Patents

Literature

83results about How to "Avoid trial and error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

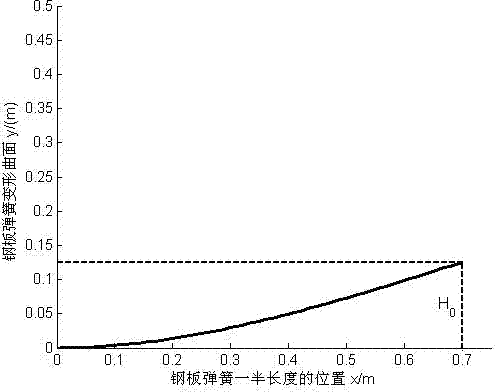

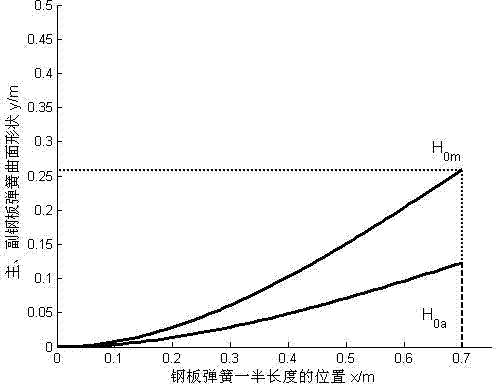

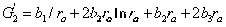

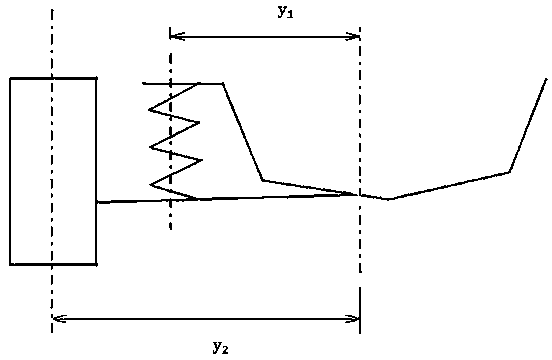

Analytical design method of camber and surface shape of automobile plate spring

InactiveCN102734364AAccurate and reliable designAvoid trial and error and modificationLeaf springsAutomotive engineeringSurface shape

The invention relates to an analytical design method of a camber and a surface shape of an automobile plate spring, belonging to the field of automobile springs. According to the invention, the performances of a suspension are influenced by the camber and the surface shape of the plate spring, but an accurate design method for the camber and the surface shape is not provided. According to the performance requirements of the automobile suspension on the plate spring, the analytical design method of the camber and the surface shape of the automobile plate spring can be established by using elastic mechanical theory. The analytical design method of the camber and the surface shape of the automobile plate spring, provided by the invention, is simple and reliable, and requirements of precise design of the thickness of the automobile plate spring can be satisfied by utilizing the analytical design method. The analytical design method can be used for design of the vehicle suspension plate spring.

Owner:SHANDONG UNIV OF TECH

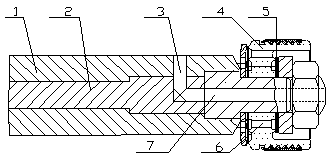

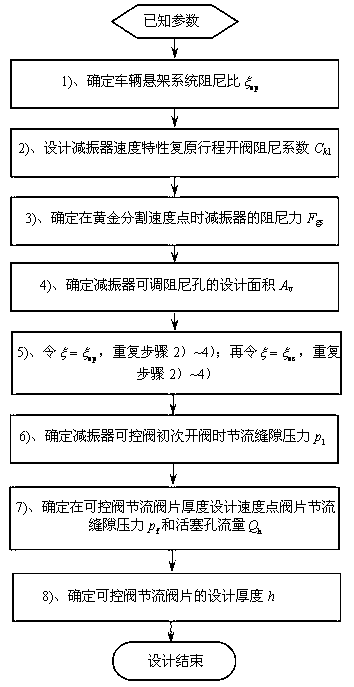

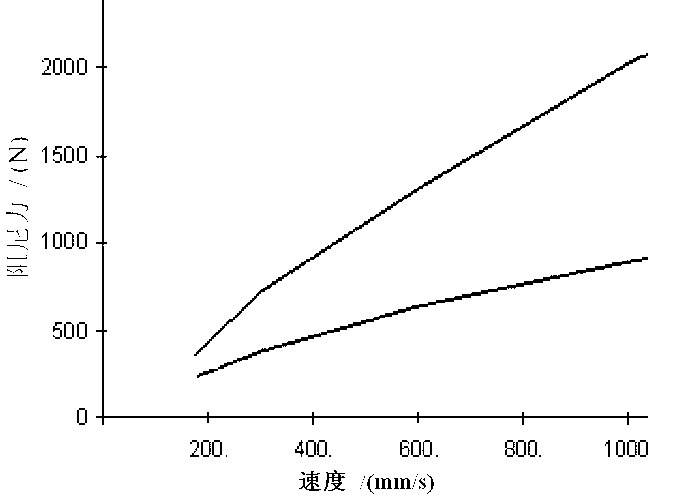

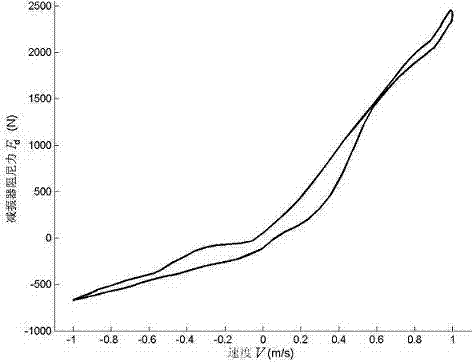

Optimal design method for parameter of controllable cylinder type hydraulic buffer of semi-active suspension

InactiveCN102840265AReduce design costShorten the development cycleSpringsShock absorbersSemi activeDamping ratio

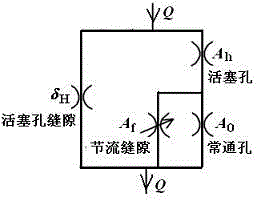

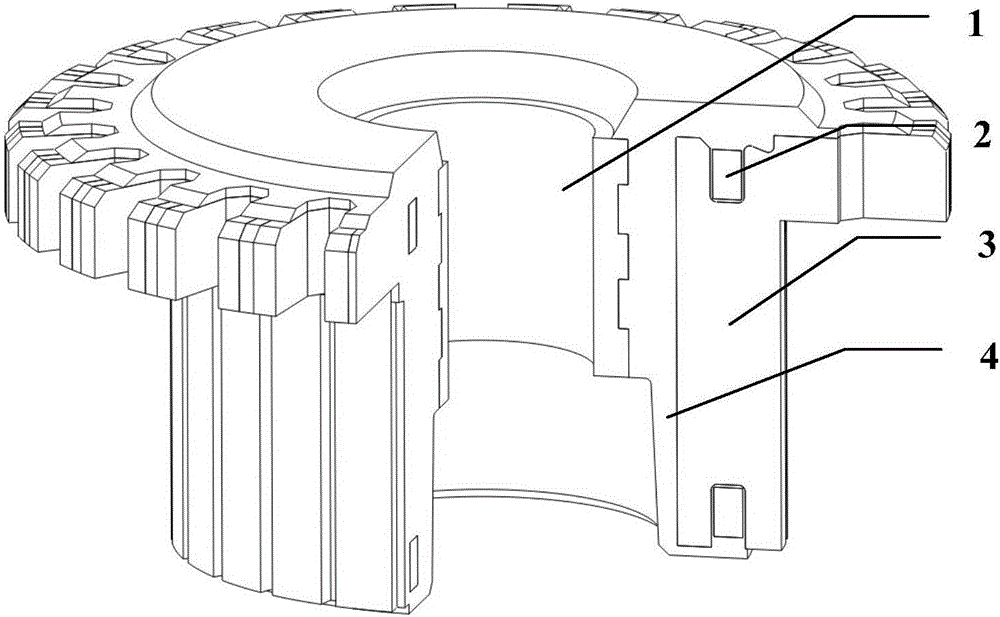

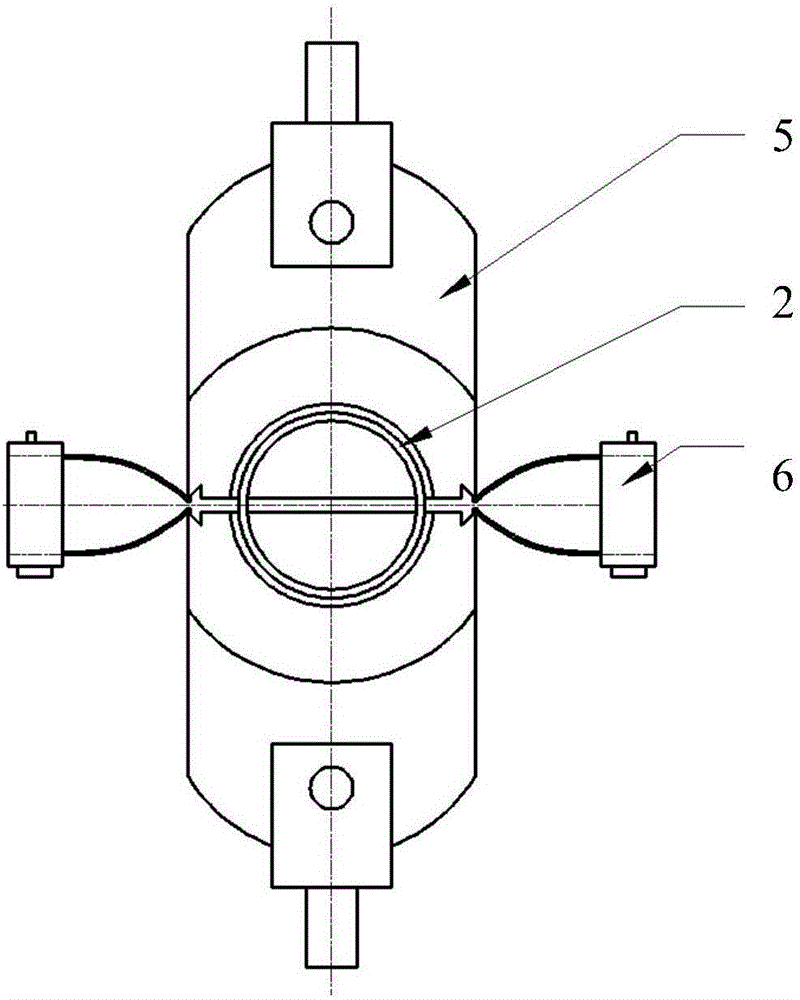

The invention relates to an optimal design method for a parameter of a controllable cylinder type hydraulic buffer of a semi-active suspension. The optimal design method is characterized by adopting the following steps: 1), determining the damping ratio of a vehicular suspension system; 2), designing an open valve damping coefficient of a buffer speed property recover route; 3), determining the damping force of the reducer at a golden cutting speed point; 4), determining the design area of an adjustable damping hole of the reducer; 5), repeating the steps 2) to 4), calculating the adjustable damping hole area required by the thickness of the design valve block is calculated; repeating the steps 2) to 4) again, and calculating the minimum area of the adjustable damping hole; 6), determining the throttle seam pressure when a controllable valve of the buffer is opened at the first time; 7), determining the throttle seam pressure and the piston hole flow rate at the thickness designed speed point of the controllable valve throttle valve block; 8), determining the design thickness of the controllable valve throttle valve block. By adopting the design method, the design value of the valve parameter is exact and reliable; the repeatedly test and modification are avoided; the design cost of the controllable buffer is reduced; and the development cycle of the buffer is shortened.

Owner:SHANDONG UNIV OF TECH

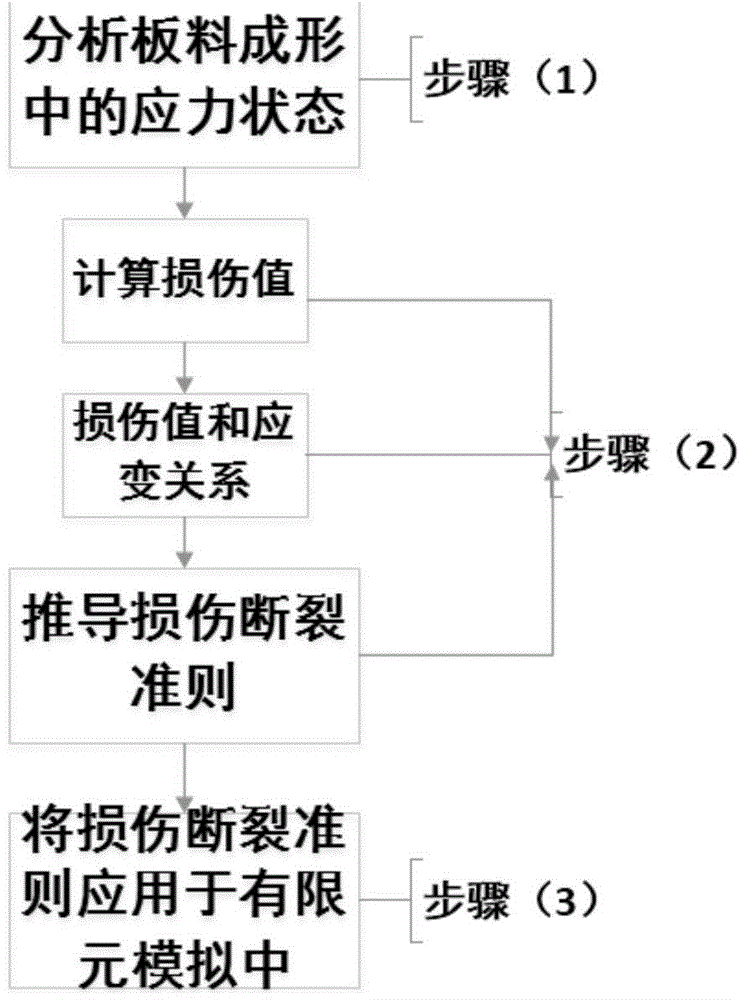

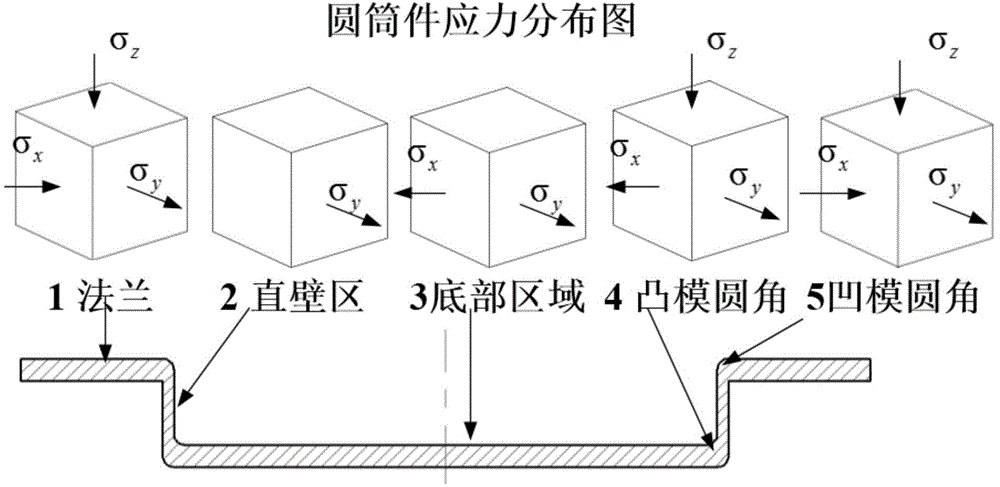

Method for predicting sheet forming fractures based on damage fracture standard numerical value

ActiveCN104636539AReduce mistakesAccurate timeSpecial data processing applicationsContinuum damage mechanicsEngineering

The invention discloses a method for predicting sheet forming fractures based on a damage fracture standard numerical value. The method includes the steps of obtaining the stress state distribution of a metal sheet cylindrical piece in the stamping process according to the thermodynamics irreversible law, obtaining a stress balance differential equation of the metal sheet cylindrical piece in the stamping process according to the stress state distribution, calculating the change rate, occurring when the metal sheet cylindrical piece is damaged, of the area of a small unit of the metal sheet cylindrical piece in the stamping process according to the continuum damage mechanics theory, obtaining the damage to the metal sheet cylindrical piece according to the change rate, calculating the relation between the damage and the strain of the metal sheet cylindrical piece, and finally deriving the relation between the damage value and the true stress, true strain and hydraulic stress of the metal sheet cylindrical piece under the unidimensional scale in the whole stamping process. By means of the method, the technical problem that when fractures during sheet forming are predicted through an existing numerical value method, errors are large can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH

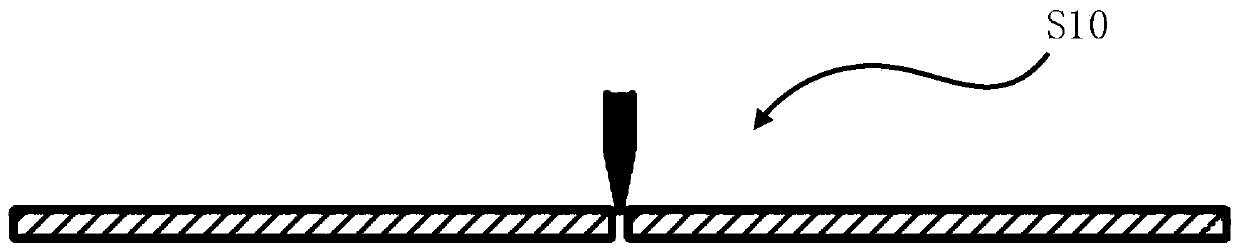

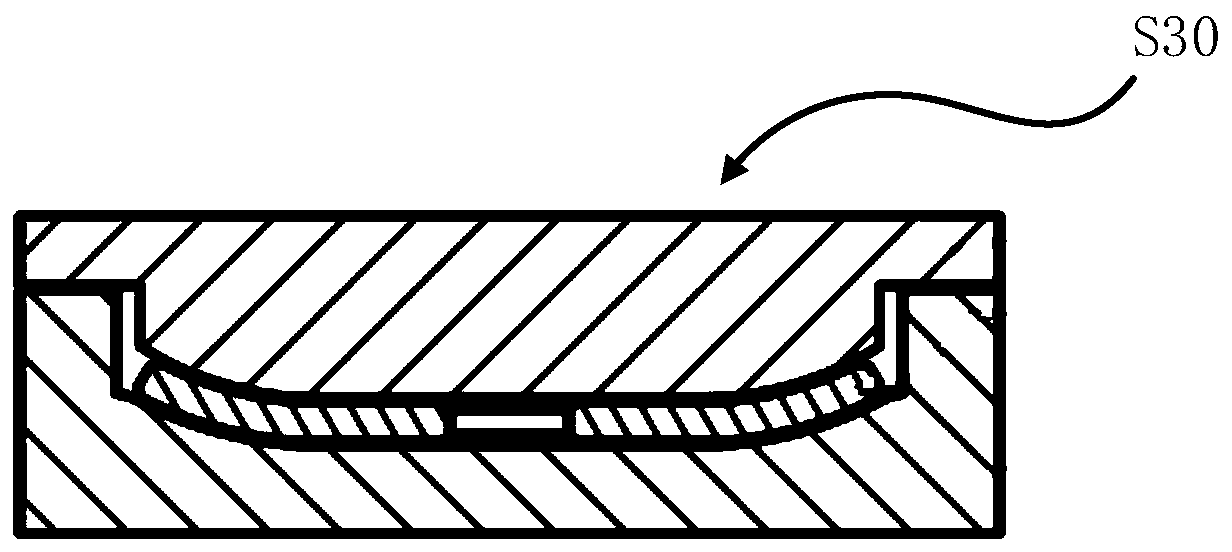

Method for manufacturing 3D glass

InactiveCN109824249AReduce development difficultyShorten the development cycleGlass reforming apparatusGlass severing apparatusWork in processLaser cutting

The invention discloses a method for manufacturing 3D glass, which comprises the following steps: step 1, cutting a large glass base material into small pieces of glass with preset sizes; step 2, placing the small pieces of glass in a mold, bending and adhering the small pieces of glass on a concave surface of the mold by vacuum adsorption at a glass hot bending temperature after the small piecesof glass are softened to form a 3D glass blank; step 3, performing laser cutting on the 3D glass blank to form a 3D glass semi-finished product; step 4, performing CNC polishing and chamfering on the3D glass semi-finished product to obtain the 3D glass; step 5, performing sweeping treatment on the surface of the 3D glass.According to the method for manufacturing the 3D glass, the required 3D glass appearance is directly formed by forming the glass with reserved processing allowance and laser cutting the appearance after forming, so that the development process of reverse derivation and repeated tests is avoided, the development difficulty of large-angle new products is reduced, the development period is shortened, the product yield is improved, and the cost is reduced.

Owner:TOMI CHENGDU APPLIED TECH RES INST CO LTD

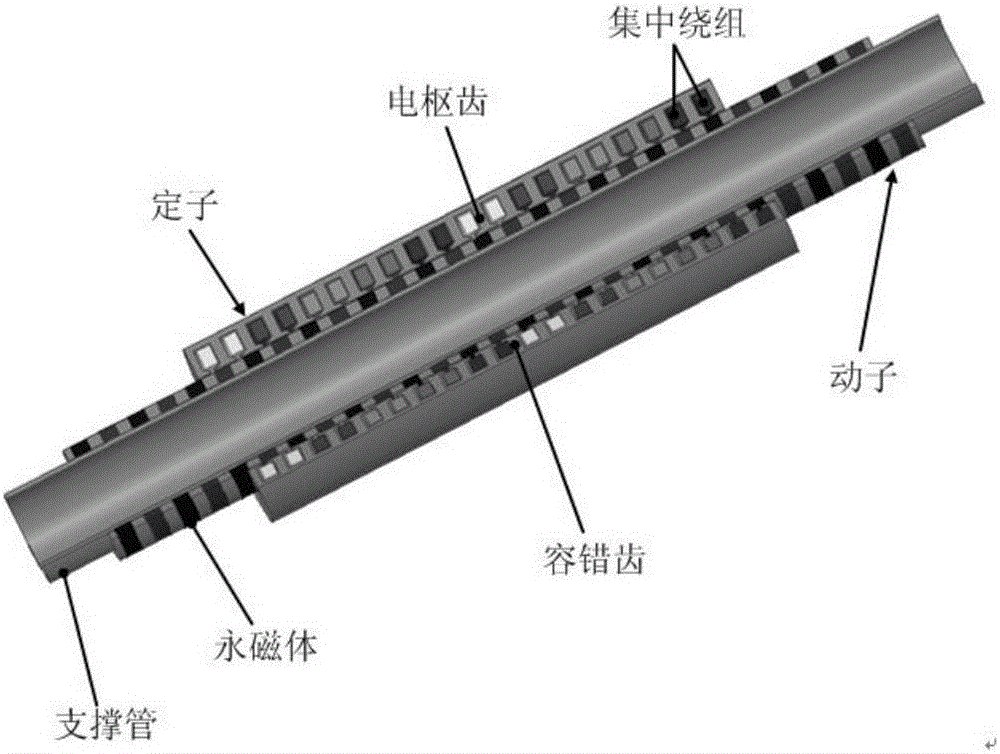

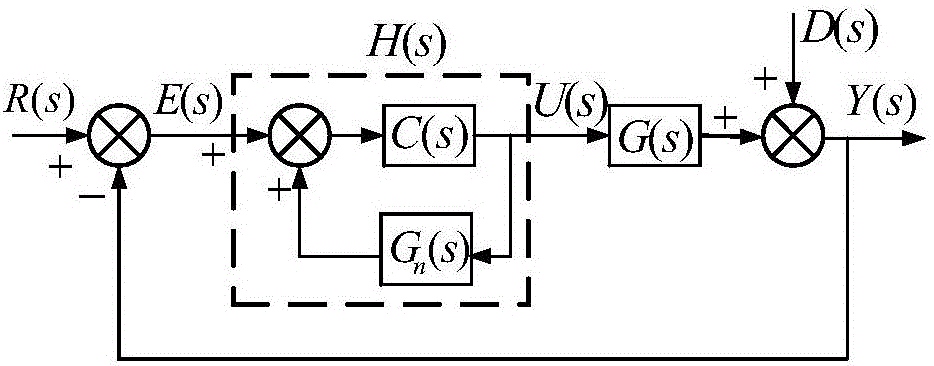

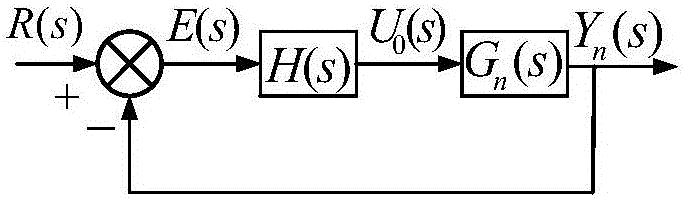

Internal-model-based sliding mode control method capable of inhibiting mismatching disturbance of permanent magnet linear motor

InactiveCN106849791ASuppress chatterNo steady state errorElectronic commutation motor controlAC motor controlMathematical modelVoltage source inverter

The invention discloses an internal-model-based sliding mode control method capable of inhibiting mismatching disturbance of a permanent magnet linear motor. The internal-model-based sliding mode control method includes the steps that a five-phase fault-tolerant permanent magnet cylindrical linear motor model with mismatching disturbance is set up; an internal model controller of an ideal system is designed by adopting an internal model control strategy; based on the motor second-order mathematic model, mismatching disturbance observers are designed to observe mismatching disturbance of a motor system; two kinds of mismatching-disturbance-based observers are designed, the sliding mode control rules (the symbol is shown in the description) of the system under the two methods are solved; the expression (the symbol is shown in the description) is equivalently transformed to contain system mismatching disturbance errors, the Lyapunov function is selected, and the obtained sliding mode control rules (the symbol is shown in the description), a d-axis voltage set value (the symbol is shown in the description), an x-axis voltage set value (the symbol is shown in the description) and a y-axis voltage set value (the symbol is shown in the description) are used for achieving high-performance operation of the internal-model-based sliding mode control system capable of inhibiting mismatching disturbance of the fault-tolerant permanent magnet cylindrical linear motor by means of a voltage source inverter through a CPWM modulation method, wherein the d-axis voltage set value, the x-axis voltage set value and the y-axis voltage set value are output by a PI current regulator.

