Method for predicting sheet forming fractures based on damage fracture standard numerical value

A numerical prediction and criterion technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as fracture errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

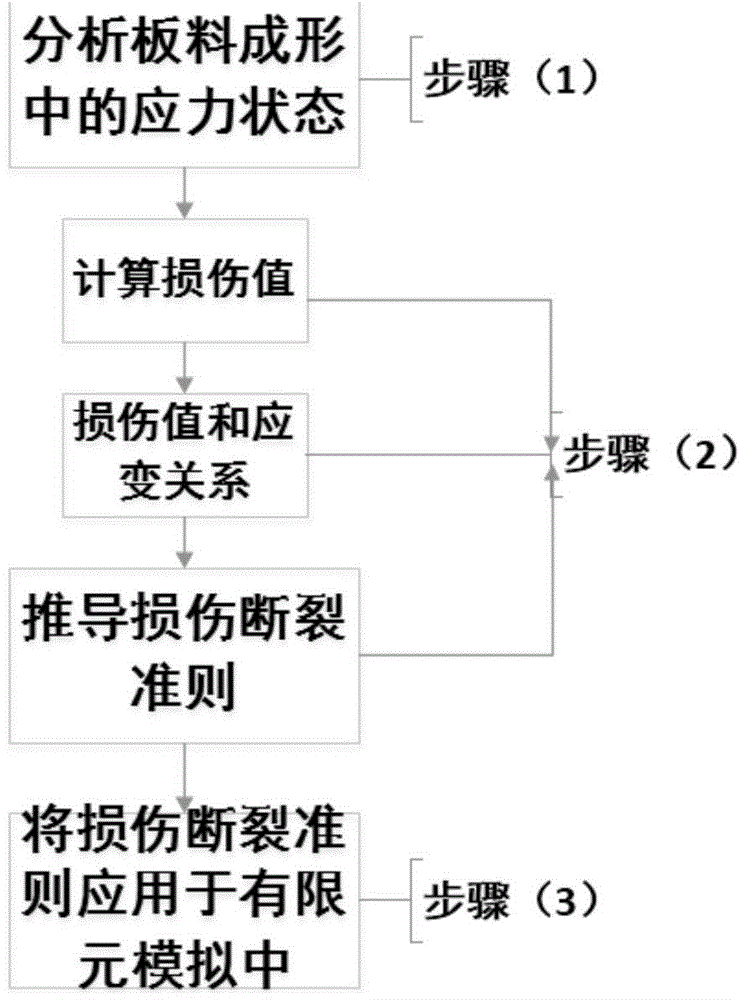

[0111] Illustrate method step of the present invention below by example:

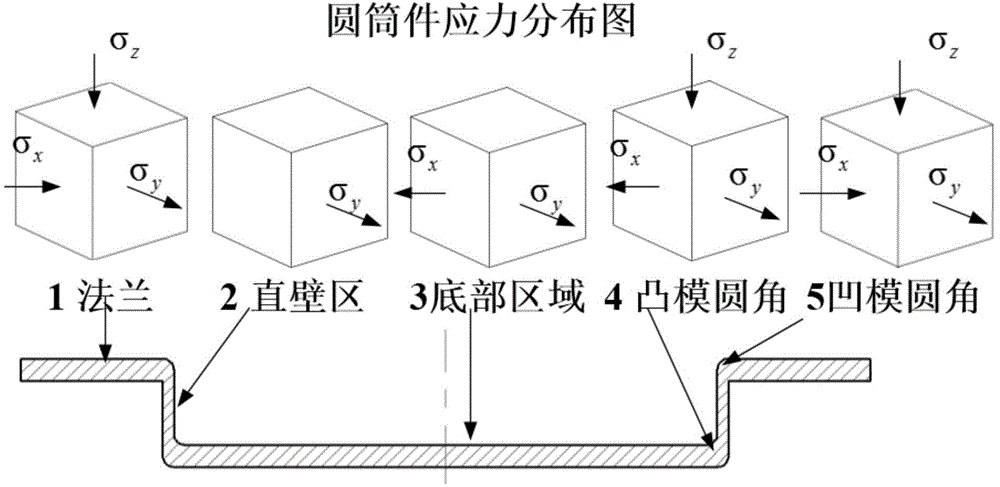

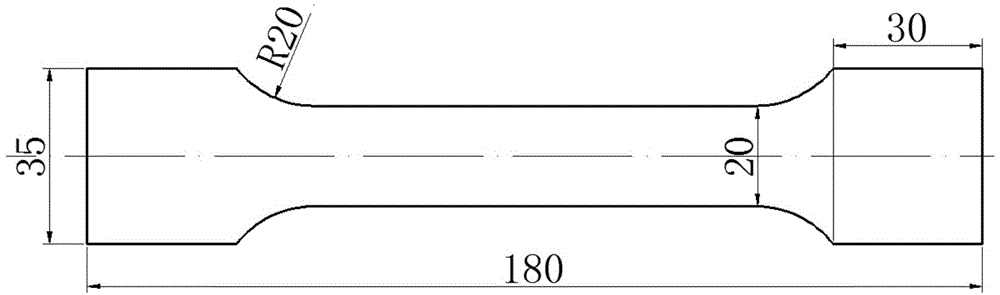

[0112] (1) The stamping experiment of metal sheet cylindrical parts is carried out on a 1000kN servo press. The diameter of the metal sheet is 180mm and the thickness is 1mm. Y-direction compressive stress load f of circle 1y With the punch pressure f 2 changes with changes, that is, f 1y =0.3f 2 . The mold parting speed adopted is 10mm / s, and the friction coefficient in the stamping experiment of metal plate cylindrical parts is lubricated with engine oil and adjusted to 0.15. The radius is 8mm, and the inner diameter of the die used is 100mm. The material of the metal sheet used is aluminum alloy 5052-O with a density of 2700kg / m 3 , the elastic modulus E is 70GPa, and Poisson's ratio is 0.33. During the stamping process of sheet metal cylindrical parts, the sheet is subjected to four surface forces, and the balance differential equation of stress can be obtained as follows:

[0113] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com