A kind of titanium alloy fine blanking forming method

A titanium alloy and fine blanking technology, applied in the direction of design optimization/simulation, special data processing applications, etc., can solve the problems of damage to the fatigue life performance of titanium alloy components, unsuitable for development needs, low material utilization, etc., to achieve crack suppression Produce and improve the plasticity and the effect of high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

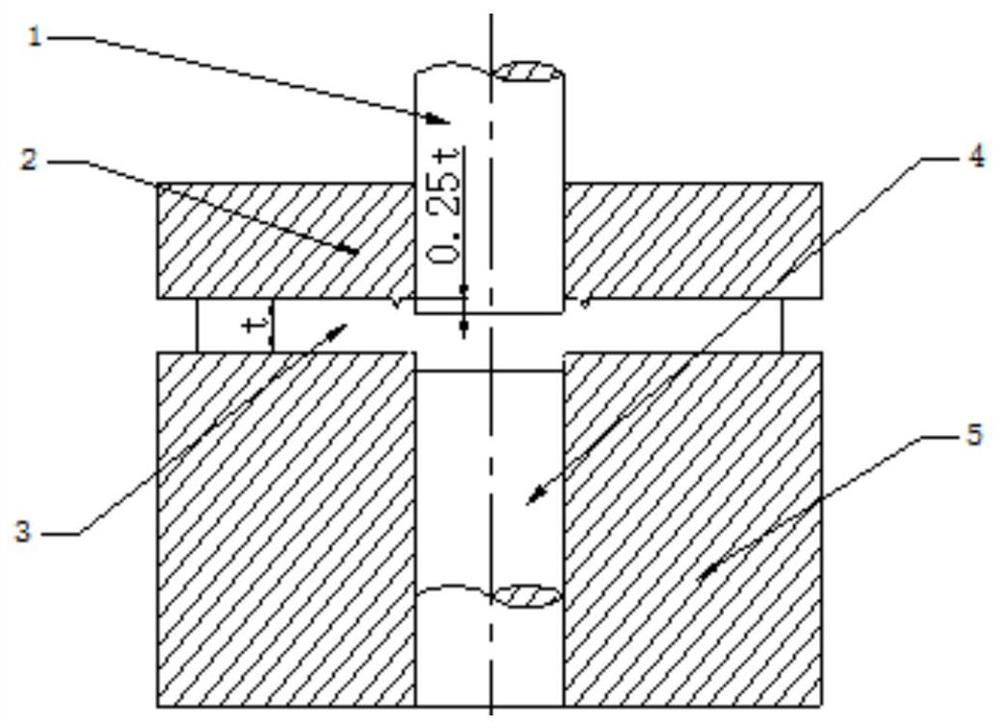

Embodiment 1

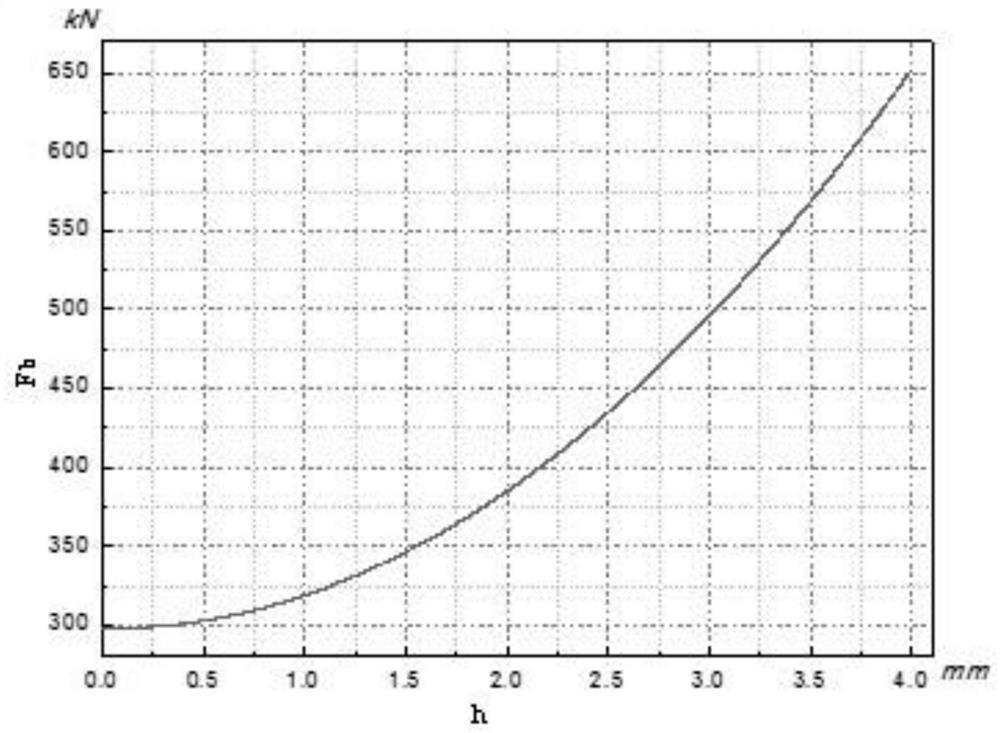

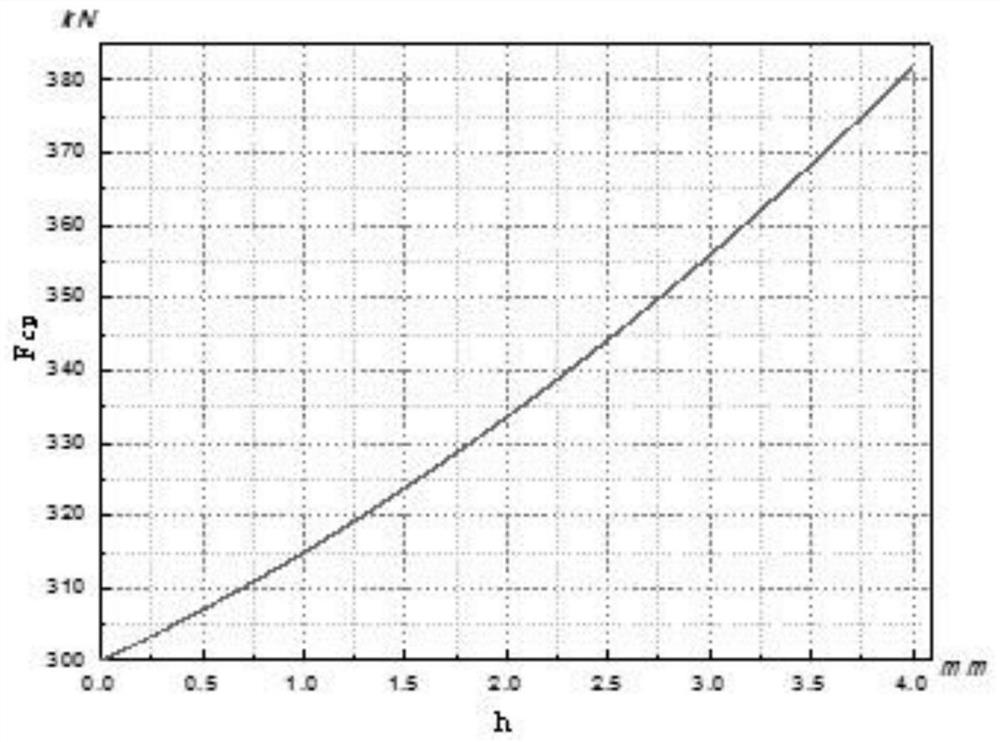

[0049] A TC4 titanium alloy sheet with a diameter of 20mm and a thickness of 4mm is punched out by a fine blanking forming process, and the tensile strength σ of the TC4 titanium alloy is obtained from the table b =1010MPa, then the punching force F under normal punching S =Ltσ b f 1 =2.2×10 5 N, blank holder force F b =L R hσ b f 2 =3.0×10 5 N, back force F cp =0.2F S =4.4×10 4 N, the initial punching speed is 15mm / s, from which the blank holder force F under this process can be obtained b (h) = 22.5h 2 -15.3h+3.0×10 5 , back force F cp =29.53h 2 -6.37h+4.4×10 4 ,The punching speed within 1mm punching stroke is 15mm / s, and the punching speed V when the punching stroke is 1-4mm p1 =9.33·h -1 +4.67.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com