Owner:JIANGSU UNIV

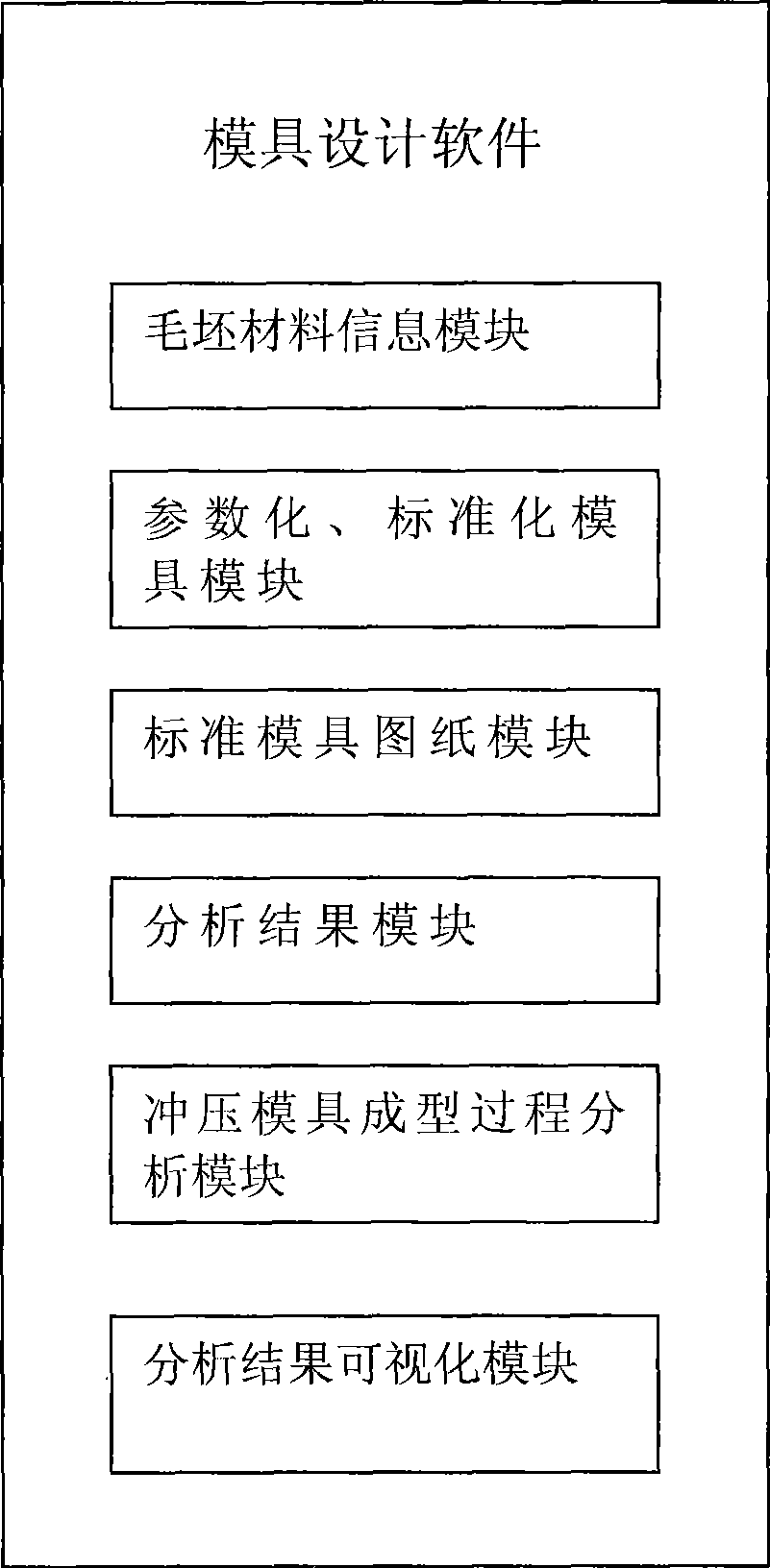

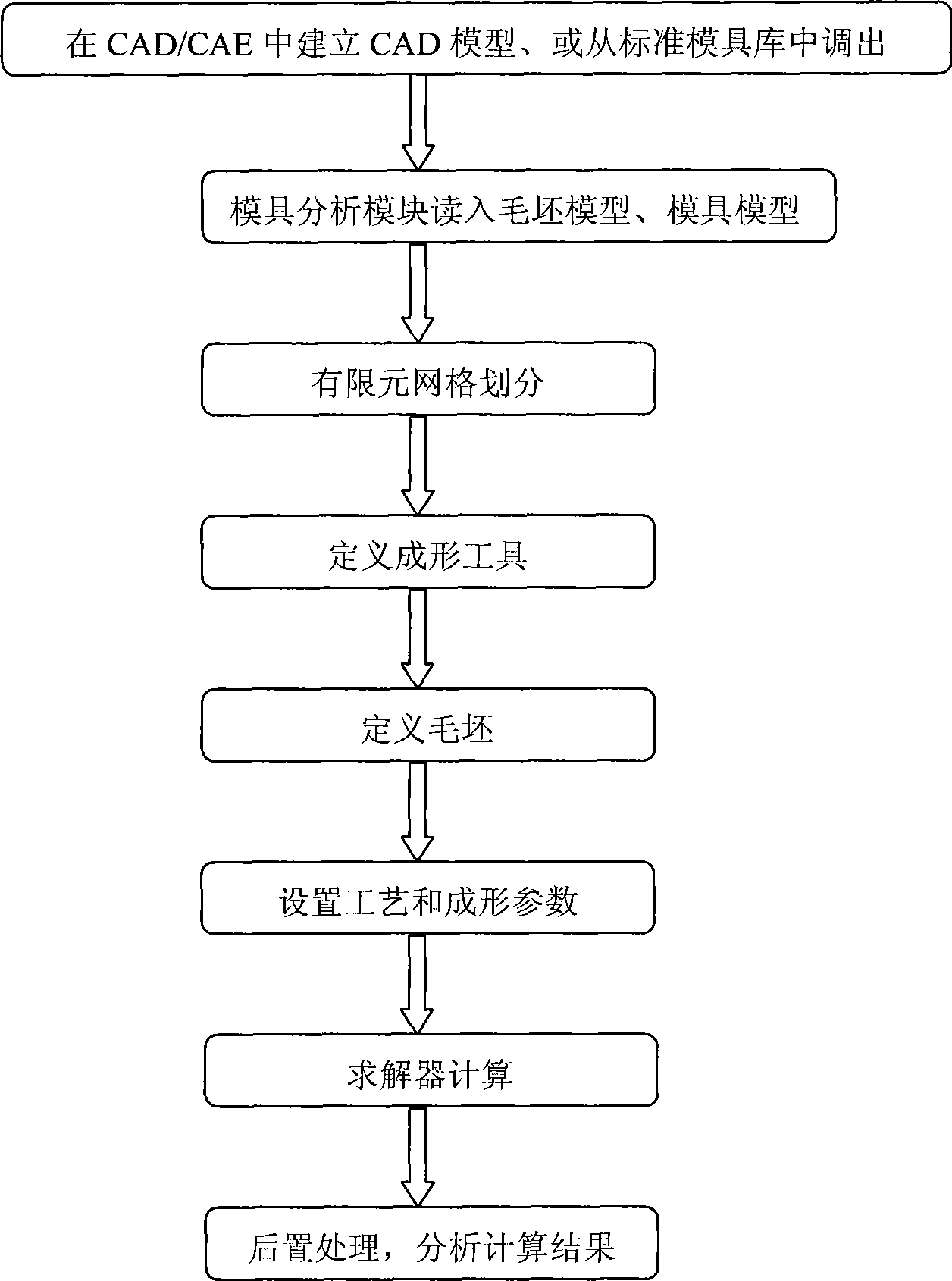

System and method for designing aerial fog jug forming and punching mold

InactiveCN101398865ARapid designEfficient designSpecial data processing applicationsPunchingRelevant information

A shaping-punching die designing system of a gas spray tank includes a blank material information module used for storing the relevant information of various blank materials, a parameterization and standardization die module used for storing the three dimensional and two dimensional die pictures of each part for manufacturing the gas spray tank; a standard die drawing module used for storing the three dimensional and two dimensional die pictures as well as the production assembling pictures of the dies during the working procedures for manufacturing each part of the gas spray tank in the actual production process; an analyzing result module used for storing the structural design picture of the original die during the shaping process for manufacturing different gas spray tank and the corresponding simulation analyzing result as well as the structural design information during the shaping process of a new gas spray tank and the analyzing result information whether the die structure of the shaping process has problems or not; the invention relates to a method for calculating the plastic deformation process of the blanks and the movement rule of a punch-die during each working procedure of punching and shaping of the top cover and the bottom cover of the gas spray tank as well as a method for designing the shaping-punching die of the gas spray tank. The invention fast and effectively reduces the cost by optimizing the die structure through a computer.

Owner:ZHEJIANG UNIV OF TECH

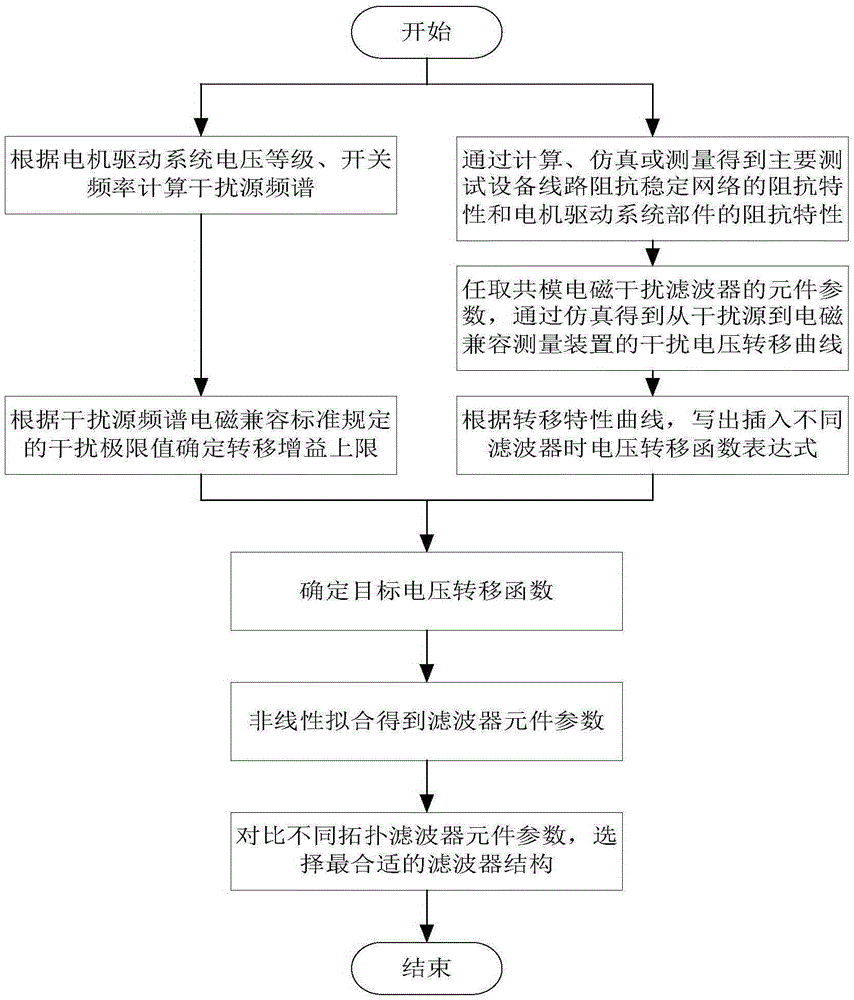

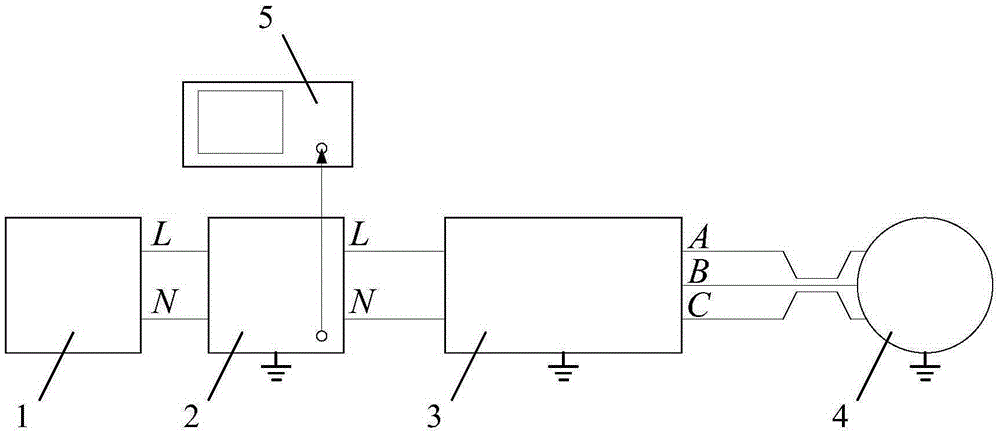

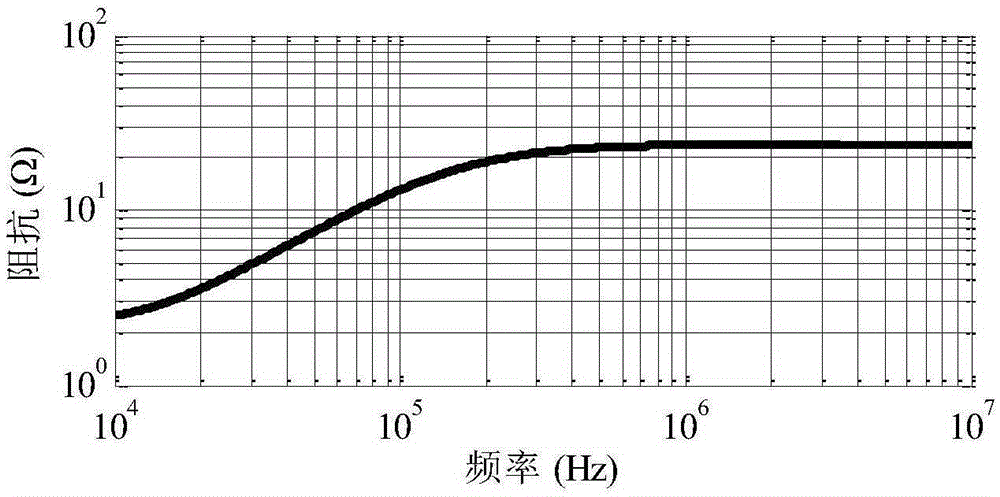

Design method for common-mode electro-magnetic interference filter for motor drive system

ActiveCN105354397AAvoid trial and errorAvoid over-engineeringSpecial data processing applicationsFrequency spectrumMinimum deviation

A design method for a common-mode electro-magnetic interference filter for a motor drive system is disclosed. The common-mode filter is designed based on a transfer function; a common-mode interference source, an interference transmission path and sensitive equipment impendence are taken into consideration quantitatively in topology selection and parameter design of the filter; a target voltage transfer function of different filter topologies is determined according to a reference limit value specified by a voltage source frequency spectrum and electromagnetic compatibility standard firstly; then a filter element value for enabling a minimum deviation between the filter design transfer function and the target transfer function is determined based on a nonlinear least square method; and filter structure and elements finally adopted by the motor drive system are determined according to realizability and operability.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

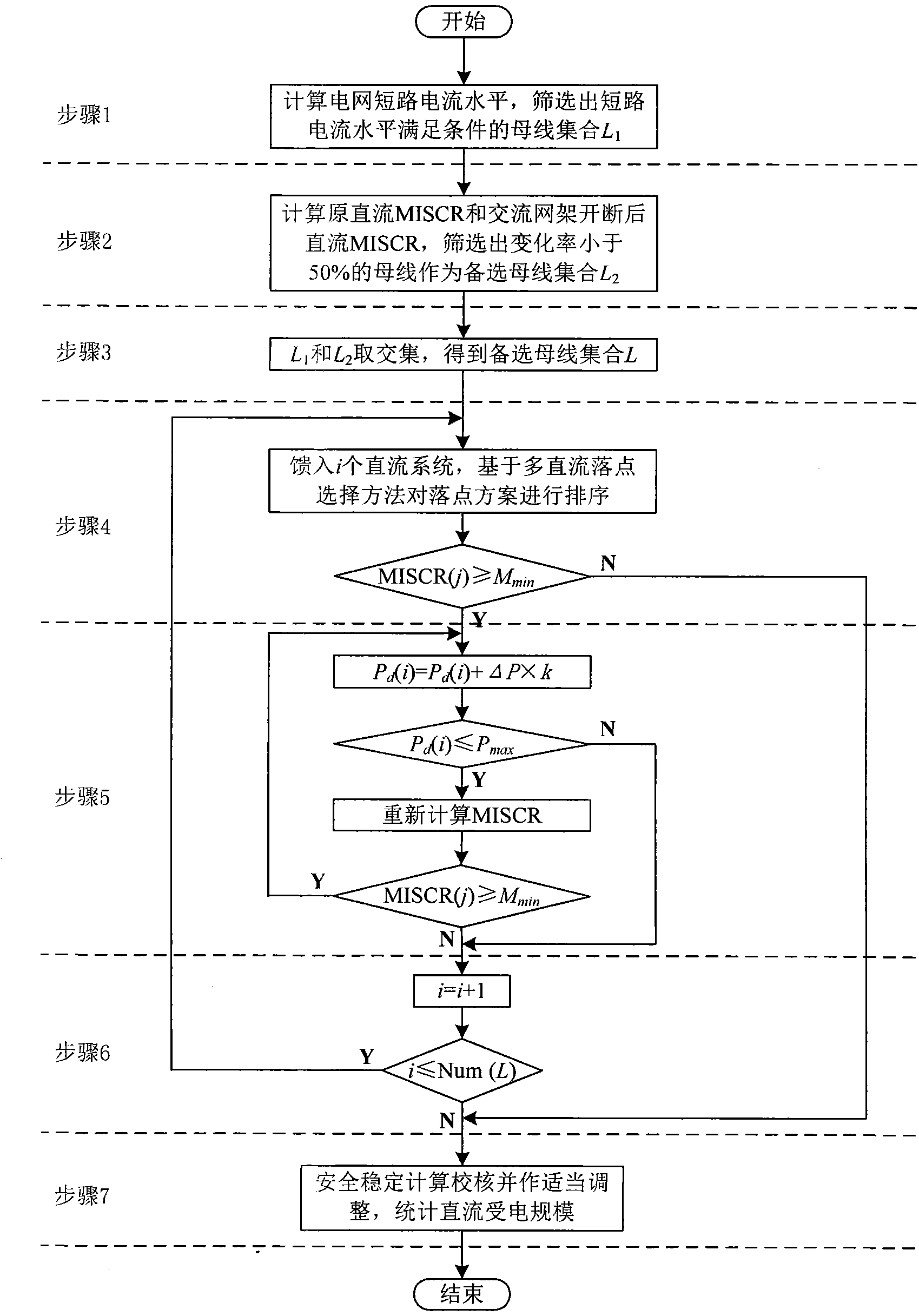

Alternating-current receiving end grid direct-current receiving scale calculation method

ActiveCN103986151ACalculation method is simpleThe calculation method is practicalDc network circuit arrangementsSpecial data processing applicationsElectricityOperability

The invention provides an alternating-current receiving end grid direct-current receiving scale calculation method. The method comprises the following steps: 1, a set L1 in which the short-circuit current level satisfies set conditions is obtained; 2, a bus set L2 in which the influences of the disconnection of an alternating-current circuit connected with some bus on direct-current system MISCR are less than set influences is screened out; 3, an intersection set L of the set L1 and the set L2 is obtained; 4, any i buses are selected from the set L so as to be fed into the direct-current system, and each direct-current MISCR value in the optimal scheme is judged whether to be less than the minimum limit value, if each direct-current MISCR value in the optimal scheme is less than the minimum limit value, then the process enters the step 5, or else the process enters the step 7; 5, the direct-current system maximum power value which can be accepted on the i direct-current fall point buses is calculated in the condition that the MISCR value of the direct-current system is not less than the minimum limit value and the direct-current power does not exceed the maximum power limit value; 6, i=i+1, and when i is judged to exceed the total number of elements, the step 7 is executed, or else, the step 4 is executed; 7, and the alternating-current receiving end grid direct-current receiving scale is obtained. The calculation method provided in the invention has advantages of simplicity and good operability, and a direct guidance scheme can be provided for planners.

