A non-intrusive method for measuring fluid pressure in pipelines

A non-intrusive, measurement method technology, applied in the direction of fluid pressure measurement, fluid pressure measurement, and measurement devices using acoustic methods, can solve problems such as low reliability and large sound attenuation, and achieve wide measurement range and simple equipment volume , easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0026] The present invention provides a non-interventional method for measuring fluid pressure in a pipeline. The specific implementation of the present invention will be described in detail below:

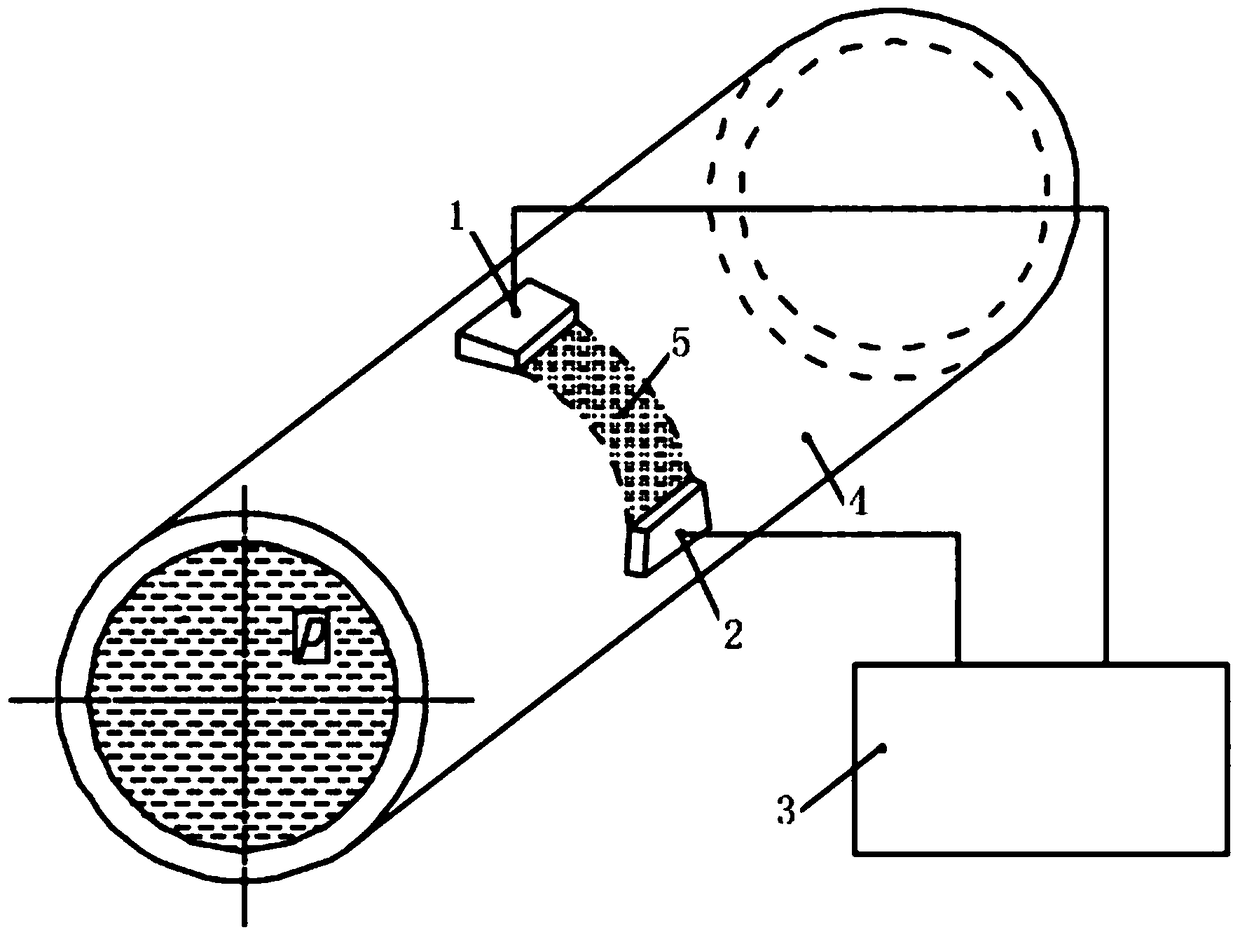

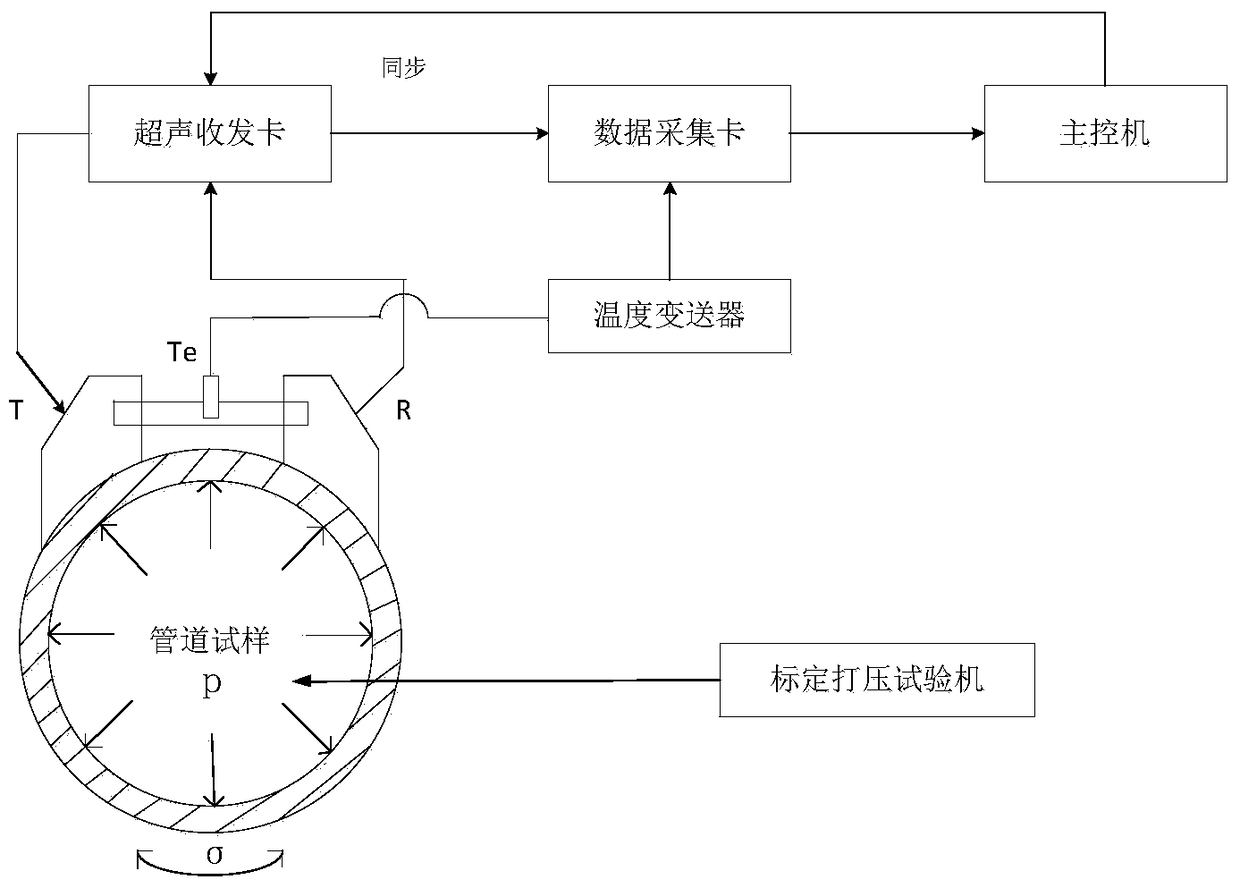

[0027] A non-invasive method for measuring fluid pressure in a pipeline, the test device used for the measurement includes an ultrasonic transmitting probe 1, an ultrasonic receiving probe 2, an industrial computer 3 and a temperature transmitter; the ultrasonic transmitting probe 1 and the ultrasonic receiving probe 2 are all connected with the industrial computer 3, and the industrial computer 3 includes an ultrasonic transceiver card, a data acquisition card and a main control computer; the steps of the method are as follows:

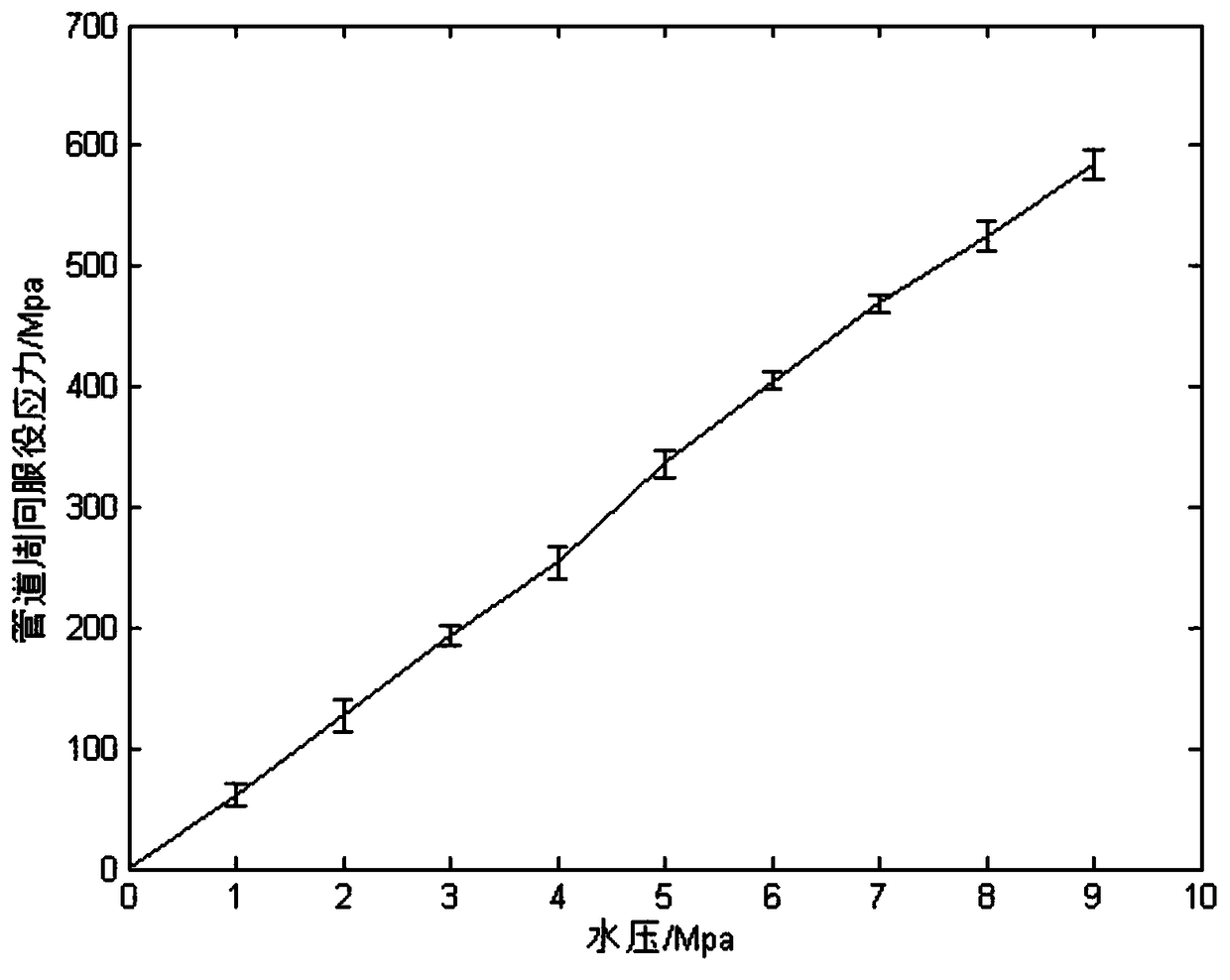

[0028] Step 1, selecting a material with the same metallographic structure and surface roughness as the tested pipeline 4 as a tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com