Method for Manufacturing Mechanical Part Excellent in Rolling Fatigue Life

a technology of mechanical parts and fatigue life, which is applied in the field of mechanical part production, can solve the problems of shortening the rolling fatigue life of steel parts, affecting the performance of mechanical parts or apparatuses, and affecting the quality of mechanical parts, so as to improve the interface state, improve the rolling fatigue life, and reduce the effect of non-metallic inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0032]The present invention will be explained with reference to examples in view of implementing conditions and obtained results. The compositions of test pieces used as steel materials for the annular matrix 2 are shown in Table 1.

TABLE 1Ingredients of Test pieces(unit: % by mass)Steel TypeCSiMnPSCuNiMoCrAlSUJ21.040.220.320.0080.007——0.031.440.011SUJ31.000.551.010.0070.0080.030.050.010.99—S45C0.440.200.700.010.01—————S53C0.520.200.650.010.01—————

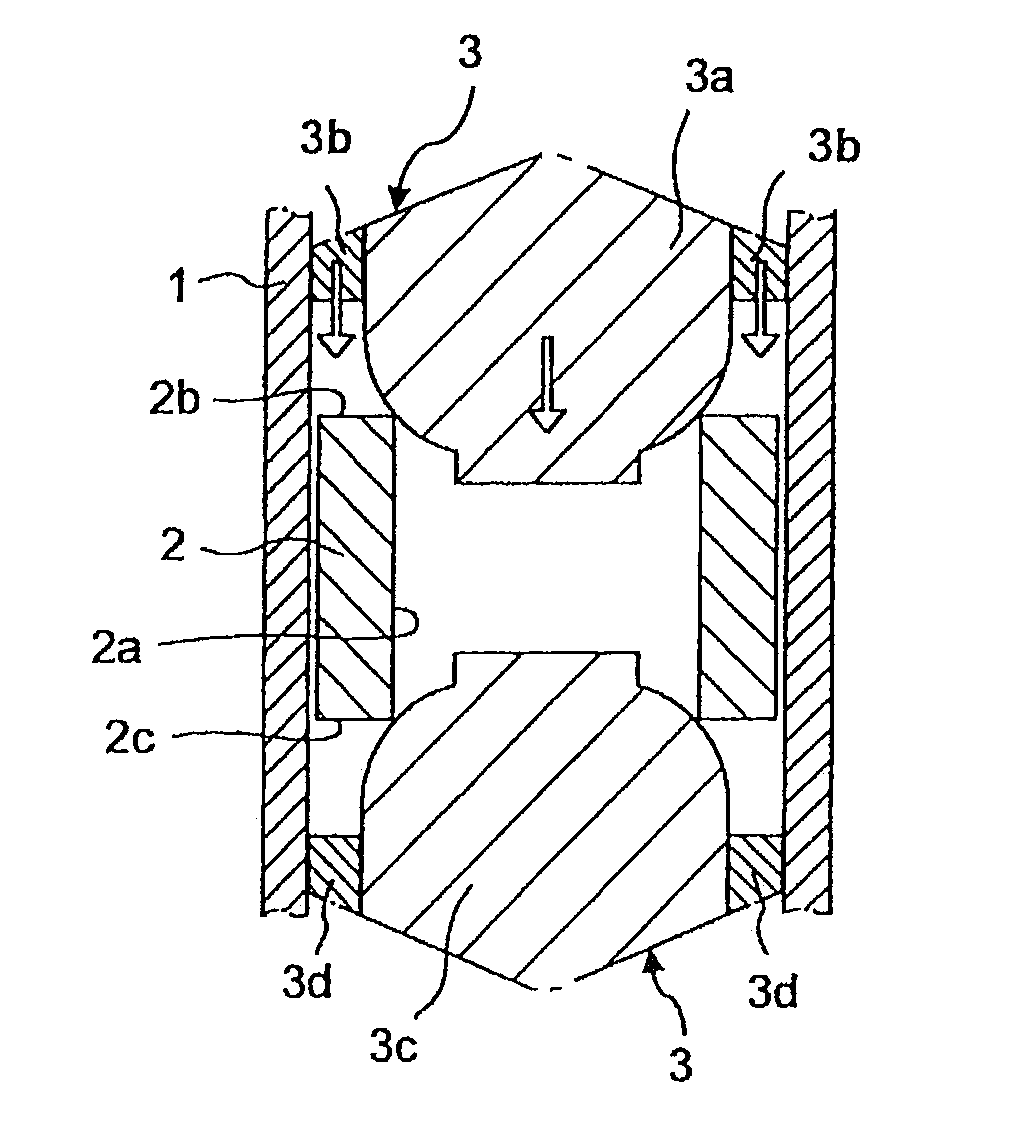

[0033]This example was implemented on test pieces of steel types shown in Table 1. First of all, molten steel was subjected to an oxidation refining in an arc melting furnace, a reduction refining in a ladle refining furnace (LF), and a degassing processing in a rotary-flow vacuum degasser (RH) for reducing the oxygen content in the molten steel, which was then subjected to continuous casting to produce a steel ingot. The steel ingot was subjected to conventional hot rolling to provide a steel material, which was then processed to form a st...