Owner:STATE GRID CORP OF CHINA +1

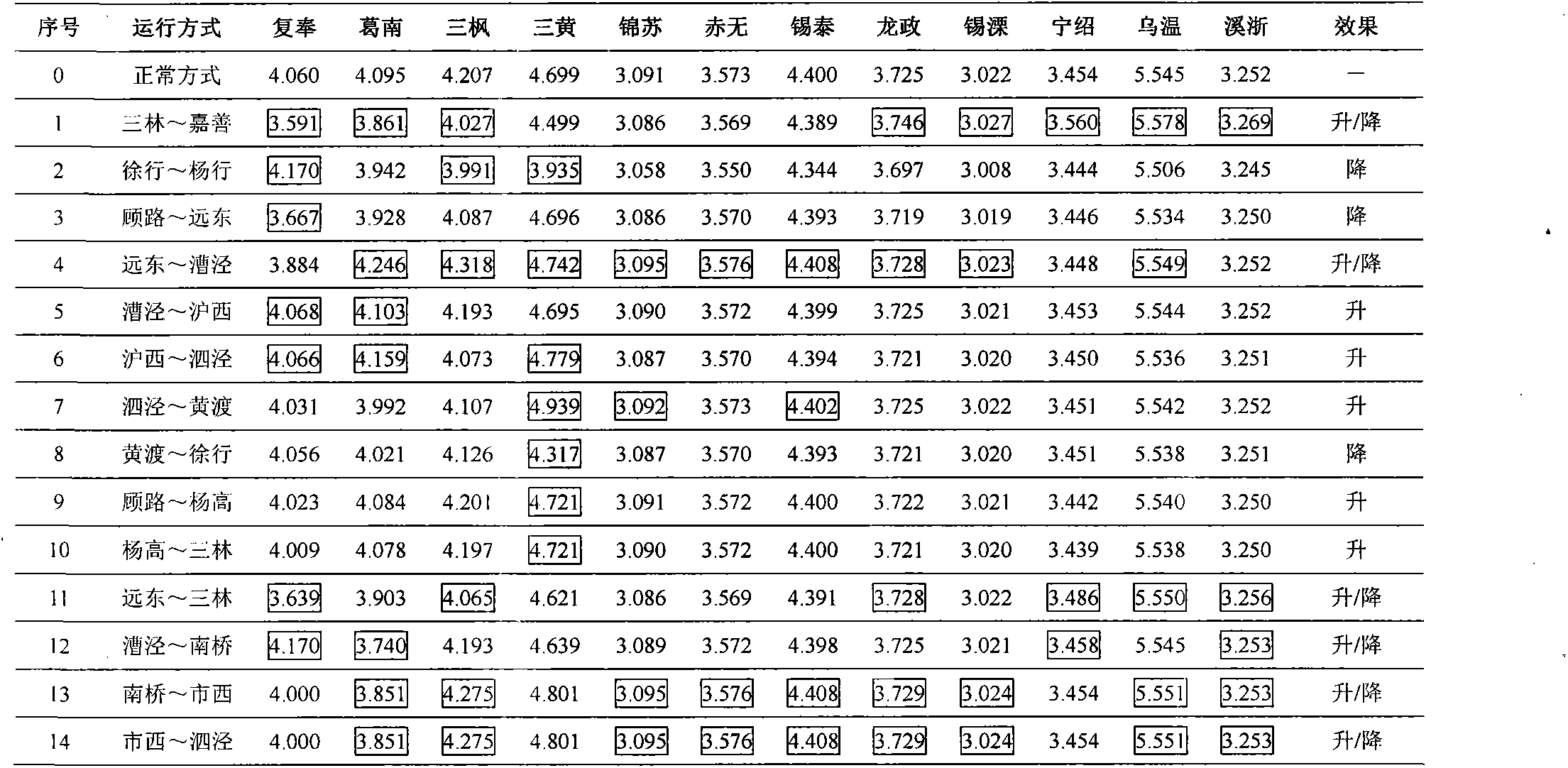

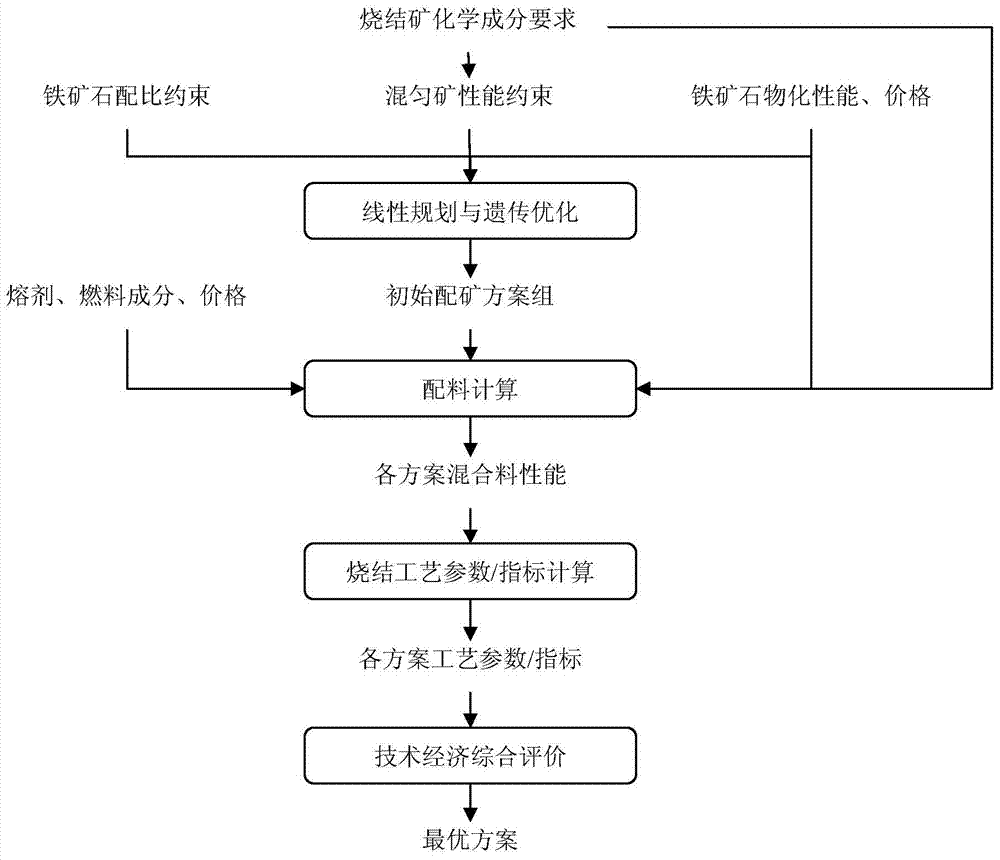

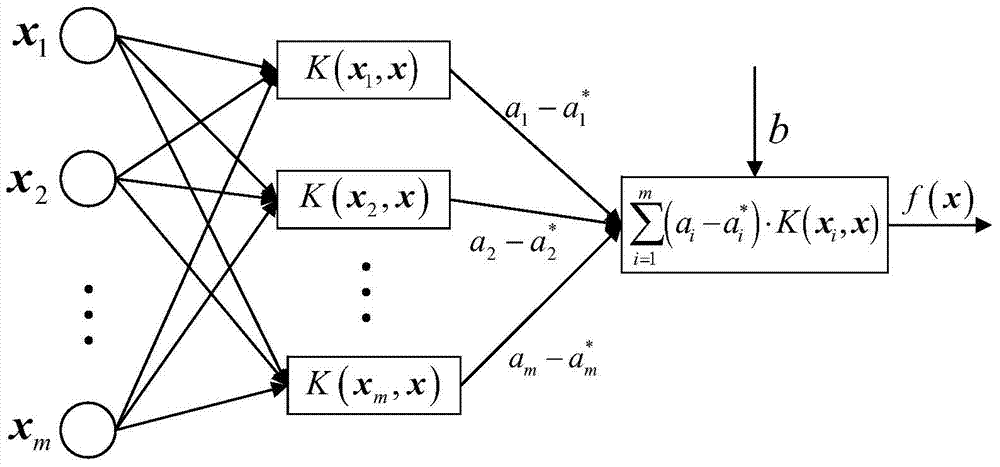

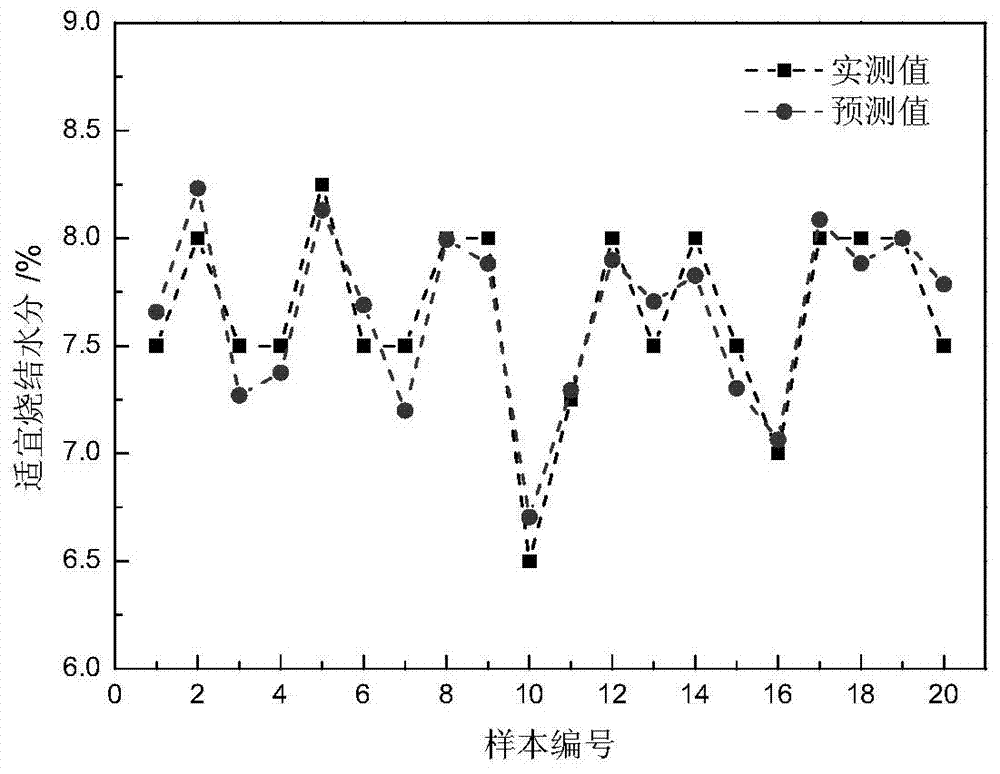

Method for calculating optimum preparing and adding proportion of iron ore sintering

The invention discloses a method for calculating the optimum preparing and adding proportion of iron ore sintering. According to the method, according to the uniformly mixed ore chemical ingredient requirements and raw material physical and chemical properties and proportioning constraints, a method of combining linear planning and a genetic algorithm is adopted for calculating an initial ore proportioning scheme group; sintering process parameters, production quality indexes and ore proportioning costs of each ore proportioning scheme are calculated; the technical economic integral evaluation index of the ore proportioning scheme is calculated according to the ore proportioning cost, the sintering solid fuel mixture ratio and the sintering ore rotating drum intensity by using the coefficient, and the highest integral evaluation index is used as the selection basis of the best ore proportioning scheme; the iron ore purchase and the sintering production are guided; the technical support is provided for the popularization and the application of new ore types.

Owner:CENT SOUTH UNIV

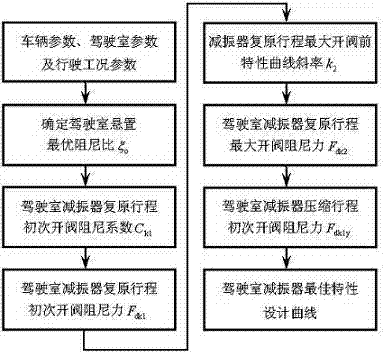

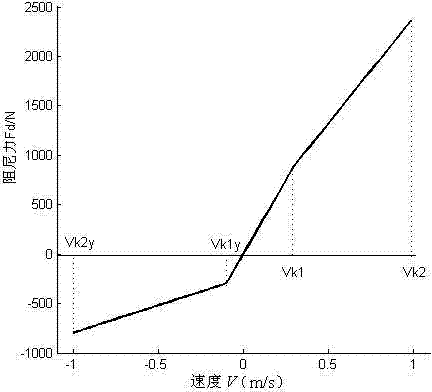

Design method for optimum speed characteristics of trunk cab damper

InactiveCN103112508ABest speed characteristicsReliable speed characteristicsLoading-carrying vehicle superstructuresDamperDamping ratio

The invention relates to a design method for optimum speed characteristics of a trunk cab damper, and belongs to the technical field of cab suspension. Because analysis and calculation of a cab three quality vibration system are very complex, none reliable design method for design of the optimum speed characteristics of the trunk cab damper exists all the time at the moment. According to the method, the three quality vibration system and an optimum damping ratio determined by the three quality vibration system are composed of wheels, a trunk body and a cab, utilizes safety ratios, bi-directional characteristics, lever ratios and installment angles of the damper to design the optimum speed characteristics of the cab damper, and obtain recovery-travel and compression-travel segmented characteristic curves required by the design. By adopting the design method, the reliable speed characteristics of the cab damper are achieved. The design of the damper can ensure that the optimum damping effects of the damper are reached, and riding comfort is satisfied. Meanwhile, repeating tests, verification and modify are avoided, and test cost of the cab damper is reduced.

Owner:SHANDONG UNIV OF TECH

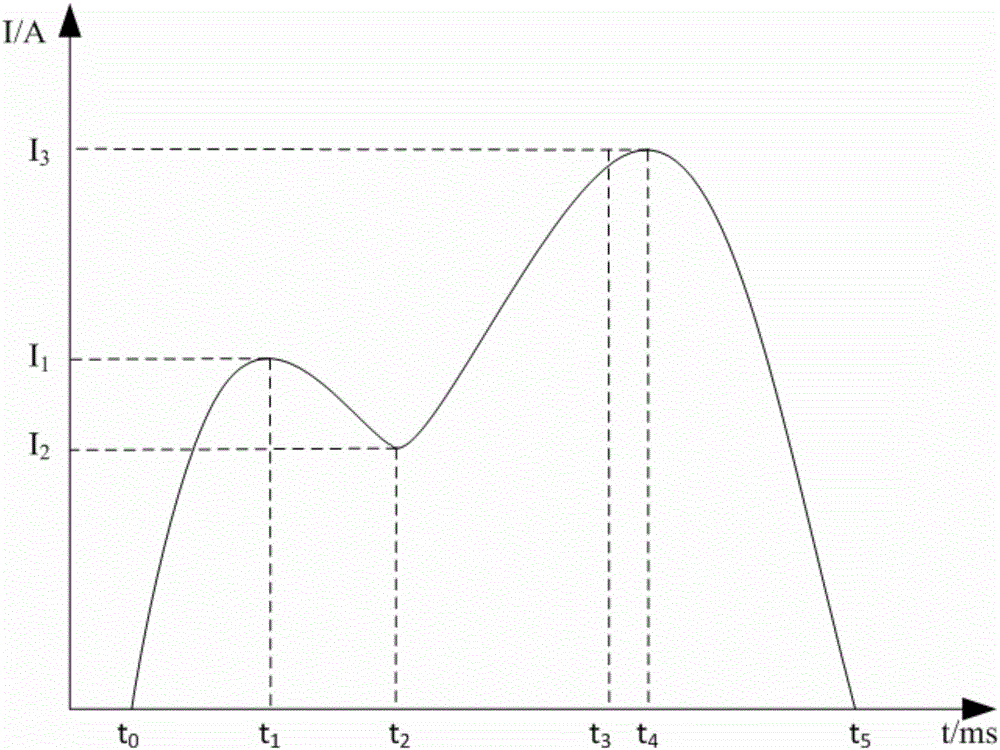

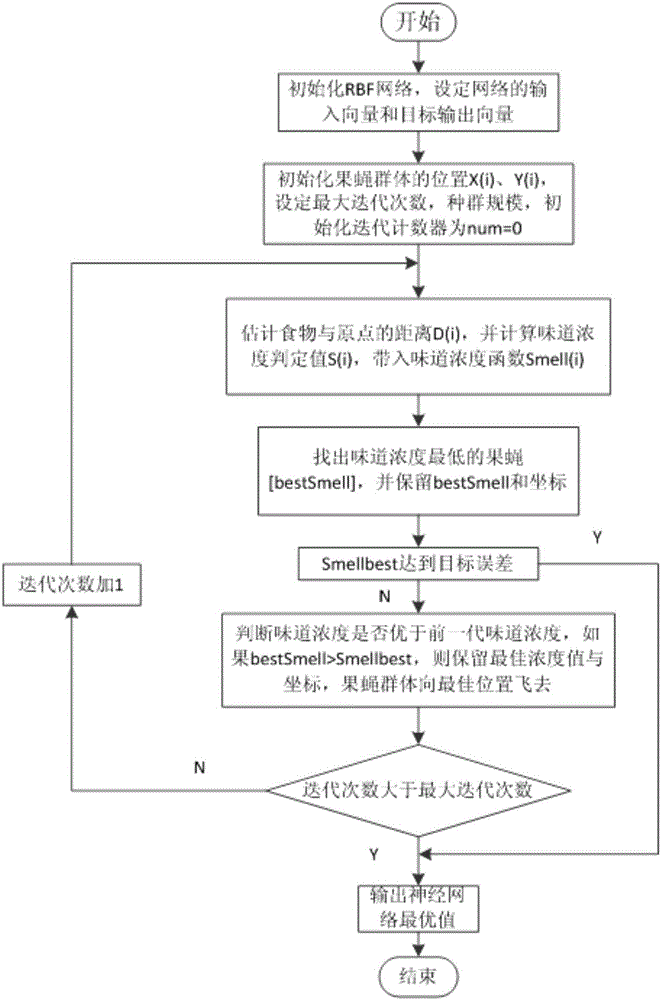

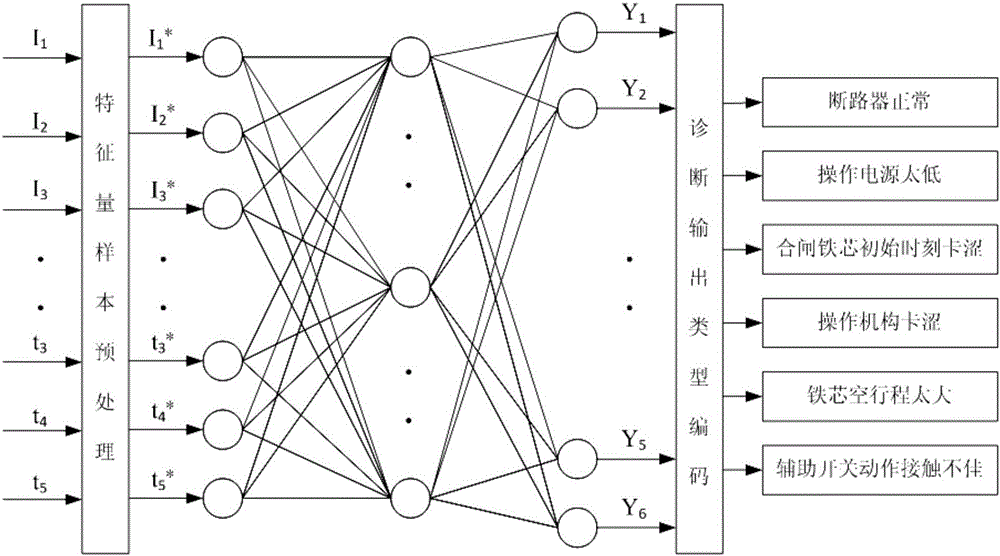

FOA-RBF based high-voltage circuit breaker fault diagnosis method

InactiveCN106707153AImprove search abilityAvoid trial and errorCircuit interrupters testingDiagnosis methodsDiagnosis Type

The invention discloses an FOA-RBF based high-voltage circuit breaker fault diagnosis method, which comprises the steps of according to the waveform, which varies along with the time, of closing current of a high-voltage circuit breaker, extracting feature variables, and selecting 24 groups of typical data to act as a feature variable sample; performing pretreatment and normalization on the feature variable sample, carrying out binary coding on six groups of diagnosis types, performing iterative optimization on a spreading parameter spread of an RBF network in the global scope, reserving an optimal spread value, and building an FOA-RBF based fault diagnosis model; selecting sample feature variables to act as input of an FOA-RBF network, enabling the six groups of diagnosis types to act as output of the FOA-RBF neural network, and performing high-voltage circuit breaker fault diagnosis. According to the FOA-RBF based high-voltage circuit breaker fault diagnosis method, an artificial intelligence method of FOA-RBF is applied to fault diagnosis for the high-voltage circuit breaker, and quick and effective detection can be performed on a fault.

Owner:BEIJING HEZONG SCI & TECH CO LTD

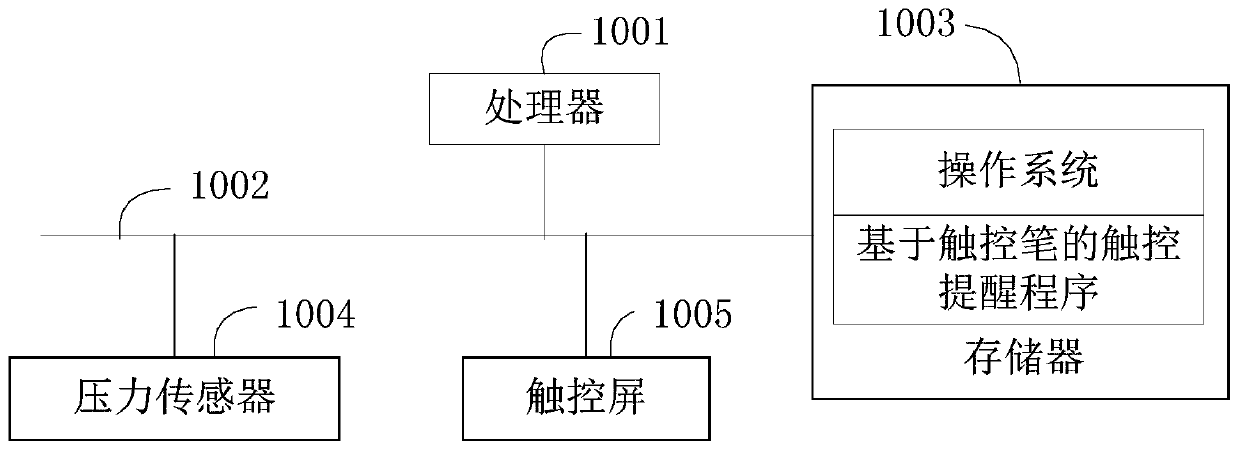

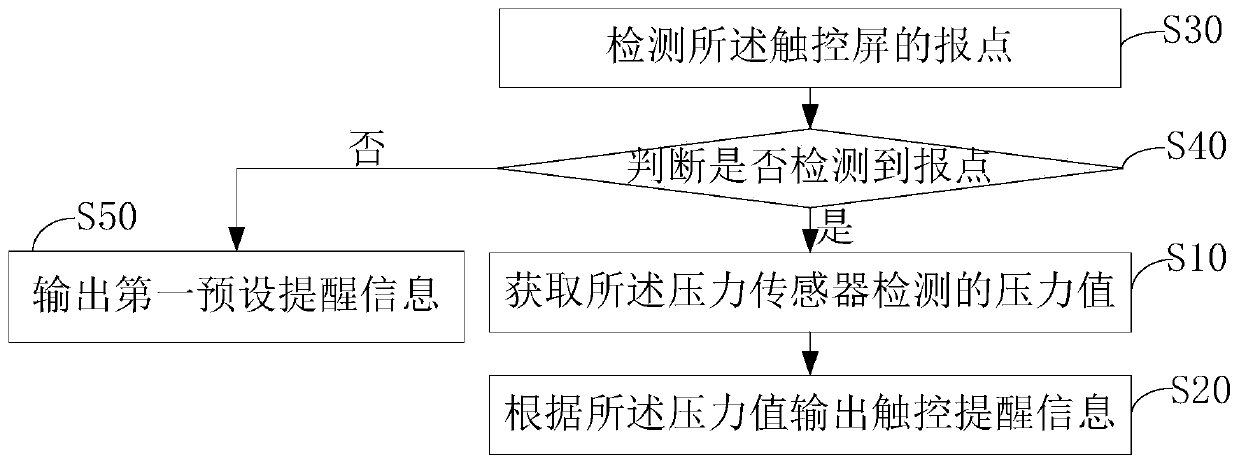

Touch reminding method based on stylus, terminal and computer readable storage medium

InactiveCN111124159AAvoid trial and errorTouch Force CorrectionInput/output processes for data processingComputer hardwareEngineering

The invention discloses a touch reminding method based on a stylus. The touch reminding method comprises the following steps: acquiring a pressure value detected by a pressure sensor; and outputting touch reminding information according to the pressure value. The invention further discloses a terminal and a computer readable storage medium. By comparing the obtained pressure value with the presetpressure value, the wrong touch strength of a user is visually and clearly reminded, so that the user masters the information of the wrong touch strength in time and corrects the wrong touch state, trial and error of the user are avoided, and the beneficial effect of saving time is achieved.

