Ethene polymer, composition containing ethene polymer, applications of ethene polymer, and pipeline

A technology of ethylene polymers and compositions, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of uneven welding wall thickness, low melt viscosity, and easy sagging, etc., and achieve high durability Effect of hydrostatic stress failure performance and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

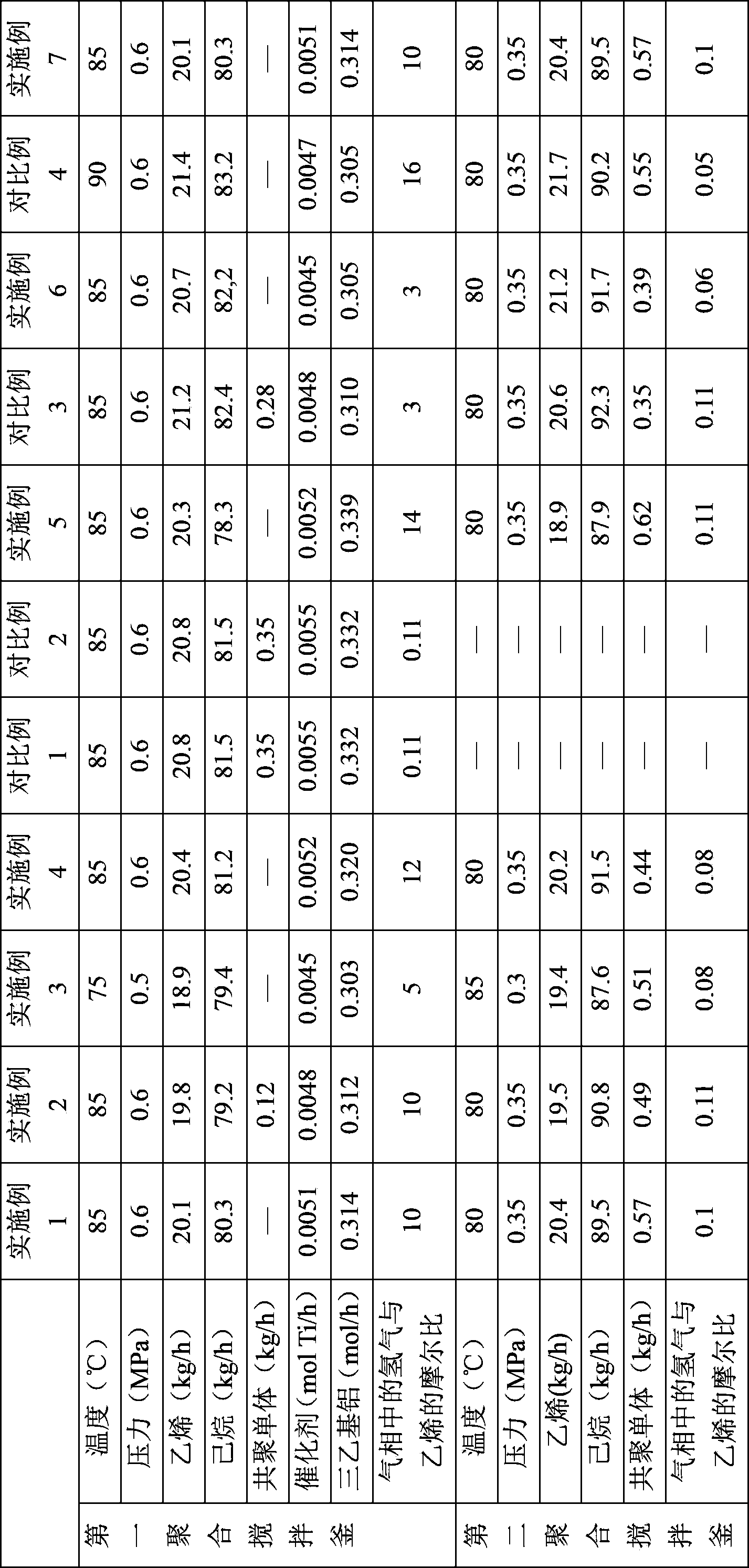

[0088] (1) Polymerize in two polymerization stirred tanks connected in series to prepare ethylene polymer, the specific steps are as follows.

[0089] Continuously add ethylene, n-hexane, Ziegler-Natta catalyst (the catalyst is prepared by the method described in Example 1 of CN1523044A), triethylaluminum and hydrogen into the first polymerization stirred tank of 500 liters, listed in Table 1 Polymerization was carried out for 2 hours under the above conditions.

[0090] The slurry from the first polymerization stirred tank is continuously transferred to the flash tank to remove unreacted hydrogen, unreacted ethylene and part of hexane, and the remaining polymer slurry is continuously transferred to the second polymerization stirred tank. At the same time, ethylene, 1-butene, n-hexane and hydrogen were added to the second polymerization stirred tank, and polymerization was carried out under the conditions given in Table 1.

[0091] The polymer slurry output from the second po...

Embodiment 2

[0095] (1) The ethylene polymer was prepared by the same method as in Example 1, except that 1-butene was added to both the first polymerization stirred tank and the second polymerization stirred tank, so as to obtain the ethylene polymer according to the present invention. The properties of the ethylene polymers are listed in Table 2.

[0096] (2) The composition was prepared by the same method as in Example 1, except that the ethylene polymer was the ethylene polymer prepared in step (1) of Example 2.

[0097] (3) Extrude the composition obtained in step (2) under the conditions listed in Table 2, so as to obtain the pipe according to the present invention. The hydrostatic stress failure times of the pipes are listed in Table 2.

Embodiment 3

[0099] (1) The ethylene polymer was prepared by the same method as in Example 1, except that the polymerization conditions were as shown in Table 1, so as to obtain the ethylene polymer according to the present invention. The properties of the ethylene polymers are listed in Table 2.

[0100] (2) The composition was prepared by the same method as in Example 1, except that the ethylene polymer was the ethylene polymer prepared in step (1) of Example 3.

[0101] (3) Extrude the composition obtained in step (2) under the conditions listed in Table 2, so as to obtain the pipe according to the present invention. The hydrostatic stress failure times of the pipes are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com