example 2

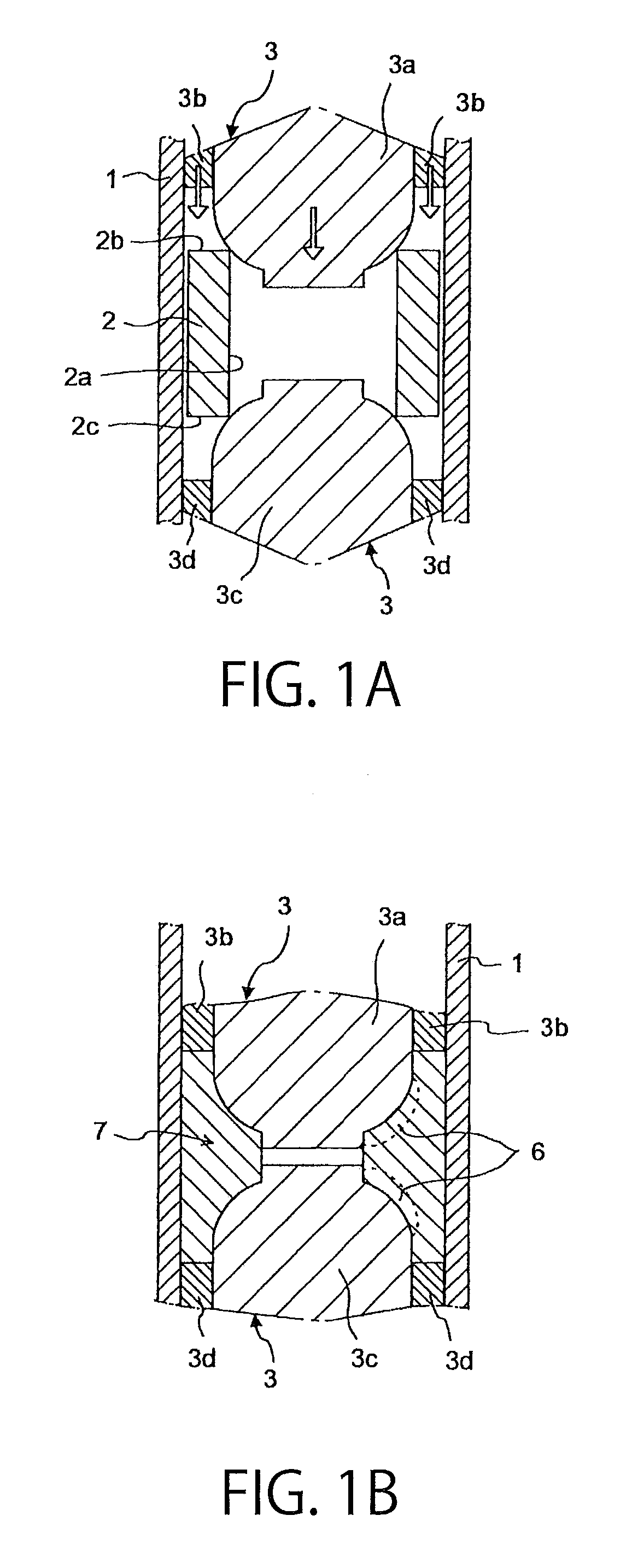

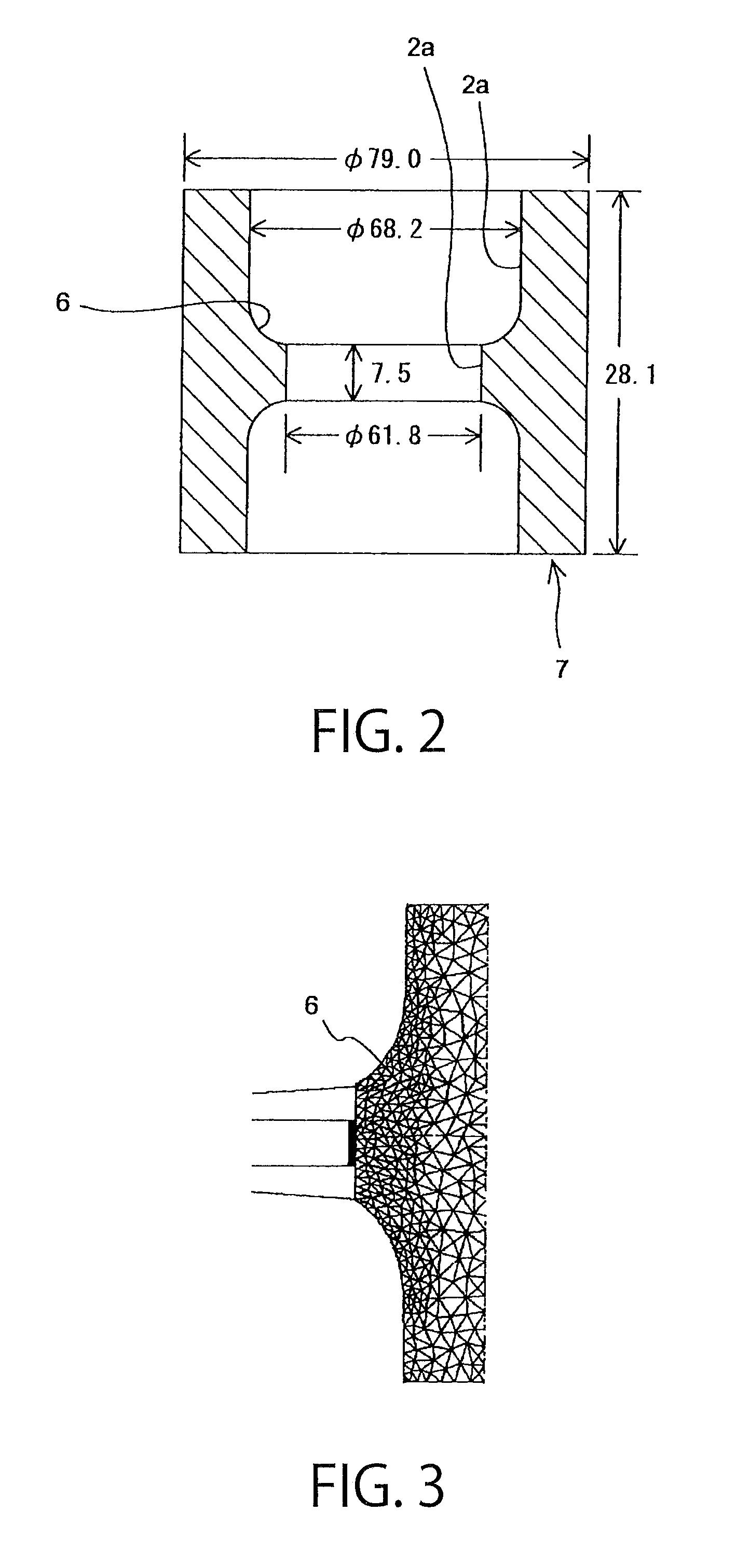

[0041]Test pieces are produced in the same way as in Example 1, except that hot forged rings are produced instead of the steel pipes. The method for producing the hot forged ring is as follows. First of all, molten steel was subjected to an oxidation refining in an arc melting furnace, a reduction refining in a ladle refining furnace (LF), and a degassing processing in a rotary-flow vacuum degasser (RH) for reducing the oxygen content in the molten steel, which was then subjected to continuous casting to produce a steel ingot. The steel ingot was subjected to conventional hot rolling to provide a steel material, which was then processed to form a billet by shear cutting. The billet was then subjected to hot forging to provide a hot forged ring having an outer diameter φ of 80 mm, a thickness of 8.7 mm and a width of 27.2 mm. The hot forged ring was subjected to conventional spheroidized annealing to prepare a hot forged ring. The outer diameter and the inner diameter of the hot forg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com