Owner:SHANGHAI TRANSSION CO LTD

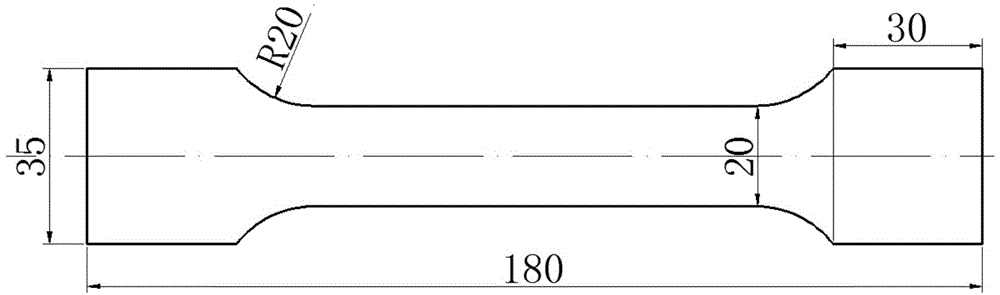

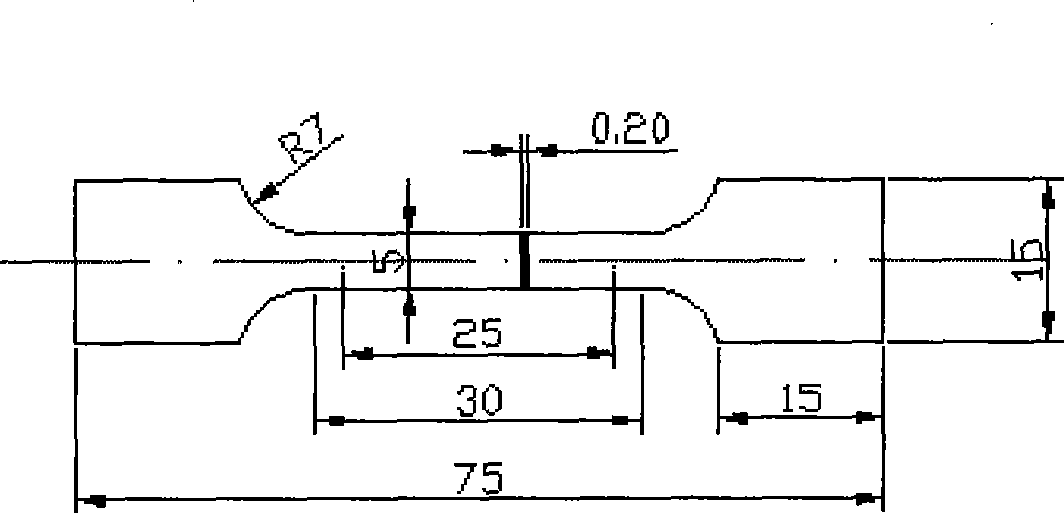

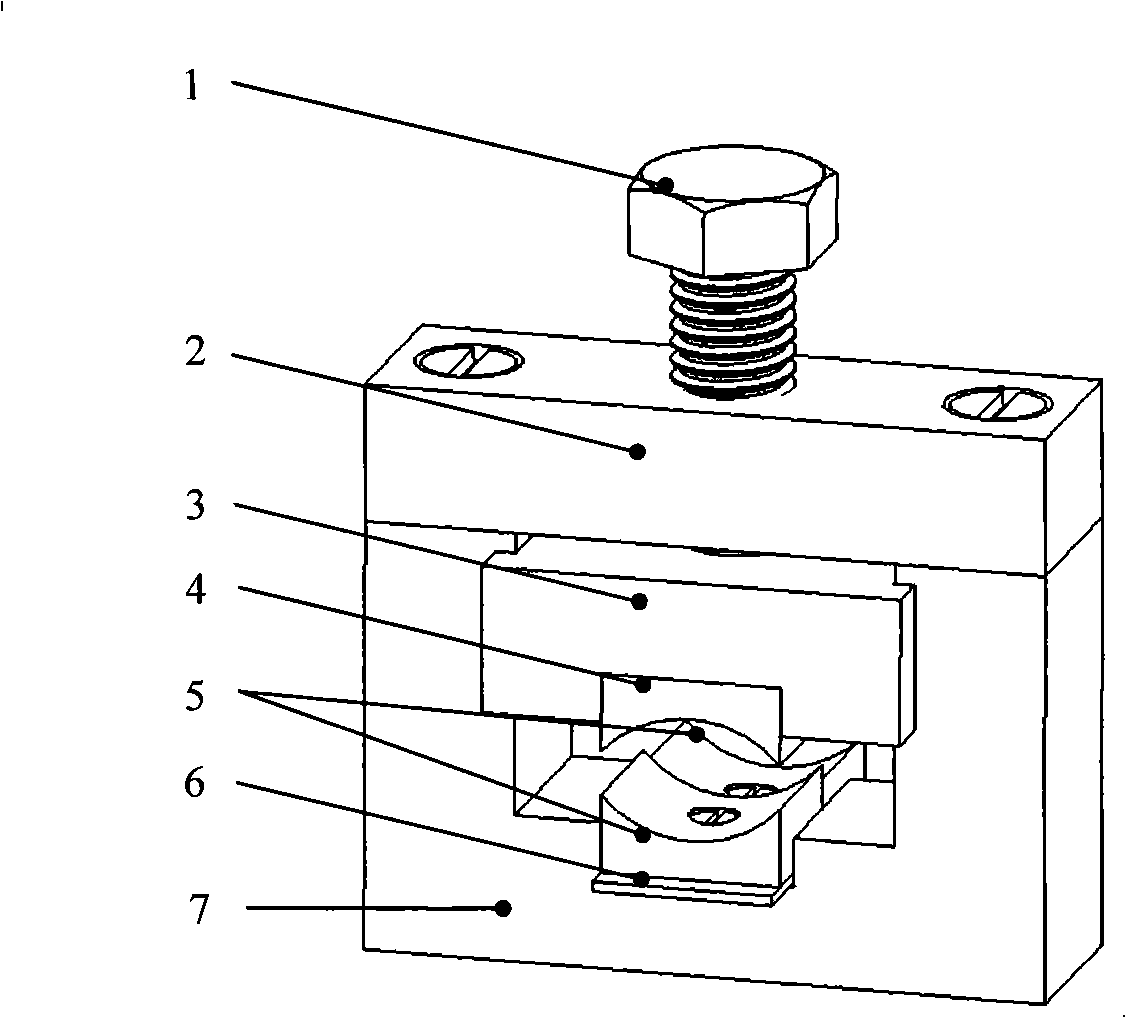

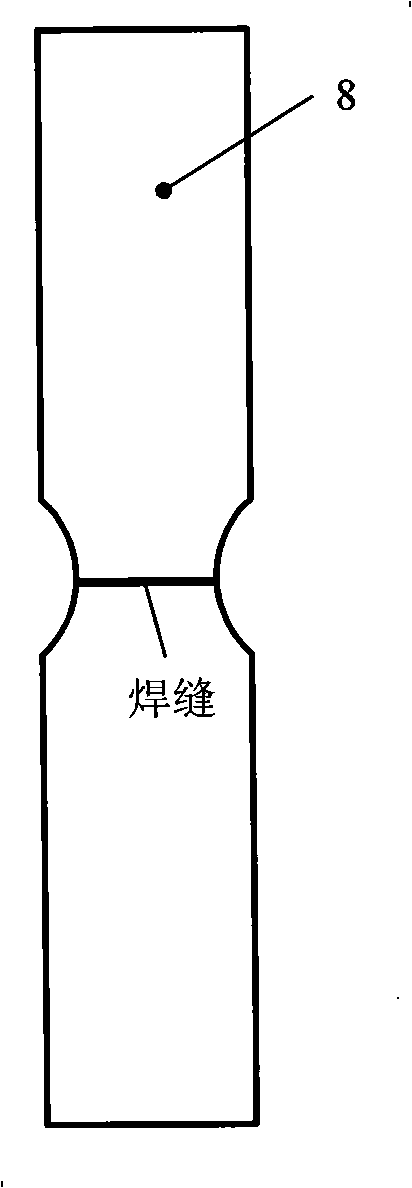

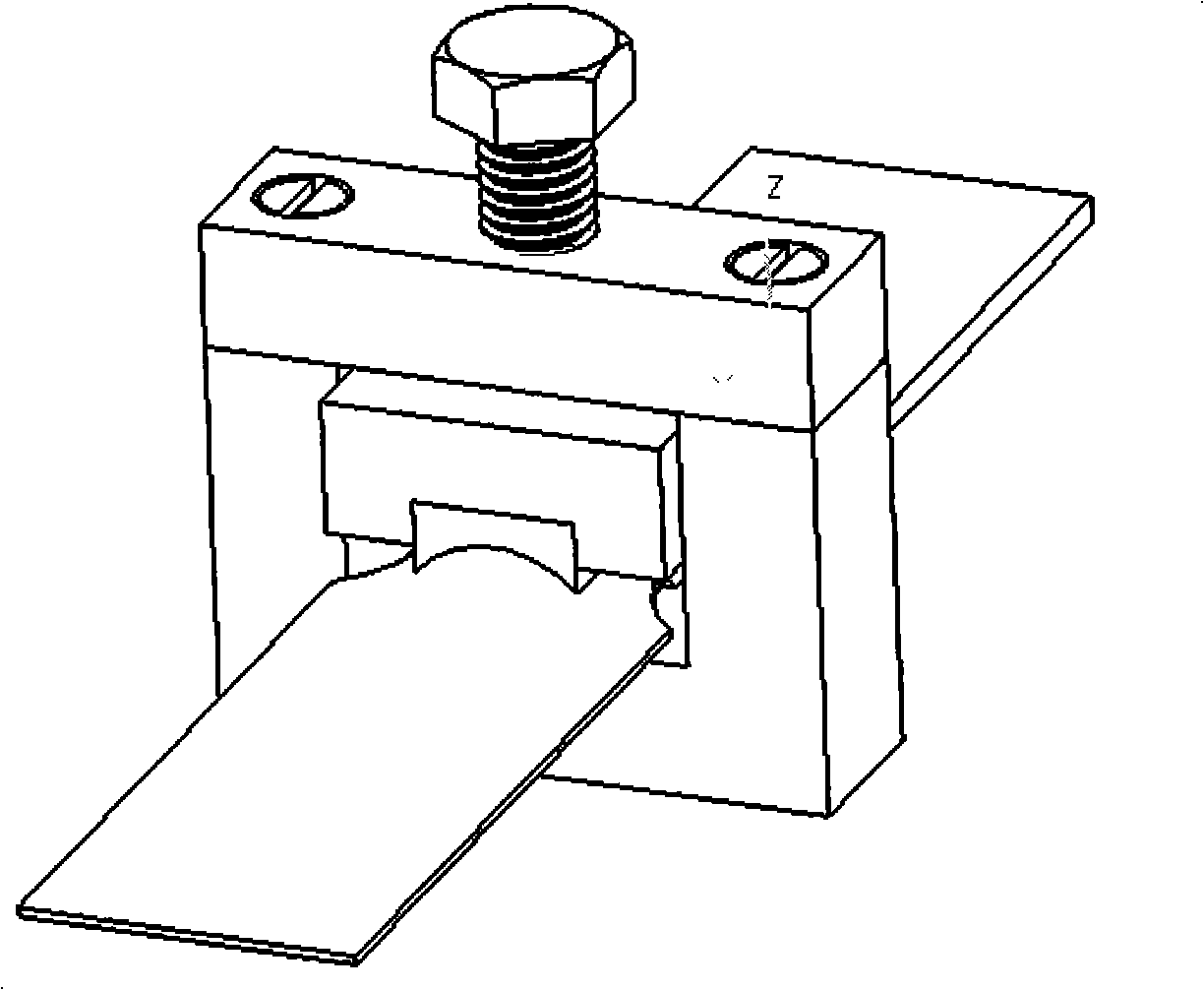

Test device and method for acquiring limit strain of laser tailor welded plate plane with different thickness

InactiveCN101294947AAccurately obtainedEasy accessTesting metalsWelding apparatusTest efficiencyLimit strain

The invention discloses a tester and method for obtaining plane limiting strain of a differential tailor welding blank; the method comprises the following steps: a splint mechanism consisting of an upper clip and a sectional lower clip, a welding blank tensile sample is positioned between the upper clip and the sectional lower clip; a height adjusting sheet is arranged between sectional lower clip and a base, the sectional lower clip and the height adjusting sheet are fixed on the base, a sliding block is arranged between the upper clip and a top pressing plate, the upper clip and the sliding block are fixedly connected by adopting a bolt passing through the middle of the top pressing plate, the tester is arranged in a conventional plate tensile test machine for uniaxial tension test and the limiting strain value is measured; the tester and method of the invention can obtain better plane strain state, have stable test result, simple structure, low test cost, simple and convenient operation, and high test efficiency and the sample is flat after the test.

Owner:JIANGSU UNIV

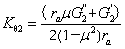

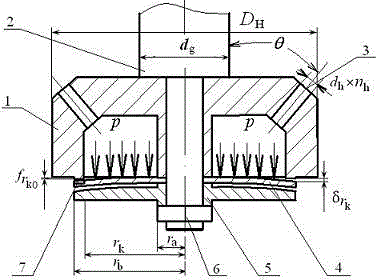

Intensity checking method of overlaying valve plates of compression valve of vehicle buffer

InactiveCN103161871AGuaranteed design lifeReduce test costsSpringsShock absorbersEngineeringStructural engineering

The invention relates to an intensity checking method of overlaying valve plates of a compression valve of a vehicle buffer, and belongs to the technical field of hydraulic buffers. At present, a reliable calculation method for checking the maximum stress and intensity of the overlaying valve plates of the compression valve is not given at home and aboard, the checking is conducted through numerical simulation by finite element software most of the time, and therefore modern design requirements of the buffers can not be satisfied. The intensity checking method is characterized in that checking of the intensity of the overlaying valve plates of the compression valve is conducted according to the thicknesses, the number of pieces, the allowable stress and the maximum stress of the overlaying valve plates of the compression valve. According to the intensity checking method, not only influences of normal open holes of a rebuilt valve, piston gaps and a circulation valve are considered, but also the stress condition of actual non uniform pressure is considered. The intensity checking method of the overlaying valve plates of the compression valve of the vehicle buffer is capable of calculating the maximum stress of the overlaying valve plates of the compression valve accurately, checking the intensity reliably, guaranteeing the design service life of the buffer, reducing maintenance cost, avoiding repeated testing and modification, reducing the cost of designing and testing, and shortening the development cycle.

Owner:SHANDONG UNIV OF TECH

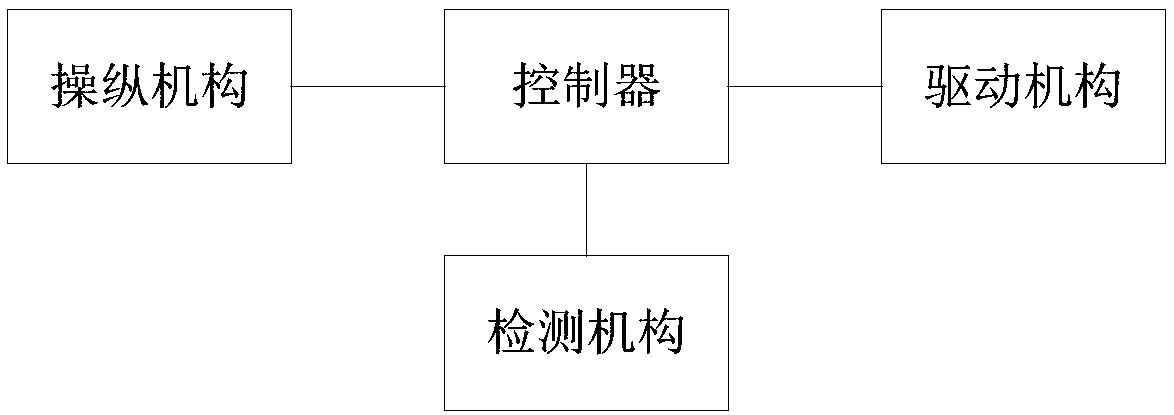

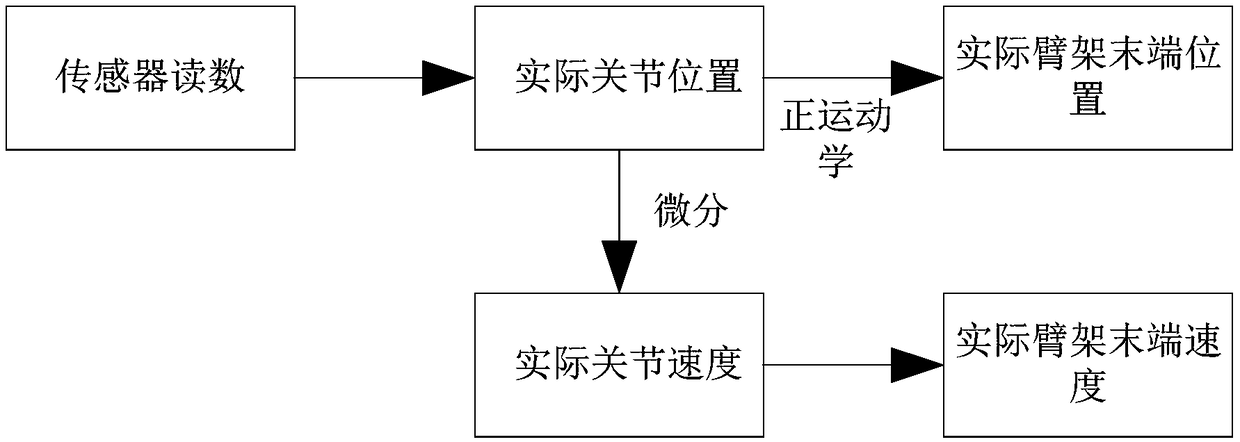

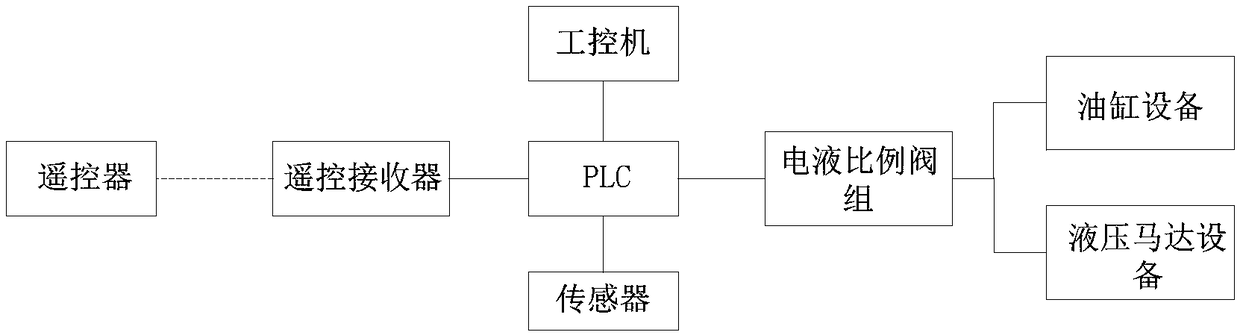

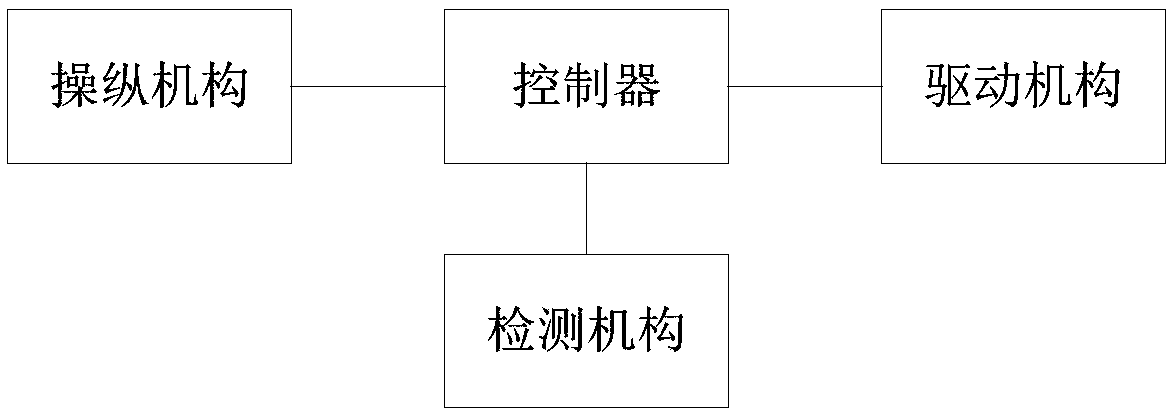

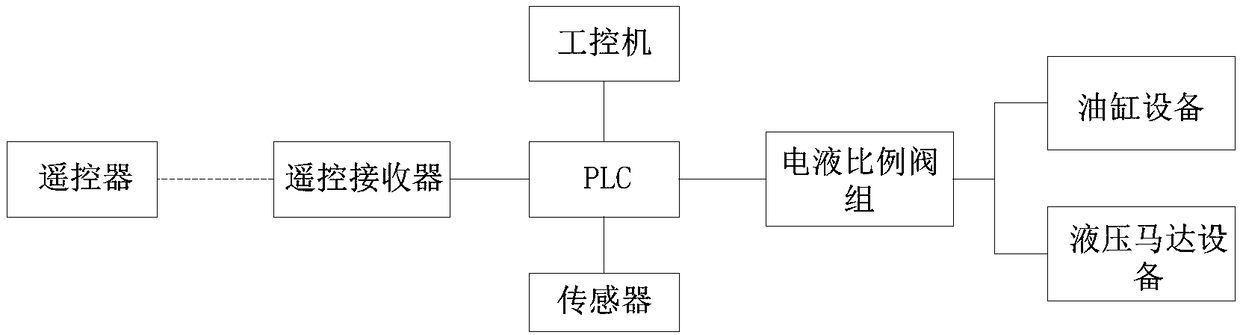

Cantilever crane end position control method and system, and construction machine including the system

InactiveCN109375585ALow level of experience requiredReduce labor intensityNumerical controlCantileverPosition control

The embodiment of the invention provides a cantilever crane end position control method and system, and a construction machine. The method comprises the following steps that: a direction and an amplitude that are indicated by a control mechanism for controlling the position of the tail end of a cantilever crane are received; an actual speed and position of the tail end of the cantilever crane arereceived; according to the direction and amplitude, the actual speed of the tail end of the cantilever crane, an accelerated speed upper limit constraint and / or speed upper limit constraint, a desiredmovement speed of the tail end of the cantilever crane under the accelerated speed upper limit constraint and / or speed upper limit constraint is determined; according to the lasting time of the indication direction and amplitude of the control mechanism, integration of the desired movement speed is carried out to obtain a displacement increment of the tail end of the cantilever crane is obtained;on the basis of the displacement increment and the actual position of the tail end of the cantilever crane, a target position of the tail end of the cantilever crane is determined; and a driving mechanism of the cantilever crane is controlled, so that the tail end of the cantilever crane moves to the target position. Therefore, the operator can control the position of the tail end of the cantilever crane directly without the need to control the position of the tail end of the cantilever crane by controlling each joint of the cantilever crane.

