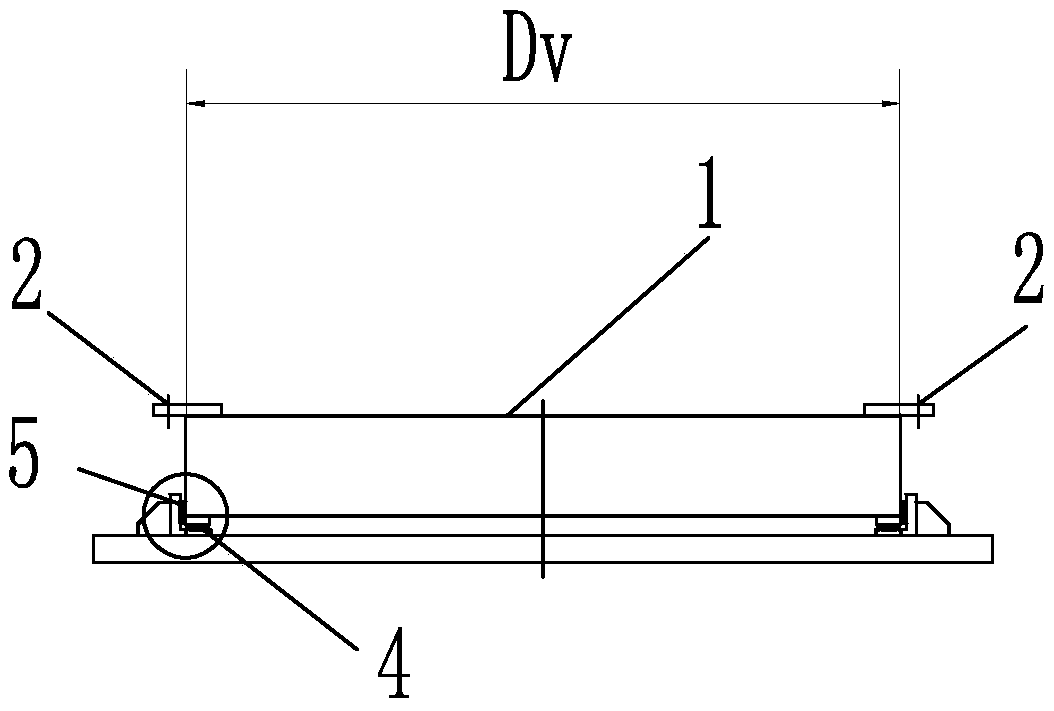

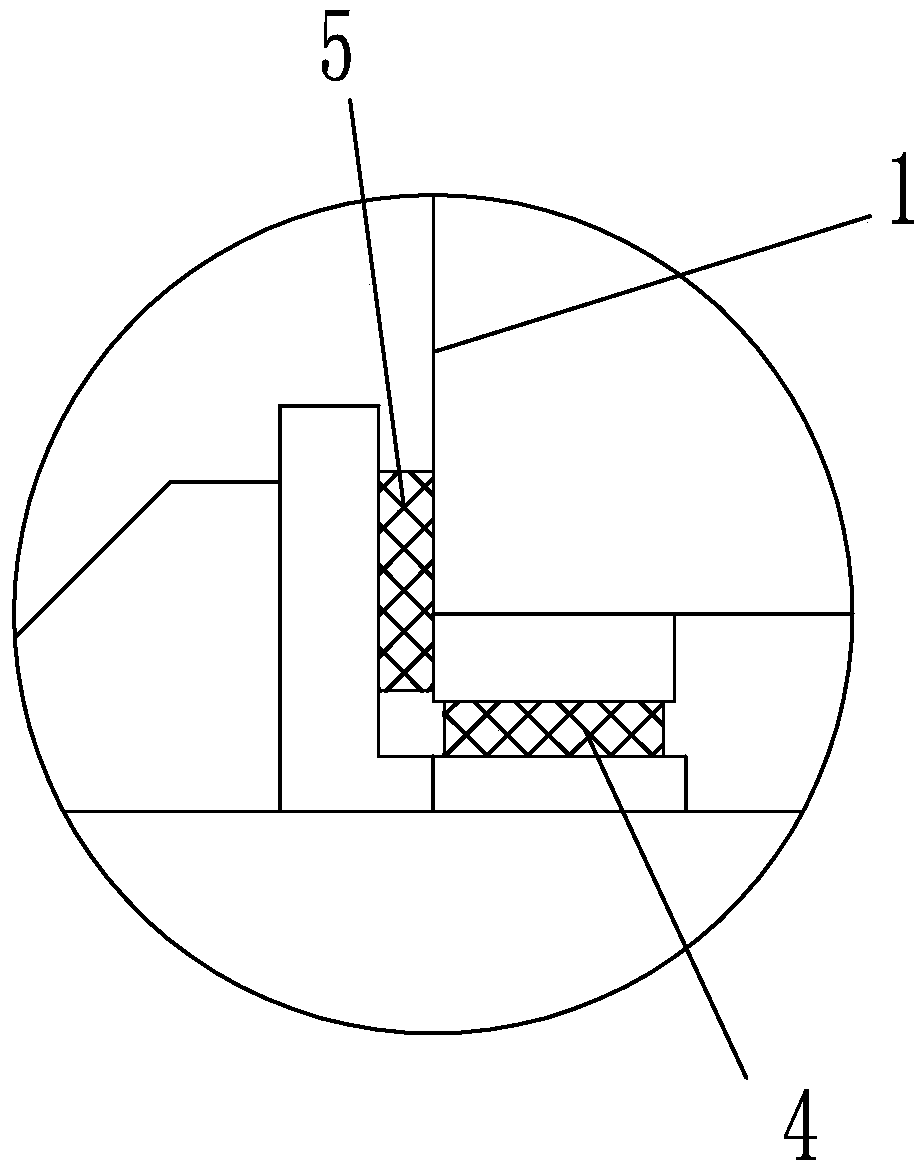

[0024] Static compressive stress P of the wear plate on the bottom surface of the control ring V=0 =G / (N*A)=G / (N*B*L), where: G is the weight of the control ring body, N is the number of wear plates on the bottom of the control ring, B is the width of a single wear plate on the bottom, L is the length of a single bottom wear plate (eg Figure 4 shown).

[0025] It is obtained through measurement: the weight of the G control ring body is 268324N, the number of wear plates on the bottom of the N control ring is 14, the width of the single bottom wear plate of B is 0.1m, and the length of the single b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com