Owner:湖南希法工程机械有限公司 +1

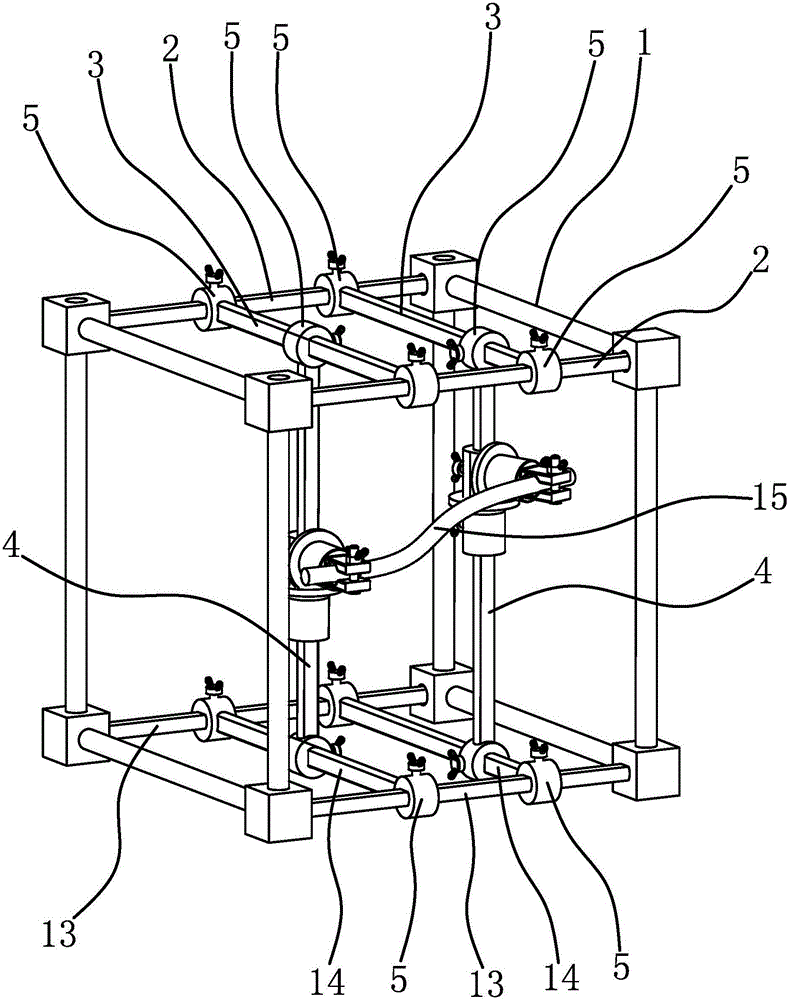

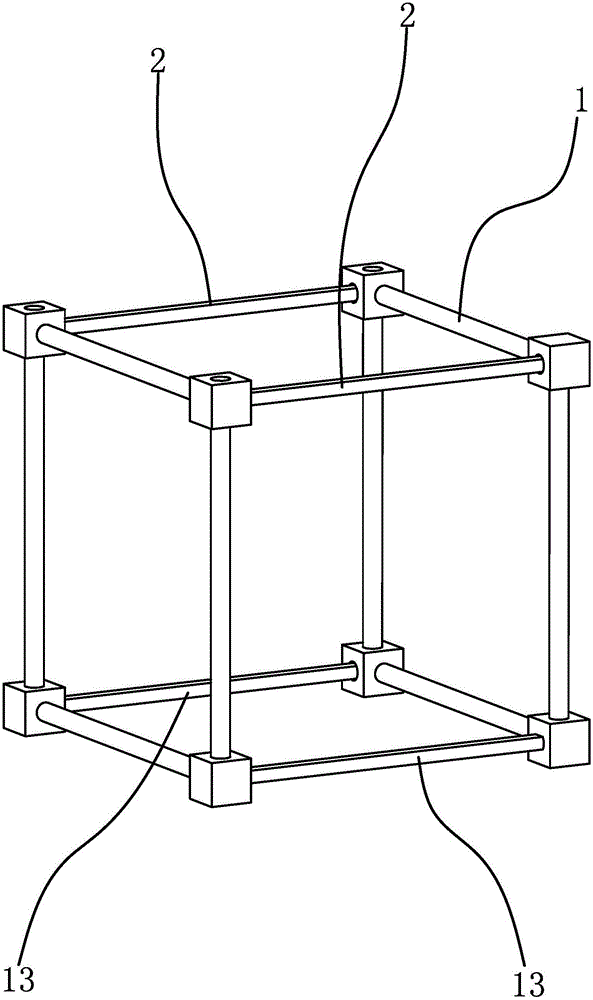

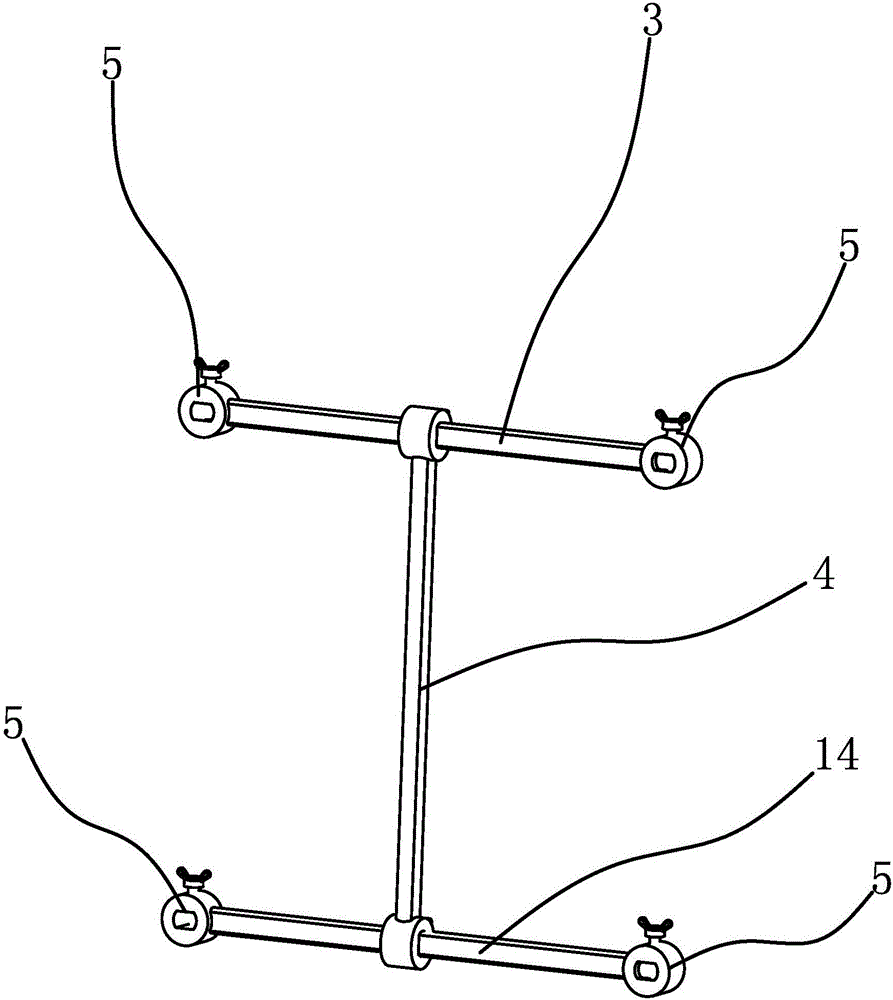

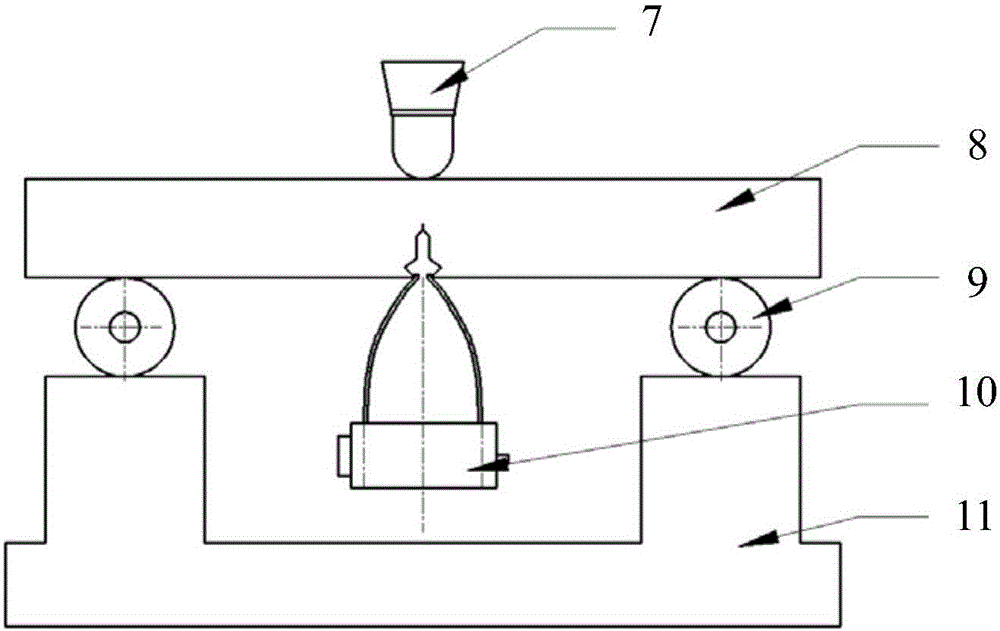

Test device for measuring and simulating brake hose

ActiveCN105758276AAvoid trial and errorImprove the success rate of a developmentMechanical measuring arrangementsEngineeringMechanical engineering

The invention provides a test device for measuring and simulating a brake hose, which belongs to the technical field of vehicles and aims at solving the problem of how to simulate the mounting environment of the brake hose in a real vehicle. The test device comprises a frame body; two mutually-parallel and parallelly-arranged X scale guide rods are fixed on the frame body; at least two Y scale guide rods are connected between the two X scale guide rods in a sliding mode; the Y scale guide rods are vertical with the above two X scale guide rods; Z scale guide rods arranged along the vertical direction and vertical with the Y scale guide rods are connected in a sliding mode onto the Y scale guide rods; and a hose clamping device for clamping and fixing the brake hose and capable of adjusting the mounting angle of the brake hose is connected in a sliding mode onto the Z scale guide rods. The test device can simulate the mounting position and the mounting angle of the brake hose in the real vehicle, the brake hose sample can be prevented from being changed repeated for assembly verification in a vehicle loading stage, the development period of the brake pipeline is shortened, and teh development cost is reduced.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

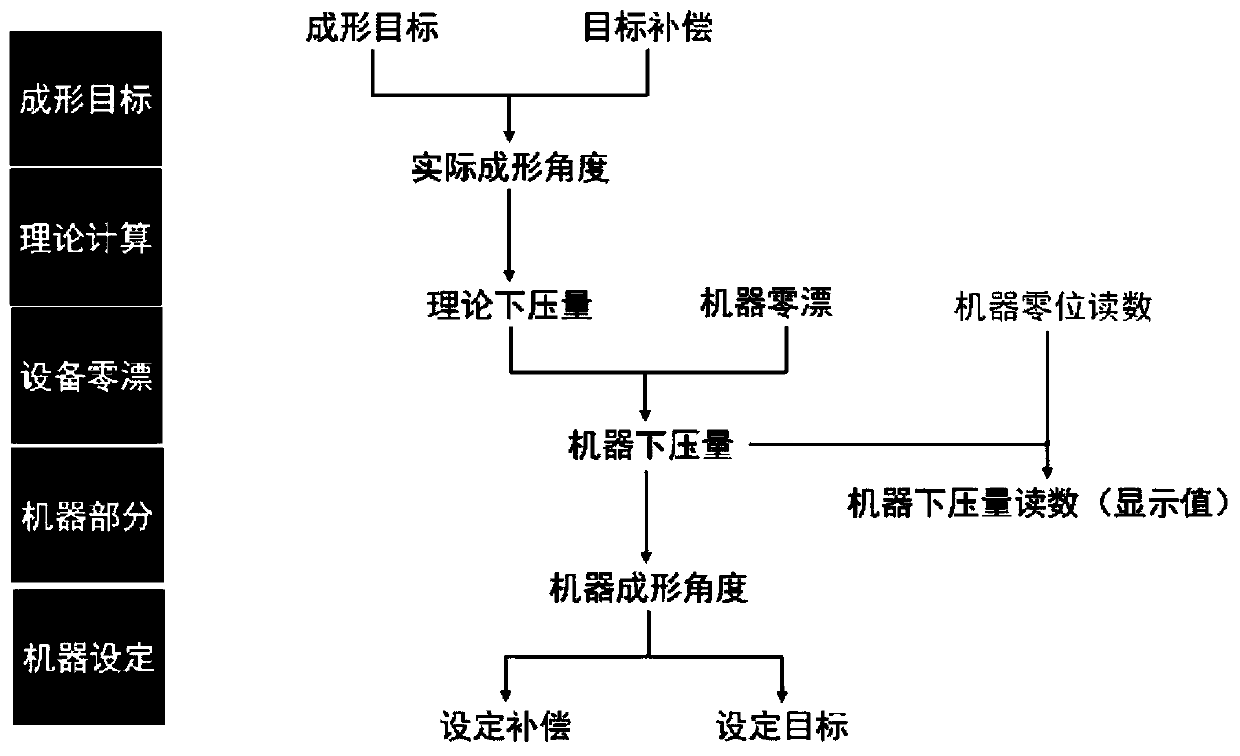

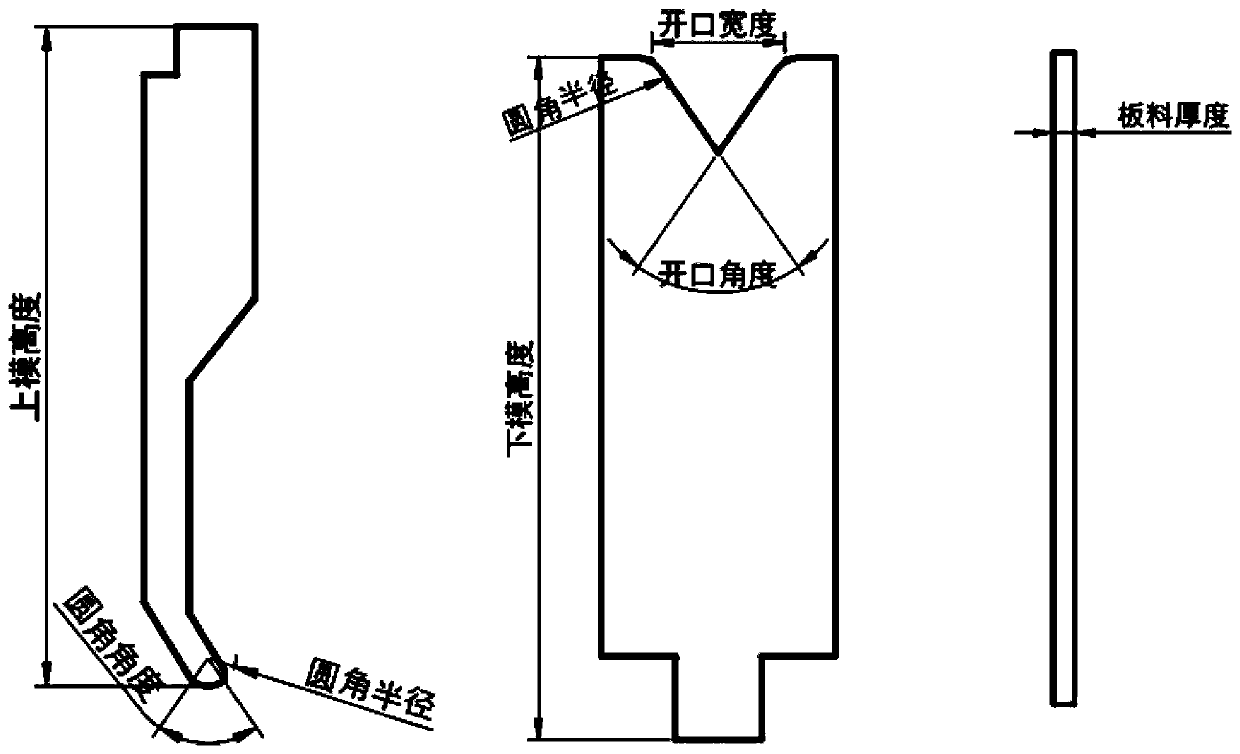

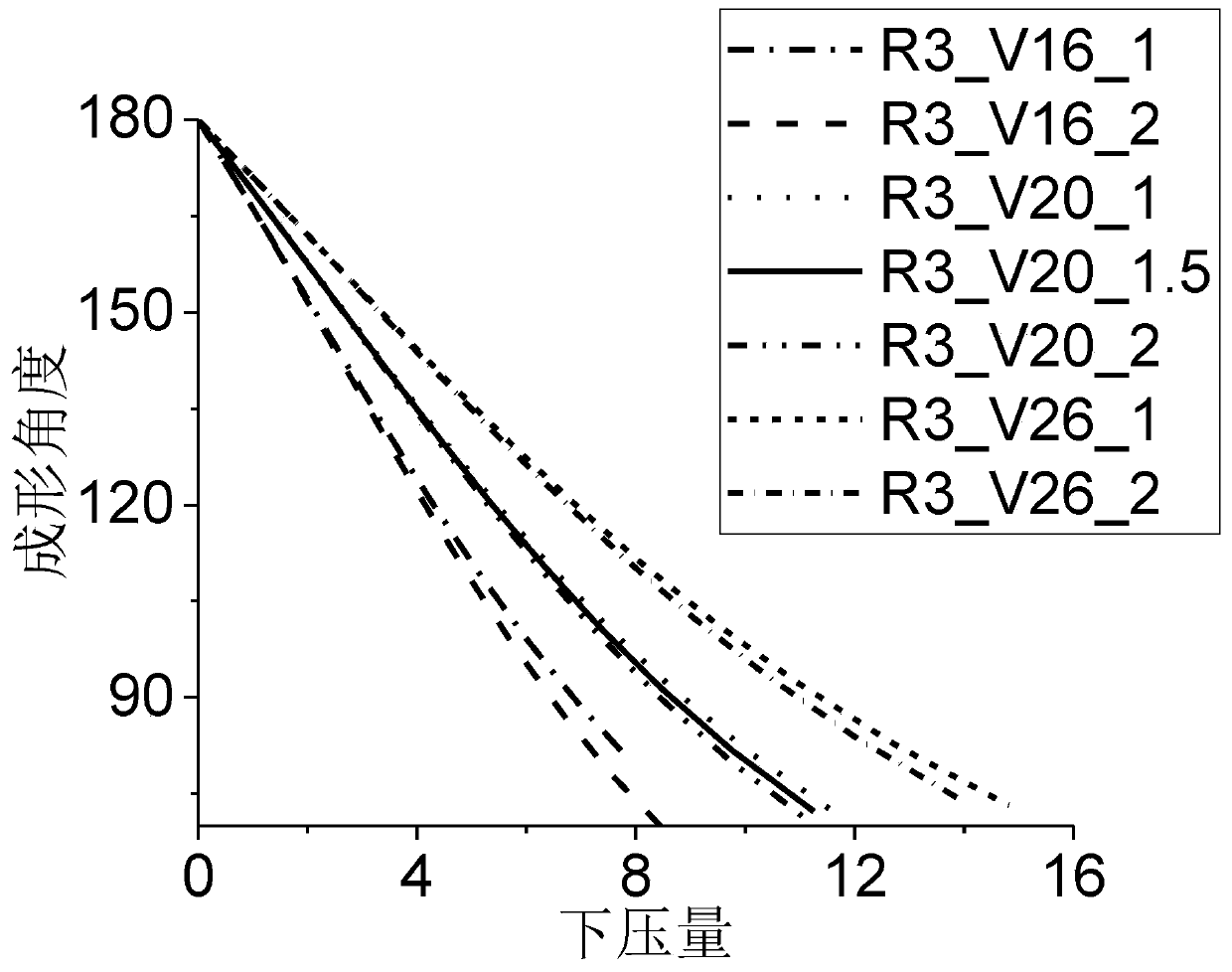

Bending forming method, system and device and medium

PendingCN109871605AImprove general performanceAvoid trial and errorVehicle componentsSpecial data processing applicationsAnalytical equationsEngineering

The invention provides a bending forming method, system and device and a medium. The bending forming method comprises the following steps that 1, the relation between set technological parameters of bending equipment and the actual forming angle of a workpiece is obtained; and 2, according to the deviation between the current forming angle and the actual forming angle, the current technological parameters of the bending equipment are processed through the relation between the set technological parameters of the bending equipment and the actual forming angle of the workpiece, and the processedtechnological parameters are obtained. The method has the beneficial effects that the importance of the zero deviation is indicated, and the measurement method and the calculation method of the zero deviation are given. When a material or a mold is replaced, parameters in a finite element or an analytical equation can be directly changed, and a new actual pressing amount-actual forming angle relation can be obtained; when the zero position of the equipment drifts, only a new zero position needs to be obtained through a test and substituted; and after the equipment or the system is replaced, only a new internal relation of the equipment needs to be obtained.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD +1

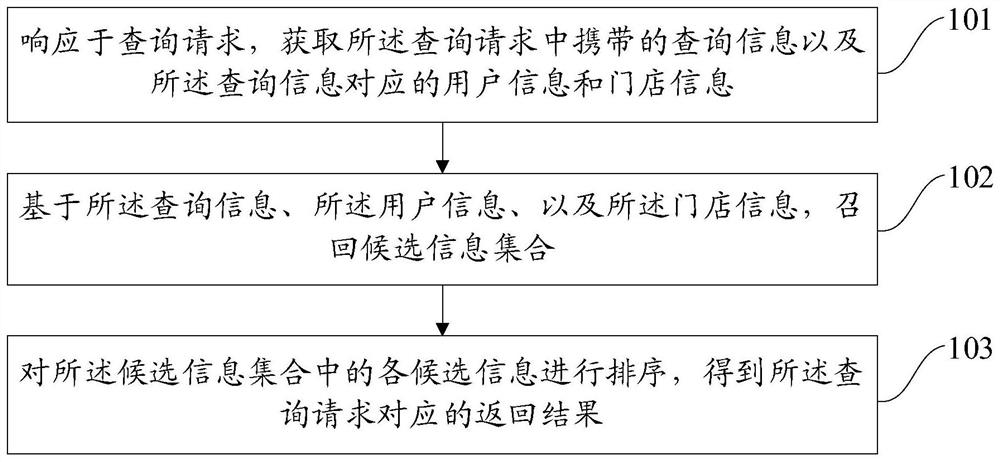

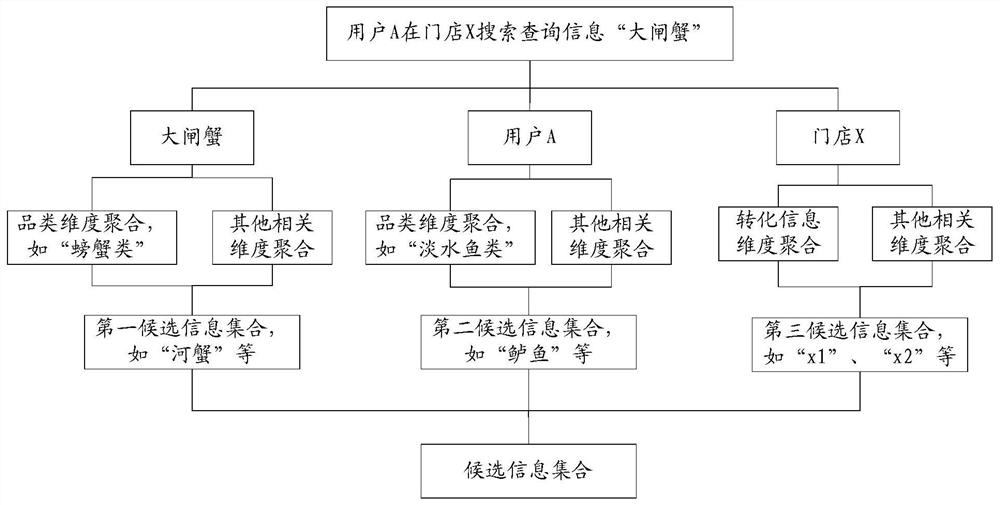

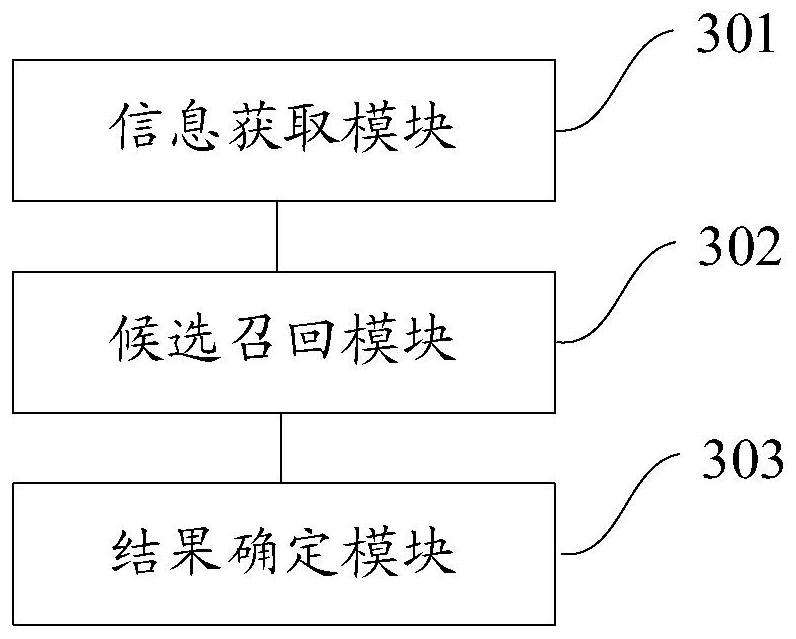

Search recommendation method and device, electronic equipment and readable storage medium

PendingCN112488781AReflect search intentAvoid trial and errorDigital data information retrievalBuying/selling/leasing transactionsInformation retrievalEngineering

The embodiment of the invention provides a search recommendation method and device, electronic equipment and a readable storage medium, and the method comprises the steps: responding to a query request, and obtaining query information carried in the query request and user information and store information corresponding to the query information; recalling a candidate information set based on the query information, the user information and the store information; and sorting the candidate information in the candidate information set to obtain a return result corresponding to the query request. According to the embodiment of the invention, the search efficiency can be improved, the user search operation process is simplified, and the user experience is improved.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

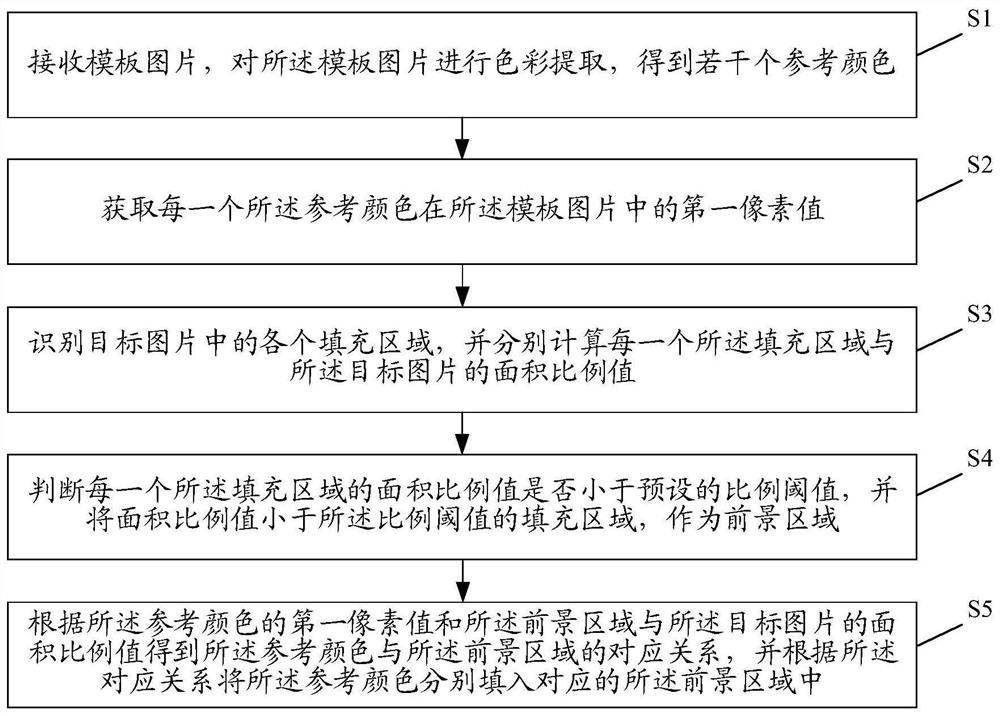

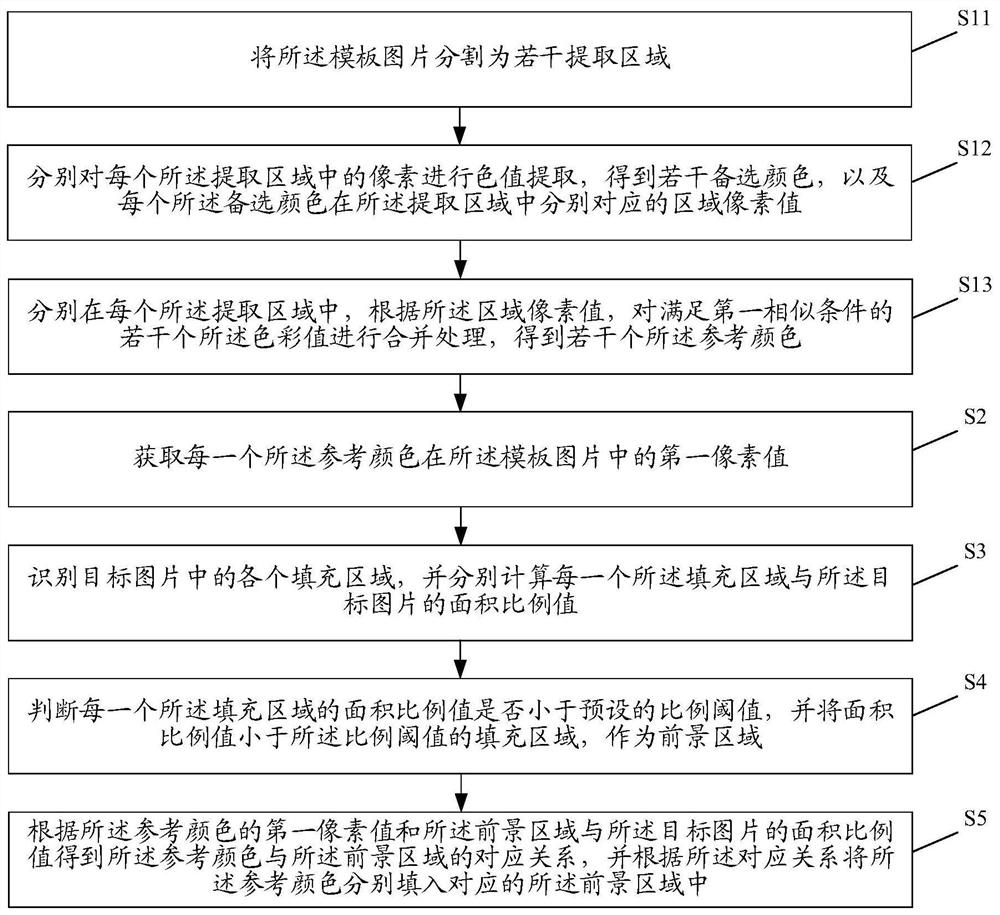

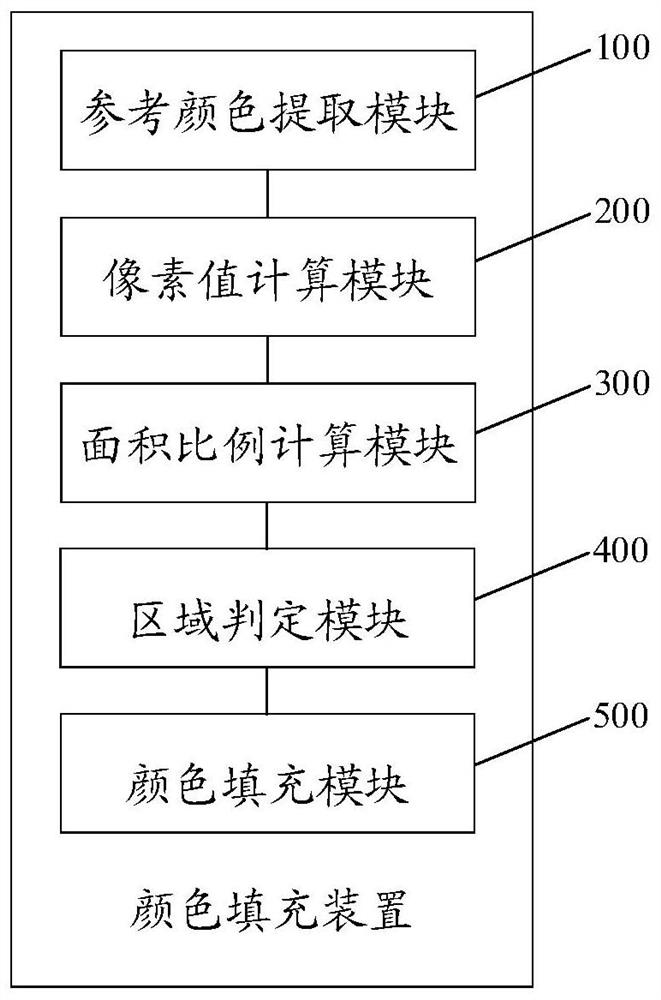

Color filling method and device, equipment and storage medium

PendingCN113808235AImprove combination efficiencyImprove reliabilityFilling planer surface with attributesComputer graphics (images)Engineering

The invention relates to the technical field of artificial intelligence, and discloses a color filling method and device, equipment and a storage medium, and the method comprises the steps: receiving a template picture, and extracting a plurality of reference colors; obtaining a first pixel value of each reference color in the template picture; identifying filling areas in a target picture, and calculating an area ratio value of each filling area to the target picture; judging whether the area proportion value of the filling area is smaller than a preset proportion threshold value or not, wherein the filling area with the area proportion value smaller than the proportion threshold value serves as a foreground area; obtaining a corresponding relation between the reference colors and the foreground areas according to the first pixel values of the reference colors and the area proportion value of the foreground areas and the target picture, and filling the corresponding foreground areas with the reference colors according to the corresponding relation; the automatic selection of the filling color is realized, so that the color matching design efficiency of the picture is improved.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

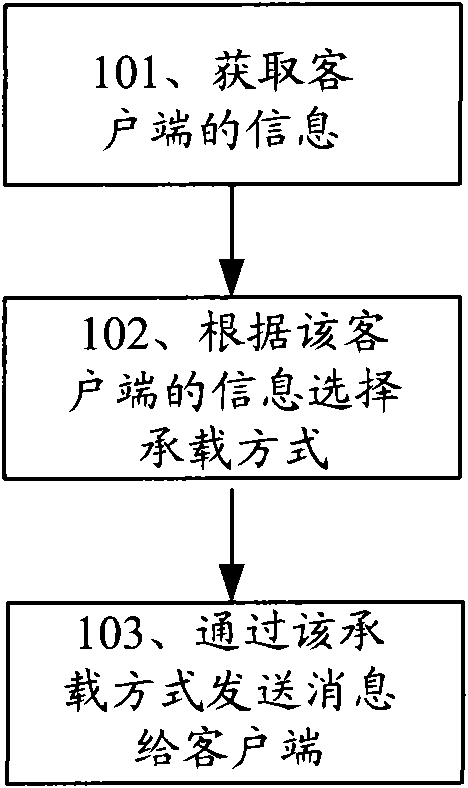

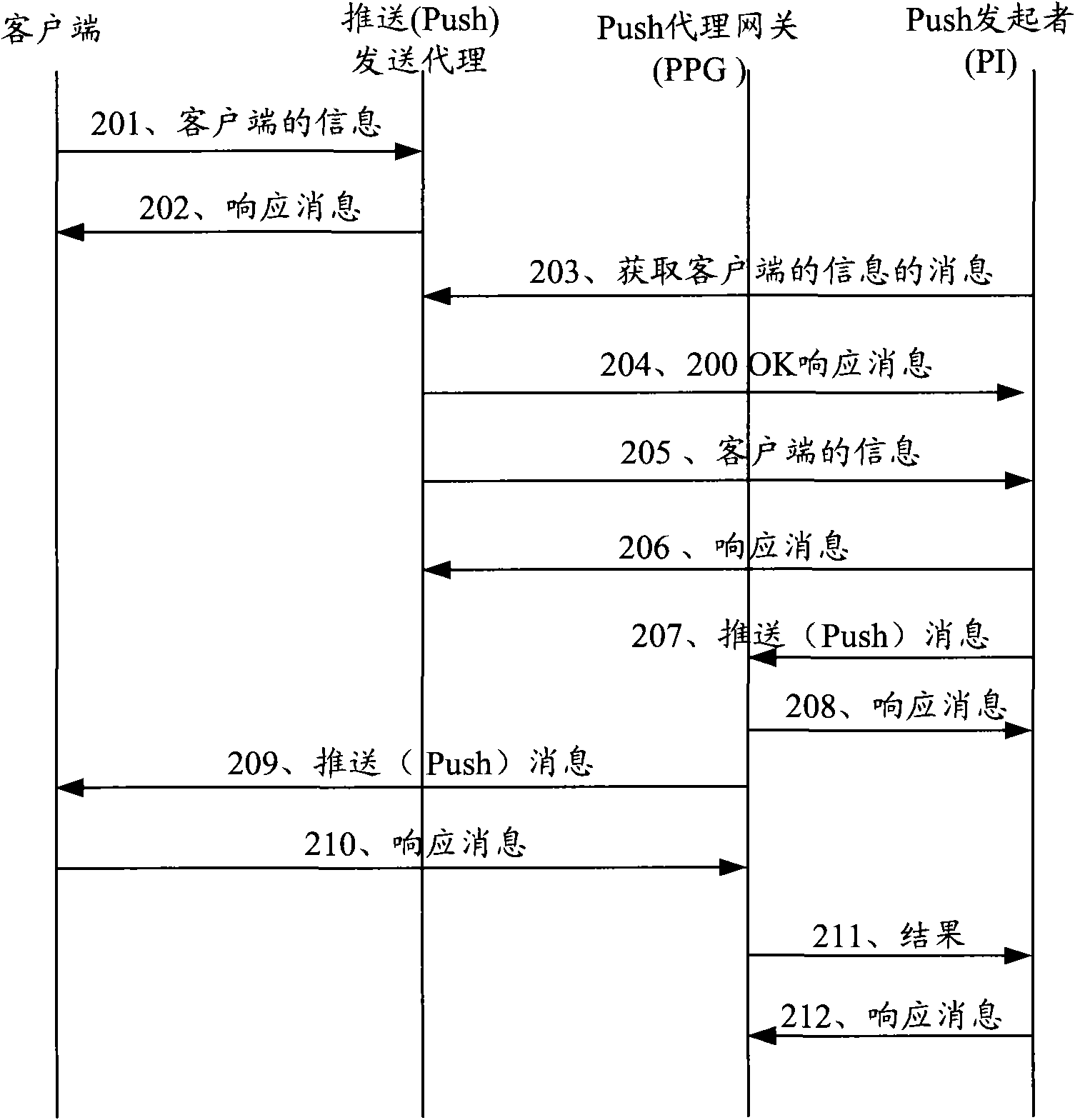

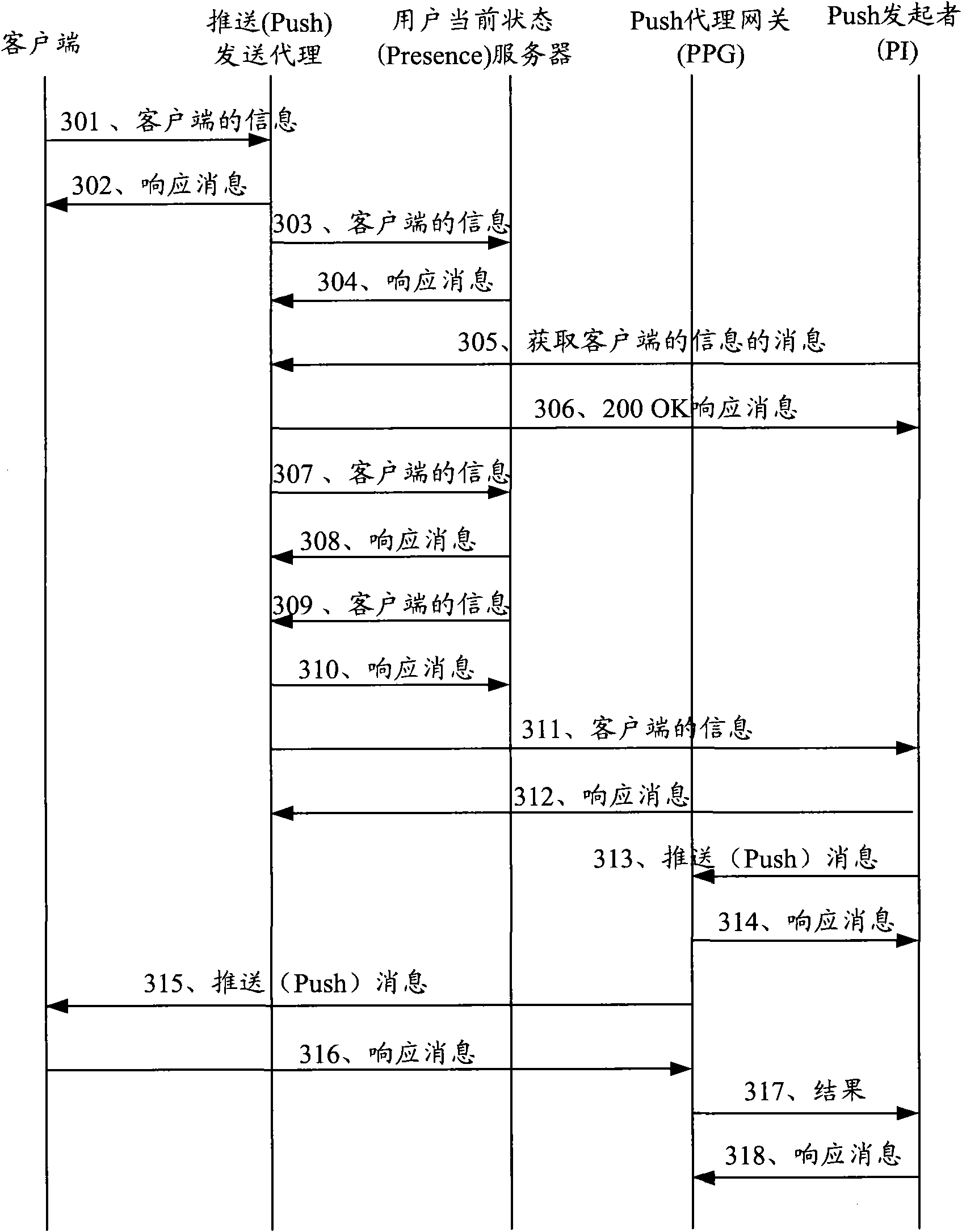

Method, device and system for sending message

InactiveCN101610204AIncrease success rateAvoid trial and errorData switching networksClient-sideTraffic volume

The invention discloses a method for sending a message. The embodiment of the invention also provides a device and a system for sending a message. A message sender of the technical scheme can obtain the information of a client terminal, select a carrying way according to the information and send the message to the client terminal, thereby preventing the condition of multi-inquiry or sending failure caused by the mismatching between the designated carrying way and the practical information of the client terminal, saving the signaling flux and improving the success rate for sending the message.

Owner:HUAWEI TECH CO LTD

Method for designing area of hydraulic shock absorber rebuilt valve normal through hole based on speed characteristics

The invention relates to a method for designing the area of a hydraulic shock absorber rebuilt valve normal through hole based on speed characteristics, and belongs to the technical field of hydraulic shock absorbers. The method is characterized by comprising the following steps of 1) determining the design speed point of the area of the normal through hole and the damping force of a shock absorber, 2) determining the throttle pressure and the flow of the piston clearance of the shock absorber, 3) determining the flow of a piston hole; 4) determining the equivalent length of the piston hole, 5) determining the throttle pressure of the piston hole and 6) designing the area of the shock absorber rebuilt valve normal through hole, actual broadband and the actual number. The method can accurately design the area of the rebuilt valve normal through hole according to the design requirements for the hydraulic shock absorber characteristics, shock absorber structure parameters and a rebuilt stroke oil path. According to the method, the accurate and reliable design value of the area of the shock absorber rebuilt valve normal through hole can be obtained, repeated testing and modification are avoided, cost for designing and testing the shock absorber is lowered, and a development period is shortened.

Owner:SHANDONG UNIV OF TECH

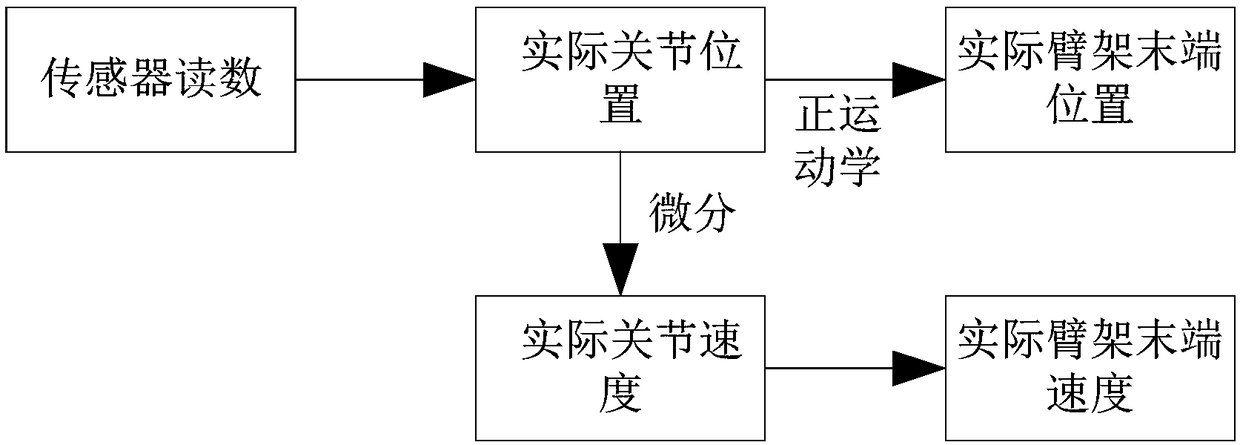

Method and system for control over position of tail end of cantilever crane and engineering machine with system

InactiveCN109469328ALow level of experience requiredReduce labor intensityBuilding material handlingCantileverControl theory

The embodiment of the invention provides a method and system for control over the position of the tail end of a cantilever crane and an engineering machine with the system. The method includes the steps that the direction and magnitude indicated by a control mechanism used for controlling the position of the tail end of the cantilever crane are received; the actual speed and position of the tail end of the cantilever crane are received; according to the direction and magnitude and the actual speed and actual position of the tail end of the cantilever crane, the target position of the tail endof the cantilever crane is determined; according to the target position of the tail end of the cantilever crane, a set of target joint positions are worked out through inverse solution; a set of target joint speeds are calculated; a driving mechanism of the cantilever crane is controlled so that one or more joints of the cantilever crane can meet the target joint positions and target joint speedsrespectively. In the scheme, an operator can directly control the position of the tail end of the cantilever crane, and it is not needed to separately control each joint of the cantilever crane to control the position of the tail end of the cantilever crane.

Owner:湖南希法工程机械有限公司 +1

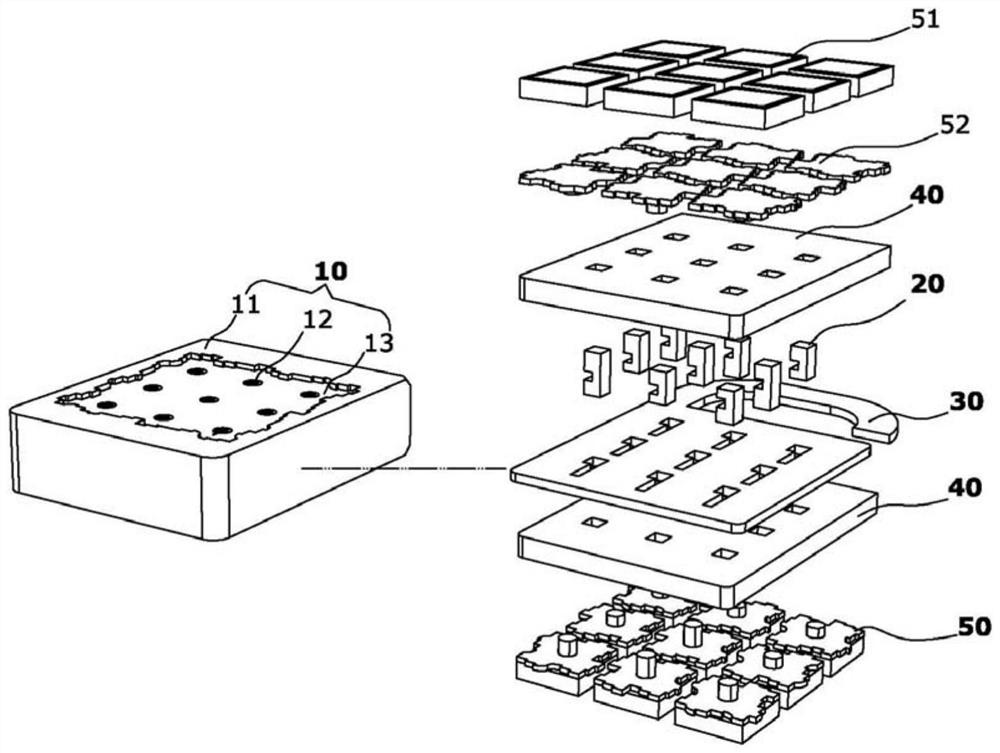

Dissimilar material brazing gap control method and system

ActiveCN113510327AImprove boundary conditionsGood capillary actionWelding/soldering/cutting articlesMetal working apparatusNumerical controlStructure analysis

The invention provides a dissimilar material brazing gap control method and system. The dissimilar material brazing gap control method comprises the steps of: presetting assembly gap values according to the actual structures of all workpieces to be assembled; determining performance parameters of all the workpieces; according to the brazing structures of all the workpieces and the brazing filler metal joint filling requirements, determining the positions of brazing seams and the boundary conditions of thermal structure analysis; according to the boundary conditions of thermal structure analysis and the performance parameters of all the workpieces, analyzing thermal displacement changes of all the workpieces, and working out brazing gap values among all the workpieces; performing comparison and re-calculation according to the brazing gap values among all the workpieces and a preset brazing gap range of a brazing material to obtain an optimal assembly gap range among the workpieces; and performing a process test according to the optimal assembly gap range to determine the actual assembly gap among the workpieces. According to the method, the initial assembly gap of the workpieces and the brazing gap are linked through simulation analysis, so that numerical control over the brazing gap of the dissimilar materials is achieved, and the brazing quality of products is guaranteed.

Owner:SHANGHAI INST OF SPACE PROPULSION

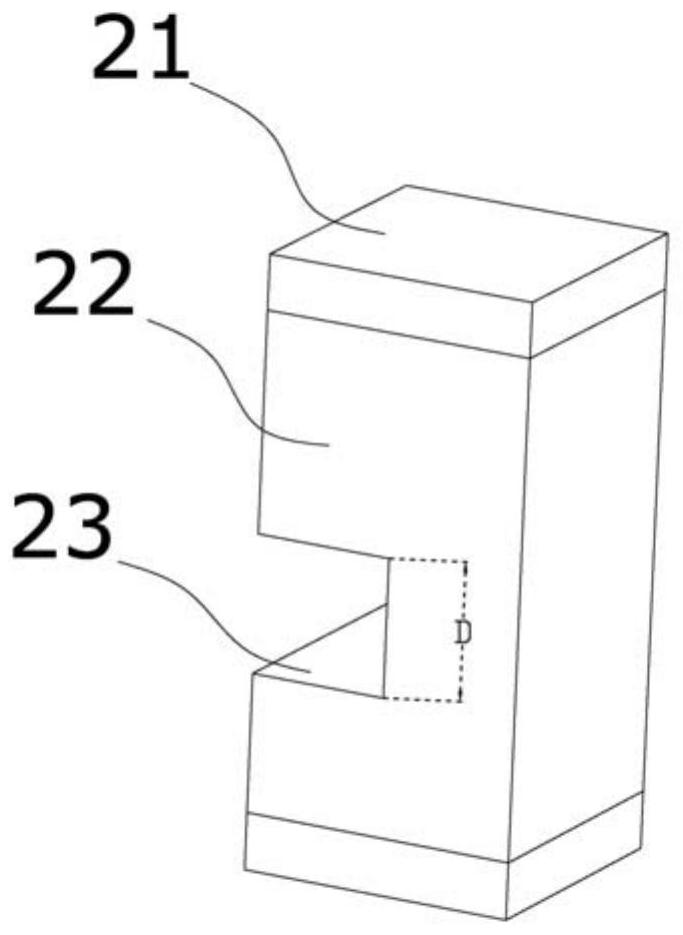

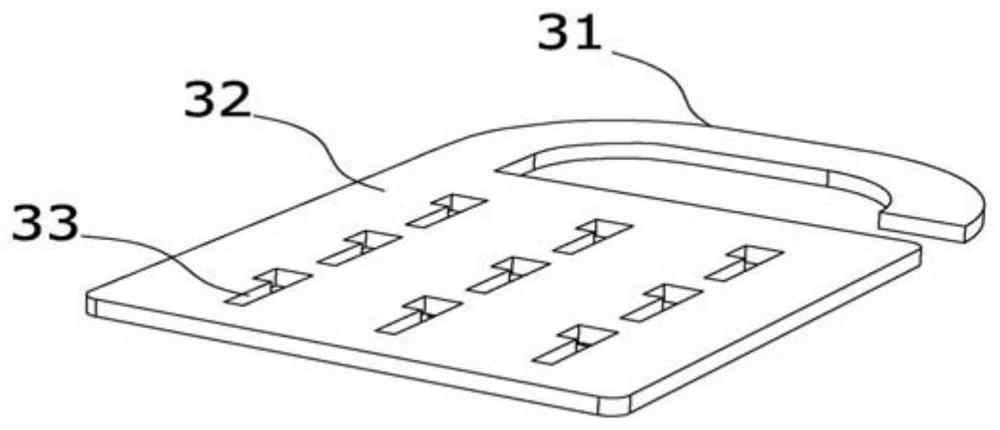

Spliced mechanical coded lock

PendingCN112302428AAvoid trial and errorNo deformationPuzzle locksPermutation locksSoftware engineeringLocking plate

The invention discloses a spliced mechanical coded lock. The spliced mechanical coded lock comprises a lock body, a lock plate, a plurality of lock keys and a plurality of jigsaw keys, wherein the lock plate is inserted into the lock body, the lock plate is provided with a plurality of movable grooves, the plurality of lock keys are movably connected to the movable grooves in a penetrating mode, the lock keys are provided with clamping grooves, when all the clamping grooves are flush with the movable grooves, the lock plate can move in the lock body, and the jigsaw keys are detachably arrangedat the upper end and the lower end of the lock body and abut against the corresponding lock keys to move so as to switch the moving or locking state of the lock plate. According to the spliced mechanical coded lock, the jigsaw pieces are different in shape and have more than 70 shapes, due to the fact that the lengths of stand columns on the jigsaw pieces are different, the spliced pieces can bespliced to form more than millions of combination styles, millions of keys can be formed after the stand columns are combined, even if other people accidentally obtain the spliced pieces, correct graphs and correct stand column arrangement modes are difficult to splice, the combination transformability of the password sets is higher, and the safety degree is higher.

Owner:周林炯

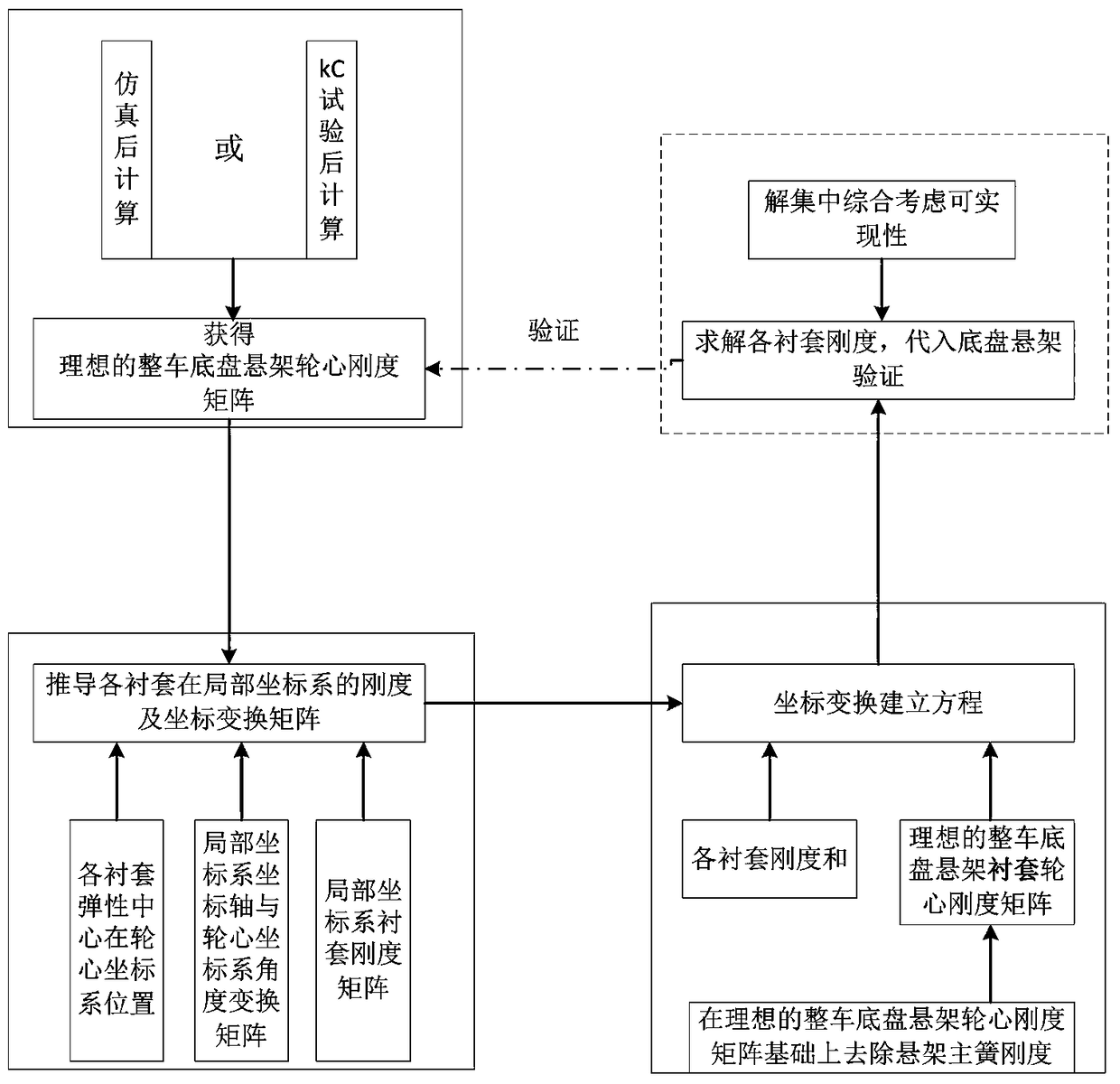

Automobile chassis lining matching method based on rigidity matrix

InactiveCN108202573AAvoid trial and errorOptimize the development matching processSuspensionsDesign optimisation/simulationKinematicsDesign stage

The invention discloses an automobile chassis lining matching method based on a rigidity matrix and relates to an automobile chassis system. As for determining of the rigidity of linings of suspension, all possible combinations of the rigidity of linings of a chassis for meeting target elastic kinematics performance are precisely provided; through the method, the current situations that the linings are selected according to experience and based on single parts, and systematic understanding to the chassis linings is lacked are improved, repeated trials and errors during matching of the chassissuspension linings are avoided, and the number of the trials is greatly decreased; the suspension development matching process is optimized, and a large number of costs can be saved in application; meanwhile, the virtual prototyping development trend of current automobile development is also met, the elastic kinematics performance of the chassis suspension can be optimized directionally without the need of manufacturing an actual automobile, the suspension matching time is shortened, and the automobile development progress is accelerated; and the optimal solution of the elastic kinematics performance of a given target can be achieved with a minimum number of the linings, the possible design redundancy at the chassis suspension lining designing stage is removed, and the automobile cost is saved.

Owner:BRILLIANCE AUTO

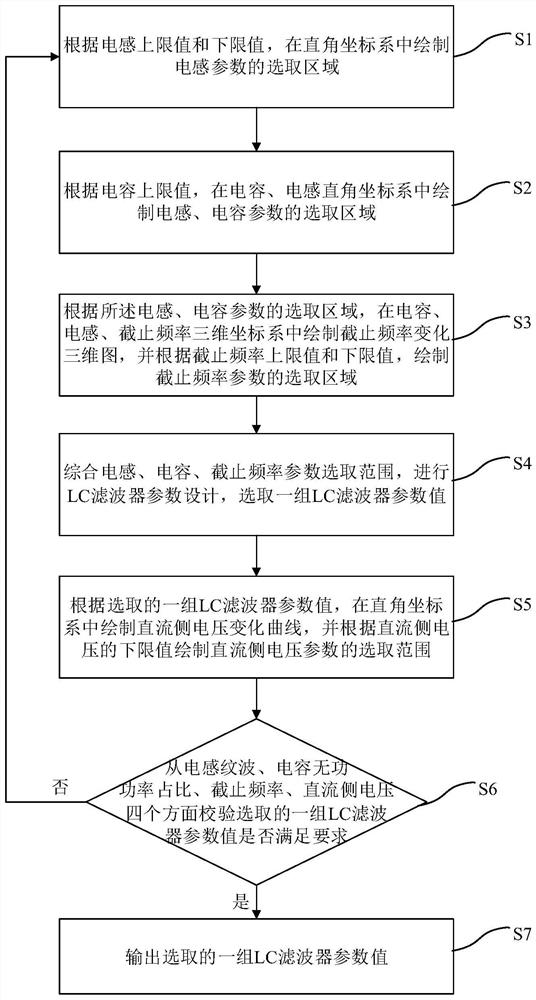

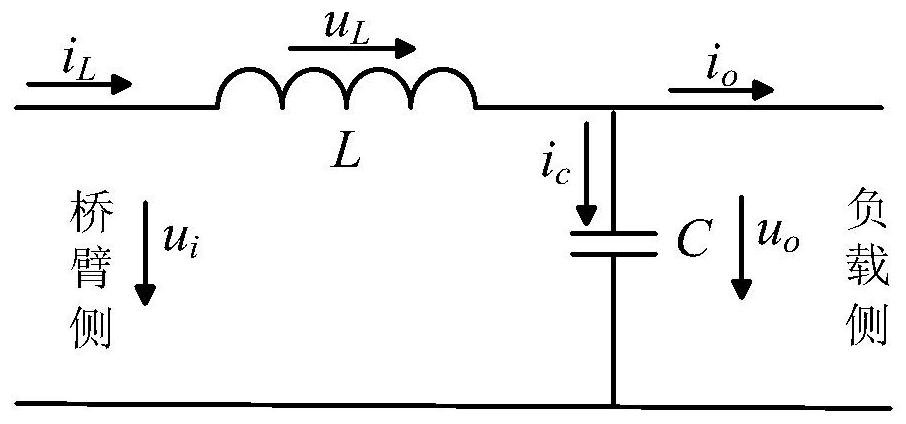

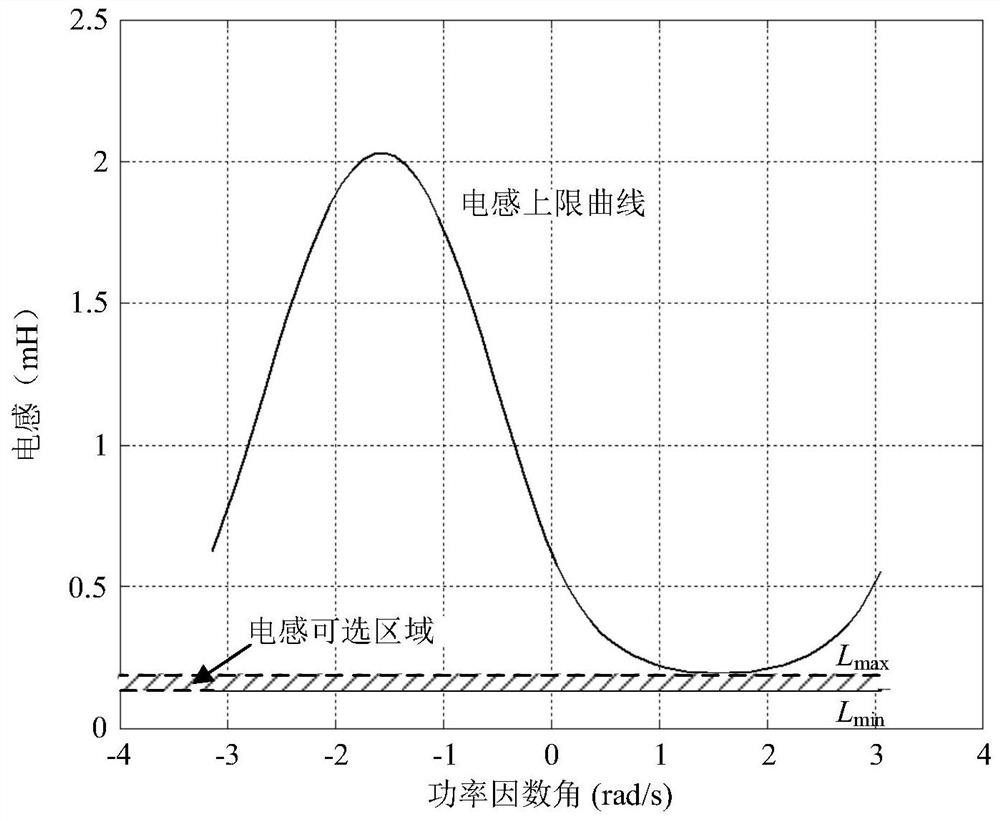

LC filter parameter visualization design method of energy storage converter

ActiveCN112528584AAvoid trial and errorCAD circuit designSpecial data processing applicationsVisualizationCapacitance

The invention provides an LC filter parameter visualization design method of an energy storage converter. The LC filter parameter visualization design method comprises the steps of S1, drawing a selection range of inductance parameters; S2, drawing a selection range of capacitance parameters; S3, drawing a selection range of cut-off frequency parameters; S4, designing LC filter parameters in combination with inductance, capacitance and cut-off frequency parameter selection ranges; S5, drawing a selection range of the direct-current side voltage; S6, verifying whether the LC filter parameters meet the design requirements or not, if not, returning to the S1 for redesign, and if yes, executing the step S7, and outputting final LC filter parameter values. Parameter design is carried out in a visual mode, parameter selectable areas and change trends can be visually obtained by drawing selectable areas of inductance, capacitance and cut-off frequency parameters, repeated trial and error areavoided, and multiple design indexes such as system cut-off frequency, reactive power, full-load voltage drop and four-quadrant operation can be met at the same time.

Owner:EAST CHINA ELECTRIC POWER TEST & RES INST +2

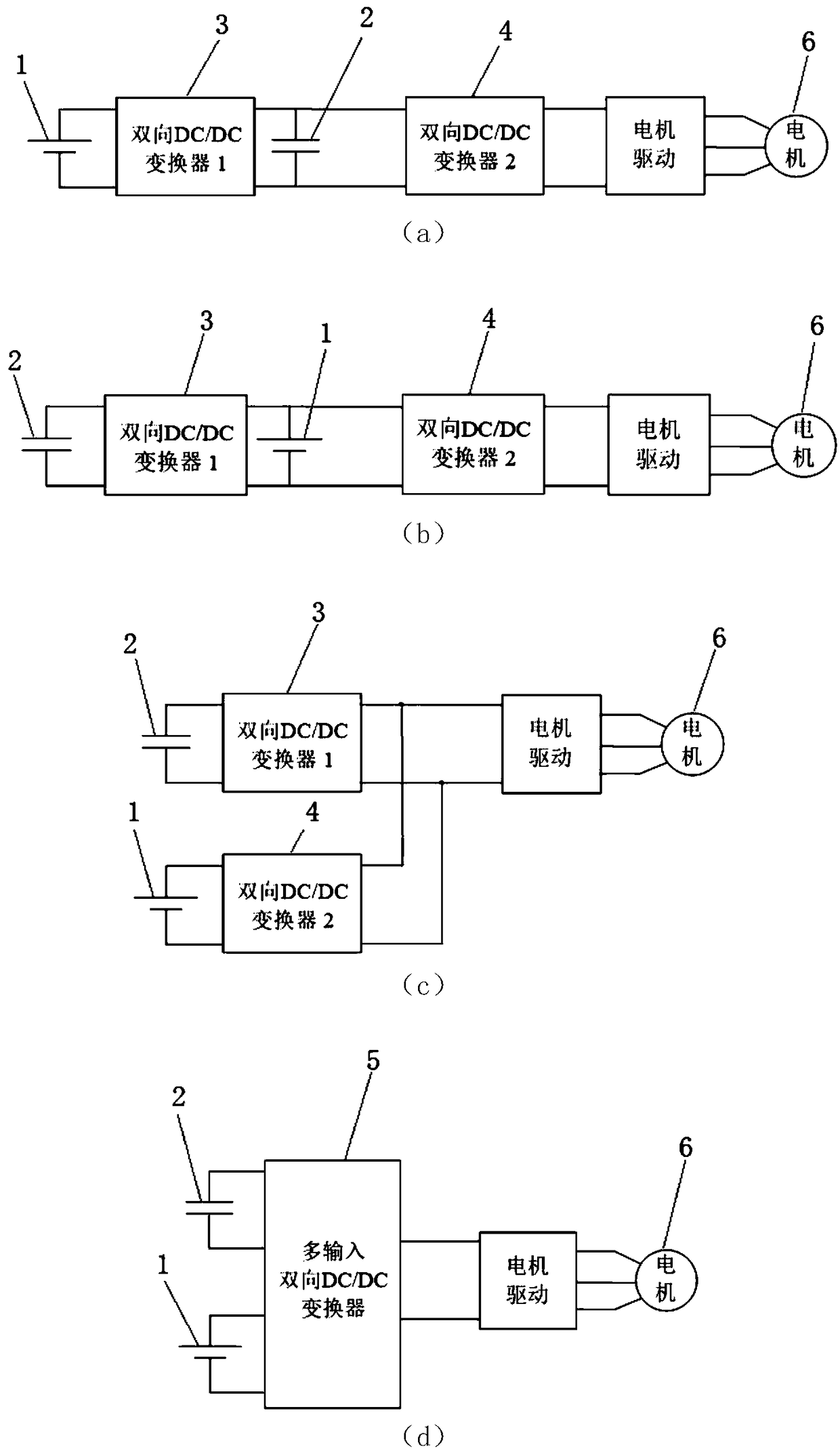

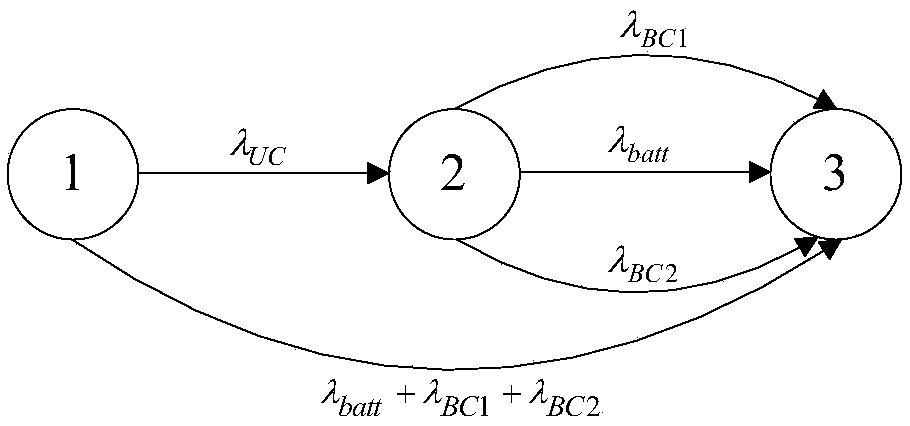

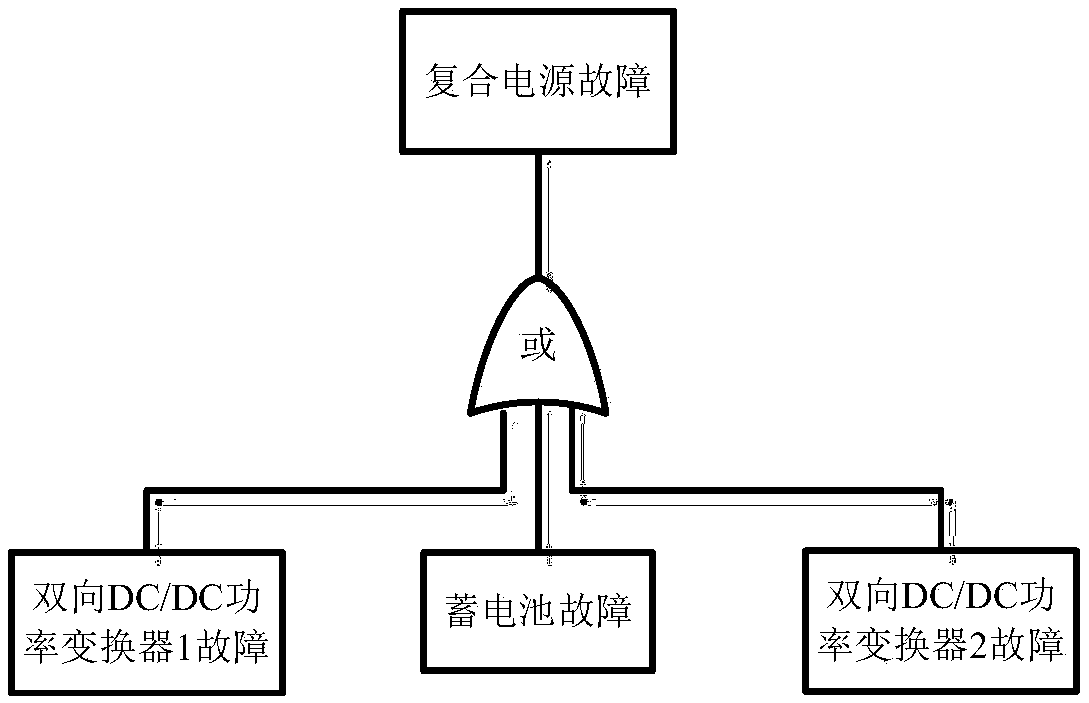

Vehicle-mounted composite power supply reliability evaluation method based on Markov chain and fault tree

ActiveCN108665153AStrong reliabilityAvoid trial and errorGeometric CADDesign optimisation/simulationMulti inputMarkov chain

The invention discloses a vehicle-mounted composite power supply reliability evaluation method based on Markov chain and fault tree, comprising the following steps of: firstly, establishing a state transition graph when composite power supplies with four different topology structures comprising a cascaded structure composite power supply with a super capacitor located in an intermediate position,a cascaded structure composite power supply with a storage battery located in the intermediate position, a parallel connection structure composite power supply and a multi-input power converter structure composite power supply break down based on Markov chain theory; secondly, according to the state transition graph when the composite power supplies with four different topology structures break down, establishing a fault tree model graph which finally makes the composite power supply break down and the system be in a state of paralysis based on the fault tree theory; finally, according to theestablished fault tree model graph, calculating break down rate of the composite power supplies with four different topology structures, performing comparative analysis, and performing reliability evaluation, so as to obtain a composite power supply with the strongest reliability, and repeated tests in engineering practice are avoided.

Owner:JIANGSU UNIV OF TECH

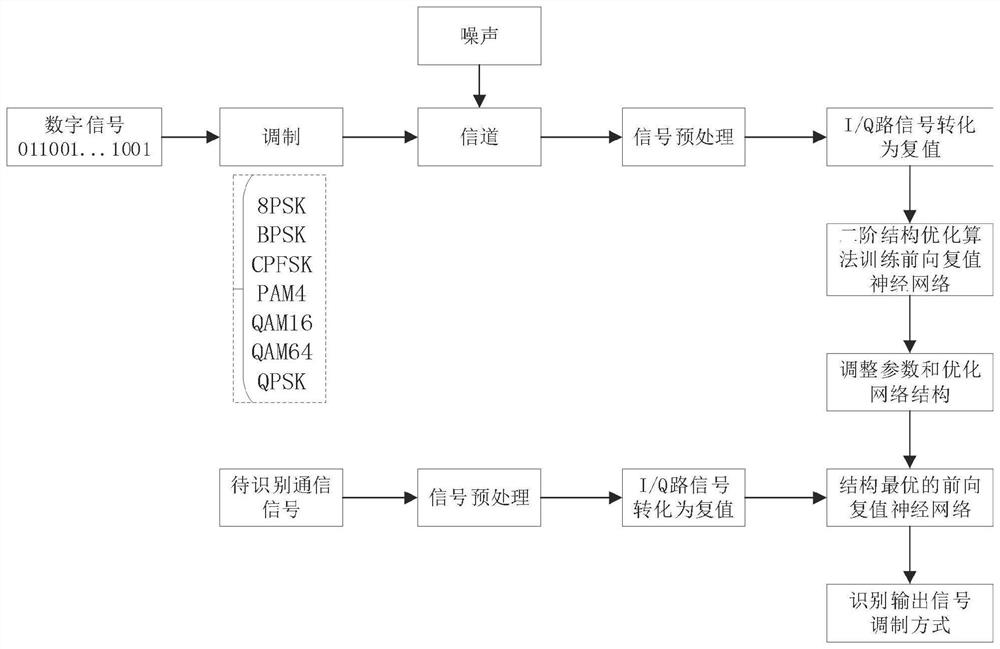

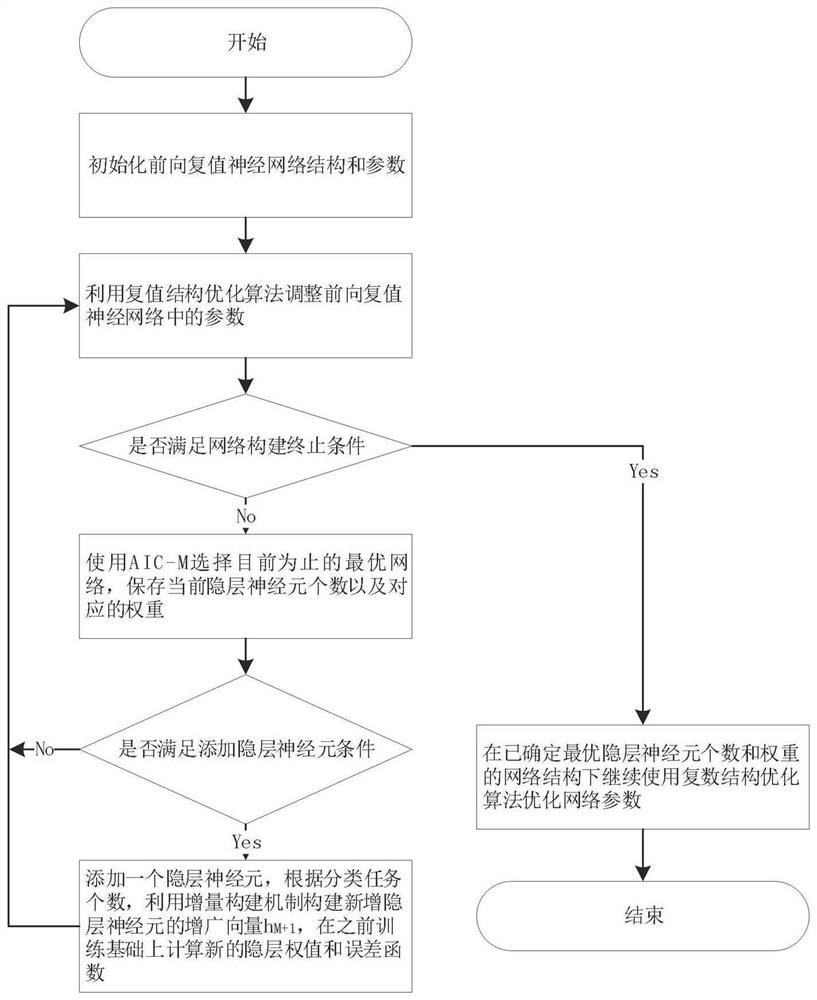

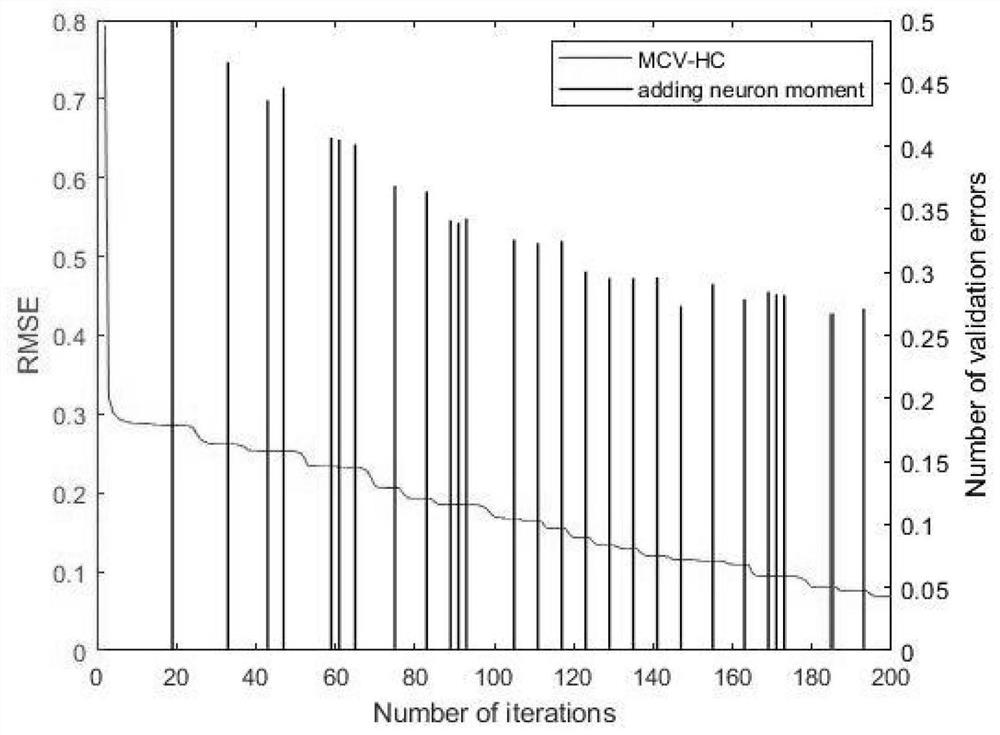

Signal modulation identification method of complex valued neural network based on structure optimization algorithm

ActiveCN113642653ARealize adaptive adjustmentImprove generalization abilityCharacter and pattern recognitionNeural architecturesPattern recognitionHidden layer

The invention discloses a signal modulation identification method of a complex valued neural network based on a structure optimization algorithm. The method comprises the following steps: initializing the structure and parameters of a forward complex valued neural network; adjusting parameters in the complex-valued neural network by using a complex-valued structure optimization algorithm, verifying the generalization performance of the forward complex-valued neural network, storing the number of current hidden layer neurons and all parameter values of the forward complex-valued neural network, and judging whether training is trapped in a local minimum point or not; if yes, adding a hidden layer neuron to the current model by using a complex value increment construction algorithm, calculating a weight of a newly added neuron, a hidden layer output matrix and a loss function value on the basis of current training, and continuing to train a new model; if not, keeping the model structure unchanged, and continuing training until an algorithm stopping condition is met. According to the method, the forward complex value neural network model with the optimal structure can be adaptively constructed, the method is used for identifying the communication signal modulation mode, and a satisfactory effect is achieved.

Owner:SUZHOU UNIV

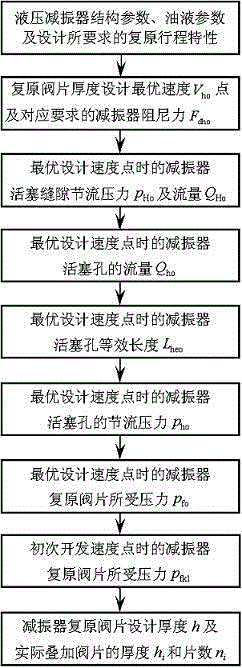

Design method for rebound valve plate thickness of hydraulic oscillating damper

The invention relates to a design method for rebound valve plate thickness of a hydraulic oscillating damper, which belongs to the technical field of oscillating dampers. The design method is characterized by comprising the following steps: a. determining the optimal design speed point and corresponding oscillating damper damping force of the thickness of a rebound valve plate; b. determining throttling pressure and flow of piston gaps; c. determining flow of a piston hole; d. determining the equivalent length of the piston hole; e. determining the throttling pressure of the piston hole; f. determining the pressure borne by the rebound valve plate at the optimal design speed point; g. determining the pressure borne by the rebound valve plate at the initial valve opening; and h. determining the design thickness h of the rebound valve plate, actual thickness of stacked valve plates hi, and plate number ni. The method can conduct optimal design of the speed point, and accurate design of the rebound valve plate thickness of the oscillating damper according to the oil line of initial valve opening of the rebound valve. Therefore, by utilizing the design method, a reliable design value of the rebound valve plate thickness can be obtained, repeated testing and modification are avoided, design and test expenses are reduced, and the development speed of the oscillating damper is accelerated.

Owner:SHANDONG UNIV OF TECH

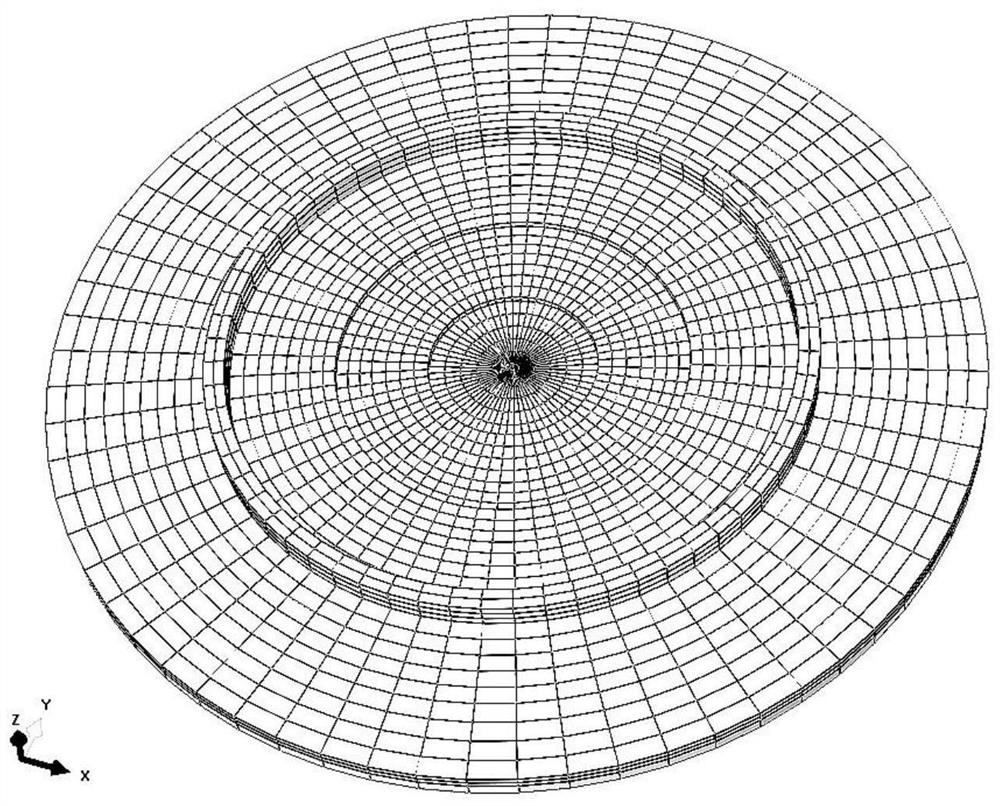

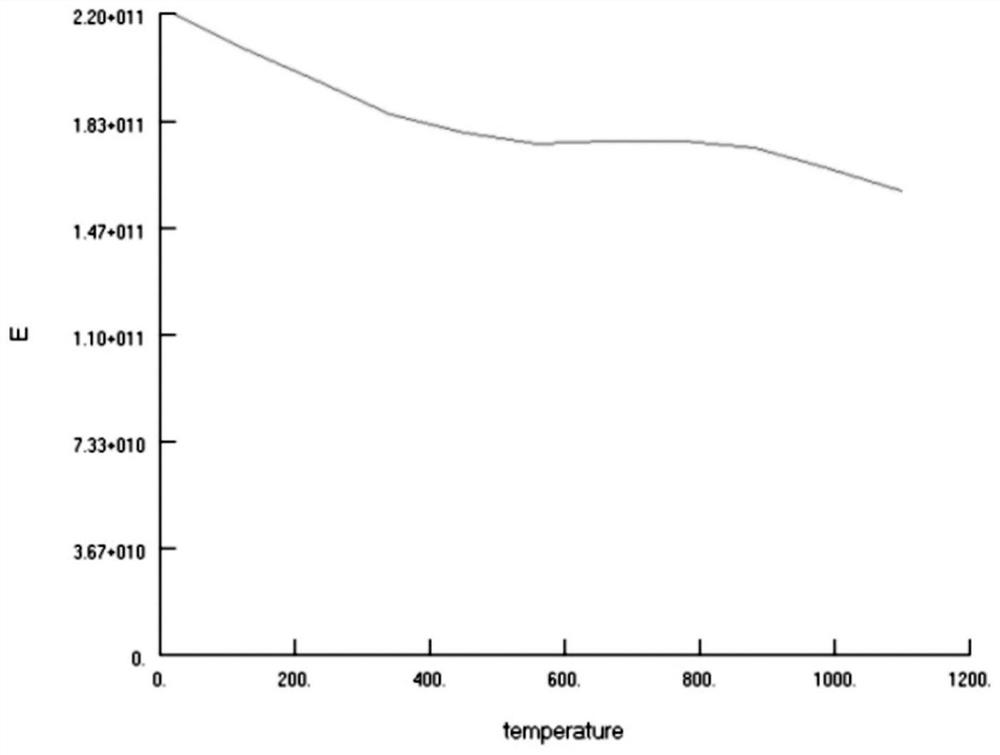

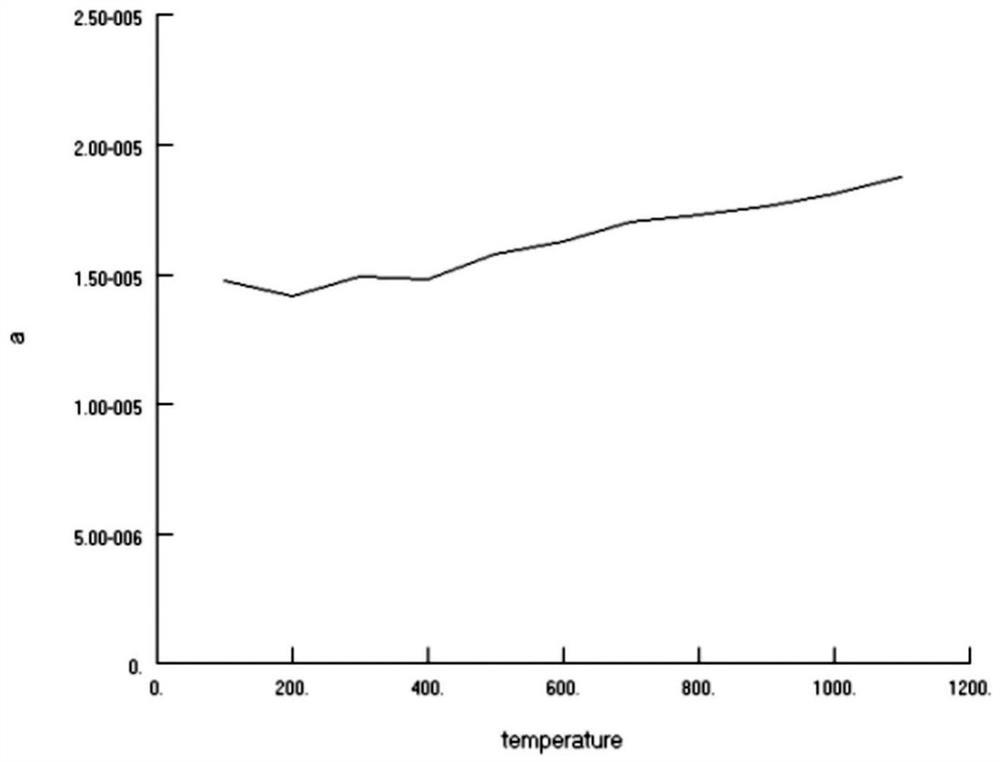

Commutator overspeed performance simulation calculation method

ActiveCN106547978AHigh speedLow costDesign optimisation/simulationSpecial data processing applicationsElement modelElement analysis

The invention provides a commutator overspeed performance simulation calculation method. According to the method, fracture mechanics is introduced in an extended finite element method, so that a commutator overspeed fracture process is simulated in finite element software. The method comprises the steps of performing a fracture mechanics test on a commutator material, obtaining fracture performance parameters, introducing fracture mechanics parameters in finite element analysis through a bilinear stress softening curve model, building a finite element model by utilizing Abaqus finite element software to simulate a commutator overspeed fracture destruction process and the like. The method adopts finite element simulation analysis and has the advantages of high speed, low cost, good observability and the like; the material fracture parameters are obtained through the fracture test and applied to the finite element analysis, so that the commutator overspeed destruction process is simulated; and stress field changes of all parts in the commutator overspeed destruction process can be obtained in a development stage, and theoretical estimation is finished before trial production of a product, so that repeated sample trial production processes are avoided, the development cost is reduced, and the development cycle is shortened.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com